Process for preparing super-thin high-purity magnesium hydroxide fire retardant by supergravity-hydrothermal method

A technology of magnesium hydroxide and hydrothermal method, applied in magnesium hydroxide, chemical instruments and methods, dyeing of low molecular weight organic compounds, etc., can solve the problems of low purity and poor dispersibility, and achieve high purity, lasting effect and environmental protection. Superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

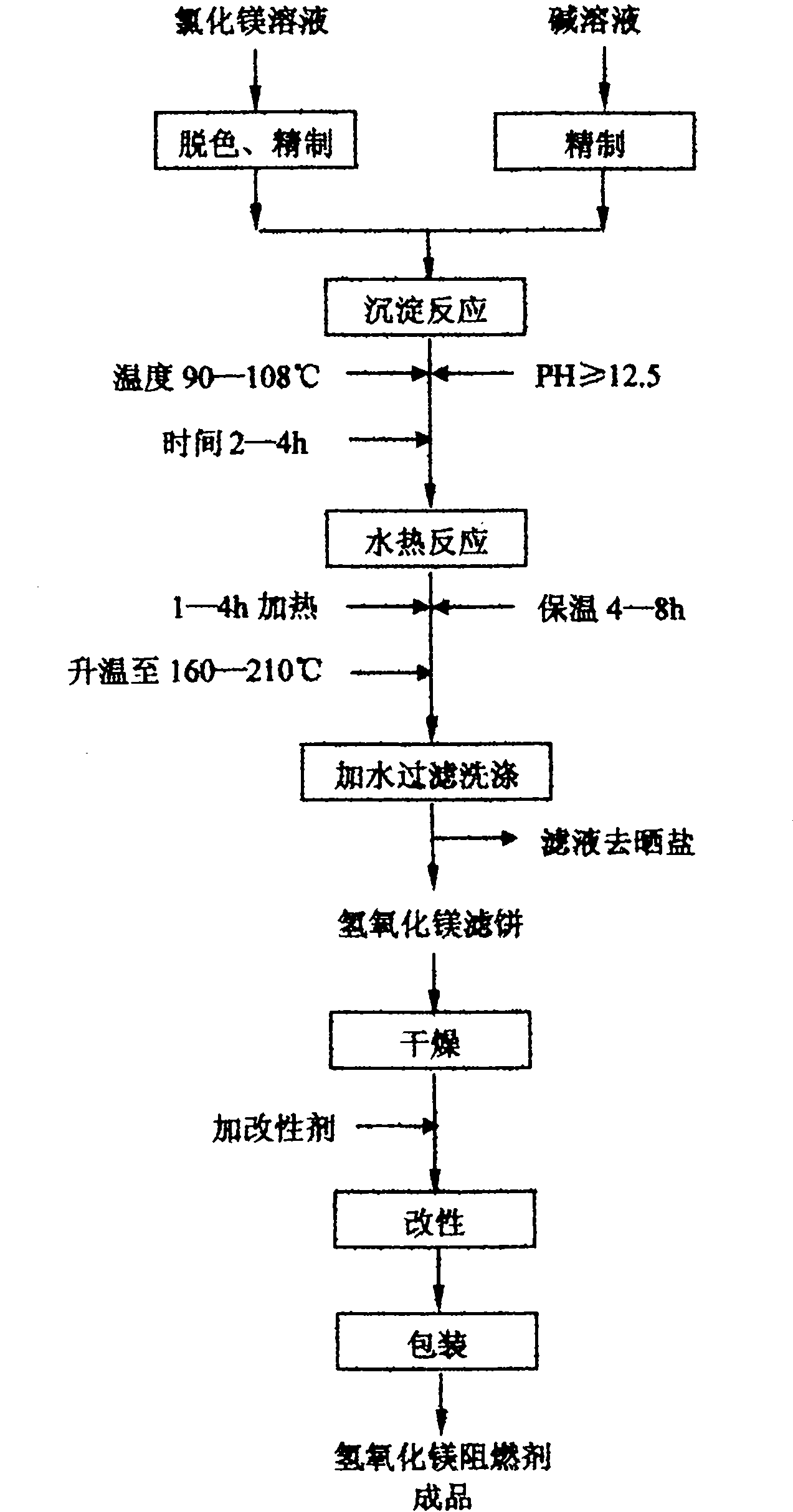

[0040] like figure 1 — Figure 9 Shown:

[0041] ⑴. Brine (magnesium chloride solution) refining process:

[0042] The old brine after salt production contains magnesium chloride M 1 =419.53g / L(kg / m 3 ) Wave Magnesium: 35.00 o Be?, PH=4.3. Take 3.0 m 3 The old brine is sent to the brine mixing tank by the brine pump, and 30 liters of 30% sodium hypochlorite solution is added to the brine mixing tank, and stirred for 1.5 hours to decolorize the brine. Then add 35 liters of 10% sodium hydroxide solution to adjust the pH value of the brine to 6.8, use a pump to send it into a filter with a precision of 1 μm to remove impurities in the brine, add the filtered brine to the refined brine storage tank, and analyze the content of magnesium chloride 410.3 g / L (kg / m 3 ), take 2.6 m 3 Filtered brine, add 1.4 m 3 The process water is prepared with a magnesium chloride concentration of 2.8M / l, 4.0 m 3 spare.

[0043] ⑵. Alkaline refining:

[0044] The concentration of the pur...

Embodiment 2

[0067] Embodiment 2: The difference with Embodiment 1 is as follows, as figure 1 , Figure 10 Shown:

[0068] Hypergravity and hydrothermal reaction: the reaction temperature is 70°C, and the reaction time is 60 minutes. The water heating time is 8 hours, PH=13.5 and the water heating temperature is 200°C. The appearance of gained magnesium hydroxide flame retardant product is as follows Figure 10 The electron microscope photo shown, SBET=5.2012m 2 / g, average particle size 0.75μm.

[0069] Other steps and advantages are the same as in Embodiment 1.

Embodiment 3

[0070] Embodiment 3: The difference with Embodiment 1 is as follows, as figure 1 , Figure 11 Shown:

[0071] Hypergravity and hydrothermal reaction: reaction temperature 40°C, reaction time 30min. The water heating time is 8 hours, PH=13.5 and the water heating temperature is 200°C. The appearance of gained magnesium hydroxide flame retardant product is as follows Figure 11 The electron microscope photo shown, SBET=7.4273m 2 / g, the average particle size is 0.43 μm.

[0072] Other steps and advantages are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com