Quantum dot assembly as well as preparation method and application thereof

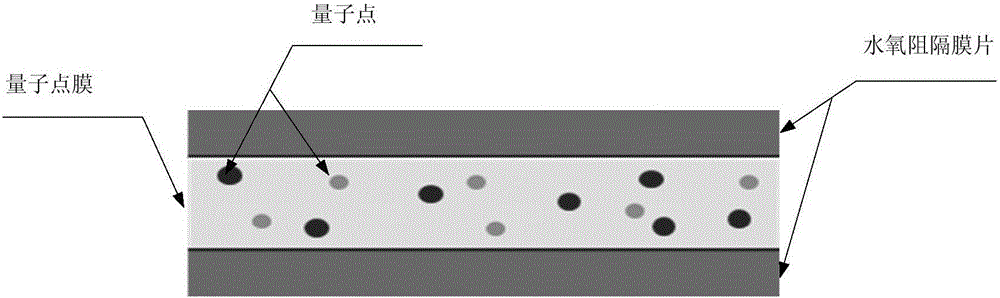

A technology of quantum dots and quantum dot materials, applied in the field of quantum dot components and their preparation, can solve the problems of affecting the light transmittance of the water-oxygen barrier film, affecting the brightness of the quantum dot film passing through, etc. The effect of low brightness and water oxygen transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

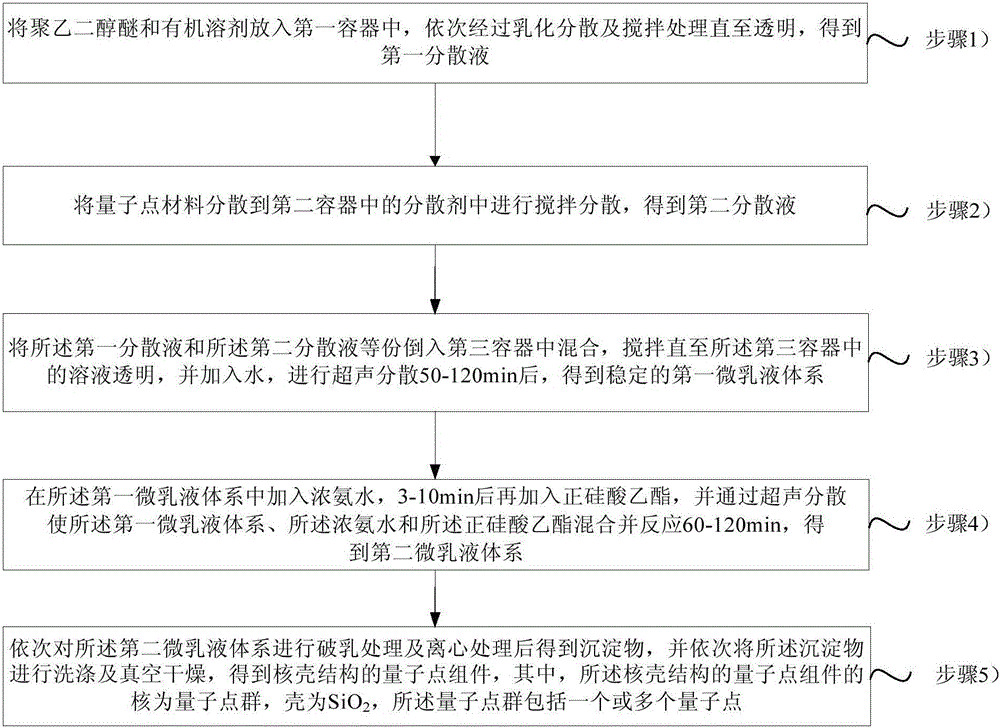

[0030] Figure 2A It is a schematic flow chart of Embodiment 1 of the preparation method of the quantum dot component of the present invention. In the embodiment of the present invention, a microemulsion method is used to prepare a quantum dot assembly with a core-shell structure. Such as Figure 2A As shown, the preparation method of the quantum dot assembly of this embodiment may include:

[0031] Step 1), put the polyethylene glycol ether and the organic solvent into the first container, undergo emulsification, dispersion and stirring treatment in turn until transparent, and obtain the first dispersion liquid.

[0032] In this step, a certain amount of polyethylene glycol ether and an organic solvent are put into a first container (such as a flask), and are sequentially emulsified, dispersed, and stirred until transparent to obtain a first dispersion; optionally, the polyglycol ether The ratio of glycol ether and organic solvent is 1:3~1:5; Optionally, described polyethy...

Embodiment 2

[0047] image 3 It is a schematic flow chart of Embodiment 2 of the preparation method of the quantum dot component of the present invention. In the embodiment of the present invention, a sol-gel method is used to prepare a quantum dot assembly with a core-shell structure. Such as image 3 As shown, the preparation method of the quantum dot assembly of this embodiment may include:

[0048] Step 1), put the quantum dot material into the first container filled with absolute ethanol for emulsification and dispersion, and add diethylamine, diethyl orthosilicate, water and ethanol sequentially under stirring to obtain the first mixed liquid; wherein, the volume of the diethylamine is 0.8%-1.5% of the preset volume, the volume ratio of the volume of the diethylamine to the diethyl orthosilicate is 1:9, the water and The volume of the mixed solution of ethanol is the same as that of the mixed solution of diethylamine and diethyl orthosilicate, and both are 8%-10% of the preset vol...

Embodiment 3

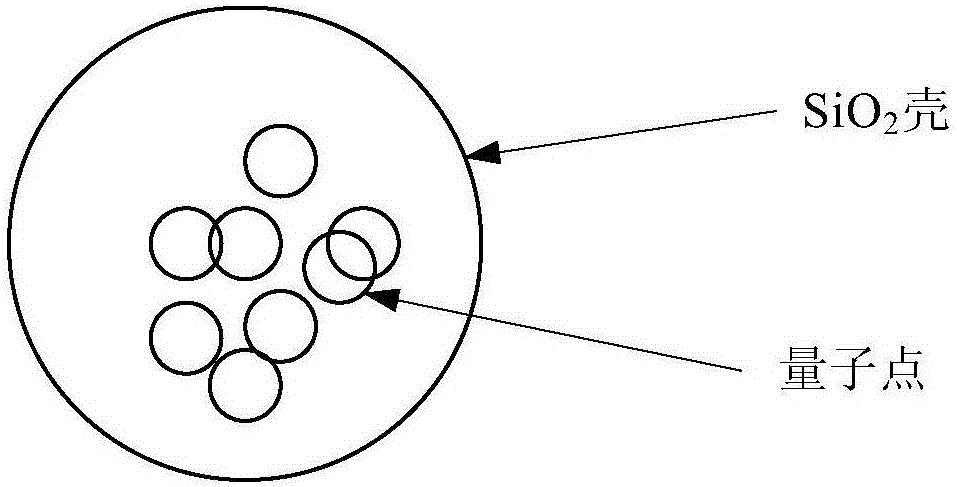

[0061] An embodiment of the present invention provides a quantum dot assembly with a core-shell structure prepared according to the method for preparing a quantum dot assembly described in the first or second embodiment above, wherein the core of the quantum dot assembly with a core-shell structure is a quantum dot group, the shell is SiO 2 , the quantum dot group includes one or more quantum dots. Visible, due to SiO 2 Compact structure, low water and oxygen transmission rate, optical transparency and light-gathering and astigmatism effects, using thin-layer silicon dioxide (SiO 2 ) As a core-shell quantum dot component obtained by coating the quantum dot group with a shell, it not only has high water and oxygen barrier properties, high light transmittance, and SiO 2 The shell has a certain divergence and brightening effect on light, which further improves the brightness of the quantum dot film composed of these core-shell quantum dot components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com