Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

451 results about "Nitrogen pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

From the densities of liquid nitrogen and nitrogen gas at standard pressure the volume ratio is about 1:700. From the phase diagram nitrogen is a gas at standard pressure and becomes supercritical at approximately 100 atm. The ideal gas law can therefore only be a guideline well below this pressure.

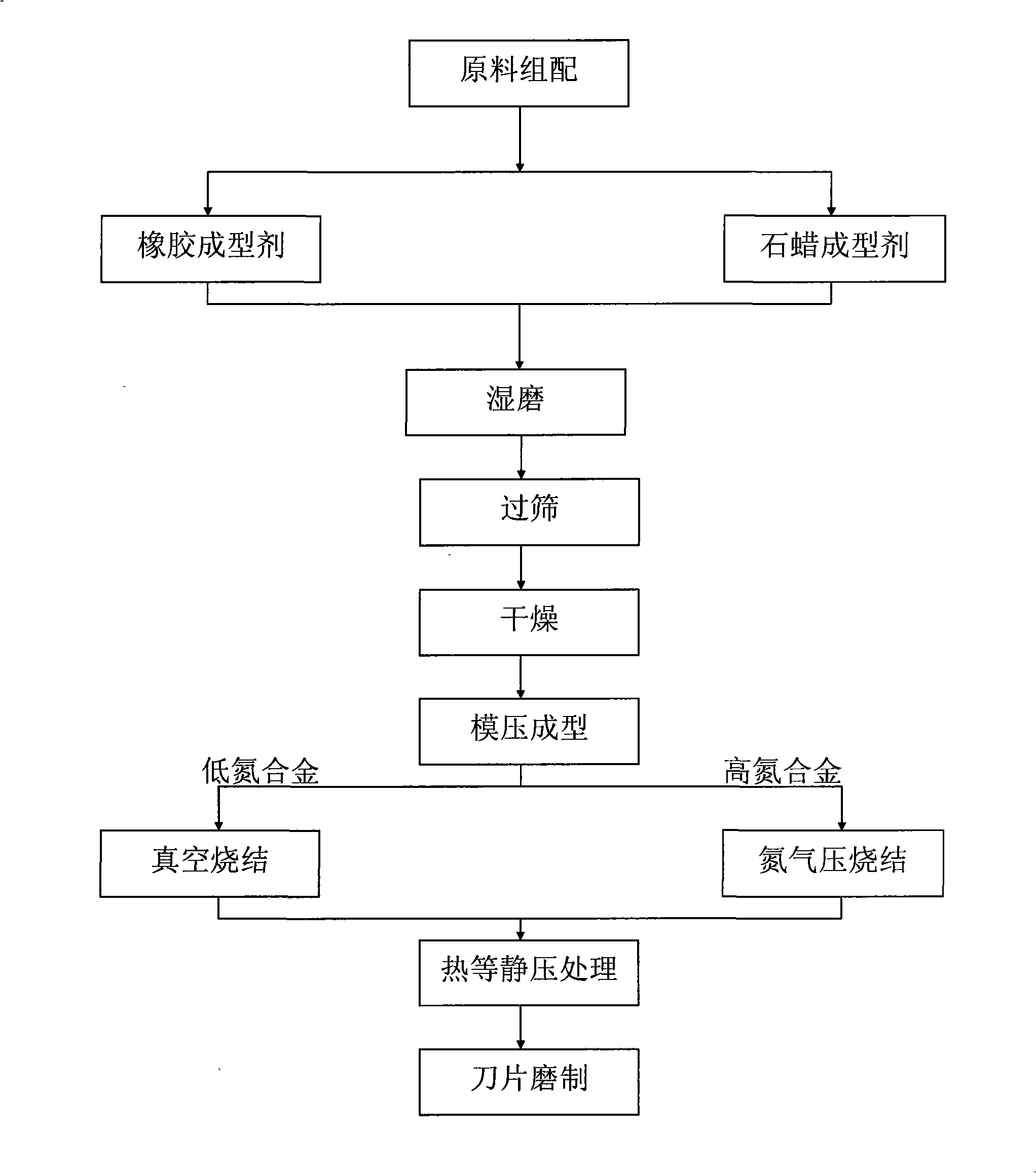

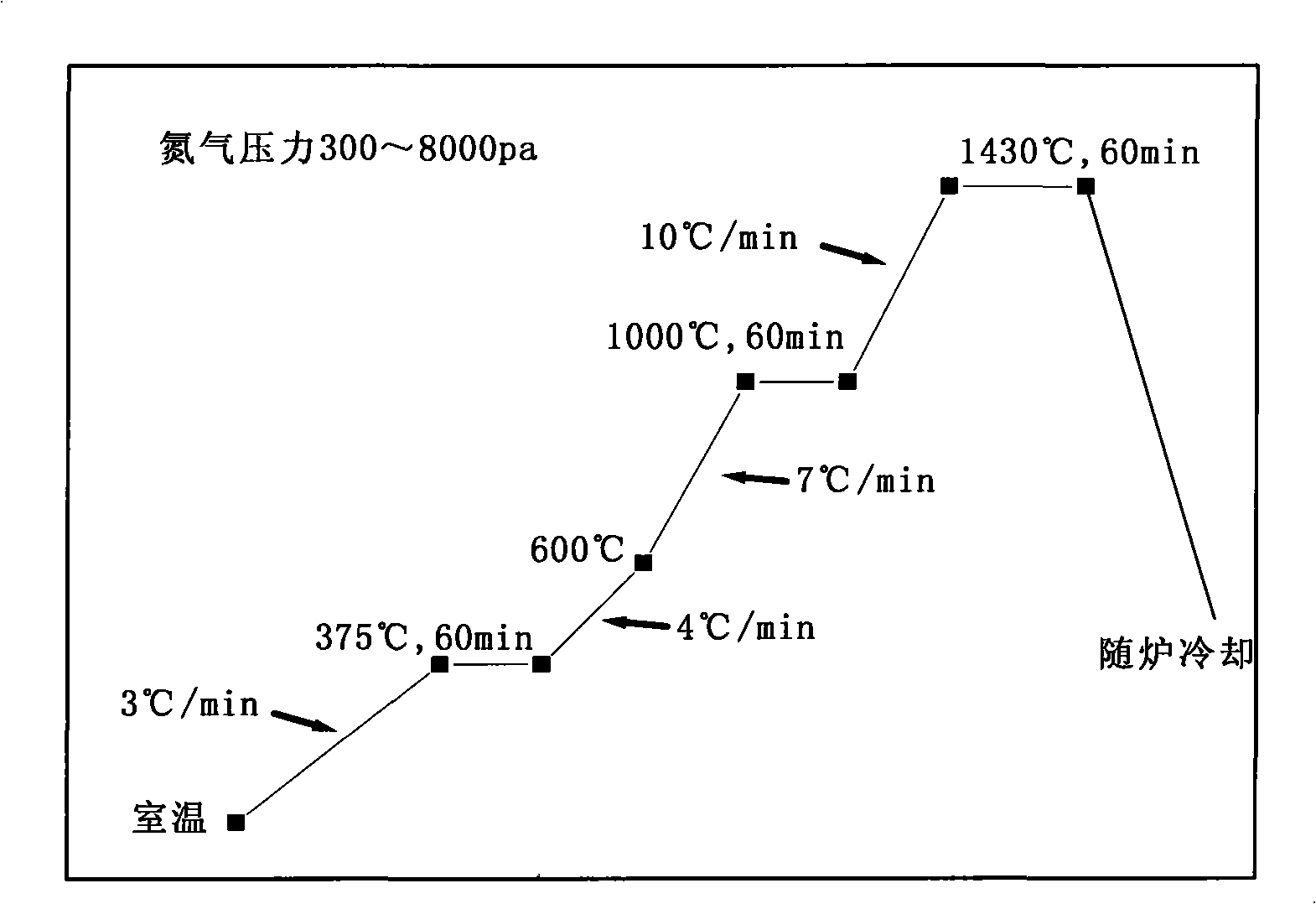

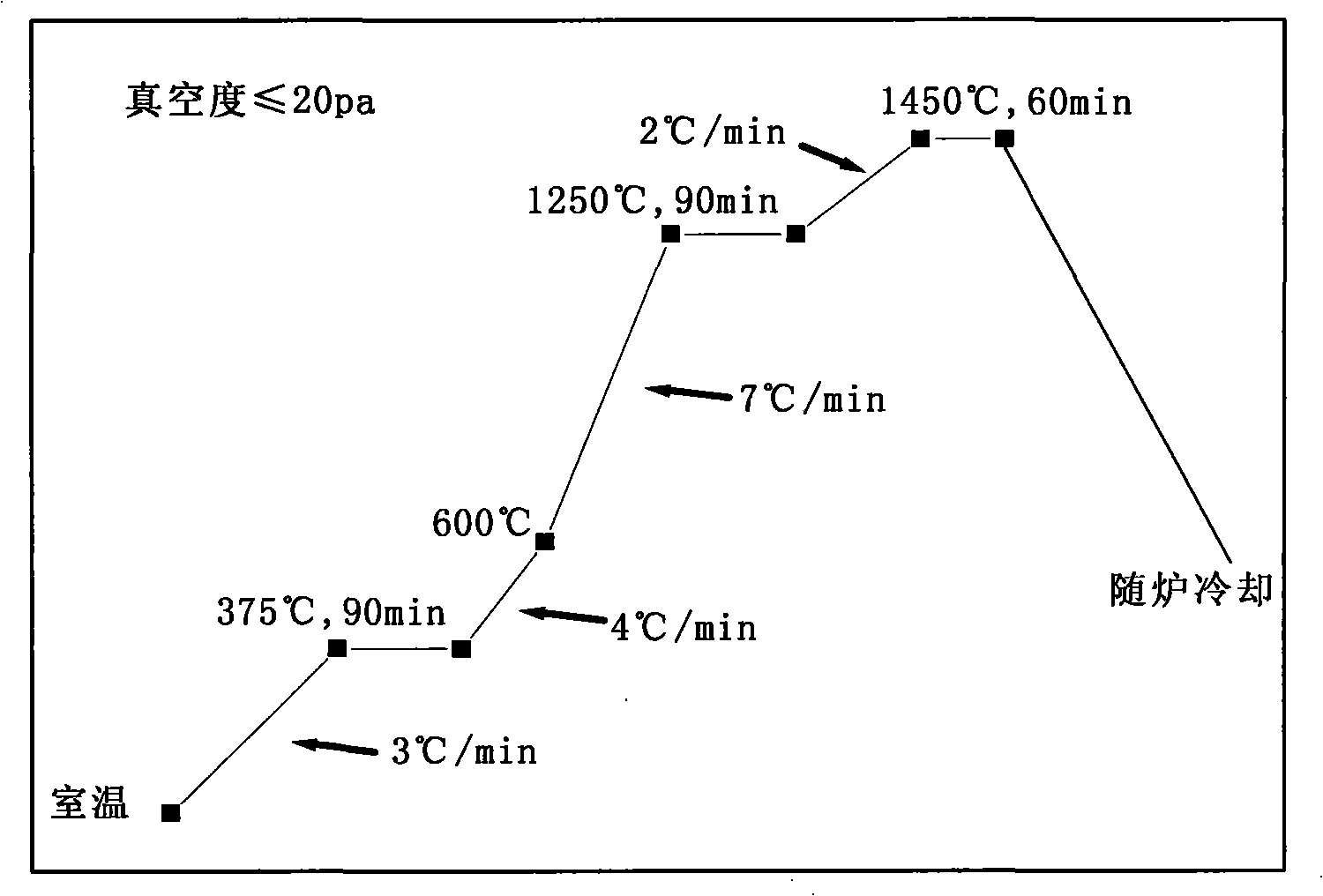

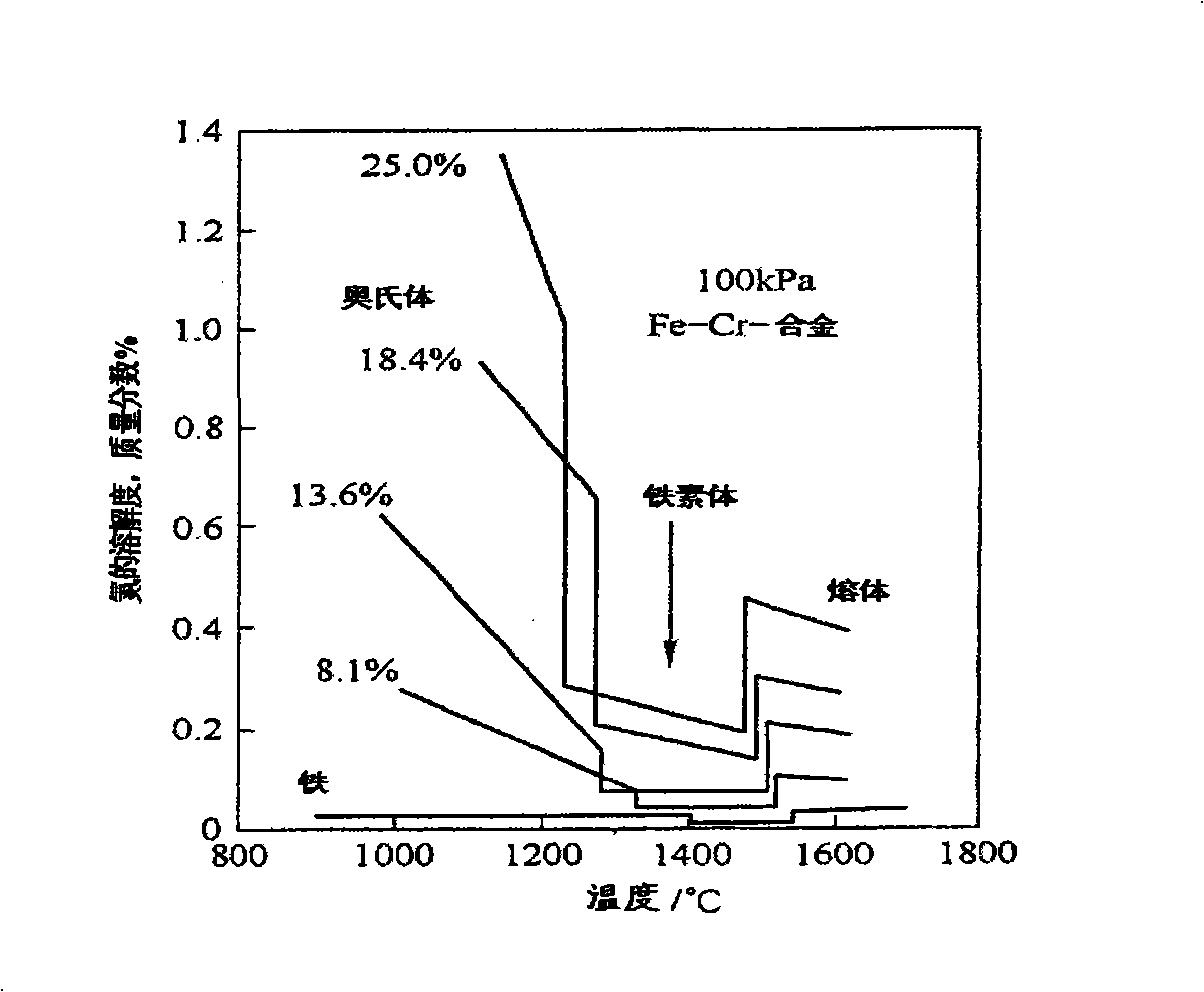

High-wear resistant Ti (C, N)-base ceramet tool bit and preparation thereof

InactiveCN101302595AReliable guarantee of high nitrogen-carbon ratioReliable Guarantee of HardnessLow nitrogenWear resistant

The invention provides a high-abrasion Ti(C, N) based metal ceramic tool and a preparation thereof. The Ti(C, N) based metal ceramic tool uses Ni and Co as a binder phase, is added with at least one carbonitride of Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x as a basic batch, and consists of at least one composition of WC, Mo2C, Co, Ni, ZrC, Cr3C2, VC, TaC and NbC, and the balance being Ti(Cx, N1-x) or (TiC)x plus (TiN)1-x, wherein, an X value for adding the carbonitride of the Ti(C, N) based metal ceramic tool is as follows: X is less than or equal to 0.5 and more than or equal to 0.4, or the X is more than 0.5 and less than or equal to 0.7. The Ti(C, N) based metal ceramic tool is prepared according to the content of nitrogen by nitrogen pressure sintering or vacuum sintering combined with hot isostatic pressing treatment, thereby preventing nitrogen from escaping during the process of sintering high-nitrogen alloy, so that the high-nitrogen-carbon ratio in matrix and material hardness can be reliably guaranteed, and anti-oxidative abrasion property and anti-diffusive abrasion property of the material can be obviously increased through adding slight ZrC, Cr3C2, VC and other carbides into the basic batch; meanwhile, compactability and buckling strength of a low-nitrogen alloy structure can be obviously improved through optimally distributing each composition and content. The Ti(C, N) based metal ceramic tool is widely suitable for high-speed cutting tools of medium-low carbon steel and low alloy steel.

Owner:HUNAN UNIV OF SCI & TECH

Resin isobaric liquid-phase impregnation densification method for rapidly filling pores inside carbon/carbon composite material

The invention relates to a resin isobaric liquid-phase impregnation densification method for rapidly filling pores inside a carbon / carbon composite material. The method comprises the following steps of by using a PIP (precursor impregnation and pyrolysis) process and a vacuum autoclave with an isobaric impregnation recovery device, and taking nitrogen as a protective gas, using an impregnating solution to impregnate a carbon fiber perform or low-density C / C body workpiece in a vacuum; allowing the impregnating solution to infiltrate into the workpiece at nitrogen pressure; isobarically recovering excess impregnating solution; continuing to isobarically heat to thermally set resin; and then carbonizing the resin into a carbon substrate for filling the pores inside the workpiece. The carbon / carbon composite material component with the required density is obtained by multiple circulating operations. The period of the method is short, and the excess impregnating solution which does not filtrate into the workpiece is isobarically recovered, so that the resin is prevented from reversely filtrating, the resin consumption and pure nitrogen consumption are reduced, and the densification efficiency and the densification uniformity are improved.

Owner:山东道普安制动材料有限公司

Method of manufacturing powder metallurgy nitrogen/high nitrogen containing stainless steel parts

The present invention relates to a method for preparing powder metallurgic nitrogen-contained / high-nitrogen stainless steel components, and comprises the following steps: raw materials preparation, forming, degreasing treatment, sintering and other static press, wherein, during the static press such as the sintering, the temperature increasing speed is 3 to 10 DEG C per minute; the sintering gas is the pure nitrogen or the mixed gas of the nitrogen, hydrogen and the argon; the pressure / partial pressure of the nitrogen is consistent with the solubility of the nitrogen in the alloy system; the sintering temperature is 1200 to 1450 DEG C, and the heat preservation period is 10 to 20 minutes; after the density is more than 90 to 95 percent, the pressure is increased to 3 to 10 MPa; the partial pressure is maintained the same during the pressure increasing process, and the pressure is distributed on the argon and the hydrogen, and the heat preservation period is 60 to 240 minutes; after the density is more than 99 percent, the pressure is decreased and rapid cooling is performed. The content of the nitrogen of the component that is made with the method hereinabove can be controlled to the highest level; the composition constitution is uniform, the density is high, the flexibility is good, the deformation is less, the precision is high and the corrosion-resistance is good.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Functionally gradient hard alloy with cubic phase-rich surface and preparation method thereof

InactiveCN102134660AHigh value-added productsEasy to realize technology transformationSolid state diffusion coatingGradient materialAlloy

The invention discloses a functionally gradient hard alloy with a cubic phase-rich surface and a preparation method thereof, and belongs to the technical field of preparation of gradient materials through surface nitriding treatment. A gradient layer of the hard alloy comprises a surface layer rich in cubic phases, and a transition layer rich in binding phases under the surface layer; and the wear resistance and toughness of the alloy can be improved simultaneously, and the alloy can be used for machining metals. In the preparation method, the functionally gradient hard alloy is prepared by a nitriding and sintering process; and by controlling the sintering temperature, sintering time and a nitrogen pressure parameter, the components and thickness of the gradient layer of the alloy are controlled. The invention has the advantages that: the conventional equipment and process are not changed greatly, and the functionally gradient hard alloy can be produced; and the invention is suitable for industrial production.

Owner:CHONGQING UNIV OF ARTS & SCI +1

Directional pyrolysis method of combustible wastes

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

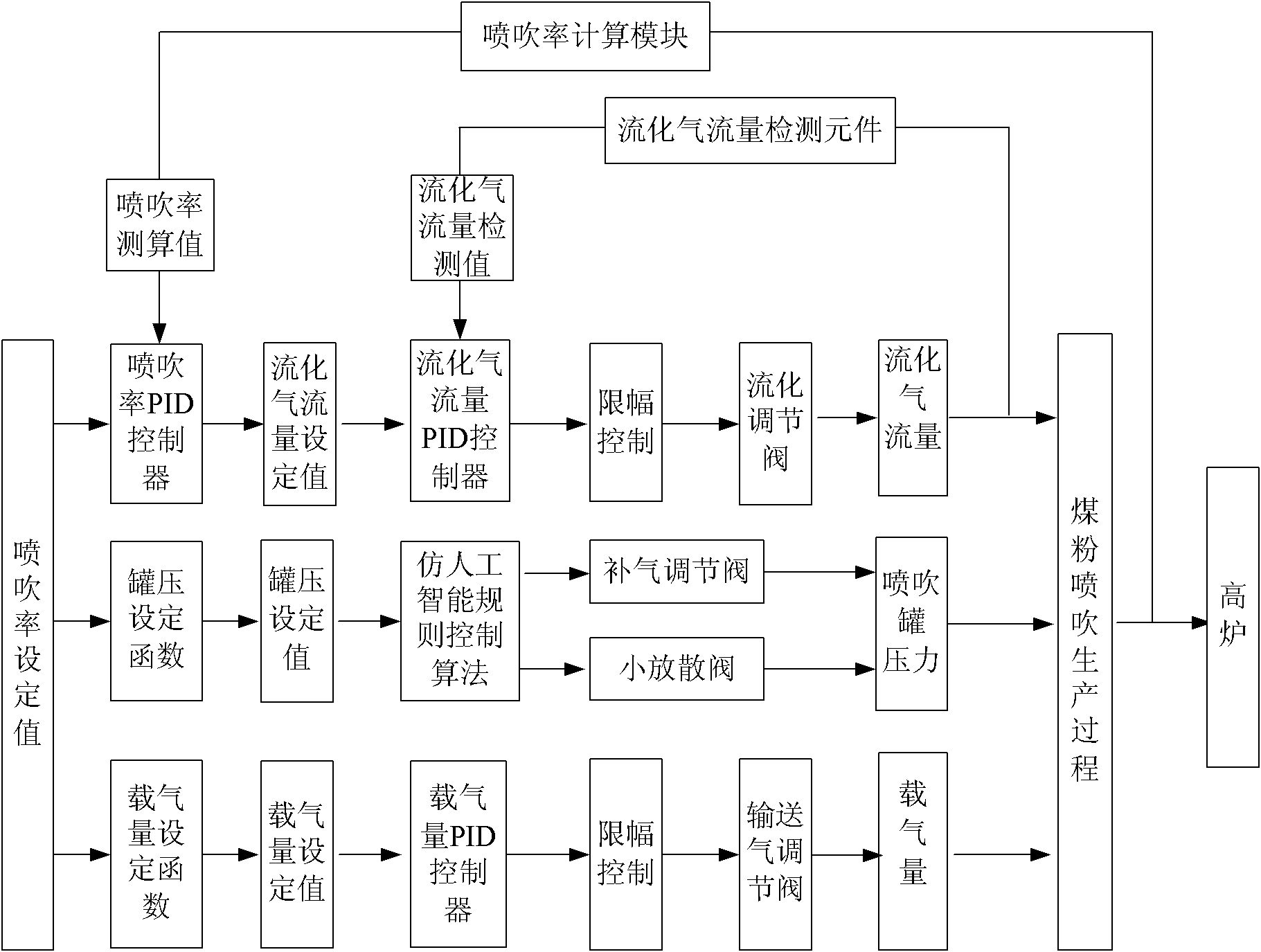

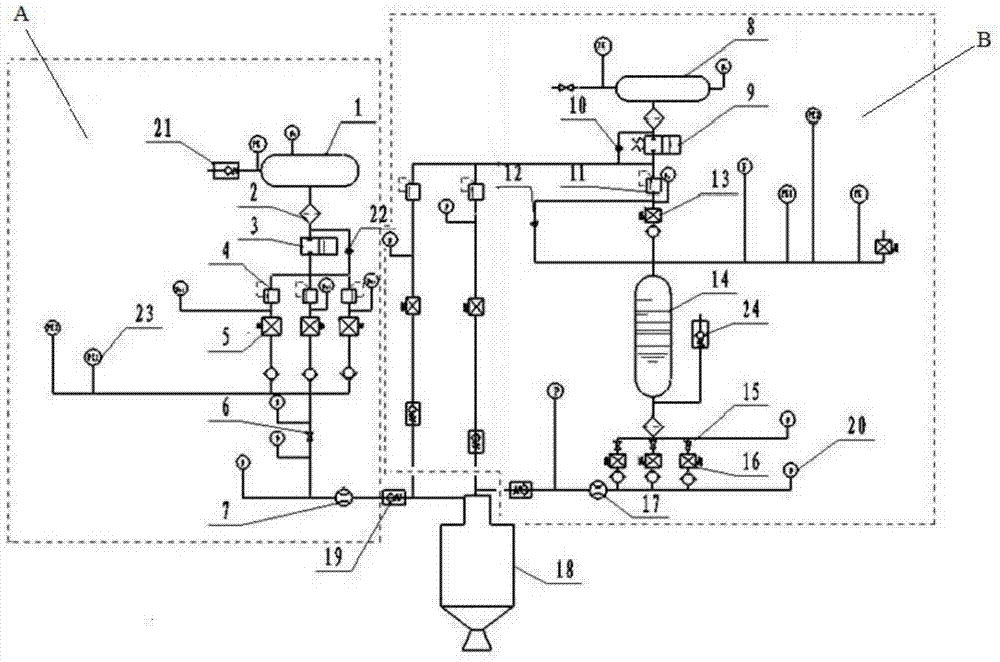

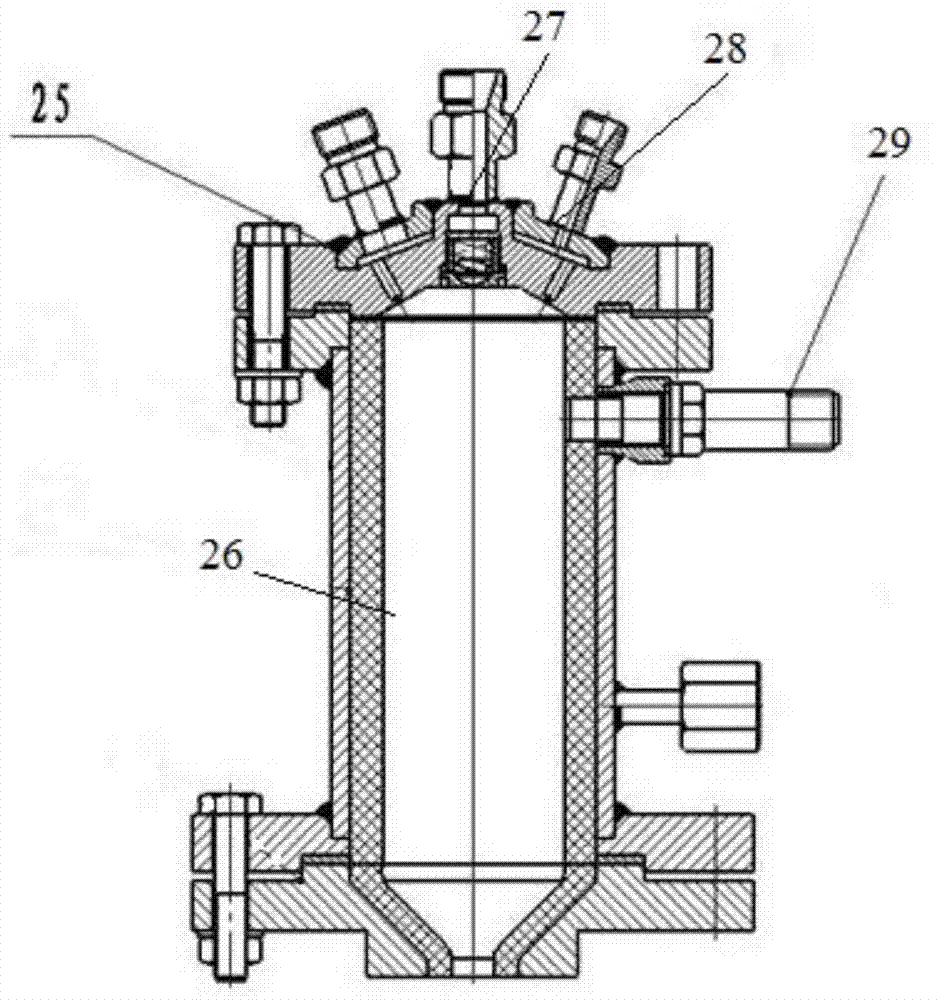

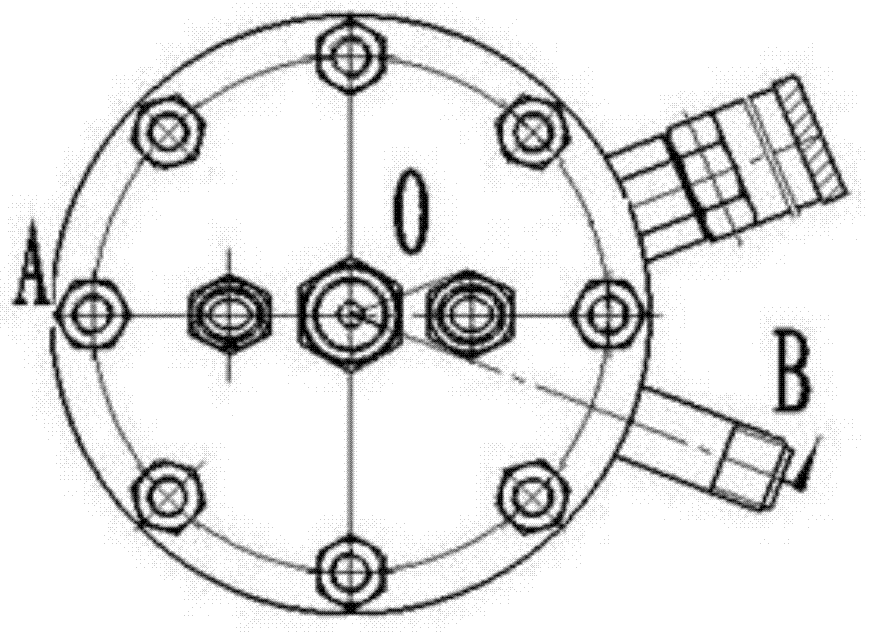

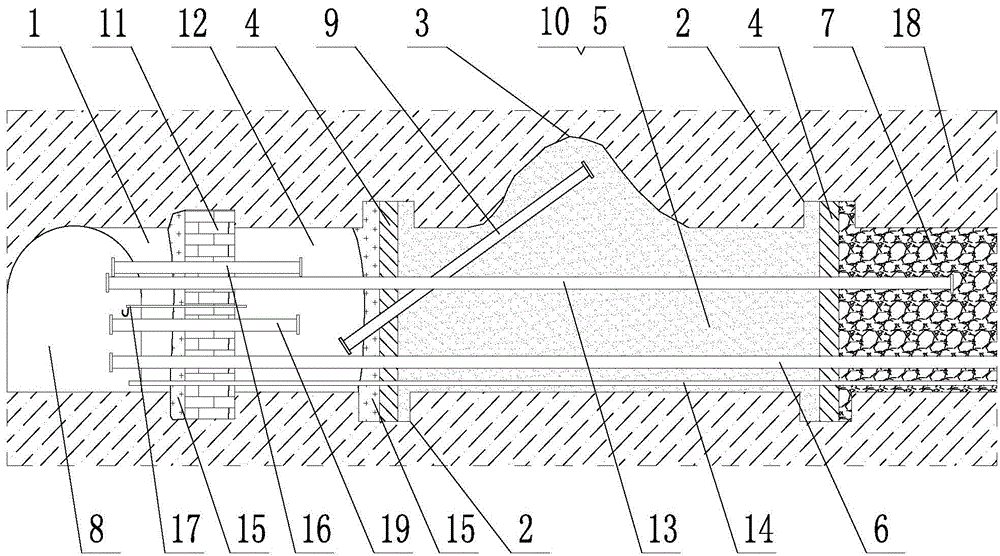

Coal injection system of blast furnace

InactiveCN101899542AAvoid interferenceFast and stable adjustmentBlast furnace componentsBlast furnace detailsEngineeringNitrogen pressure

The invention relates to a coal injection system of a blast furnace, which comprises a plurality of injection tanks, wherein the upper parts of the injection tanks are connected with a coal powder bin (1) through pipelines, charging dump valves (14) and blanking dump valves (15) for injection of materials in the tanks, and are respectively connected with the coal powder bin through pipelines, small bleeding dump valves (12) and large bleeding dump valves (13) for bleeding of the injection tanks at the same time; the middle parts of the injection tanks are respectively connected with a nitrogen pressure regulating station (2) through three connecting pipelines and valves in three ways, wherein one way is used for pressure complement of the injection tanks, one way is used for pressure recharging of the injection tanks, and the last way is used for fluidizing the coal powder in the injection tanks; and the lower parts of the injection tanks are respectively connected with a mixer (4) through pipelines and coal injection dump valves (19), and the mixer is connected with a dispenser (5) and each blast hole of a blast furnace (6) through pipelines. The invention can effectively prevent interference of furnace pressure fluctuation on the injection rate, prevent lagging and large fluctuation in the process of tank pressure regulation and ensure the fast, stable and uniform regulation of tank pressure.

Owner:WISDRI ENG & RES INC LTD

Variable working condition type primary rocket system of rocket based combined cycle engine

The invention discloses a variable working condition type primary rocket system of a rocket based combined cycle engine. The variable working condition type primary rocket system comprises a propellant supply system and a primary rocket engine thrust chamber which are connected through a pipeline, wherein the propellant supply system comprises an oxidant supply system and a fuel supply system, the oxidant supply system comprises an oxygen flow rate control system, the oxygen flow rate control system comprises a plurality of oxygen conveying pipelines, each oxygen conveying pipeline is provided with an oxygen pressure relief valve for opening and closing the corresponding oxygen conveying pipeline, an outlet of each oxygen conveying pipeline is connected with an oxygen perforating plate, the fuel supply system comprises a plurality of fuel conveying pipelines, an outlet of each fuel conveying pipeline is provided with a cavitation venturi pipe, and an inlet of each fuel conveying pipeline is connected with a nitrogen pressure relief device. The variable working condition type primary rocket system of the rocket based combined cycle engine has the advantages that the flow rate of a propellant can be accurately, controllably, stably and quickly adjusted, the complexity is low, and the operation is simple.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Mechanical activation-reaction heat treating preparation process of nanometer titanium carbonitride

InactiveCN1974403AGood dispersionThe temperature of the carbothermal nitriding reaction is loweredNitrogen compoundsTitanium compoundsGranularityTechnological factor

The mechanical activation-reaction heat treatment process of preparing nanometer titanium carbonitride powder with nanometer titania and nanometer carbon powder as material includes the technological steps of: compounding, mechanical activating, (drying,) loading, reaction heat treatment, and sieving. The process is simple, low in cost and easy in industrial scale production. By means of controlling C / Ti ratio, mechanical ball milling activation time, reaction heat treatment temperature and time, nitrogen pressure and other technological factors, nanometer titanium carbonitride powder in different carbon contents ay be synthesized. The prepared nanometer titanium carbonitride powder is spherical, and has high dispersivity, average granularity below 100 nm and purity over 99 %.

Owner:SICHUAN UNIV

A flexible DC power transmission converter valve water-cooling system for islands

InactiveCN103746539AGuaranteed uptimeConstant entryCooling/ventilation/heating modificationsPower conversion systemsEpoxyIon exchange

The invention provides a flexible DC power transmission converter valve water-cooling system for islands. The water-cooling system comprises main circulation water pumps, an air cooler, main filters, a converter valve and a degassing tank which are in pipeline connection to form a main circulation loop. The main circulation loop is connected in parallel with a water treatment loop. Buffer tanks are connected with a nitrogen pressure stabilizing system. An Ion exchange is connected with a water-supplementing system. The heat exchange tube bundle of the air cooler is made of stainless steel 316L material. Fins utilize epoxy resin coating aluminium sheets. An internal framework employs stainless steel 316Ti material and the external surface of the internal framework is sprayed with powder. The flexible DC power transmission converter valve water-cooling system effectively cools the converter valve, constant-flow cooling water is guaranteed to go into the converter valve, and valve-going temperature is stable without sudden rising and dropping. The flexible DC power transmission converter valve water-cooling system can change the water cooling heat dissipation capacity based on the change of IGBT thermal loads so as to control the valve-going temperature to be stale in a certain range, and guarantee the converter valve to operate stably.

Owner:GUANGZHOU GOALAND ENERGY CONSERVATION TECH

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584ASolve processabilitySolve product problemsWelding/cutting media/materialsSoldering mediaAlloyGraphite

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

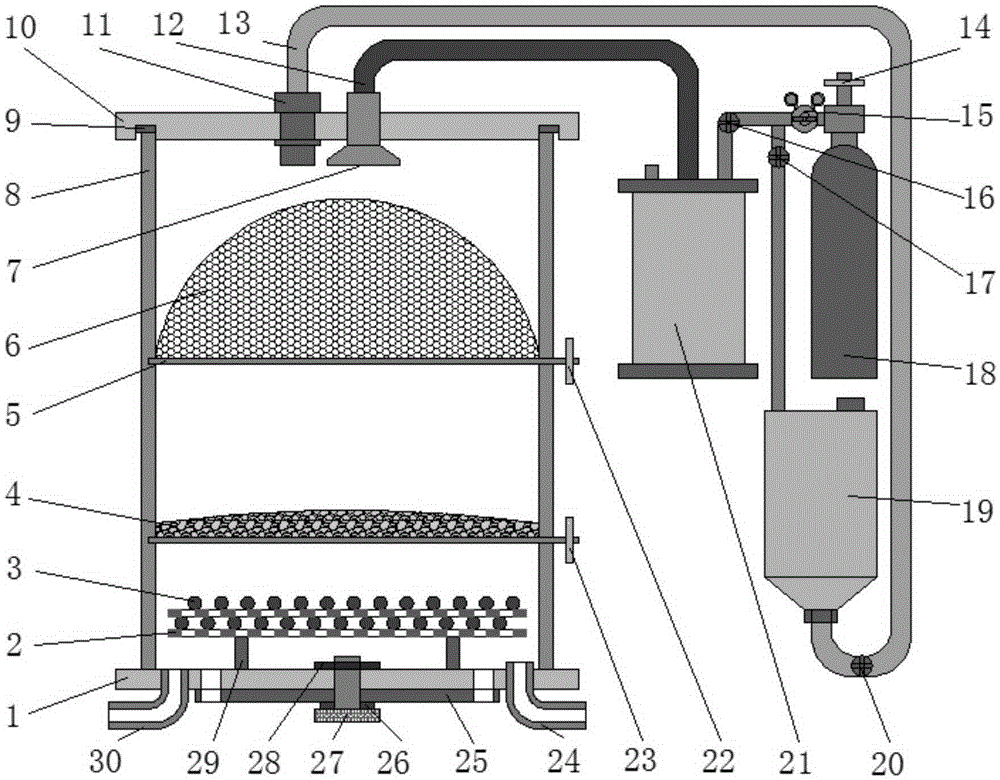

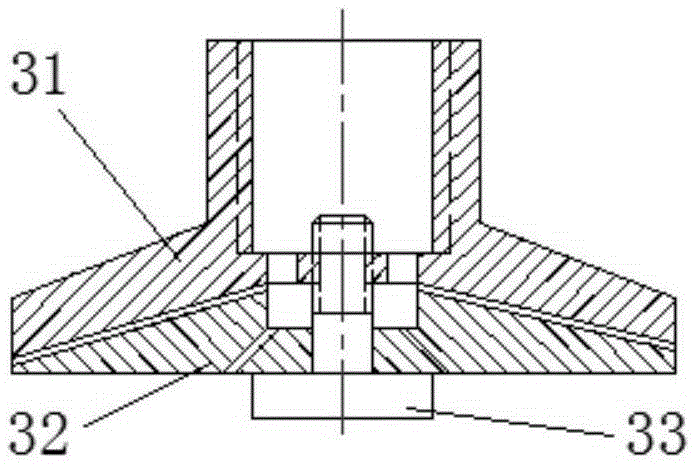

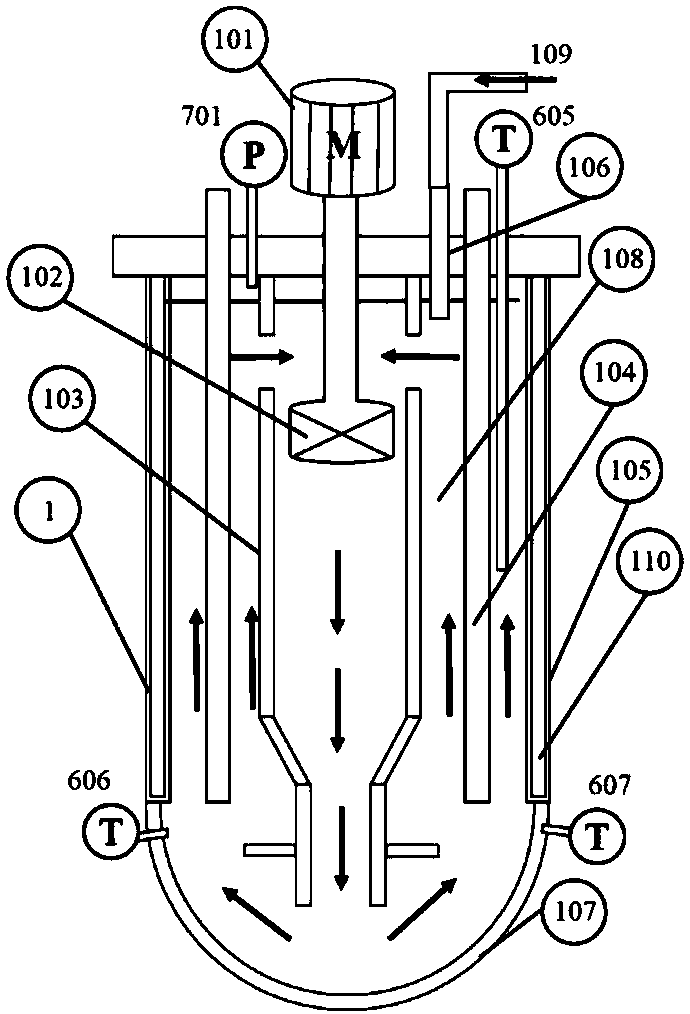

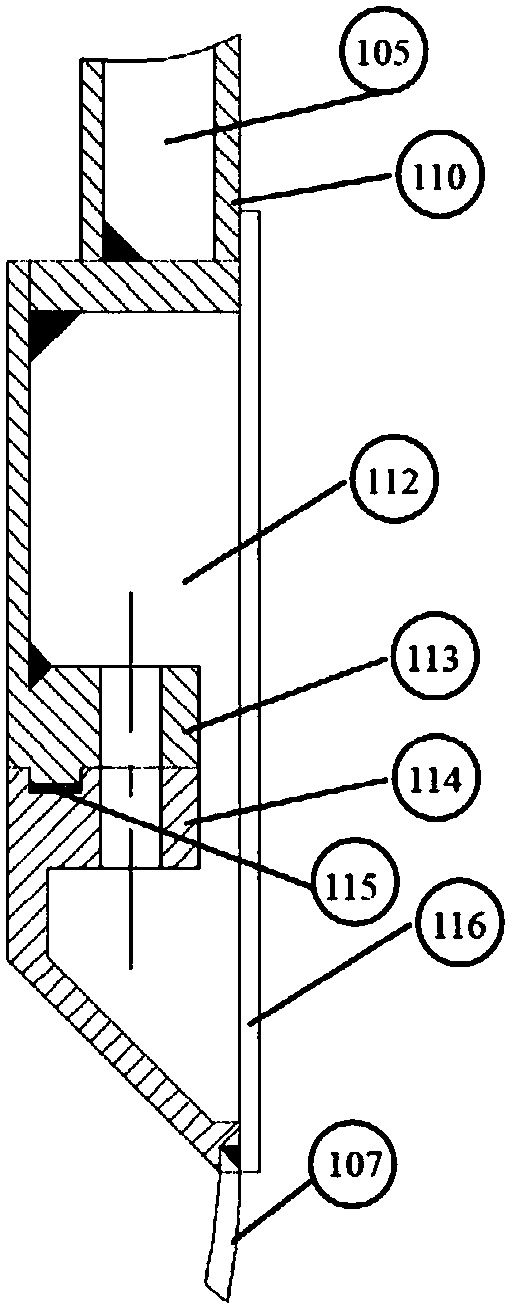

Liquid nitrogen spay frozen granulation vacuum drying device and working method

ActiveCN106268503AIncreased sublimation surface areaEnough to migrateGranulation by liquid drop formationHigh energyFreeze-drying

The invention discloses a liquid nitrogen spray frozen granulation vacuum drying device and a working method. The device solves the problem that in the biotechnology field, when liquid materials are frozen and dried directly, due to the fact that the water sublimation surface is small and air current channels among particles are not smooth, the speed is low, and the efficiency is low. The device sprays the liquid materials into continuously sprayed ultralow-temperature liquid nitrogen mist through nitrogen pressure, material liquid drops are rapidly frozen to be amorphous spherical particles, the amorphous particles are in a non-balanced high-energy state, and drying is easy. Particle materials made through co-spray are stacked on screens which can be folded in a spray chamber and have a heating function, and the larger sublimation surface of the particle materials and through moisture migration and overflowing channels formed by particle voids and the porous screens are beneficial for rapid drying of the materials. In addition, when co-spray granulation is conducted, low-temperature nitrogen flow flows through made material particles and condenser pipes from top to bottom, and the material particles can keep low temperature and fully utilize residual cool.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

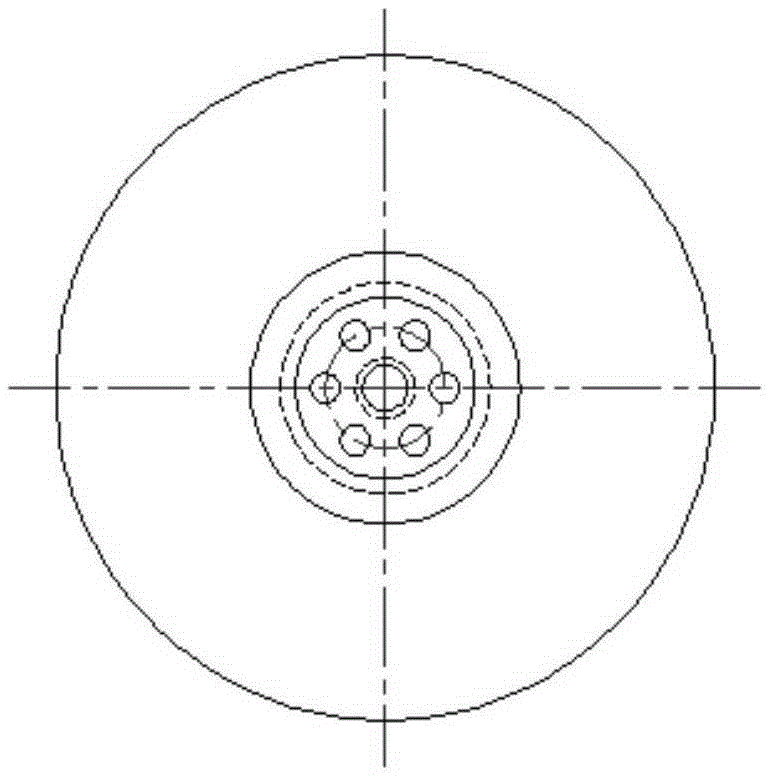

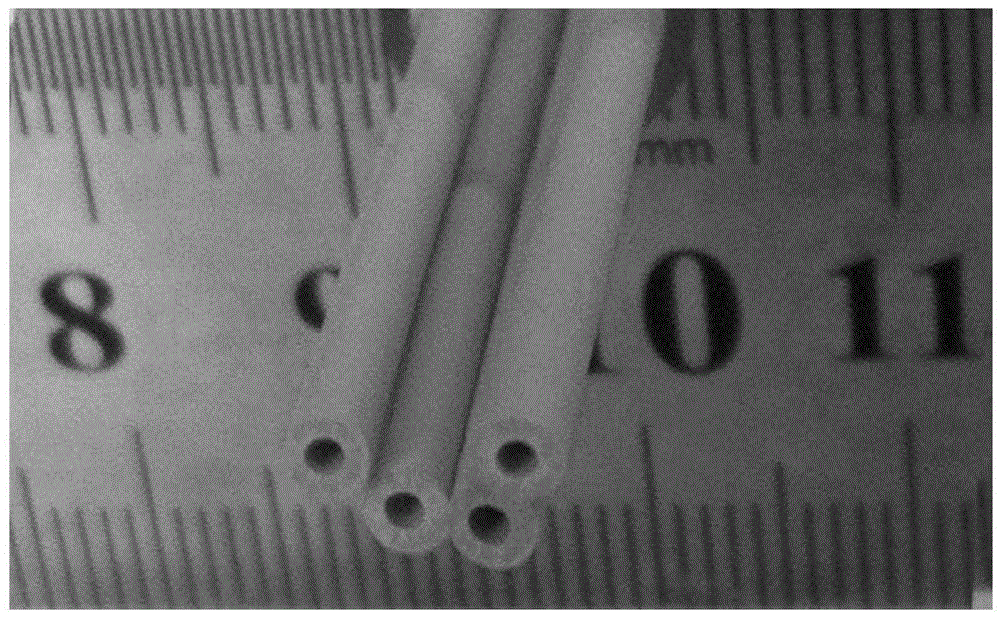

Mullite ceramic hollow fiber membrane and preparation method for same

InactiveCN105536559AHigh mechanical strengthOvercome the disadvantage of easy breakageCatalyst carriersUltrafiltrationFiberPorosity

The invention discloses a mullite ceramic hollow fiber membrane and a preparation method for the same. The preparation method comprises the following steps of adding ceramic powder into a polymer solution prepared from an organic polymer, an additive and a solvent to prepare membrane casting slurry; performing stirring to obtain uniformly-dispersed membrane casting slurry; adding the membrane casting slurry into a slurry tank on a spinning device, performing vacuumizing, introducing core liquid, applying nitrogen pressure to extrude the vacuumized membrane casting slurry into a spinneret, immersing a wet fiber membrane extruded from the spinneret in an external coagulating bath through a 0 to 20cm dry spinning path, performing gelation solidification to form a ceramic hollow fiber membrane green body, naturally drying the green body, and placing the green body in a high-temperature furnace; raising the temperature to 700 DEG C to remove the organic polymer, raising the temperature to 800 to 1,600 DEG C for sintering, reducing the temperature to 500 DEG C, and then performing natural cooling. A prepared mullite ceramic hollow fiber membrane finished product is strong in strength, high in porosity, large in water flux, environmentally friendly and low in cost, can be directly used as a basement membrane of a micro-filtration or ultra-filtration membrane or a carrier of a catalyst in a membrane reactor, and can be industrialized on large-scale.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Coal mine gob area sealing method

ActiveCN104481588AFast fillWon't enterMining devicesGas removalSpontaneous combustionDifferential pressure

The invention discloses a coal mine gob area sealing method, and belongs to the technical field of coal mine gob area gas extraction. When retaining walls of a first sealing chamber or roadway surrounding rocks between the retaining walls are cracked, cracks can be rapidly filled by the aid of fine sand with flowability under the action of ground stress and mining dynamic stress, and tightness is ensured. By the aid of positive and negative differential pressure characteristics of a second sealing chamber, nitrogen pressure in the second sealing chamber is constantly higher than air pressure in a ventilating roadway, a gob area is separated from the ventilating roadway by the second sealing chamber, air in the ventilating roadway cannot enter the gob area, and gas in the gob area cannot permeate into the ventilating roadway. By double sealing of the first sealing chamber and the second sealing chamber, sealing reliability of the gob area is greatly improved, the probabilities of spontaneous combustion of float coal and gas explosion are minimized, and safety of nearby roadways or working faces is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for manufacturing a stainless steel product

ActiveUS20090218011A1Avoid separationMicrostructural stabilitySolid state diffusion coatingLower limitNitrogen pressure

The invention relates to a method for making a thin finished product to be formed by deformation that combines strength with resistance to a highly corrosive environment. The method comprises forming a sheet of stainless steel with a microstructure consisting predominantly of ferrite, austenite, martensite or a mixture thereof, with a thickness of less than 3 mm, to a three dimensional semi finished product, treating said semi finished product with a nitrogen-containing atmosphere at a temperature of between 1000° C. and 1200° C. during a time and under a nitrogen pressure, sufficient to saturate the product through the thickness with a nitrogen content between a lower limit of 0.3 wt % and an upper limit that is provided by the beginning of nitride separation, cooling down said product at such a rate and nitrogen pressure that nitride separation is avoided, and subsequently machining the nitrogen saturated semi- finished product to the finished product. The invention further relates to a rotary shaving assembly prepared by the method of the invention.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Preparation method of porous silicon nitride ceramic material with spherical pore structure

The invention relates to a preparation method of a porous silicon nitride ceramic material with a spherical pore structure. The method comprises the following steps: uniformly mixing silicon nitride powder with a mono-dispersed polymethyl methacrylate (PMMA) spherical pore forming agent to prepare a stable slurry, preparing microsphere powder (the silicon nitride powder and / the spherical pore forming agent are uniformly dispersed in the above microspheres) with good fluidity and regular shape through a spray drying process, carrying out a direct cold isostatic pressing technology on the microsphere powder to prepare a blank with uniform density, carrying out an optimized batching technology to completely remove the pore forming agent and other organic matters, and sintering in nitrogen pressure atmosphere to obtain the complete non-crack porous silicon nitride ceramic material. The porous silicon nitride ceramic material prepared through the method has the advantages of uniform space distribution, uniform size spherical pores, high bending strength and small discreteness.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

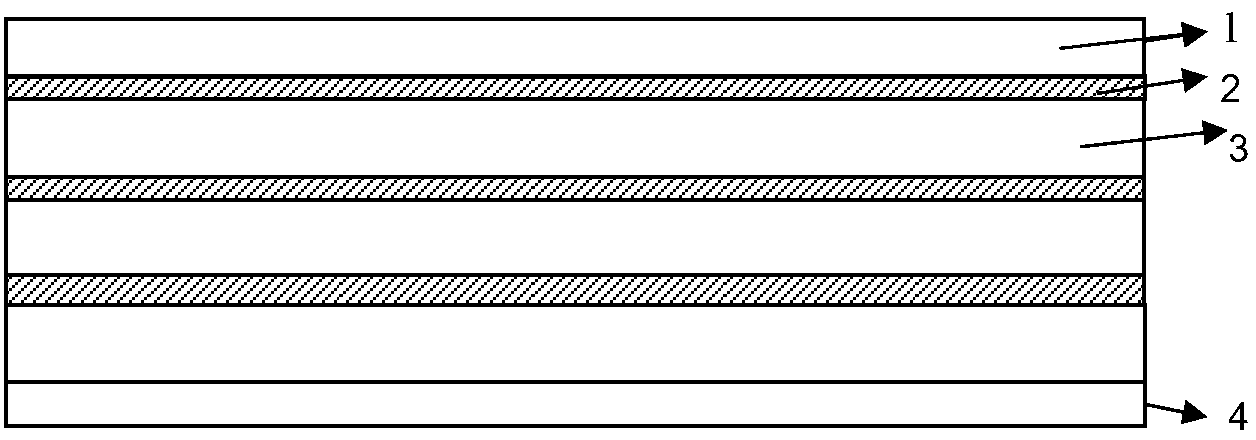

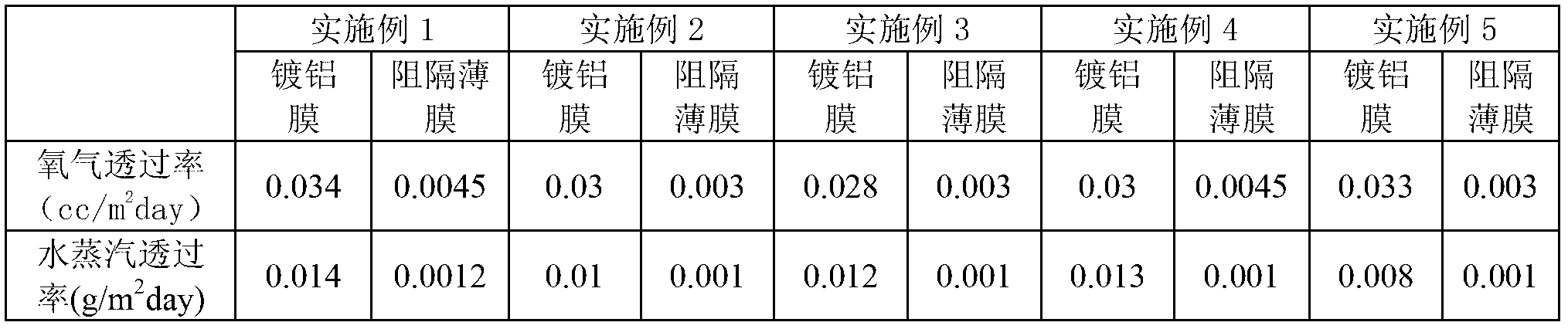

Barrier film and vacuum insulating board adopting same

ActiveCN103057212AHigh gas barrierHigh barrierVacuum evaporation coatingSputtering coatingPolyethylene terephthalateSurface layer

The invention provides a barrier film and a vacuum insulating board compounded by utilizing the barrier film. The barrier film is formed by adhering a surface layer, a gas barrier layer and a heat seal layer, wherein the gas barrier layer consists of at least one aluminum-plated polyethylene terephthalate (PET) film layer. The preparation process of the aluminum-plated PET film comprises the following of: (1) arranging a PET substrate film in an aluminum-plating chamber for performing vacuum aluminum plating, and forming an aluminum-plating layer on the surface of the PET substrate film; and (2) introducing nitrogen into the aluminum-plating chamber in stages after aluminum plating is ended, introducing the nitrogen until the nitrogen pressure is 800-1200pa at the first time, maintaining for 8-12 hours, introducing the nitrogen until the nitrogen pressure is 1300-1500pa, maintaining for at least 12 hours, and obtaining the aluminum-plated PET film. Compared with the conventional aluminum-plated film prepared by the prior art, the aluminum-plated film has the advantages that the overall barrier performance of the barrier film can be effectively improved, so that the requirements can be met in occasions with strict barrier performance requirement.

Owner:中亨新型材料科技有限公司

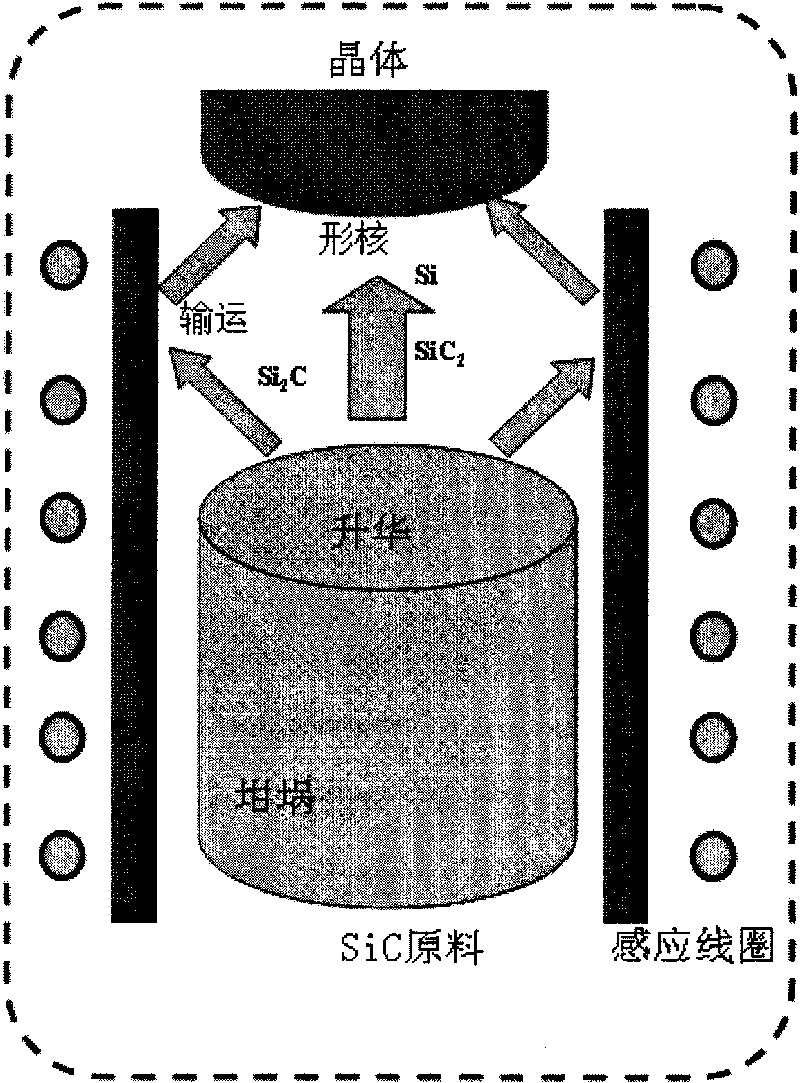

Method for growing high-quality conductive silicon carbide crystal

ActiveCN101724906AGrow fastHigh resistivityPolycrystalline material growthFrom condensed vaporsGas phaseNitrogen gas

The invention discloses a method for high-efficient growth of a silicon carbide crystal, which is the method for preparing the high-quality conductive silicon carbide crystal through rapid growth. The growth speed of the crystal is generally in the range of 0.1-0.5mm and the resistivity is not less than 0.025 ohm.cm during the growth process of the conductive silicon carbide crystal according to the traditional physical vapor transport method. The higher raw material temperature (2300-2700 DEG C) and the lower growth interface temperature (1800-2300 DEG C) are adopted in the method, nitrogen pressure is used for assisting the control of a growth system, the high crystal growth speed (0.6-3mm / h) can be obtained, the resistivity of the crystal can achieve 0.01 ohm.cm, and the crystallization quality of the crystal is very high. The method can realize the rapid growth of the silicon carbide crystal with high quality and low resistivity, thereby providing necessary conditions for improving the yield of the silicon carbide crystal and reducing the cost. In addition, the rapid growth of the silicon carbide crystal further has the advantages of amplifying the crystal, reducing defects of the crystal and the like.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

Preparation method of chromium nitride

InactiveCN103318855AHighlight substantiveEasy to storeNitrogen-metal/silicon/boron binary compoundsMetallic materialsChromium nitride

The present invention relates to a preparation method of chromium nitride, and belongs to the technical field of inorganic non-metallic material preparation. In the method, metal chromium powder is taken as raw material, the granularity of which is more than 200 meshes and high purity reagent is at least 3.5N. A crucible containing the raw material is placed in an atmosphere-controllable high-temperature furnace for high-temperature reaction synthesis in flowing ammonia at a temperature of 800-1200 DEG C for 2-20 hours, wherein the oxygen pressure in furnace ranges from 1.013*104.55 to 1.013*104.58 Pa, and the nitrogen pressure ranges from 1.013*103.11 to 1.013*106.41Pa. The resultant is cooled to room temperature in ammonia flow after the completion of reaction to obtain a product and the product is taken out and is fully grinded to powder. The chromium nitride prepared by the invention is analyzed by XRD and only has chromium nitride phase, wherein characteristic peaks of other impurities are not observed; other impurities are not contained; and oxygen content is less than 1.65%. The production process is simple and the raw material can be easily preserved and is suitable for large-scale production.

Owner:SHANGHAI UNIV

Low-cost MIM manufacturing process for high-nitrogen and non-magnetic high-strength stainless steel part

InactiveCN109014211ASolve the shortcomings of poor dimensional stability and difficult performance guaranteeGuaranteed performanceTransportation and packagingMetal-working apparatusNitrogen atmosphereNitrogen gas

The invention discloses a low-cost MIM manufacturing process for a high-nitrogen and non-magnetic high-strength stainless steel part. The low-cost MIM manufacturing process comprises the steps of rawmaterial preparation, forming, degreasing, sintering and solid solution; in the step of sintering, a billet after catalytic degreasing is sintered to be dense by adopting a vacuum batch furnace, the sintering process is conducted under the whole-process nitrogen atmosphere, and the nitrogen atmosphere sintering is mainly carried out in two steps of the first low pressure sintering for being denseand the second high-pressure nitriding for ensuring the performance; and the low-pressure sintered nitrogen pressure is 10-30 kpa, the intake flow is 20-50 L / min, the sintering temperature is 1150-1250 DEG C, the heat insulation time is 90-360 min, the high-pressure nitriding nitrogen pressure is 60-90 kpa, the intake flow is 20-50 L / min, the sintering temperature is 1280-1320 DEG C, and the heatinsulation time is 90-120 min. By means of the low-cost MIM manufacturing process, the mass production feasibility of the self-made feeding which is cheaper than BASF feeding is achieved, and the shortcomings that the dimensional stability is poor, and the performance is difficult to guarantee when the self-made feeding adopts a conventional sintering process for mass production are overcome.

Owner:SHANGHAI FUTURE HIGH-TECH CO LTD

Method for smelting high-nitrogen austentite stainless steel through pressurized electroslag remelting gas nitriding

The invention belongs to the technical field of high-nitrogen steel smelting, and particularly relates to a method for smelting high-nitrogen austentite stainless steel through pressurized electroslag remelting gas nitriding. The method is characterized in that a consumable electrode base material with the nitrogen content being (0.75-0.9)x[%N] is smelted in a smelting furnace according to target steel grade ingredients, and the consumable electrode base material is forged into a consumable electrode; arcing slagging is conducted through a solid-state arcing method under protection of nitrogen; and nitrogen is led into a smelting chamber to increase the pressure to 1 MPa to 3 MPa, the cooling water pressure is synchronously increased, and smelting and feeding forming are conducted at a low smelting speed under the voltage ranging from 40 V to 45 V and the current ranging from 3000 A to 4200 A. The method has the beneficial effects that alloying of nitrogen in the high-nitrogen austentite stainless steel is efficiently conducted through the gas nitriding method by reasonably controlling the current, the voltage, the nitrogen pressure and other parameters, and the technical support is provided for development of the high-nitrogen austentite stainless steel high in nitrogen content, uniform in ingredient and excellent in performance.

Owner:NORTHEASTERN UNIV

Bottom blowing method for KR method desulfurizing tank

InactiveCN1944686AImprove desulfurization performanceShorten the working time of the processSulfurNitrogen gas

The bottom blowing desulfurizing tank KR method includes blowing with high pressure nitrogen before skimming and regulating minimum permeating state to result in molten iron turning over in one tenth of tank volume, bottom blowing nitrogen while stirring in the flow rate of 12-23 Nm3 / hr and pressure of 0.3-0.8 MPa and sampling to measuring molten iron temperature, bottom blowing nitrogen after skimming by 3-8 min in the pressure 0.5- 0.8 MPa. The method has shortened desulfurizing period, low desulfurizing cost and high desulfurizing efficiency.

Owner:WUHAN IRON & STEEL (GROUP) CORP

External cooling test system and method for pressure vessel

ActiveCN107564593ASolve the problem of low heat fluxMeet high heat flux requirementsNuclear energy generationNuclear monitoringData acquisitionEngineering

The invention discloses an external cooling test system and method for a pressure vessel and belongs to the technical field of external cooling of the pressure vessel. The test system comprises a testpiece, a high-temperature molten pool, a cooling water supply loop, a steam cooling loop, a nitrogen source as well as a corresponding power distribution cabinet, instrument control equipment and data collection equipment. The test method comprises steps as follows: metal in the high-temperature molten pool is molten into a liquid state, and molten metal is delivered to the test piece under nitrogen pressure; the test piece adopts an impeller to drive electrically heated liquid metal to circularly flow in the test piece, the liquid metal is utilized to simulate in-reactor melt under a seriousaccident, heat is transmitted to a lower sealing head of the test piece, and the outer surface of the lower sealing head soaked in cooling water is boiled to realize heat exchange; the cooling waterrequired by the test is guaranteed by the cooling water supply loop and the steam cooling loop. According to the system and the method, the work of studying influence of the outside structure surfaceand a flow channel structure of the lower sealing head on external cooling performance of the pressure vessel can be carried out, thereby being beneficial to improvement ofsafety margin of external cooling of the pressure vessel.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

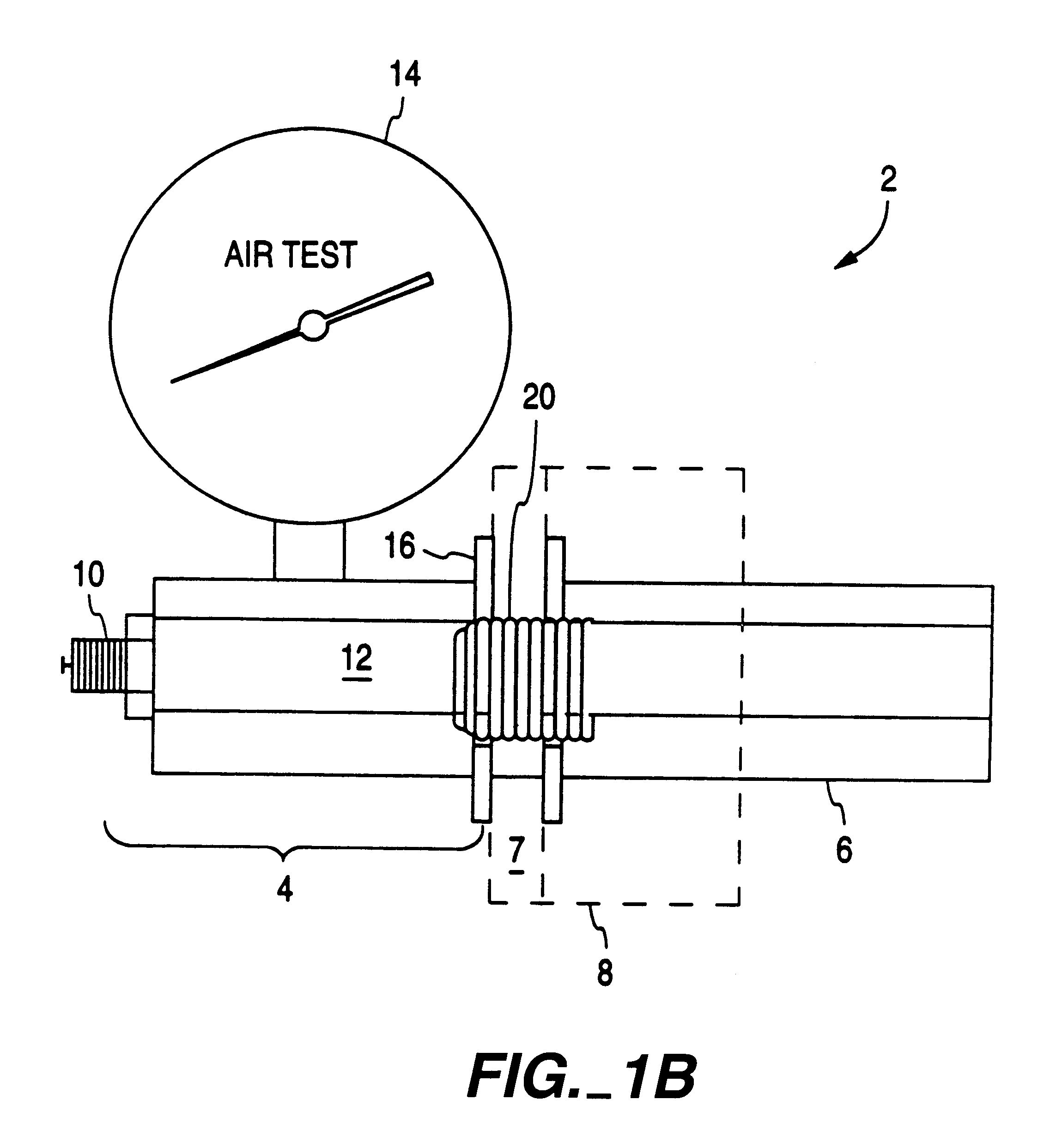

Air test apparatus

InactiveUS6378356B1Detection of fluid at leakage pointMeasurement of fluid loss/gain rateAtmospheric pressureNitrogen pressure

The present invention provides a single compact fitting for air, CO2, or nitrogen pressure testing either gas piping or waste piping. Each fitting is used for gas pipes of a particular outside diameter and waste pipes of a single larger diameter. The typical plumber would have a set, for example four, of the inventive fittings available, one for each size waste pipe that is be tested. The inventive fitting couples easily to either gas fuel piping or waste piping. A single air-pressure gauge is used to test either type of piping system. The inventive fitting is not limited to waste, vent, or gas piping systems; it can also be used to couple to other piping systems. The inventive fitting, in addition to being more versatile than conventional air-pressure test fittings, is also smaller and more compact. The inventive fitting can be made from a one-piece core body or from several conventional component pieces.

Owner:RUIZ JAMES L +1

Aluminum nitride porous ceramic and preparation method thereof

InactiveCN101734923AFine grainUniform distribution of poresCeramicwareNitrogen gasHigh temperature electronics

The invention discloses an aluminum nitride porous ceramic and a preparation method thereof. The aluminum nitride porous ceramic comprises the following components by weight percent: 60-72 percent of aluminum oxide, 1-10 percent of sintering assistant, 18-30 percent of carbon black and 1-10 percent of aluminum nitride seed crystal. The preparation method comprises the following steps of: carrying out ball milling mixture on the components with a wetting method to obtain mixed powder; carrying out mould pressing on the components for forming; placing a forming body into an atmosphere furnace, heating the forming body to 1650-1750 DEG C when the nitrogen pressure is higher than one pressure atmosphere and keeping the temperature for 1-4 hours to obtain a sintering body. The aluminum oxide and the carbon black with low cost are used as raw materials to prepare the aluminum nitride porous ceramic with high porosity, therefore, the invention can overcome the defects of the complicated process of preparing the aluminum nitride porous ceramic by using the traditional method and the excessive cost, and can be widely applied in photoelectricity fields of high-temperature electronic devices, microwave integrated circuits, mixed integrated circuits, power electronic modules, laser diodes and the like as well as reinforced phases of metal-based composite materials.

Owner:XI AN JIAOTONG UNIV

Vacuum isothermal heat treatment process of large die-casting mould

InactiveCN101880760AGuaranteed service lifeRapid coolingFurnace typesHeat treatment furnacesSurface layerStructure property

The invention relates to a vacuum isothermal heat treatment process of a large die-casting mould, which is characterized by comprising the steps of: inserting thermocouples into the core and the surface layer of a mould, raising the temperature of a furnace to 550-625 DEG C at the speed of 150-200 DEG C per hour firstly, then raising the temperature of the furnace to 825-875 DEG C at the speed of 100-150 DEG C per hour, raising the temperature of the furnace (Tf) to reach an austenization sate within 20 minutes and preserving the temperature for 30 minutes; quickly cooling under cooling pressure not lower than 9Bar, decreasing the cooling pressure to 2Bar when the temperature of the surface of the mould (Ts) is decreased to 427 DEG C, stopping the rotation of a cooling fan and turning on a convection fan; and filling nitrogen pressure to be above 6Bar after isothermy, turning off the convection fan and restarting the cooling fan to rotate so as to realize quick cooling. Therefore, the invention can achieve the most ideal structure property and the minimum deformation, can guarantee the service life of the large die-casting mould, and has scientific and reasonable process, obvious technological advance and considerable economic values and market prospect.

Owner:FAW GROUP

Method for preparing boron nitride ceramic material through stepped sintering

The invention relates to a method for preparing aboron nitride ceramic material through stepped sintering and belongs to the field of insulating material preparation. The method comprises the steps of firstly mixing BN-based powder, additive and sintering aid and performing granulation; then containing the mixed powder into a graphite mold and then performing stepped hot-pressed sintering; and obtaining the boron nitride ceramic material after sintering. In the method, the hot-pressed sintering process comprises a low-temperature vacuum maintaining step, a medium-temperature nitrogen pressure maintaining step and a high-temperature inert atmosphere pressure maintaining step. By adopting the process, the discharge of gas impurities can be effectively facilitated and the density and strength of the boron nitride ceramic material are improved.

Owner:长兴鑫宇耐火材料有限公司

Method for preparing silicon nitride reinforced aluminium-based composite material

The invention discloses a method for preparing a silicon nitride reinforced aluminium-based composite material, which comprises the following steps: performing wet ball milling and drying on 60 to 67.5 weight percent of silicon oxide, 22.5 to 30 weight percent of carbon black, 1 to 10 weight percent of alpha-Si3N4 seed crystal, and 1 to 10 weight percent of Y2O3 to prepare mixed powder, sieving and granulating the mixed powder, and forming a blank piece through mold pressing; heating the blank piece to 1,750DEG C under the condition that the nitrogen pressure is six times of atmospheric pressure, preserving heat for 2 hours, and sintering to obtain a porous silicon nitride prefabricated body of which the relative density is between 20 and 30 percent; putting the porous silicon nitride sintered body in a die cavity of a die casting machine, and heating the die cavity to the temperature of between 500 and 700 DEG C, or firstly separately preheating the sintered body to the temperature of between 500 and 700 DEG C and then putting the preheated sintered body to the die cavity of the die casting machine; simultaneously, heating aluminium alloy to a melting state, pouring the molten aluminium alloy into the die cavity in which the prefabricated body is arranged, and pressing the molten aluminium alloy into the porous silicon nitride prefabricated body through a press machine; and finally, taking an ingot out after cooling, and performing heat treatment to obtain the silicon nitride reinforced aluminium-based composite material.

Owner:XI AN JIAOTONG UNIV

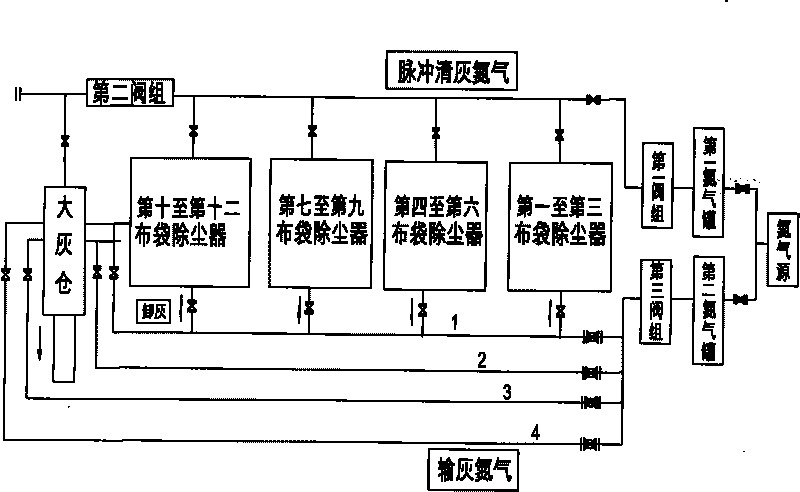

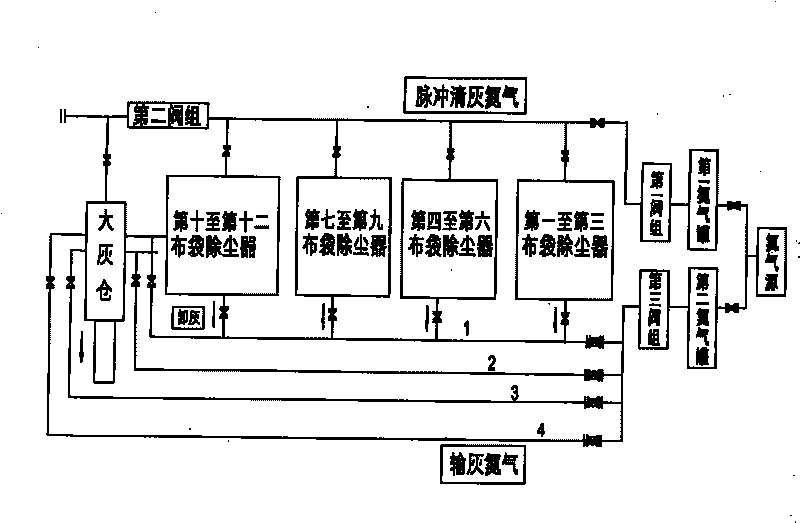

Group control method of blast furnace gas cloth bag dust catcher system for pipeline dust conveying

InactiveCN101708406ARealize multi-level grouping controlImprove work efficiencyDispersed particle filtrationDust arrestersBaghouseNitrogen gas

The invention relates to a group control method of blast furnace gas cloth bag dust catcher system for pipeline dust conveying, which adopts a group control device of the blast furnace gas cloth bag dust catcher system for pipeline dust conveying to realize the multi-stage group control of the blast furnace gas cloth bag dust catcher system. The device comprises a big dust cabin, a plurality of groups of cloth bag dust catchers and a valve bank. The method comprises the following steps of: controlling the sleeve bodies of the cloth bag dust catchers and the pulse blowing nitrogen pressure of the big dust cabin by grade, setting a dust conveying nitrogen pressure, and realizing group control management for the sleeve bodies of the cloth bag dust catchers by separately controlling each dust conveying pipeline. The group control method of the invention can improve the operation efficiency, prolong the service life of equipment, realize the multi-grade control of a dust clearing gas source pressure and safe production of a blast furnace, and is suitable for the improvement of newly-built or traditional de-dusting systems.

Owner:WISDRI ENG & RES INC LTD

Method for preparing TiB2-Co coating by supersonic-speed flame spraying

InactiveCN102363877AImprove wear resistanceGood mechanical propertiesMolten spray coatingPorosityWear resistant

The invention discloses a method for preparing a wear-resistant TiB2-Co coating by supersonic-speed flame spraying. Metal ceramic mixed TiB2-based and Co-based alloying powder is formed by performing ball-milling by mechanical alloying at room temperature at the rotation speed of 440 revolutions per minute for six hours; the surface of a piece to be sprayed which is obtained after sand blasting is uniform and coarse; a coating of which thickness is 150 to 200mu m is sprayed on the piece to be sprayed; supersonic-speed flame spraying process parameters are specifically that: oxygen pressure is 1.02Mpa, propane pressure is 0.4 to 0.6Mpa, nitrogen pressure is 0.65Mpa, oxygen flow is 10 to 12.5m<3>h, propane flow is 1,100 to 1,200L / min, nitrogen flow is 1,000 to 1,100L / miunm, vertical speed of a spraying area is 50mm / s, and horizontal speed of the spraying area is 170mm / s, and spraying distance is 185mm; and the invention has the advantages that the TiB2-Co coating which has high wear resistance can be obtained by performing supersonic-speed flame spraying of TiB2-Co composite metal ceramic powder. The TiB2-Co coating has a good mechanical property, and a compact layer structure, is low in porosity.

Owner:JIUJIANG UNIVERSITY

Method for preparing mesophase pitch through hydrogenation upgrading and co-carbonization of FCC (Fluid Catalytic Cracking) decant oil

InactiveCN107312561AImprove spin performanceReduce usageWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

The invention provides a method for preparing a petroleum-based mesophase pitch with high anisotropic structure content and low softening point. The method comprises the following steps: conducting reduced pressure distillation on an FCC (Fluid Catalytic Cracking) decant oil of a naphthenic crude, taking a cut fraction with the boiling point of 400-540 DEG C as a raw material, and reacting for 1-8 hours at the temperature of 400-460 DEG C and under the pressure of 4 MPa to obtain a petroleum pitch; then adding a hydrogen donor, reacting under condition of the self-generated pressure at the temperature of 380-450 DEG C at the initial nitrogen pressure of 5 MPa, then reducing the pressure to the normal pressure, cooling to 340 DEG C, and blowing with high-purity nitrogen for 0.5 hour to obtain a hydrogenated pitch; finally adding a co-carbonization additive, and reacting for 2-16 hours at the temperature of 400-480 DEG C at the pressure of 4MPa to obtain the high-quality mesophase pitch. The preparation process is simple, the production cost is low, the anisotropic structure content (more than 98%) of the prepared mesophase pitch is high, the softening point (230-270 DEG C) is low, the spinning property is good, and the mesophase pitch is an excellent precursor for preparing a high-modulus carbon fiber.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com