Preparation of polyaspartate polyurea waterproof coating material

A technology of polyaspartic ester and waterproof coatings, which is applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., and can solve problems such as low adhesion, short gel time, and large thermal shrinkage problems, to achieve the effect of good weather resistance, obvious effect and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

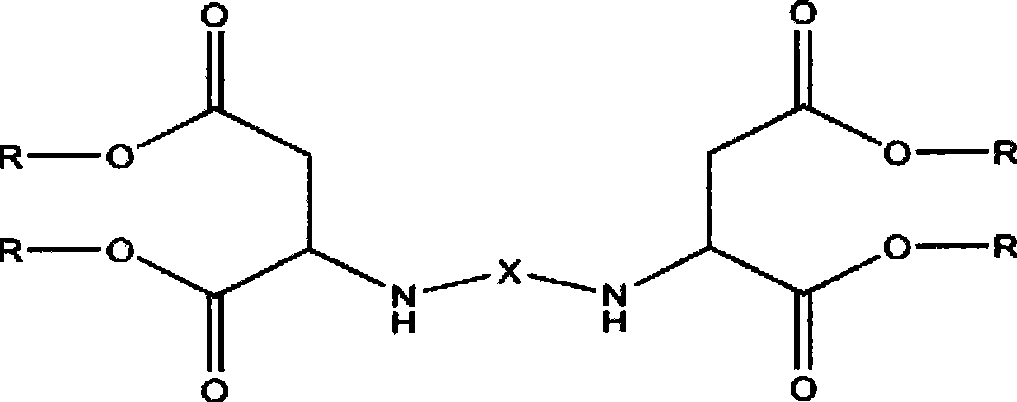

[0023] The first step is to prepare polyaspartate (Code 230):

[0024] Add 100 parts by weight of Jeffamine D-230 and 198 parts by weight of dibutyl maleate to a reactor equipped with a stirrer, heating and temperature control device and a condenser. The addition time is 30 minutes and the temperature is kept at 60°C for 12 hours. The dibutyl maleate can be removed by distillation under reduced pressure. The measured amine value is 152.

[0025] The second step is to prepare waterproof coating:

[0026] Weigh out 100 parts of polyaspartate 230, 60 parts of titanium dioxide, 140 parts of barium sulfate, 10 parts of pigment dispersant (BYK-110 produced by BYK, Germany-a copolymer solvent containing acidic functional groups- The same below), grind the fineness to 25μm by a three-roller, and filter out the material as the B component of the coating; the A component is N3390 (HDI trimer) produced by Bayer, Germany, and it is used according to the B component / A Component = 4.7:1 (by wei...

Embodiment 2

[0028] The first step is to prepare polyaspartate (code 400):

[0029] Add 100 parts by weight of Jeffamine D-400 and 114 parts by weight of dibutyl maleate to a reactor equipped with a stirrer, heating temperature control device and condenser. The addition time is 30 minutes, and the temperature is kept at 60°C for 12 hours. The dibutyl maleate can be removed by distillation under reduced pressure. The measured amine value is 131.

[0030] The second step is to prepare waterproof coating:

[0031] Weigh 100 parts of polyaspartic acid ester 400, 60 parts of titanium dioxide, 70 parts of barium sulfate, 70 parts of talc and 10 parts of pigment dispersant BYK-110, grind the fineness to 25μm by a three-roller machine, and filter out. As the B component of the coating; the A component is N3390 (HDI trimer) produced by Bayer, Germany, and it is mixed according to the B component / A component = 5:1 (by weight) when used.

Embodiment 3

[0033] The first step is to prepare polyaspartate (code 403):

[0034] Add 100 parts by weight of Jeffamine T-403 and 171 parts by weight of dibutyl maleate to the reactor equipped with agitator, heating temperature control device and condenser. The dripping time is 30 minutes and the temperature is kept at 60°C for 12 hours. The dibutyl maleate can be removed by distillation under reduced pressure. The measured amine value is 155.

[0035] The second step is to prepare waterproof coating:

[0036] Weigh 100 parts of polyaspartic acid ester 403, 60 parts of titanium dioxide, 70 parts of barium sulfate, 70 parts of talc and 10 parts of pigment dispersant BYK-110, grind the fineness to 25μm with a three-roller machine, and filter out. As the B component of the coating; the A component is N3390 (HDI trimer) produced by Bayer, Germany, and it is mixed according to the B component / A component=4.5:1 (by weight) when used.

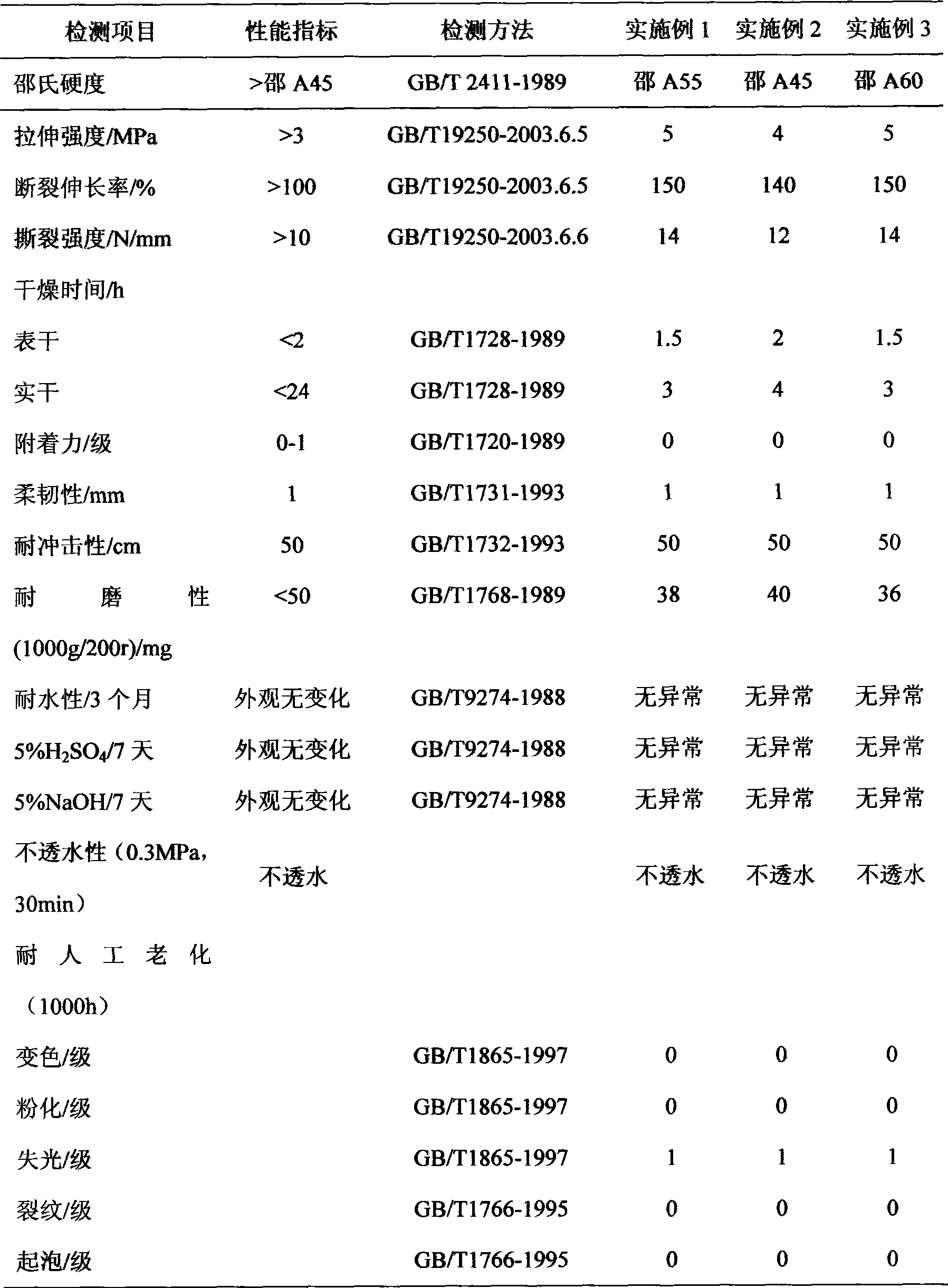

[0037] The performance indexes and measured values of the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com