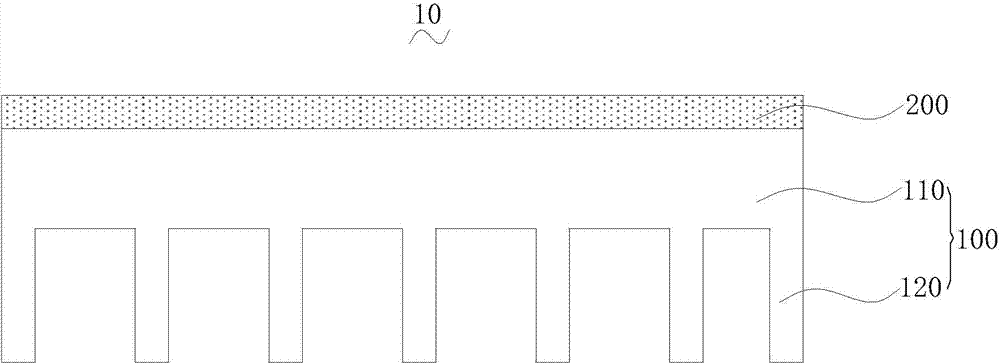

Cooling fin

A heat sink and dispersant technology, applied in the direction of conjugated diene coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor heat dissipation and poor thermal conductivity, and achieve lower temperature and production The effect of low cost and improved heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

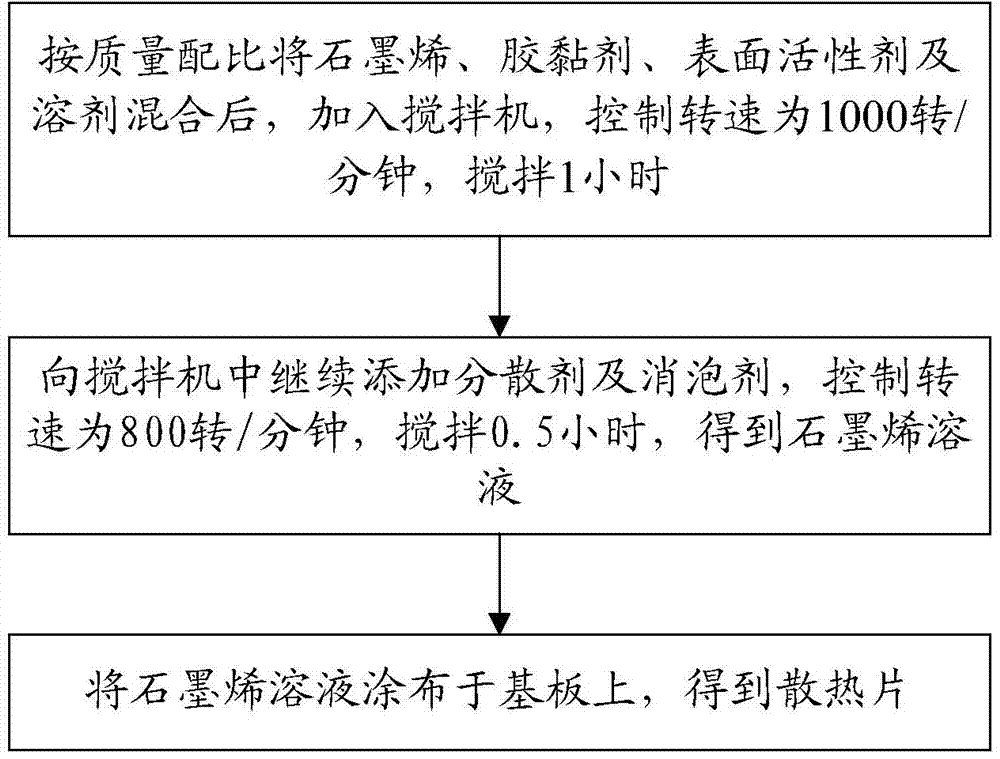

Method used

Image

Examples

Embodiment 1

[0094] 1. Production of substrate:

[0095] According to parts by weight: aluminum: 77.8 parts; zinc: 12 parts; copper: 9 parts; boron: 0.3 parts; nickel: 0.05 parts; manganese: 0.5 parts; Heating to 800°C to 850°C.

[0096] After melting into molten aluminum alloy, reduce the temperature in the furnace to 710°C-750°C, add refining agent to the molten aluminum alloy, refine for 15-25 minutes, and then carry out slag removal.

[0097] For example, the refining agent is evenly blown into the aluminum alloy liquid through a powder spraying tank for refining. During refining, the nitrogen pressure is 0.2MPa, and the nitrogen purity is greater than 99 parts. For another example, after refining for 15 to 25 minutes, remove the scum on the surface of the aluminum alloy liquid.

[0098] Control the temperature in the furnace at 750°C to 770°C, and let it stand for 25 to 35 minutes to degas and remove slag.

[0099] Specifically, after the standing is completed, the aluminum alloy l...

Embodiment 2

[0109] 1. Production of substrate:

[0110] According to parts by weight: aluminum: 69.7 parts; zinc: 18 parts; copper: 10.5 parts; boron: 0.7 parts; nickel: 0.05 parts; manganese: 1.0 parts; Heating to 800°C to 850°C.

[0111] After melting into molten aluminum alloy, reduce the temperature in the furnace to 710°C-750°C, add refining agent to the molten aluminum alloy, refine for 15-25 minutes, and then carry out slag removal.

[0112] For example, the refining agent is evenly blown into the aluminum alloy liquid through a powder spraying tank for refining. During refining, the nitrogen pressure is 0.2MPa, and the nitrogen purity is greater than 99 parts. For another example, after refining for 15 to 25 minutes, remove the scum on the surface of the aluminum alloy liquid.

[0113] Control the temperature in the furnace at 750°C to 770°C, and let it stand for 25 to 35 minutes to degas and remove slag.

[0114] For example, after the standing is completed, the aluminum alloy...

Embodiment 3

[0125] 1. Production of substrate:

[0126] According to parts by weight: aluminum: 72 parts; zinc: 15 parts; copper: 11 parts; boron: 0.35 parts; nickel: 0.3 parts; manganese: 1.2 parts; Heating to 800°C to 850°C.

[0127] After melting into molten aluminum alloy, reduce the temperature in the furnace to 710°C-750°C, add refining agent to the molten aluminum alloy, refine for 15-25 minutes, and then carry out slag removal.

[0128] For example, the refining agent is evenly blown into the aluminum alloy liquid through a powder spraying tank for refining. During refining, the nitrogen pressure is 0.2MPa, and the nitrogen purity is greater than 99 parts. For another example, after refining for 15 to 25 minutes, remove the scum on the surface of the aluminum alloy liquid.

[0129] Control the temperature in the furnace at 750°C to 770°C, and let it stand for 25 to 35 minutes to degas and remove slag.

[0130] Specifically, after the standing is completed, the aluminum alloy li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com