Flexible display device and manufacturing method thereof

A flexible display device and flexible display technology, applied in static indicators, nonlinear optics, instruments, etc., to achieve the effect of not being damaged easily, and having good water and oxygen barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

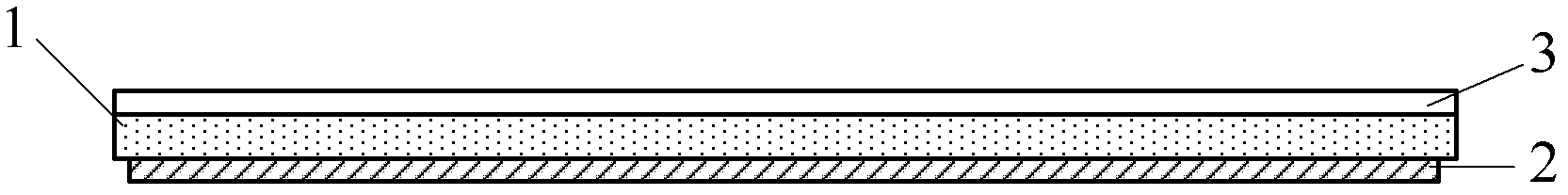

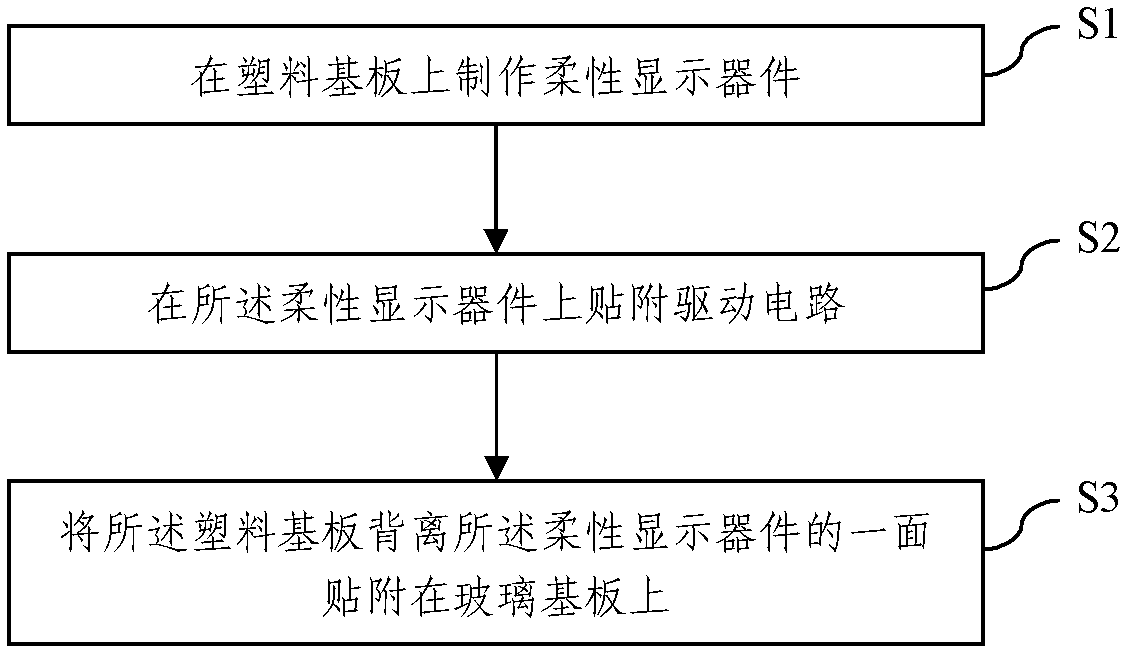

[0047] Such as figure 1 As shown, the flexible display device of this embodiment includes: a plastic substrate 1 , a flexible display device 2 formed on the surface of the plastic substrate 1 , and a glass substrate 3 located on the side of the plastic substrate 1 away from the flexible display device 2 . Wherein, the glass substrate 3 in the present invention is an ultra-thin glass substrate, specifically refers to a glass substrate with a thickness less than or equal to 0.1 mm. Laser cutting is used to obtain smooth edges, so that the glass substrate 3 has the performance of not being damaged after conventional bending.

[0048]Further, the flexible display device of this embodiment further includes a driving circuit (not shown in the figure) for driving the flexible display device. The driving circuit may be a driving circuit directly formed around the display area of the flexible display device on the first flexible substrate to drive the flexible display device, simila...

Embodiment 2

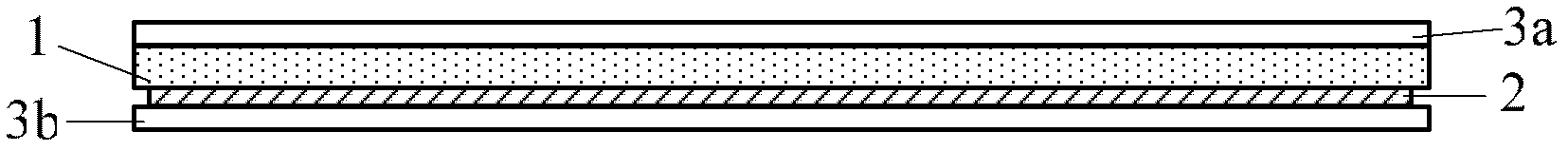

[0061] In order to achieve better encapsulation and better water and oxygen barrier, on the basis of Embodiment 1, a glass substrate is attached to the other side of the plastic substrate 1 , that is, the surface of the flexible display device 2 . Such as image 3 As shown, the surface of the plastic substrate 1 away from the flexible display device 2 is attached to the glass substrate 3a, and the surface of the flexible display device 2 is attached to the glass substrate 1a.

[0062] During production, the plastic substrate 1 and the glass substrate 3b are attached after step S3, or the surface of the flexible display device 2 is attached to the glass substrate 3b after step S2, and then step S3 is performed, that is, the plastic substrate 1 is separated from the flexible display device 3b. One side of the display device 2 is attached to the glass substrate 3a. The attachment of the plastic substrate 1 and the glass substrate 3b can be realized by means of adhesive or atmosp...

Embodiment 3

[0065] The flexible display device in this embodiment is a flexible display device obtained by replacing the glass substrate 3 in the flexible display device in Embodiment 1 or Embodiment 2 with a metal foil 5, which also achieves better water and oxygen barrier properties. Its preparation process is similar to that of Example 1 or Example 2, and will not be repeated here. Such as Figure 4 shows a flexible display device in which the glass substrate 1 in the flexible display device in Example 1 is replaced with a metal foil 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com