Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about How to "Play a filling role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-seepage, anti-freeze-thaw self-compacting concrete and preparation method thereof

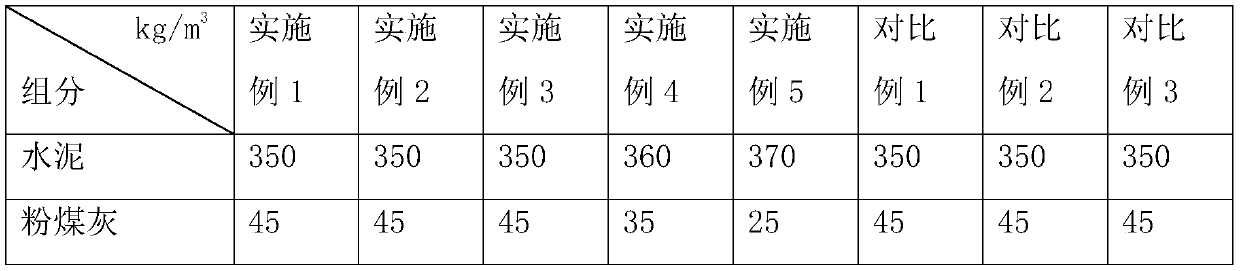

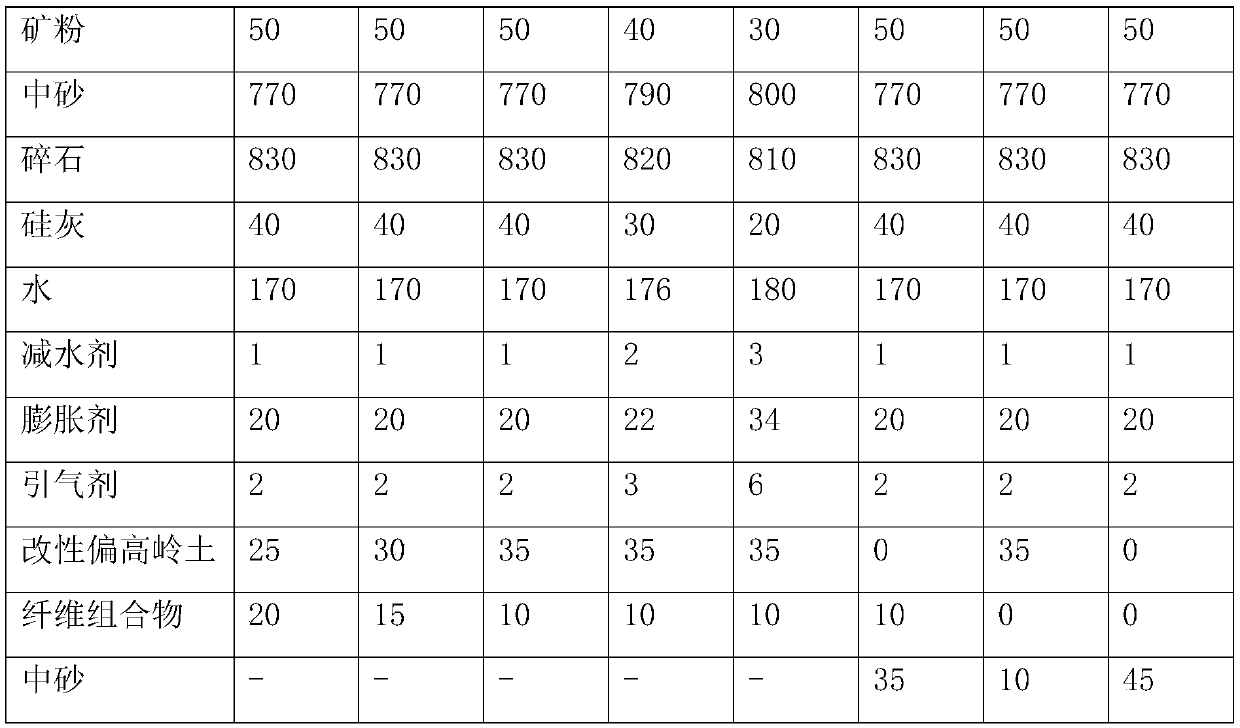

The invention discloses anti-seepage, anti-freeze-thaw self-compacting concrete and a preparation method thereof. The anti-seepage, anti-freeze-thaw self-compacting concrete comprises the following components in parts by weight: 350-370 parts of cement, 25-45 parts of fly ash, 25-35 parts of modified metakaolin, 30-50 parts of mineral powder, 770-800 parts of medium sand, 810-830 parts of crushedstone, 20-40 parts of silica fume, 170-180 parts of water, 1-3 parts of a water reducing agent, 20-34 parts of an expansion agent, 2-6 parts of an air entraining agent, and 10-20 parts of a fiber composition, wherein the fiber composition is prepared by mixing a modified polyester fiber, a basalt fiber and a polyacrylonitrile fiber in a mass ratio of 1:0.6-0.9:0.3-0.6. The anti-seepage, anti-freeze-thaw self-compacting concrete has the advantages of good workability and fluidity, and excellent anti-seepage performance and anti-freezing performance.

Owner:西安新意达建筑制品有限公司

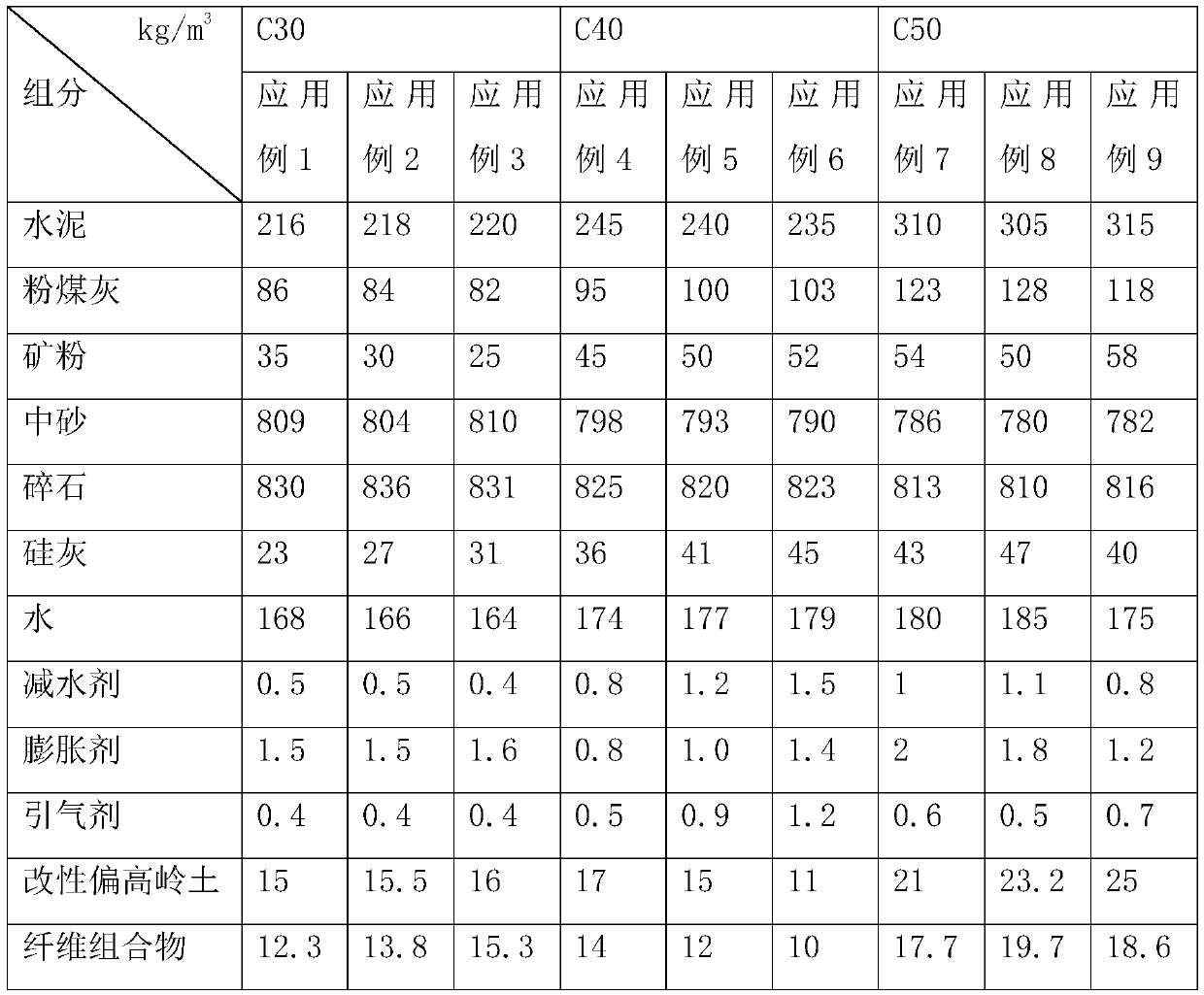

Superhigh-thermal conductivity silica brick for coke oven charing chamber furnace wall and preparation method thereof

The invention discloses a superhigh-thermal conductivity silica brick for a coke oven charing chamber furnace wall and a preparation method thereof. The superhigh-thermal conductivity silica brick comprises, by weight, 60-70% of crystalline silica, 10-20% of fused silica, 3-20% of waste silica bricks, 1-15% of Si3N4, 1-4% of an additive, 6.9-9.5% of a binder and 0.1-0.3% of a water reducer. The preparation method comprises the following steps of carrying out wet-grinding blending on the raw materials with the above ratio, carrying out mechanical pressing molding and carrying out drying roasting to obtain the superhigh-thermal conductivity silica brick. The superhigh-thermal conductivity silica brick has thermal conductivity of 2.50-2.60w / m.k improved by more than 25% than the traditional silica brick thermal conductivity and has obvious energy saving and emission reduction effects.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP +1

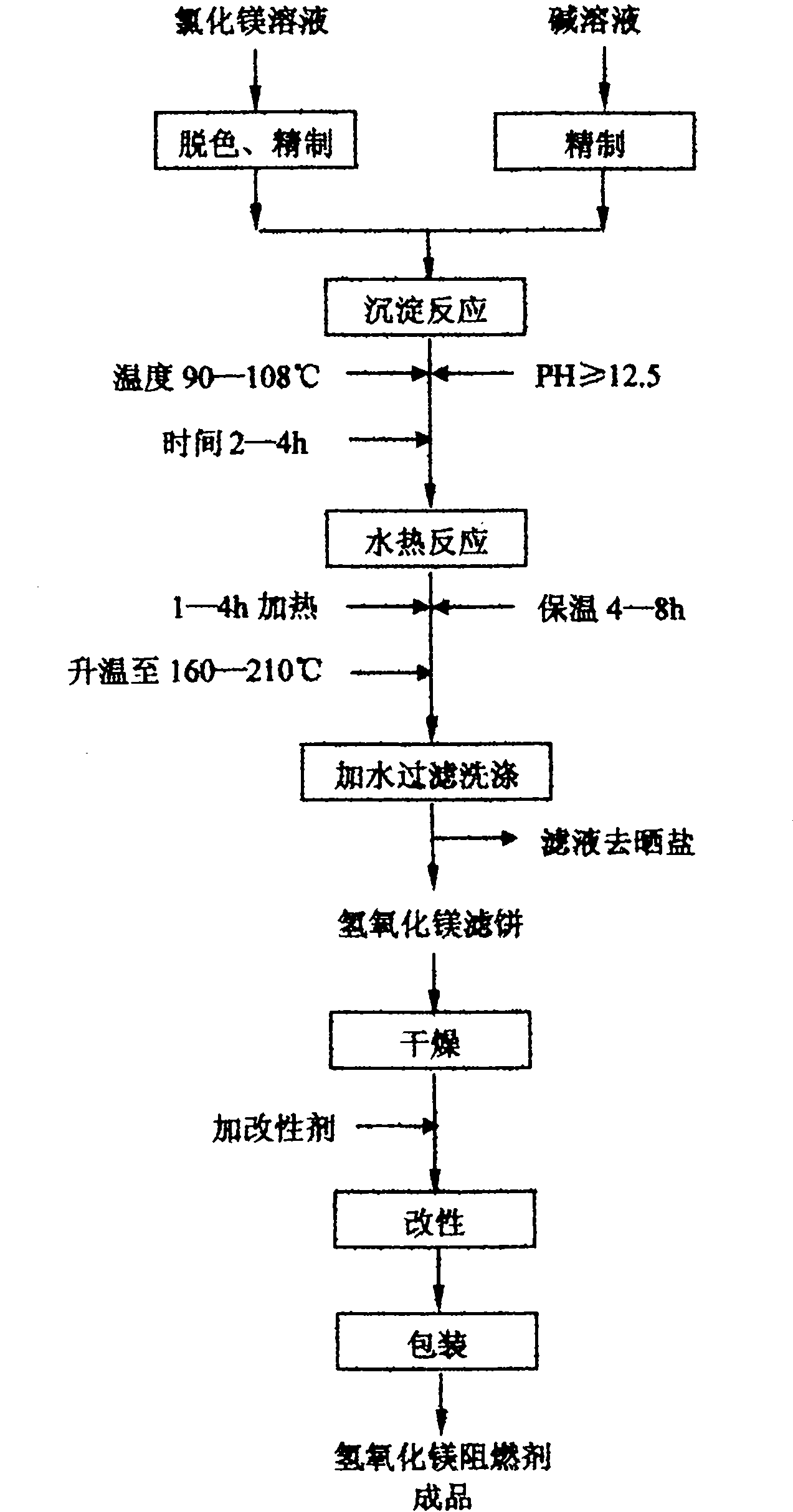

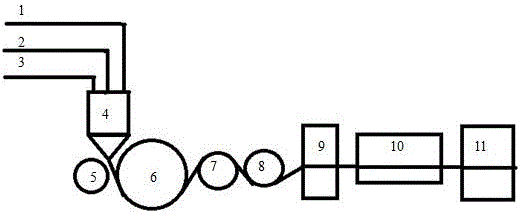

Process for preparing super-thin high-purity magnesium hydroxide fire retardant by supergravity-hydrothermal method

InactiveCN102031021AEnvironmental protection is goodFlame retardantMagnesium hydroxidePigment treatment with non-polymer organic compoundsToxic gasWastewater

The invention relates to a process for preparing a super-thin high-purity magnesium hydroxide fire retardant by a supergravity-hydrothermal method, which comprises the following steps of: performing precipitation on de-colored and refined aged brine and aqueous alkali in a supergravity reactor; allowing a reaction product to enter a hydrothermal reactor and heating the reaction product; filtering and washing discharged materials to obtain a magnesium hydroxide filter cake; obtaining a magnesium hydroxide product with a moisture content of less than 0.2 percent by two steps of drying; and performing dry-process modification on magnesium hydroxide powder, which is to pour materials into a high-speed stirrer, heat and pour titanate or a silicane modifier for surface treatment. The process fully uses the magnesium resources of the aged brine and is favorable for prolonging the product chain of sea salts and salty lake resources; the waste water of the process is sodium chloride brine which can be recycled, the production process is environmentally-friendly and contributes to the purification of oceans; the organic fire retardant grain is super-thin, is 0.4 to 0.8 mu m wide, high in purity and low in price, has the fire-retardant and filling functions, generates no corrosive or toxic gases in a fire retarding process and is highly environmentally-friendly.

Owner:天津长芦汉沽盐场有限责任公司 +1

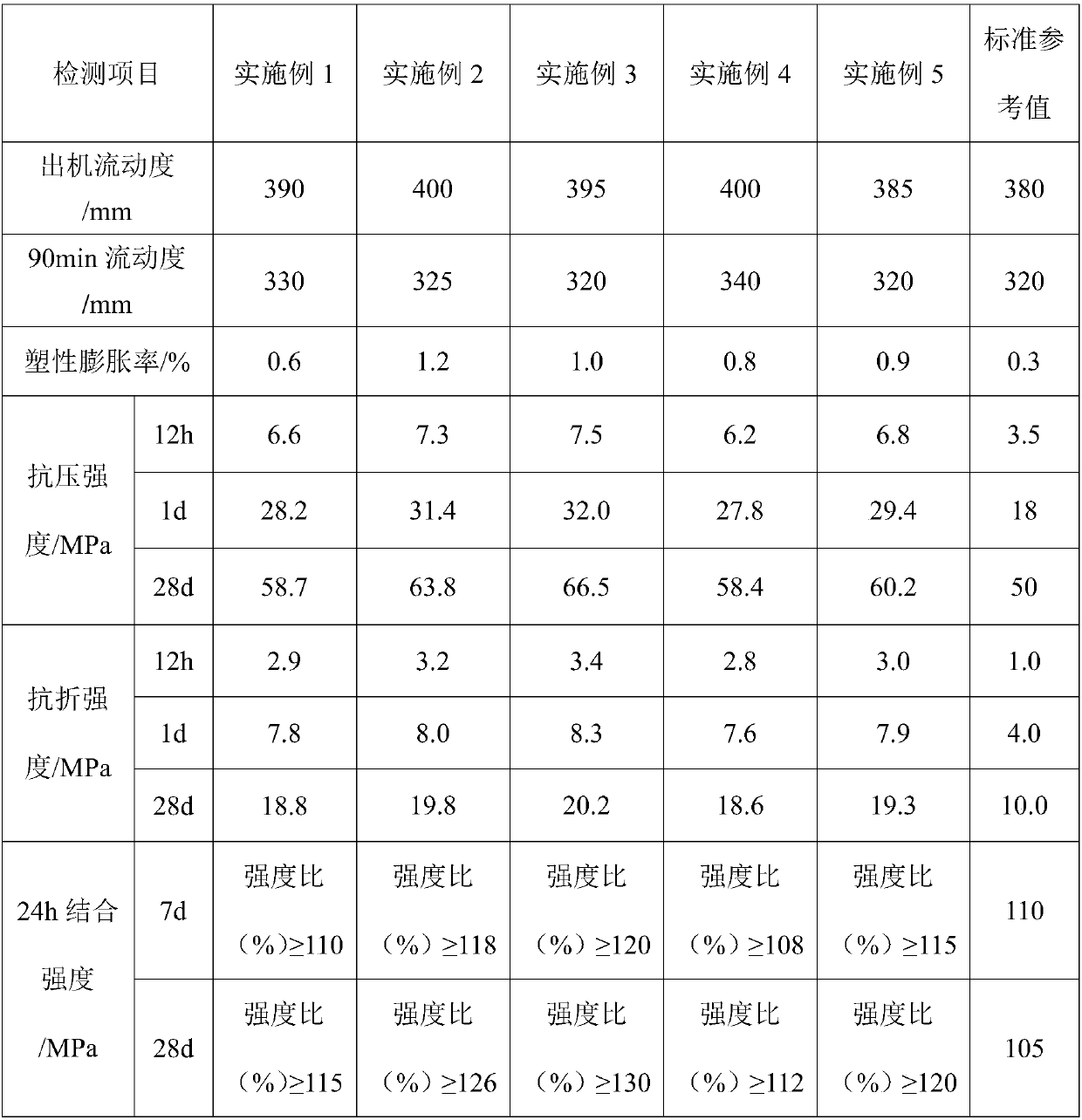

Micro-expansive grouting material for tunnel lining vault mold grouting

The invention discloses a micro-expansive grouting material for tunnel lining vault mold grouting in order to mainly solve the problems of disengaging, crack and other quality defects of tunnel vaults, caused by easy shrinkage deformation, poor compatibility and poor bonding property of existing like grouting materials. The micro-expansive grouting material is obtained through adding water to 750-800 parts of a gelling component, 900-1350 parts of compounded quartz sands, 100-150 parts of a graphene oxide modified mineral admixture, 8-10 parts of a volume stability regulator and 2-3 parts of areinforced water reducer, and mixing and stirring the above raw materials and the water, wherein a ratio of the water to the total materials is 0.16 to 0.19. The micro-expansive grouting material hasgood fluidity and good pumpability, and has a binding performance with lining concrete, and has significant economic and social benefits in the infrastructure industry.

Owner:WUHAN UNIV OF TECH

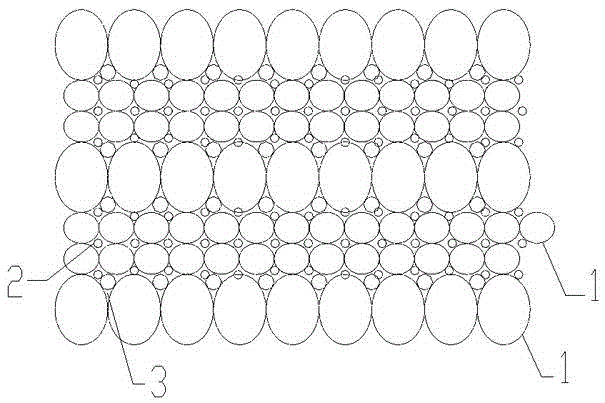

Micro-particle sound-insulating plate and preparation method thereof

The invention discloses a micro-particle sound-insulating plate. Micro-particles are adopted as a substrate for the sound-insulating plate and the micro-particle sound-insulating plate comprises a skeleton and a filling material, wherein gaps of the skeleton are filled with the filling material; and the skeleton is formed by binding skeleton micro-particles and the filling material comprises filling micro-particles, a binder and a coupling agent. The micro-particle sound-insulating plate has the advantages of good sound absorption performance as well as good corrosion and water resistance, can be directly used as external walls and meanwhile, since the sound-insulating plate has the color of the micro-particles, the requirement of customers on aesthetic feeling of the appearance of the sound-insulating plate can be met by combining micro-particles with different colors. In addition, the invention also discloses a preparation method of the sound-insulating plate through compaction by jolting in layer-by-layer and step-by-step manners, through the preparation method, gaps among the micro-particles are staggered, small-sized micro-particles are added in some times so that small-sized micro-particles enter the gaps among large-sized micro-particles so as to achieve filling effect and ensure that the micro-particle sound-insulating plate is dense and seamless.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

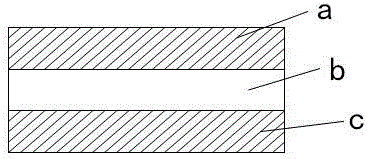

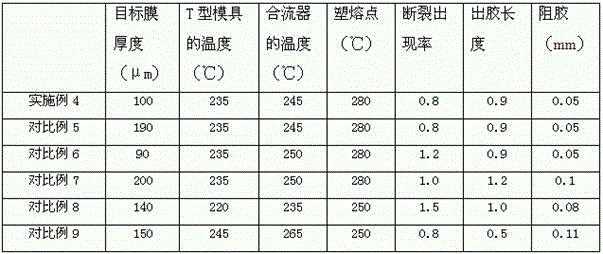

Three-layer co-extrusion high-temperature-resistant glue blocking release film and production process thereof

ActiveCN105838046AImprove liquidityLow viscositySynthetic resin layered productsPolytetramethylene terephthalatePolymer science

The invention discloses a three-layer co-extrusion high-temperature-resistant glue blocking release film and a production process thereof. The glue blocking release film is formed by combining two outer film bodies and a glue blocking filling film body, the outer film bodies comprise an upper release film body and a lower release film body, and the glue blocking filling film body is arranged between the upper release film body and the lower release film body. Each outer film body is prepared from, by mass, 49-51% of polybutylece terephthalate (PBT), 24-26% of polyamide resin PA66, 5% of compatilizer and 20% of glassfiber reinforced plastics. The glue blocking filling film body is prepared from, by mass, 68-72% of polybutylece terephthalate (PBT), 14-16% of EVA-vinyl acetate copolymer, 9-11% of LDPE low-density polyethylene, 3% of compatilizer and 2% of stabilizer. The thickness of the upper release film body and the thickness of the lower release film body in the high-temperature-resistant release film each account for 30% of the total thickness of the release film. While high temperature resistance of the release film is ensured, the glue blocking performance is improved, the glue output length is 0.9 mm, and the qualification rate of a flexible printed circuit (FPC) can be increased effectively.

Owner:久裕电子科技(江苏)有限公司

Pavement super-sticky thin adhesive cement sealing layer mixture and preparation method thereof

ActiveCN105802266AIncrease coefficient of frictionHigh strengthBuilding insulationsAdhesive cementEpoxy

The invention discloses pavement super-sticky thin adhesive cement sealing layer mixture and a preparation method thereof. The pavement super-sticky thin adhesive cement sealing layer mixture comprises the following components in mass percent: 30 to 50 percent of modified emulsified asphalt, 4 to 10 percent of silicate thixotropic lubricant, 10 to 20 parts of fine-grained sand, 0 to 6 percent mineral filler, water-borne epoxy resin, water-borne epoxy resin curing agent and balance of water; the total mass of the water-borne epoxy resin and the water-borne epoxy resin curing agent is 5 to 10 percent of the mass of modified emulsified asphalt, wherein a mass ratio of the water-borne epoxy resin to the water-borne epoxy resin curing agent is 1:1 to 1:2. The pavement super-sticky thin adhesive cement sealing layer mixture disclosed by the invention can effectively seal pavement micro-cracks, prevent aggregate from being loosened and falling, prevent water from downwards seeping, obvious improve pavement appearance and is low in maintenance costs.

Owner:GUANGZHOU MUNICIPAL ENG MAINTENANCE DEPT

Amphoteric calcium carbonate filling and preparation method thereof

InactiveCN101058963ASimple processEasy to controlPaper/cardboardInorganic compound additionFiberRetention ratio

The present invention involves new amphiprotic calcium carbonate filler and the preparation method. The raw materials components are: protein water solution which protein content weight percentage is 0. 01% - 8%; mixture which molar ratio of calcii chloridum and carbonas is 0. 8 - 2:1; the weight ratio of protein and carbonate is 0. 01-4:1. On the role of specific matrix, the mixing reaction of calcium salt and carbonates prepares amphiprotic calcium carbonate with different shapes and controllable grain size, the two phases are prepared after reaction: upper liquid phase containing chlorinated salt and lower white calcium carbonate solid phase containing certain matrix. The shape of calcium carbonate includes petal-shaped, spindle, spherical and piece and so on. The amphiprotic calcium carbonate filler can be used for paper making filler to improve the combination between fiber and filler and between fibers, increase the retention ratio of filler and fine fiber in pulp; and increase the filler content and improve the quality of the paper.

Owner:QILU UNIV OF TECH

Casla solid wood coating construction method

InactiveCN107185789ASmall molecular weightImprove permeabilityPretreated surfacesCoatingsSolid woodOff Treatment

The invention relates to a casla solid wood coating construction method. The method comprises the following steps that (1) material treatment is conducted; (2) ground color treatment is conducted; (3) sealing treatment is conducted: two crosses are sprayed on a casla solid wood blank obtained after the step (2) with a seal primer by utilizing high pressure wetting, gun repairing is required for the local position with a large conduit; the seal primer comprises, by mass, 1 part of hypertonic DiDeBao, 0.3-0.5 part of curing agent and 1.2-1.5 parts of diluting agents; (4) sanding treatment is conducted; (5) brush-off treatment is conducted; (6) color repairing and edge blackening treatment are conducted; (7) primer treatment is conducted: a primer is prepared, two crosses are sprayed by adopting high pressure wetting, gun repairing is required for the local position with a large conduit; the primer comprises, by mass, 1 part of net flavor PU transparent primer, 0.5 part of curing agent and 0.9-1.3 parts of diluting agents; (8) secondary sanding treatment is conducted; (9) overhauling treatment is conducted; and (10) finishing coat treatment is conducted. The steps enable a wood substrate to tend to be uniform, have not too many pot holes, and no pinhole is generated.

Owner:鹤山市君子兰涂料有限公司

Thermoplastic polymer composite material containing nano diamond ene and preparation method of thermoplastic polymer composite material

The invention discloses a thermoplastic polymer composite material containing nano diamond ene, and belongs to the technical field of high polymer materials. The thermoplastic polymer composite material is prepared from, by weight, 90-95 parts of a thermoplastic polymer and 5-10 parts of nano diamond ene. A corresponding preparation method of the thermoplastic polymer composite material comprises the following steps that 1, the thermoplastic polymer and nano diamond ene are mixed in proportion; 2, melt extruding, drawing, cooling, pelletizing and drying are conducted on a double-screw extruder, and then the thermoplastic polymer composite material is obtained. According to the thermoplastic polymer composite material, nano diamond ene is added into the thermoplastic polymer, the heat conductivity coefficient of the polymer material is 5-10 W / (m.K), and the heat conductivity of the overall polymer material is improved; the composite material has a lamellar single crystal structure and is high in strength and good in wear resistance, the strength of the polymer material is improved, and the service life of the polymer material is prolonged; the preparation method of the composite material is simple and low in production cost, and only the double-screw extruder is utilized as the equipment.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

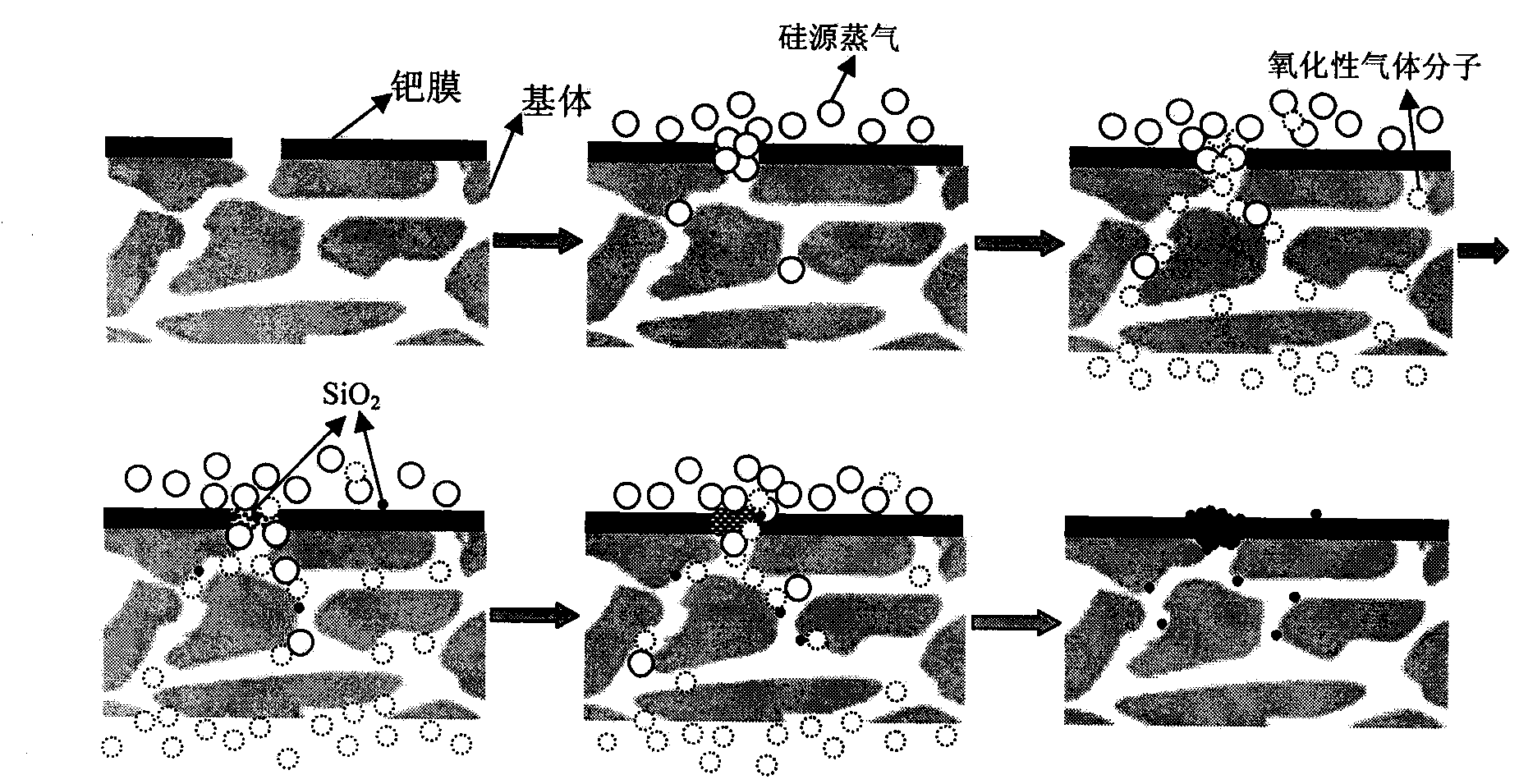

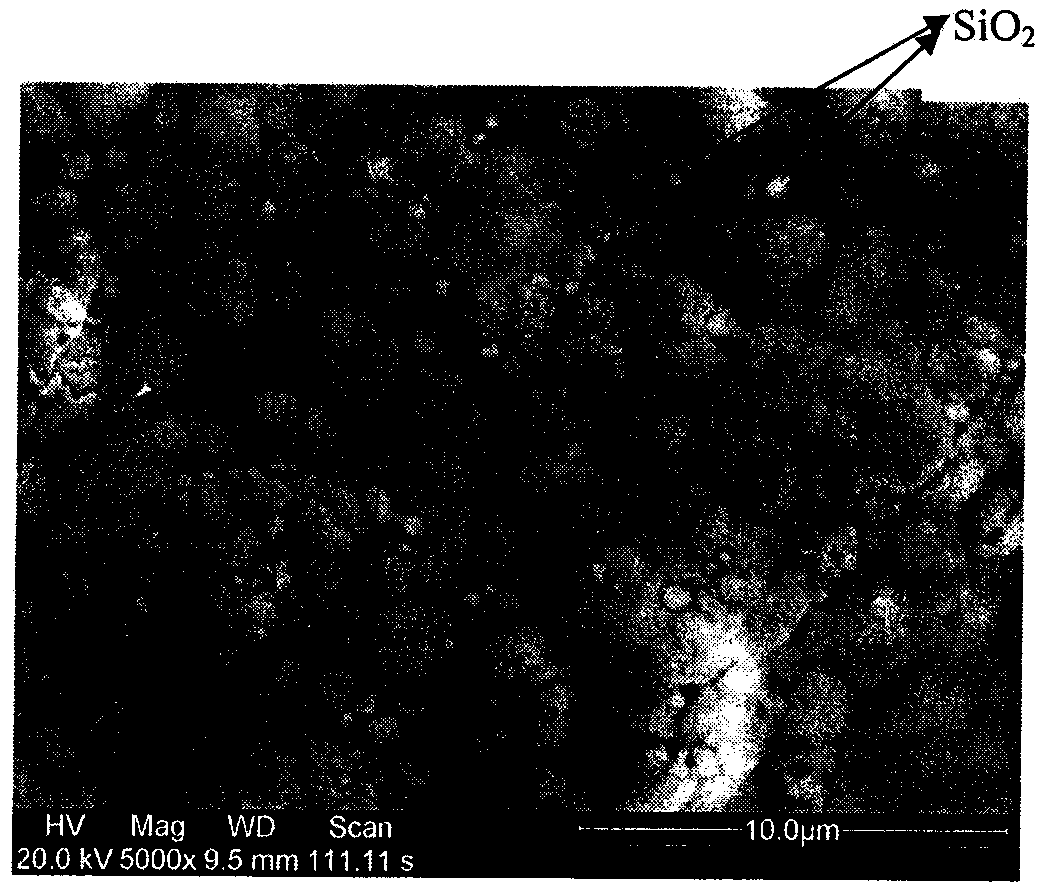

Defect mending method of palladium composite membrane

ActiveCN103638821APlay a filling roleEasy to operateSemi-permeable membranesHydrogen separation using solid contactGas phaseSolid particle

The invention relates to a defect mending method of a palladium composite membrane. According to the defect mending method, SiO2 is deposited at the defect part of the membrane by gas-phase reaction, so that in-situ mending is directly carried out on the palladium membrane in a component without need of disassembling the component, and a mending scheme is provided for the defects generated in the use process of the membrane. According to the specific technical scheme, the defect mending method comprises the steps that the membrane component is arranged in a high-temperature furnace, a silicon source is introduced into the membrane side of the palladium composite membrane in the component, steam of the silicon source occupies the defect position of the membrane, and then oxidative gas is introduced into the base side of the palladium composite membrane in the component, moves to the defect part under the driving of concentration difference, is in contact with the steam of the silicon source and reacts quickly to produce solid particles which are deposited at the defect part, so that the mending purpose is achieved. The defect mending method has the advantages that the defects generated in the use process of the membrane can be mended, the service life of the membrane can be greatly prolonged, the practicability is wide and the operation is convenient.

Owner:RISON HI TECH MATERIALS CO LTD

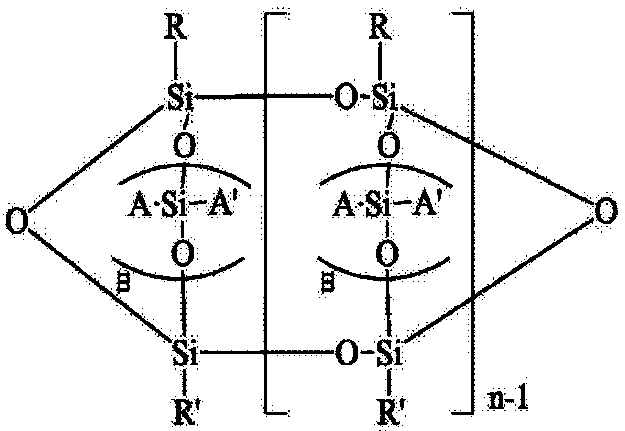

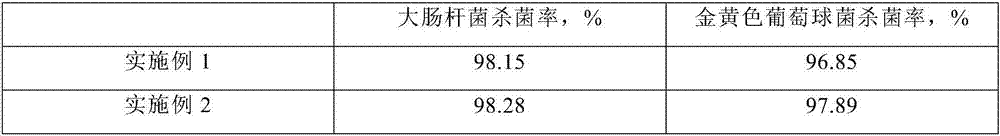

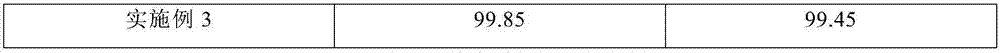

Organopolysiloxane rubber coating for protective coating layer

PendingCN111534222AEmission reductionNo pollution in the processAnti-corrosive paintsPtru catalystSilicic acid

The invention belongs to the field of organosilicon rubber coating, relates to the field of metal protective organosilicon rubber coating, and particularly relates to organopolysiloxane coating for aprotective coating layer. The coating comprises, by mass, 100 parts of a low-viscosity siloxane prepolymer, 5-20 parts of rutile titanium dioxide, 3-5 parts of hydrophobic modified fumed silica, 5-10parts of precipitated white carbon black, 10-30 parts of antirust powder, 20-50 parts of wollastonite, 1-10 parts of color paste, 8-15 parts of tetraethoxysilane, 1-6 parts of silicone oil, 5-15 partsof an adhesion promoter and 0.2-2 parts of catalyst. The invention also provides a preparation method. By introducing the organopolysiloxane rubber, the elasticity of the coating layer is fully guaranteed, the cracking phenomenon of the coating layer due to ultraviolet rays and high and low temperature effects in use is avoided, and the coating has higher corrosion resistance, is environment-friendly and pollution-free, and has longer service lifetime.

Owner:无锡米克新材料有限公司

High-performance asphalt composition and preparation method thereof

InactiveCN109251543AImprove high temperature resistanceImprove stabilityBuilding insulationsCrack resistanceAsphalt

The present invention relates to a high-performance asphalt composition and a preparation method thereof, wherein the high-performance asphalt composition comprises petroleum asphalt and polyimide powder accounting for 5-15% of the weight of the petroleum asphalt, and the polyimide powder has a particle size of 400-500 mesh, and is self-end-capping trapezoidal polysiloxane modified polyimide powder. According to the present invention, the high-performance asphalt composition has advantages of crack resistance, rutting resistance and flame retardancy, and cannot produce penetration or crackingin a low temperature and humid environment.

Owner:WUXI CHUANGCAI OPTICAL MATERIALS

Preparation method for high-wear-resistance micro-arc oxide layer of titanium alloy well-drilling workpiece

InactiveCN110484956AEasy to fillEvenly distributedSurface reaction electrolytic coatingMicro arc oxidationComposite film

The invention provides a preparation method for a high-wear-resistance micro-arc oxide layer of a titanium alloy well-drilling workpiece. The preparation method for the high-wear-resistance micro-arcoxide layer of the titanium alloy well-drilling workpiece comprises the following steps: step 1, carrying out oil removal treatment on the surface of the workpiece; step 2, preparing an electrolyte according to the components with the following concentrations: 16-26g / L of NaH2PO2, 16-28g / L of Na2SiO3 and 15-25g / L of NaAlO2; step 3, adding CE64 and PEG into the electrolyte; step 4, adding nanoscaleSiC powder, Al2O3 powder and graphite powder into the electrolyte in the step 3, and carrying out ultrasonic-assisted dispersion; and step 5, placing the workpiece into the electrolyte, and under anultrasonic condition, preparing a composite film layer on the surface of the workpiece by a direct-current pulse micro-arc oxidization method. The high-wear-resistance micro-arc oxide layer, preparedby the preparation method, of the titanium alloy well-drilling workpiece is high in film layer uniformity, low in surface roughness, and better in corrosion resistance and wear resistance because of being carried with a self-lubricating particle modified surface layer.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Lithium ion battery isolating membrane based on dual-drive self-assembly and preparation method thereof

InactiveCN111063849AImprove hydrophilicityHigh moisture absorptionSecondary cellsCell component detailsPhysical chemistryMethacrylate methyl

The invention discloses a lithium ion battery isolating membrane based on dual-drive self-assembly and a preparation method of the lithium ion battery isolating membrane. The isolating membrane comprises two layers of modified non-woven fabric base membranes and a reinforced coating arranged between the two layers of modified non-woven fabric base membranes, and the modified non-woven fabric basemembranes are prepared by modifying and processing polypropylene non-woven fabric. According to the invention, the polypropylene non-woven fabric is used as a raw material; firstly, methyl methacrylate is used as a monomer, and methyl methacrylate is copolymerized on the surface of acrylic acid, so that the hydrophilicity of the non-woven fabric is improved, and the moisture absorption rate and the water retention rate of the non-woven fabric are further improved; then silicon dioxide is crosslinked and fixed in the non-woven fabric through a silane coupling agent, so that a filling effect isachieved, the equivalent aperture of the non-woven fabric is reduced, and the aperture distribution of the non-woven fabric is more uniform; finally, a layer of honeycomb net structure is formed on the surface of the non-woven fabric intermediate, so that the modified non-woven fabric base membrane is obtained; and the non-woven fabric base membranes have good adsorption capacity and permeation selectivity.

Owner:YANGZHOU POLYTECHNIC INST

Exterior wall insulation waterproof crack-resistant putty powder

InactiveCN107383989AGuaranteed insulation effectInsulation and waterproof guaranteeFilling pastesCalcium bicarbonateCrack resistance

The invention relates to an exterior wall insulation waterproof crack-resistant putty powder, which contains the following raw materials (by weight): 100-200 parts of white cement, 60-80 parts of fine quartz sand, 30-50 parts of powdered steatile, 80-100 parts of calcium bicarbonate powder, 20-30 parts of Chinese medical stone powder, 1-2 parts of hydroxypropyl methylcellulose, 3-5 parts of dispersible latex powder, 1-3 parts of adhesive powder for putty, 1-2 parts of an antibacterial mildew inhibitor, 6-8 parts of hollow glass beads and 0.5-1 part of a UV-absorber. The exterior wall putty powder has long storage stable period, good construction performance, excellent bonding strength, scratch resistance, water resistance, thermal insulation property, ultraviolet absorption and cracking resistance.

Owner:苏州振振好新型建材科技有限公司

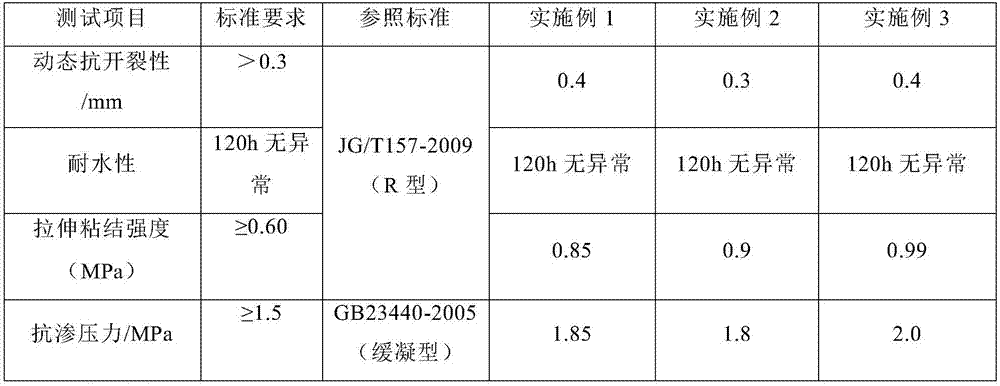

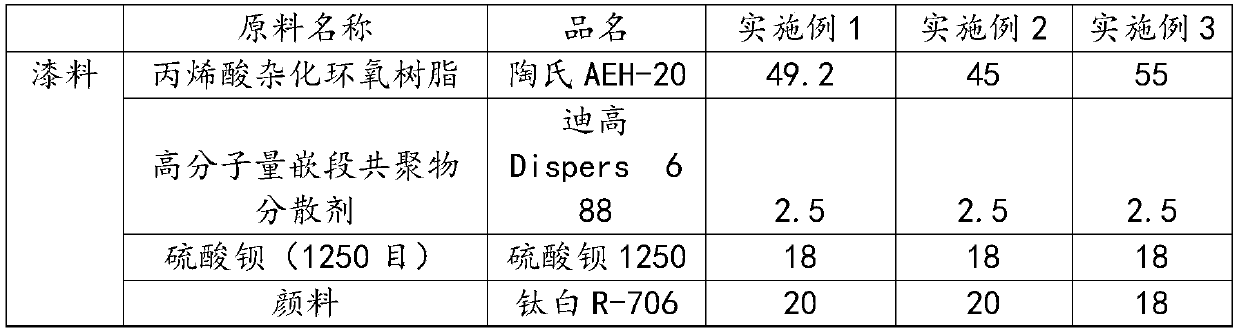

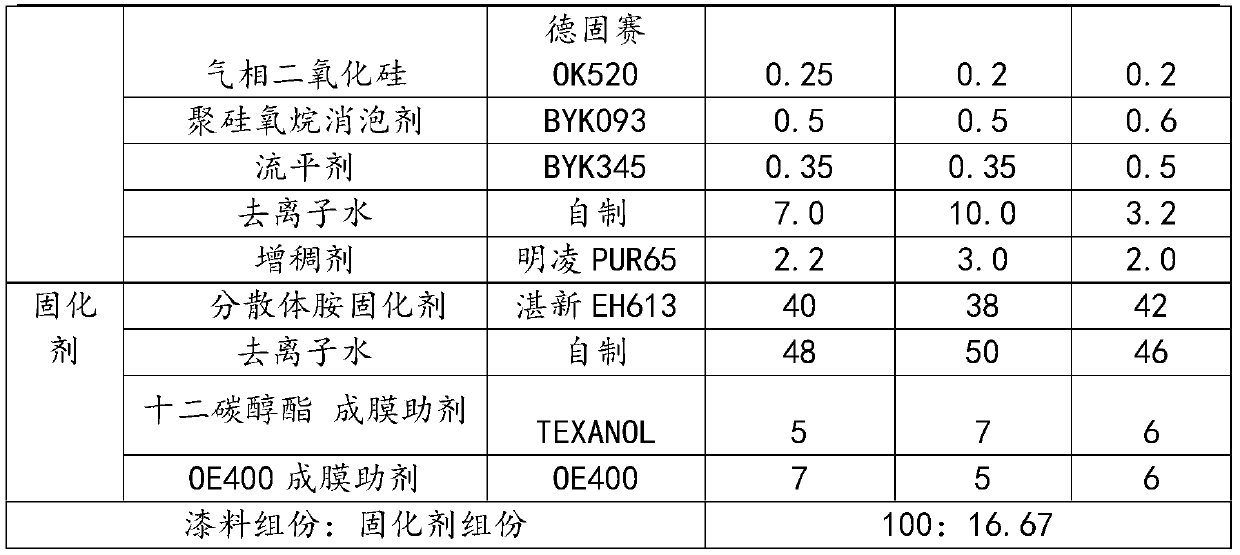

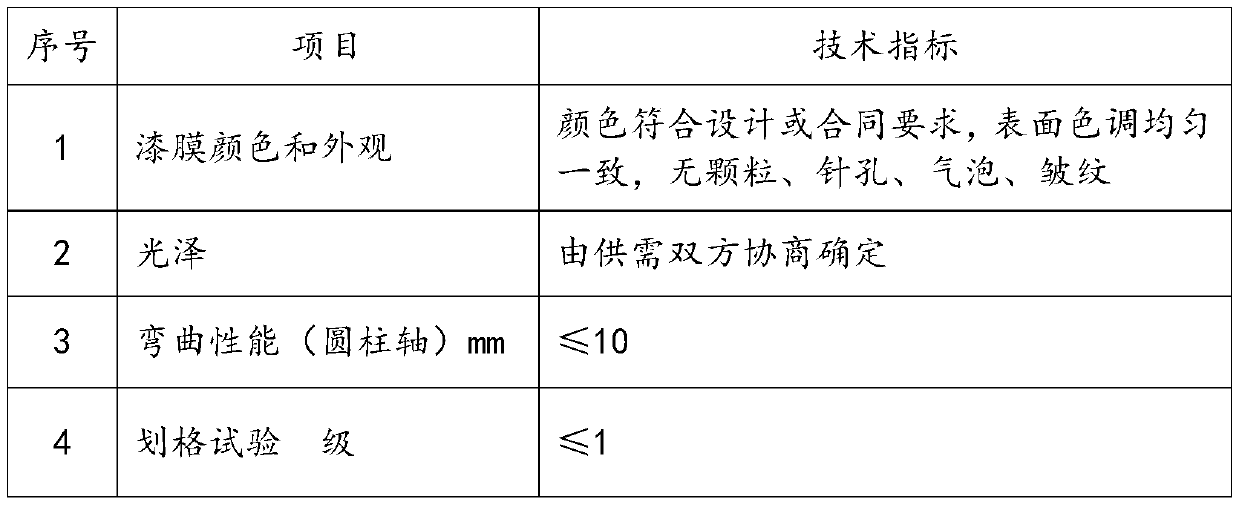

Thick-coating waterborne epoxy finish paint for rail transit vehicles and preparation method thereof

ActiveCN110885616AStrong adhesionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentEngineering

The invention discloses a thick-coating waterborne epoxy finish paint for rail transit vehicles. The thick-coating waterborne epoxy finish paint comprises a paint vehicle and a curing agent. Specifically, the paint vehicle comprises the following raw materials by weight: 45-55 parts of water-based acrylic acid hybrid epoxy resin, 15-20 parts of barium sulfate, 0.2-0.4 part of fumed silica, 2-2.5 parts of a high molecular weight block copolymer dispersant, 19-22 parts of a pigment, 0.5-0.6 part of a polysiloxane defoamer, 0.3-0.5 part of a leveling agent, 2.0-3.0 parts of a thickener and the balance deionized water. The invention also discloses a preparation method of the paint. The overall comprehensive performance of the paint prepared according to the invention can meet the Q / CR 546.4-2016 standard requirements of China State Railway Group Co., Ltd.

Owner:株洲市九华新材料涂装实业有限公司

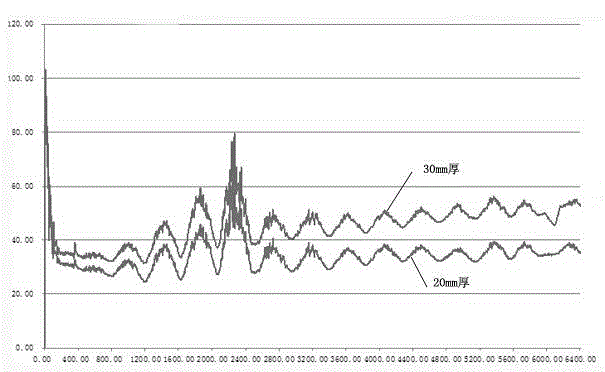

Self-lubricating cylinder piston

InactiveCN106481478AHigh hardnessGrain refinementMolten spray coatingMachines/enginesGraphene coatingGraphite

The invention discloses a self-lubricating cylinder piston. The surface of the piston is provided with a plasma-sprayed Ni-coated micron graphite and graphene coating with the thickness being 20 microns 30 microns. According to the self-lubricating cylinder piston, the friction coefficient and the wear rate are lowered at the same time through the composite plating, the friction coefficient is low, and compared with a Cr plating, the composite plating is higher in wear resistance. Under various loads, compared with a matrix, the wear rate is lowered by over 50%.

Owner:WUXI MINGSHENG STRONG BLOWER

Road curing agent and road curing method

InactiveCN108707463AHigh strengthImprove water absorptionIn situ pavingsBuilding constructionsPolyvinyl acetateCarvacryl acetate

The invention belongs to the technical field of road construction and particularly relates to a road curing agent and a road curing method. The road curing agent contains two parts, namely a water agent and a powder agent, wherein the water agent contains the following components by weight percent: 45%-54% of polyvinyl acetate copolymer, 6%-7% of fatty alcohol-polyoxyethylene ether and 40%-49% ofwater; the powder agent contains the following components by weight percent: 80%-90% of desulfurated ash, 9%-18% of quick lime and 1%-2% of nano-clay. The road curing agent has the advantages of low production cost, high strength after being cured, good water tolerance and slight influence to surrounding environments, can be applied to the curing of sandy soil and macadam and is an environment-friendly road curing material.

Owner:南京友西科技集团股份有限公司

Preparation method of bamboo fiber molding composite

ActiveCN111516073AEfficient use ofIncrease the gapRadiation/waves wood treatmentPressure wood treatmentFiberCeramic materials

The invention provides a preparation method of a bamboo fiber molding composite. The method comprises the steps that after bamboo chips are ground into a loose state, the bamboo chips are soaked intoa nano calcium carbonate solution, a chelating agent is added, flash-explosion treatment is carried out, and modified bamboo fiber crude products are obtained; the residual solution is filtered to obtain bamboo basic structure crude products; the bamboo fiber crude products are soaked into a nano calcium carbonate solution to be ultrasonically treated, and modified bamboo fibers are obtained; theresidual solution is filtered to obtain bamboo basic structure crude products; the bamboo basic structure crude products obtained in the two times are combined, washing and airing are carried out, andbamboo basic structures are obtained; and the bamboo basic structures are soaked into water, a thickening agent is added, stirring and filtering are carried out, modified bamboo basic structures areobtained, the dried modified bamboo fibers and the modified bamboo basic structures are mixed and subjected to mold pressing, and the bamboo fiber molding composite is obtained. The bamboo fiber molding composite is good in uniformity and high in fiber yield, the bamboo basic structures can be effectively utilized, and efficient utilization of bamboo is achieved.

Owner:ZHEJIANG FORESTRY ACAD

Process method for making building material from straw fiber and pulp

The invention discloses a process method for making a building material from straw fiber and pulp. A formula of the building material comprises the following components in percentage by mass: 60 to 80 percent of plant fiber, 5 to 15 percent of talcum powder, 5 to 15 percent of magnesium oxide and 5 to 15 percent of a modifying agent, wherein the modifying agent is composed of the following components in percentage by mass: 10 percent of sodium dodecyl benzene sulfonate, 30 percent of powdered activated carbon, 40 percent of pulping black liquor, 10 percent of sodium silicate and 10 percent of liquid paraffin. The straw fiber or the pulp serves as raw materials, and by utilizing the reduction characteristic of lignin, a produced building material product does not contain formaldehyde and any colloid, is non-toxic, tasteless, radiation-free, water-proof, damp-proof, fire-proof, sound-proof, thermally insulated, acid-base-resistant, ageing-resistant and moth-proof, and has the advantages of light weight, high strength, low cost and environmental protection.

Owner:北京秸大环保科技有限公司

Assembled steel tube high-strength concrete columns and construction method thereof

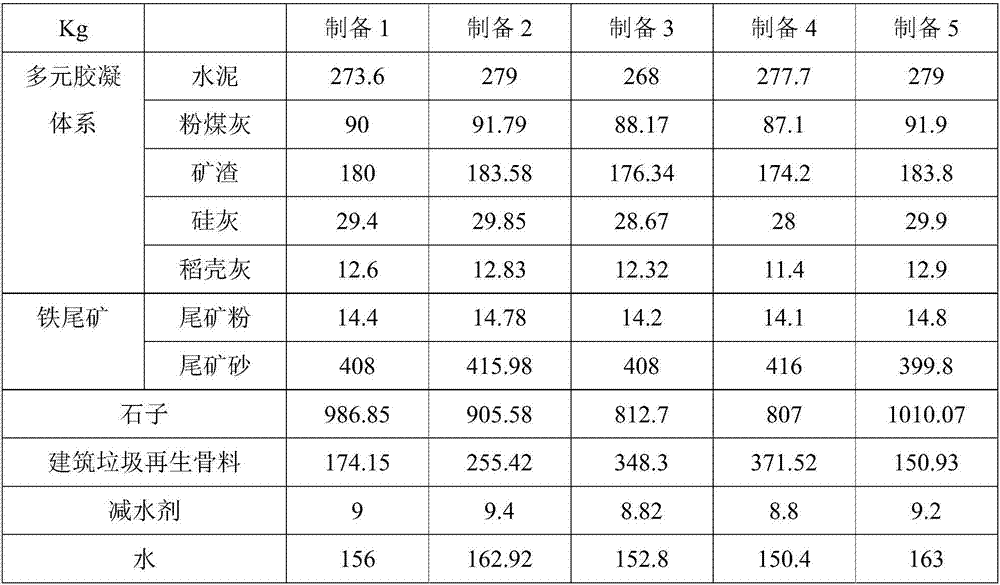

ActiveCN107460994AIncreased durabilityImprove fire performanceStrutsSolid waste managementHigh strength concreteSteel tube

The invention relates to the technical field of assembled steel tube high-strength concrete columns, and discloses the assembled steel tube high-strength concrete columns and a construction method thereof. The assembled steel tube high-strength concrete columns are formed by sequential connecting of prefabricated standard column joints, and the standard column joints comprise steel tubes, high-strength concrete, stiffening ribs and ordinary concrete, wherein the high-strength concrete is poured in the steel tubes; the stiffening ribs are arranged on the outer side of the steel tubes in a surrounding mode, and the ordinary concrete is poured at the outside of the steel tubes; the high-strength concrete is high-strength concrete with added iron tailings and construction waste; vertical rib groups are fixed to the inner walls of the steel tubes in a welded mode; horizontal end plates are arranged on the outer circumferences of the steel tubes along the section direction in a surrounding mode; through holes are evenly formed in the horizontal end plates at intervals; the stiffening ribs penetrate through the through holes and are arranged in the length directions of the steel tubes in a full-length mode; one ends of the stiffening ribs extend out of the standard column joints, and the other ends of the stiffening ribs are provided with half grouting sleeves which are connected with the stiffening ribs extending out of the adjacent standard column joints. The assembled steel tube high-strength concrete columns are fireproofing, corrosion resisting, high in bearing capacity, and excellent in durability.

Owner:江苏悦港新材料科技有限公司

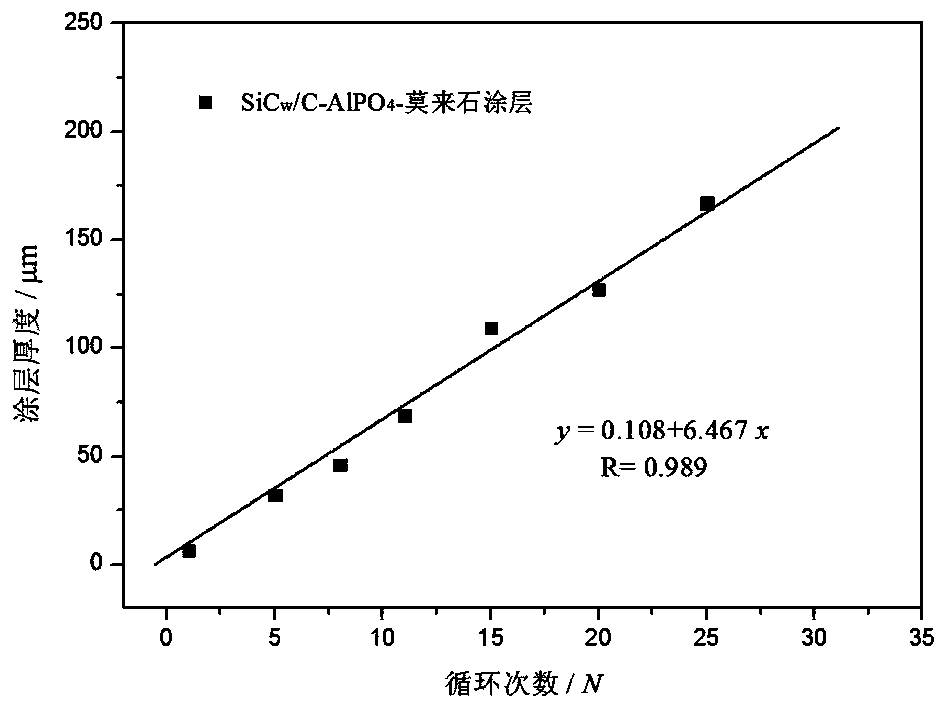

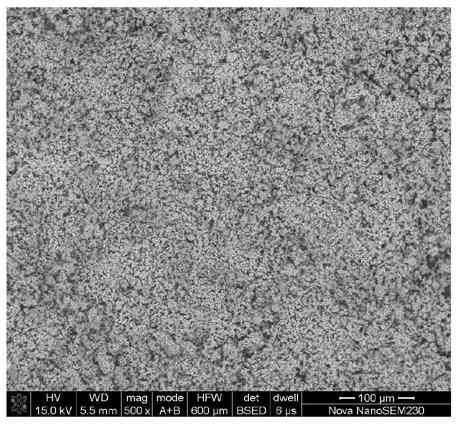

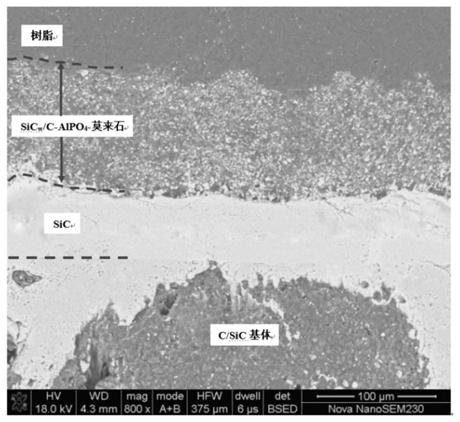

Method for preparing SiC whisker and C-AlPO4 powder synergistic modification mullite coating

The invention relates to a method for preparing a SiC whisker and C-AlPO4 powder synergistic modification mullite coating. A C / SiC composite material is selected as a matrix, a SiC inner coating is prepared by a chemical vapor deposition method, a SiC whisker and C-AlPO4 powder synergistic modification mullite coating precursor is prepared on a SiC inner coating-coated C / SiC composite material bya sol-gel process combined with air spray coating, and the SiC whisker and C-AlPO4 powder synergistic modification mullite coating precursor is sintered to finally obtain the SiC whisker and C-AlPO4 powder synergistic modification mullite coating. The method improves the defects of the coating prepared by a traditional sol-gel process, such as easy cracking, uneven distribution and low bonding strength, can meet the thickness control of a micron-scale coating, has simple preparation process, low preparation cost and high preparation efficiency, can meet many advantages such as large componentand heterogeneous component preparation, is convenient for large-scale industrial application, and has broad development prospects.

Owner:CENT SOUTH UNIV

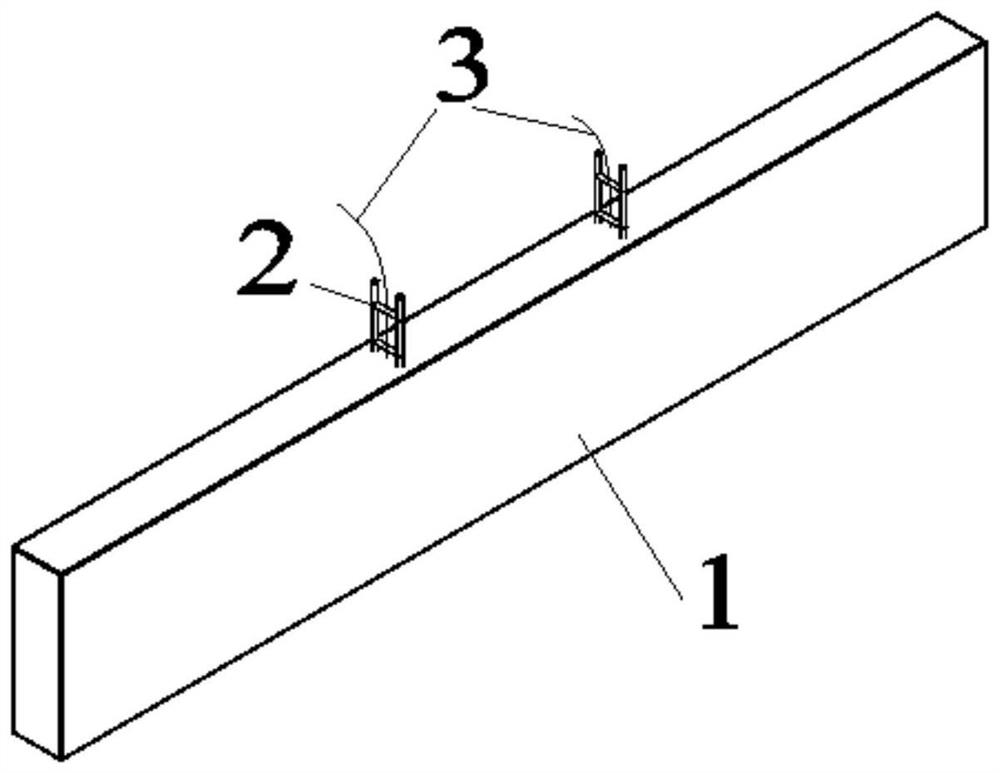

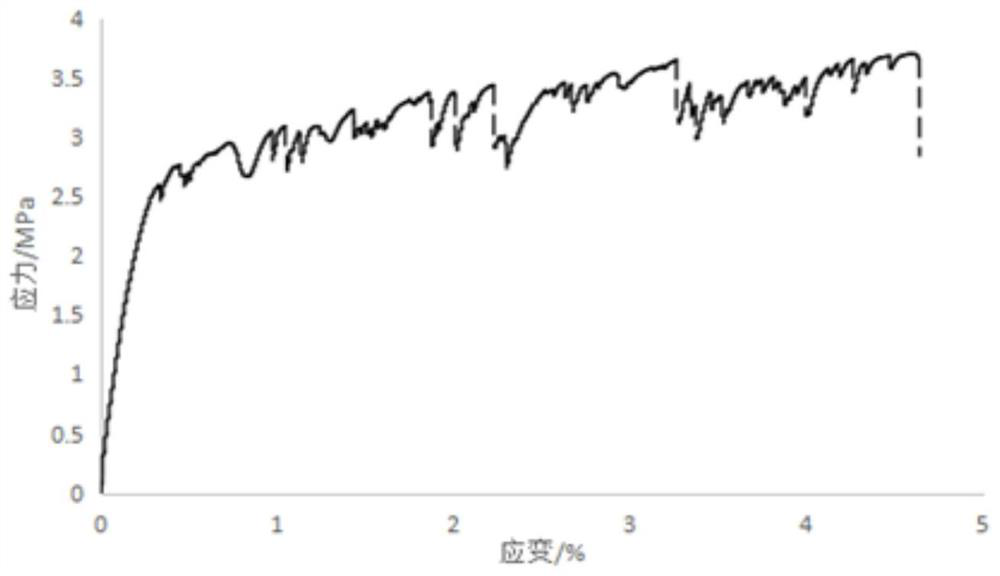

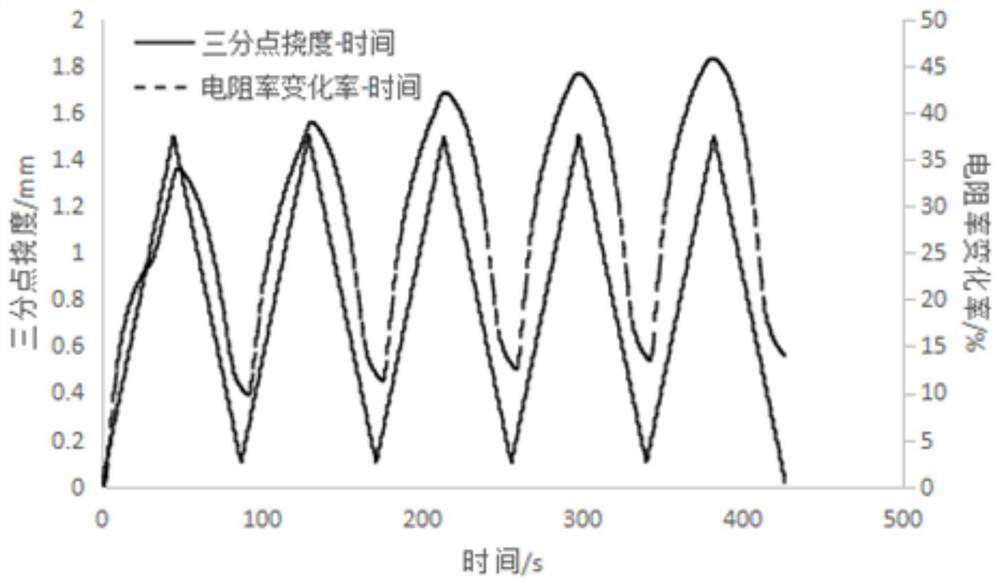

Ultra-high performance cement-based composite material for sensor, sensor and preparation method thereof

InactiveCN111620617ALow resistivityImprove frost resistanceElectrical/magnetic solid deformation measurementFiberSurface-active agents

The invention relates to an ultra-high performance cement-based composite material for a sensor, the sensor and a preparation method thereof, and belongs to the technical field of civil engineering materials, and the ultra-high performance cement-based composite material comprises cement, fly ash, quartz sand, fibers, a water reducing agent, starch gel, water, carbon nanotubes, graphite powder anda surfactant. The tensile strain of the ultra-high-performance cement-based composite material is 3% or above; the defects of brittleness, low tensile strength, poor toughness, easiness in cracking and the like of a common cement-based material are overcome; the strain monitoring range of the manufactured sensor is far larger than that of a sensor made of a common smart cement-based material; thecarbon nano tube and the graphite powder are used as conductive phase materials, the manufacturing cost is low, the sensor is good in compatibility with a concrete structure, excellent in conductivity and smart, stable and reliable in performance, long in service life and easy to manufacture, and due to the addition of the starch gel, shrinkage deformation of the composite material is greatly reduced.

Owner:SHANDONG UNIV

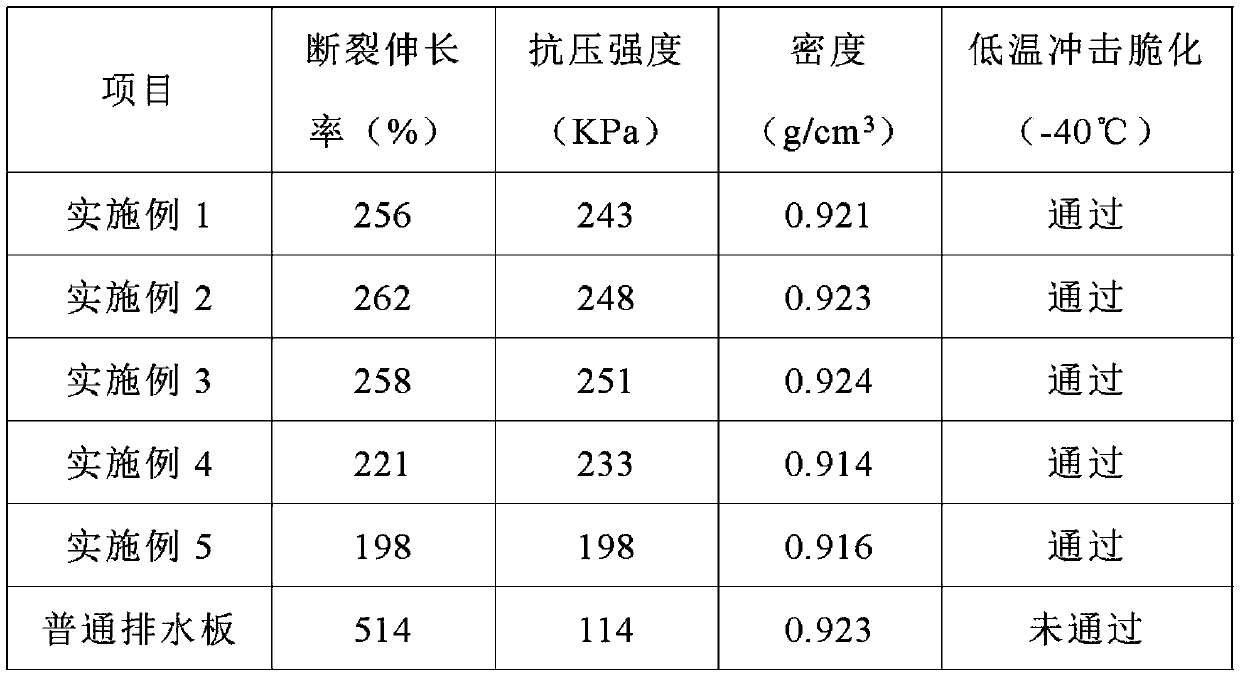

Biodegradable drain board, and preparation method thereof

The invention discloses a biodegradable drain board, and a preparation method thereof. The biodegradable drain board comprises components such as polystyrene emulsion, modified polylactic acid, and modified wood fiber. The conventional drain boards are prepared from polystyrene; polystyrene is poor in chemical stability, no grease resistance is achieved, biodegradation is difficult to realize, andenvironment pollution is easily caused. According to the preparation method, wood fiber is added, so that toughening effect on polylactic acid and polystyrene is achieved, at the same time, wood fiber is cheap, and is easily biodegraded, and waste recycling is realized. The formula of drain board is improved, the preparation technology is optimized, the obtained biodegradable drain board possesses excellent corrosion resistance, water resistance, mechanical performance, excellent biodegradability, and high practicality, and is friendly to the environment.

Owner:盐城市涌泉排水板有限公司

Preparation method of seawater mixing cemented soil

The invention provides a preparation method of seawater mixing cemented soil. The preparation method comprises the steps of adding seawater and cement into a mixing tank to be mixed together at first, and then pouring the mixed liquid into a stratum to be mixed with sludge, wherein the using amount of the cement accounts for 10-20% of the amount of the sludge, and the mass ratio of the seawater to the cement is (1-1.2):2; adding superfine silica fume with the fineness of 0.1 micronmeter-0.2micronmeter as a doping material in a mixing process, wherein the mass ratio of the doping material to the cement is 1:(4-5); and with a compound which is formed by mixing sodium bicarbonate and sodium hydrogen phosphate according to the mass ratio of 1:(1-2) as an exciting agent and a corrosion inhibitor, dissolving the compound into the seawater according to that the ratio of mass g to volume ml in the seawater is 0.5-1%, and then feeding the mixture into the mixed sludge. Compared with the prior art, the seawater mixing cemented soil has a comprehensive inhibiting effect on the erosion of sulfates, chlorine salts and magnesium salts in the seawater to the cemented soil, the expansion growth is not more than 10%, the strength of the obtained cemented soil is not only not influenced but also improved by about 50%, and the erosion of the seawater to machines and tools can also be eliminated.

Owner:ZHEJIANG OCEAN UNIV +1

High-temperature-resistant tough well cementation cement slurry system

ActiveCN114350334AHigh compressive strengthGood adaptability to high temperature admixturesSolid waste managementDrilling compositionPoly ether ether ketoneToughening

The invention discloses a high-temperature-resistant tough well cementation cement slurry system, and relates to the technical field of well cementation materials for oil and gas field development. The well cementation cement slurry system is composed of the following raw materials in percentage by weight: 47-60 wt% of low hydration heat cement; 25 wt%-30 wt% of a high temperature strength stable material; 10 wt%-15 wt% of a high temperature strength reinforcing material; 2 wt%-5 wt% of a high-temperature toughening material; 2 wt% of a high-temperature stabilizer and 0.5 wt% of a dispersant; the high-temperature strength reinforcing material is a mixture formed by mixing silicon nitride micro powder and organic silicon resin micro powder; the high-temperature toughening material is polyether-ether-ketone resin. The high-temperature-resistant tough well cementation cement slurry system has the advantages of high-temperature strength recession resistance and high toughness, can effectively relieve the problems of strength recession and insufficient toughness of set cement under a high-temperature condition, and meets the requirements of oil and gas well cementation.

Owner:JIAHUA SPECIAL CEMENT

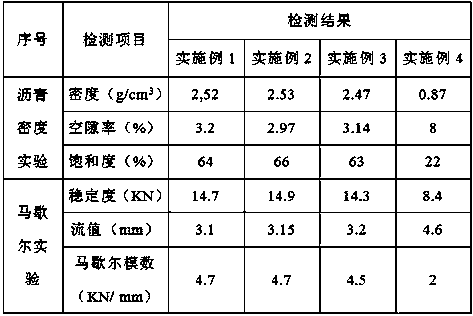

Bituminous mixture for heavy-load transportation road surface and preparation technology of bituminous mixture

ActiveCN109761541AGood compatibilityImprove mechanical propertiesSolid waste managementFiberRoad surface

The invention discloses a bituminous mixture for a heavy-load transportation road surface and a preparation technology of the bituminous mixture. The problems that under the current market condition,polytetrafluoroethylene fibers are used for modifying bituminous, but the polytetrafluoroethylene fibers have the defects that the abrasion-resistant property is poor, the hardness is low, the dimensional stability is poor and the like, and the abrasion resistance and the mechanical properties of the bituminous mixture are greatly influenced are solved; and aiming at the problems, nano-silicon dioxide is added to the bituminous, the polytetrafluoroethylene fibers are filled with the nano-silicon dioxide, the thermal conducting property of polytetrafluoroethylene fibers is appropriately improved, the creep resisting property of the polytetrafluoroethylene fibers is improved, large-area strip-shaped abrasive dust is prevented from being generated in the friction process of the bituminous mixture, and the abrasion resistance of the polytetrafluoroethylene fibers is improved. According to the bituminous mixture for the heavy-load transportation road surface and the preparation technology of the bituminous mixture, appropriate proportion is obtained through multiple experiments, the technology is reasonable, the mechanical strength and the abrasion resistance property of the bituminousmixture are effectively improved, the compatibility between the bituminous and components is further improved, and the bituminous mixture is more stable and is high in practicability.

Owner:六安市共鑫道路材料有限公司

Evaporation residue solidification process based on landfill leachate full-quantitative treatment

ActiveCN111960765AInhibition releaseBenign environmental effectSolid waste managementWater contaminantsSlagFirming agent

The invention discloses an evaporation residue solidification process based on landfill leachate full-quantitative treatment, and belongs to the technical field of solid waste treatment. The evaporation residue solidification process based on landfill leachate full-quantitative treatment comprises the following steps: mixing evaporation residues with a neutralizing curing agent, wherein the neutralization curing agent is selected from the group consisting of water-quenched slag, steel slag and furnace slag. The process provided by the invention completely replaces lime required to be added inthe existing process, saves the cement consumption, improves the compressive strength of the cured body while ensuring higher curing efficiency, avoids the generation of ammonia gas, and is environment-friendly, efficient and economic.

Owner:湖南天为环保科技有限公司

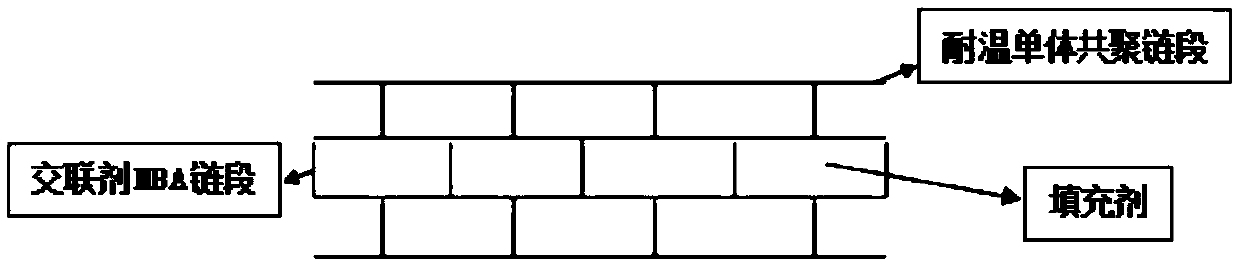

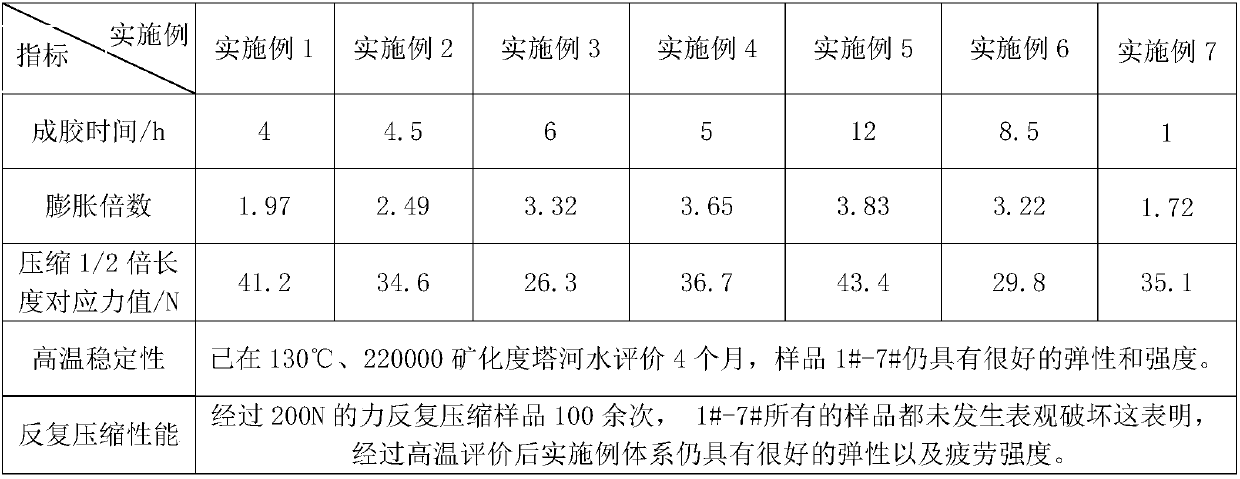

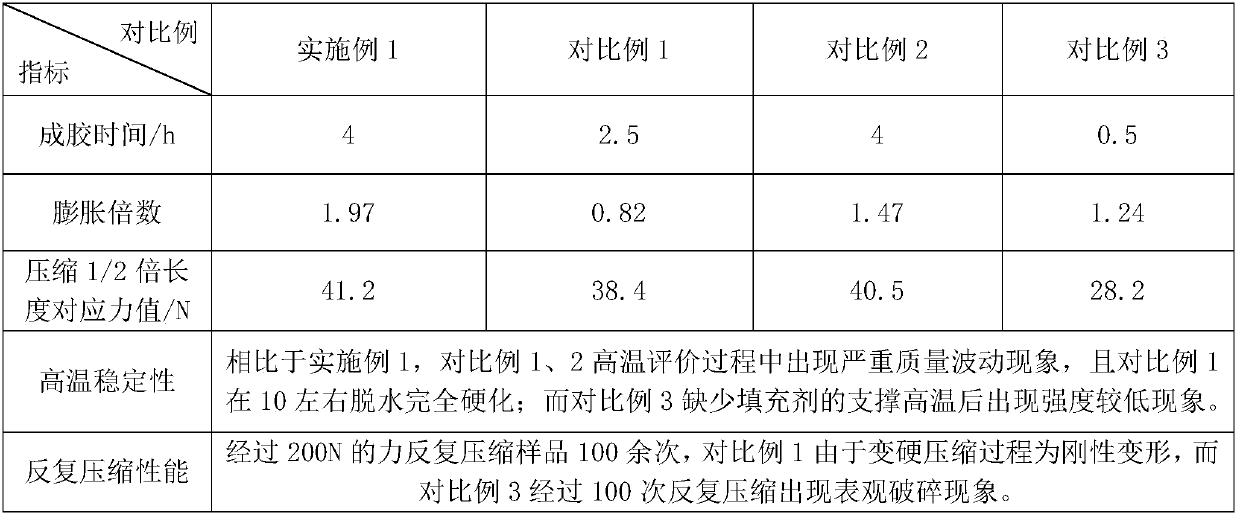

High temperature resistance water swelling body with high degree of mineralization, preparation method and application thereof

The invention relates to a high temperature resistance water swelling body with high degree of mineralization, a preparation method and application thereof. The water swelling body comprises the following components in percent by mass: 20 to 30 percent of a main agent, 0.04 to 0.08 percent of a cross-linking agent, 3 percent of a filler, 0.06 to 0.14 percent of an initiator, and water for the surplus, wherein the sum of the mass percent of all the components is 100 percent. The main agent is formed by compounding N, N-dimethylacrylamide and p-vinyl sodium benzenesulfonate according to a certain ratio; the cross-linking agent adopts N, N-methylene bisacrylamide; the filler adopts clay / silica sol; the initiator is formed by compounding sodium persulfate and 2, 2'-azobis (2-methylpropionamide) dihydrochloride according to a mole ratio being 1:1. The water swelling body is formed by performing polymerization reaction in 50 DEG C, is excellent in temperature resistance, and can achieve effective blocking effect on large-pore reservoirs in severe conditions that the temperature is 130 DEG C and the degree of mineralization is 22*104mg / L.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com