Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Improve desulfurization performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

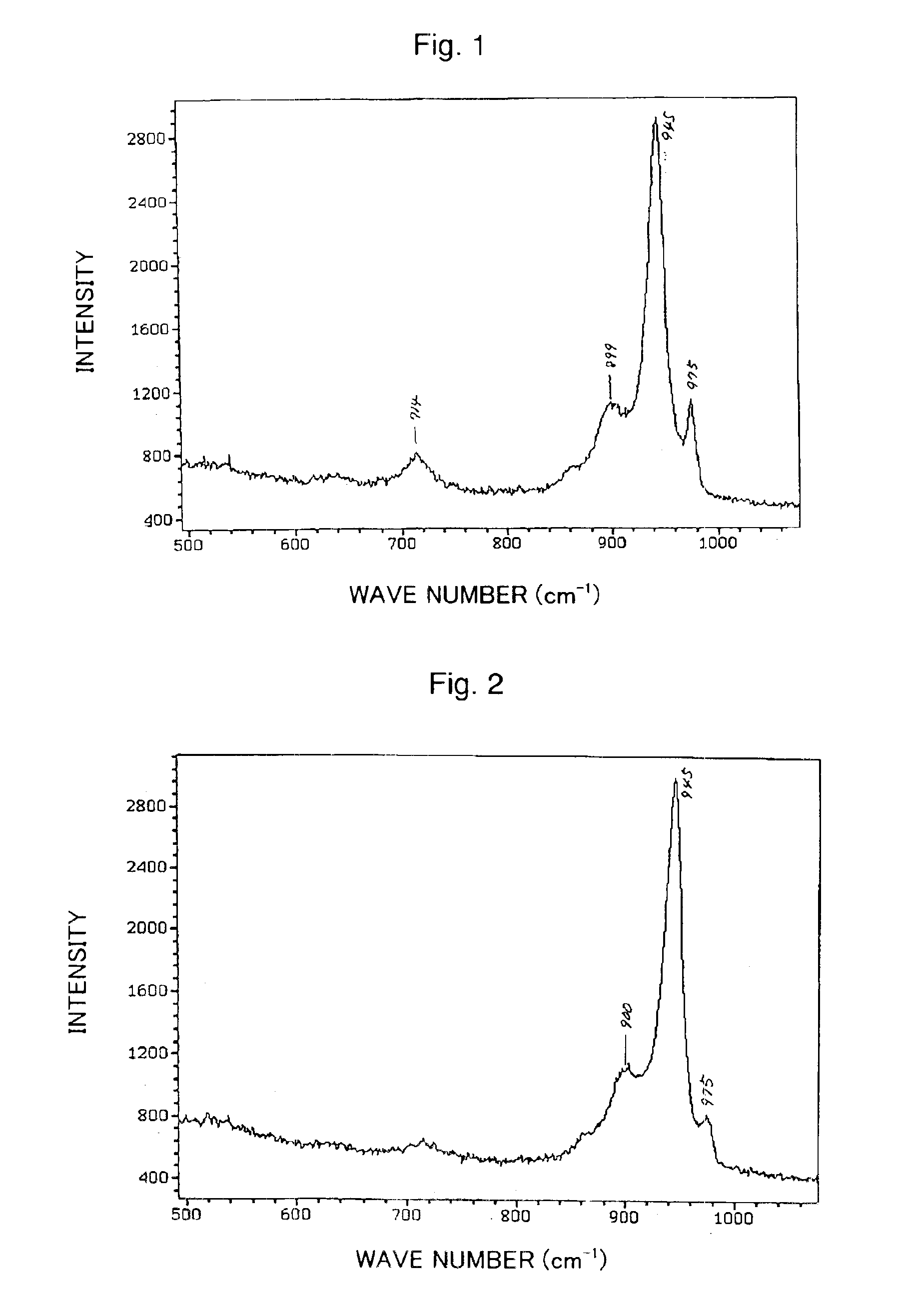

Hydrodesulfurization catalyst for hydrocarbon oil, process of producing same and method for hydrorefining

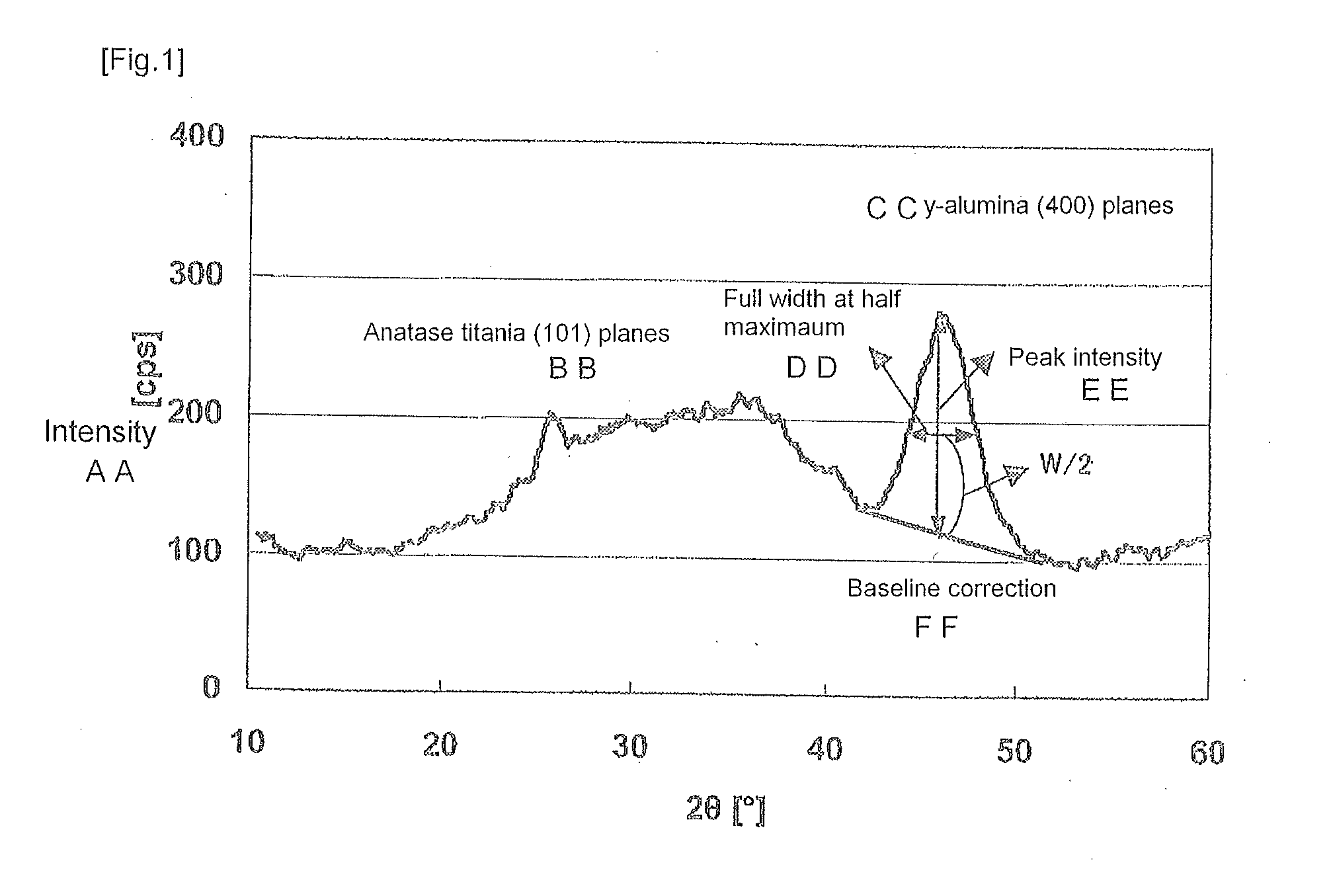

ActiveUS20120181219A1High desulfurization activityInexpensiveCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationX-ray

The present invention provides a hydrodesulfurization catalyst that exhibits a high desulfurization activity when used in hydrotreatment of hydrocarbon oil, in particular straight-run gas oil. The catalyst includes at least one type of metal component selected from Groups VIA and VIII in the periodic table, supported on a silica-titania-alumina support where the total of the diffraction peak area indicating the crystal structure of anatase titania (101) planes and the diffraction peak area indicating the crystal structure of rutile titania (110) planes is ¼ or less of the diffraction peak area indicating the aluminum crystal structure ascribed to γ-alumina (400) planes, as measured by X-ray diffraction analysis. The catalyst has (a) a specific surface area (SA) of 150 m2 / g or greater, (b) a total pore volume (PVo) of 0.30 ml / g or greater, (c) an average pore diameter (PD) of 6 to 15 nm (60 to 150 Å), and (d) the ratio of the pore volume (PVp) of pores having diameters within ±30 percent of the average pore diameter (PD) being 70 percent or greater of the total pore volume (PVo).

Owner:JX NIPPON OIL & ENERGY CORP +1

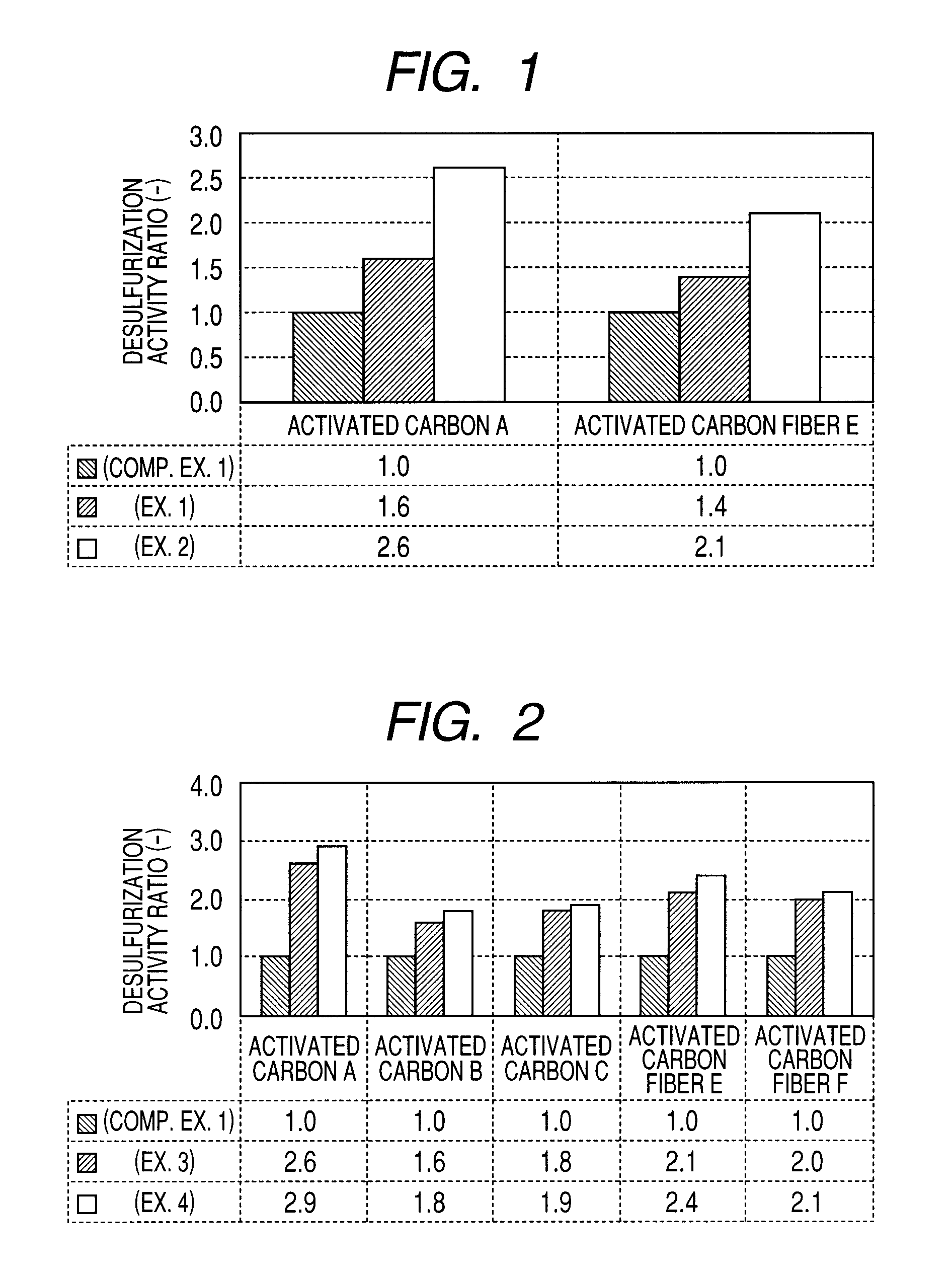

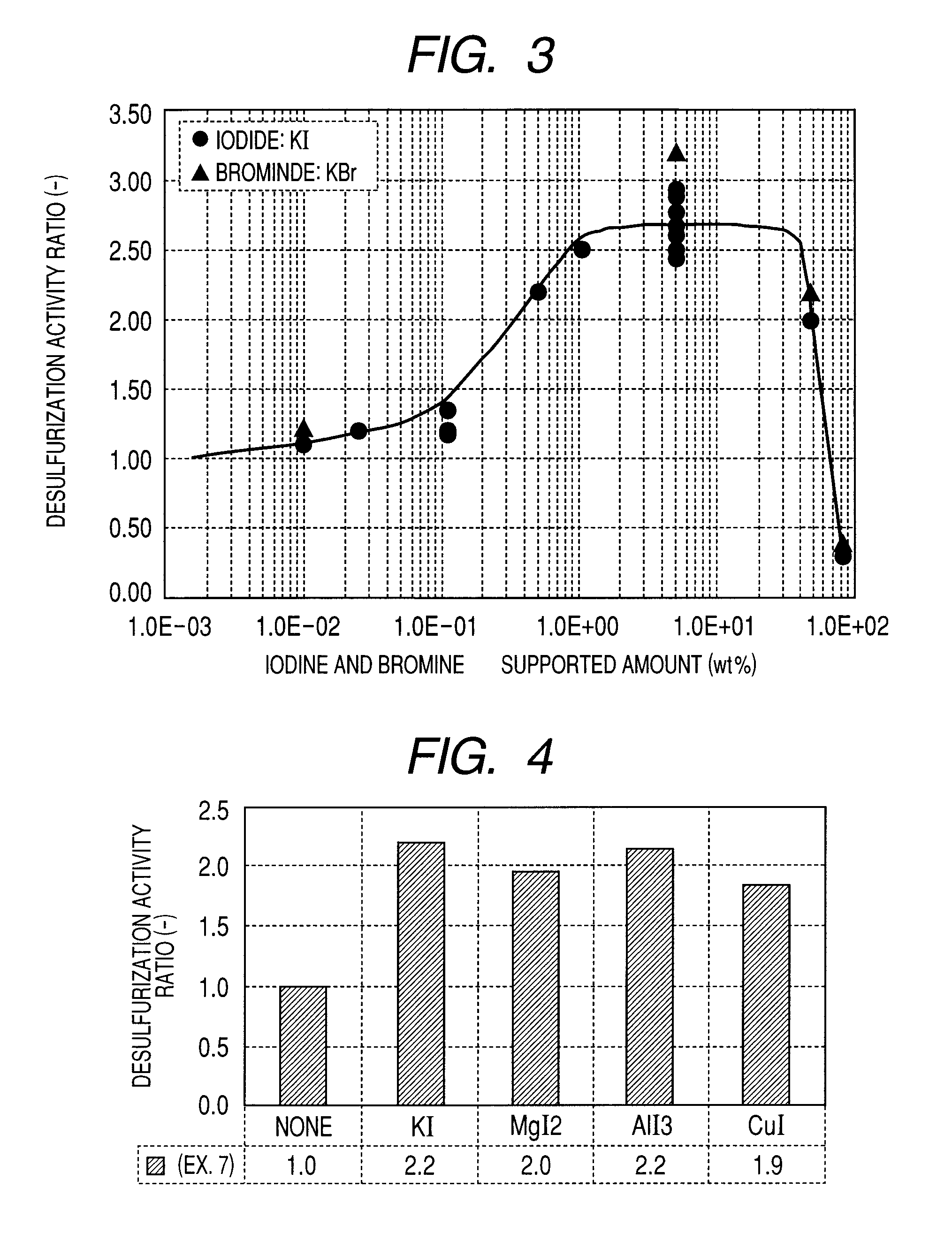

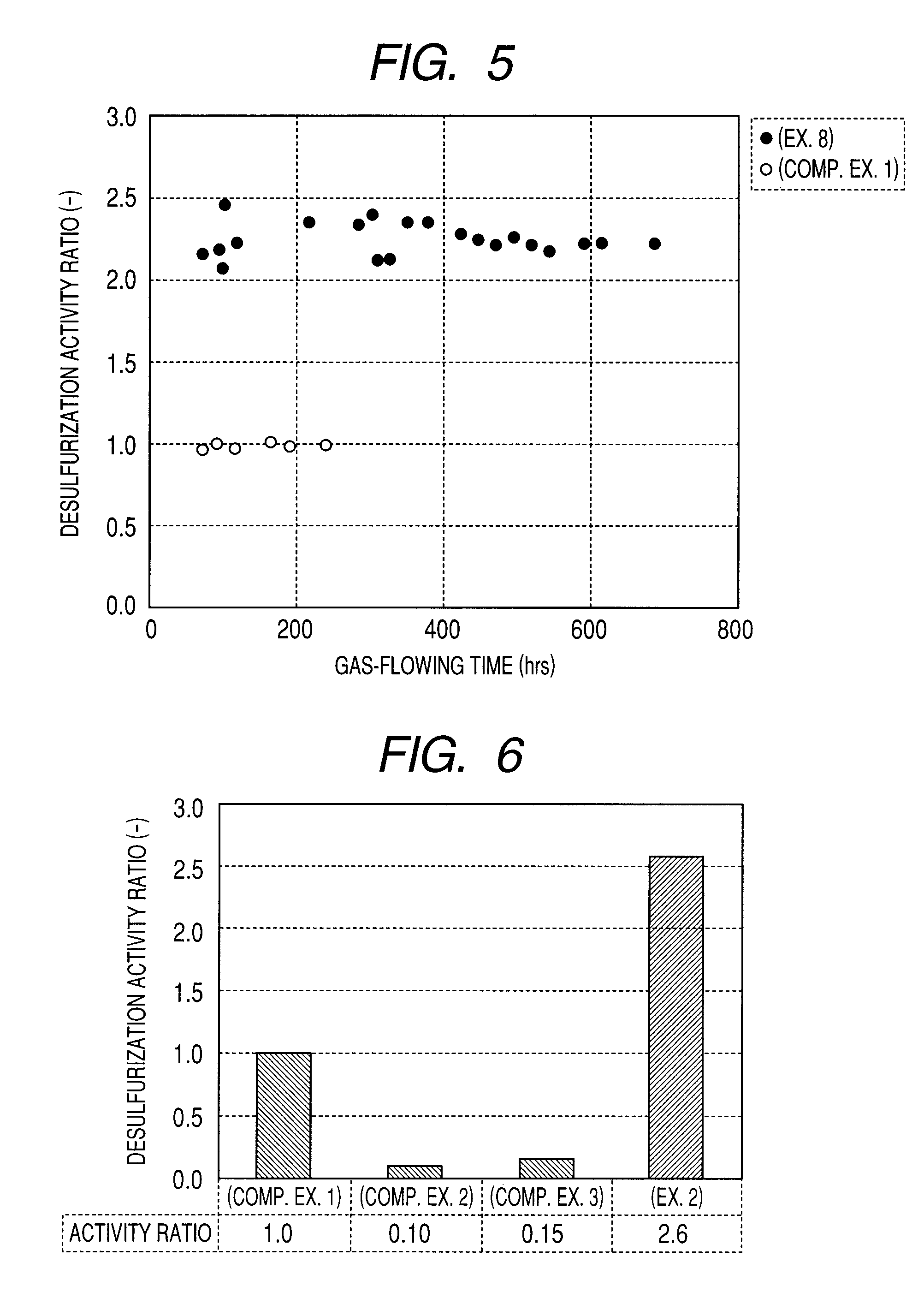

Carbon-based catalyst for flue gas desulfurization and method of producing the same and use thereof for removing mercury in flue gas

ActiveUS8524186B2Improve desulfurization performanceReduce the amount requiredGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsWater vaporSorbent

A carbon-based catalyst for flue gas desulfurization is brought into contact with a flue gas containing at least SO2 gas, oxygen and water vapor so that the SO2 gas can react with the oxygen and the water vapor to form sulfuric acid which is to be recovered. On a surface of the carbon-based catalyst, iodine, bromine or a compound thereof is added, ion exchanged or supported and a water-repellent treatment is applied. The carbon-based catalyst can also be used as a mercury adsorbent for flue gas treatment for adsorbing and removing metallic mercury from a flue gas containing metallic mercury, SO2 gas, oxygen and water vapor.

Owner:CHIYODA CORP

Efficient flue gas desulfurization and denitrification method and materials adopted by same

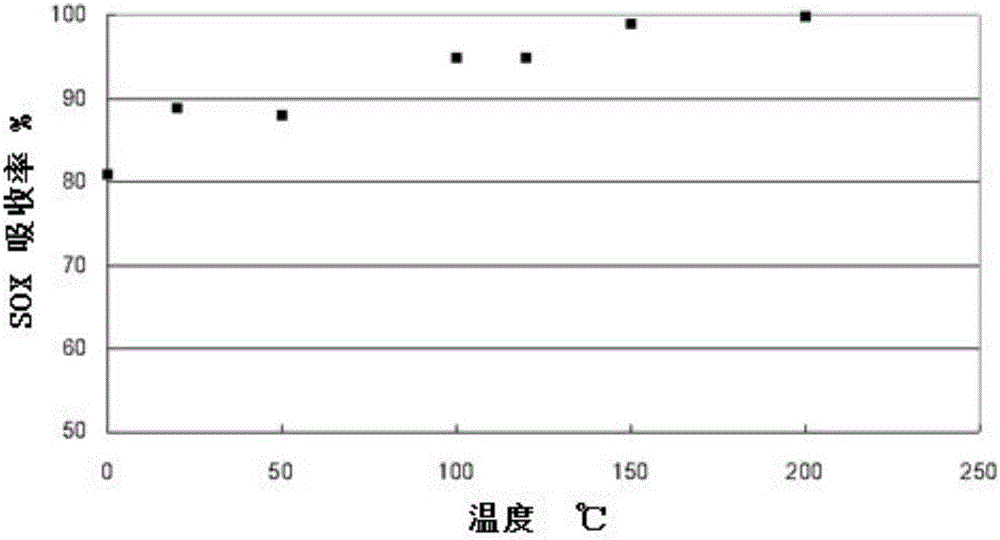

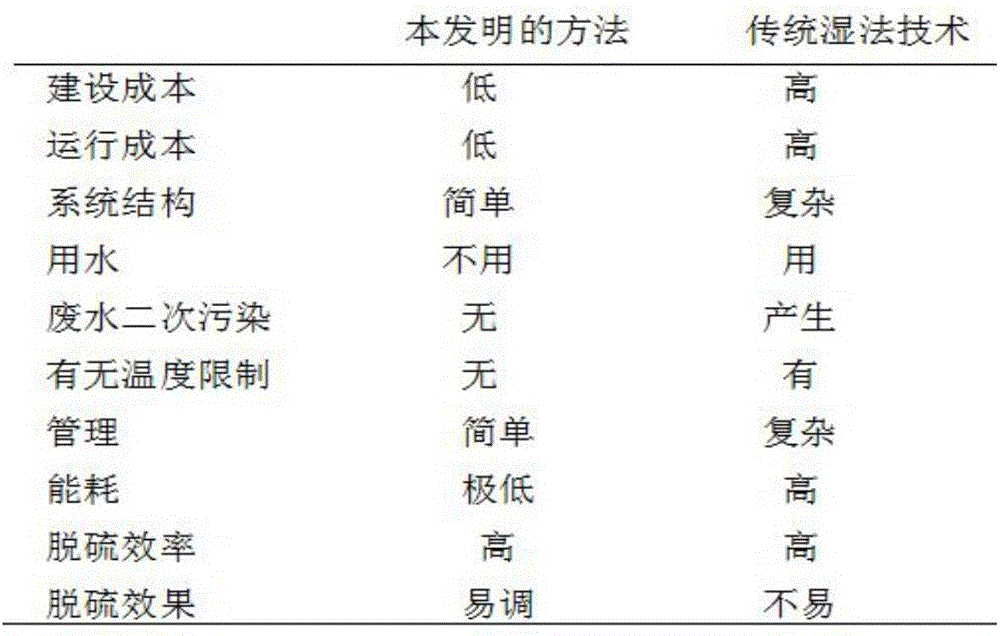

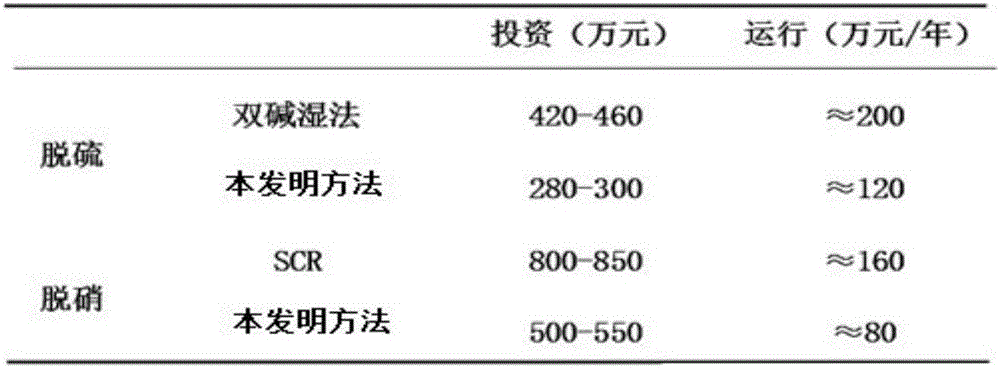

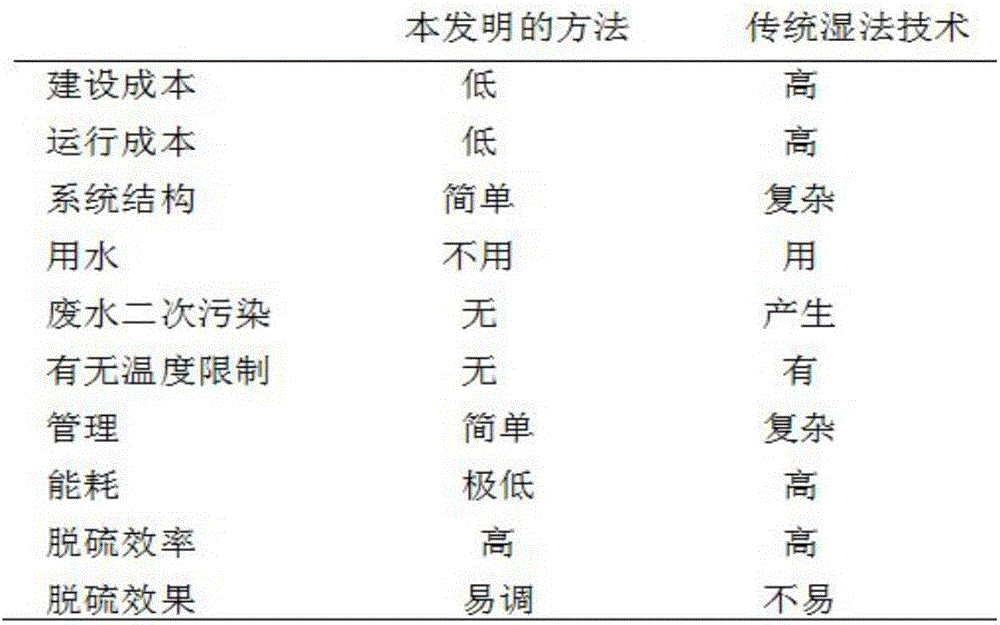

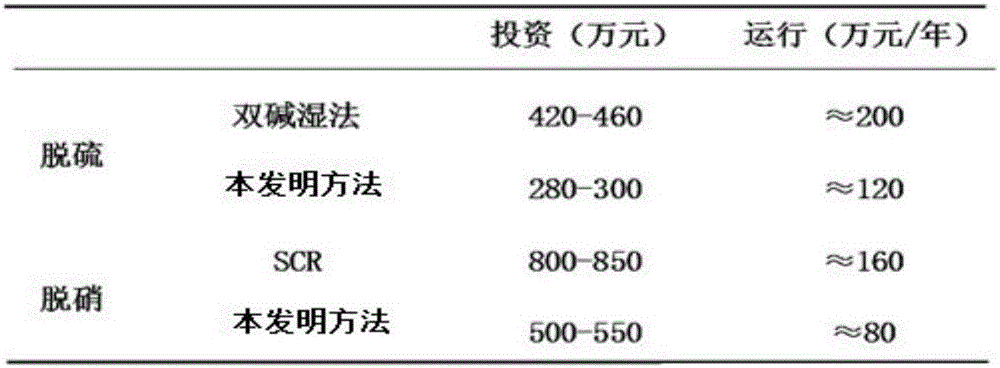

InactiveCN105727730AImprove desulfurization efficiencyLow investment costGas treatmentDispersed particle separationSodium bicarbonateSulfate radicals

The invention relates to a method for highly efficient desulfurization and denitrification of flue gas and materials used. The main material is at least one of 50-99wt% calcium hydroxide, calcium carbonate, magnesium hydroxide, magnesium carbonate, sodium carbonate or sodium bicarbonate, Auxiliary material oxidizing agent: 1-50wt%. 0.1-10wt% binder can also be added. The desulfurization principle of the high-efficiency desulfurization and denitrification material provided by the invention is to oxidize sulfur dioxide into sulfur trioxide and then perform desulfurization reaction to generate calcium sulfate or other sulfate radical compounds. The compound no longer needs secondary treatment and is harmless to the environment, so The method can fundamentally eliminate the discharge of subsequent pollutants from flue gas desulfurization, and is environmentally friendly.

Owner:TIANJIN BINHUAN CHEM ENG TECH RES INST

Flue gas desulfurization and denitrification method

InactiveCN105771617AImprove desulfurization efficiencyLower investment and operating costsOther chemical processesDispersed particle separationCalcium hydroxideMagnesium

The invention relates to an efficient desulfurization and denitrification material, comprising at least one of calcium hydroxide, calcium carbonate, magnesium hydroxide, magnesium carbonate and sodium carbonate or sodium bicarbonate. A binder that is 0.1-10% by weight is added, diatomite or kaolin that is 5-10% of total weight of materials is added, and cerium dioxide that is 0.2-1% of the total weight of the materials is added. The desulfurization principle of the efficient desulfurization and denitrification material provided herein refers to oxidizing sulfur dioxide into sulfur trioxide and carrying out desulfurization reaction to generate calcium sulfate or other sulfate compounds, these compounds require no secondary treatment, and no environment damage is caused; therefore, this method enables the emission of subsequent pollutants from flue gas desulfurization to be substantially avoided and is environment-friendly.

Owner:TIANJIN BINHUAN CHEM ENG TECH RES INST

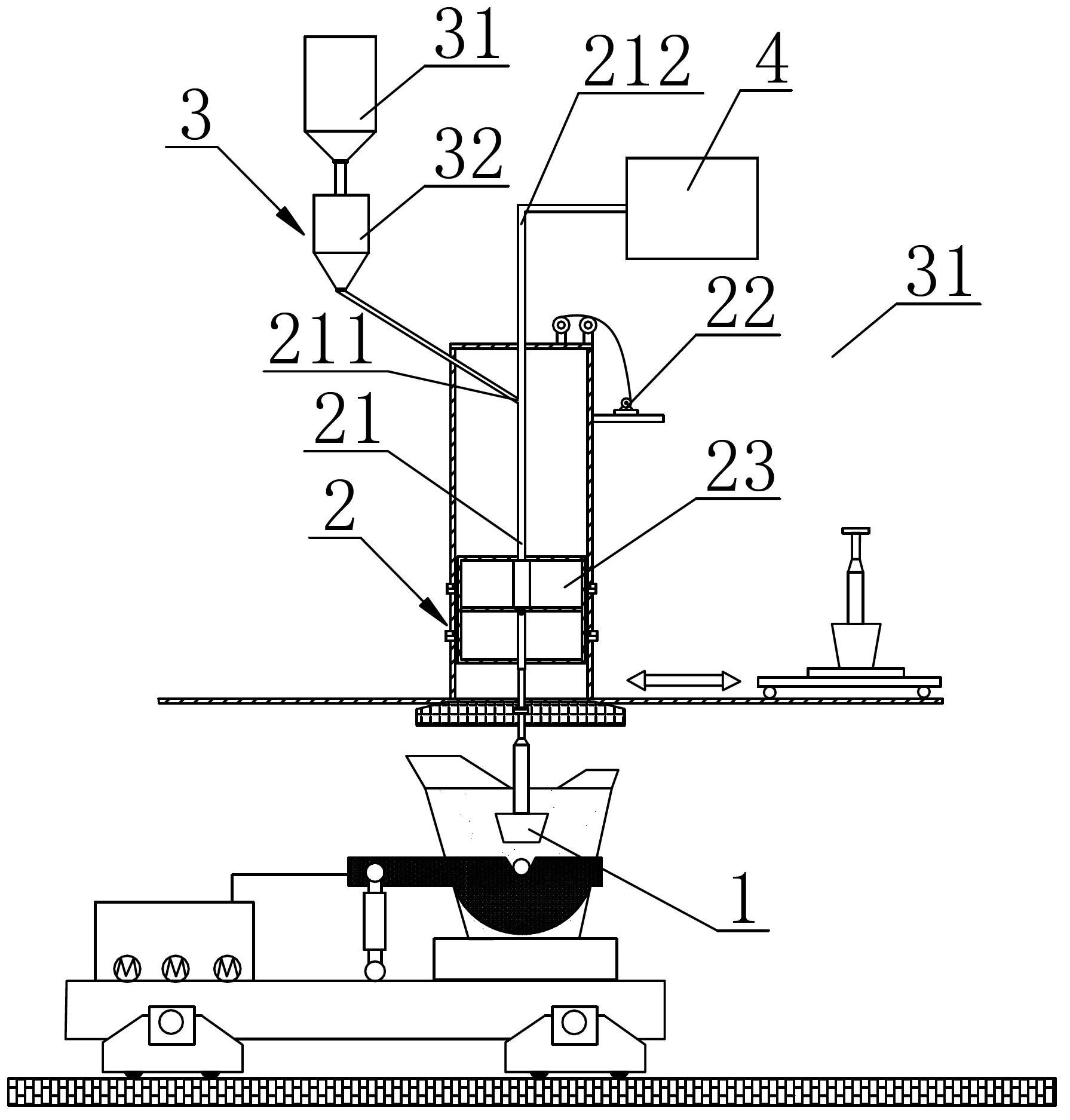

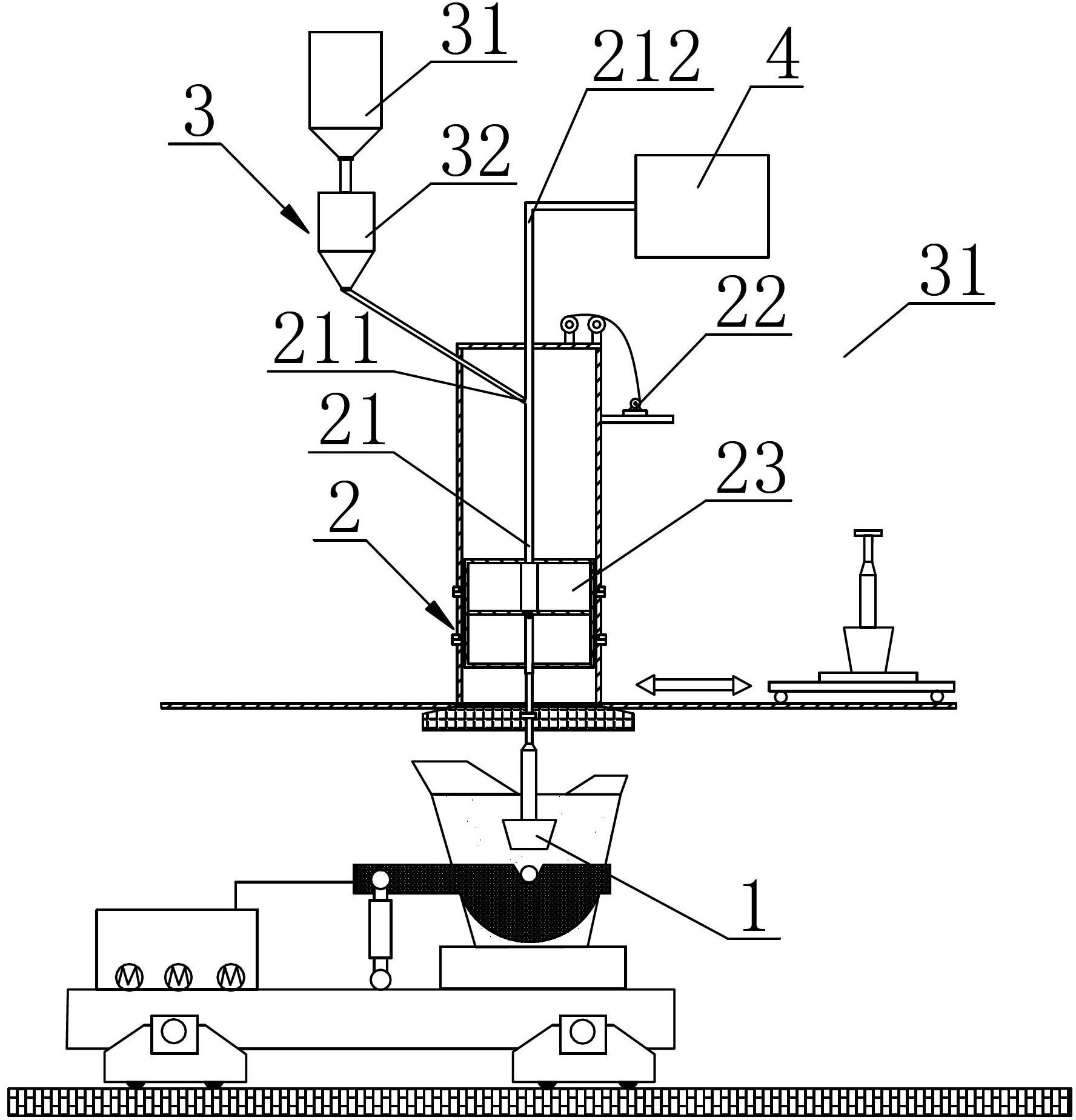

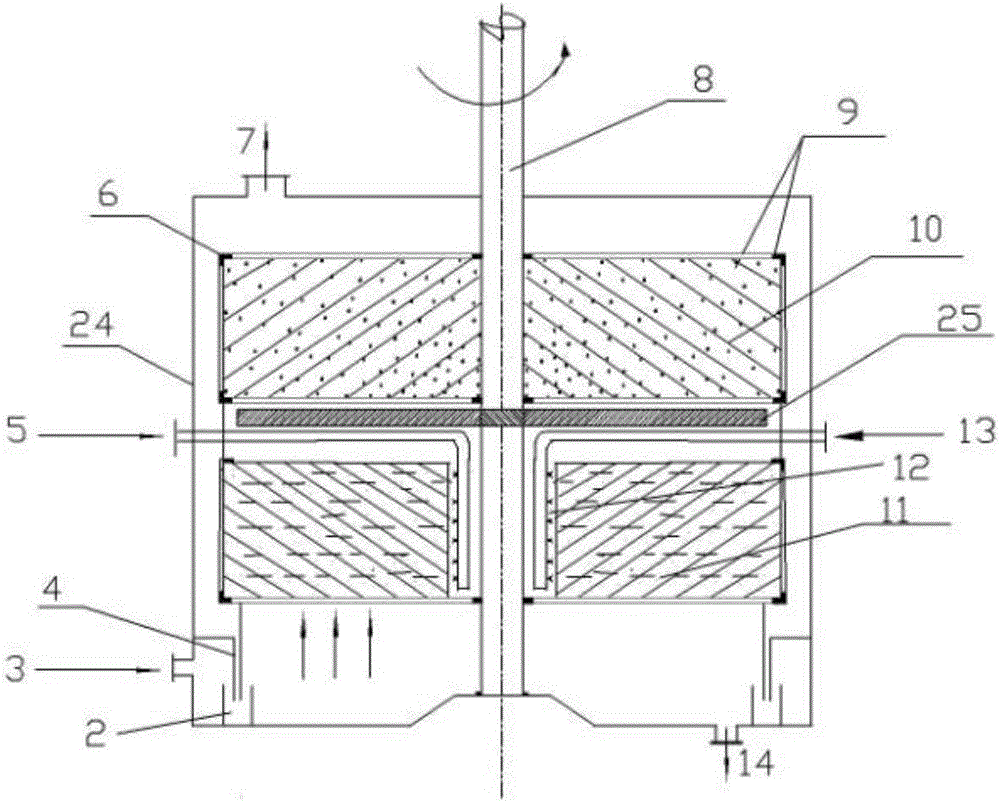

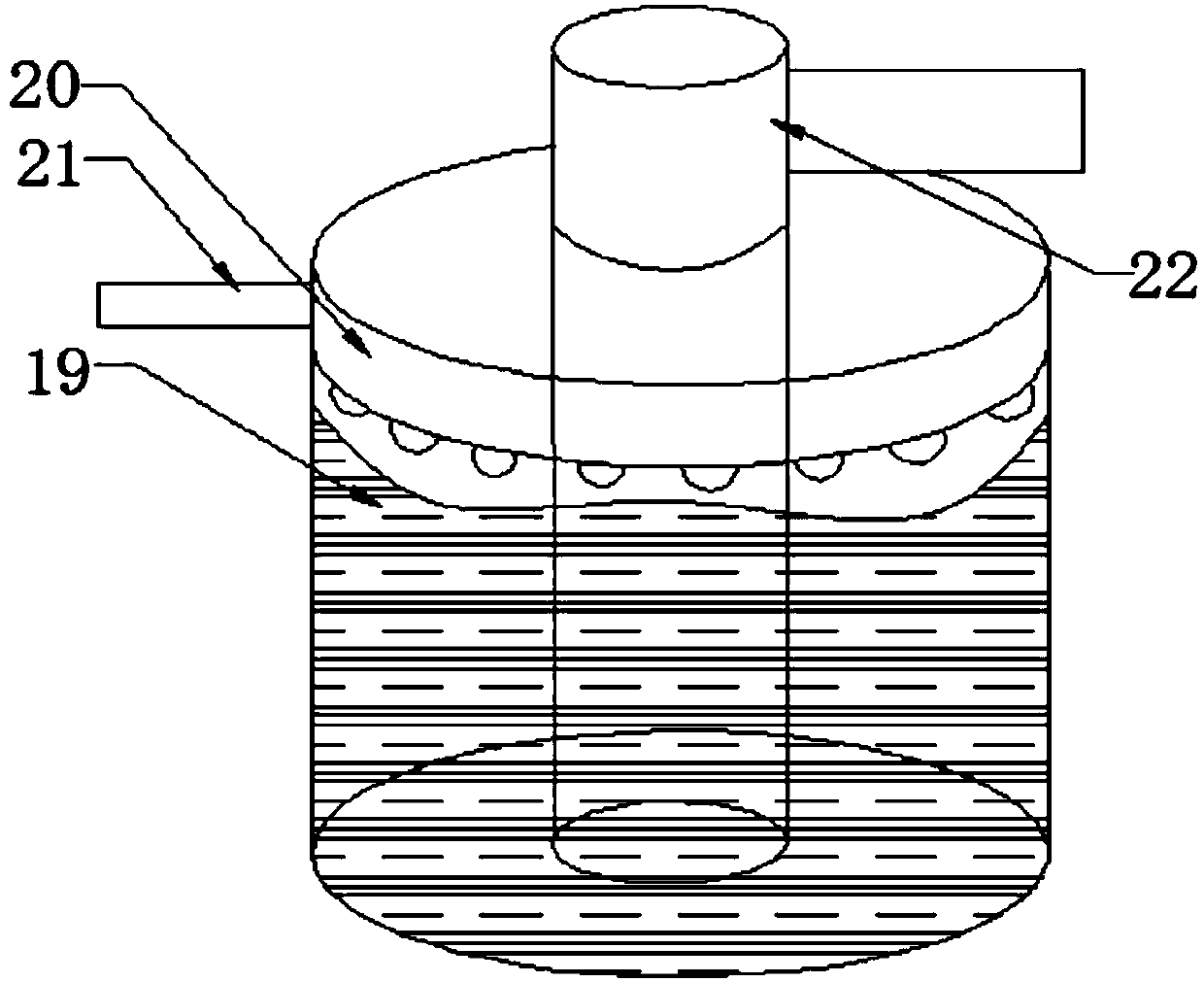

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

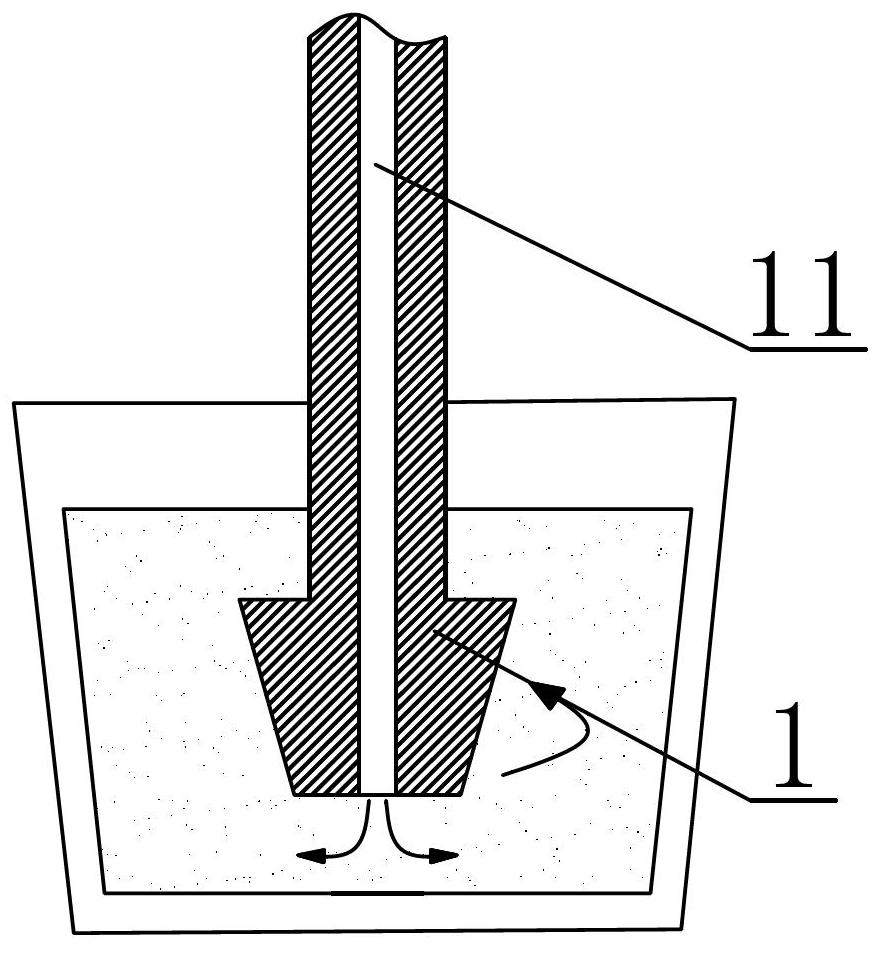

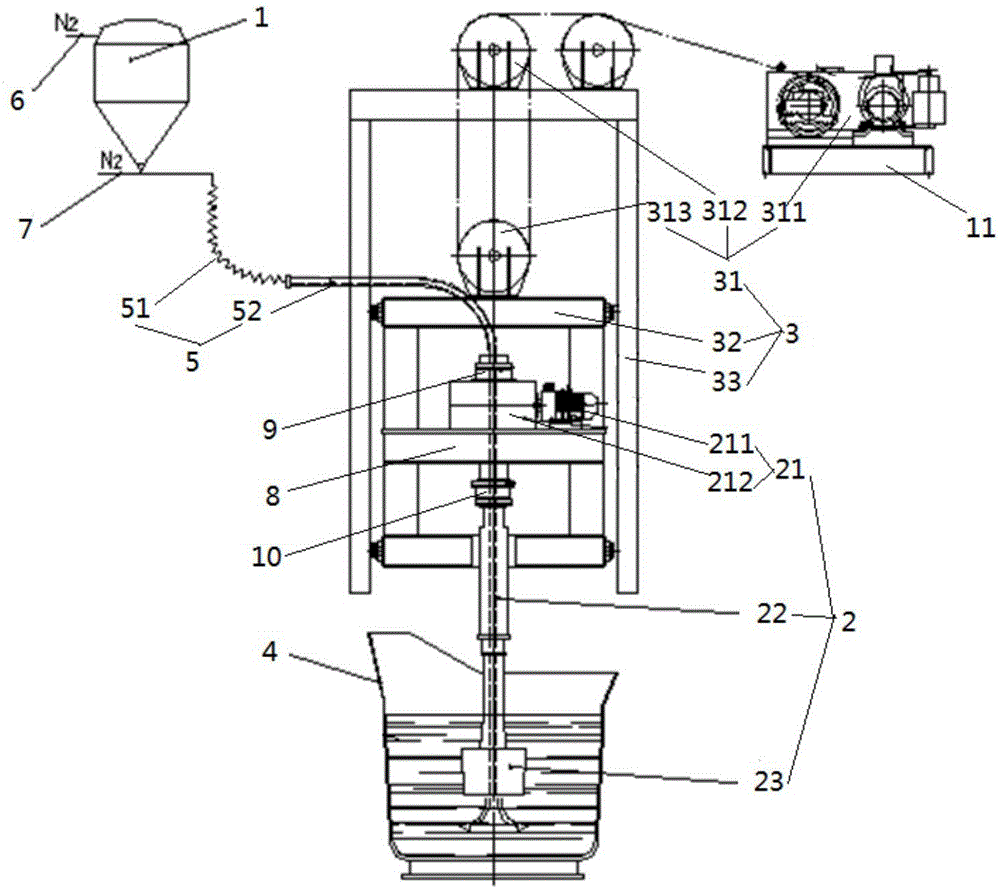

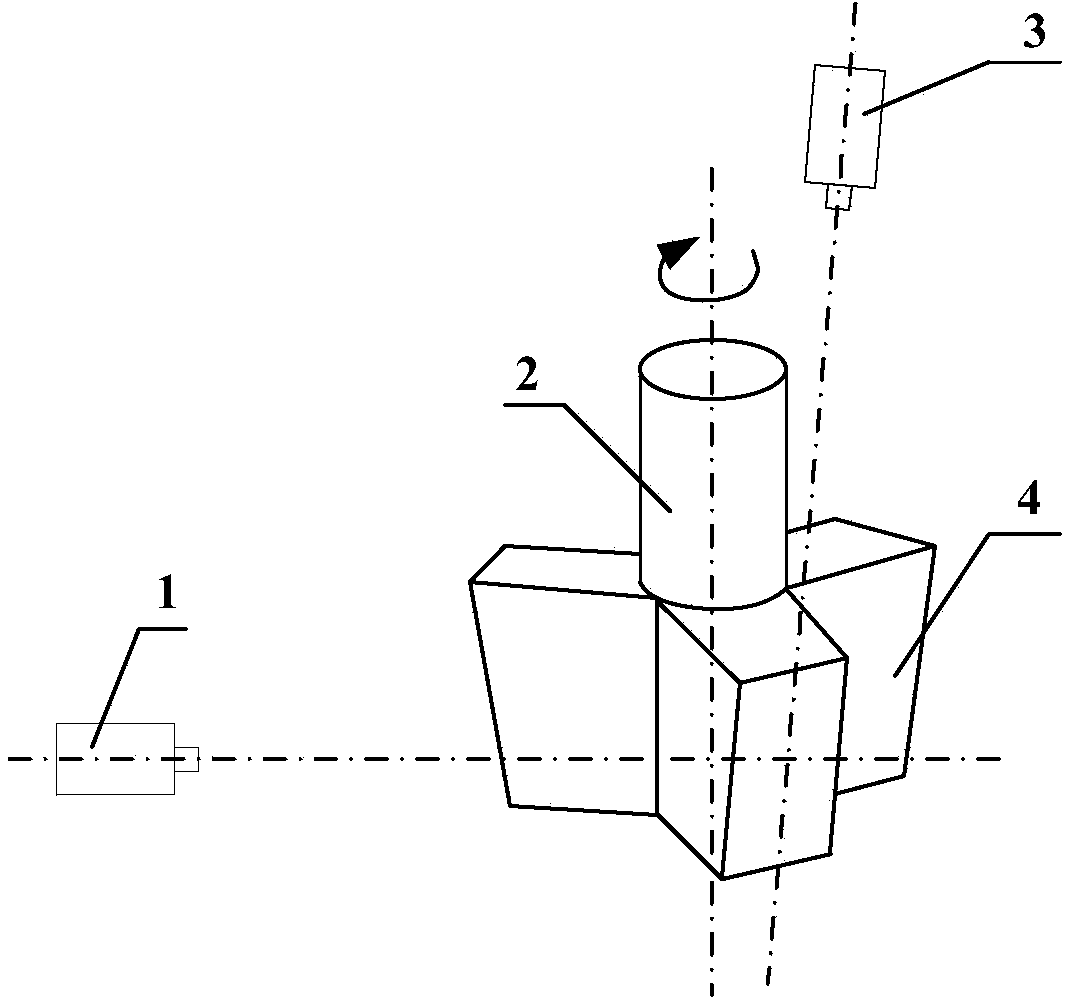

Molten iron desulphurization device and method

InactiveCN106086312AImprove desulfurization efficiencyShortened desulfurization treatment timeMetallurgyMaterials science

The invention provides a molten iron desulphurization device which comprises a blowing tank (1), a stirring unit (2), a lifting unit (3) and a molten iron tank (4). A discharge outlet in the bottom of the blowing tank (1) is connected with the stirring unit (2) through a conveying pipe (5). The molten iron tank (4) is arranged under the stirring unit (2). The lifting unit (3) is connected with the stirring unit (2) to control the stirring unit (2) to go up and down. Furthermore, the invention provides a molten iron desulphurization method adopting the molten iron desulphurization device. By means of the molten iron desulphurization device and method, good dynamic conditions and stable and efficient desulfurization capacity are achieved, and the purpose of efficient desulfurization with low consumption can be achieved.

Owner:WISDRI ENG & RES INC LTD

Molten iron desulphurization method

The invention relates to a molten iron desulphurization method which comprises the following steps: adding a KR desulfurizer into an iron ladle, pouring molten iron into the iron ladle, stirring to carry out a desulphurization reaction between the KR desulfurizer and molten iron; and blowing granulated magnesium to the iron ladle so as to conduct desulphurization. The KR desulfurizer has advantages of low granularity, large reaction area and good average molten iron desulphurization effect. With the addition of the KR desulfurizer, CaO content of iron slag is effectively increased, alkalinity of iron slag is raised, iron slag is modified, and it is beneficial to adsorption of granulated magnesium desulphurization products and removal of desulphurization slag. According to the molten iron desulphurized by a two-step method, first-hit yield of desulphurization by blowing granulated magnesium is raised, and molten iron resulfurization in a converter is minimized. Thus, desulphurization cost during the whole molten iron desulphurization process is reduced.

Owner:BEIJING SHOUGANG CO LTD

Al-Mg-Ca-Fe alloy contg. micro-carbon, low silicon, low phosphorous, low-sulphur used for steelmaking

The invention relates to a micro low carbon, low silicon, low phosphor, and low sulfur Al-Mg-Ca-Fe alloy used in steel-making. It uses as deoxidizer and contains 20-85wt% Al, 5-20wt% Mg, 1-15wt% Ca, C less than 0.02wt%, Si less than 1.0wt%, P less than 0.02wt%, S less than 0.02wt%, the rest is Fe. It is smelted from line frequency furnace. The invention has the advantage of easy to use, stable, and could improve the recovery factor of the metal element. The molten steel treated by the deoxidizer has good fluidity, high work rates, high benefits, etc. The deoxidizer could discharge the impurity, and it has good mechanical behavior, good quality, long useful life and good social benefit.

Owner:本溪冶炼集团有限公司

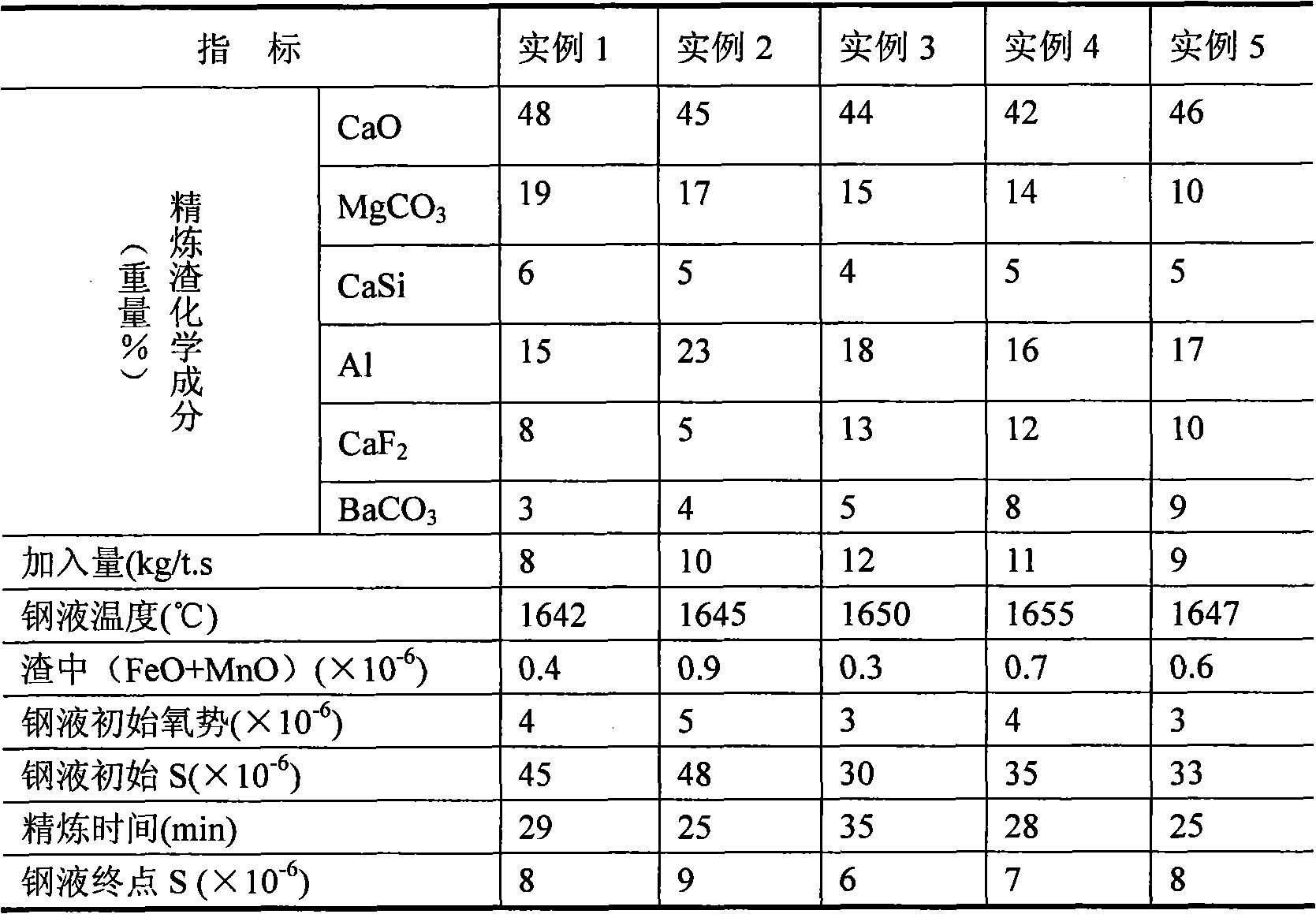

Premelting compound refining slag for producing ultra-low sulfur steel

The invention discloses premelting compound refining slag for producing ultra-low sulfur steel. A mixture is prepared from the following chemical constituents in percent by mass: 40 to 50 percent of CaO, 10 to 20 percent of MgCO3, 5 to 15 percent of CaF2, 2 to 10 percent of BaCO3, 15 to 25 percent of Al and 4 to 6 percent of CaSi, wherein the sum of the mass percent of the substances and unavoidable impurities is 100 percent, and a ratio of CaO to CaSi is between 8 and 11. The refining slag of the invention has good desulfuration effect and can reduce the S content in molten steel from 30 to 50*10<-6> to 10*10<-6>. The desulfuration effect is stable, the molten steel resulfurization and the molten steel recarburization and hydrogen increase do not exist, the corrosion of a furnace liner is light, the use is convenient, and the refining slag can be directly added onto the slag surface and can be also made into core wires to be fed into the molten steel.

Owner:ANGANG STEEL CO LTD

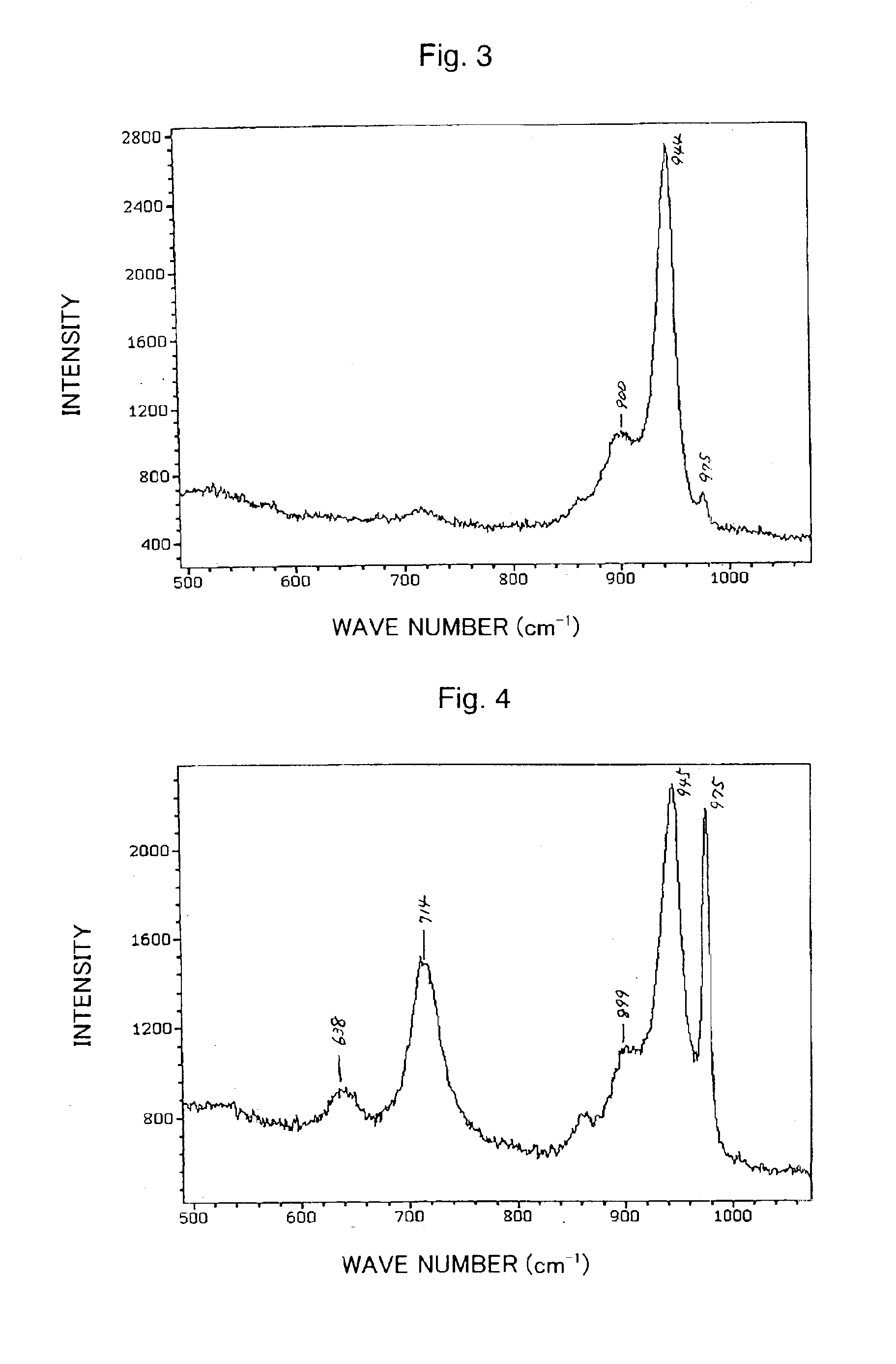

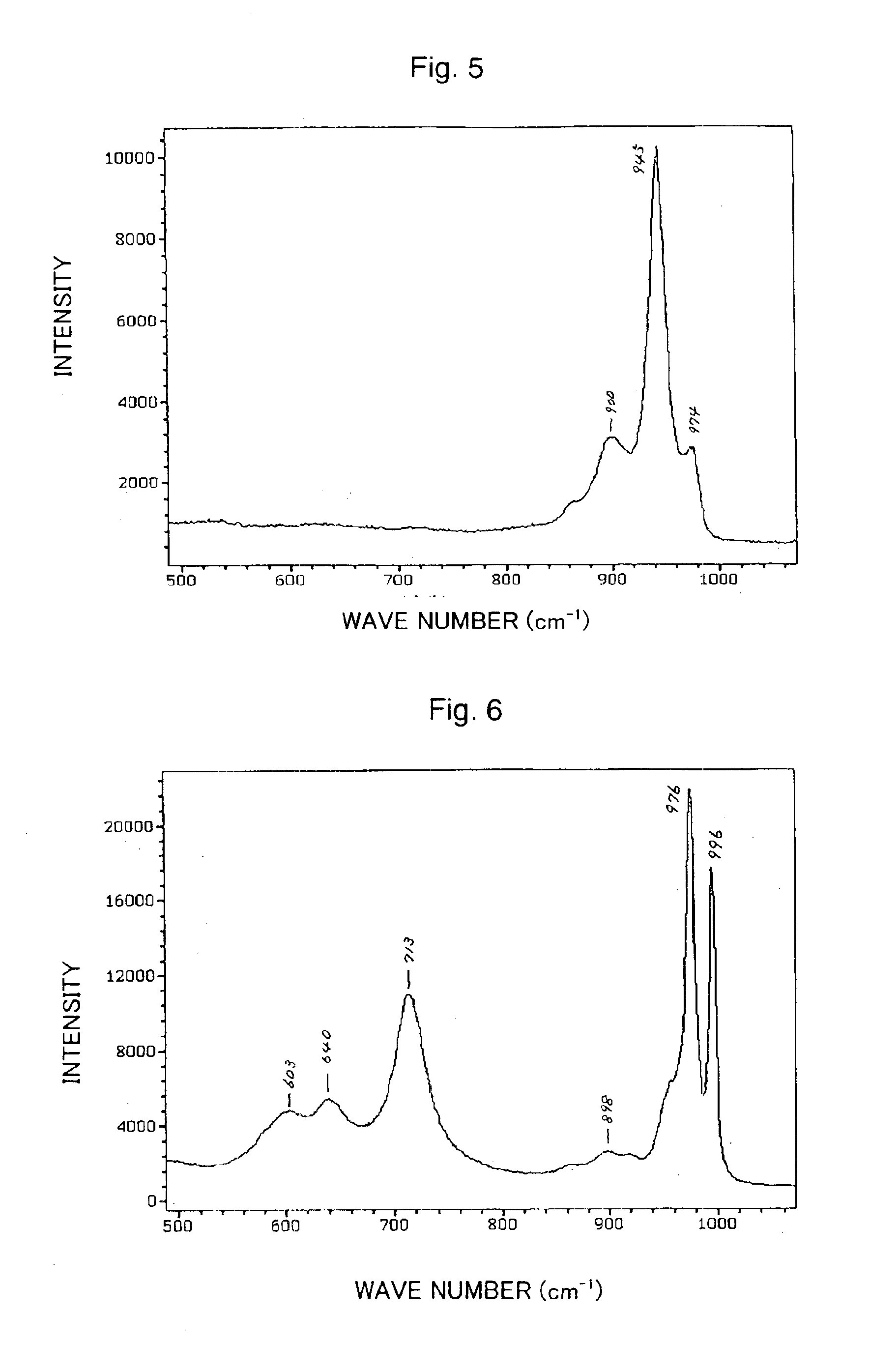

Desulfurization adsorbent for fuel cell and desulfurizing method using the same

InactiveUS20070093385A1Improve desulfurization performancePromote regenerationMethane captureMolecular-sieve silicatesAlkaline earth metalSorbent

A desulfurization adsorbent for a fuel cell has a structure according to Formula 1 below, and a desulfurizing method uses the desulfurization adsorbent. The desulfurization adsorbent displays remarkably excellent adsorption performance for adsorbing sulfur compounds as well as excellent regeneration performance, compared with conventional desulfurization adsorbents. Thus, the desulfurization adsorbent does not need to be replaced even after prolonged use, thus stabilizing the operation of a fuel cell system and reducing costs. (M1)a-(Si)x—(Ti)y-(M2)z-O [Formula 1]wherein M1 is at least one selected from alkali metals, alkaline earth metals, hydrogen, ammonium, rare earths, and transition metals; 4≦x / y≦500, 0≦z / y≦3, 0≦a / (y+z)≦1; and M2 is aluminum (Al), boron (B) or a trivalent metal. The desulfurizastion adsorbent is produced by subjecting a mixture of a silicon source, a titanium source, and optionally, aluminum, boron or a trivalent metal in an alkali solution to a hydrothermal treatment to obtain a crystalline porous molecular sieve.

Owner:SAMSUNG SDI CO LTD

Biogas desulfurization method in series of wet method with dry method

InactiveCN103013600AHigh sulfur capacityMeet quality requirementsGaseous fuelsCooling towerTherapeutic effect

The invention discloses a biogas desulfurization method in series of a wet method with a dry method, which comprises the following steps: crude gas is boosted by a fan and enters a wet desulphurization tower after the temperature is lowered by a cooling tower; in the countercurrent contact process of crude gas and a desulfurization solution in the tower and a catalyst, most of impurities such as hydrogen sulfide are removed, and then the biogas is subjected to the dry desulfurization again after the moisture is separated through a dehydrating tower to further remove hydrogen sulfide so as to be lowered below 15 mg / Nm<3> to enter a biogas cabinet for use, and a rich fluid containing H2S is recycled in a regeneration tank. The method disclosed by the invention has the advantages of large treatment amount, stable treatment effect, high sulfur recovery rate, easily regenerated desulfurizer and long service life, and ensures that the hydrogen sulfide content of biogas meets the use requirements. The service life of the equipment pipeline in the biogas industrial application can be prolonged, the environmental problem of secondary pollution in use of biogas is eliminated, and a guarantee for further purifying and utilizing biogas is provided.

Owner:ZHONGJU TIANGUAN BIOLOGICAL ENERGY

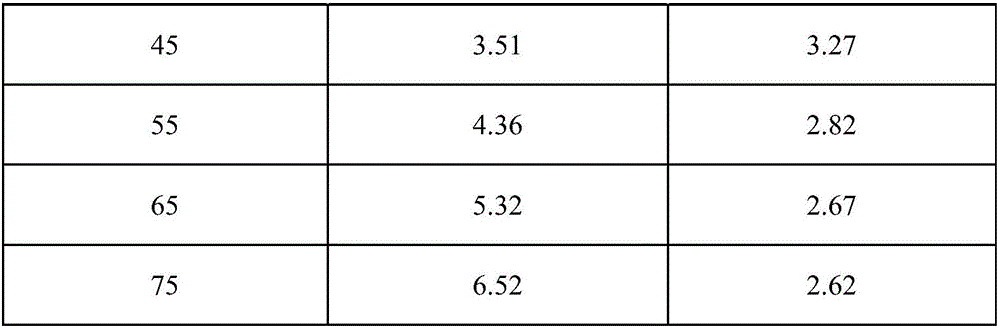

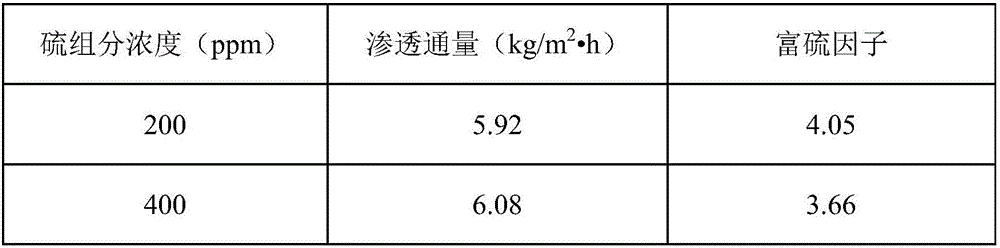

MOF particle filled silicone rubber pervaporation desulfurization film and preparation method thereof

InactiveCN106000118AImprove desulfurization performanceTight and flawlessDistillationPervaporationPolyvinylidene fluoride

An MOF particle filled silicone rubber pervaporation desulfurization film and a preparation method thereof are provided. The preparation method comprises the steps: after mixing and stirring evenly polydimethylsiloxane and an organic solvent, adding CPO-27-Ni type MOF particles, continuing to stir, then adding a cross-linking agent and a catalyst, mixing evenly, and carrying out static defoaming to obtain a film casting solution; and pouring the film casting solution on a polyvinylidene fluoride base film and scraping the film, after the solvent is volatilized, cross-linking, forming a polydimethylsiloxane layer on the polyvinylidene fluoride base film, and thus obtaining the MOF particle filled silicone rubber pervaporation desulfurization film. The prepared mixed matrix film is simple in preparation process and low in cost; and when the film is used in thiophene-n-heptane system separation, desulfurization is carried out prior. The preparation method is stable and reliable, and can improve the permeation flux and sulfur rich factors, is suitable for filling of other types of organic films, and has good industrial application prospects.

Owner:NORTHWEST UNIV

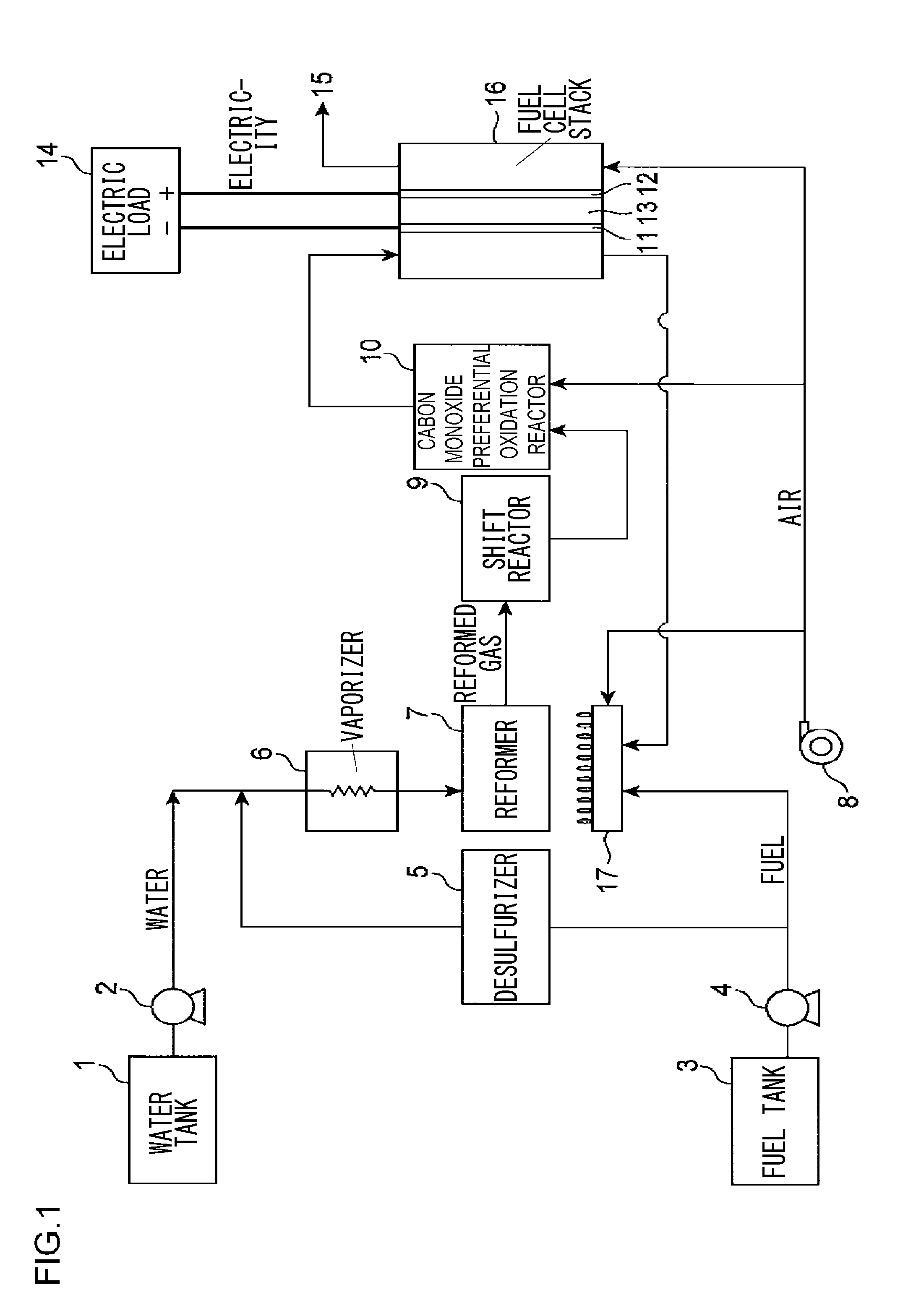

Precursor of desulfurizing agent for hydrocarbon and manufacturing method thereof, calcined precursor of desulfurizing agent for hydrocarbon and manufacturing method thereof, desulfurizing agent for hydrocarbon and manufacturing method thereof, hydrocarbon desulfurization method, and fuel cell system

InactiveUS20120021305A1Remarkably-improved endurance timeImprove performanceHydrogenOther chemical processesHydrogenFuel cells

A desulfurizing agent for a hydrocarbon comprises: 10 to 30 percent by mass of a porous inorganic oxide based on the total mass of the desulfurizing agent; 3 to 40 percent by mass of zinc oxide; and 45 to 75 percent by mass of a nickel atom in terms of nickel oxide, wherein the reduction degree of the nickel atom is 50 to 80 percent, and wherein the amount of hydrogen adsorption per unit desulfurizing agent mass is 3.5 to 4.6 ml / g.

Owner:JX NIPPON OIL & ENERGY CORP

Method for producing hydro-refining catalyst

InactiveUS6903048B2High activityImprove desulfurization performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCobaltCitric acid

A method for producing a hydrorefining catalyst has the steps of preparing an impregnation solution containing molybdenum, phosphorus, cobalt and / or nickel, and citric acid, bringing a carrier into contact with the impregnation solution, and then calcinating the carrier in an oxidizing atmosphere at a temperature at which citric acid is removed. In the impregnation solution, a molar ratio of molybdenum / phosphorus is 6 to 13, a molar ratio of (cobalt and nickel) / phosphorus is 0.5 to 7, and a molar ratio of (cobalt and nickel) / citric acid is 0.5 to 2. As for the hydrorefining catalyst obtained by this method, the activity of the catalyst is high, and the catalyst life is long.

Owner:JAPAN ENERGY CORP

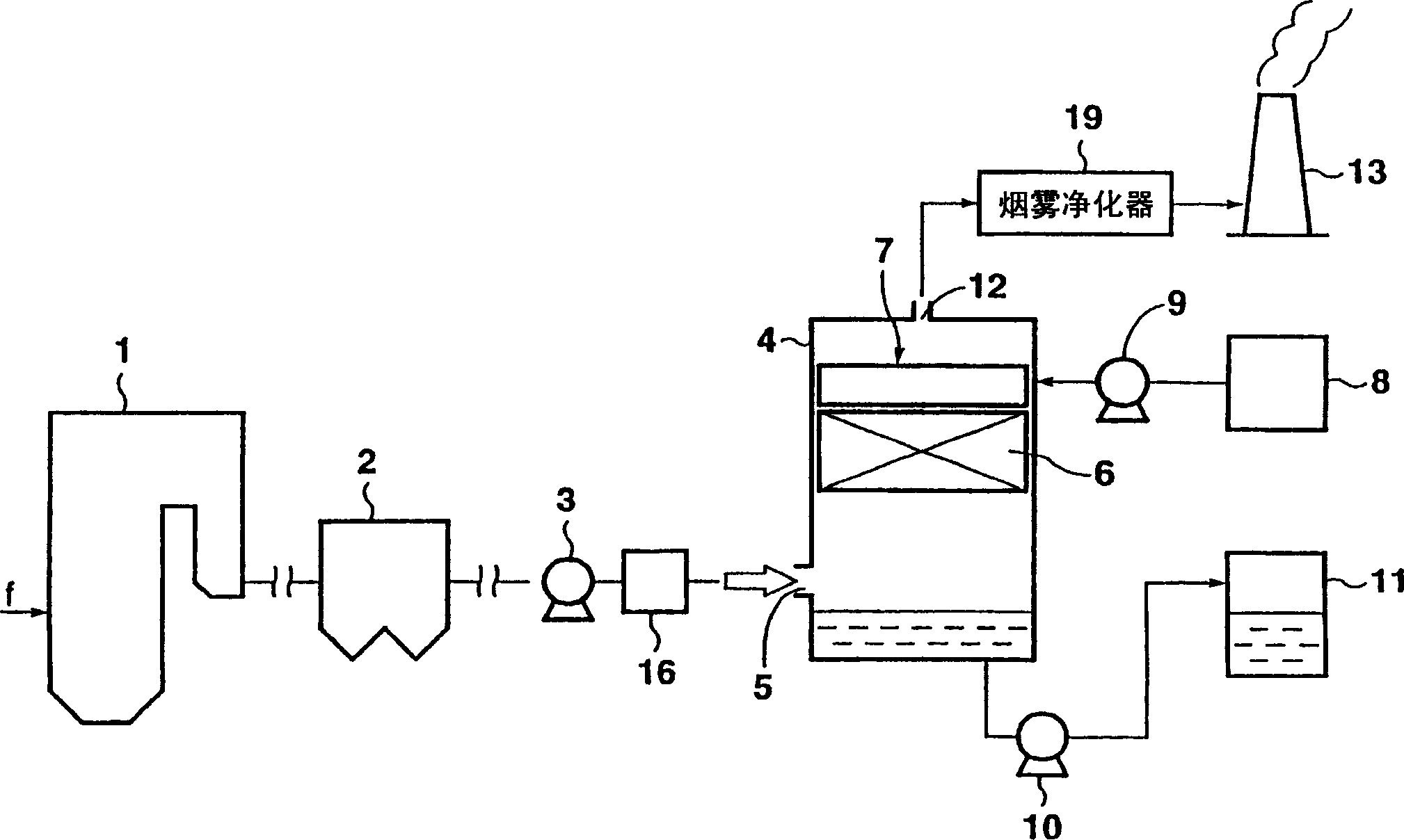

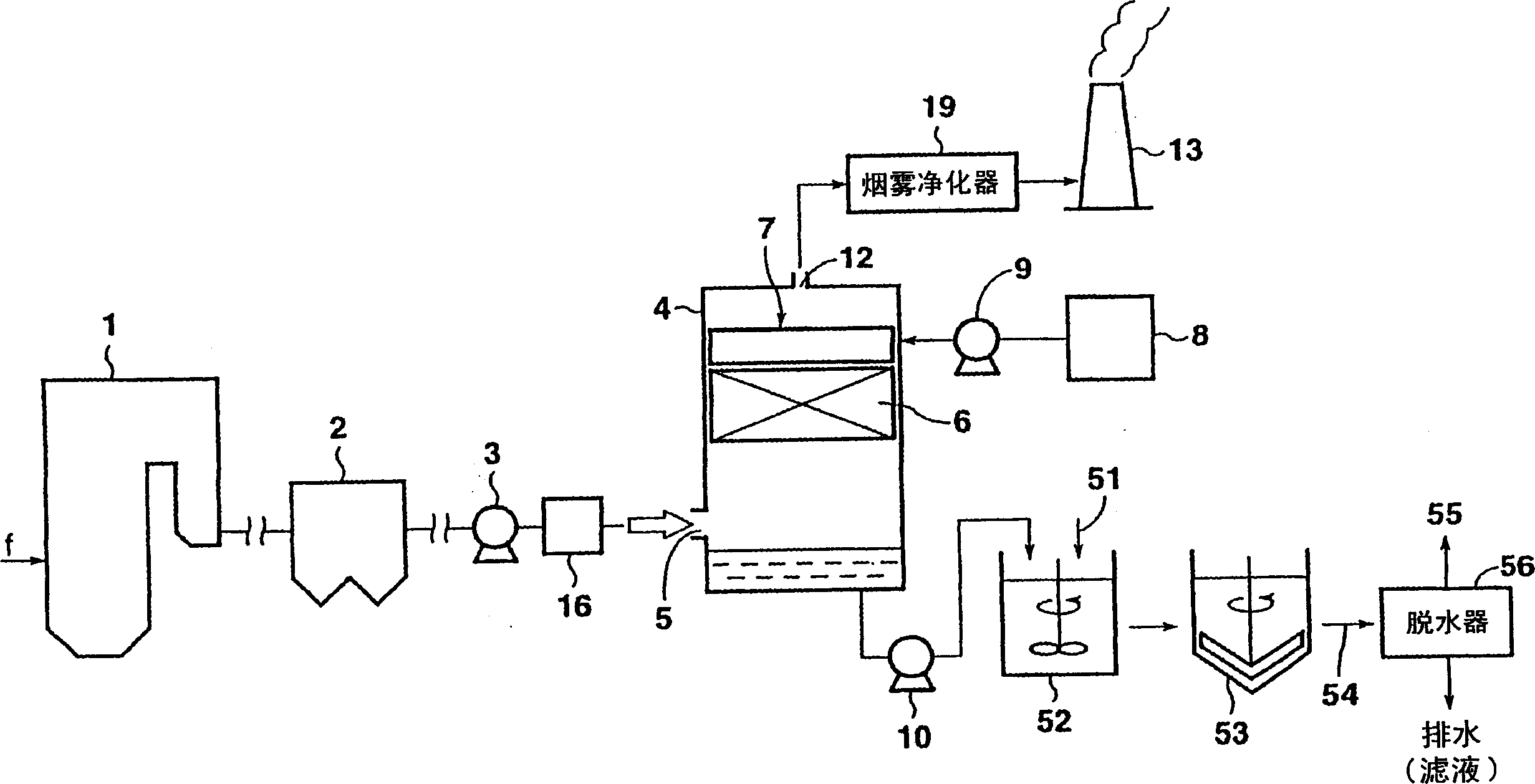

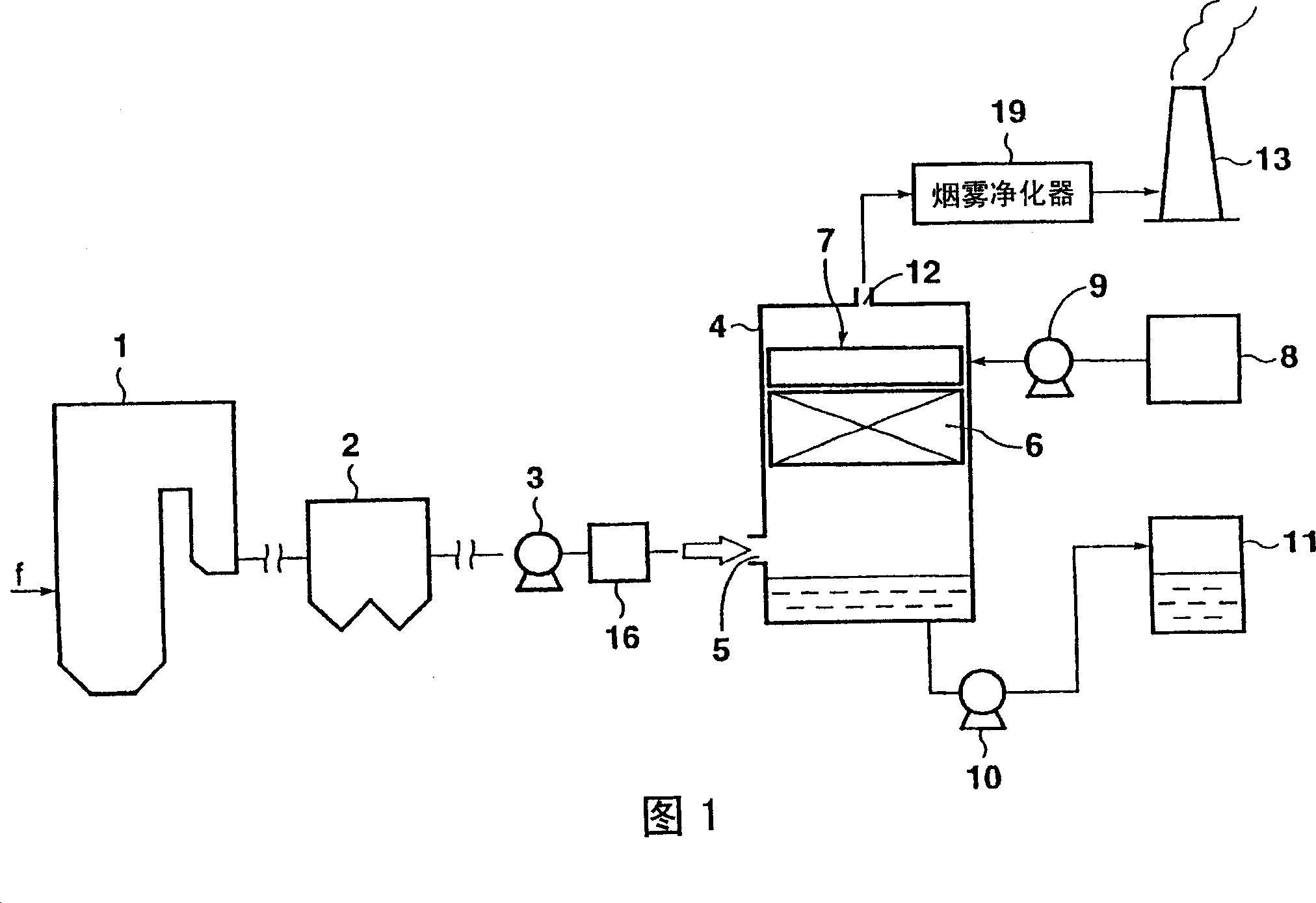

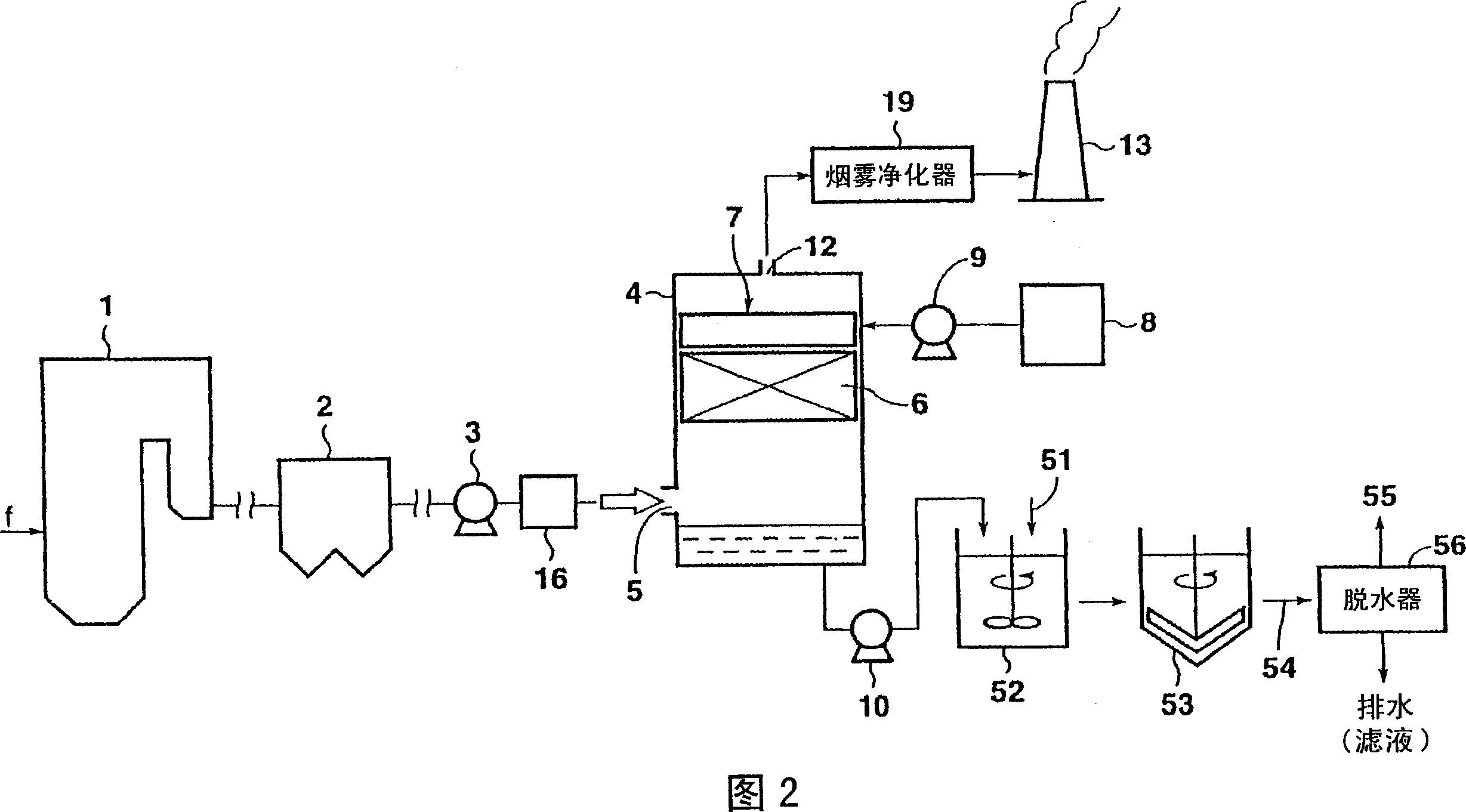

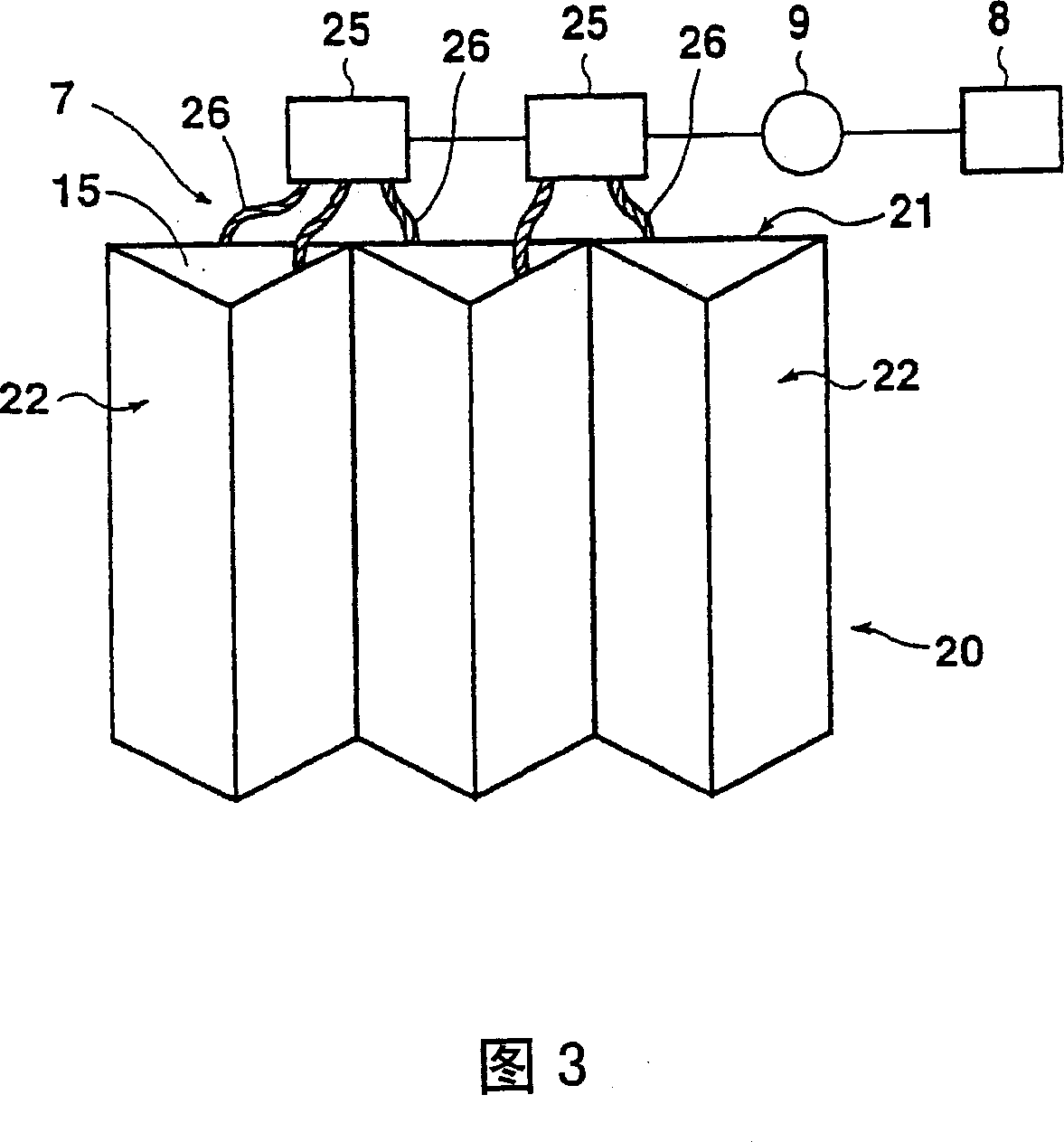

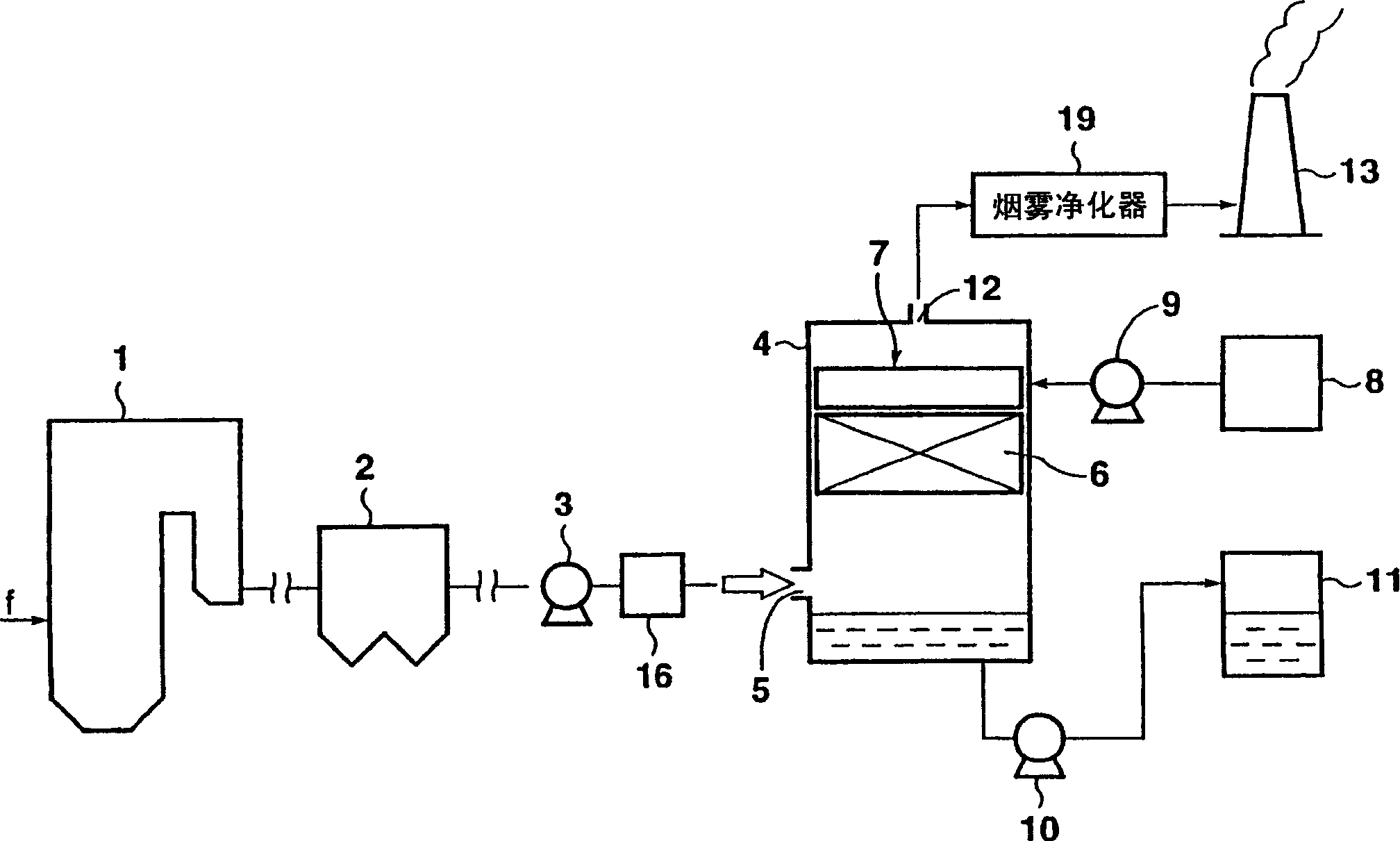

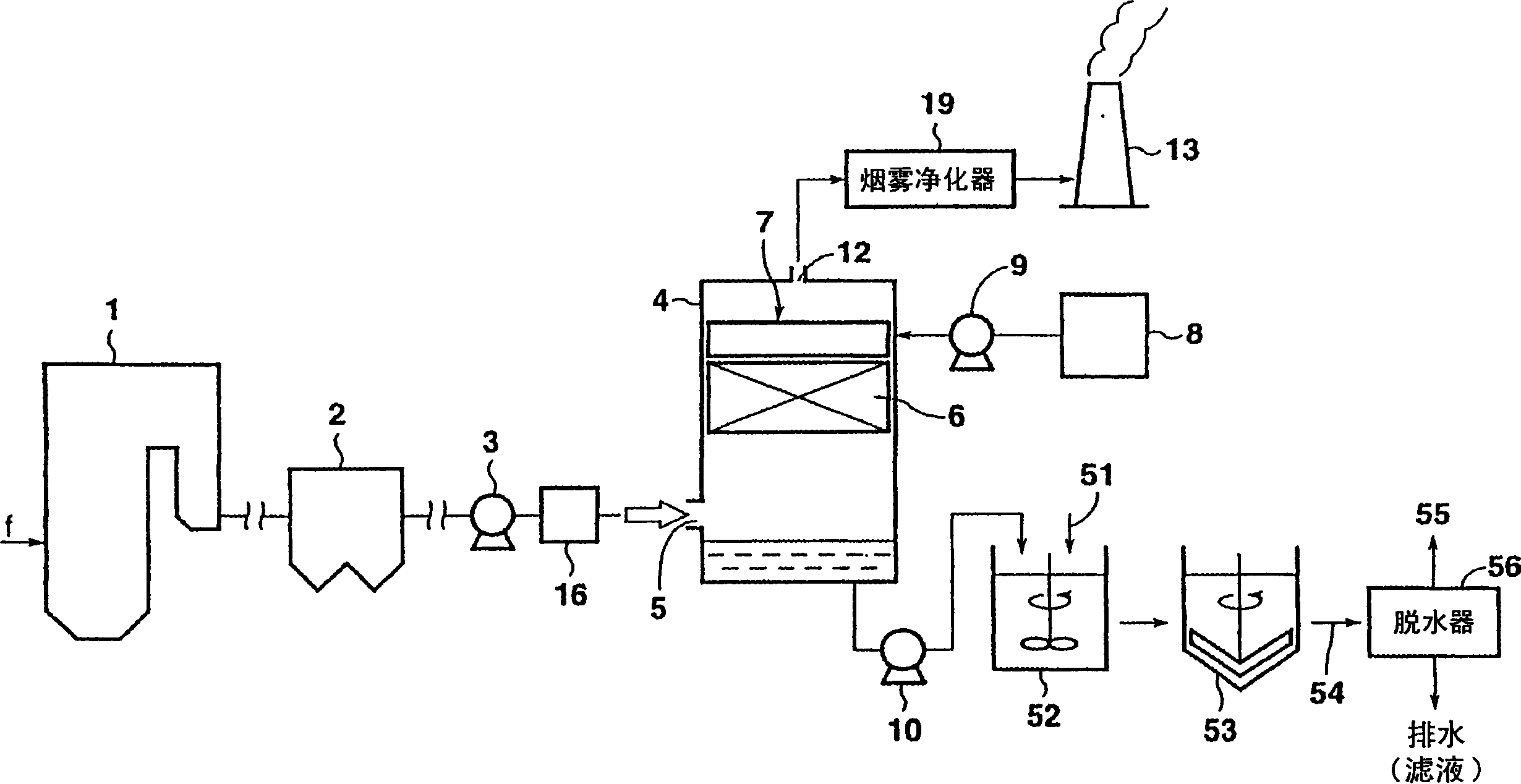

Flue gas desulfurization apparatus, flue gas desulfurizationsystem, and method for operating flue gas desulfurization apparatus

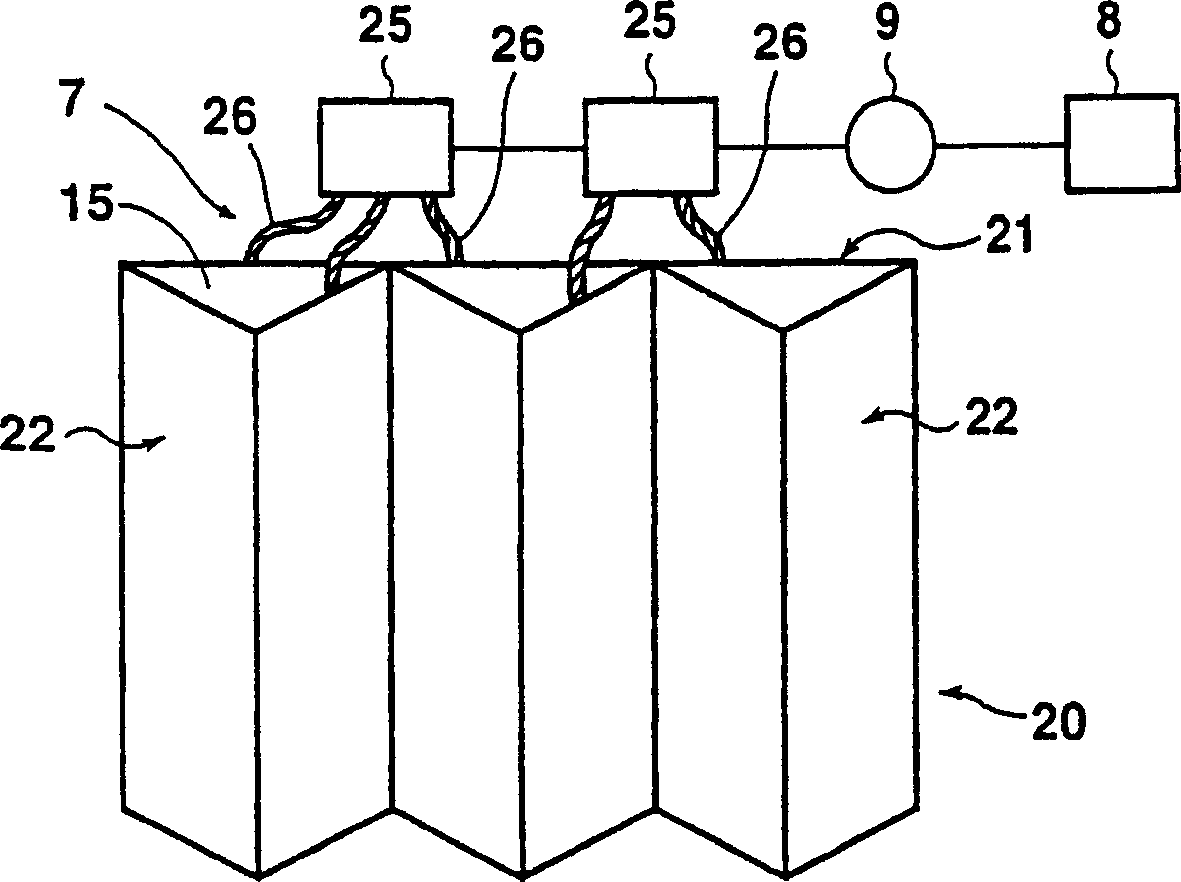

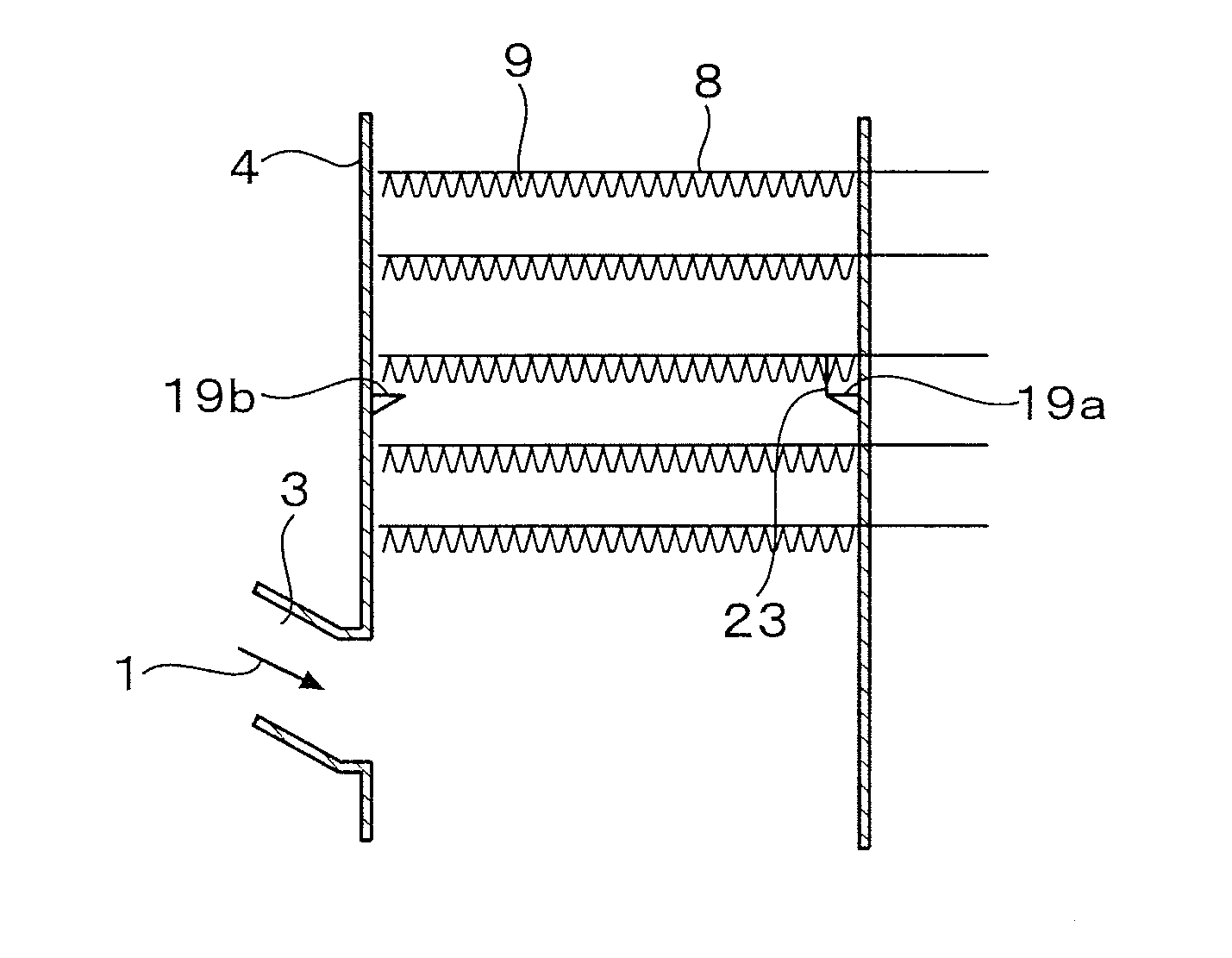

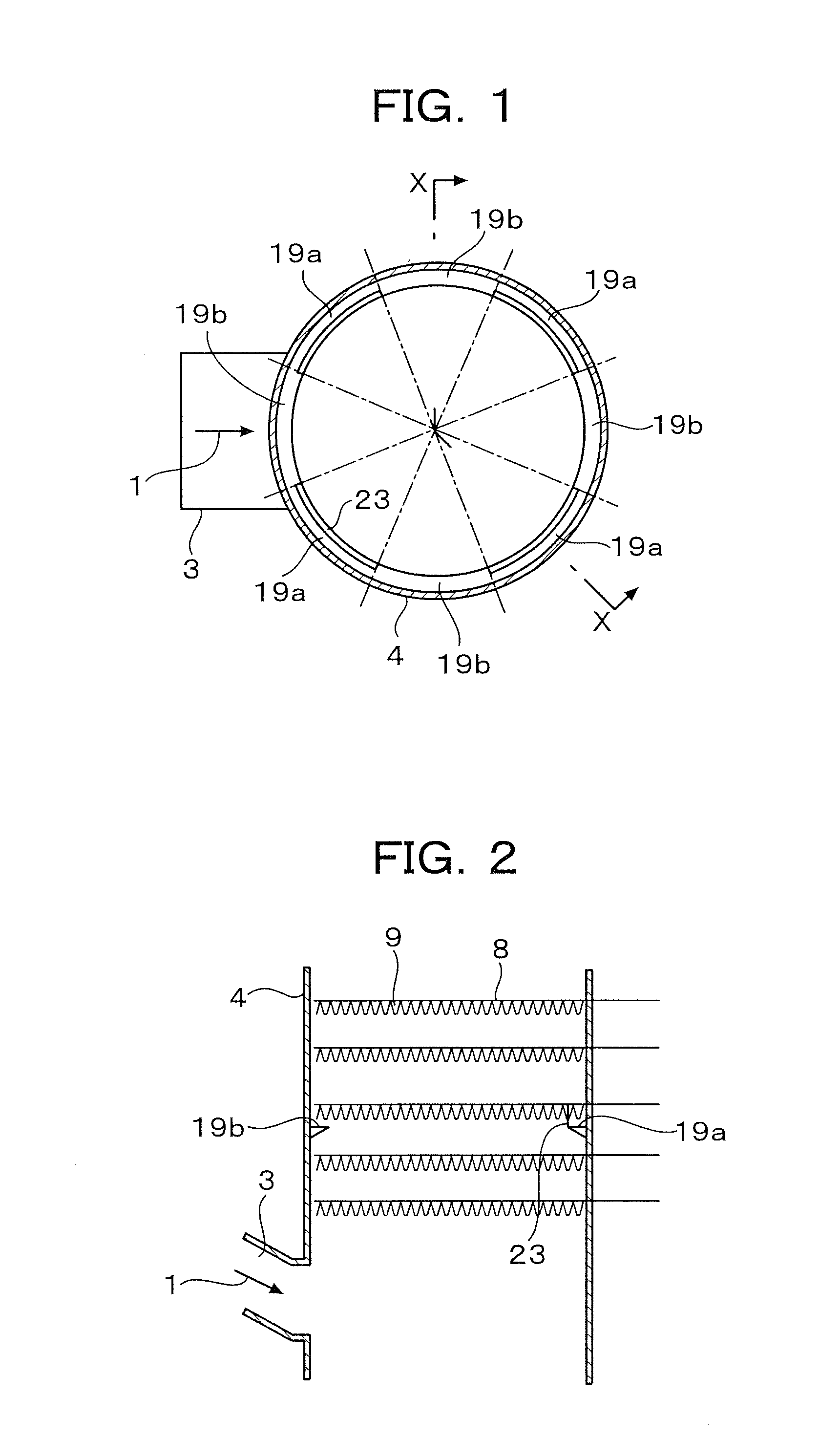

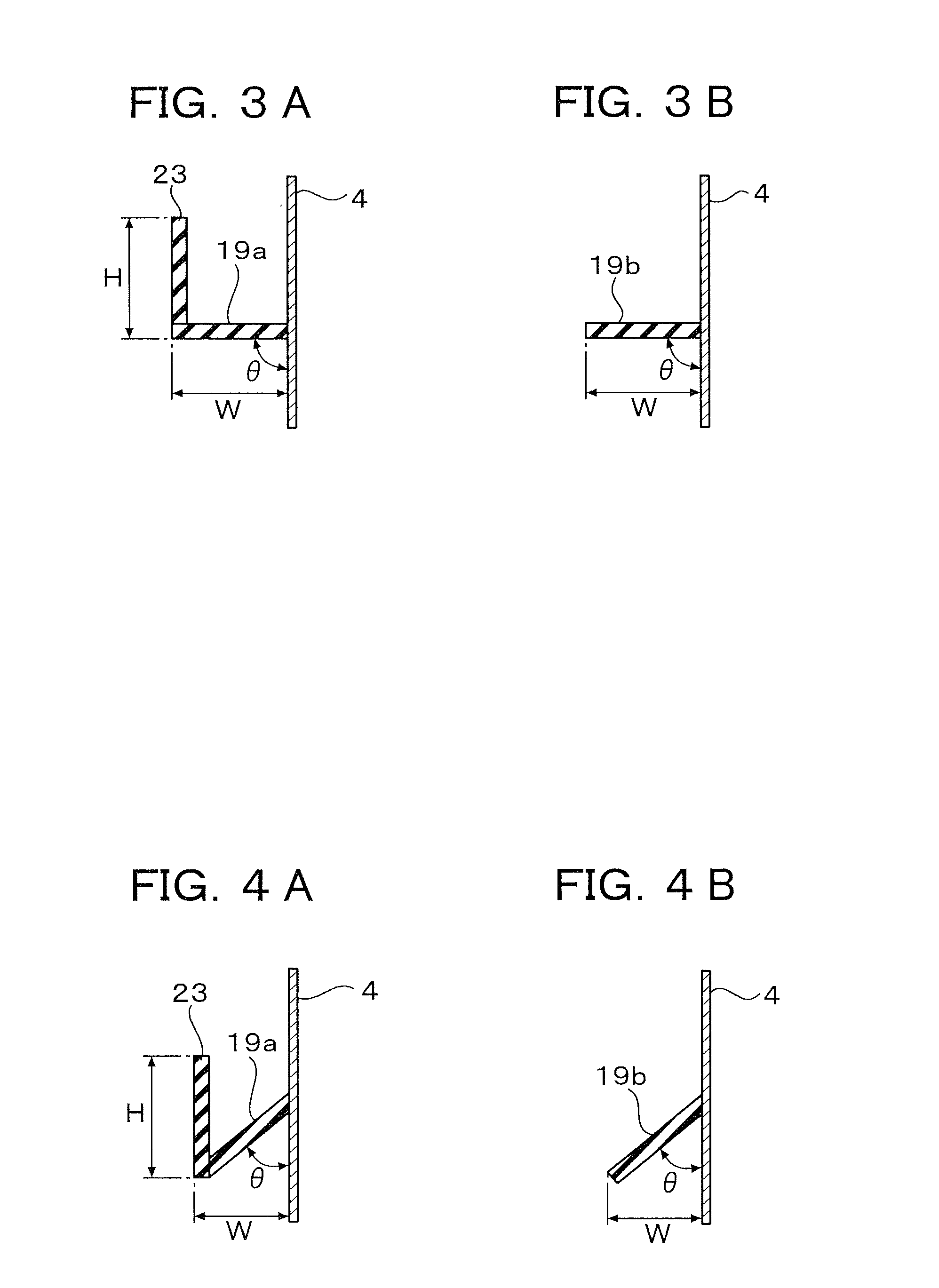

A kind of flue gas desulfurization device, by alternately stacking flat plate activated carbon fiber thin plates and corrugated wave plate activated carbon fiber thin plates, forming the state that the passage extends in the up and down direction, and constituting the activated carbon fiber layer of the catalyst layer (6) ( 20), and the activated carbon fiber layer (20) of the catalyst layer (6) is supplied by the water utilized for generating sulfuric acid by capillary penetration, and the minimum amount of water can be used to add moisture evenly to the activated carbon fiber layer (20) to remove sulfur oxides ( SOX), which can reduce the water used to remove sulfur oxides (SOX).

Owner:MITSUBISHI HEAVY IND LTD

Wet Flue Gas Desulfurization Device

InactiveUS20130020730A1Improve desulfurization performanceLow pressure lossFlow mixersUsing liquid separation agentExhaust gasFlue

A wet flue gas desulfurization device includes, an absorber provided with: a absorber tank provided at a lower part of the absorber so as to store an absorption liquid; an absorption portion provided above the absorber tank and having multiple stages of spray headers for spraying the absorption liquid; an absorption liquid circulation system for circulating the absorption liquid in the absorber tank to the spray headers; an exhaust gas inlet portion provided in a sidewall between the absorber tank and the absorption portion; and a gas blow-out prevention member provided along an entire circumference of an inner surface of the sidewall between the exhaust gas inlet portion and the uppermost-stage spray header. Dams are intermittently provided at an inner peripheral end of the gas blow-out prevention member to extend along a circumferential direction thereof.

Owner:BABCOCK HITACHI KK

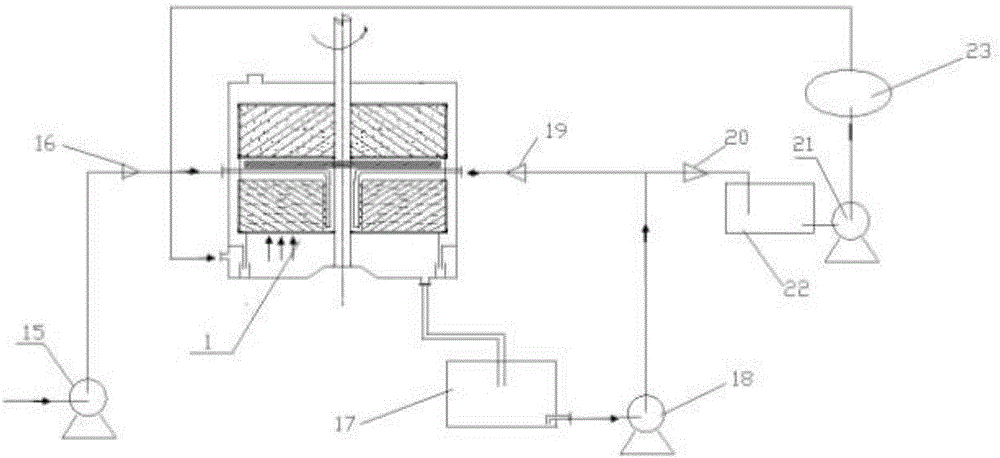

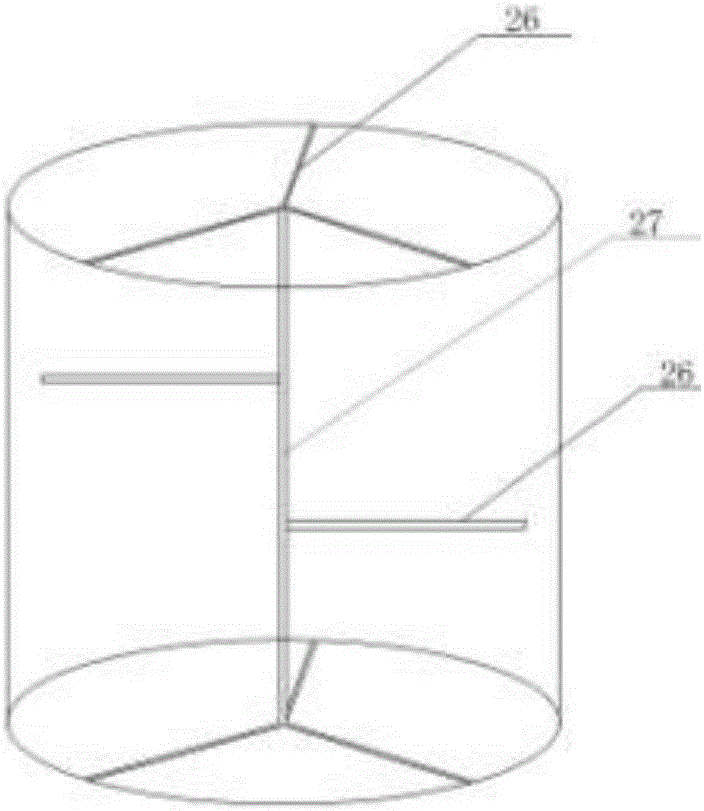

Desulfurizer recovery device for organic amine desulfurization process and desulfurizer recovery method

ActiveCN106268320ASettle the lossEfficient recyclingGas treatmentDispersed particle separationRecovery methodPulp and paper industry

The invention discloses a desulfurizer recovery device for an organic amine desulfurization process and a desulfurizer recovery method utilizing the same. A supergravity revolving bed is communicated with a recovery tank; the recovery tank is communicated with a solution tank, a new water supply system is used for supplying new water to the supergravity revolving bed, and another pipeline is used for returning the solution in the recovery tank back to the supergravity revolving bed, and the solution tank is connected with a desulfurization system; an outlet for fume obtained by desulfuration of the desulfuration system is connected with the supergravity revolving bed; a padding of the supergravity revolving bed is divided into two parts, the upper padding part is an annular padding made of a polypropylene material, the lower padding part is a stainless steel deflector padding, and a three-blade fan is arranged between the two paddings. The device and the method are capable of efficiently recovering the desulfurizer, ensuring stable desulfurizer concentration and desulfuration effect of the desulfuration system, and greatly lowering the operation cost of the process.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing fine desulfurizer with water quenching slag of nickel concentrates

ActiveCN101708472AImprove desulfurization performanceLow costDispersed particle separationCatalyst activation/preparationSocial benefitsSlag

The invention discloses a method for preparing a fine desulfurizer with water quenching slag of nickel concentrates, which is characterized by using the water quenching slag of nickel concentrates as the raw material for preparing the fine desulfurizer, using acid to treat the water quenching slag and then adding alkali for neutralization under the condition of introducing air and stirring, mixing the obtained precipitates and binders evenly and preparing the fine desulfurizer by extrusion molding after kneading by adding water. The water quenching slag contains the compounds of Ni, Cu, Zn, Fe and Cr. The method makes good use of the industrial and metallurgical wastes harmful to the environment. The prepared fine desulfurizer has less than 0.1*10-6(v / v) degree of purification toward the feed gases, stable desulfurization effect and low cost, realizes energy conservation and emission reduction, changes wastes into valuables and has obvious economic and social benefits.

Owner:吉林卓创新材料有限公司

Desulfurizing tower

InactiveCN107739637AIncrease contact areaExtension of timeGaseous fuelsDispersed particle separationContact timeEngineering

The invention discloses a desulfurizing tower which comprises a tower body, a spraying chamber and an alkali liquid tank, wherein a spraying chamber is formed inside the tower body; spraying heads arefixed at the top and on the side surface of the spraying chamber; a gas inlet tube is inserted into the bottom end of the spraying chamber; a first valve is fixed at one end of the gas inlet tube; afiltering plate is fixed at the other end of the gas inlet tube; the alkali liquid tank is fixed at the bottom of the spraying chamber; and the bottom of the alkali liquid tank is fixedly connected with the top of a residue collection tank. According to the desulfurizing tower disclosed by the invention, one end of the gas inlet tube takes the shape of an inverted funnel, the middle axis of the inverted funnel is overlapped with that of the spraying chamber, and then a fed gas is diffused around; as the spraying heads are arranged at the top end and the side surface of the spraying chamber, the gas-liquid contact area is increased, the gas-liquid contact time is prolonged, and relatively thorough desulfuration is achieved; an alkali liquid in the alkali liquid tank can be circulated, so that the purpose of environmental protection and emission reduction is achieved, and the consumption is reduced; and the alkali liquid can be stirred by stirring blades in the alkali liquid tank, so that the alkali liquid is uniform in concentration, and a stable desulfuration effect is ensured.

Owner:NANJING HONGBO ENVIRONMENTAL PROTECTION IND

Preparation method and application of efficient zinc oxide fine desulfurizing agent

ActiveCN107398279AImprove desulfurization performanceGood high temperature stabilityMaterial nanotechnologyHeterogenous catalyst chemical elementsSodium carbonateChemistry

The invention relates to a preparation method of an efficient zinc oxide fine desulfurizing agent. The preparation method comprises the steps of enabling a sodium carbonate solution and a mixed solution of soluble zinc salt, soluble active aid salt and soluble carrier aid salt to react in a reactor of a microwave heating oven, carrying out microwave radiation aging and filtration under a stirring condition, preparing material liquid from a filter cake, carrying out spray drying and roasting, so as to obtain the finished desulfurizing agent. The efficient zinc oxide fine desulfurizing agent is high in sulfur capacity, simultaneously applicable to low-temperature, medium-temperature and high-temperature desulfurization and good in thermal stability.

Owner:江苏天东新材料科技有限公司

Flue gas desulfurizing agent, preparation method and application thereof

ActiveCN112295395AIncrease alkalinityImprove water absorptionGas treatmentDispersed particle separationCalcium hydroxideManganese sulphate

The invention relates to the technical field of dry flue gas desulfurizers, particularly to a flue gas desulfurizing agent, a preparation method and application thereof. The flue gas desulfurizing agent comprises the following components in percentage by mass: 25-80% of modified calcium hydroxide, 5-40% of calcium carbonate and the balance of an additive and a binder, wherein the additive is two or three of iron oxide, sodium carbonate and manganese sulfate, the binder is selected from one or more of pseudo-boehmite, bentonite and a dilute nitric acid solution, and the modified calcium hydroxide is surfactant modified calcium hydroxide. According to the invention, the problems that an existing desulfurizing agent is poor in mechanical strength, harsh in temperature application range, low in desulfurizing agent utilization rate and the like after being formed are solved, and the desulfurizing agent provided by the invention does not need to be roasted at high temperature, has high mechanical strength, also has good desulfurizing performance under medium and low temperature conditions, and can be applied to SO2 removal.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

Micro-carbon, low-silicon, low-phosphor and low-sulphur aluminum-magnesium-calcium-iron alloy used for smelting steel and deoxidizing

The invention discloses an aluminum magnesium calcium ferroalloy with micro-carbon, low silicon, low phosphorus and low sulfur used in steelmaking deoxidization, which is characterized in that the weight percent of the invention is 10 to 98 Al, 0.1 to 5 Mg and 0.5 to 65 Ca; C is no more than 0.02; Si is no more than1.0; P is no more than 0.02; S is less than 0.02 and the rest is Fe. The invention is to provide the aluminum magnesium calcium in ferro with micro-carbon, low silicon, low phosphorus and low sulfur used in steelmaking deoxidization to solve the problem existing in prior art that white smoke bursts during the process of steelmaking deoxidization, which affects observation of liquid steel and lowers the steel quality.

Owner:本溪冶炼集团有限公司

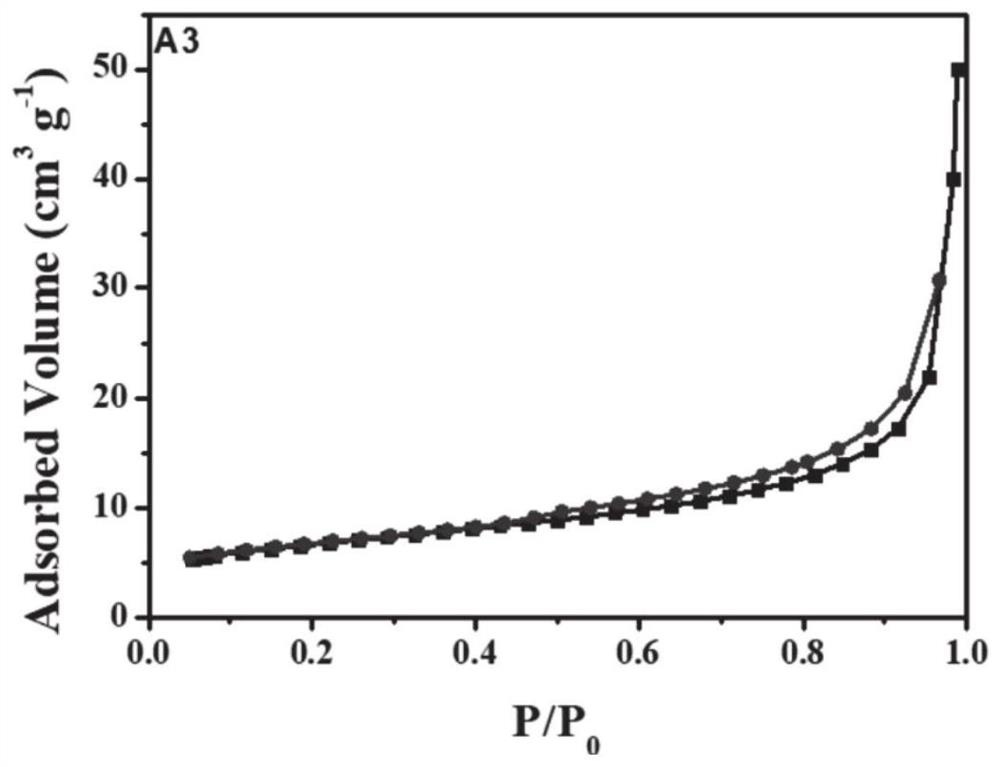

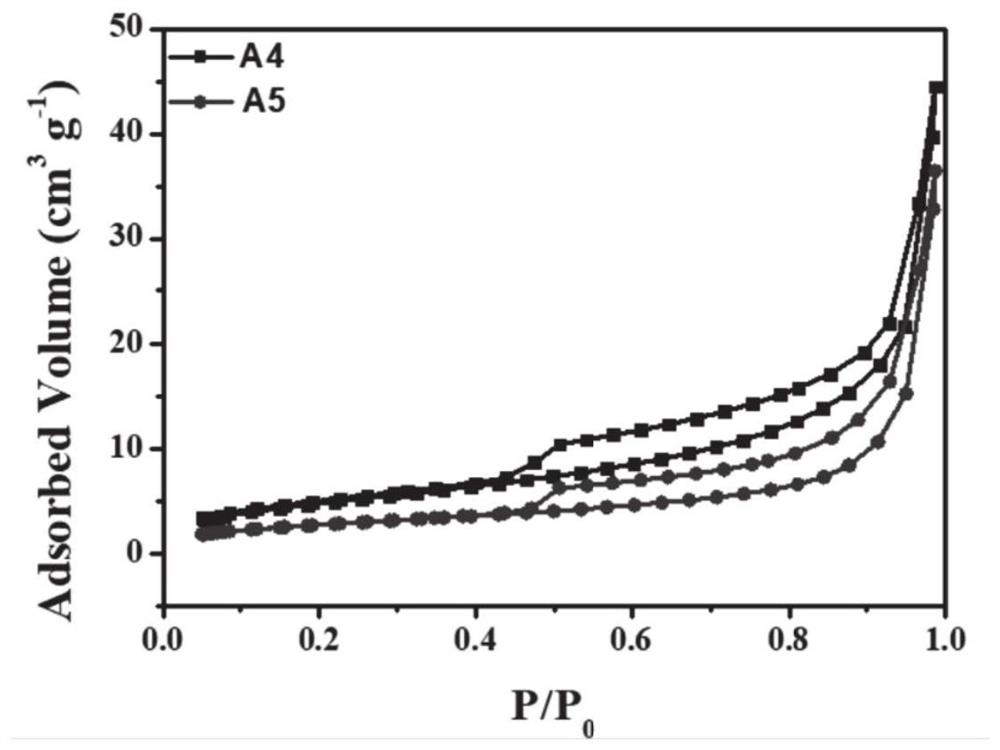

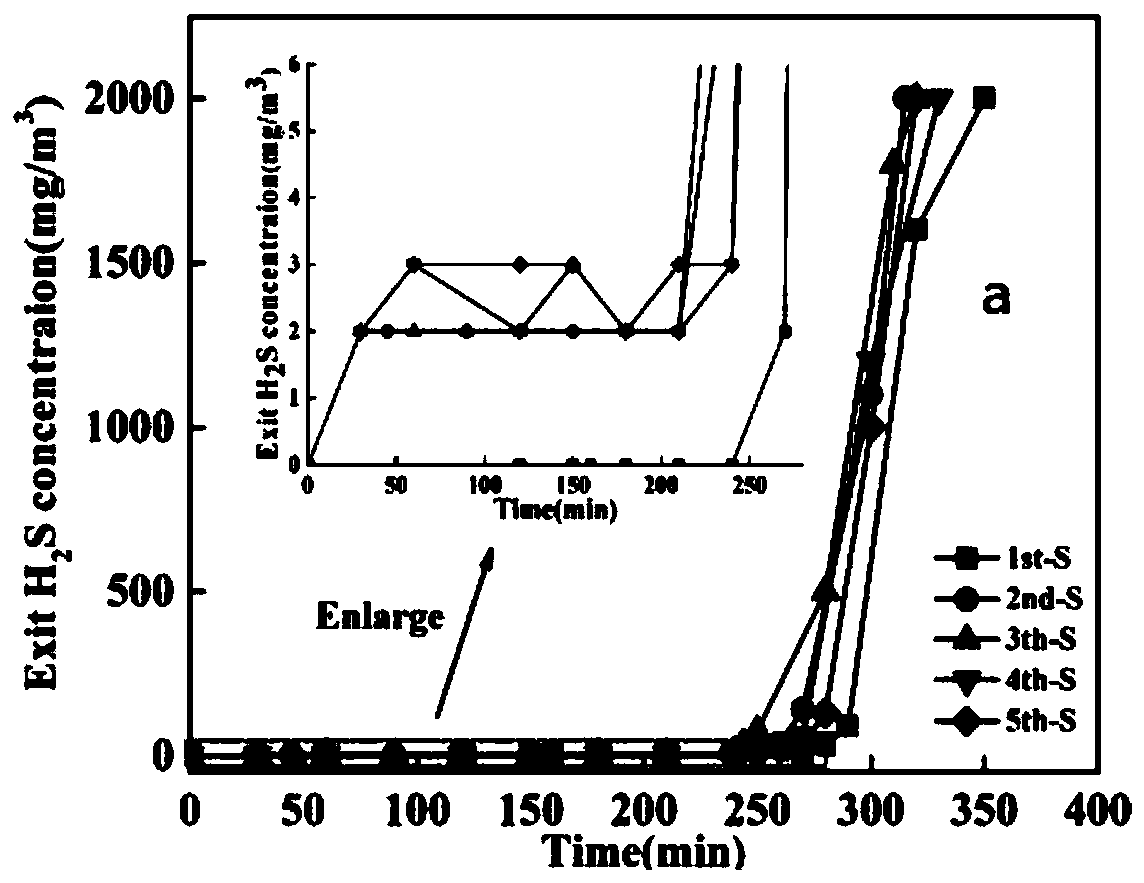

Composite adsorbent for removing hydrogen sulfide at high temperature, and preparation method and application thereof

ActiveCN110801821AImprove desulfurization effectReduce hydrogen sulfide contentGas treatmentOther chemical processesReducing atmosphereManganese oxide

The invention belongs to the technical field of desulfurization adsorbents, and particularly relates to a composite adsorbent for removing hydrogen sulfide at a high temperature, and a preparation method and application thereof. The composite adsorbent for removing hydrogen sulfide provided by the invention comprises the following components in percentage by weight: 10%-50% of manganese oxide, 30%-40% of alumina, and 2%-15% of an auxiliary agent, wherein the auxiliary agent is selected from a mixture of at least two of lanthanum oxide, cerium oxide, barium oxide or nickel oxide. The compositeadsorbent for removing hydrogen sulfide can work normally at 800 DEG C or more, and has the following advantages: 1) the desulfurization effect of the fresh adsorbent is good, in the simulated reducing atmosphere desulfurization experiment, a removal rate of hydrogen sulfide is close to 100%, and the content of hydrogen sulfide in a tail gas is less than 1 mg / m<3>; 2) the desulfurization performance of the adsorbent is stable during the desulfurization-regeneration cycle process, the breakthrough sulfur capacity and desulfurization efficiency are both kept stable, and the hydrogen sulfide content in the tail gas is less than 3 mg / m<3> during the desulfurization process; and 3) the adsorbent is in a dry state, no aqueous solution is required during use, and thereby the water consumption isreduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

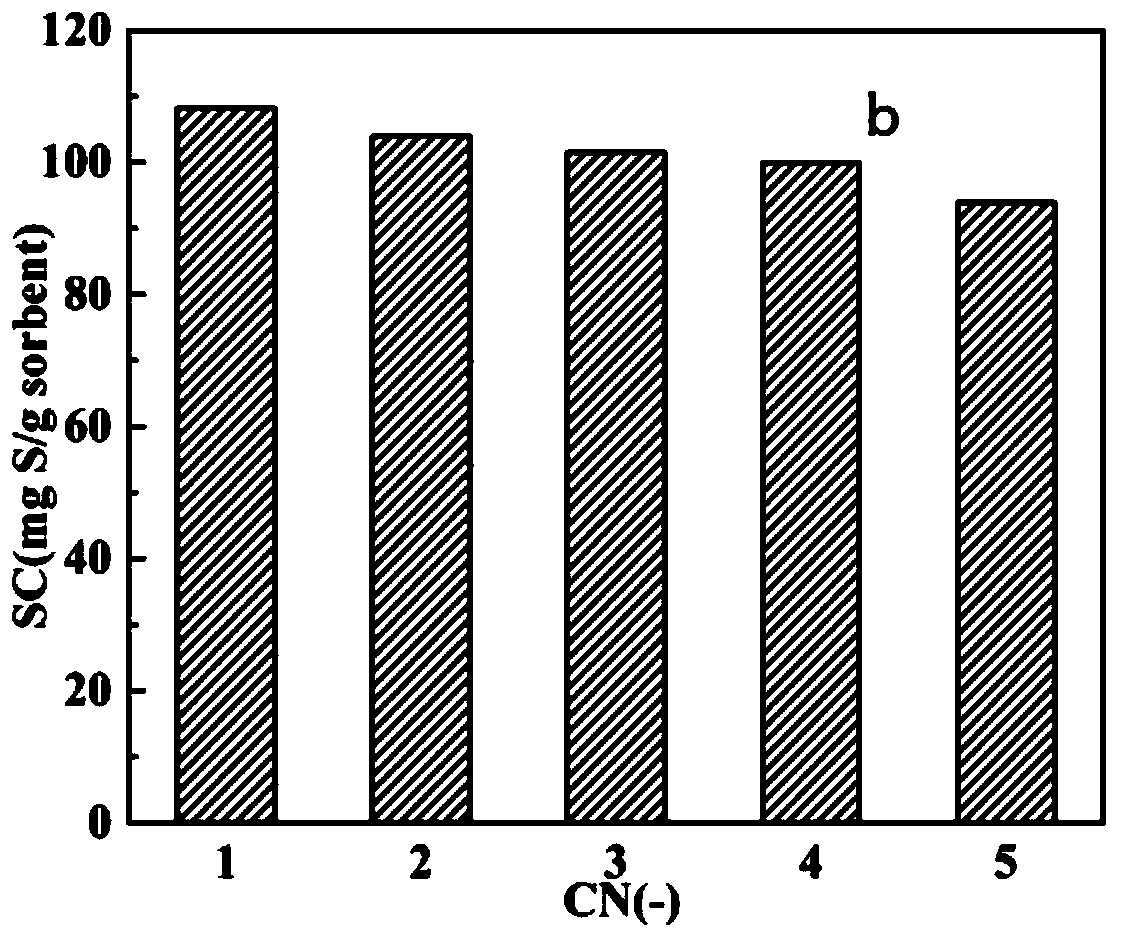

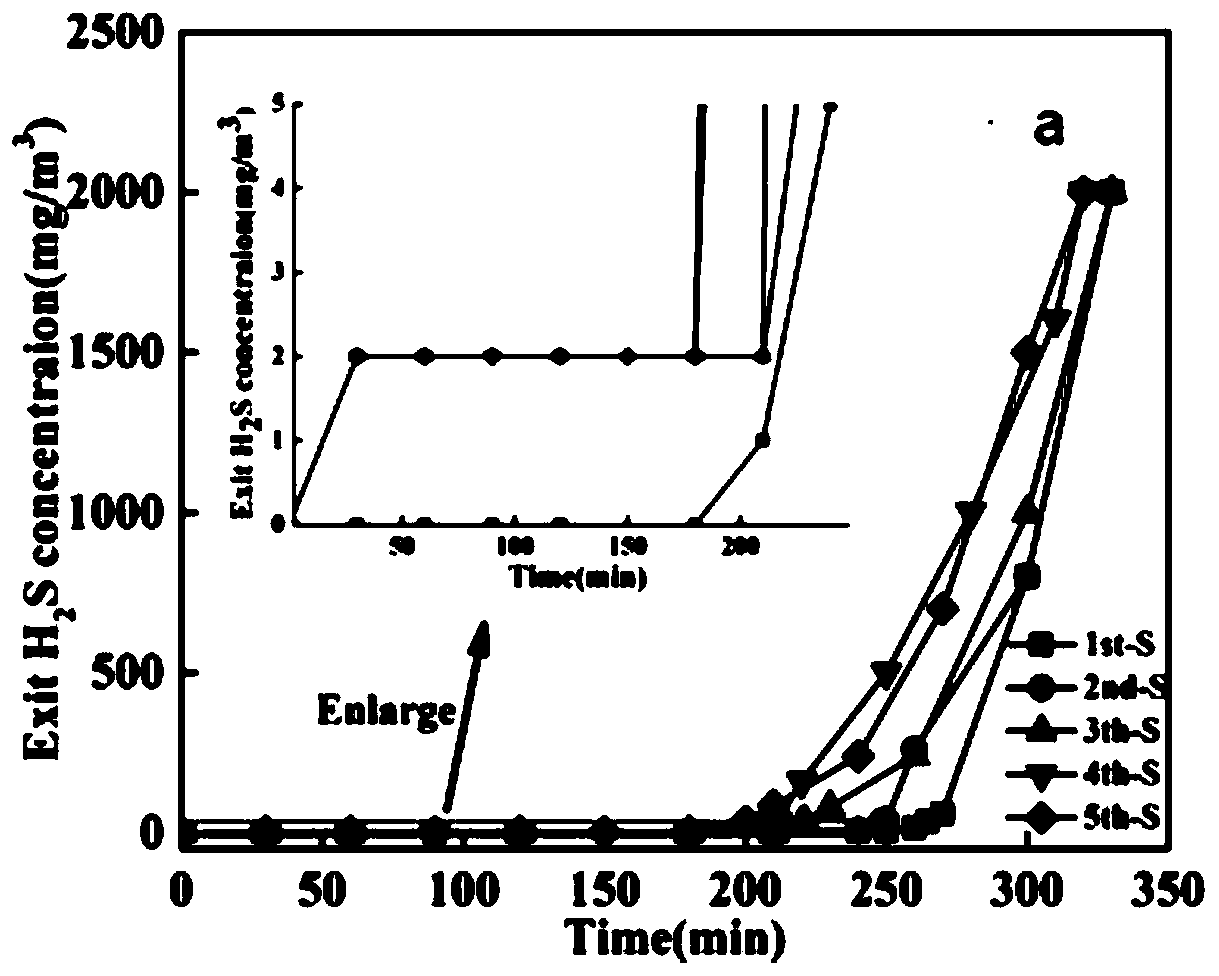

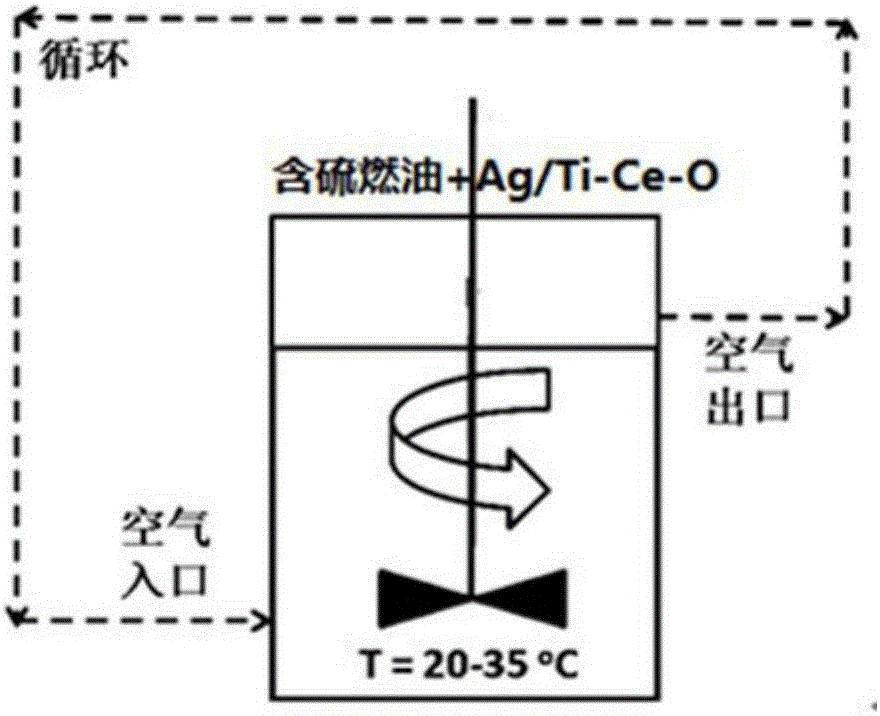

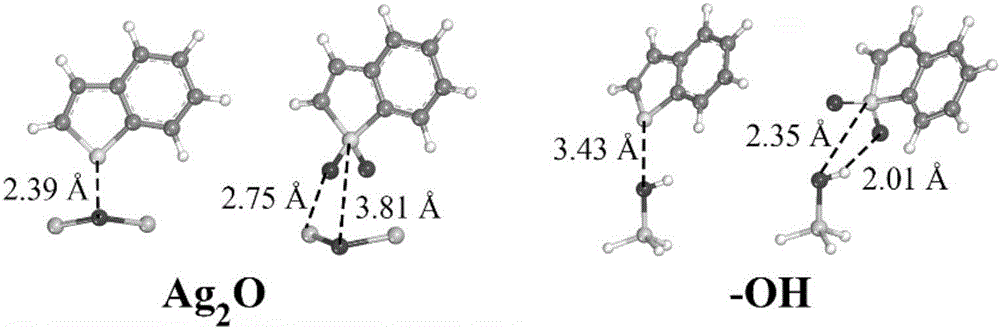

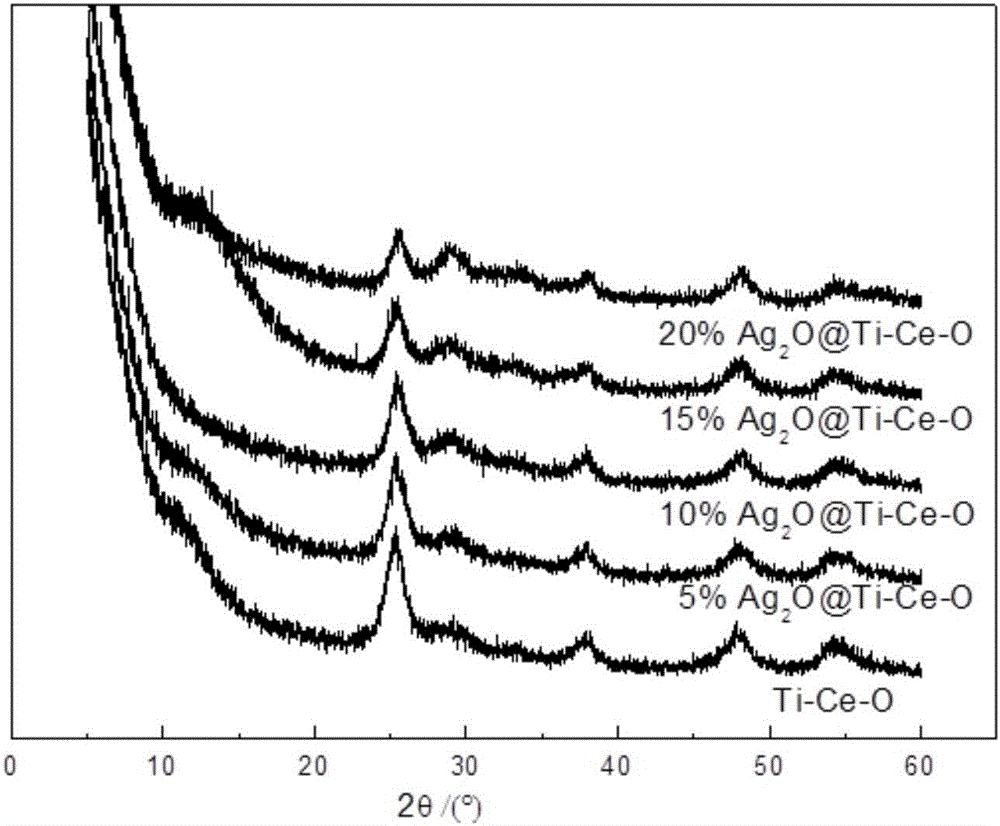

Ag2O@Ti-Ce-O difunctional catalytic adsorption desulfurizer, and preparation method and application thereof

ActiveCN106492797AExcellent deep desulfurization effect of fuel oilImprove desulfurization performanceHeterogenous catalyst chemical elementsHydrocarbon oils refiningSilver nitrateUrea

The invention relates to an Ag2O@Ti-Ce-O difunctional catalytic adsorption desulfurizer, and a preparation method and application thereof. The preparation method comprises the following steps: (1) adding a precursor of Ti and Ce into a urea solution and carrying out stirring until the precursor is completely dissolved so as to obtain a mixed solution, wherein a mol ratio of Ti to Ce in the precursor of Ti and Ce is 1: 9 to 9: 1; (2) heating the mixed solution, then carrying out isothermal stirring for a reaction and subjecting obtained gel to filtering, washing, drying and calcining in the air successively so as to obtain a Ti-Ce-O substrate material; and (3) with the loading amount of silver of 5 to 20 wt.%, uniformly loading a silver nitrate solution on the Ti-Ce-O substrate material by using an equivalent-volume impregnation method, and successively carrying out drying, grinding and calcining in the air so as to obtain the Ag2O@Ti-Ce-O difunctional catalytic adsorption desulfurizer. The Ag2O@Ti-Ce-O difunctional catalytic adsorption desulfurizer has improved desulphurization efficiency and cycle usage stability.

Owner:PETROCHINA CO LTD +1

Al-Mn-Ca-Fe alloy contg. trace carbon, low silicon, low phosphorus, low sulphur used for steelmaking

The invention relates to a micro low carbon, low silicon, low phosphor, and low sulfur Al-Mn-Ca-Fe alloy used in steel-making. It uses as deoxidizer and contains 20-85wt% Al, 4-20wt% Mg, 1-15wt% Ca, C less than 0.02wt%, Si less than 1.0wt%, P less than 0.02wt%, S less than 0.02, the rest is Fe. It is smelted from line frequency furnace. The invention has the advantage of easy to use, stable, and could improve the recovery factor of the metal element. The molten steel treated by the deoxidizer has good fluidity, high work rates, high benefits, etc. The deoxidizer could discharge the impurity, and it has good mechanical behavior, good quality, long useful life and good social benefit.

Owner:本溪铸新冶炼有限公司

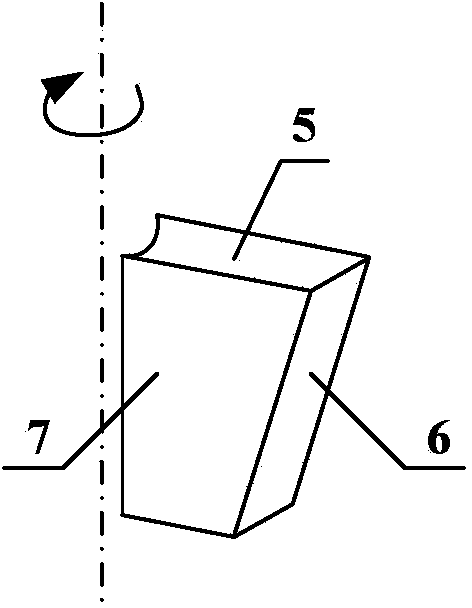

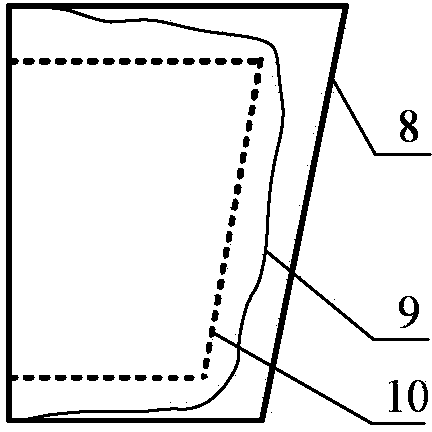

Blade abrasion evaluation method of KR desulfuration paddle agitator

ActiveCN103968780AEasy to operateThe assessment results are accurateUsing optical meansEvaluation resultEngineering

The invention relates to a blade abrasion evaluation method of a KR desulfuration paddle agitator. According to the technical scheme, blade abrasion evaluation positions are set in advance, the initial standard outline and the usage limit outline of each blade (4) of an unused KR desulfuration paddle agitator (2) in the corresponding blade abrasion evaluation position are determined respectively, and then the abrasion replacement value W1 and the abrasion repair value W2 of each blade (4) of the KR desulfuration paddle agitator (2) in the using process are determined; then, a series of images of the blades (4) in the rotating process of the KR desulfuration paddle agitator (2) are acquired through a first industrial camera (1) and a second industrial camera (2), the abrasion virtual outline of each blade (4) is calculated according to the series of images to be compared with the corresponding initial standard outline and the corresponding usage limit outline, and the comprehensive abrasion evaluation rate R of each blade (4) is obtained; finally, the abrasion evaluation result is given according to the comprehensive abrasion evaluation rate R, and the abrasion replacement value W1 and the abrasion repair value W2 of each blade (4). The blade abrasion evaluation method of the KR desulfuration paddle agitator has the advantages of being easy to operate, accurate in evaluation and capable of quantizing abrasion.

Owner:WUHAN UNIV OF SCI & TECH

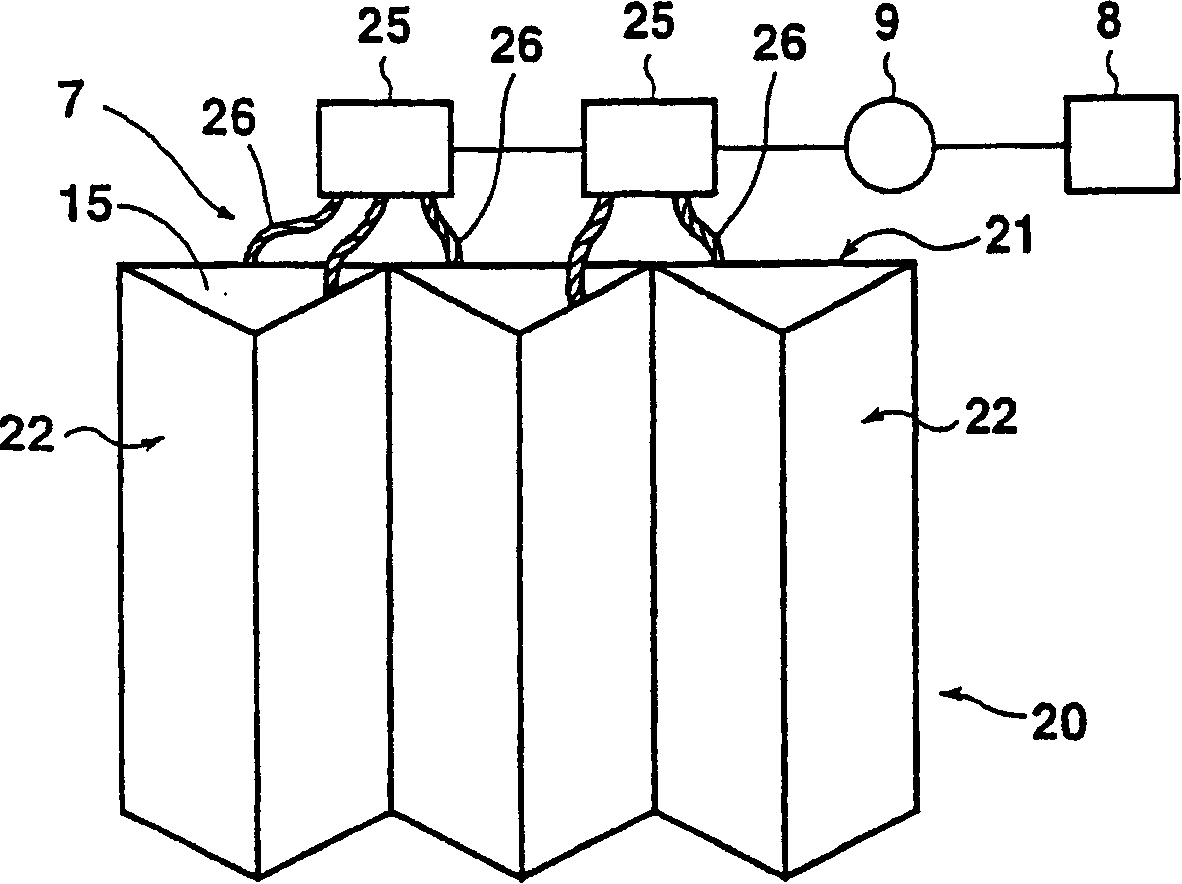

Flue gas desulfurization apparatus, flue gas desulfurization system, and method for operating flue gas desulfurization apparatus

The invention provides a flue gas desulfurization apparatus includes at least one activated carbon fiber board 20 provided in a catalyst unit 6, the board being formed by alternatingly juxtaposing one or more plate-like activated carbon fiber sheets and one or more corrugated activated carbon fiber sheets so as to provide vertically extending conduits, wherein water for producing sulfuric acid is supplied, through a capillary phenomenon, to the activated carbon fiber board 20 provided in the catalyst unit 6. The flue gas desulfurization apparatus attains removal of sulfur oxides (SOx) by adding a minimum required amount of water to the activated carbon fiber board 20 so as to attain uniform water distribution and can reduce the amount of water required for removing sulfur oxides (SOx).

Owner:MITSUBISHI HEAVY IND LTD

Flue gas desulfurization apparatus, flue gas desulfurization system, and method for operating flue gas desulfurization apparatus

The invention provides a flue gas desulfurization apparatus includes at least one activated carbon fiber board 20 provided in a catalyst unit 6, the board being formed by alternatingly juxtaposing one or more plate-like activated carbon fiber sheets and one or more corrugated activated carbon fiber sheets so as to provide vertically extending conduits, wherein water for producing sulfuric acid is supplied, through a capillary phenomenon, to the activated carbon fiber board 20 provided in the catalyst unit 6. The flue gas desulfurization apparatus attains removal of sulfur oxides (SOx) by adding a minimum required amount of water to the activated carbon fiber board 20 so as to attain uniform water distribution and can reduce the amount of water required for removing sulfur oxides (SOx).

Owner:MITSUBISHI HEAVY IND LTD

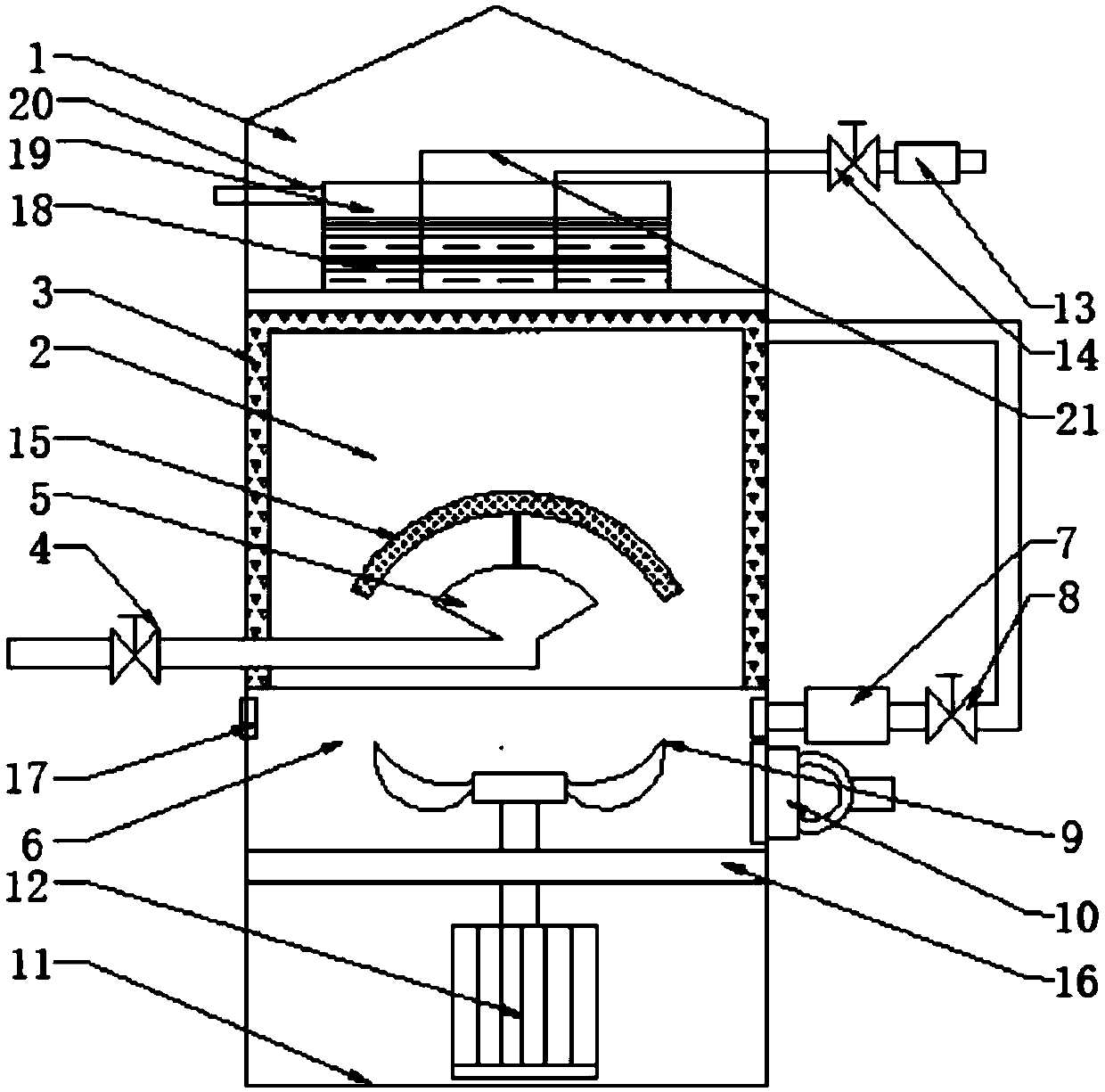

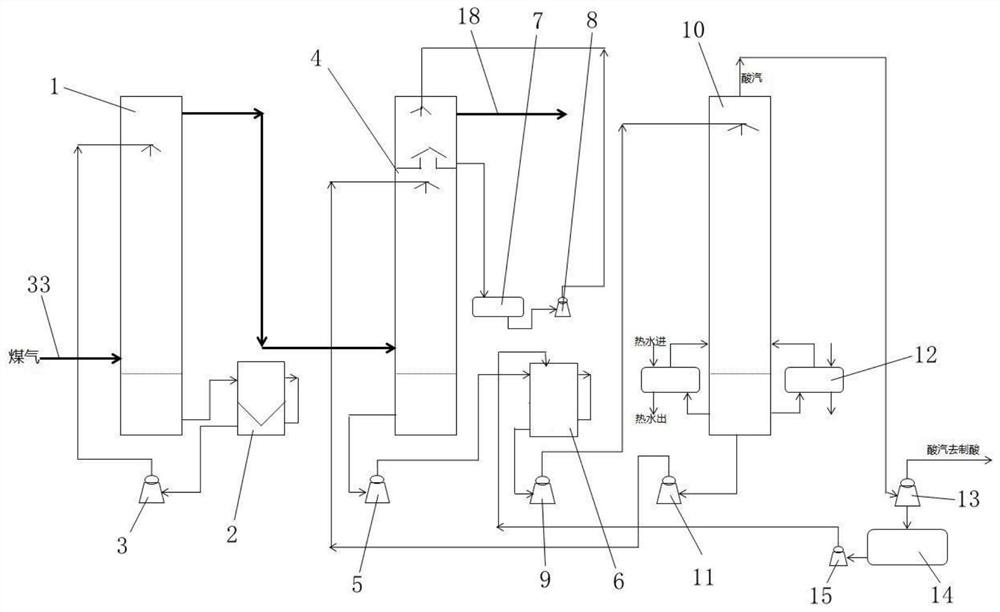

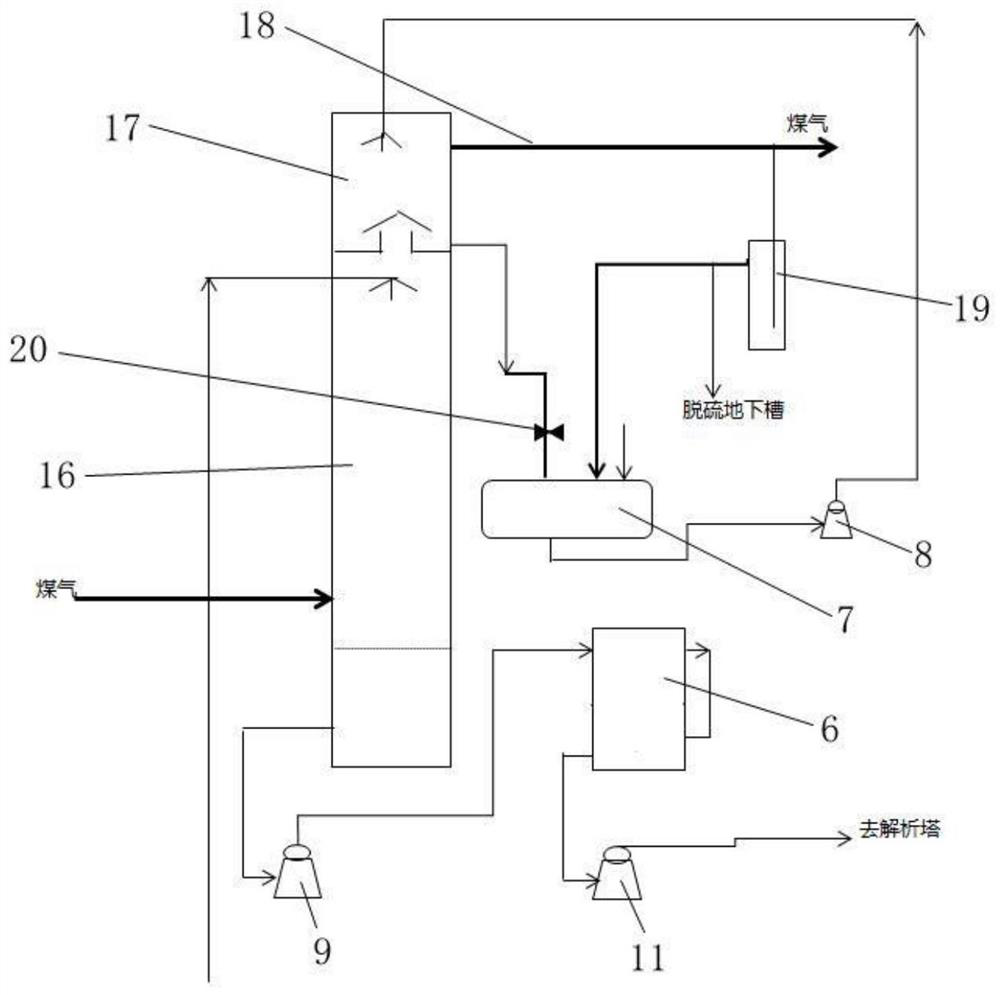

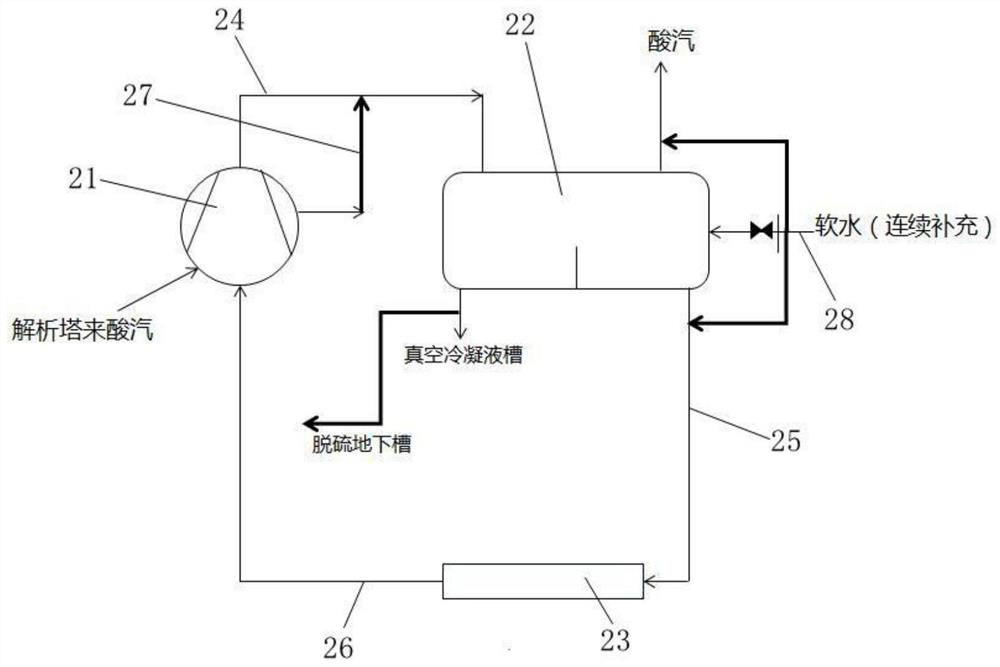

Desulfurization anddesorption system and use method

ActiveCN113355138AImprove desulfurization performanceImprove desulfurization efficiencyGas contaminants removalThermodynamicsReboiler

The invention relates to a desulfurization and desorption system and a use method. The desulfurization analysis system comprises a washing module, a desulfurization module and a desorption module. The washing module comprises a washing tower and a washing tank, the washing tower is communicated with the washing tank, and the washing tank is communicated with the washing tower through a washing circulating pump. The desulfurization module comprises a desulfurization tower and a rich liquor tank, the desulfurization tower comprises an upper alkali washing layer and a lower desulfurization layer, the desulfurization layer is communicated with the water scrubber, the desulfurization layer is communicated with the rich liquor tank through a rich liquor pump, the alkali washing layer is communicated with an alkali liquor tank, and the alkali liquor tank is communicated with the alkali washing layer through an alkali liquor pump. The desorption module comprises a desorption tower and a hot water reboiler, the rich liquor tank is communicated with the desorption tower through a desorption feeding pump, the desorption tower is communicated with the desulfurization layer through a barren liquor pump, and the hot water reboiler is arranged at the outer bottom end of the desorption tower and is communicated with the desorption tower through a pipeline. The desorption tower is communicated with a vacuum condensate tank through a vacuum pump module, and the vacuum condensate tank is communicated with the rich liquor tank through a vacuum condensate pump. The desulfurization effect is stable, the desulfurization efficiency is high, and the desorption effect is good.

Owner:SGIS SONGSHAN CO LTD

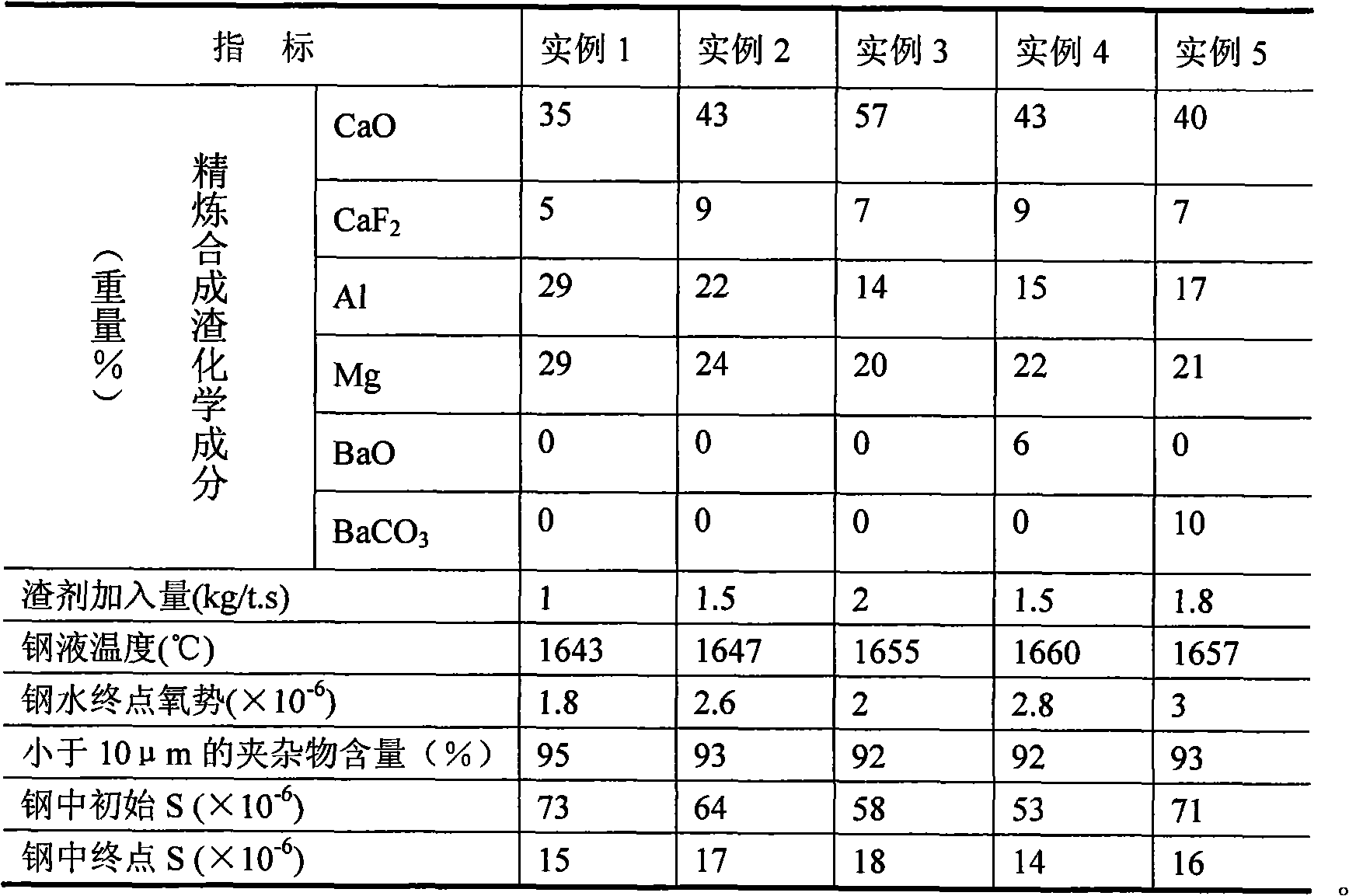

Aluminium killed steel refined deoxidizing and desulfurizing synthetic slag

The invention discloses aluminium killed steel refined deoxidizing and desulfurizing synthetic slag. A mixture is prepared from the following chemical components in weight percentage: 35-60 percent of CaO+BaO, 5-10 percent of CaF2, 10-30 percent of Al and 20-30 percent of Mg, wherein BaO accounts for 0-10 percent of the total weight percentage of the slag, and the proportion of Mg to Al is 1-1.5.The synthetic slag is convenient and easy to use and has a good deoxidizing effect, can reduce S in liquid steel to be less than 20*10<-6> and has a stable desulfurizing effect. The liquid steel does not resulfurize, the impurity content in the steel is low and a water gap is not blocked if continuous casting is carried out. The invention has simple method of application, obvious liquid steel deoxidizing and desulfurizing effect, obvious effect of reducing the impurity content in the steel and is suitable for producing high-quality clean steel.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com