Thick-coating waterborne epoxy finish paint for rail transit vehicles and preparation method thereof

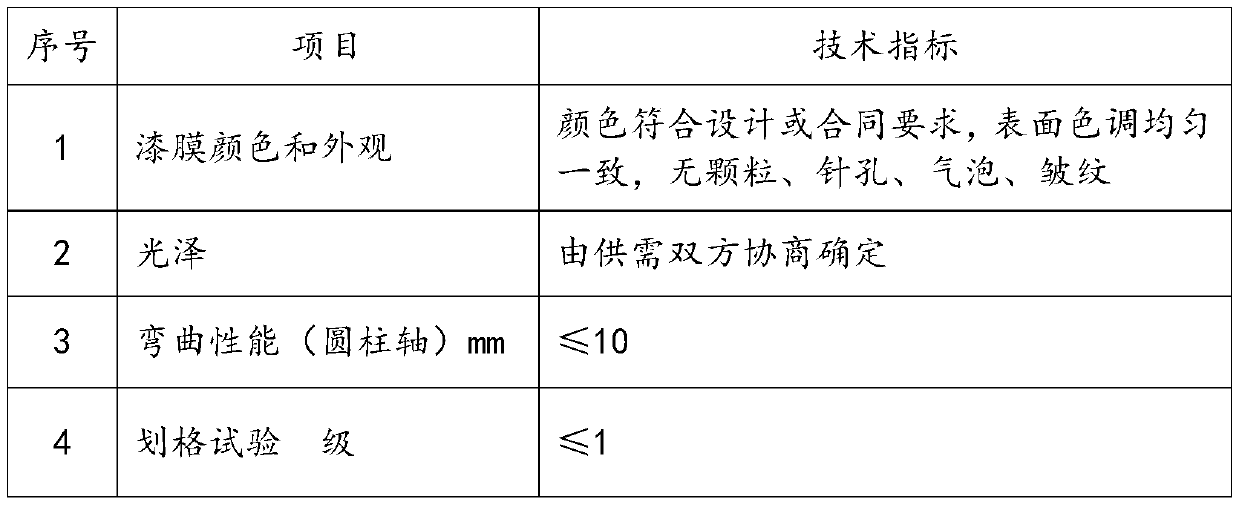

A rail transit vehicle, thick coating technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of paint film wear and tear, foreign body friction and oil erosion, paint film not resistant to stone attack, etc. Excellent water resistance and acid and alkali resistance, good impact resistance, and the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of thick coating type waterborne epoxy topcoat for rail transit vehicle, comprises the following steps:

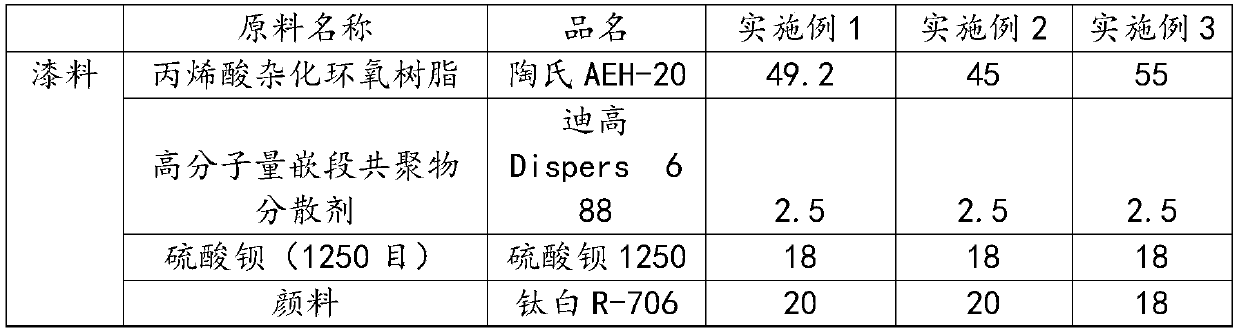

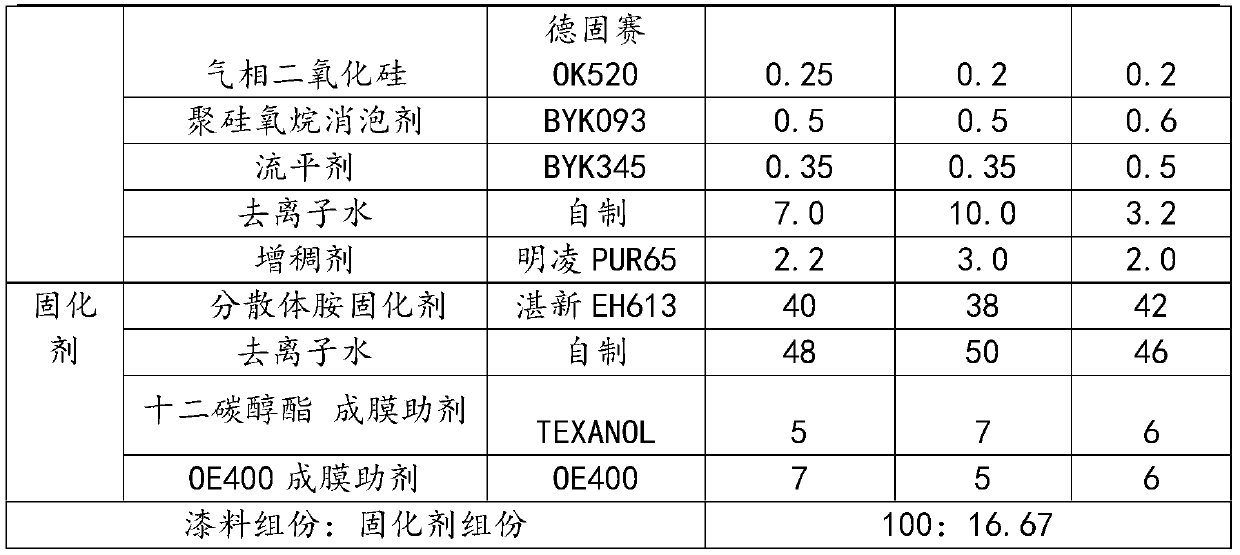

[0041] (1) Preparation of paint: Weigh the raw materials that make up the paint according to the weight ratio, pour the acrylic hybrid epoxy resin into the container vat, and place the container vat under the disperser to disperse, and adjust the rotating speed to 600 rpm / minute, and then add dispersant, barium sulfate, pigment, fumed silica, and polysiloxane defoamer in turn under stirring. After the feeding is completed, adjust the speed of the disperser to 1000 rpm and stir for 25 minutes to obtain the pre-dispersed slurry; then pump the pre-dispersed slurry into the sand mill with a diaphragm pump, and discharge the material when it is ground to a fineness of ≤20 μm. Add leveling agent, deionized water, and thickener in sequence, adjust the speed of the disperser to 1000 rpm, stir for 20 minutes, filter with a 120-mesh filter to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com