Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

908 results about "Graphene coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

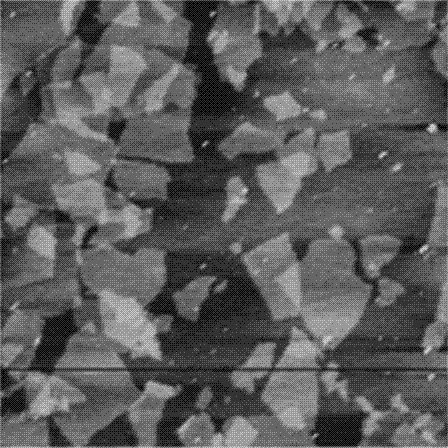

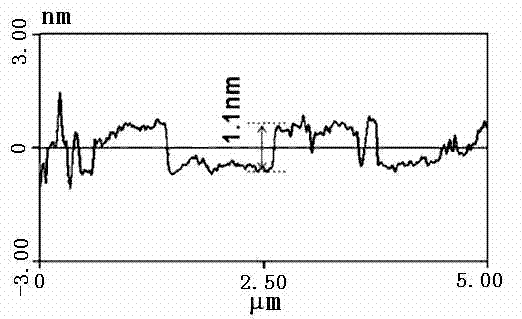

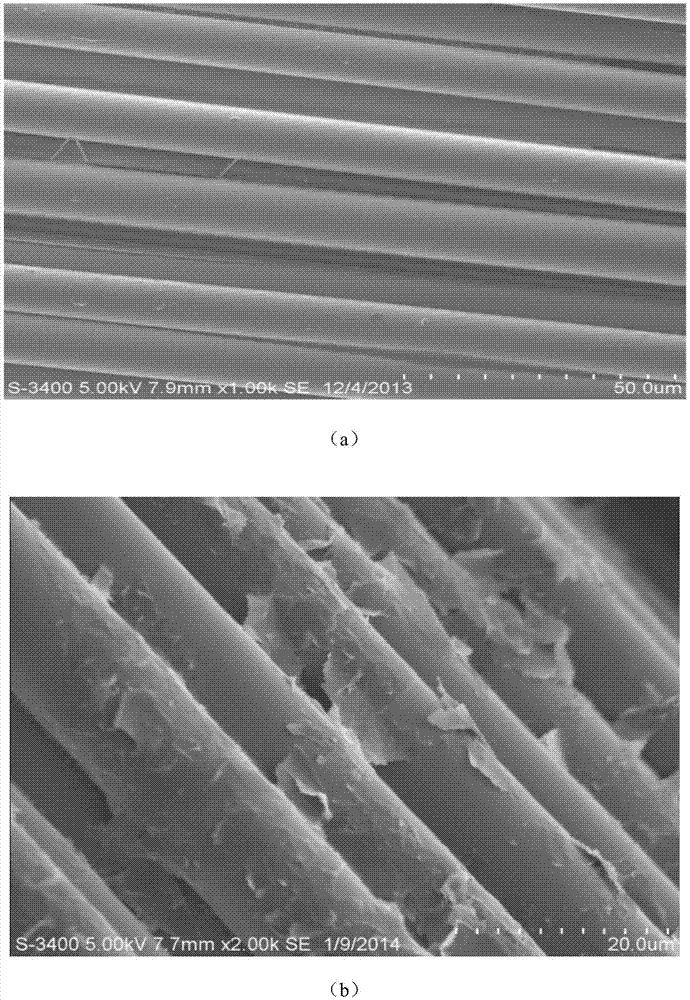

Graphene and carbon fiber composite material, and preparation thereof

The invention relates to a Graphene and carbon fiber-based composite material and a preparation method thereof. The composite material is prepared by taking the Graphene and the carbon fiber as raw materials, and coating a Graphene coating layer on the surface of the carbon fiber by a coating method, and the thickness of the coating layer is 1nm-5mum. The Graphene is taken as a surface coating material of the carbon fiber, and the Graphene and the carbon fiber are carbon materials and have high compatibility, thus Graphene solution coated on the surface of the carbon fiber can form the high-performance composite material and further improve the mechanical property, conductivity and heat resistance of the carbon fiber. The composite material has low cost, simple operation and strong applicability.

Owner:NANKAI UNIV

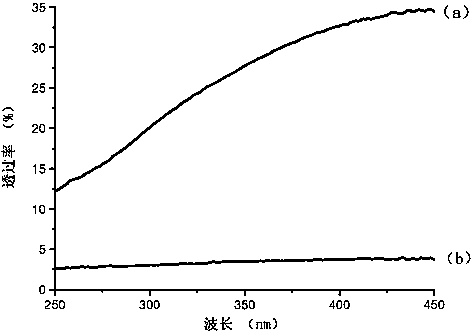

Preparation method of ultraviolet-proof antistatic graphene coating textile fabric

ActiveCN103469555ASimple production processEasy to operateVegetal fibresGraphene coatingFixation time

The invention provides a preparation method of ultraviolet-proof antistatic graphene coating textile fabric. The method is characterized by comprising the following steps: adding a graphene solution to a water-soluble polyurethane solution after shaking and dispersing so as to obtain a mixed solution; fully stirring the mixed solution; putting a graphene screening agent solution into a padder immersion tank; processing textile base fabric under room temperature through implementing a two-dipping and two-rolling procedure; padding the graphene screening agent on a textile, putting kinds of textiles on which the graphene screening agent is padded into a high-temperature oven for drying, wherein the temperature of the high-temperature oven is 75-95 DEG C; the high-temperature fixation time lasts for 5-30 minutes, so as to prepare the ultraviolet-proof antistatic graphene coating textile fabric. The method is simple in process, and easy to operate, and the yield is high; the produced textile fabric has the excellent function of preventing ultraviolet rays and static electricity.

Owner:QINGDAO UNIV

Graphene coating as well as preparation method and coating method thereof

The invention belongs to the technical field of materials and in particular relates to a graphene coating as well as a preparation method and a coating method thereof. The graphene coating is prepared from the components by weight: 5-95wt percent of less layer of grapheme, 5-95wt percent of adhesive, 0.01-50wt percent of dispersant and surfactant, 0.01-10wt percent of defoamer and the balance of solvent. With the adoption of the graphene coating, the thickness of an electricity and heat conductive coating can be controlled to be 100nm-20 microns; when the graphene coating is used on a plastic matrix, the volume resistivity can reach a range from 10<-2>ohm.cm to 10<-4>ohm.cm; while the graphene coating is used on a metal matrix, the volume resistivity can reach 10<-6>ohm.cm. The graphene coating can be applied to the metal surface so as to improve the cohesiveness, the electricity / heat conduction performance and the corrosion and oxidation resistance. When the graphene coating is coated on the plastic surface, the frictional resistance, the electricity and heat conduction performances and the static resistance can be lowered, and the graphene coating can be applied to the fields of printed circuits, electronic devices, radio frequency devices, touch screens, thin film solar energy, LEDs, magnetic shielding, radio frequency shielding and the like.

Owner:SUPERCDONGGUAN TECH

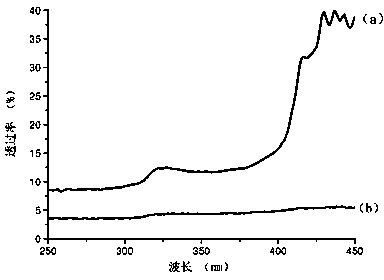

Method for preparing oxidized graphene coated film

InactiveCN102173145AHigh transparencyImprove securitySynthetic resin layered productsCoatingsGraphene coatingMetallurgy

The invention provides a method for preparing an oxidized graphene coated film, which comprises the following steps of: adding oxidized graphene into water, and performing ultrasonic treatment and stirring simultaneously to obtain colloid suspension of the oxidized graphene, wherein 1mg of oxidized graphene is added into 1mL of water; and coating the colloid suspension of the oxidized graphene onthe surface of a general film in a spraying or rolling mode, drying to form an oxidized graphene film, coating a plurality of layers, and after the uppermost oxidized graphene coating is dried to form a film, covering a layer of general film on the uppermost oxidized graphene film to obtain the oxidized graphene coated film. The method has the advantages that: the oxidized graphene coated film prepared by the method has good transparency, high safety, good environment friendliness, and excellent barrier property; the barrier property to CO2 gas is greatly improved particularly; and the methodis used for packaging foods and medicines with higher requirement on barrier property.

Owner:XIAN UNIV OF TECH

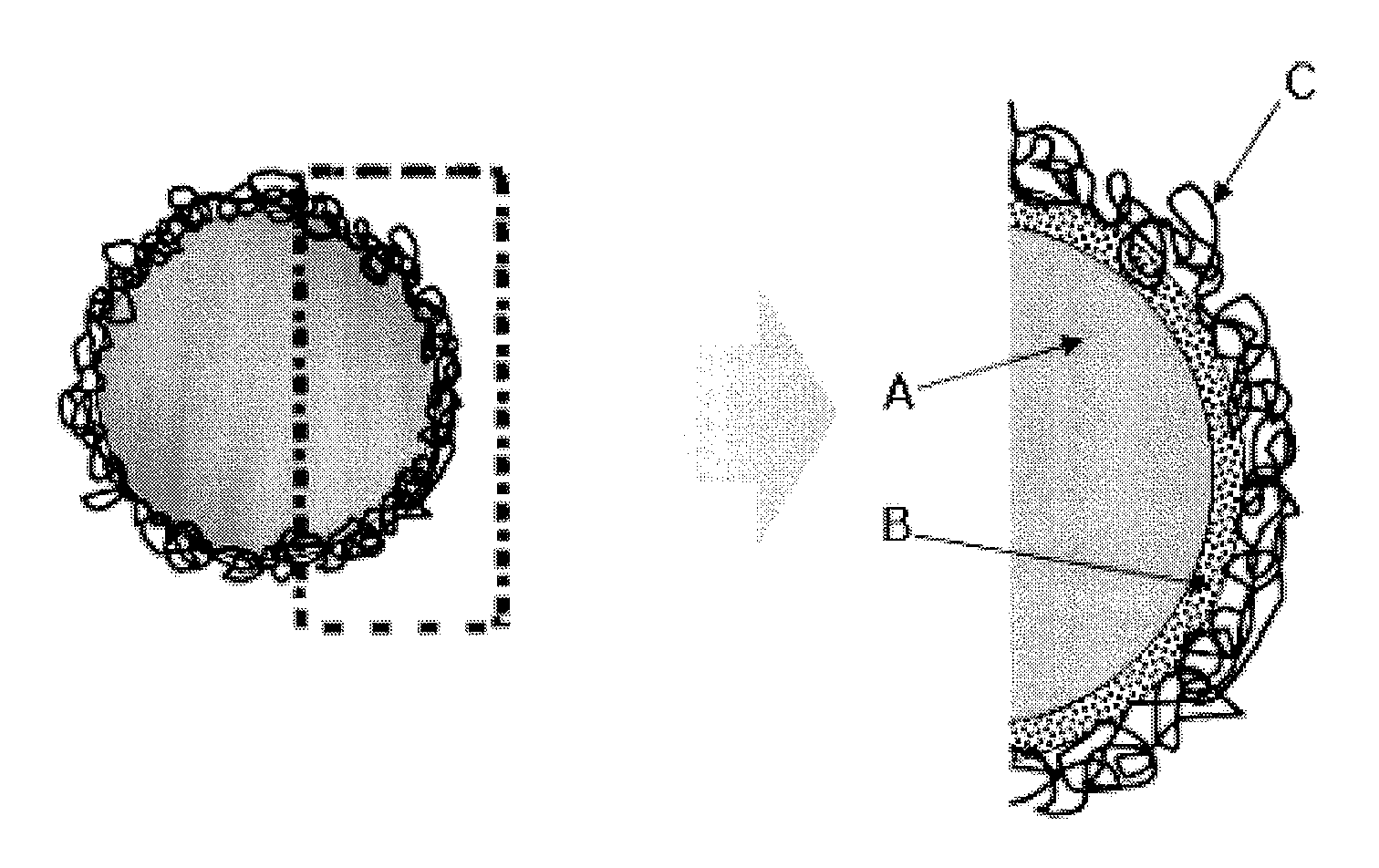

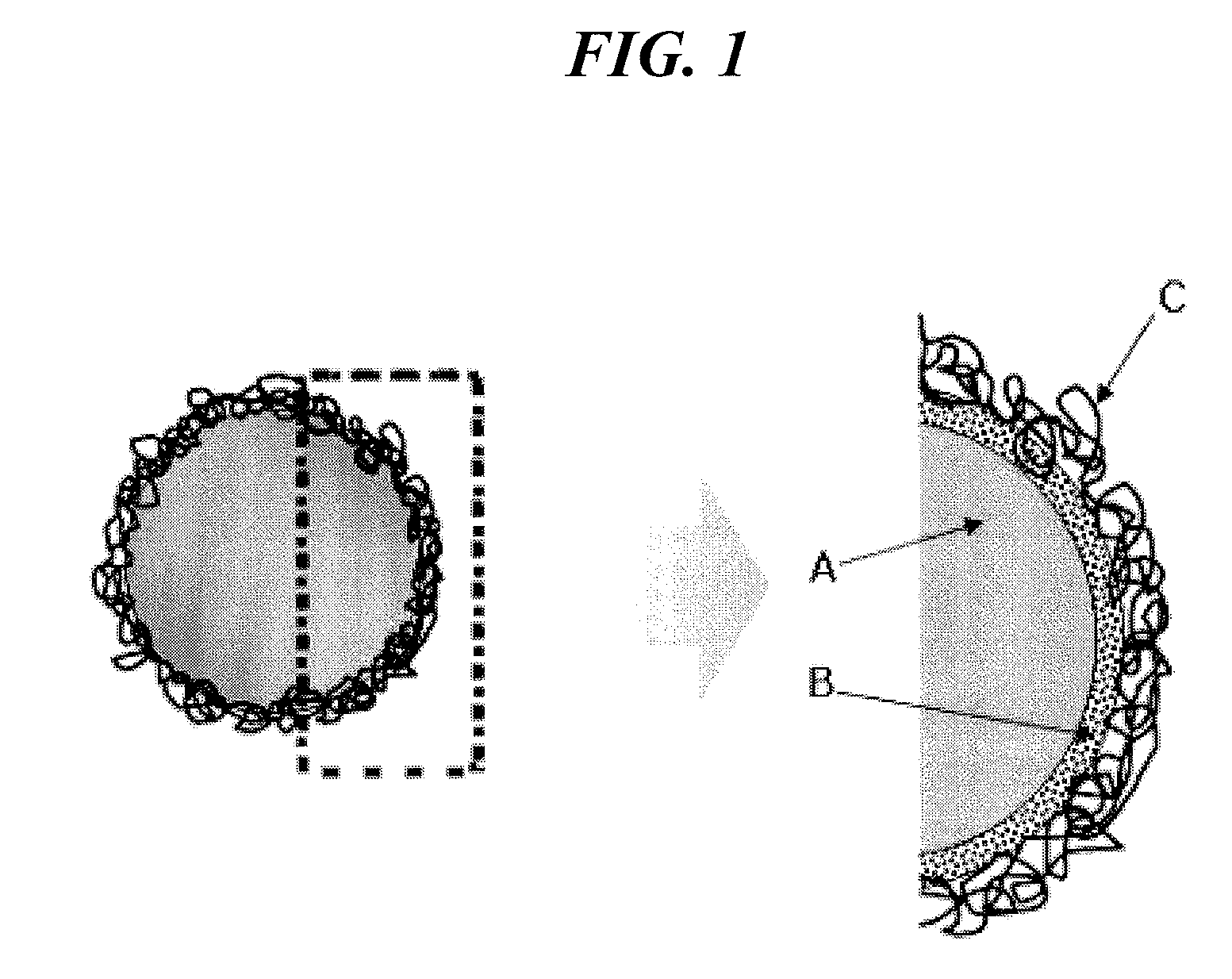

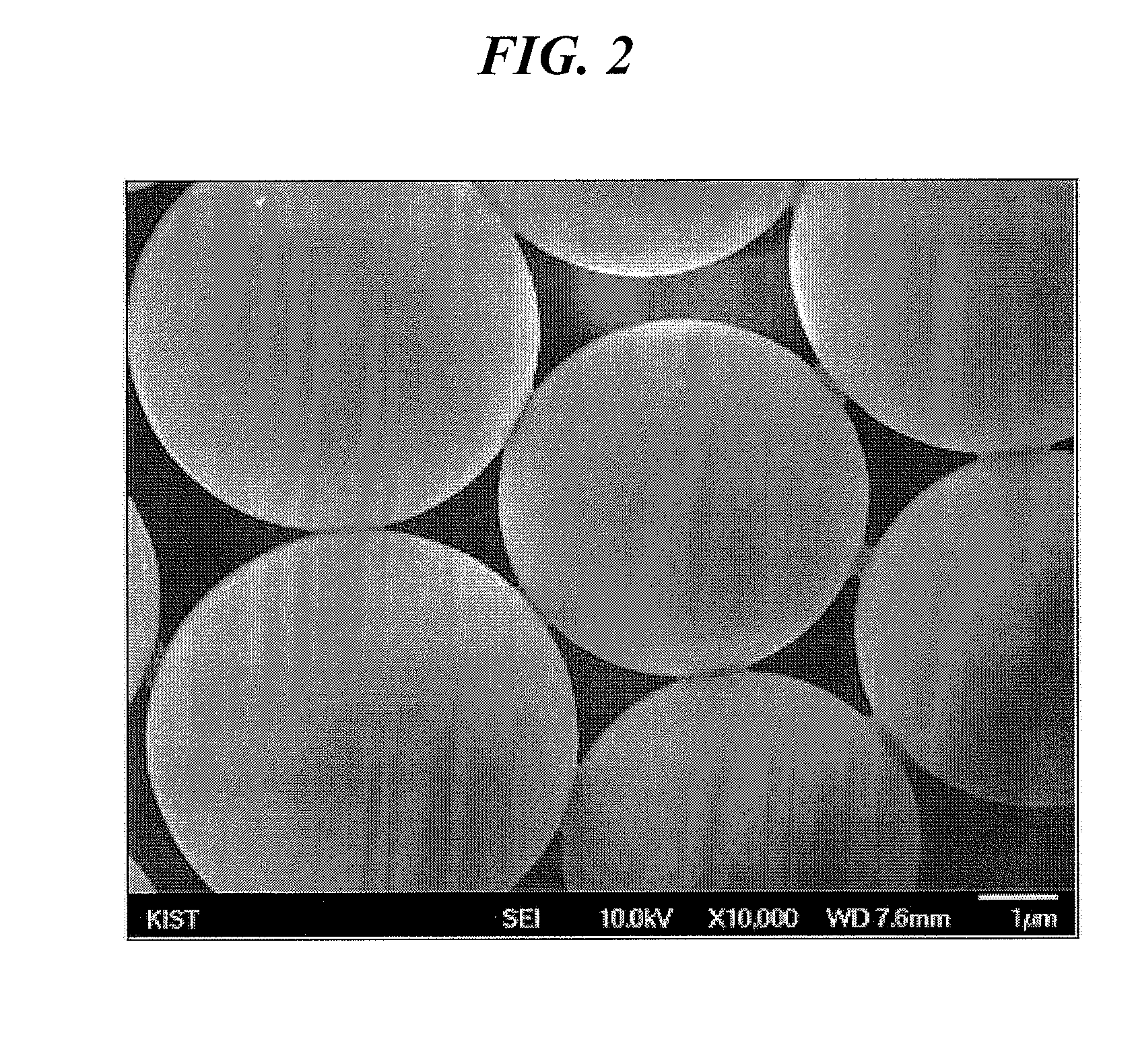

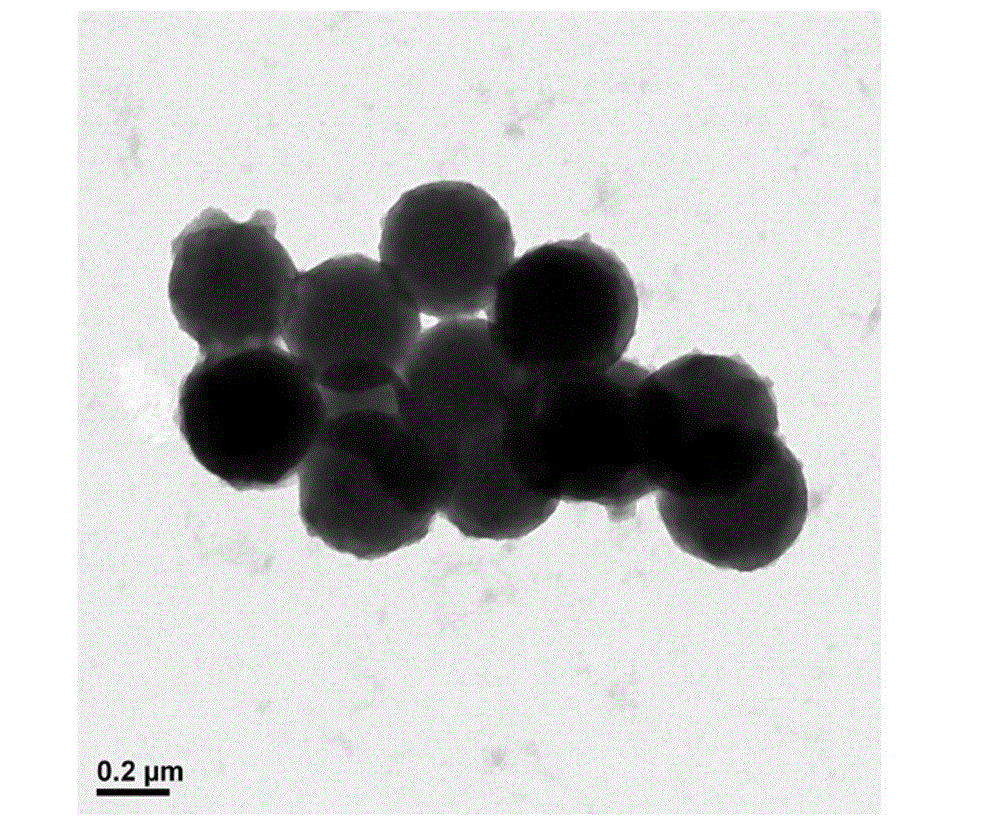

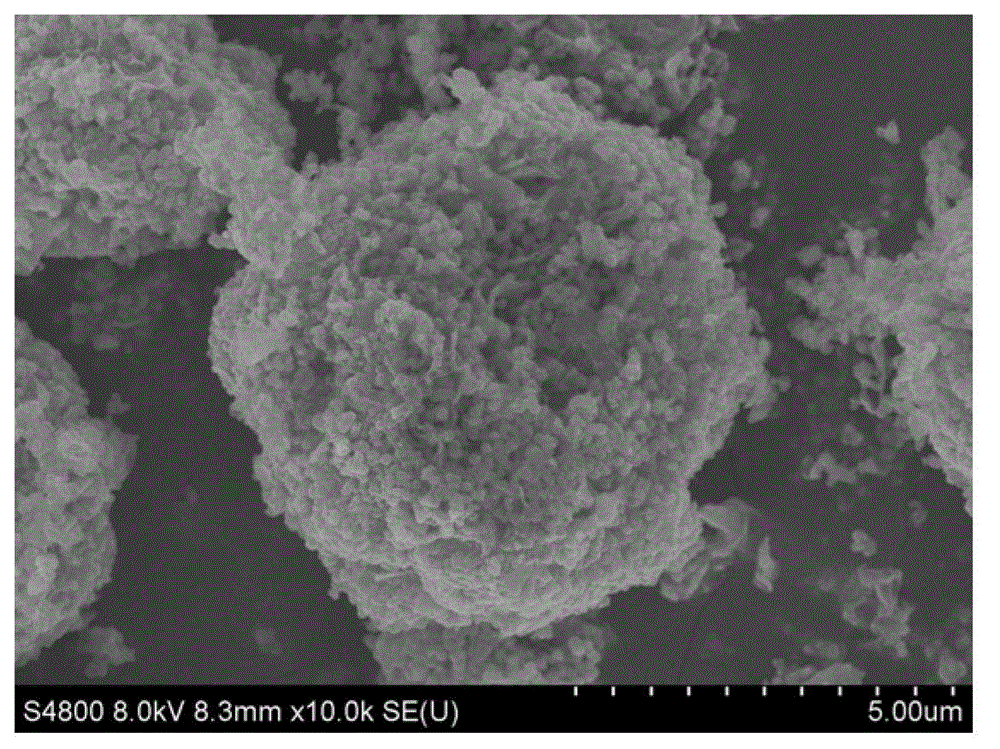

Electroconductive particle and anisotropic conductive film comprising same

InactiveUS20100247892A1Performance in of long-termLong-term of resistanceLiquid surface applicatorsConductive materialAnisotropic conductive filmGraphene coating

The present invention discloses an electroconductive particle comprising (a) a polymer microparticle, and (b) a graphene coating layer grafted on the polymer microparticle, which has improved long-term stability of the conductivity, surface conductivity, durability, and thermal resistance, and is applicable for producing an anisotropic conductive film used for packaging electronic devices.

Owner:KOREA INST OF SCI & TECH

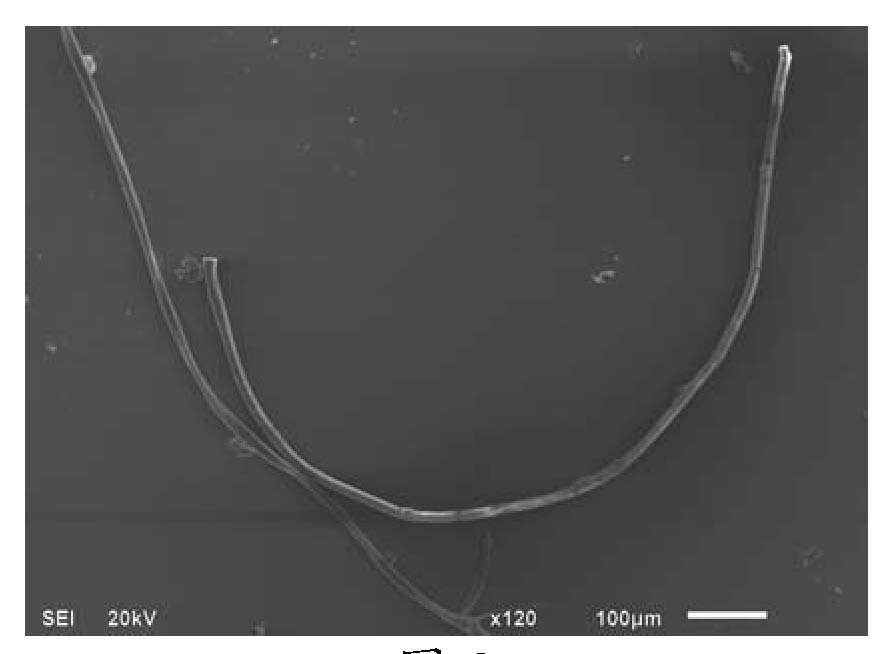

Three-dimensional graphene/metal line or metal wire composite structure and preparation method thereof

InactiveCN102560415AImprove conductivityThe structure is complete and free of defectsMaterial nanotechnologyPolycrystalline material growthGraphene coatingElectrical battery

The invention provides a three-dimensional graphene / metal line or metal wire composite structure and a preparation method thereof. According to the invention, metal lines or metal wires are adopted as a catalyst template; with a chemical vapor deposition method, a carbon source directly form graphene coatings on the outer surfaces of the metal lines, such that the graphene / metal line or metal wire composite structure is formed. The diameters of the metal lines or metal wires are 10nm-5000mum. The layer number of graphene is 1-100. The three-dimensional graphene / metal line or metal wire composite structure or graphene tube provided by the invention has excellent electric conductivity and corrosion resistance. The technology provided by the invention is simple, and the process is easy to control. The composite structure is advantaged in excellent electric conductivity and low preparation cost, and is suitable to be used in fields of solar energy devices, storage batteries, conductive composite materials, and corrosion resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of graphene composite conductive fiber

The invention discloses a preparation method of a graphene composite conductive fiber and relates to the technical field of graphene. The method comprises the following steps: processing a common textile polymer fiber with an organic solvent to remove impurities such as an oiling agent on the fiber surface; dipping the textile polymer fiber into an alkali liquor and an oxidized graphene solution, and enabling the fiber surface to fully contact the oxidized graphene; and dipping the dried fiber with an oxidized graphene coating into a solution containing a reducing agent to obtain the graphene composite conductive fiber. By adopting a simple dip coating method, the obtained composite fiber has mechanical property, high temperature resistance and flexibility performance of a traditional high polymer material and also has good conductivity. The method is easy to operate, environment-friendly and convenient to industrialize.

Owner:宁国市龙晟柔性储能材料科技有限公司

Preparation method and application of polyaniline/titanium dioxide/graphene conductive composite membrane

InactiveCN103144388ABroaden the photoresponse rangeImprove photocatalytic efficiencyNon-macromolecular adhesive additivesOrganic-compounds/hydrides/coordination-complexes catalystsQuantum yieldIn situ polymerization

The invention discloses a preparation method and application of a polyaniline / titanium dioxide / graphene conductive composite membrane. The preparation method comprises the steps of: adding 3-60wt% of titanium dioxide, 0.05-5wt% of graphene and 0.6-10wt% of polyaniline into protonic acid solution, and adopting an in-situ polymerization method to obtain a polyaniline / titanium dioxide / graphene conductive composite; sequentially and evenly coating conductive resin and polyaniline / titanium dioxide / graphene coatings to matrixes such as polypropylene, glass slides, metal plates and the like, wherein each coating is 30-500mu m thick; and drying at 60-80 DEG C to obtain the needed product. According to the preparation method, the titanium dioxide is embedded in a conductive material to prepare the membrane, the defects that the nano TiO2 is not easy to recover and the quantum yield is low can be overcome, the separation efficiency of photoproduction electrons and cavities can be improved, the photoresponse range can be extended, and the photocatalytic efficiency can be improved.

Owner:SICHUAN AGRI UNIV

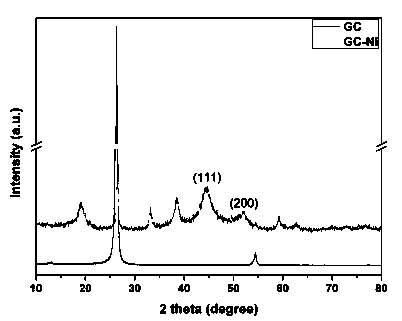

Chemical nickel-plating graphene preparation method

ActiveCN103361637AUniform thicknessFlat surfaceLiquid/solution decomposition chemical coatingGraphene coatingGraphite

The invention provides a chemical nickel-plating graphene preparation method and particularly provides a process method for improving the performance of graphene by nickeling the graphene. Chemical nickel-plating graphene is prepared by coarsening, sensitizing, activating, reducing, nickelizing and refining the graphene. A coating is added to the graphene by adopting a chemical nickel-plating technology. The preparation method is simple and can be used for continuous production. The prepared graphene coating is uniform in thickness and voidless and has a bright, clean and smooth surface.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Aqueous anticorrosive modified graphene coating material, and preparation method and application thereof

ActiveCN105838183AImprove mechanical propertiesImprove water resistanceAnti-corrosive paintsPolymer modifiedWater dispersible

The invention relates to an aqueous anticorrosive modified graphene coating material, and a preparation method and an application thereof. The preparation method comprises the following steps: oxidizing natural graphite in an oxidant, modifying the surface of the obtained graphite oxide with an atom transfer radical polymerization (ATRP) initiator with different structures, adding a monomer, a high-valence catalyst, a ligand and a reducing agent to make the monomer undergo atom transfer radical polymerization (AGET ATRP) on the surface of graphene for electron transfer to generate an activator, and reducing graphene oxide (GO) by the reducing agent to obtain a water-dispersible polymer modified graphene material. The polymer modified graphene material can be used to prepare aqueous coatings, can be used to protect the surfaces of metal materials, can effectively isolate a corrosion medium from a substrate, and has excellent water, corrosion and weather resistance, and the preparation method has the advantages of simplicity, high efficiency, easy industrial production and wide application values.

Owner:CHANGZHOU HUAKE POLYMERS

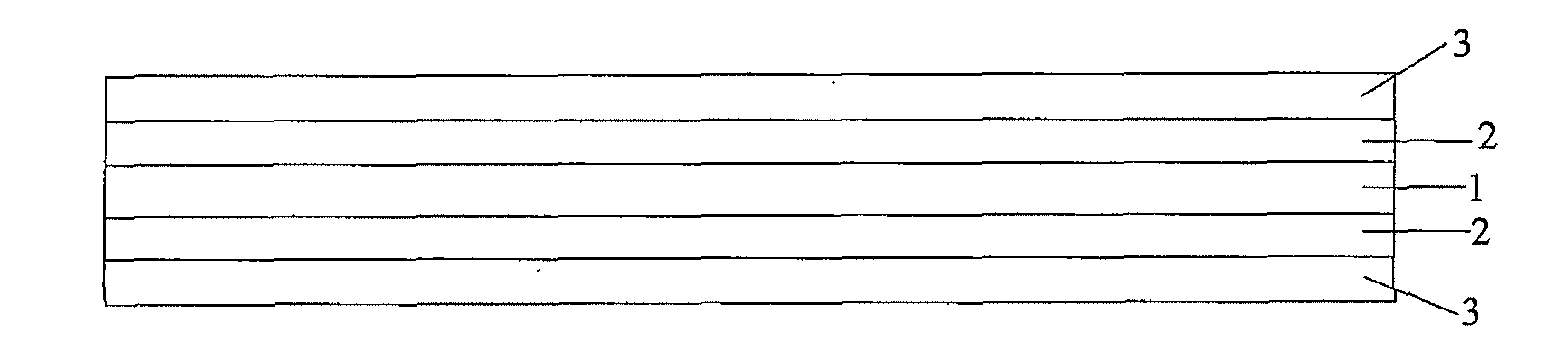

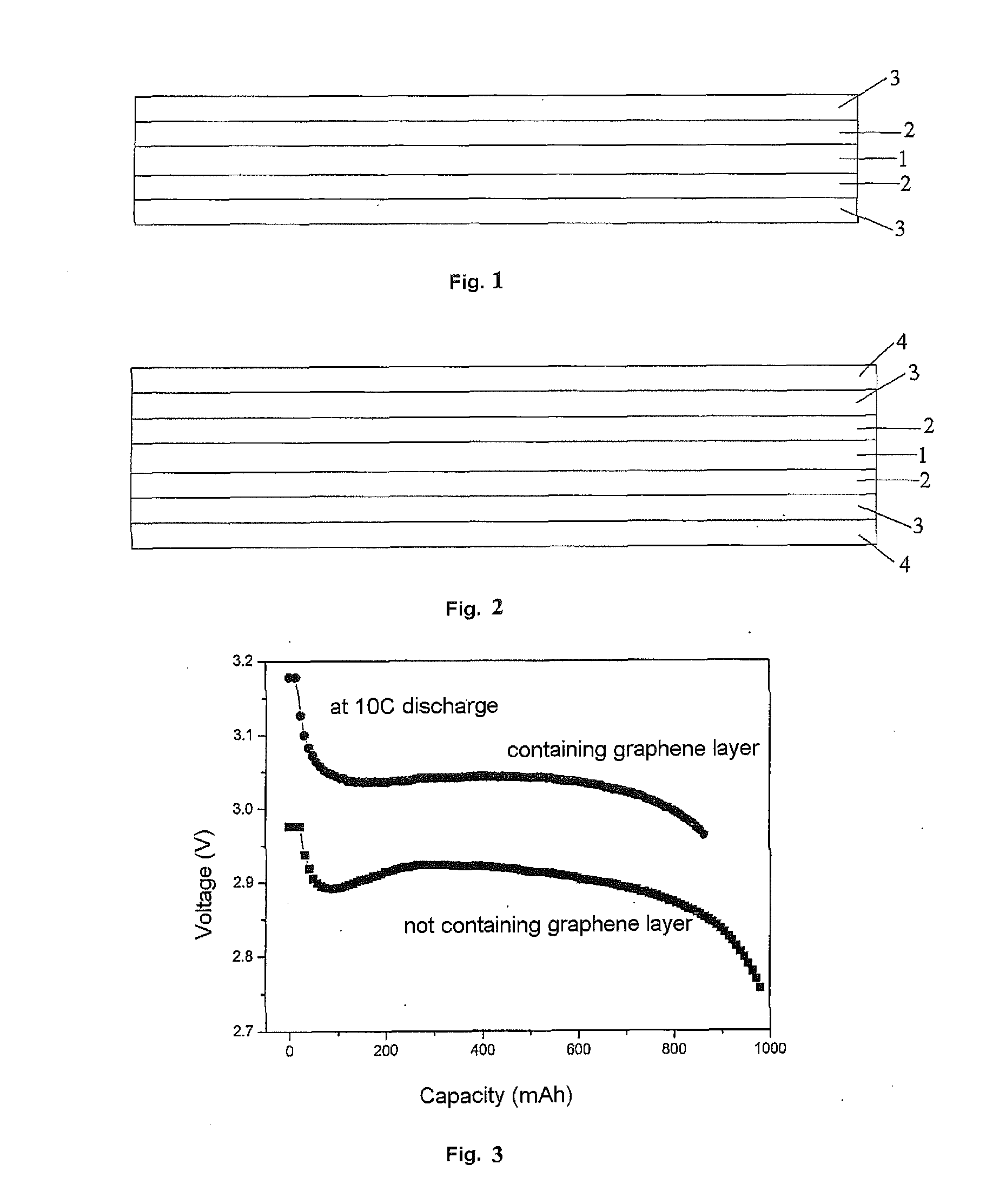

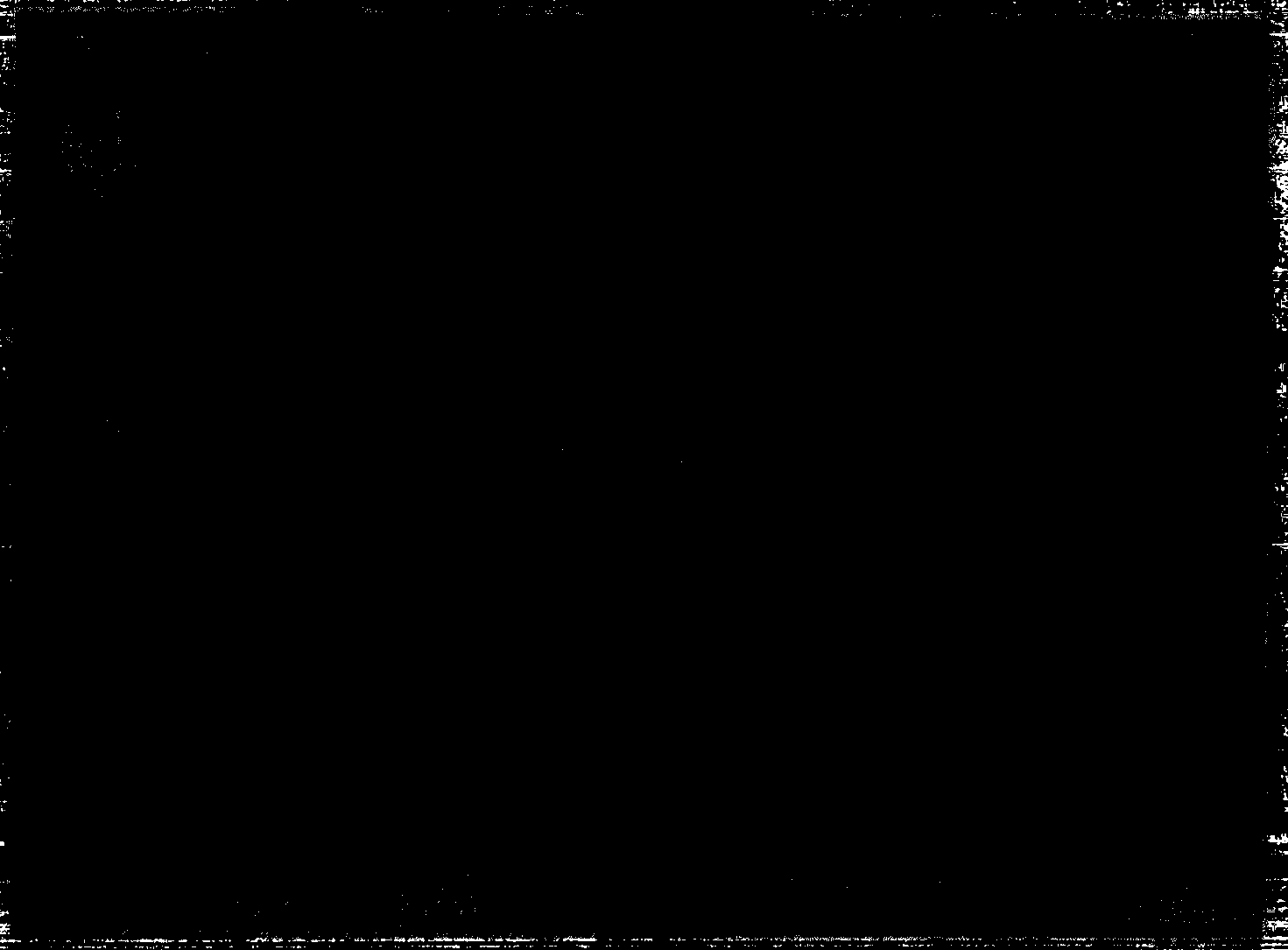

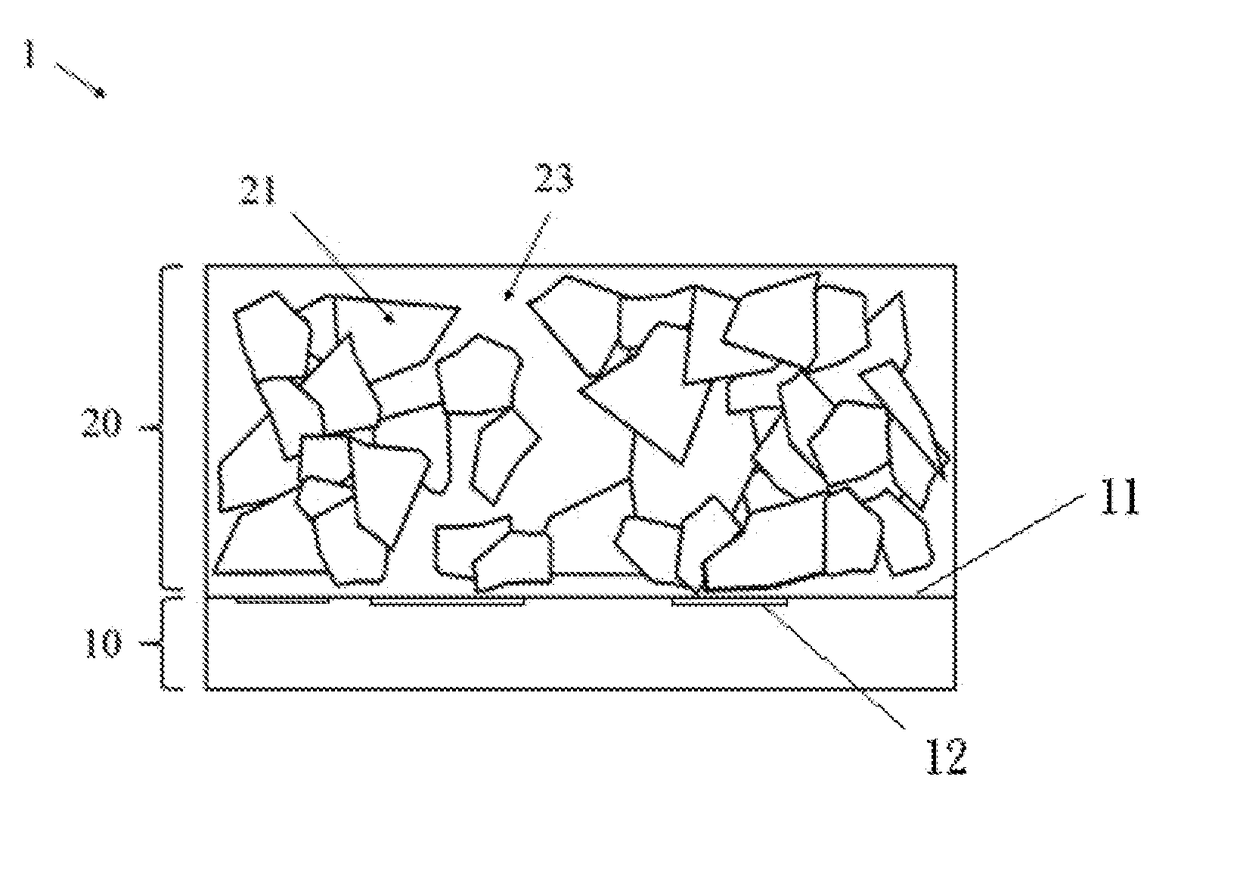

Graphene coating modified electrode plate for lithium secondary battery and method for producing the same

ActiveUS20140315083A1Improve conductivityIncreases electrical conductivity and dissipation functionElectrode collector coatingNon-aqueous electrolyte accumulator electrodesGraphene coatingLithium-ion battery

The present invention provides a graphene coating-modified electrode plate for lithium secondary battery, characterized in that, the electrode plate comprises a current collector foil, graphene layers coated on both surfaces of the current collector foil, and electrode active material layers coated on the graphene layers. A graphene coating-modified electrode plate for lithium secondary battery according to the present invention comprises a current collector foil, graphene layers coated on both surfaces of the current collector foil, and electrode active material layers coated on the graphene layers. The graphene-modified electrode plate for lithium secondary battery thus obtained increases the electrical conductivity and dissipation functions of the electrode plate due to the better electrical conductivity and thermal conductivity of graphene. The present invention further provides a method for producing a graphene coating-modified electrode plate for lithium secondary battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

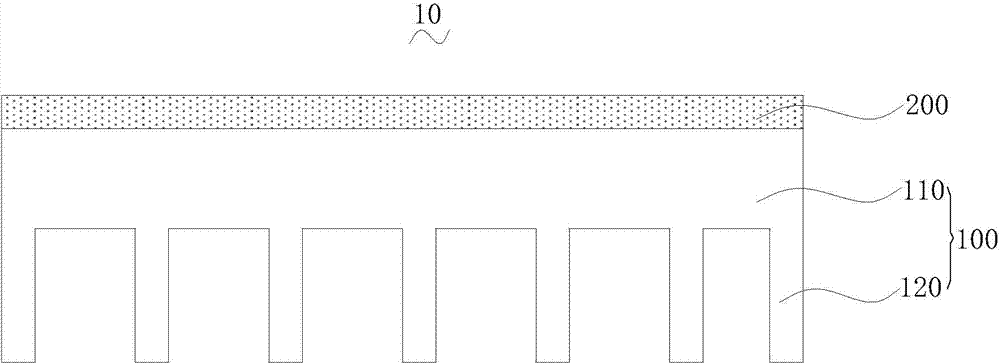

Graphene-coating mesoporous carbon-base metal oxide as well as preparation method thereof and application

InactiveCN103647064AHigh charge and discharge capacityImprove cycle performanceMaterial nanotechnologyHybrid capacitor electrodesMesoporous silicaSilicon dioxide

The invention relates to a graphene-coating mesoporous carbon-base metal oxide as well as a preparation method of the graphene-coating mesoporous carbon-base metal oxide and application of the graphene-coating mesoporous carbon-base metal oxide. The preparation method of the graphene-coating mesoporous carbon-base metal oxide comprises the following steps of (1) preparing mesoporous silicon dioxide; (2) filling a pore channels of a silicon dioxide template with carbon-base metal oxide; (3) aminating the surface of the silicon dioxide template; (4) preparing graphene oxide; (5) preparing silicon dioxide with carbon-base metal oxide contained in the graphene-oxide-coating pore channels in a self-assembling way; (6) reducing the graphene oxide to the graphene; (7) removing the silicon dioxide template; and (8) centrifuging, washing and drying. The graphene-coatinng mesoporous carbon-base metal oxide has excellent electrochemical properties and can be used as an electrode material of a lithium battery and a super-capacitor.

Owner:BEIJING NORMAL UNIVERSITY

Graphene-coated glass fiber reinforced resin-based composite material and preparation method thereof

ActiveCN104262953ASolve the problem of fragmentationImprove bending strengthGlass fiberGraphene coating

The invention provides a graphene-coated glass fiber reinforced resin-based composite material. The preparation method comprises the following steps of dispersing graphene modified by a silane coupling agent in water to obtain a uniformly-dispersed aqueous dispersion, dipping glass fibers into the aqueous dispersion of the modified graphene so that compact and uniform graphene coatings are formed on surfaces of the glass fibers under the action of electrostatic adsorption, and carrying out compounding molding on the glass fibers with the graphene coatings and a resin matrix to obtain a composite material. The graphene coatings are arranged on the surfaces of the glass fibers so that the interaction area and interface bonding strength of the fibers and the matrix are improved, graphene dispersion is avoided and excellent composite material mechanical properties are obtained. The preparation method has simple processes, a low cost and good practicality.

Owner:JUSHI GRP CO

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

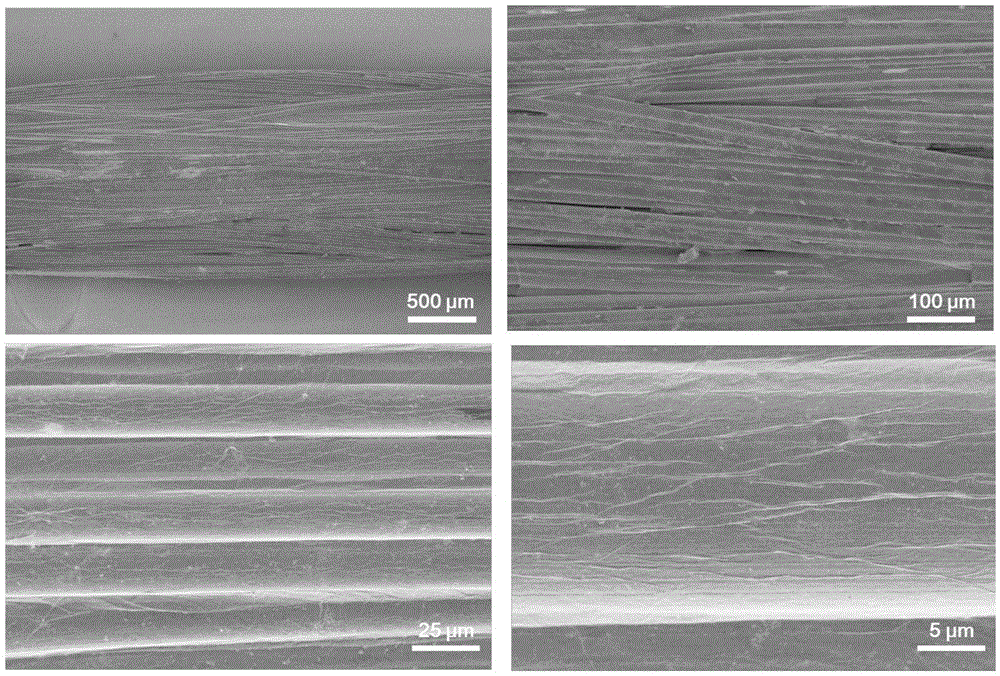

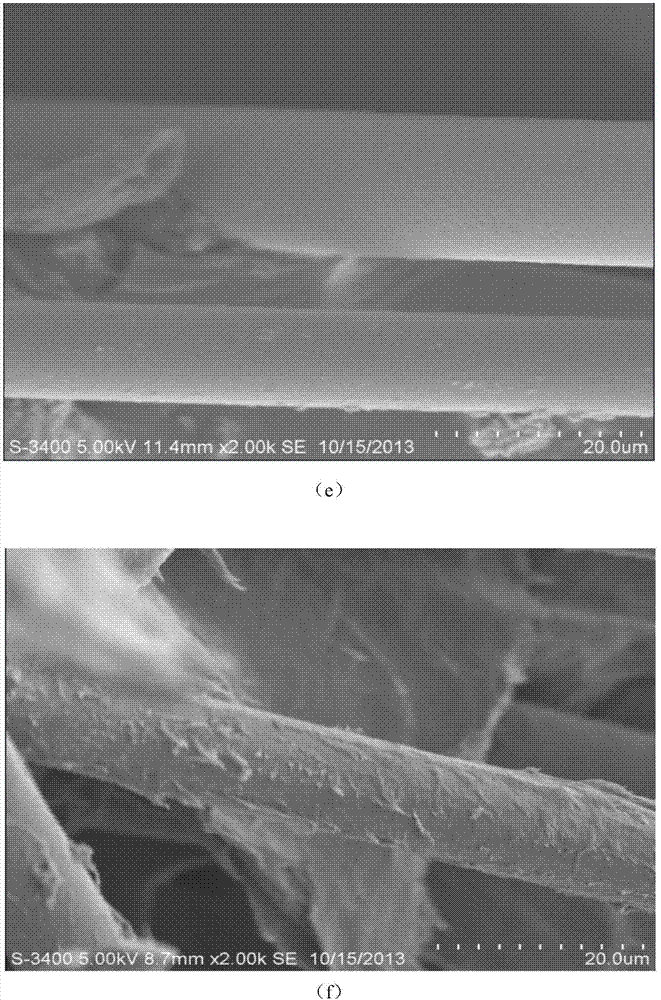

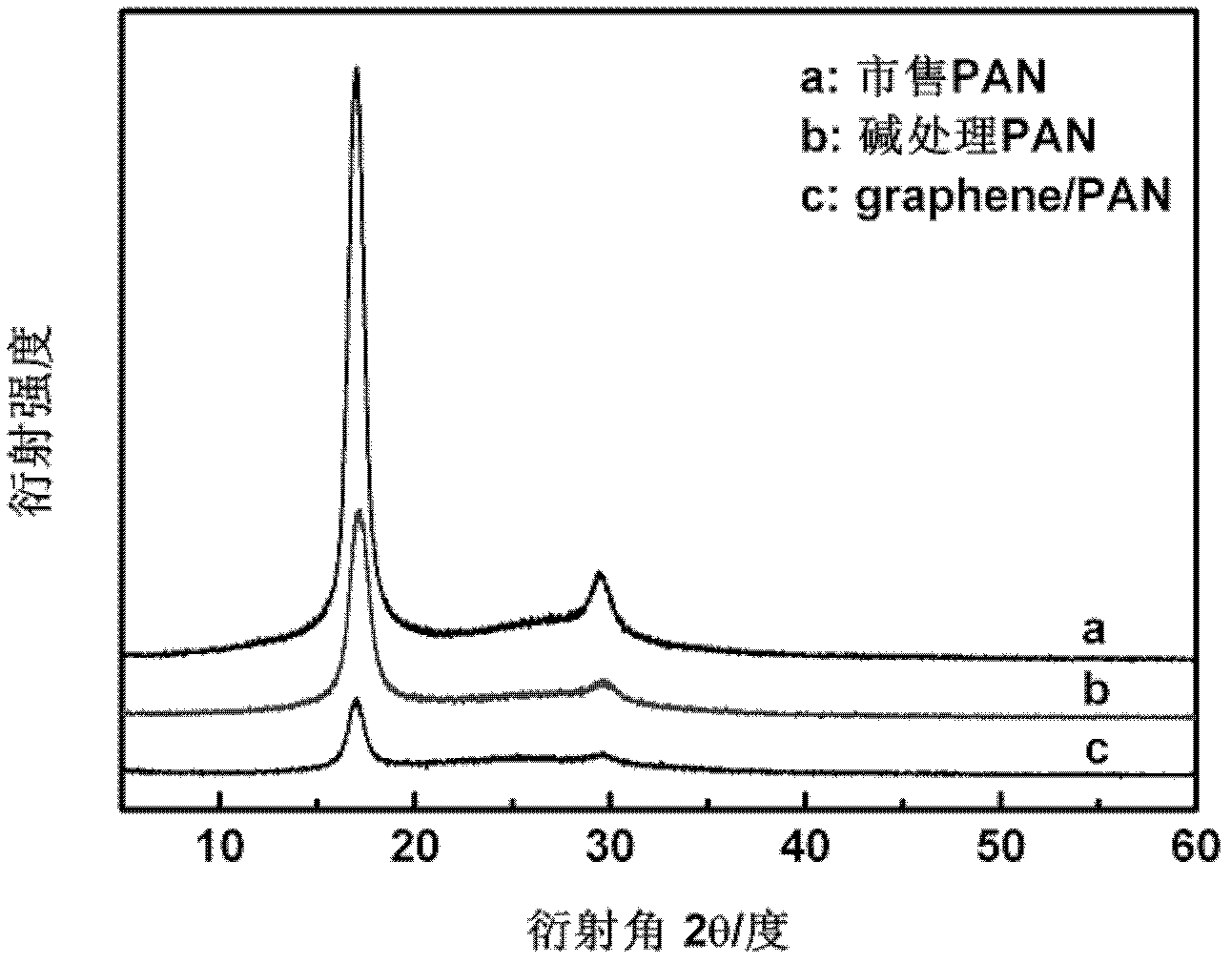

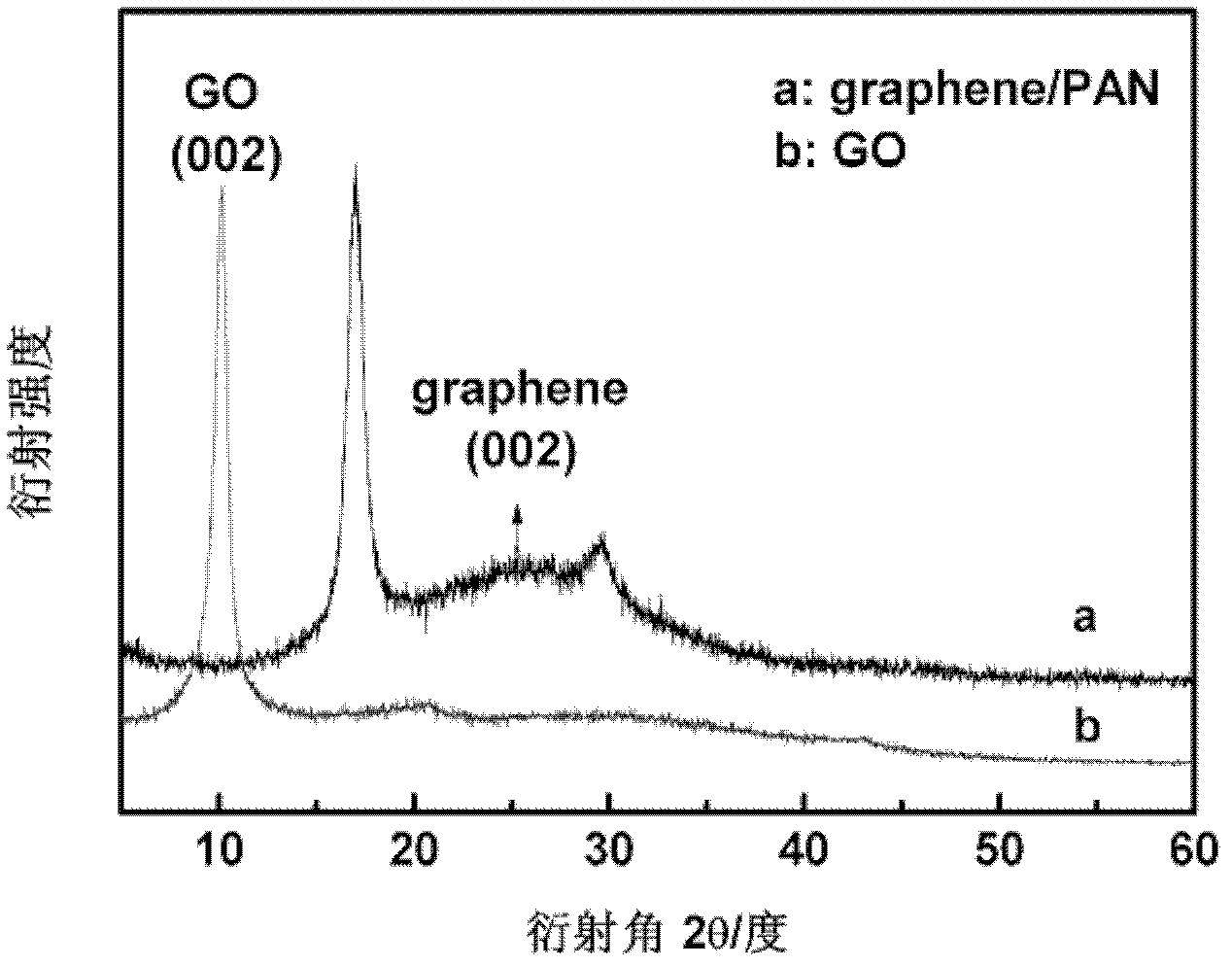

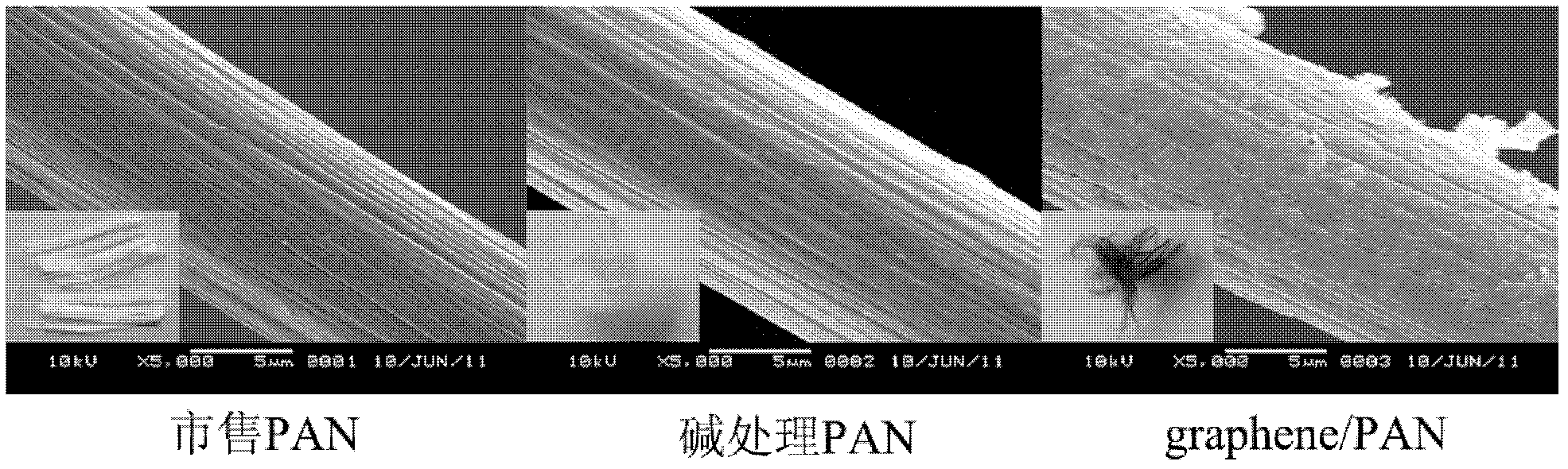

Preparation method of graphene coating polyacrylonitrile fiber composite material

ActiveCN102619080APromote functional designSimple methodFibre typesGrapheneGraphene coatingHydrazine compound

The invention relates to a preparation method of a graphene coating polyacrylonitrile fiber composite material. The preparation method comprises the following steps of: (1) processing polyacrylonitrile by using alkali; (2) preparing a polyacrylonitrile fiber with modified single layer KH550; (3) preparing a polyacrylonitrile fiber with modified single layer graphite oxide; (4) using the polyacrylonitrile fiber with the modified single layer graphite oxide as a raw material, repeating the step (2) and the step (3), and obtaining the polyacrylonitrile fiber with modified multiplayer graphite oxide; and (5) placing the polyacrylonitrile fiber with the modified multiplayer graphite oxide in a graphite oxide dispersion liquid, then dropwise adding a hydrazine hydrate aqueous solution, carrying out heating reaction, finally cooling, washing and drying to obtain the graphene coating polyacrylonitrile fiber composite material. The preparation method provided by the invention is simple; the graphite of the composite material provided by the invention is good in reduction degree and uniformly coats the surface of the polyacrylonitrile; and compared with a commercial finished product, the composite material has the advantages that the resistivity of a single wire is reduced by six order of magnitudes, and the composite material has the application prospect of conductive fiber preparation.

Owner:SHENGQUAN HEALTANG

Supporting anti-corrosive coating modified by graphene, preparation and application thereof

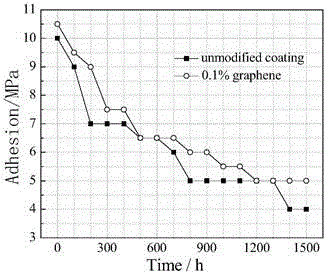

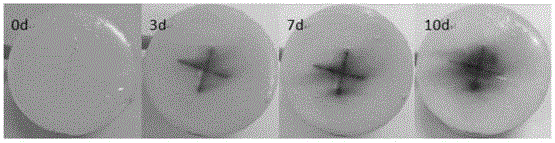

ActiveCN105419437AEvenly dispersedAvoid reunionLiquid surface applicatorsAnti-corrosive paintsOrganic solventGraphene coating

The invention relates to anti-corrosive coatings and particularly provides a supporting anti-corrosive coating modified by graphene, preparation and an application thereof. The supporting anti-corrosive coating is composed of an undercoat, an intermediate coating and a finishing coat, wherein the undercoat and the intermediate coating are modified graphene coatings and the finishing coat is polyurethane finishing coat or fluorocarbon finishing coat. The modified graphene coating is prepared by mixing a surfactant, as a modifier, with graphene to modify the graphene, dispersing the modified graphene in an organic solvent, and adding the dispersed mixture to organic resin, a curing agent and an additive. The supporting anti-corrosive coating is excellent in anti-water-seepage and salt-fog-resistant performance, is simple in process and is low in cost, and can be used as a heavy anti-corrosion coating for coating oil pipelines, oil storage tanks, chemical devices, ships and marine platforms and the like substrates for prolonging service life of the metal substrates.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Negative pole material of lithium ion battery, preparation method of material and lithium ion battery

ActiveCN102881881AImprove cycle performanceImprove Capacitive PerformanceCell electrodesTin dioxideElectrical battery

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

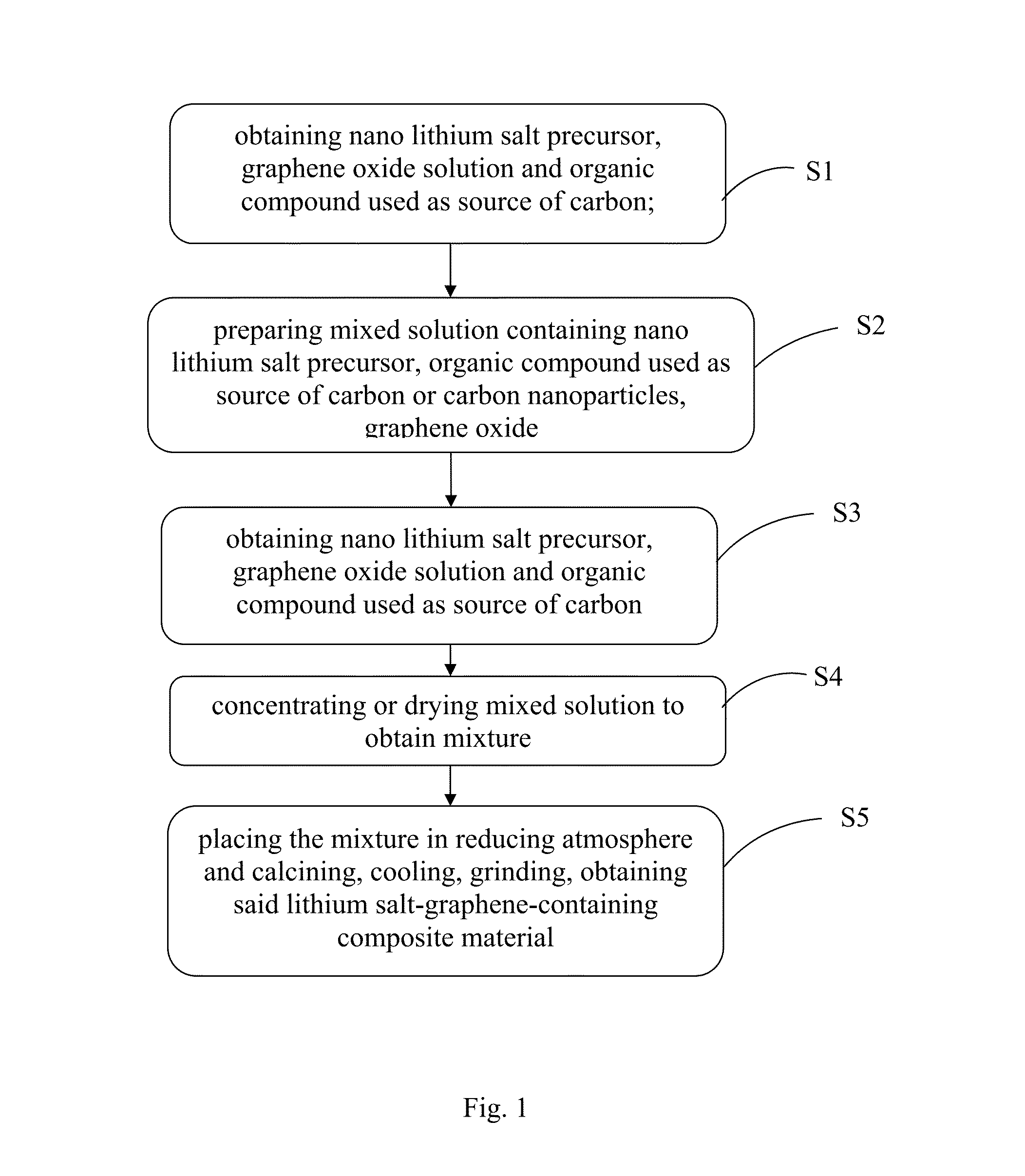

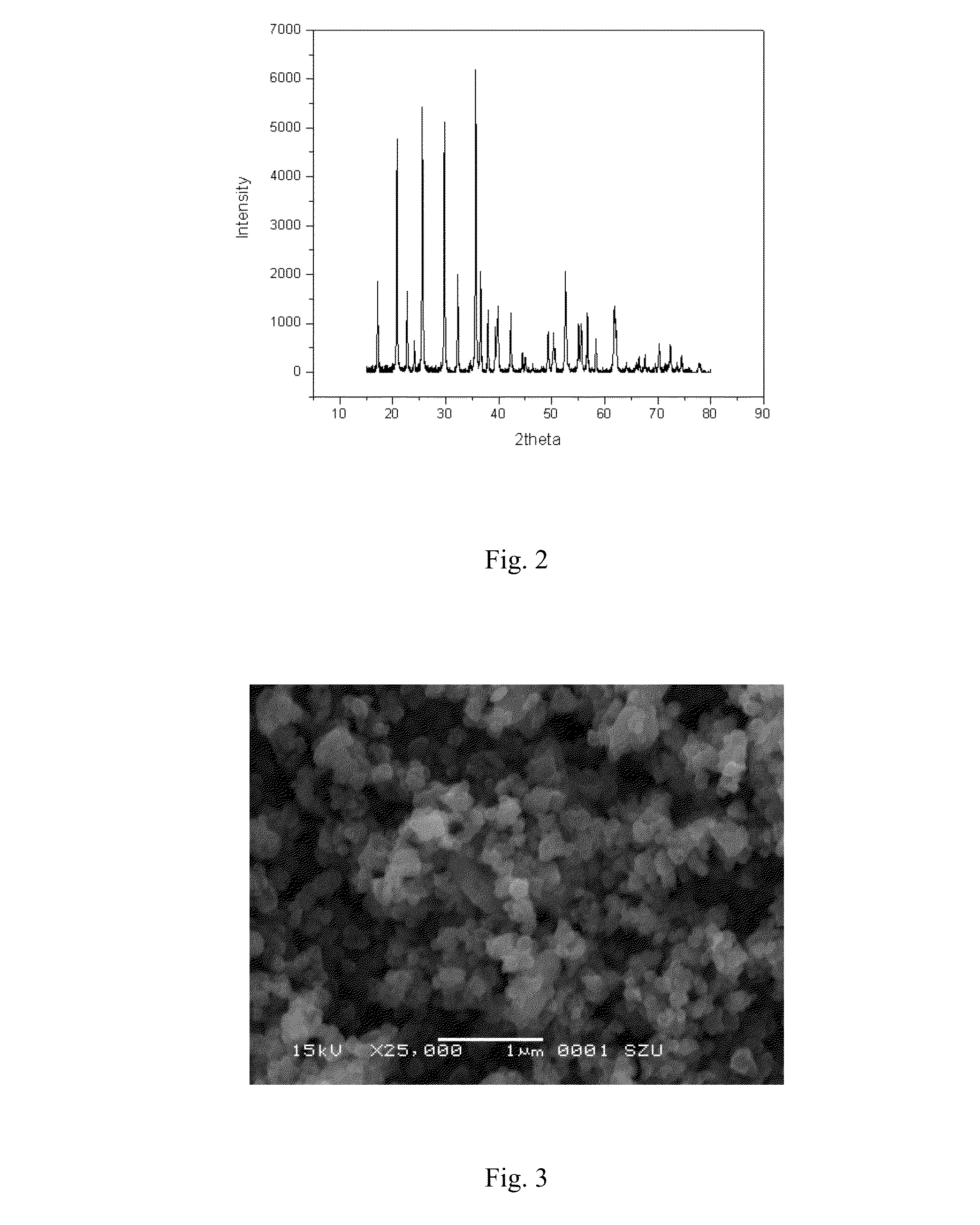

Lithium salt-graphene-containing composite material and preparation method thereof

InactiveUS20130157135A1Low conductivityLow costMaterial nanotechnologyElectrode thermal treatmentCarbon coatingGraphene coating

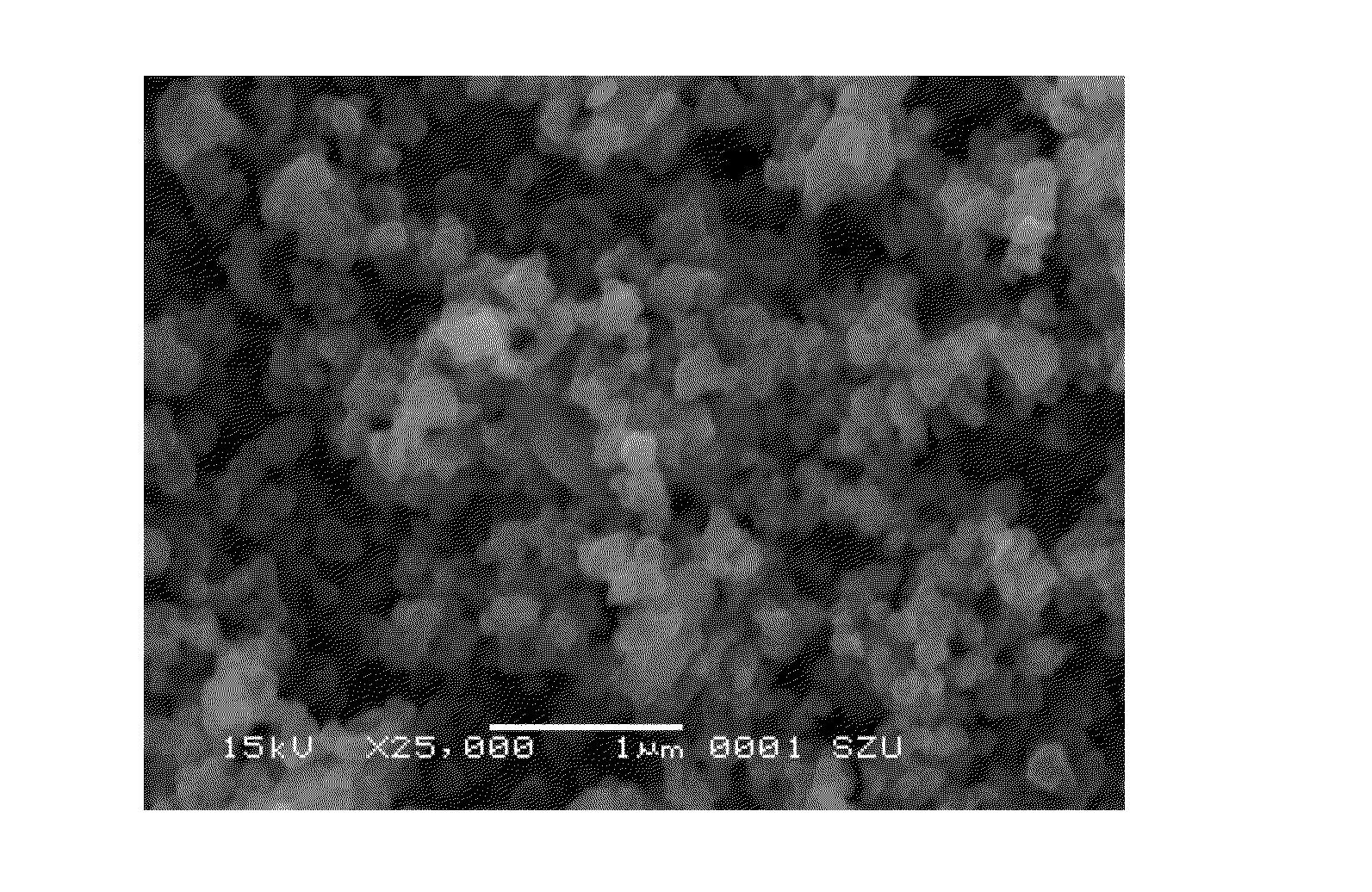

A lithium salt-graphene-containing composite material and its preparation method are provided. The composite material has the microstructure which comprises carbon nanoparticles, lithium salt nanocrystals and graphene, wherein the surface of lithium salt nanocrystals is coated with carbon nanoparticles and graphene. The preparation method comprises concentrating and drying a mixed solution, then calcinating the solid. The lithium salt-graphene-containing composite material has excellent electric performance and stability since the problem of low electric performance resulted from carbon coating on the surface of lithium salt or coating imperfection resulted from graphene coating on the surface of lithium salt is effectively solved. For the more uniform and compacted combination between graphene and lithium salt nanocrystals, the graphene will not fall off and the composite material has a high capacity ratio, energy density and conductivity. Furthermore, particle agglomeration and growing up are reduced in the process of calcination.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

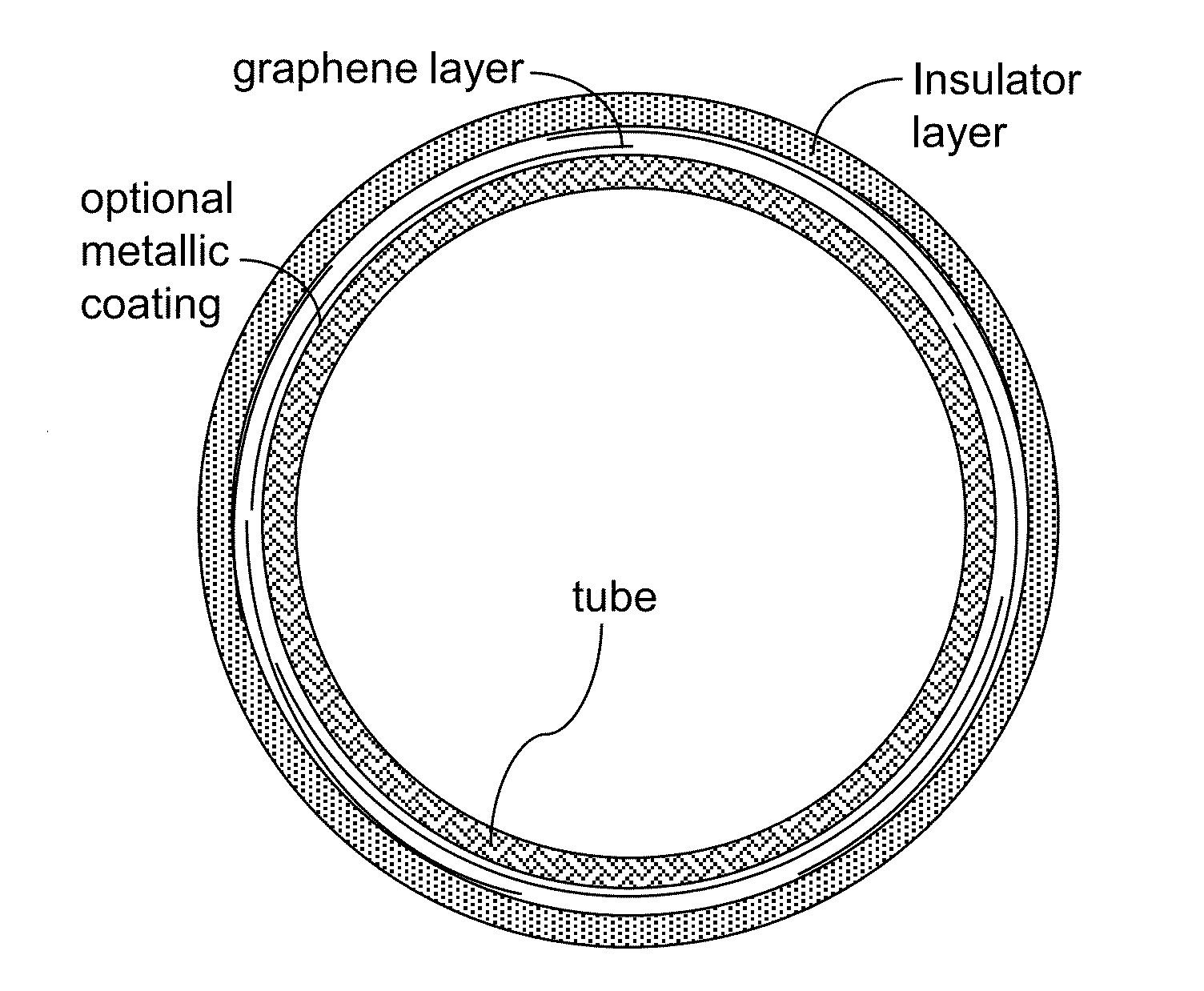

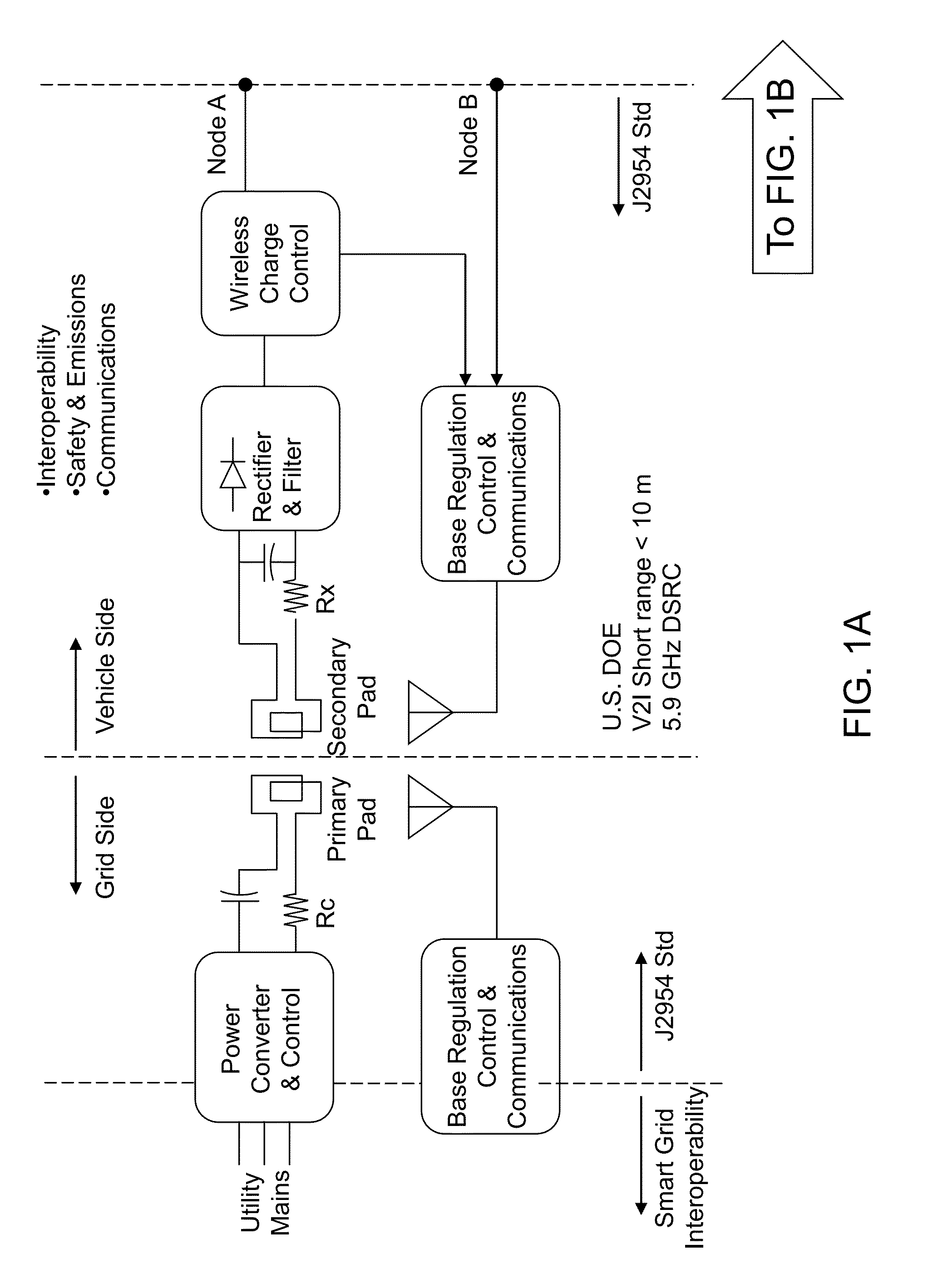

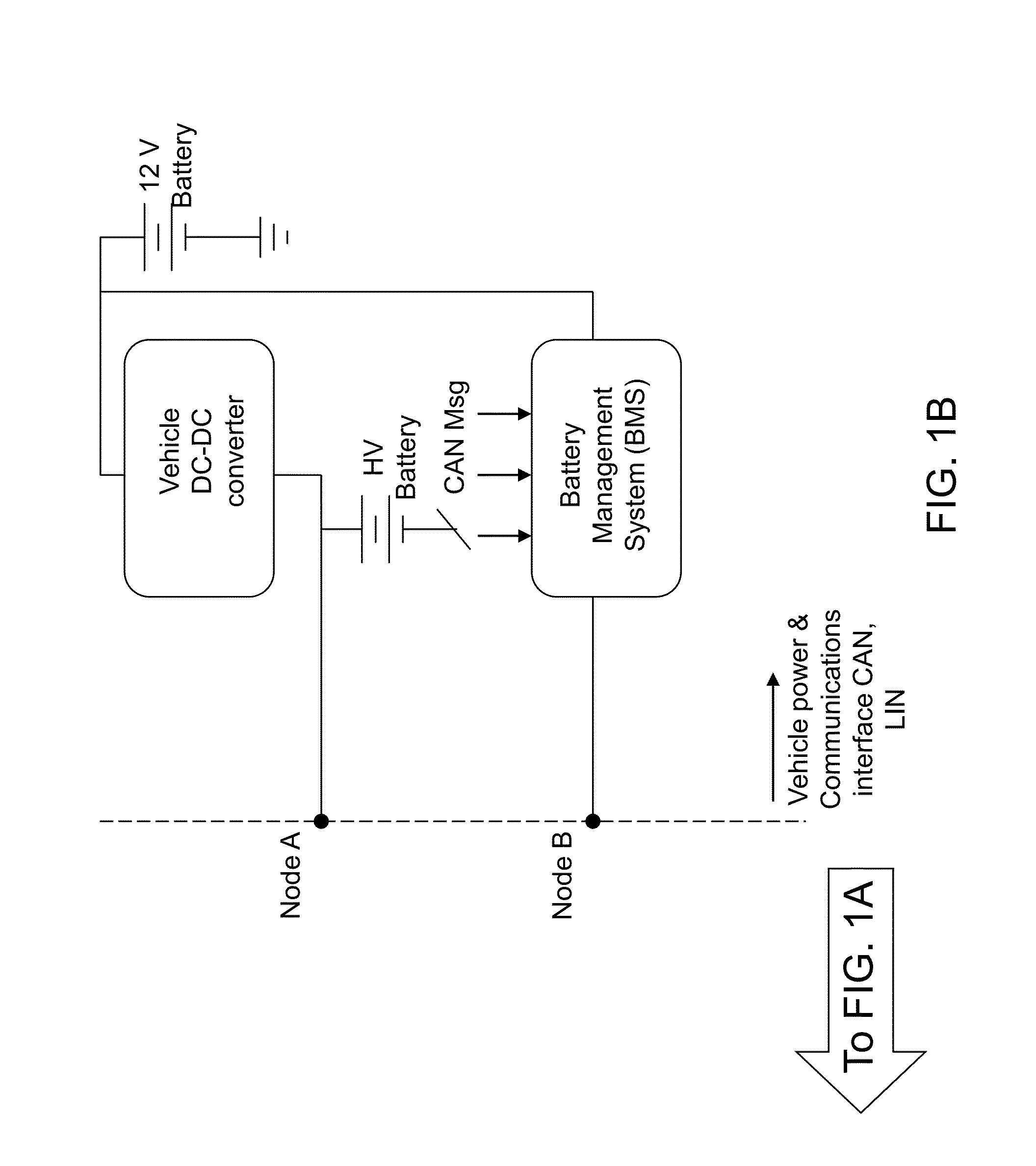

Graphene-coated coupling coil for ac resistance reduction

InactiveUS20130020877A1Improve conductivityNon-insulated conductorsElectromagnetic wave systemAlternating currentElectric power

At least one graphene layer is formed to laterally surround a tube so that the basal plane of each graphene layer is tangential to the local surface of the tube on which the graphene layer is formed. An electrically conductive path is provided around the tube for providing high conductivity electrical path provided by the basal plane of each graphene layer. The high conductivity path can be employed for high frequency applications such as coupling coils for wireless power transmission to overcome skin depth effects and proximity effects prevalent in high frequency alternating current paths.

Owner:UT BATTELLE LLC

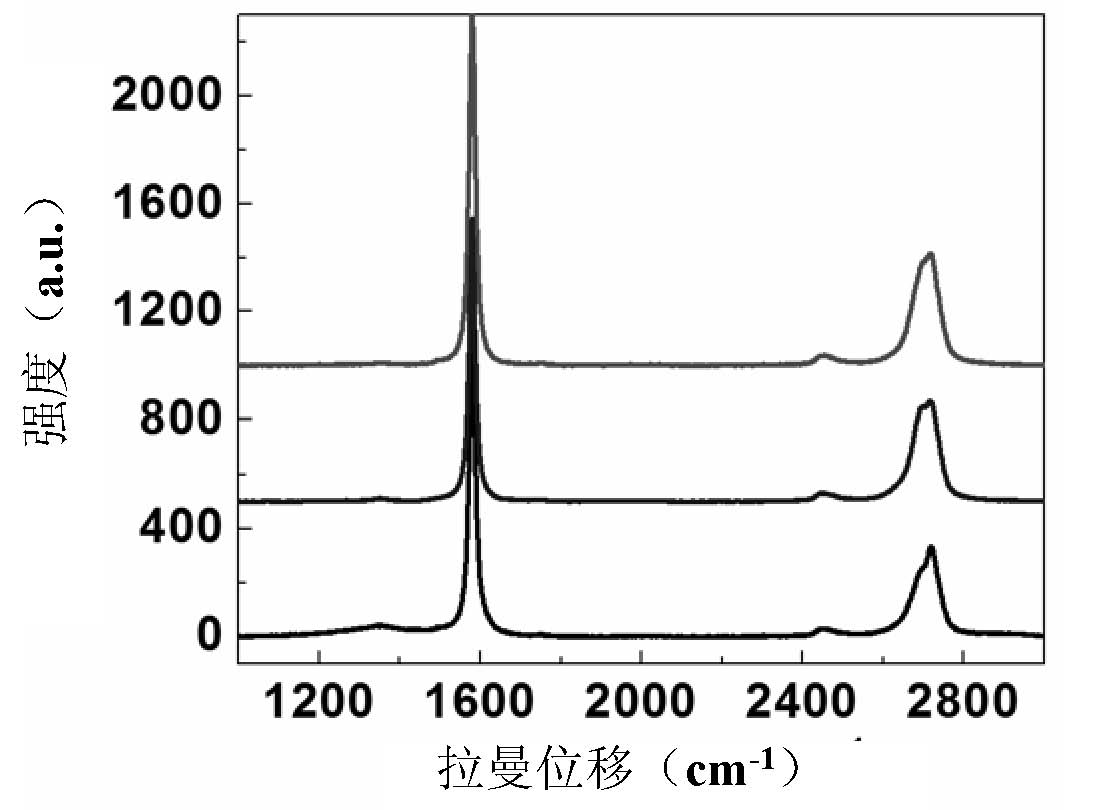

High-conductivity composite carbon fiber and preparation method thereof

InactiveCN103144356ALow resistivityImprove conductivityVacuum evaporation coatingSputtering coatingMetal coatingYarn

The invention discloses a high-conductivity composite carbon fiber and a preparation method thereof, and belongs to composite carbon fibers and a preparation method thereof. The high-conductivity composite carbon fiber provided by the invention consists of carbon fibers as well as metal coatings and graphene coatings, which are sequentially adhered on the surfaces of the carbon fibers from bottom to top; the carbon fibers are carbon fiber yarns, carbon fiber bundles, carbon fiber cloth, carbon fiber paper or carbon fiber fabrics; the metal coatings are a metal copper coating, a metal nickel coating or a metal iridium coating; and the thicknesses of the metal coatings are 50-500nm. The composite carbon fiber prepared by the invention has excellent conductivity and heat conductivity, can conduct or dissipate lightning stroke energy rapidly, and improves the thunder stroke resistant capability of the carbon fiber material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

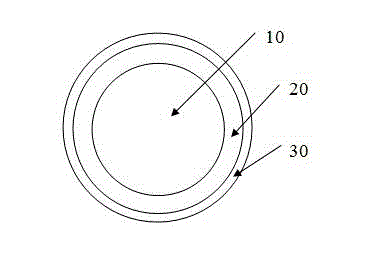

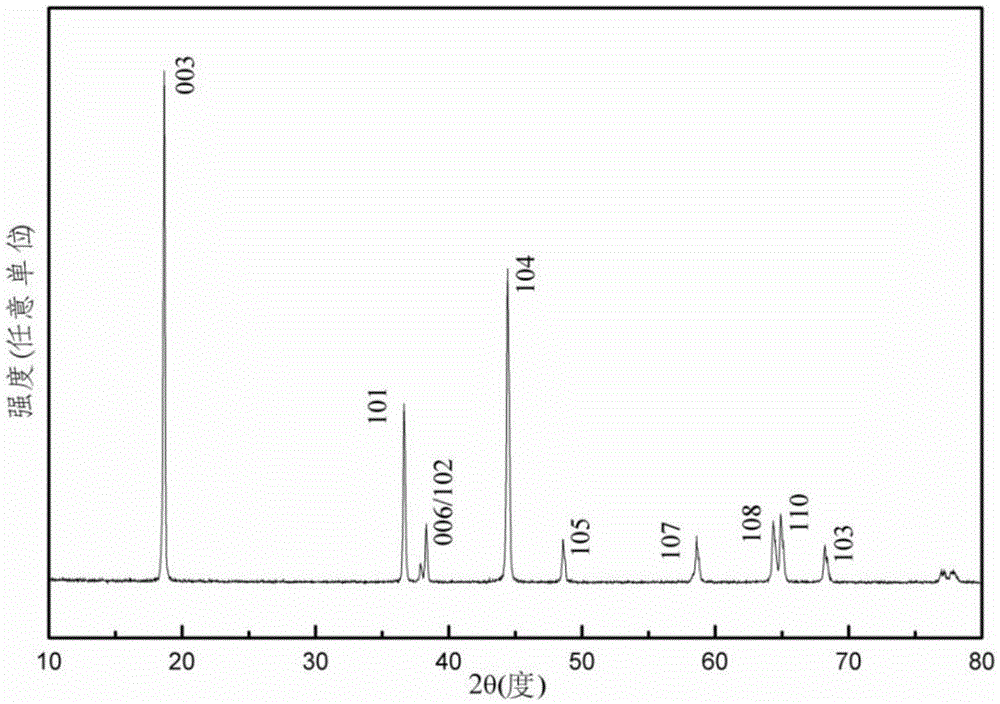

Modified lithium nickel cobalt manganese oxide cathode material and preparation method thereof

ActiveCN105552360AImprove Interface StabilityImprove electronic conductivityCell electrodesSecondary cellsGraphene coatingManganese oxide

The invention provides a modified lithium nickel cobalt manganese oxide cathode material which comprises a lithium nickel cobalt manganese oxide material, LiMnPO4 combined on the surface of the lithium nickel cobalt manganese oxide material, and graphene combined on the surface of LiMnPO4. According to the invention, the lithium nickel cobalt manganese oxide material is modified through double combination, wherein a layer of LiMnPO4 coating the surfaces of particles can improve the interface stability of the material under a high cut-off voltage, and graphene coating at the outer layer can improve the electronic conductivity of the material and weak the polarization effect.

Owner:四川浩普瑞新能源材料股份有限公司

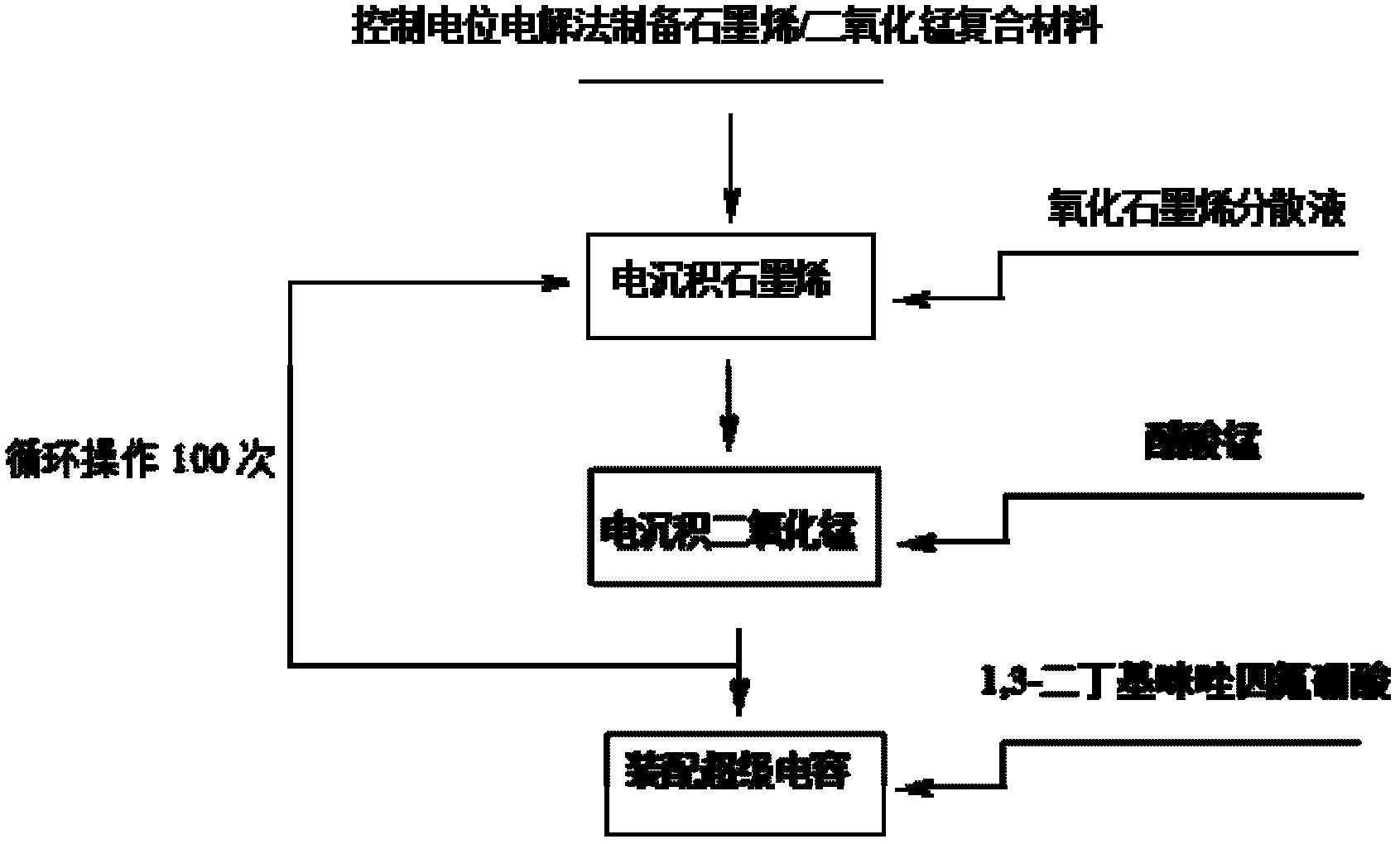

Method for electrochemically preparing graphene/manganese dioxide composite material, and application of graphene/manganese dioxide composite material

ActiveCN102568847ASmall particle sizeControl distribution densityElectrolytic capacitorsMANGANESE ACETATESupporting electrolyte

The invention relates to a method for electrochemically preparing a graphene / manganese dioxide composite material, and application of the graphene / manganese dioxide composite material, and belongs to the technical field of electrochemistry. The method comprises the following steps of: taking sodium carbonate as a supporting electrolyte; reducing a graphene oxide into graphene by a controlled potential electrolysis method, and uniformly fixing the graphene on a surface of an electrode; and precisely controlling the thickness of a graphene coating layer according to the concentration of the graphene oxide, potential, temperature and time during electro-deposition; respectively taking manganese acetate and sodium sulfate as a manganese precursor and a supporting electrolyte; adjusting the acidity of the electrolyte by sulfuric acid, performing controlled potential electrolysis, electrically depositing manganese dioxide on the surface of the graphene, and precisely controlling the particle size and the distribution density of the manganese dioxide; and repeating the operation for 100 times, and preparing the graphene / manganese dioxide composite material. Test shows that the obtained graphene / manganese dioxide composite material is an electrode or a super assembly capacitor, in which ionic liquid is used as the electrolyte; the capacity is more than 500 F / g; and after the super assembly capacitor is cyclically charged and discharged for 1,000 times, the capacity can still be kept over 99 percent.

Owner:JIANGSU SUNPOWER

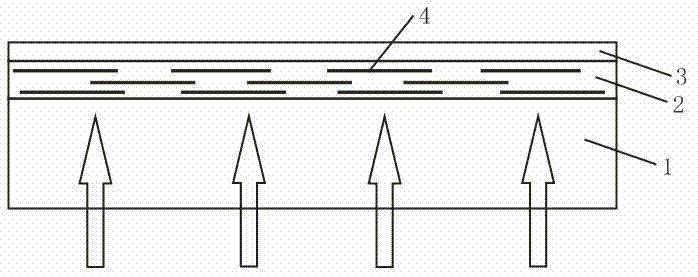

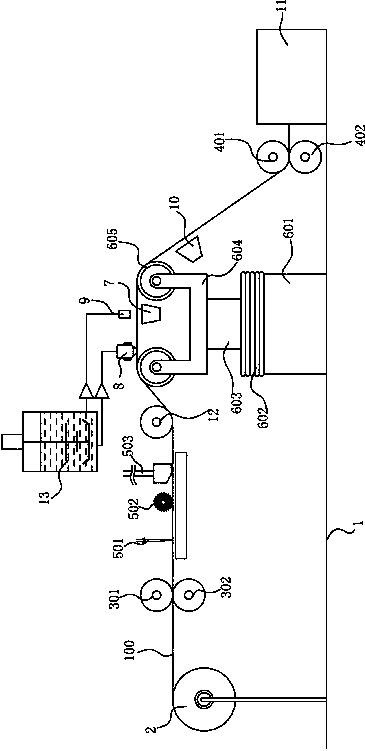

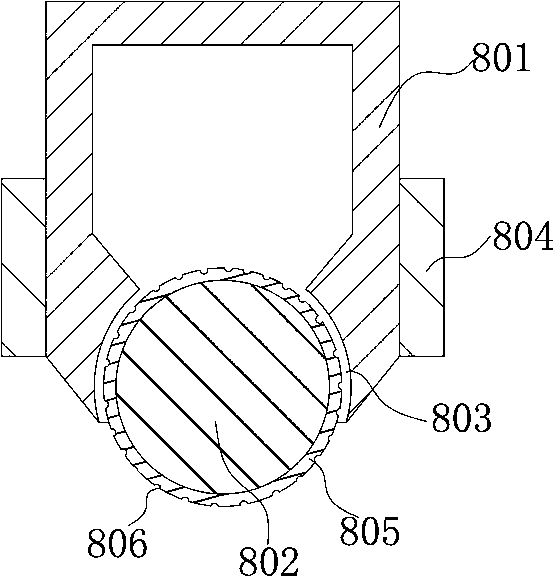

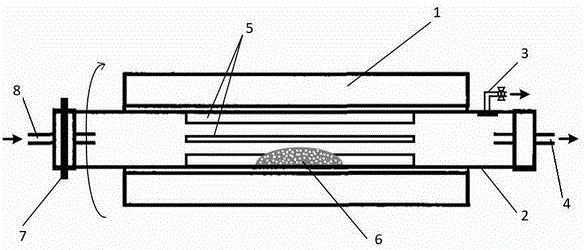

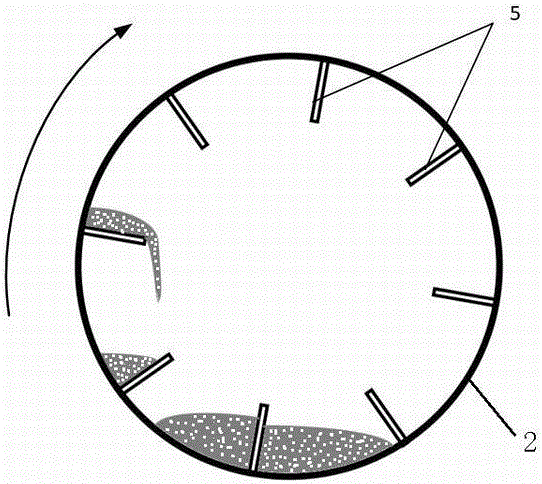

Graphene coating aluminum foil coating machine

ActiveCN105944920AUniform coatingClose contactLiquid surface applicatorsCoatingsGraphene coatingEngineering

The invention relates to a graphene coating aluminum foil coating machine. The machine comprises a base, and an aluminum foil coil, a front tension mechanism, a dust removing mechanism, a transmission mechanism, a vibration mechanism, a coating mechanism, a heating mechanism, a spraying mechanism, a drying mechanism, a back tension mechanism and a storage device arranged on the base; the dust removing mechanism, the transmission mechanism, the coating mechanism and the spraying mechanism are arranged rightly above the section of aluminum foil basal plate in a walking direction of the aluminum foil basal plate; the vibration mechanism and the heating mechanism are arranged below the section of aluminum foil basal plate; the vibration mechanism is perpendicular and corresponding to the coating mechanism and the spraying mechanism; and the heating mechanism is perpendicular and corresponding to the spraying mechanism. The machine is uniform in obtained product coatings, tight in contact with aluminum foil substrates, stable in performance, high in continuity of whole coating process and high in machining efficiency.

Owner:FOSHAN SINO SCI NANO TECH MATERIAL CO LTD

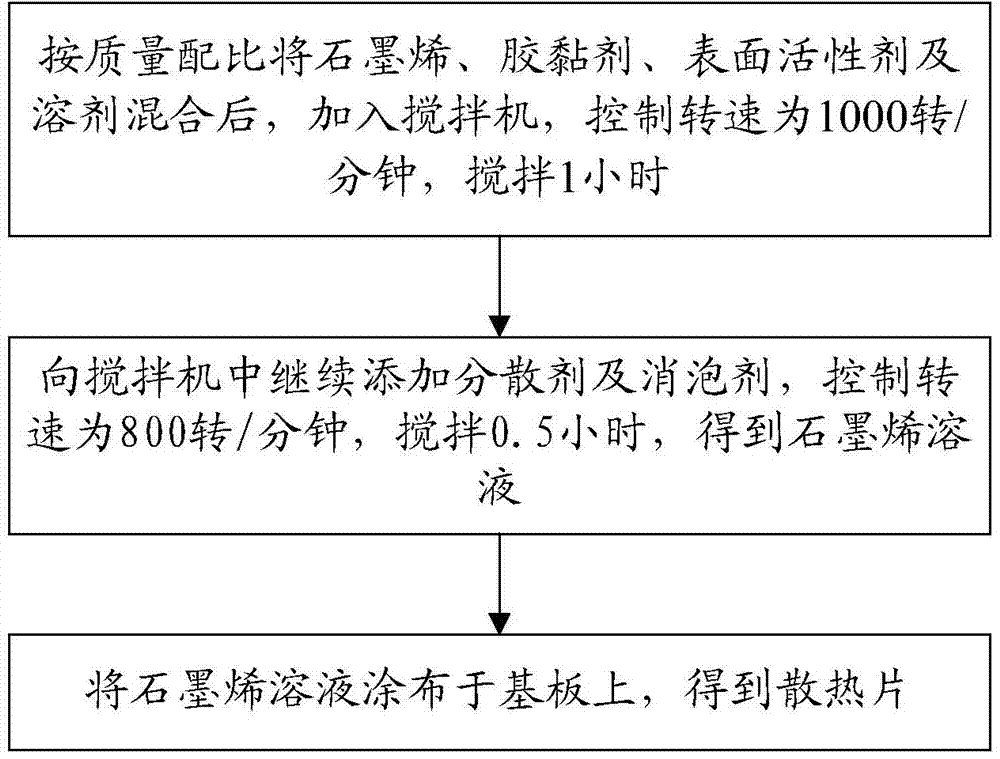

Cooling fin

ActiveCN104710912ASpeed up heat dissipationSimple preparation processConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsGraphene coatingAdhesive

The invention discloses a cooling fin. The cooling fin comprises a base plate and a coating, wherein the coating is arranged on the base plate and is prepared from graphene solutions; the graphene solutions comprise the following components in parts by weight: 5-15 parts of graphene, 20-70 parts of adhesives, 0.25-0.6 part of dispersing agent, 0.05-0.3 part of surfactant, and 0.5-5 parts of antifoaming agents. According to the cooling fin, the graphene coating is coated on the surface of the base plate; by utilizing the extremely-high heat conductivity of the graphene, the surface transmission of the heat energy can be quickly carried out along a graphene film, and the heat energy is quickly transmitted to the inside of the cooling fin, so that the time for transferring the heat to the cooling fin from a heat-conductive interface material or a heating device is shortened, the cooling speed of the cooling fin is improved, and the temperature of the cooling device is reduced. In addition, the cooling fin is simple in preparation process and relatively low in production cost.

Owner:东莞市闻誉实业有限公司

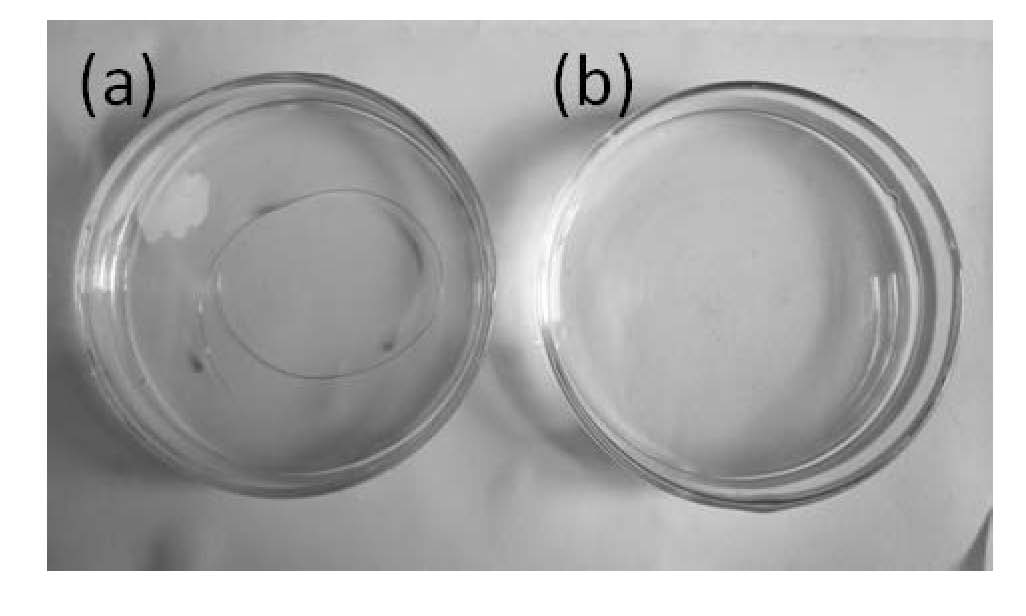

Preparation method of stable graphene colloid

The invention discloses a preparation method of stable graphene colloid. Inorganic nanoparticles (such as carbon nanometer quantum dot, oxidized graphene, acidified nanotube, and graphene quantum dot) are used, a surfactant (such as 3-[3-cholamidopropyl)dimethylammonium]-1-propanesulfonate, dihexadecyldimethylammonium bromide, cetyl dimethyl benzyl ammonium bromide, n-hexadecyl-beta-D-maltoside, and a polymer (octadecanol ethylene oxide polyether, cellulose nanometer crystal) and one or several kinds of additives are assisted; high speed mixing and shearing, ultrasonic exfoliation and dispersion of graphite or graphene are carried out, in order to obtain long-term stable graphene colloid. The method is simple, the graphene colloid is long-term stable, the graphene colloid can be divided into water-soluble colloid and oil soluble colloid, in order to facilitate practical application of graphene. After pumping filtration of the graphene colloid is carried out and film is formed, the film is hopeful to be used as a graphene electrode, a graphene composite material, a graphene coating, and a graphene fiber composite material.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

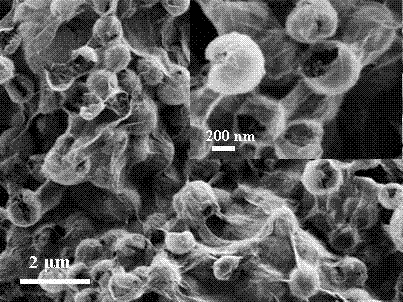

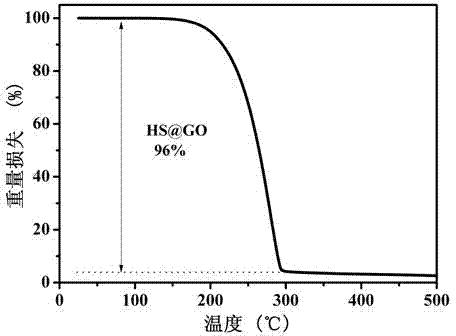

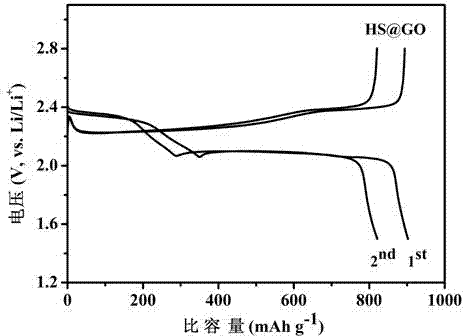

Grapheme oxide-coated sulfur particle composite anode material for lithium-sulfur battery and preparation method thereof

ActiveCN104852025ASimple preparation processInhibition of dissolutionCell electrodesLi-accumulatorsGraphene coatingHigh energy

The invention discloses a graphene oxide-coated sulfur particle composite anode material for a lithium-sulfur battery and a preparation method thereof, and belongs to the field of new-generation energy materials. The composite anode material comprises graphene oxide, modified graphene oxide and graphene-coated micro-scale sulfur particles, nano-scale sulfur particles and hollow sulfur particles. The composite anode material consists of an inner-layer sulfur core and graphene oxide coated on an outer layer. The preparation method comprises the following steps: preparing the micro-scale sulfur particles, the nano-scale sulfur particles and the hollow sulfur particles; after graphene oxide or graphene dispersion liquid is added, preparing an outer-layer graphene oxide or graphene coating layer; and performing washing and drying treatment to obtain the graphene oxide-coated sulfur anode material. The preparation method is simple in process, low in cost, and suitable for industrial production. The prepared composite anode material for the lithium-sulfur battery has the advantages of high energy density, high cycle performance, excellent rate performance and the like, and has a wide application prospect in the energy storage related field.

Owner:深圳特新界面科技有限公司

Transparent Antistatic Films

InactiveUS20170190925A1Improve antistatic performanceImprove performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceGraphene coating

A transparent antistatic film of the present application includes a substrate and a transparent graphene coating, the substrate at least includes a first surface, and the transparent graphene coating is disposed above the first surface of the substrate. The transparent graphene coating has a surface resistance less than 1012 ohm / sq and a visible transmittance greater than 70% at wavelength of 550 nm, and the transparent graphene coating includes a plurality of surface modified graphene nanosheets and a carrier resin, wherein the plurality of surface modified graphene nanosheets is uniformly dispersed in the carrier resin. With characteristics of the transparent graphene coating, the transparent antistatic film of the present application can prevent various risks of electrostatic breakdown, have a function of electromagnetic wave shielding, and keep original transmittance of the substrate, so that the transparent antistatic film is suitable for use in electronic devices which are sensitive to electrostatic or electromagnetic.

Owner:ENERAGE INC

Preparation method and application of graphene-coated sulfur-selenium co-impregnated porous carbon positive electrode material

InactiveCN106602010AImproved magnification performanceImprove cycle stabilityCell electrodesSecondary cellsHigh rateGraphene coating

The invention discloses a preparation method and an application of a graphene-coated sulfur-selenium co-impregnated porous carbon positive electrode material. By adoption of a sulfur-selenium fusion co-impregnated process, and by virtue of a synergistic effect of sulfur and selenium and a synergistic effect generated by combination of excellent conductivity of selenium and high theoretical capacity of sulfur, generation of a shuttle flying reaction is effectively restrained, and a composite positive electrode material with high rate capability and high cycling stability is obtained; by virtue of a graphene coating layer, the sulfur content in the composite material can be increased while dissolution and dispersion of a polysulfide can be suppressed; due to a synergistic effect of the graphene coating layer and porous carbon, the material obtains excellent electrochemical performance; the reversible capacity can reach 680mAhg<-1> and 560mAhg<-1> at current density of 0.1C and 1C after 100 discharging cycles; and in addition, greater than 96% of coulombic efficiency is constantly maintained.

Owner:江华中科能源科技有限公司

Preparation method of graphene coating metal base composite powder through vapour deposition

InactiveCN106077622AEvenly distributedEasy to operateTransportation and packagingMetal-working apparatusGraphene coatingGas phase

The invention discloses a preparation method of graphene coating metal base composite powder through vapour deposition, which is easy to operate and low in cost. Through the adoption of the method, many limits in conventional methods for preparing graphene reinforcing metal base composite powder can be effectively avoided, and the produced graphene reinforcing metal base composite powder can be adapted to conventional powder metallurgy and the manufacturing process of a plurality of additional materials. According to the method disclosed by the invention, a single layer or a few layers of graphene can be uniformly coated on the surface of metal matrix powder, the combination between the metal matrix powder and the graphene is reliable, and not liable to fall, and the method disclosed by the invention is adapted to large-scale industrial production.

Owner:石京

Fabric with doped-type graphene coating and preparation process of fabric

InactiveCN104294584AAntibacterialDeodorizingLayered productsFibre treatmentGraphene coatingCvd graphene

The invention provides a fabric with a doped-type graphene coating. The fabric is characterized in that the surface of the fabric is coated with doped-type graphene, and doped elements are non-metal elements. The fabric provided by the invention has the advantages that the catalytic, adsorbing and conducting characteristics of non-metal doped graphene are utilized, and the surface of the common fabric is coated with one layer of or multilayer non-metal doped graphene, so that the fabric has the characteristics of antisepsis, deodorization and dustproof, antifogging and antistatic effects; non-metal doped graphene of the coating has non-toxic and pollution-free effects and is easy to produce and manufacture; the preparation process is simple, and the fabric product is light and is high in practicability.

Owner:黄勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com