Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

285results about "Molecular-sieve silicates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

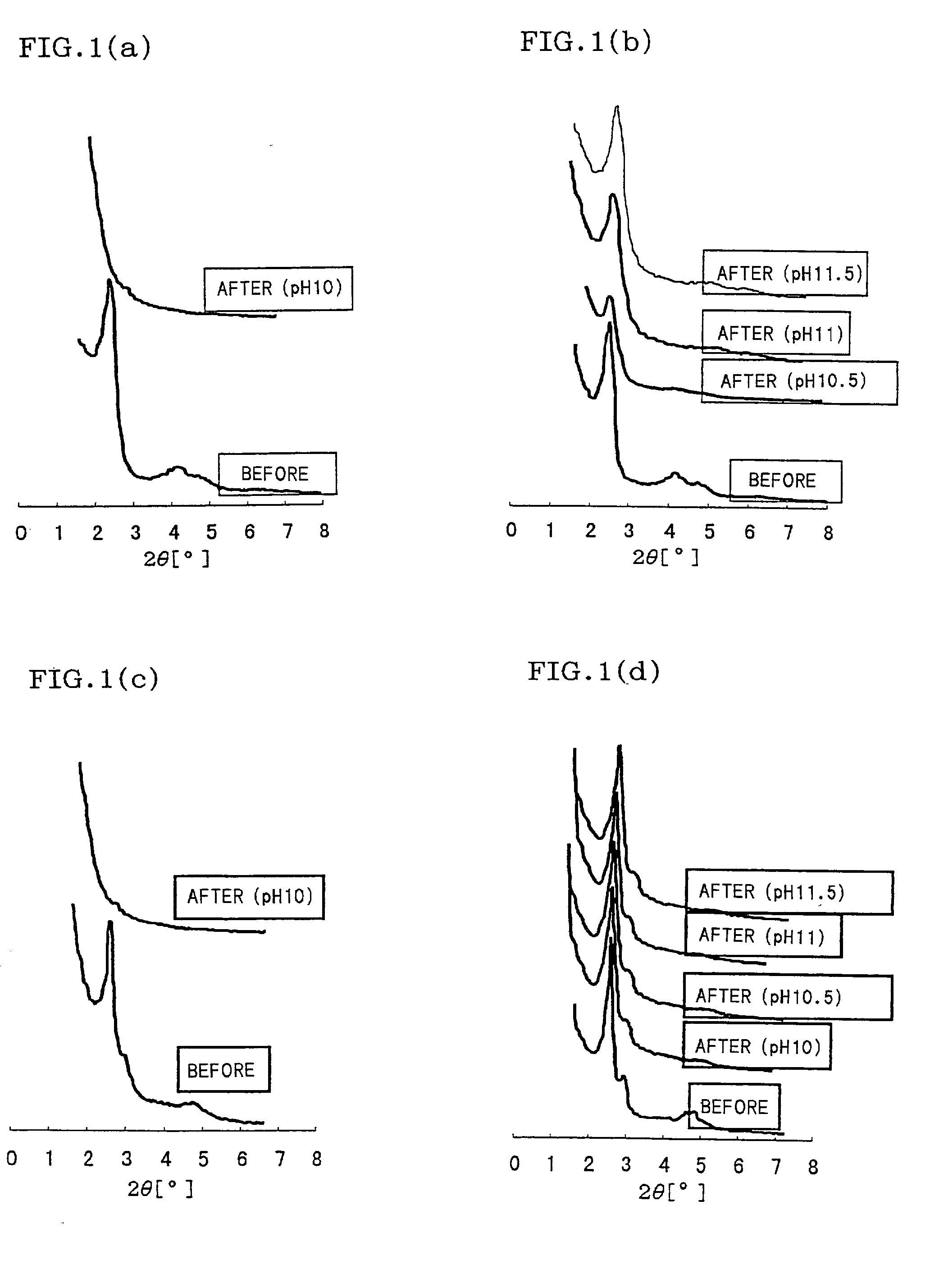

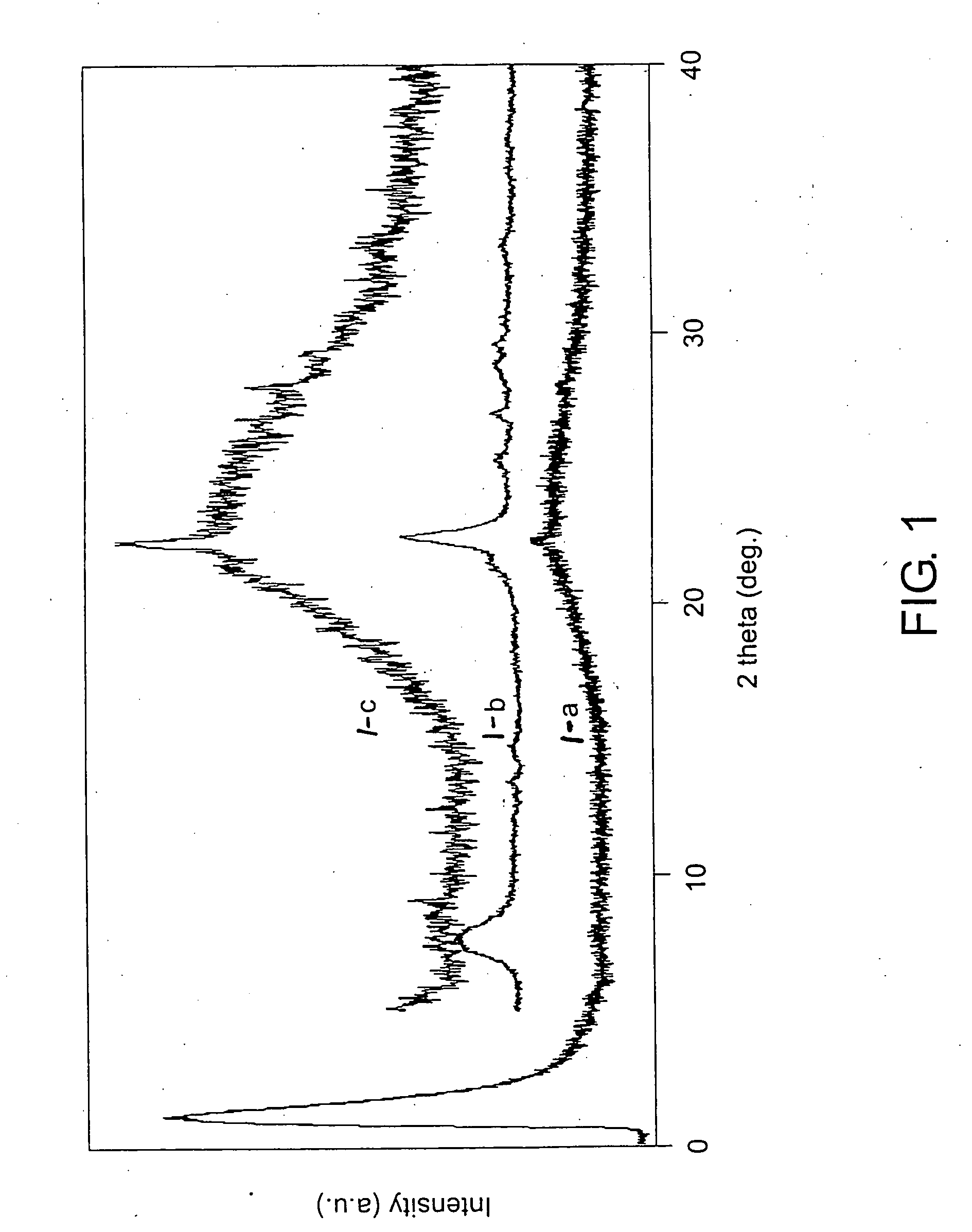

Method of the preparation of microporous crystalline molecular sieve possessing mesoporous frameworks

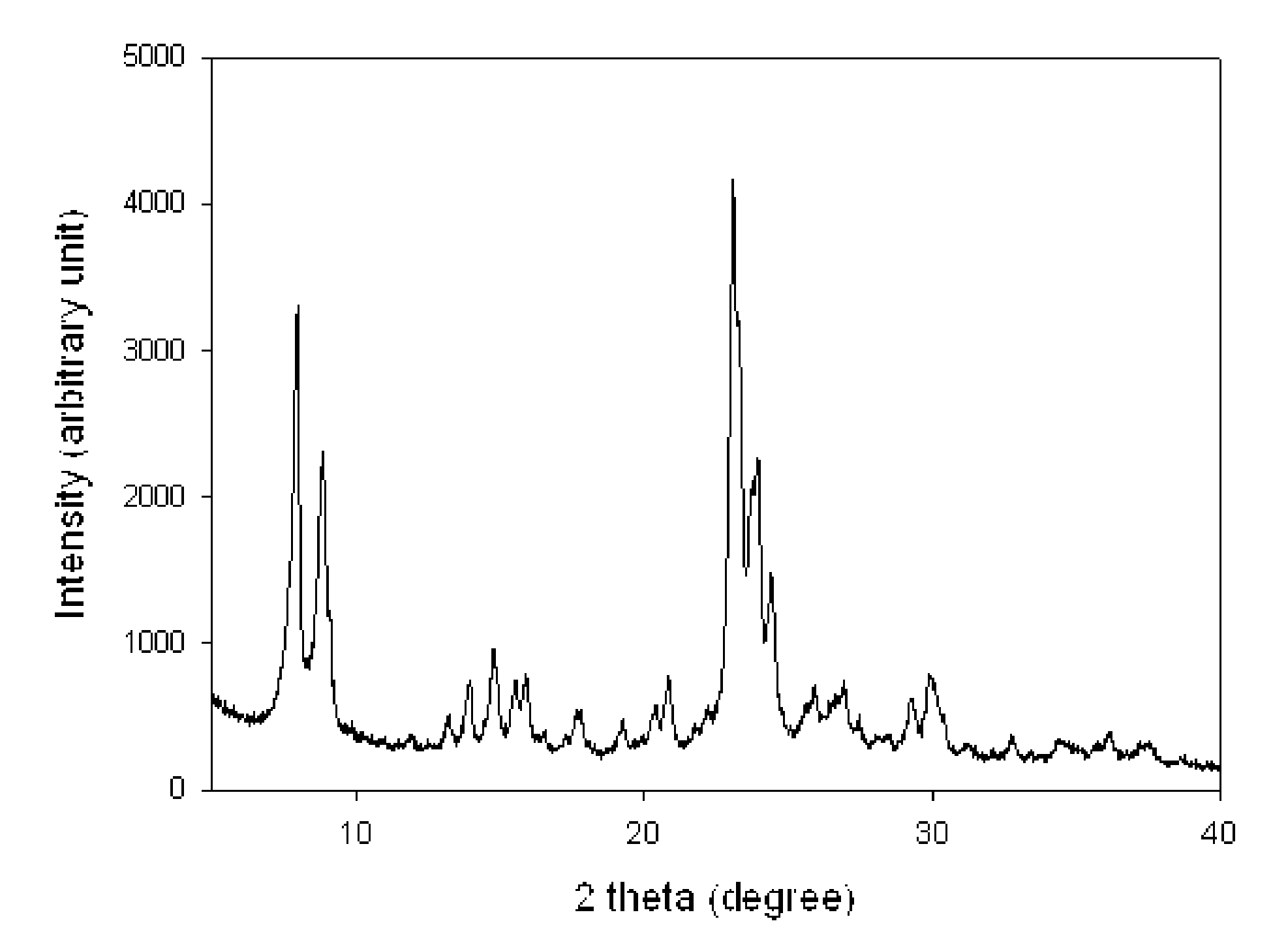

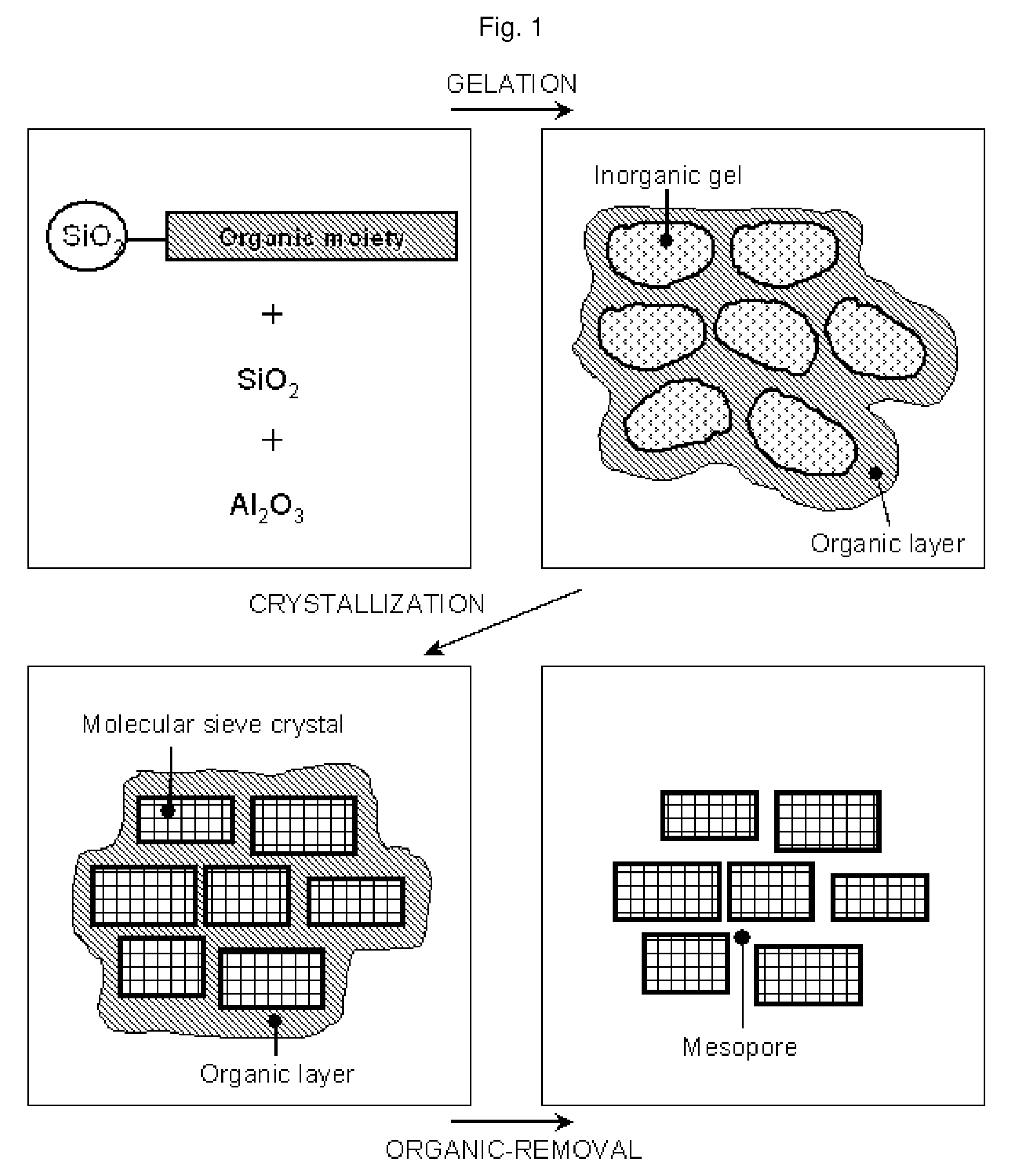

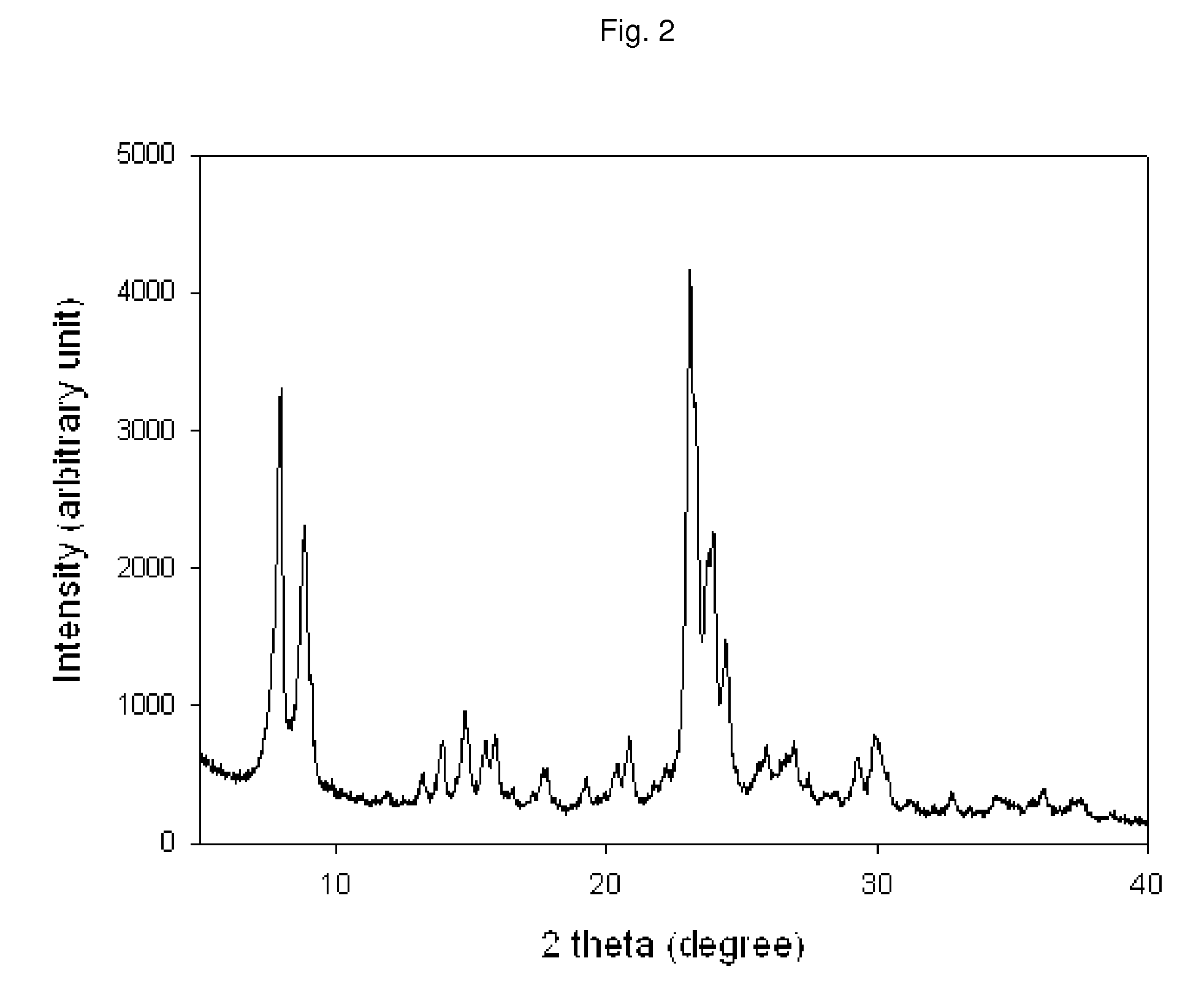

InactiveUS7785563B2Facilitate diffusion and adsorptionImprove overall utilizationAluminium compoundsSilicaMolecular sieveChemical treatment

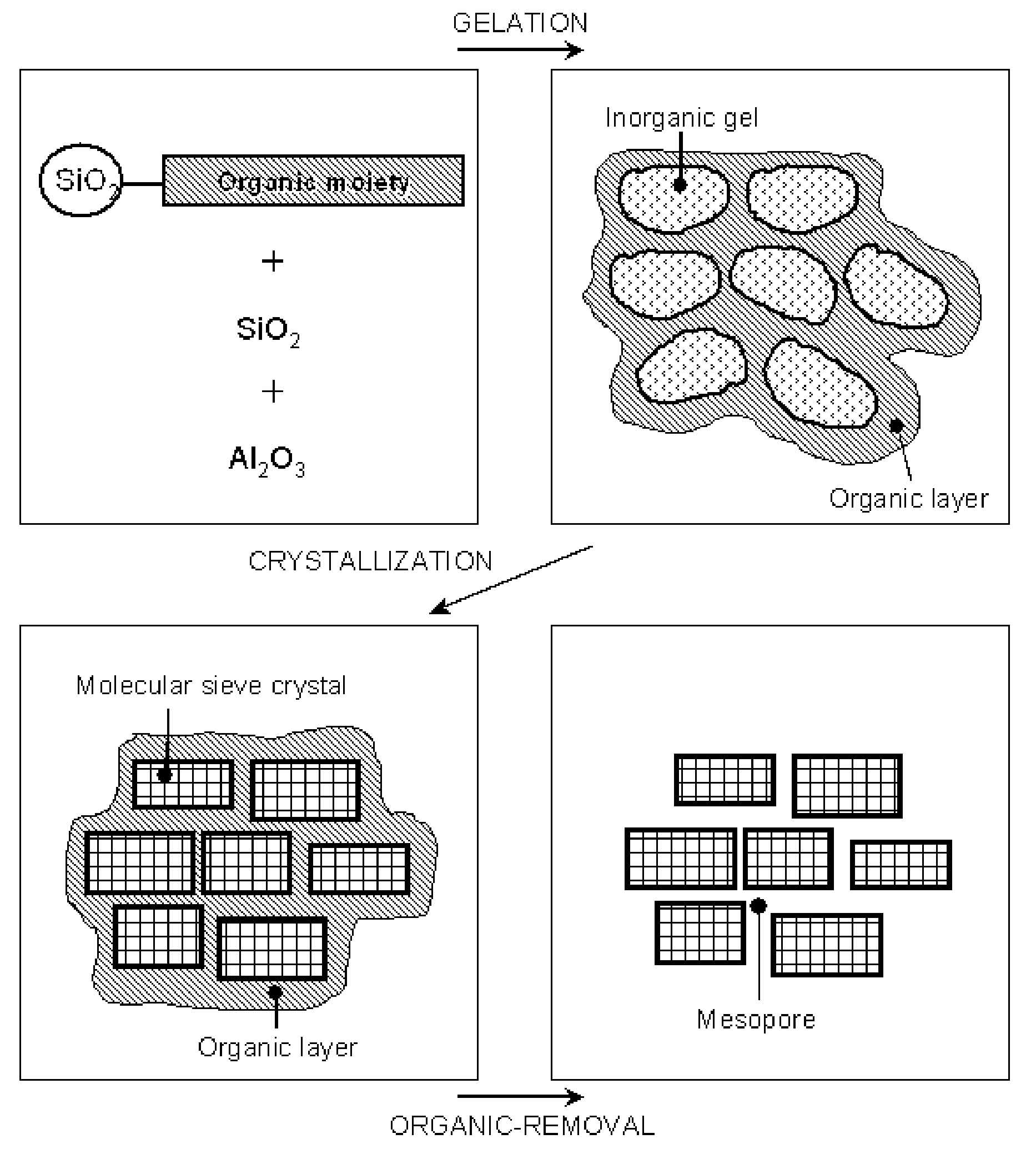

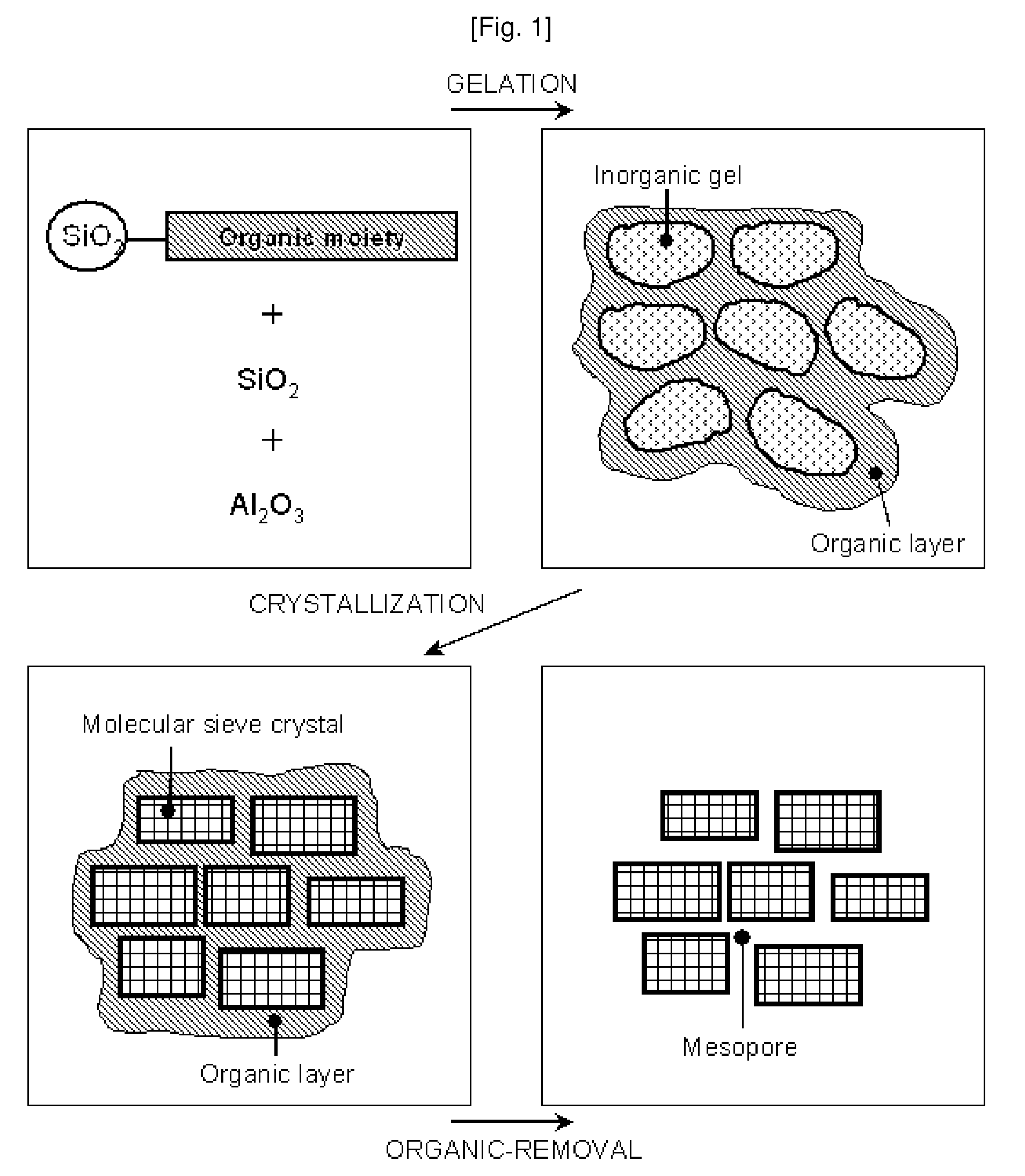

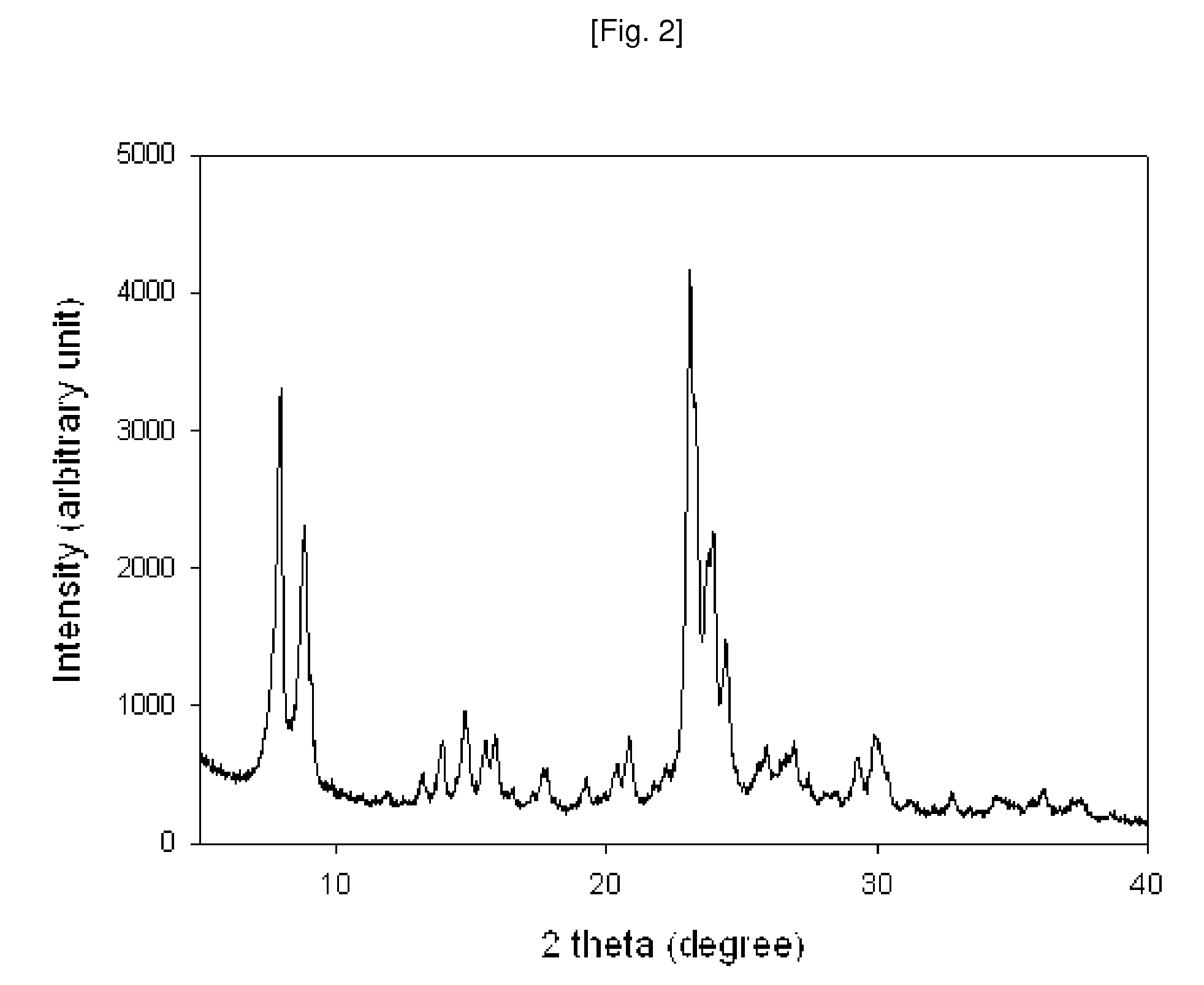

The present invention relates to a method of preparing a microporous crystalline molecular sieve having mesoporous skeleton, comprising following steps: (a) adding a meso-SDA (meso-Structure Directing Agent) into a gel composition of synthesizing molecular sieve, (b) subjecting the mixture obtained in the above step (a) to crystallization by a hydrothermal reaction, a microwave reaction, a dry-gel synthesis, etc., and (c) removing selectively organic materials from the resulted material obtained in the above step (b) by a calcination or a chemical treatment. Molecular sieve having mesoporous skeleton synthesized by the present invention exhibits, as compared with conventional zeolite, a good molecule diffusion ability and a greatly improved catalytic activity.

Owner:KOREA ADVANCED INST OF SCI & TECH

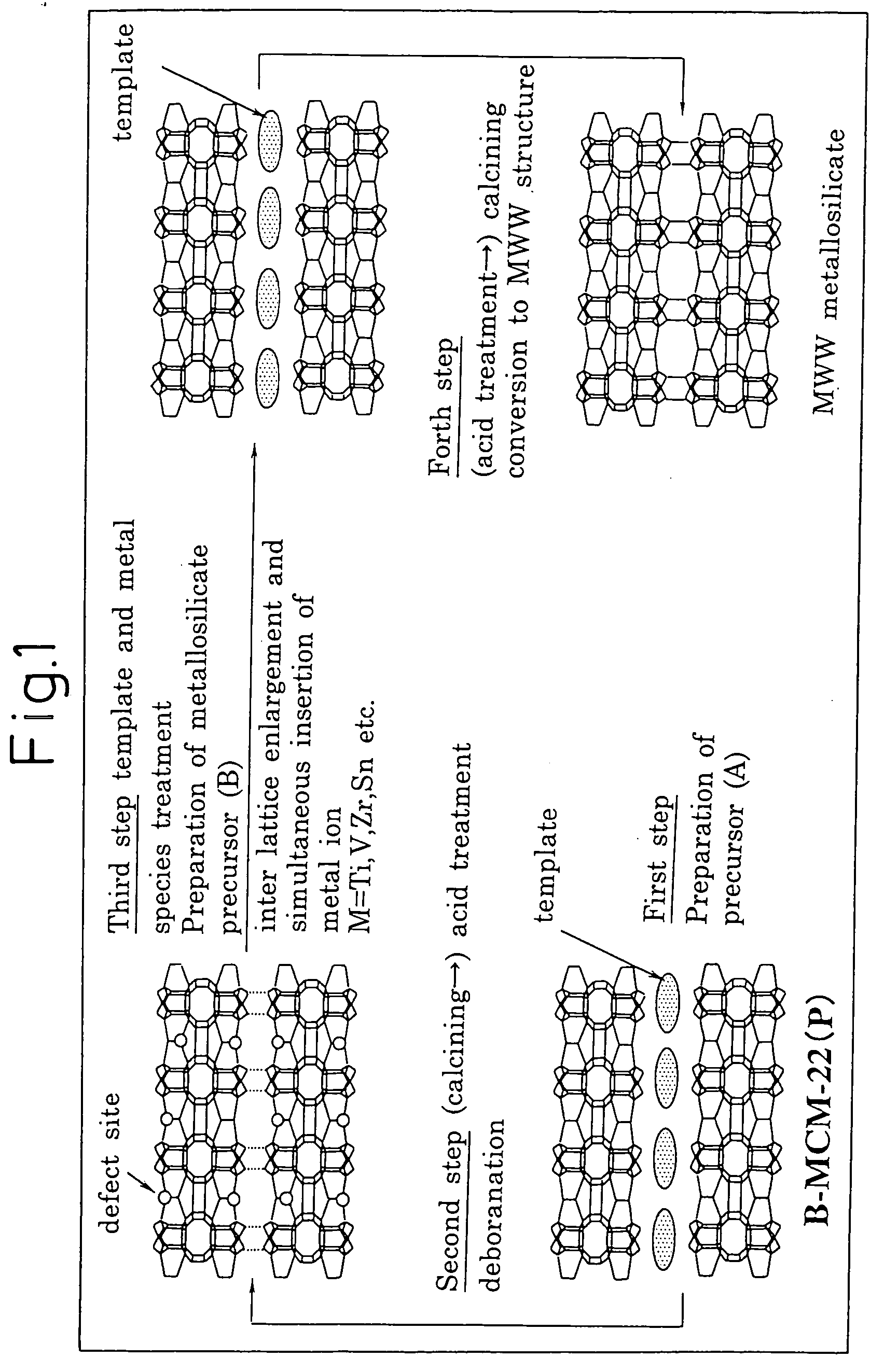

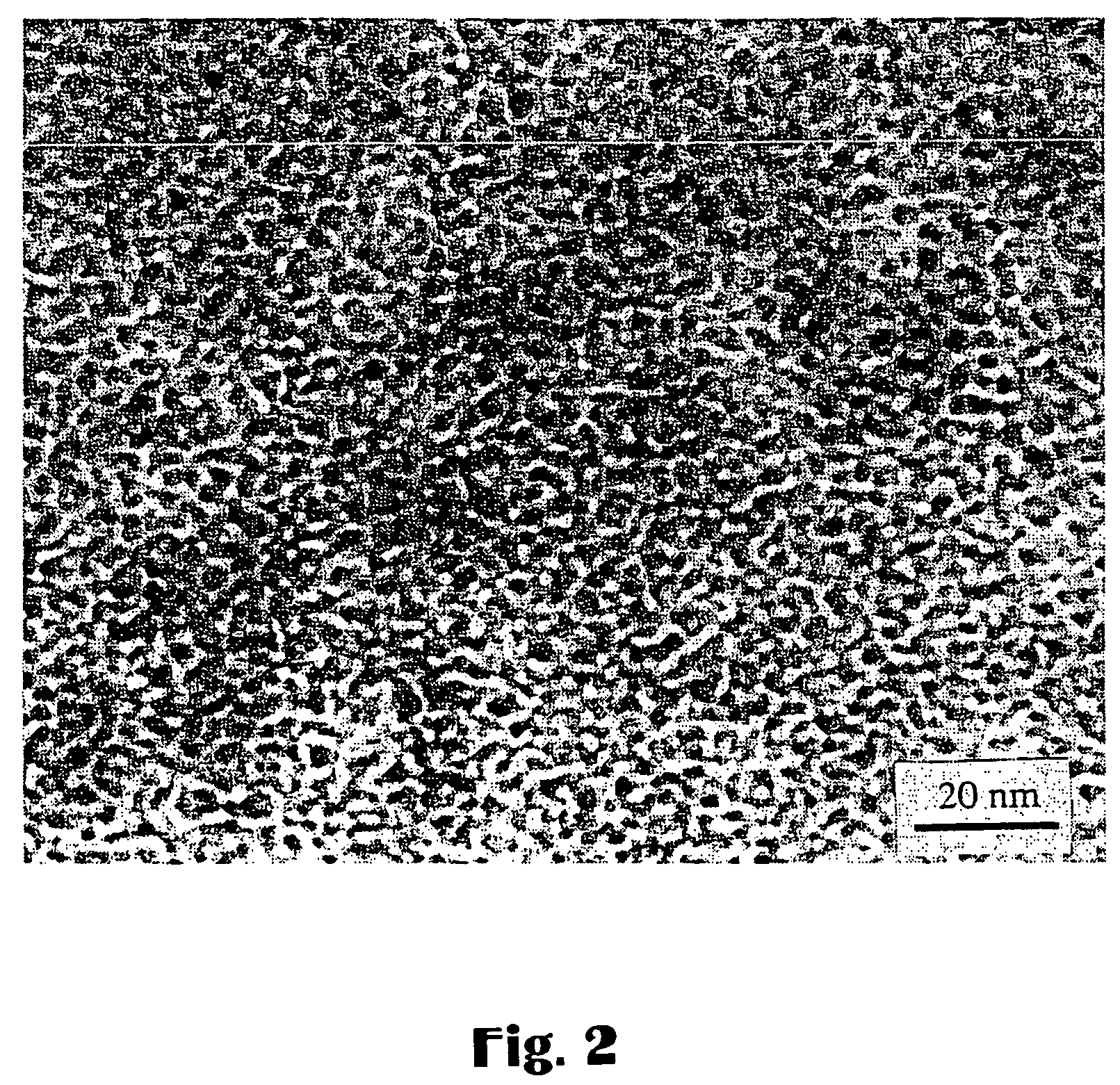

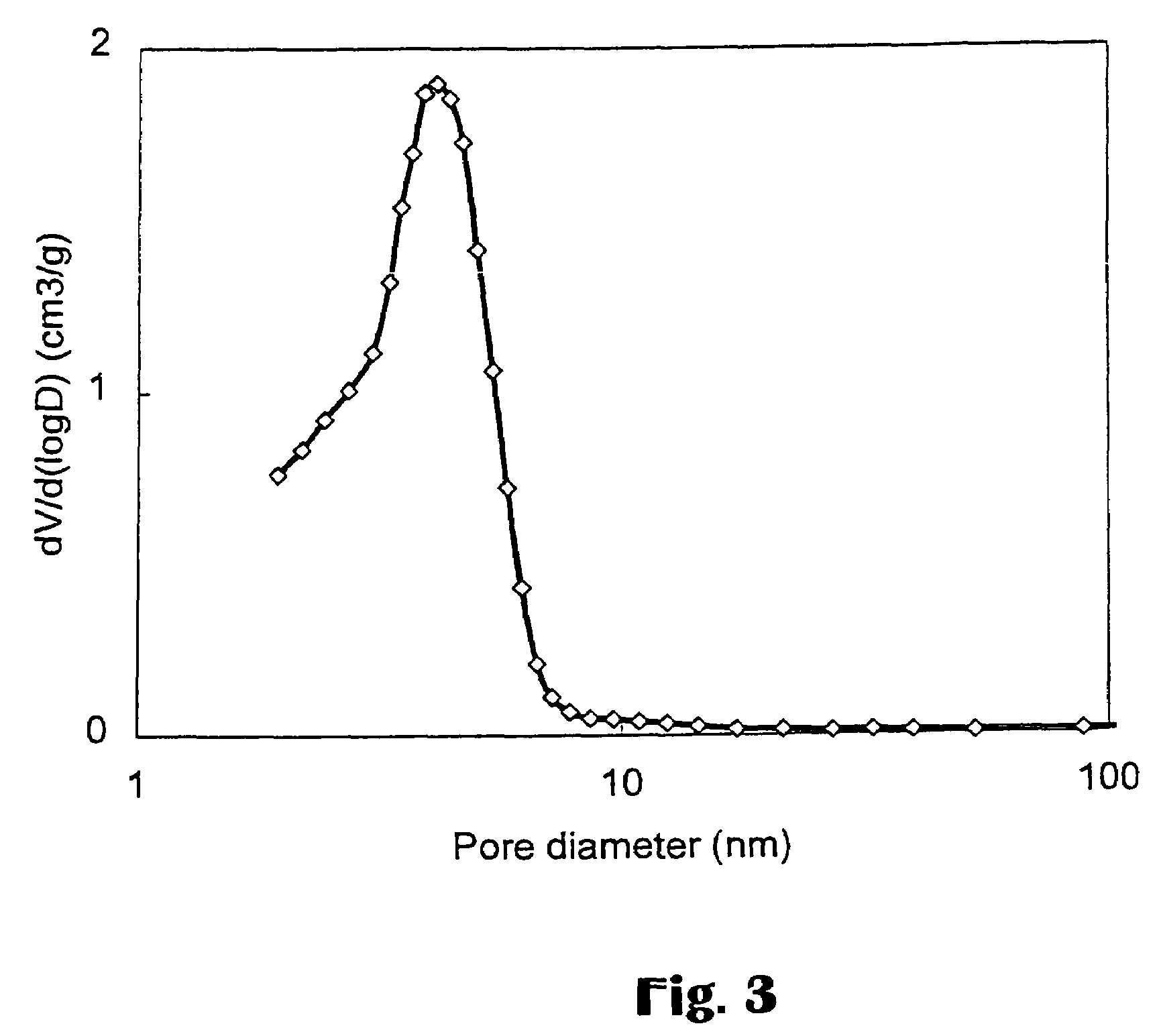

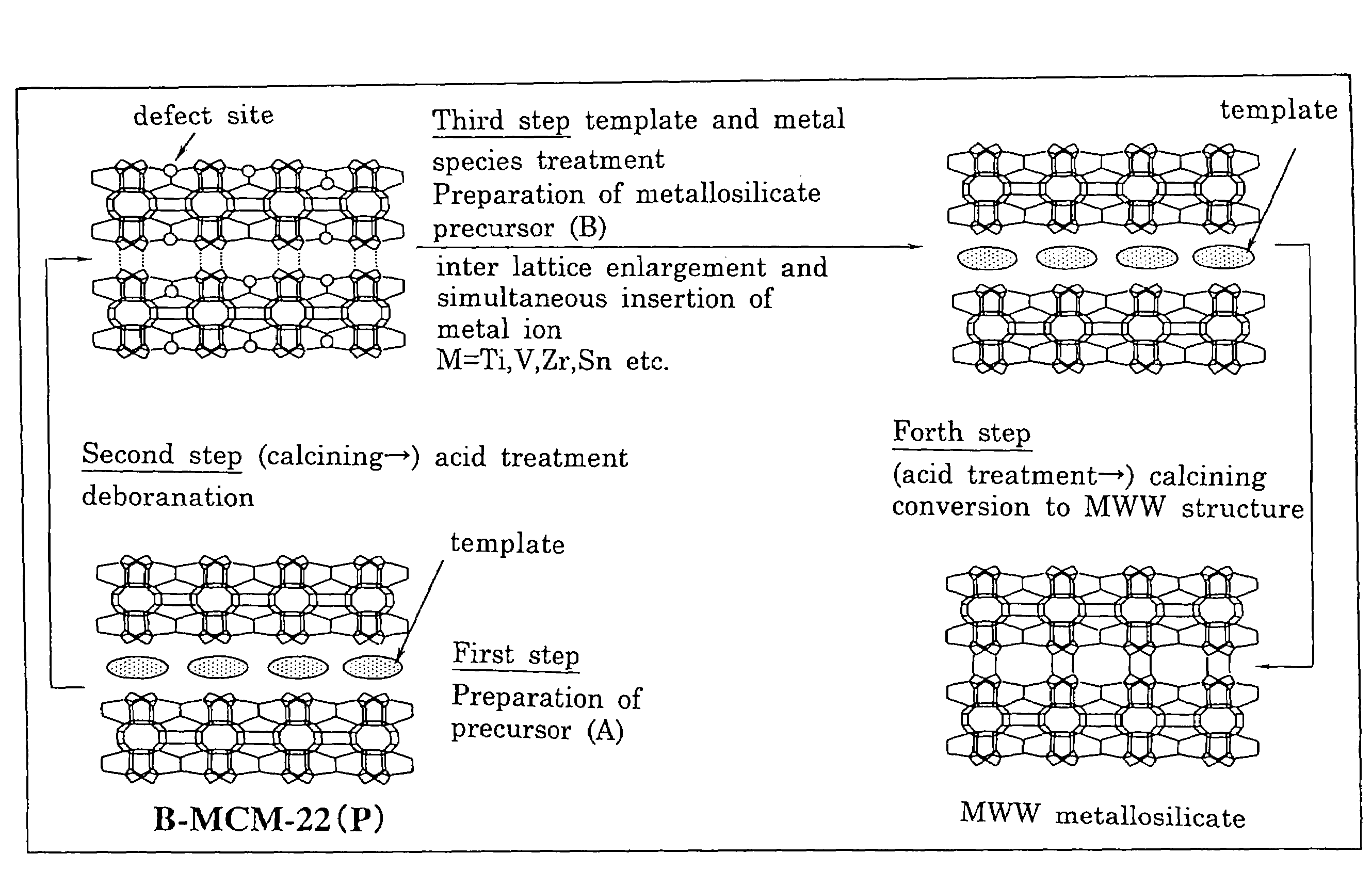

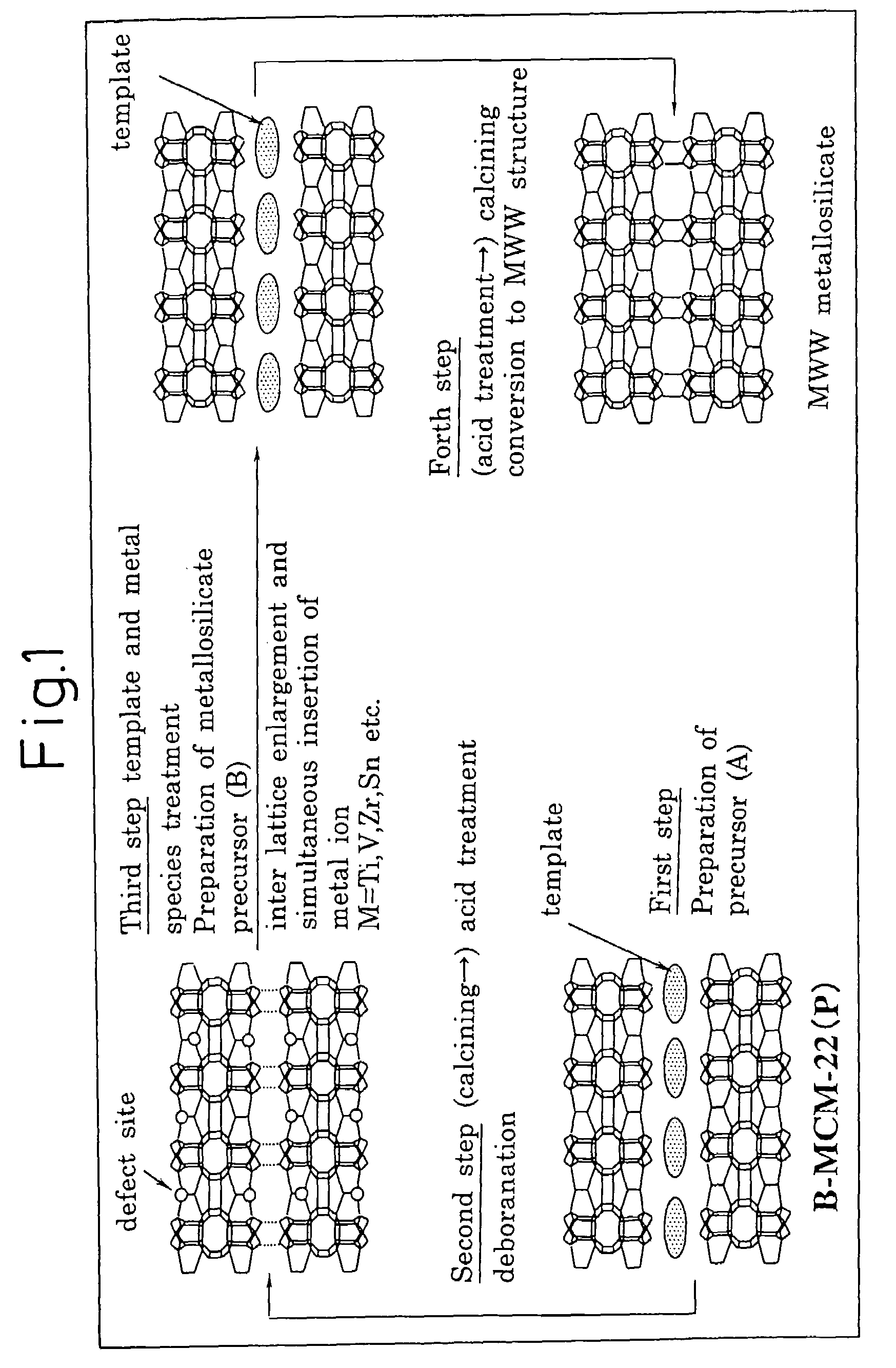

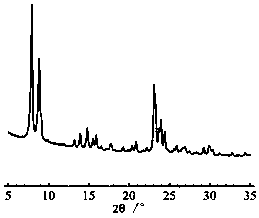

Mww type zeolite substance, precursor substance therefor, and process for producing these substances

ActiveUS20050158238A1Easy to synthesizeRaise the ratioAluminium compoundsMolecular sieve catalystsCompound (substance)Silicon

A process for easily synthesizing a zeolite substance containing an element having a large ionic radius in the framework at a high ratio. This process comprises the following first to fourth steps: First Step: a step of heating a mixture containing a template compound, a compound containing a Group 13 element of the periodic table, a silicon-containing compound and water to obtain a precursor (A); Second Step: a step of acid-treating the precursor (A) obtained in the first step; Third Step: a step of heating the acid-treated precursor (A) obtained in the second step together with a mixture containing a template compound and water to obtain a precursor (B); and Fourth Step: a step of calcining the precursor (B) obtained in the third step to obtain a zeolite substance.

Owner:SHOWA DENKO KK

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

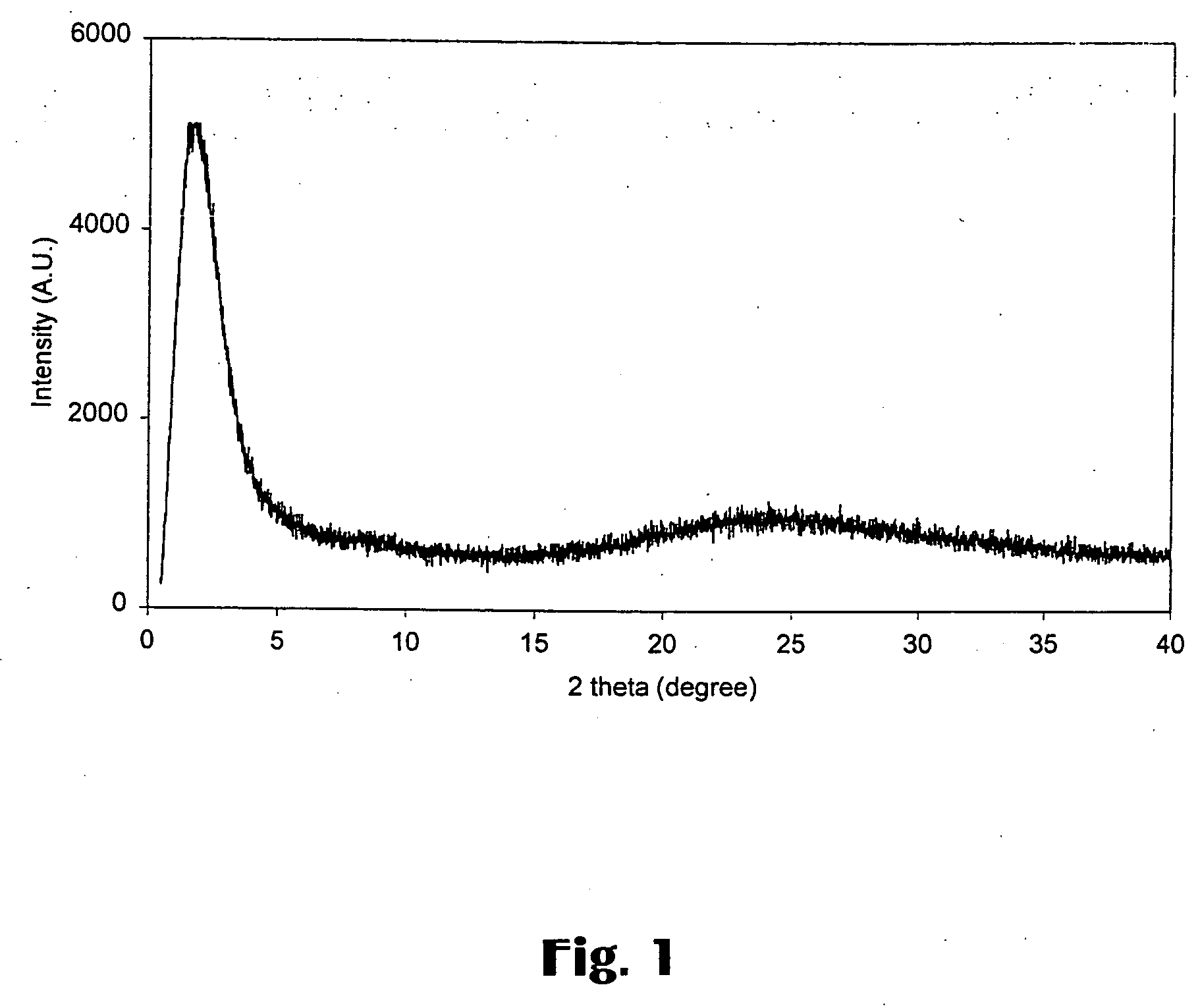

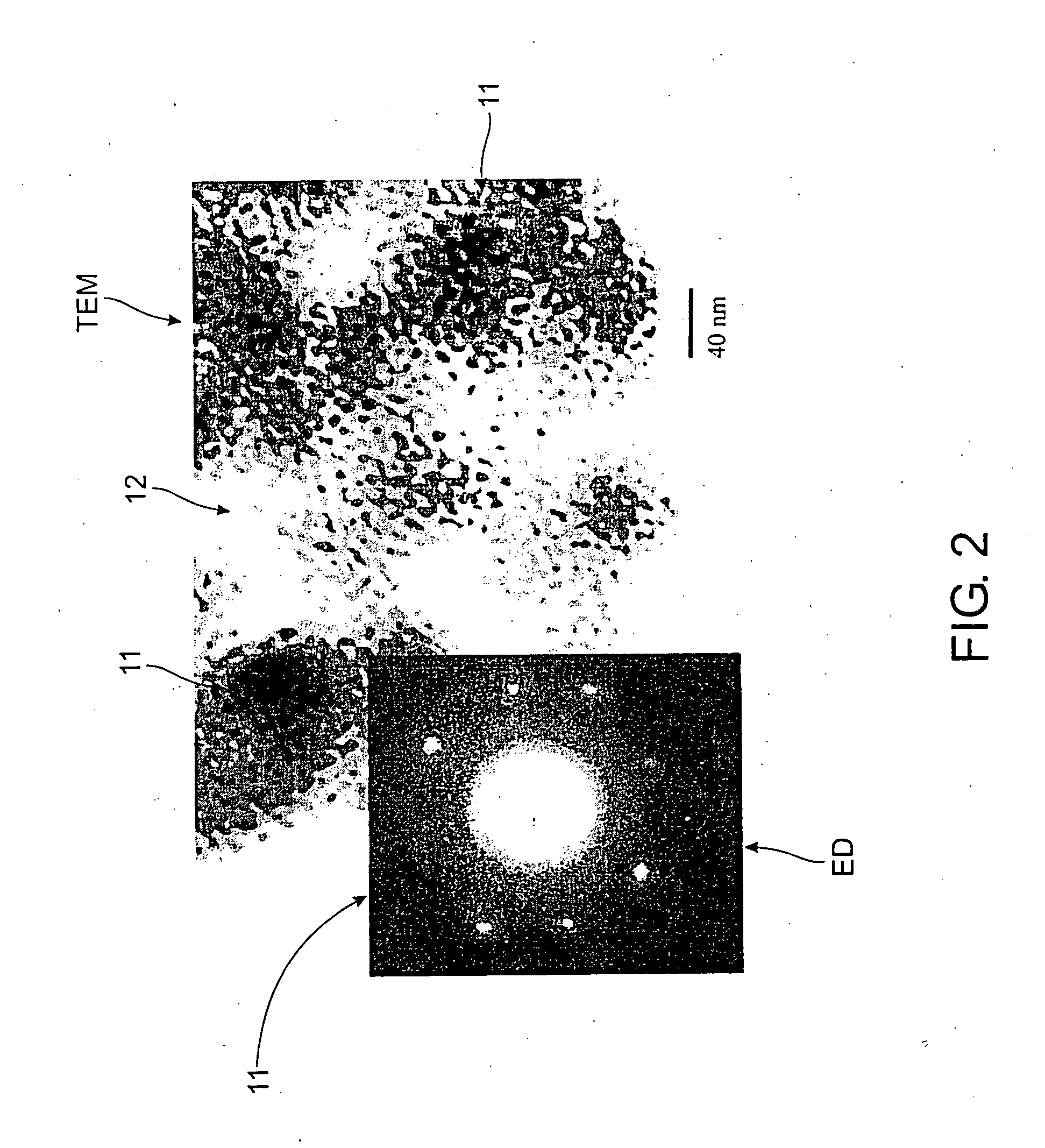

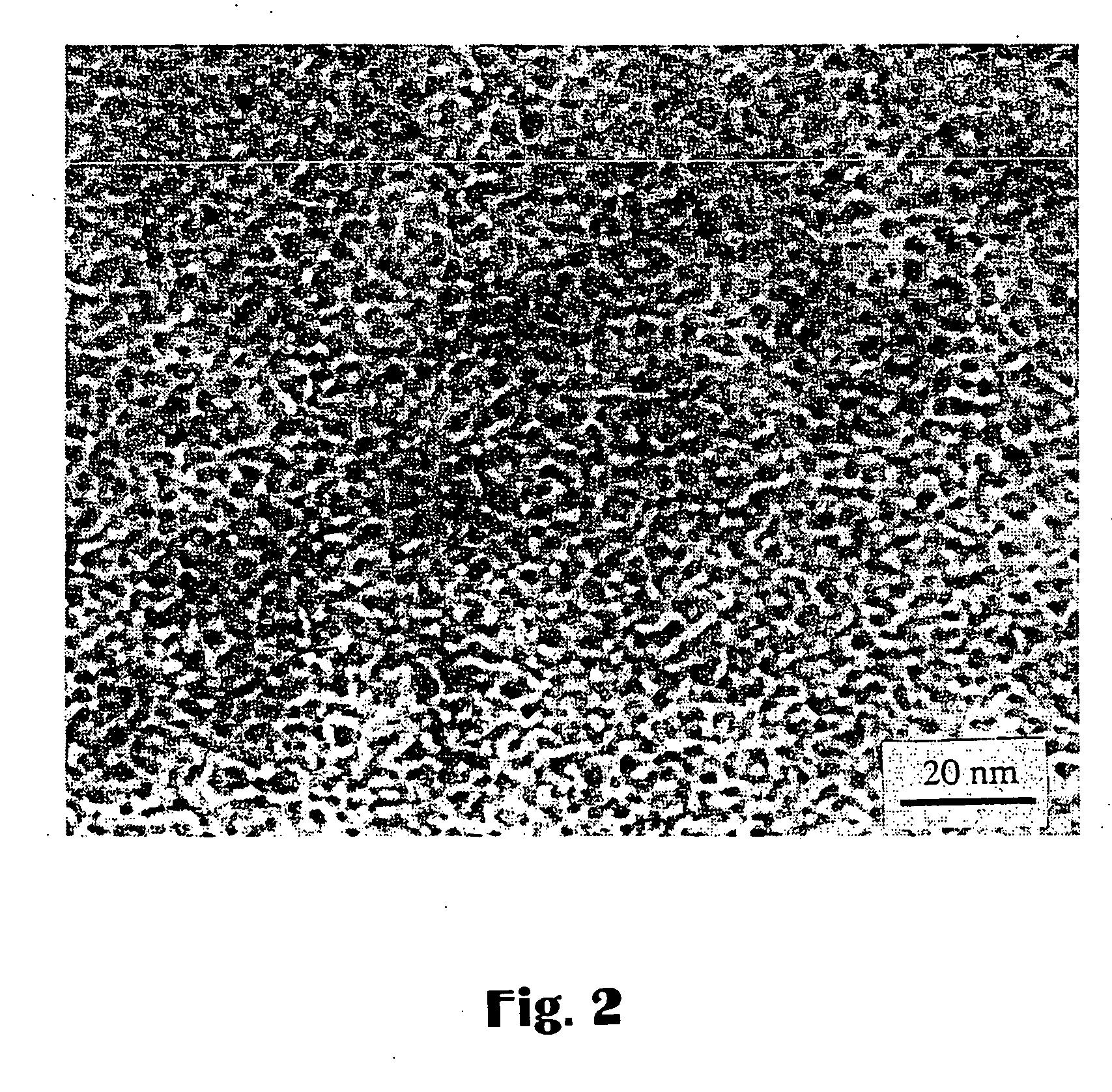

Mesostructured material incorporating particles of nanometric dimensions

InactiveUS6866925B1High crystallinityNanostructure manufactureSilicaMesoporous materialCrystallinity

The invention concerns a heat-stable ordered mesoporous or mesostructured material comprising a mineral phase wherein are dispersed particles of nanometric dimension at least partly crystaline, the global crystallinity index of said mesostructured or ordered mesoporous material being less than 10% in volume. The invention also concern a method for obtaining such a material.

Owner:RHODIA CHEM SA

Crystalline MWW-type titanosilicate catalyst for producing oxidized compound, production process for the catalyst, and process for producing oxidized compound by using the catalyst

InactiveUS20040092757A1Material nanotechnologyPreparation by oxidation reactionsDouble bondOxidizing agent

A crystalline titanosilicate catalyst which is usable as a catalyst in the oxidation reaction of a compound having a carbon-carbon double bond and at least one other functional group, a process for producing the catalyst, and a process for producing an oxidized compound by an oxidation reaction using the catalyst. It has been found that a crystalline titanosilicate having a structural code of MWW effectively functions as a catalyst in an oxidation reaction of a compound having a carbon-carbon double bond and at least one other functional group wherein the carbon-carbon double bond of the compound is oxidized by using a peroxide as an oxidizing agent, thereby to highly selectively provide an intended oxidized compound.

Owner:SHOWA DENKO KK

Rapid synthesis of beta zeolites

ActiveUS9108190B1Shorten the timeShorten the compositing timeSugar derivativesMolecular sieve catalystsIsomerizationHeteroatom

The invention provides methods for rapidly synthesizing heteroatom containing zeolites including Sn-Beta, Si-Beta, Ti-Beta, Zr-Beta and Fe-Beta. The methods for synthesizing heteroatom zeolites include using well-crystalline zeolite crystals as seeds and using a fluoride-free, caustic medium in a seeded dry-gel conversion method. The Beta zeolite catalysts made by the methods of the invention catalyze both isomerization and dehydration reactions.

Owner:UNIV OF MASSACHUSETTS

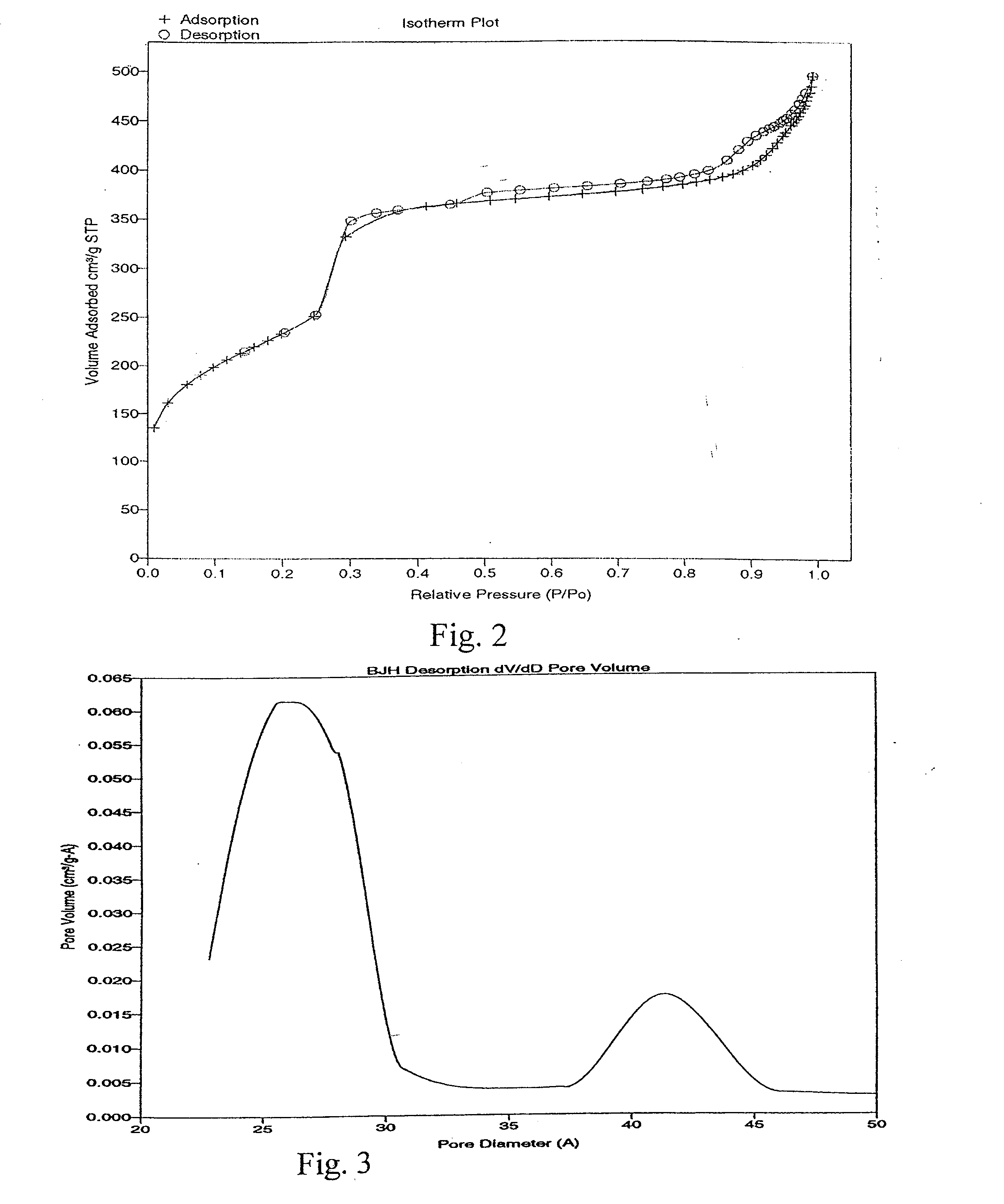

Mesoporous material with active metals

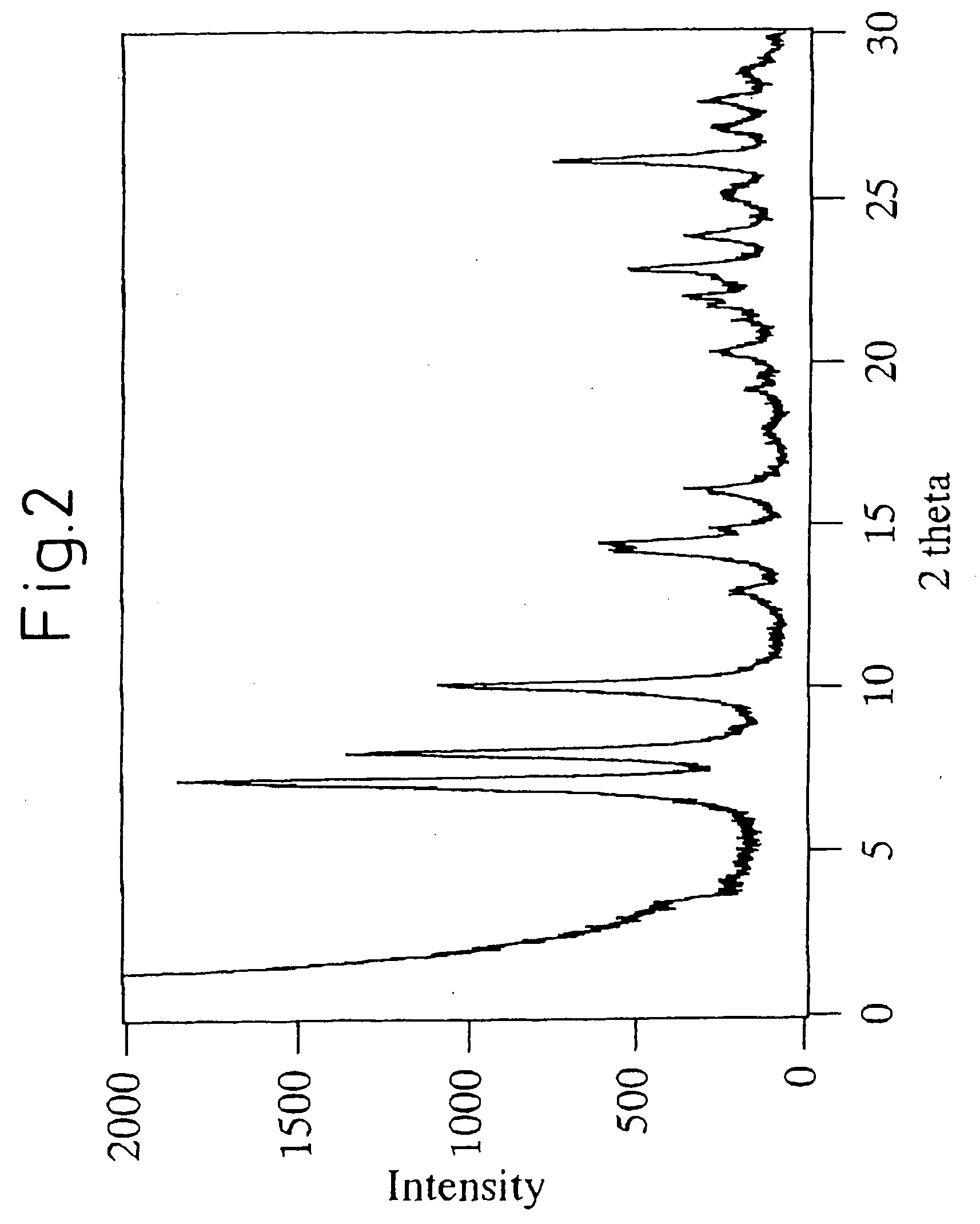

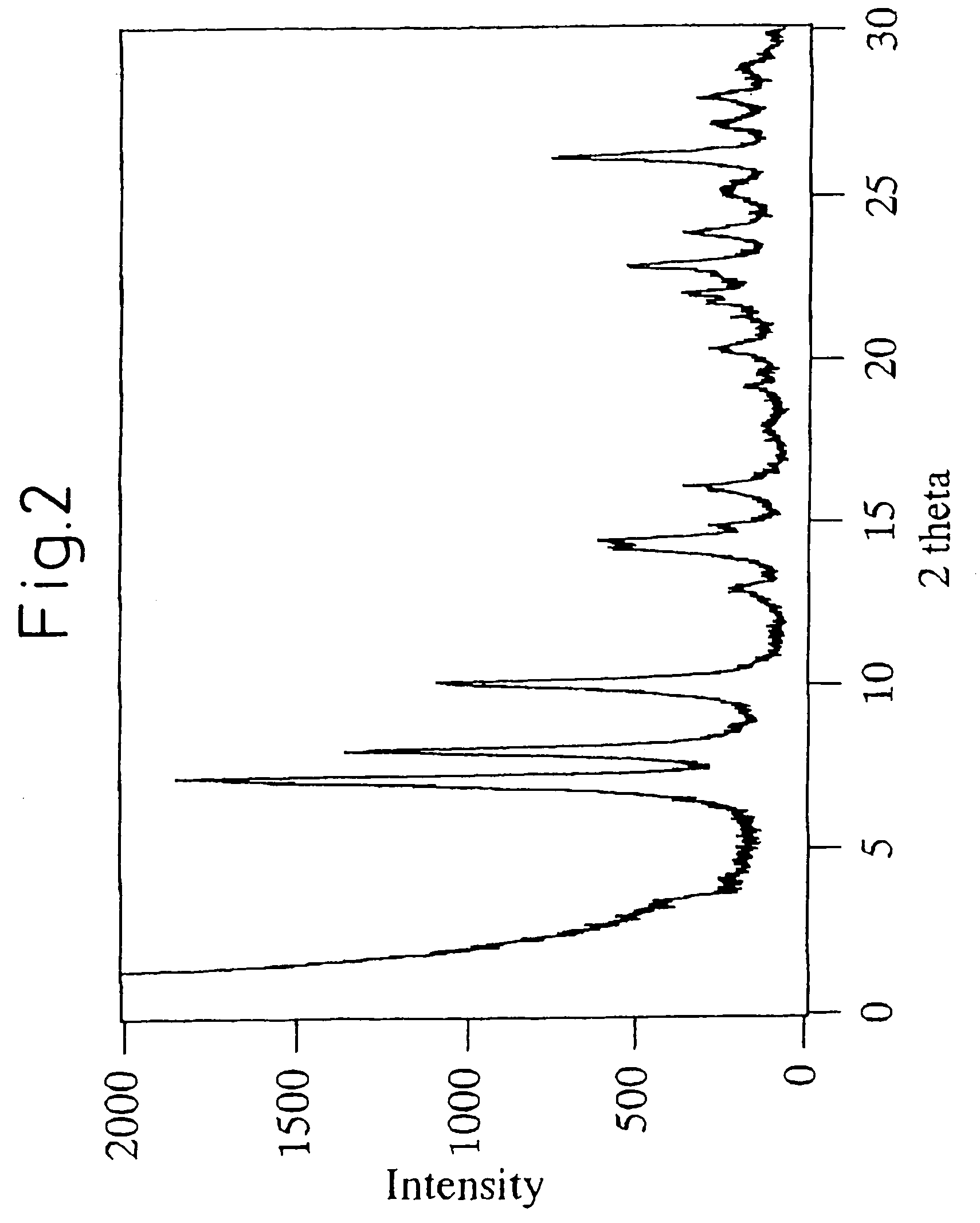

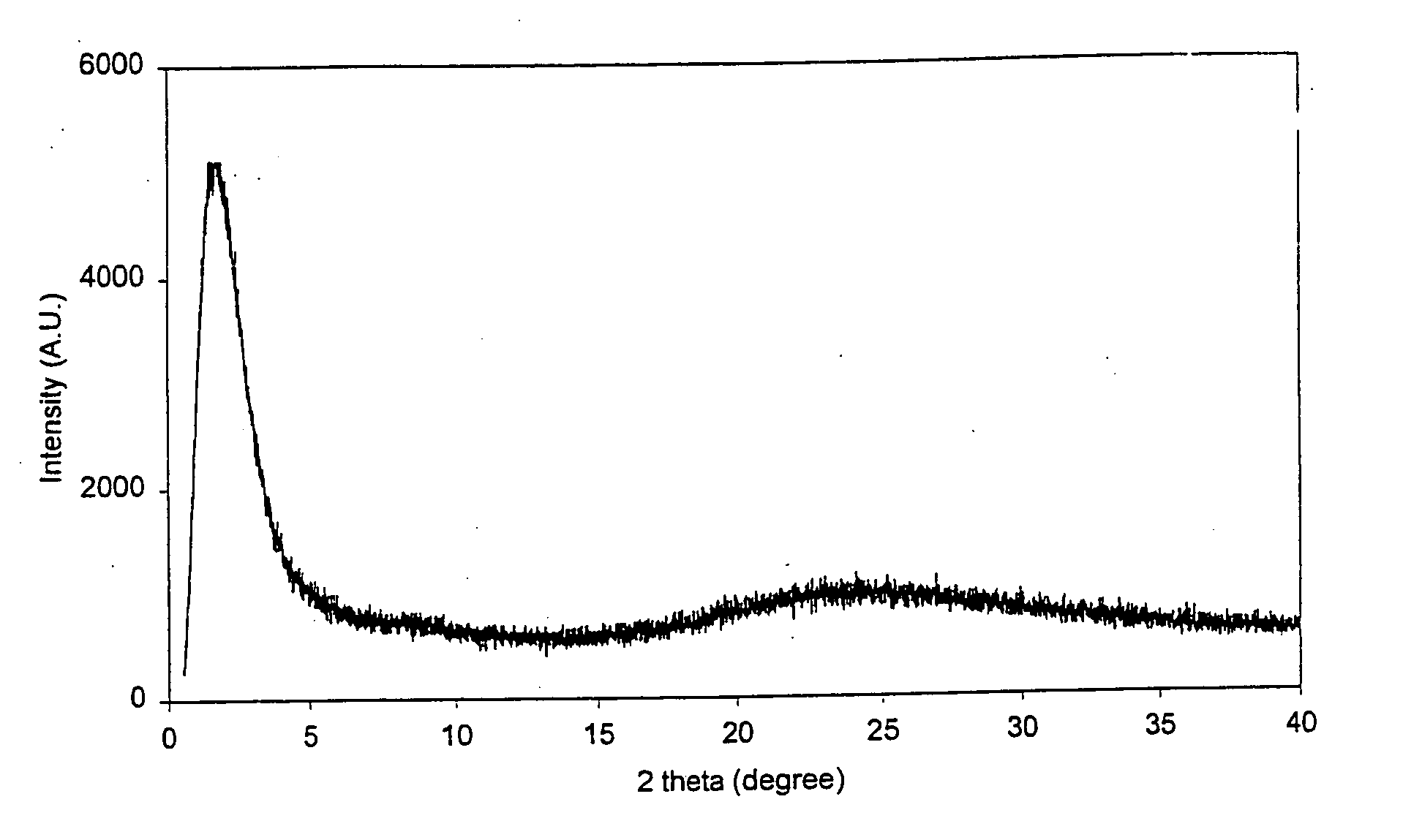

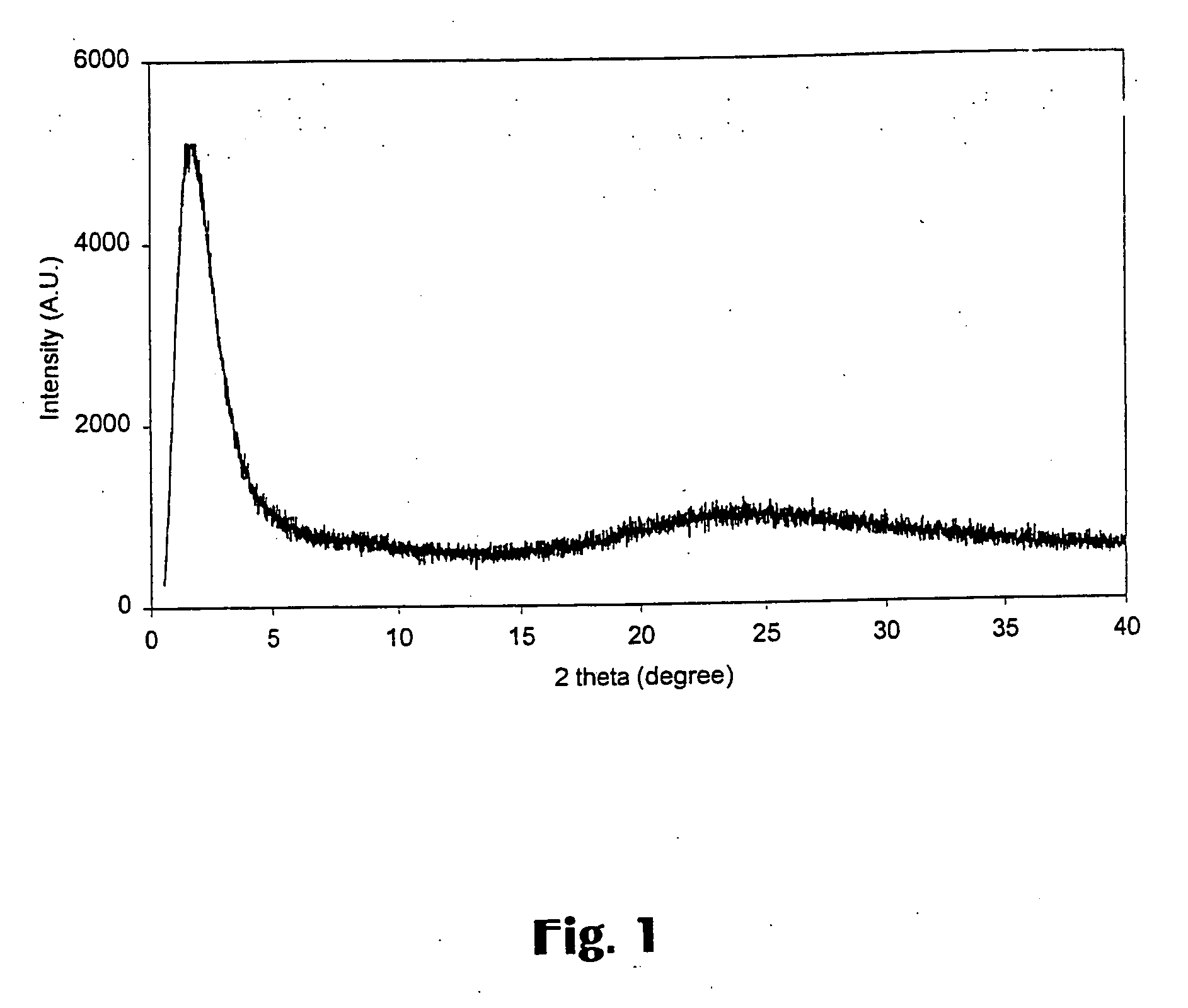

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of refractory oxide containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2 theta (θ). The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:LUMMUS TECH INC

MWW type zeolite substance, precursor substance therefor, and process for producing these substances

ActiveUS7326401B2Easy to synthesizeRaise the ratioAluminium compoundsMolecular sieve catalystsSiliconPrecursor substance

A process for easily synthesizing a zeolite substance containing an element having a large ionic radius in the framework at a high ratio. This process comprises the following first to fourth steps:First Step:a step of heating a mixture containing a template compound, a compound containing a Group 13 element of the periodic table, a silicon-containing compound and water to obtain a precursor (A);Second Step:a step of acid-treating the precursor (A) obtained in the first step;Third Step:a step of heating the acid-treated precursor (A) obtained in the second step together with a mixture containing a template compound and water to obtain a precursor (B); andFourth Step:a step of calcining the precursor (B) obtained in the third step to obtain a zeolite substance.

Owner:SHOWA DENKO KK

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:SHAN ZHIPING +5

Method for synthesizing a crystalline metalloaluminosilicate by direct synthesis

The invention concerns a method for preparing a crystalline metalloaluminosilicate by direct synthesis using at least one source of aluminium and, as the source of silicon and as the source of at least one other metal M, at least one lamellar siliceous material containing metals in its framework. The invention also concerns the novel solids obtained, in particular solids with a given zeolitic structure containing particular metals in its zeolitic framework.

Owner:INST FR DU PETROLE

Preparation of titanosilicate zeolite TS-1

InactiveUS20070059237A1Reduce processing stepsRetain its shapeAluminium compoundsMolecular sieve catalystsCrystallizationExternal Liquid

A method is disclosed for preparing crystalline titanosilicate zeolite TS-1 from a reaction mixture containing only sufficient water to produce zeolite TS-1. In one embodiment, the reaction mixture is self-supporting and may be shaped if desired. In the method, the reaction mixture is heated at crystallization conditions and in the absence of an added external liquid phase, so that excess liquid need not be removed from the crystallized product.

Owner:CHEVROU USA INC

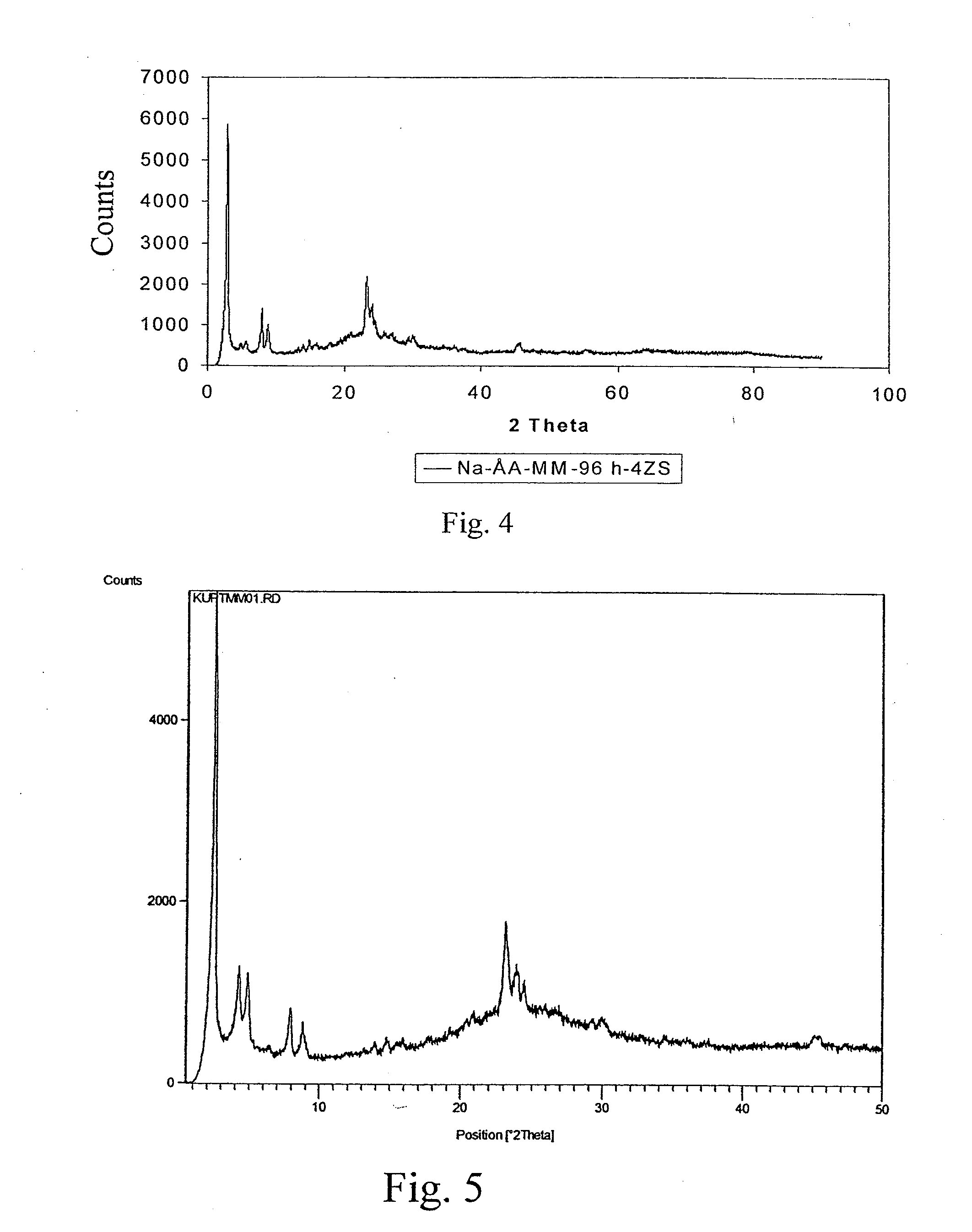

Method of the preparation of microporous crystalline molecular sieve possessing mesoporous frameworks

InactiveUS20090156389A1Easy to diffuseEasy for adsorptionAluminium compoundsSilicaChemical treatmentMolecular sieve

The present invention relates to a method of preparing a microporous crystalline molecular sieve Inorganic gel having mesoporous skeleton, comprising following steps: (a) adding a meso-SDA (meso-Structure Directing Agent) into a gel composition of synthesizing molecular sieve, (b) subjecting the mixture obtained in the above step (a) to crystallization by a hydrothermal reaction, a microwave reaction, a dry-gel synthesis, etc., and (c) removing selectively organic materials from the resulted material obtained in the above step (b) by a calcination or a chemical treatment. Molecular sieve having mesoporous skeleton synthesized by the present invention exhibits, as compared with conventional zeolite, a good molecule diffusion ability and a greatly improved catalytic activity.

Owner:KOREA ADVANCED INST OF SCI & TECH

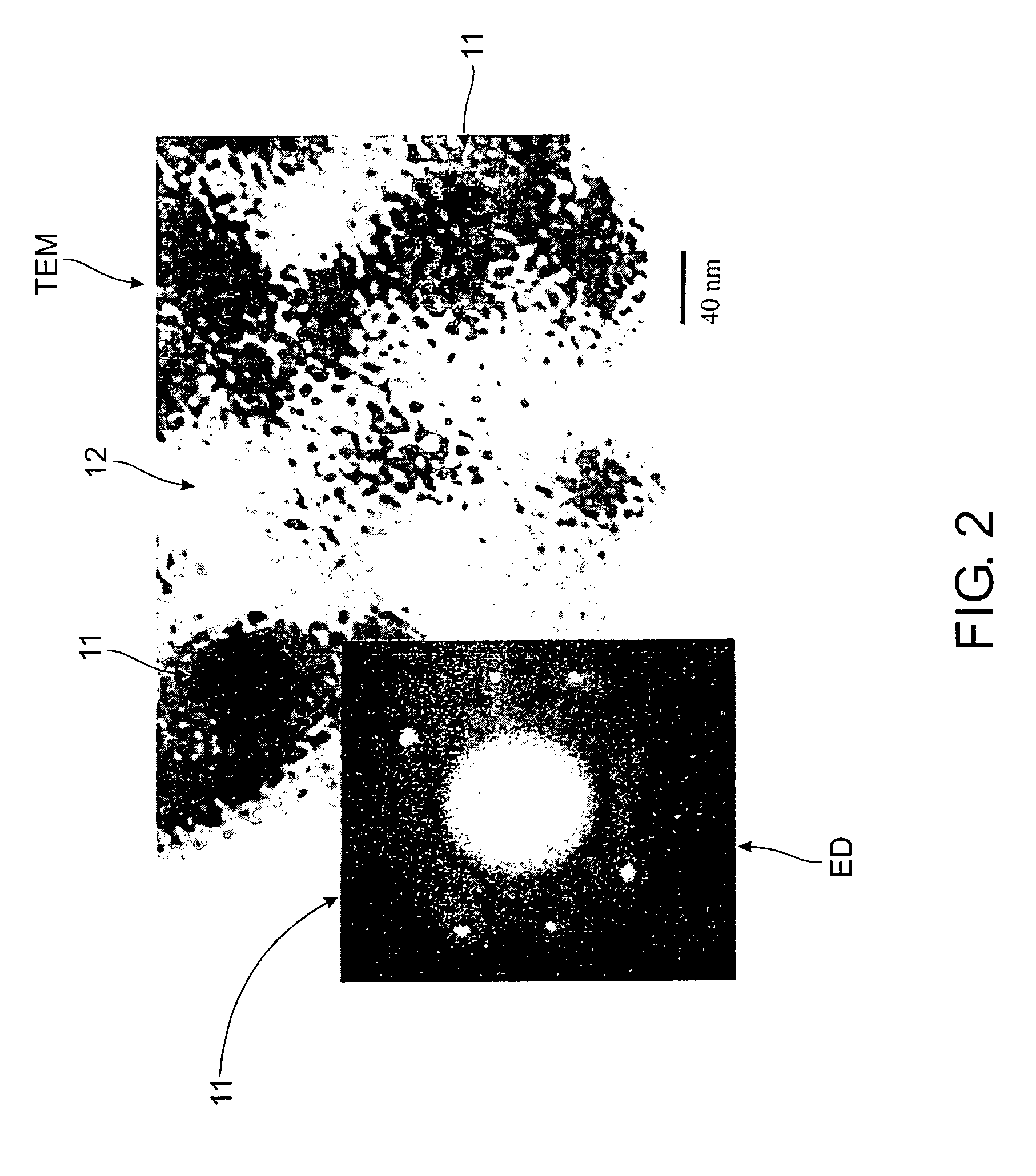

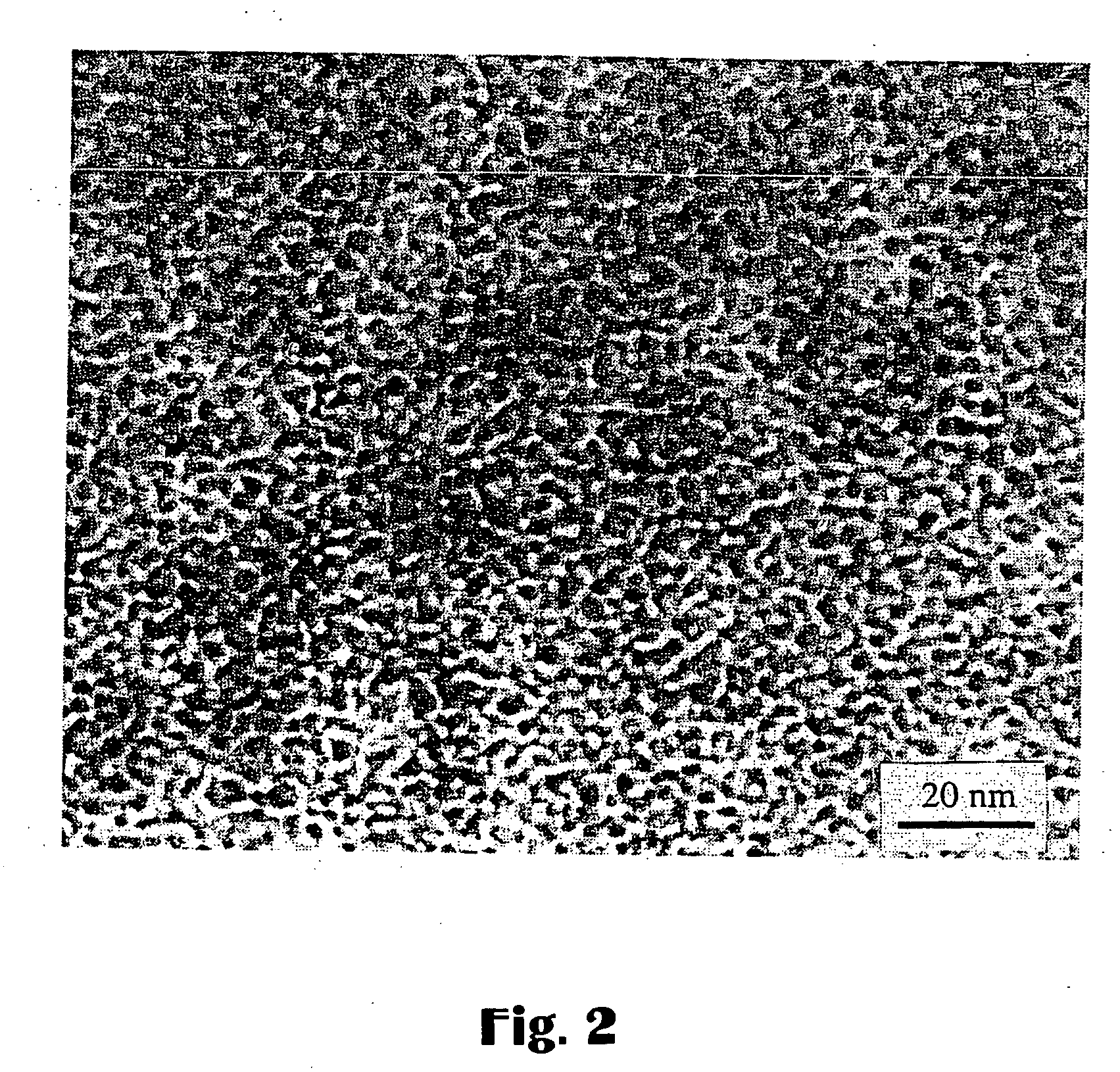

Inorganic material made of spherical particles of specific size and having metallic nanoparticles trapped in a mesostructured matrix

An inorganic material is described, which consists of at least two elementary spherical particles, each one of said spherical particles comprising metallic nanoparticles of size ranging between 1 and 300 nm and a mesostructured matrix based on an oxide of at least one element X selected from the group made up of silicon, aluminium, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium, and the mixture of at least two of these elements, said mesostructured matrix having a pore diameter ranging between 1.5 and 30 nm and having amorphous walls of thickness ranging between 1 and 30 nm, said elementary spherical particles having a diameter D greater than 10 μm and less than or equal to 100 μm. Said material can also contain zeolite nanocrystals trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

Process for making titanium-MWW zeolite

ActiveUS8124555B2Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsTitaniumBoron

Titanium-MWW zeolite is prepared by heating a gel formed from a titanium compound, a silicon source, a boron source, an MWW-templating agent, and water at a temperature in the range of 35° C. to 75° C. for a period of 8 to 30 hours to form a pre-crystallized gel, and heating the pre-crystallized gel to a temperature in the range of 160° C. to 190° C. for a period of 5 or more days to form the titanium-MWW zeolite. The zeolite, after it is contacted with an acid, is useful in olefin epoxidation with hydrogen peroxide.

Owner:LYONDELL CHEM TECH LP

Process for making titanium-MWW zeolite

ActiveUS20110190517A1Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsTitaniumBoron

Titanium-MWW zeolite is prepared by heating a gel formed from a titanium compound, a silicon source, a boron source, an MWW-templating agent, and water at a temperature in the range of 35° C. to 75° C. for a period of 8 to 30 hours to form a pre-crystallized gel, and heating the pre-crystallized gel to a temperature in the range of 160° C. to 190° C. for a period of 5 or more days to form the titanium-MWW zeolite. The zeolite, after it is contacted with an acid, is useful in olefin epoxidation with hydrogen peroxide.

Owner:LYONDELL CHEM TECH LP

Method of manufacturing mesoporous zeolite agglomerates

A method of preparing a mesoporous zeolite material is disclosed. The method comprises forming template-occluded primary metal-doped silicate particles having an amorphous structure and aggregating the particles into mesoporous agglomerates. The amorphous structure is further transformed into a microporous nanocrystalline zeolite structure, thereby forming a mesoporous zeolitic material. Forming the mesoporous zeolite material includes removing the template from the template-occluded particles.

Owner:NALCO CO

Mesoporous silica, mesoporous silica composite material, and processes for production thereof

A mesoporous silica has uniform mesopores and a periodic structure, which contains a Zr element in the form of a Si-O-Zr bond and wherein the Zr content in the Si-O-Zr bond, represented by [Zr / (Si+Zr)] is 0.05 to 20 mole %. The mesoporous silica is superior in alkali resistance and is suitably used particularly as a separation membrane (e.g. a ceramic membrane) and a catalytic support for solid-liquid system, in which an alkaline liquid may be used.

Owner:NGK INSULATORS LTD +1

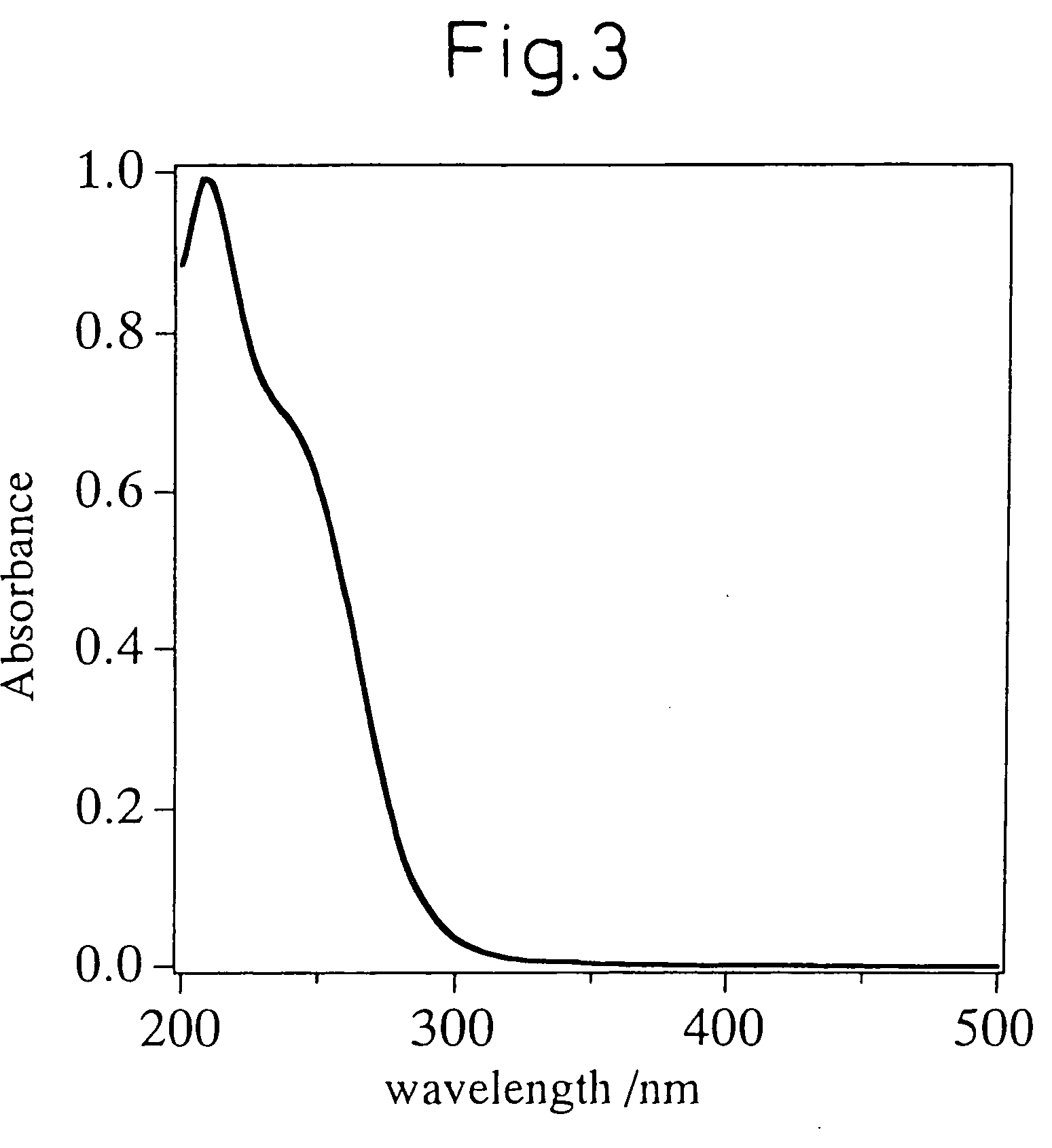

Process for the microwave induced preparation of crystalline microporous titanium silicalite

InactiveUS6387349B1Raise the ratioImprove solubilityAluminium compoundsMolecular sieve catalystsPhysical chemistryTitanium

The present invention relates to a process for the microwave induced preparation of crystalline, microporous titanium silicalite. More particularly; the present invention relates to a process for the preparation of crystalline microporous titanium silicalite of the formula: xTiO2:(1-x)SiO2 wherein x is greater than 0.043 and less than or equal to 0.11. These silicalites, prepared under microwave irradiation have the same physico-chemical properties as titanium silicalite prepared by hydrothermal methods.

Owner:COUNCIL OF SCI & IND RES

Mesoporous nanocrystaline zeolite composition and preparation from amorphous colloidal metalosilicates

Owner:ECOLAB USA INC

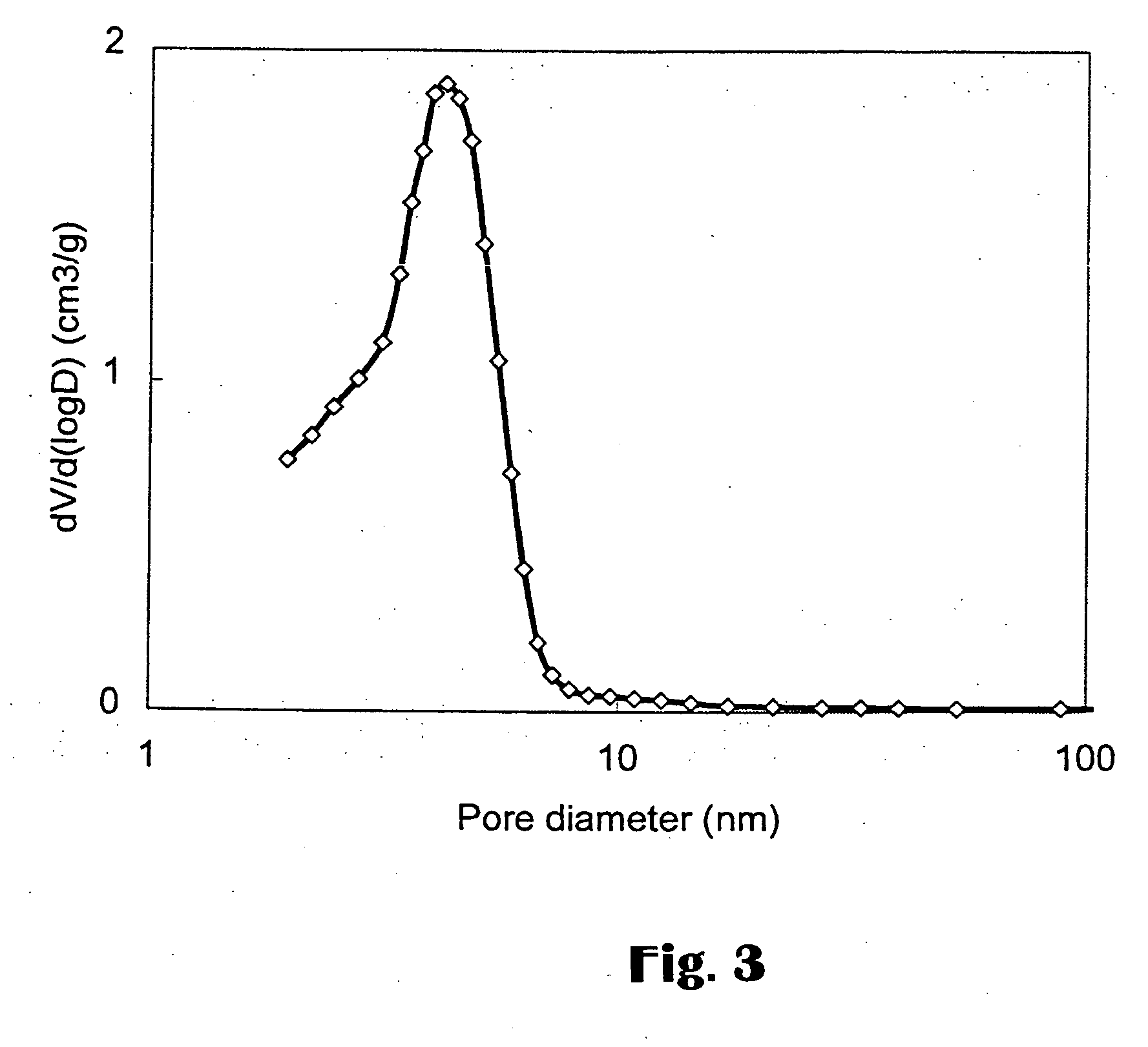

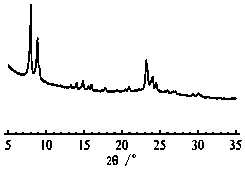

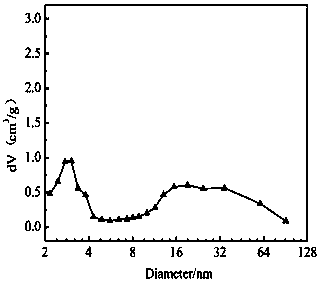

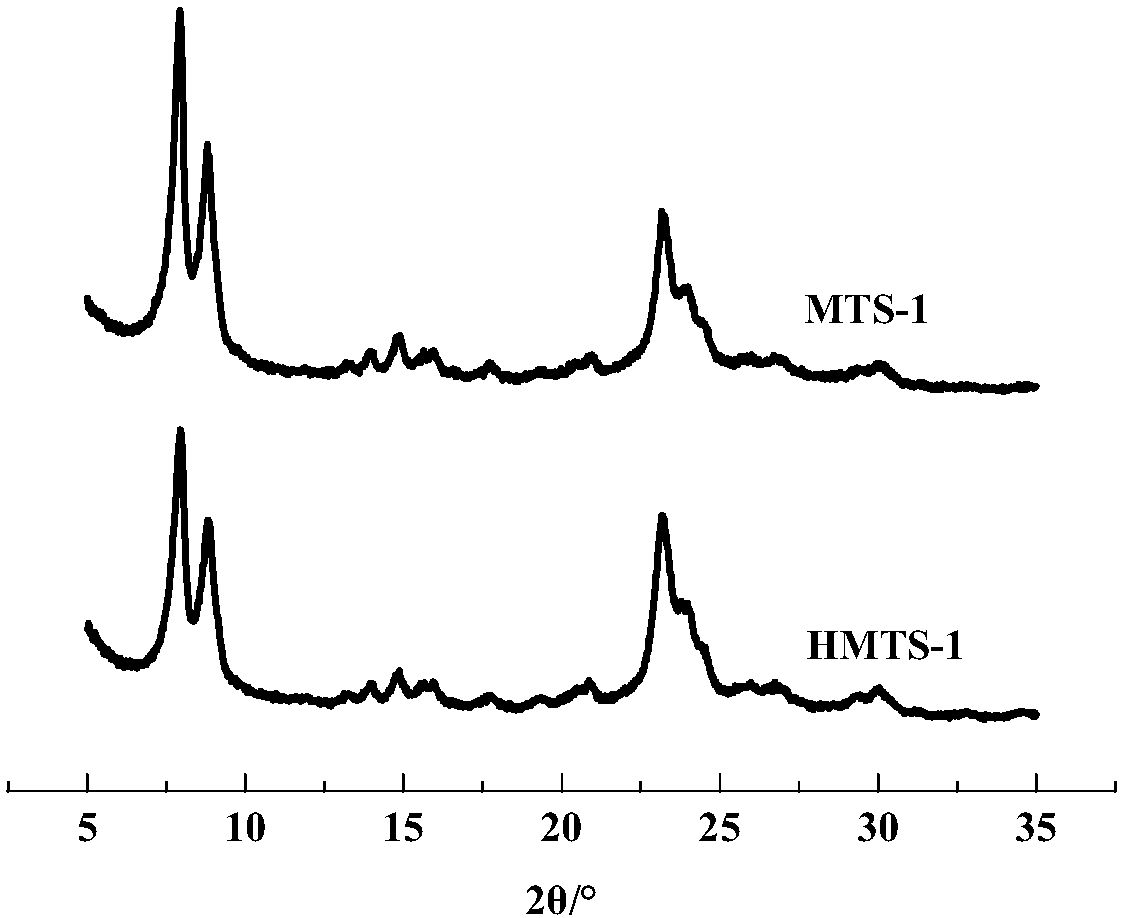

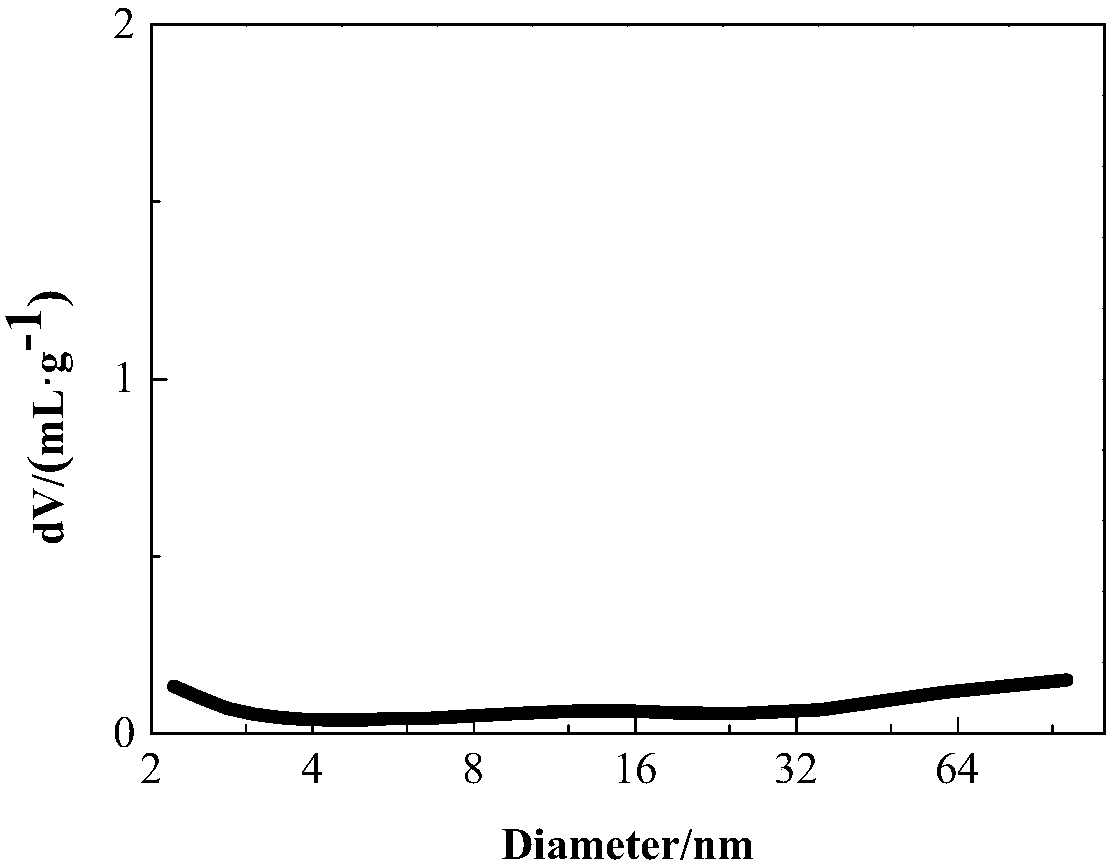

Hierarchical porous titanium-silicon molecular sieve as well as preparation method thereof and olefin epoxidation method

ActiveCN108726528AIncreased mesopore volumeImprove conversion rateOrganic chemistryMolecular sieve catalystsMolecular sievePore diameter

The invention relates to a hierarchical porous titanium-silicon molecular sieve as well as a preparation method thereof and an olefin epoxidation method. The hierarchical porous titanium-silicon molecular sieve has a grain size of 600-700 nm, has relative crystallinity of 55-64%, has a specific surface area of 660-725 m<2> / g, has a total pore volume of 0.55-0.7 cm<3> / g, and has a mesoporous volumeof 0.3-0.5 cm<3> / g; the volumes of pores with the pore diameters of 0.5-2 nm of the hierarchical porous titanium-silicon molecular sieve account for 15-36% of the total pore volume, the volumes of pores with the pore diameters of 2-4 nm account for 1-25% of the total pore volume, and the volumes of the pores with the pore diameters of 4-16 nm account for 20-45% of the total pore volume, and the volumes of the pores with the pore diameters greater than 16 nm account for 20% or lower of the total pore volume. The hierarchical porous titanium-silicon molecular sieve disclosed by the invention isgreater in mesoporous volume, is higher in proportion of the total pore volume, and can remarkably increase an olefin conversion rate and can improve selectivity of alkyleneoxide while used for olefin oxidization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the preparation of titanium containing molecular sieves

InactiveUS6054112ASimpler and less liable to cause problemsAluminium compoundsOrganic chemistryMolecular sieveTitanium

Titanium-containing molecular sieves are prepared by adding an aqueous template solution to a mixture of tetraalkyl orthosilicate and tetraalkyl orthotitanate, crystallizing the reaction mixture in an autoclave and separating the solid obtained optionally, the solid is washed and calcined. The titanium-containing molecular sieves can be used as catalysts, inter alia in the epoxidation of olefins.

Owner:EVONIK DEGUSSA GMBH

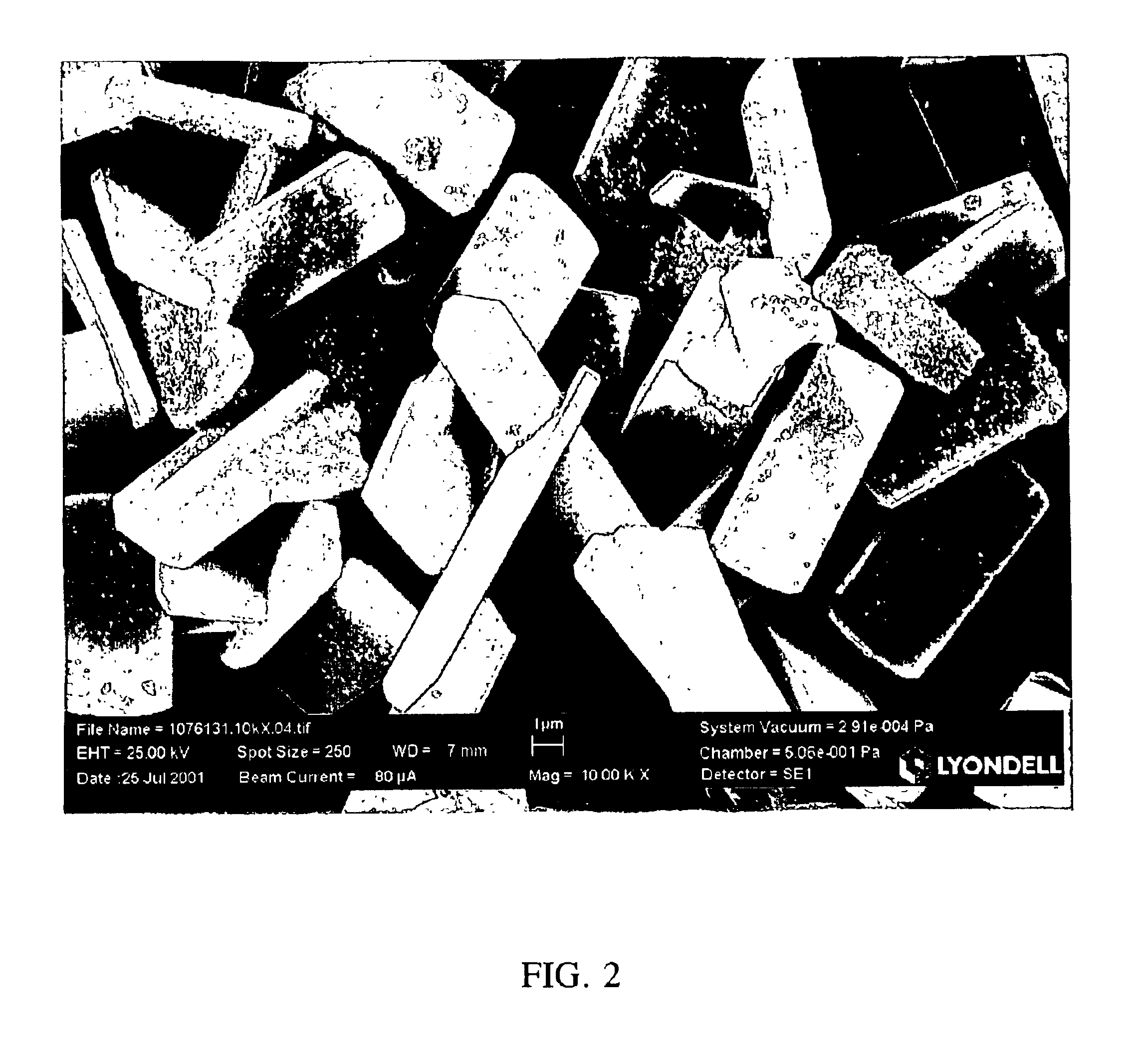

Process for direct oxidation of propylene to propylene oxide and large particle size titanium silicalite catalysts for use therein

InactiveUS6960671B2Avoid excessive additionOrganic chemistryMolecular sieve catalystsTitaniumSilicon dioxide

Large crystals of titanium silicalite or intergrowths of intergrown smaller crystals, having a mean particle size greater than 2 μm, have been found catalytically effective at commercially reasonable rates for the epoxidation of olefins in the presence of hydrogen peroxide. Crystals synthesized with a silica source having a low sodium content exhibit high levels of production and selectivity. The crystals have a low attrition rate and are easily filterable from a product stream.

Owner:LYONDELL CHEM TECH LP

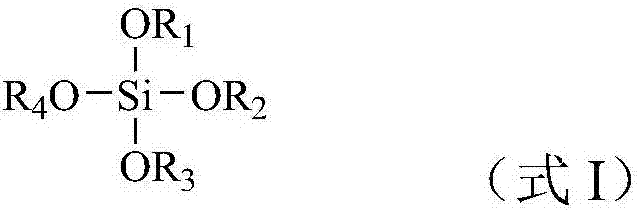

Titanium silicon molecular sieve, and preparation method and application thereof

The invention relates to a titanium silicon molecular sieve, and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a titanium source, a template tetraalkoxysilane and water, carrying out hydrolysis and remove alcohol; and (2) adding a compound with a structure as shown in a formula (I) and carrying out crystallization. The method can prepare the titanium silicon molecular sieve containing more mesopores; and the prepared titanium silicon molecular sieve is applicable to catalysis of the reactions of macromolecules.

Owner:CHINA PETROLEUM & CHEM CORP +1

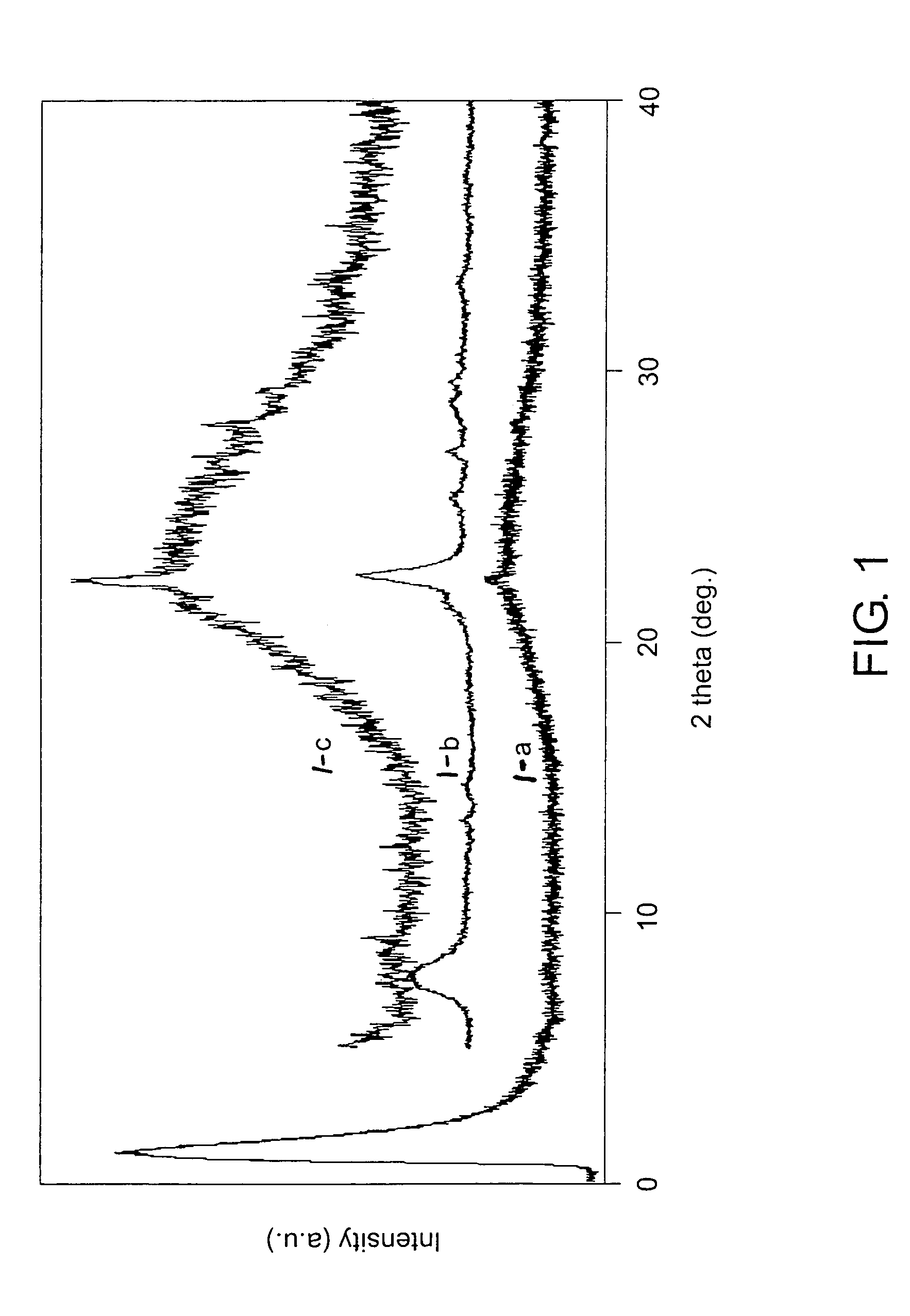

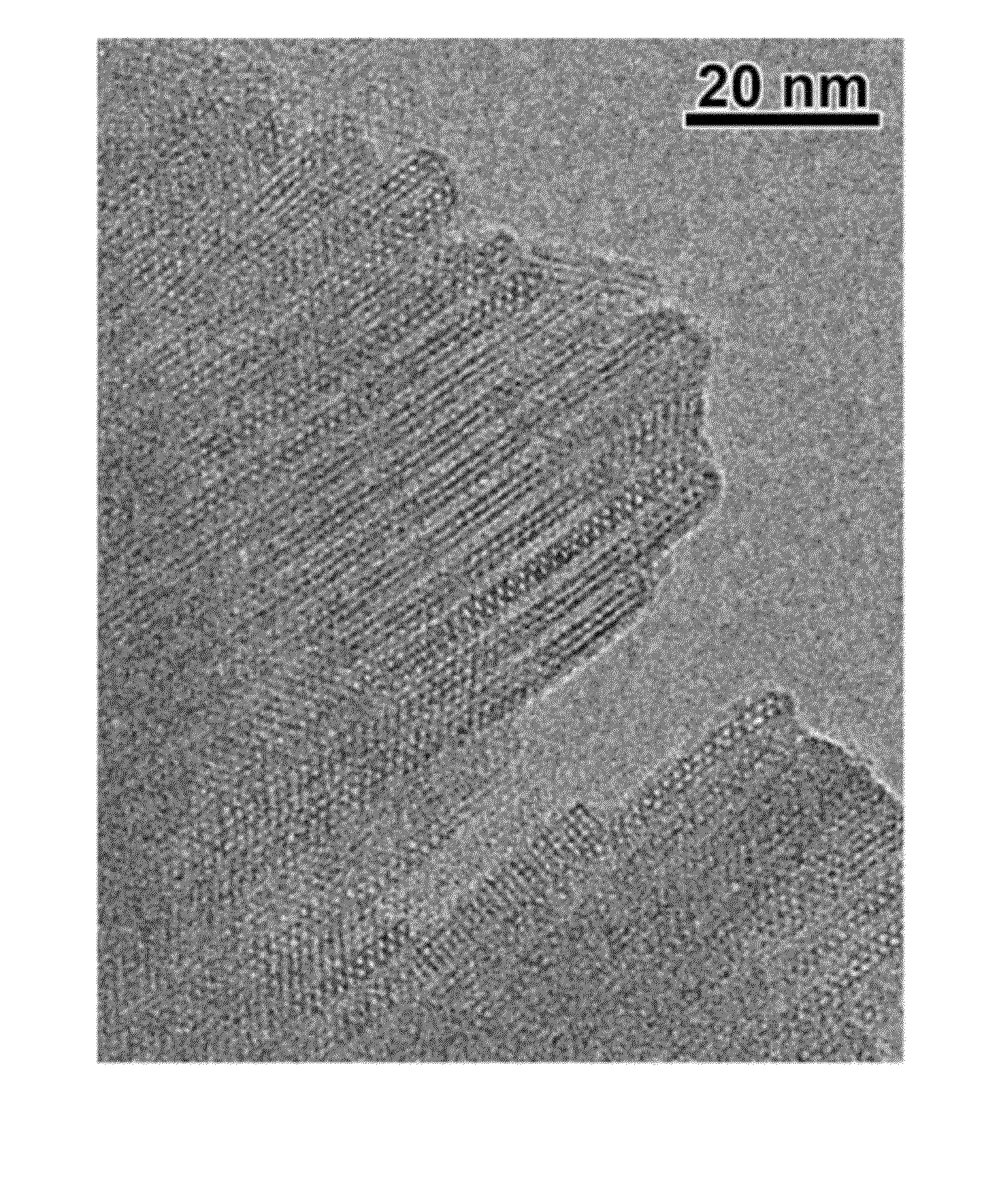

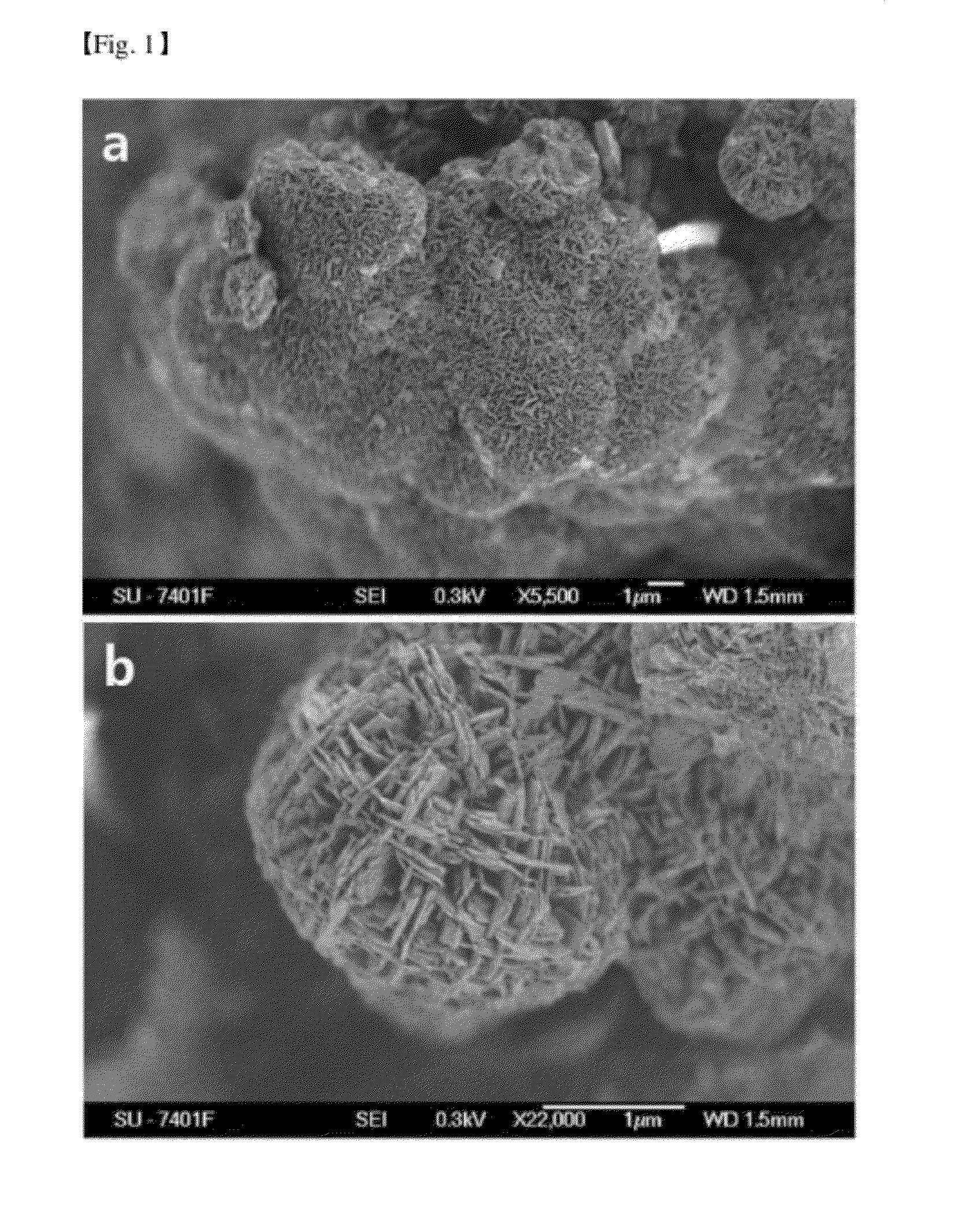

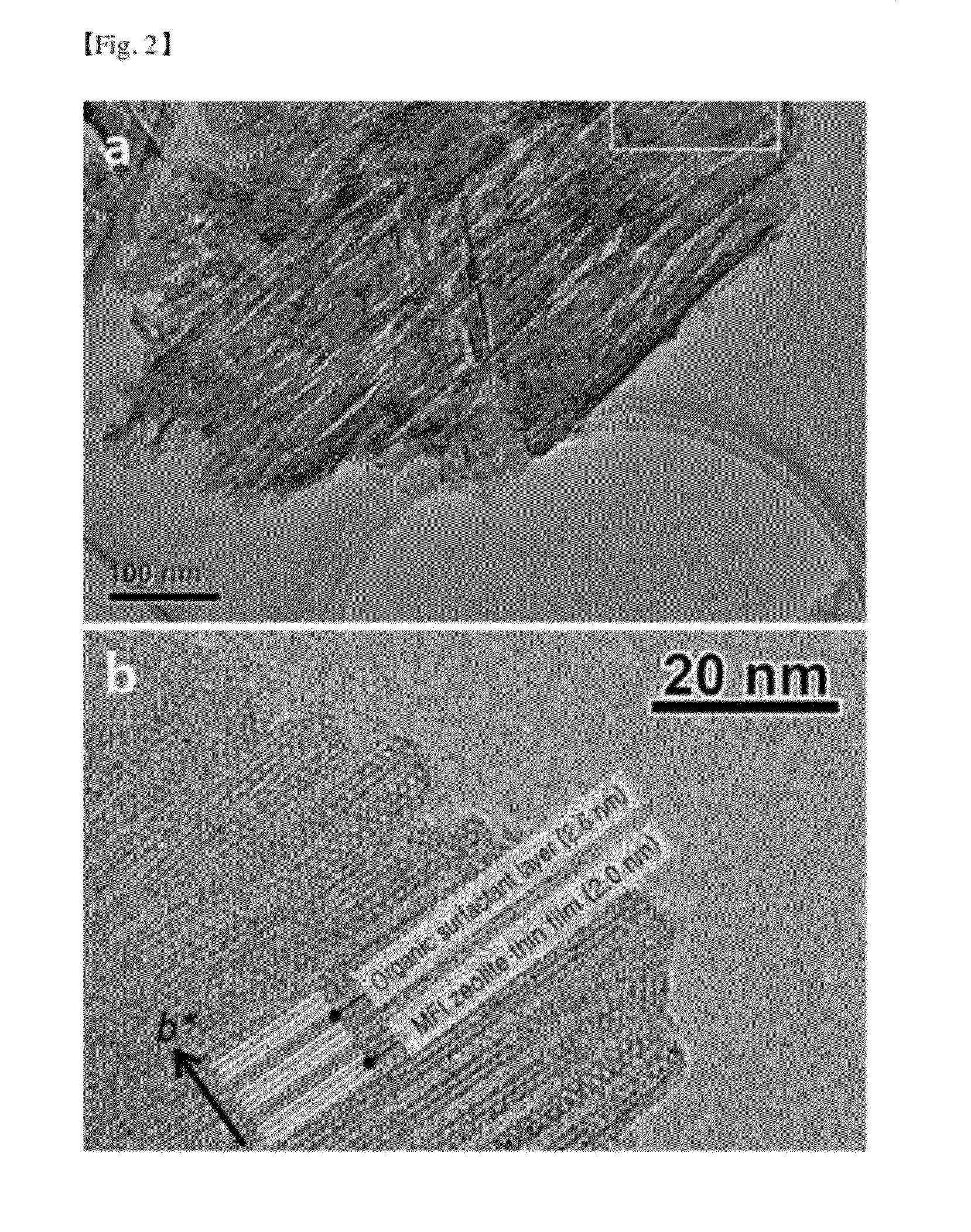

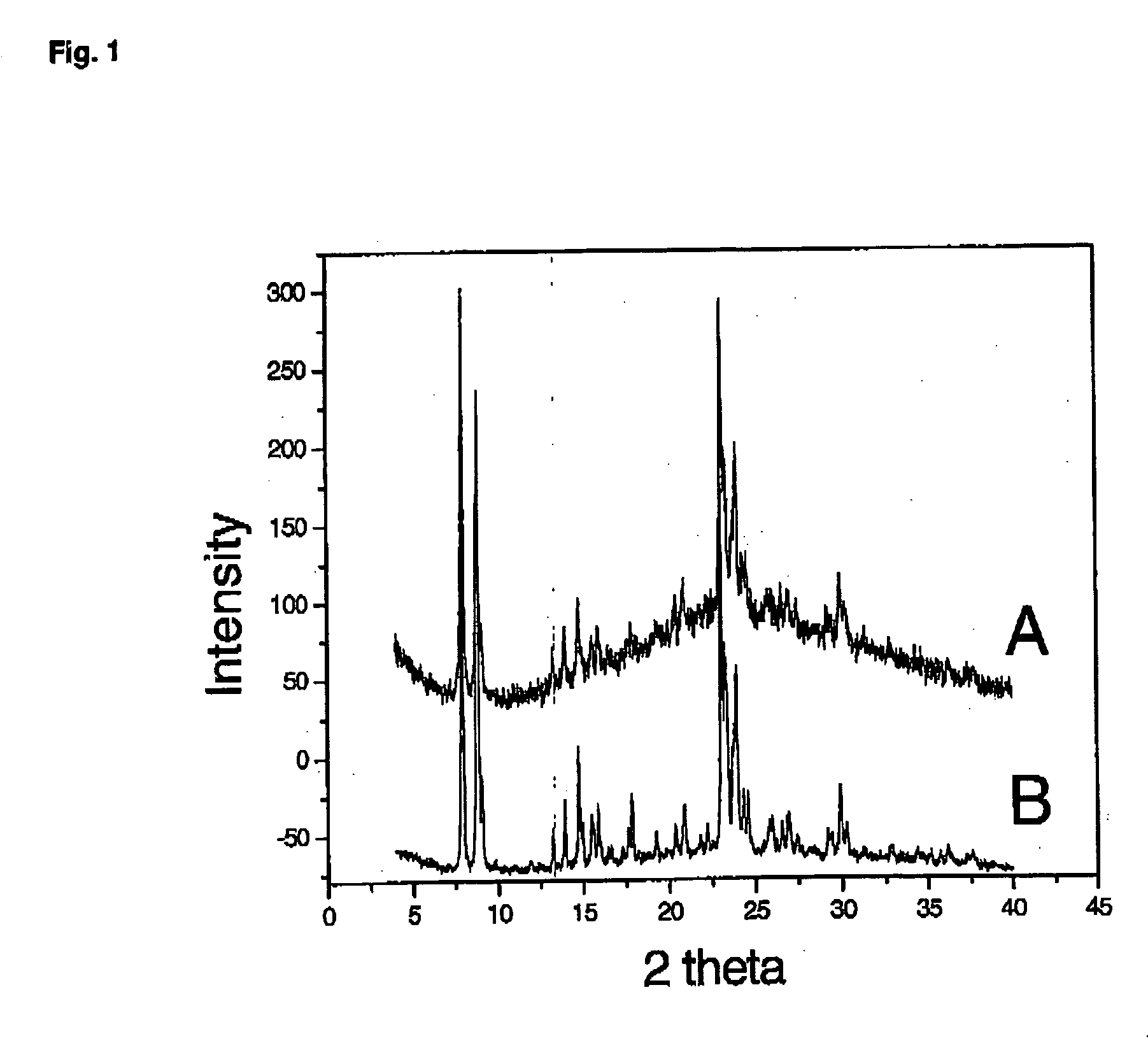

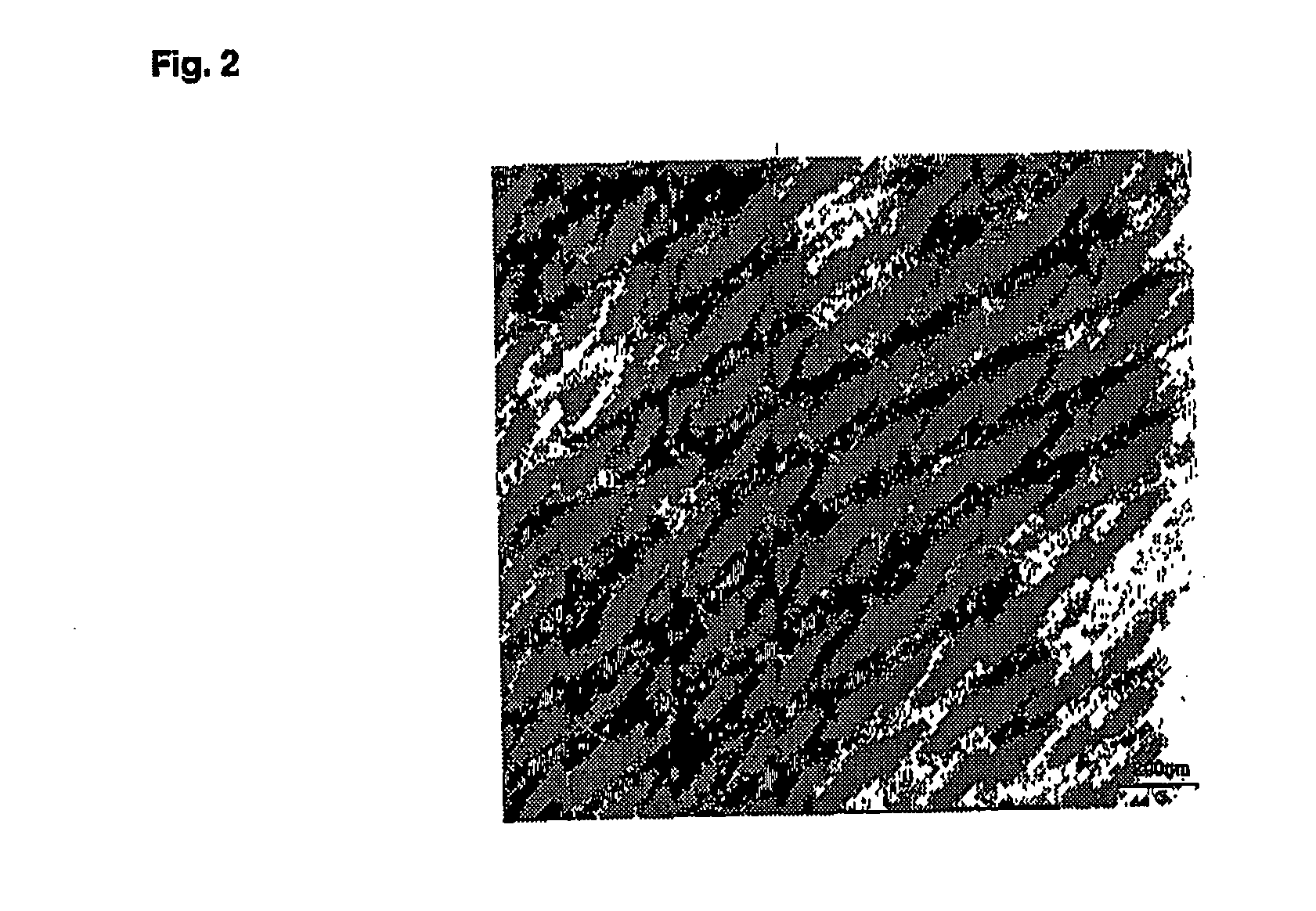

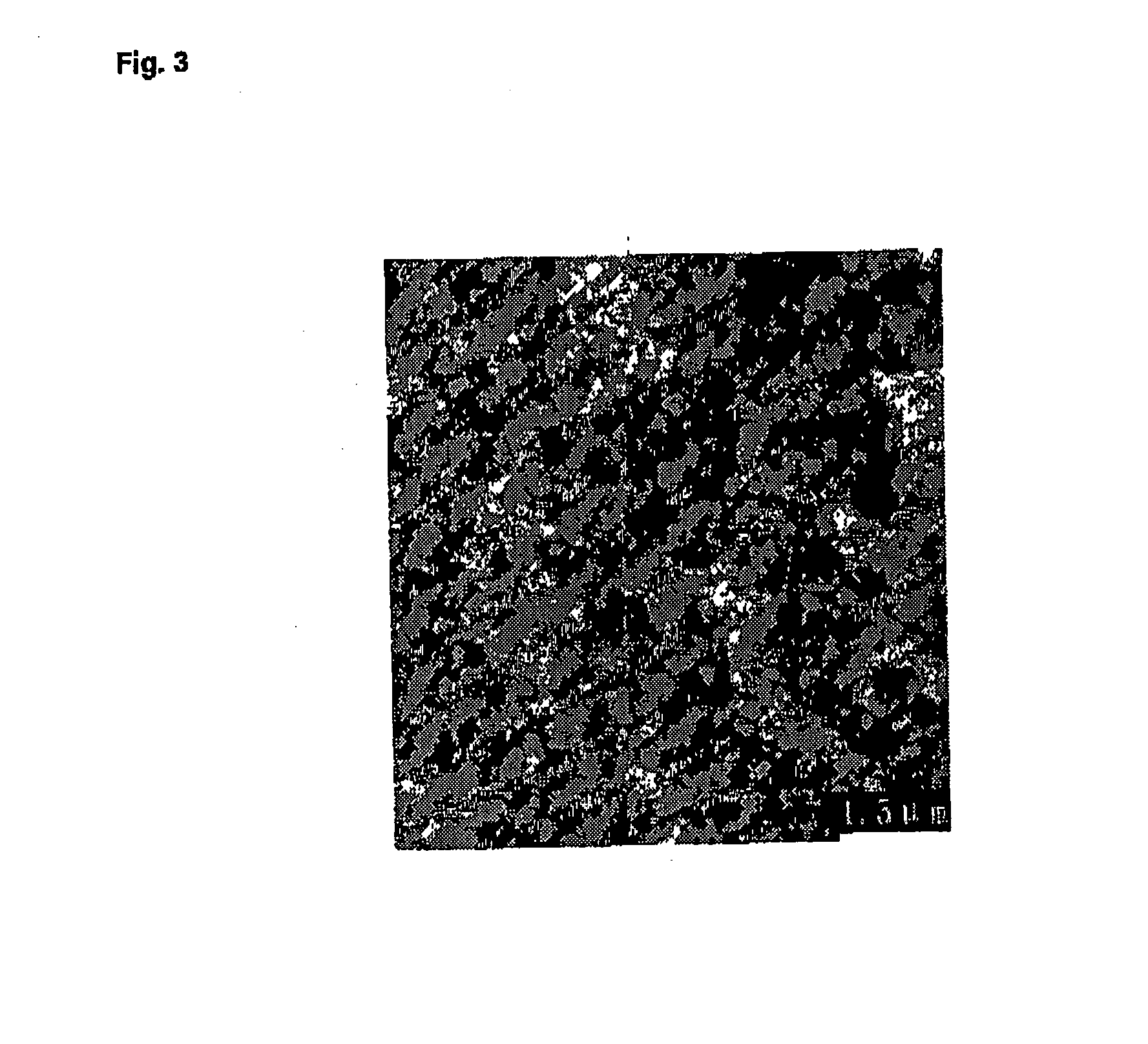

Regularly stacked multilamellar and randomly aligned unilamellar zeolite nanosheets, and their analogue materials whose framework thickness were corresponding to one unit cell size or less than 10 unit cell size

InactiveUS20120165558A1Increase surface areaHigh catalytic activityHydrogenAluminium compoundsIon exchangeOrganic reaction

The present invention relates to microporous molecular sieve materials and their analogue molecular sieve materials having a crystalline unilamellar or multilamellar framework with a single unit cell thickness in which layers are aligned regularly or randomly, the molecular sieve materials being synthesized by adding an organic surfactant to the synthesis composition of zeolite. In addition, the present invention relates to micro-mesoporous molecular sieve materials activated or functionalized by dealumination, ion exchange or other post treatments, and the use thereof as catalyst. These novel materials have dramatically increased external surface area by virtue of their framework with nano-scale thickness, and thus exhibit improved molecular diffusion, and thus have much higher activities as catalyst and ion exchange resin than conventional zeolites. In particular, the materials of the present invention exhibit high reactivity and dramatically increased catalyst life in various organic reactions such as carbon-carbon coupling, alkylation, acylation, etc. of organic molecules.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method for modifying TS (Titanium silicalite)-1 based on mixed liquor of quaternary ammonium salt and inorganic base

InactiveCN102502690AImprove catalytic performanceLow costOrganic chemistryMolecular sieve catalystsQuaternary ammonium cationIodide

The invention belongs to the technical field of inorganic chemicals synthesis and relates to a method for modifying titanium silicalite. The method is characterized by comprising the following steps: preprocessing the TS (titanium silicalite)-1; modifying the preprocessed TS-1 by mixed liquor containing quaternary ammonium salt and inorganic base, wherein the quaternary ammonium salt refers to tetrapropyl ammonium fluoride, tetrapropylammonium chloride, tetrapropylammonium bromide, tetrapropylammonium iodide and a mixture of tetrapropyl ammonium fluoride, tetrapropylammonium chloride, tetrapropylammonium bromide and tetrapropylammonium iodide, and the inorganic base refers to lithium hydroxide, sodium hydroxide, potassium hydroxide and a mixture of lithium hydroxide, sodium hydroxide and potassium hydroxide; and postprocessing the modified TS-1. The method for modifying the titanium silicalite has general applicability, and is suitable for TS-1 molecular sieves synthesized by various methods, in particular the TS-1 molecular sieves synthesized by inexpensive systems; and the catalytic performance of epoxidation of gas phase and liquid phase propylenes of the TS-1 molecular sieves can be simultaneously improved.

Owner:DALIAN UNIV OF TECH

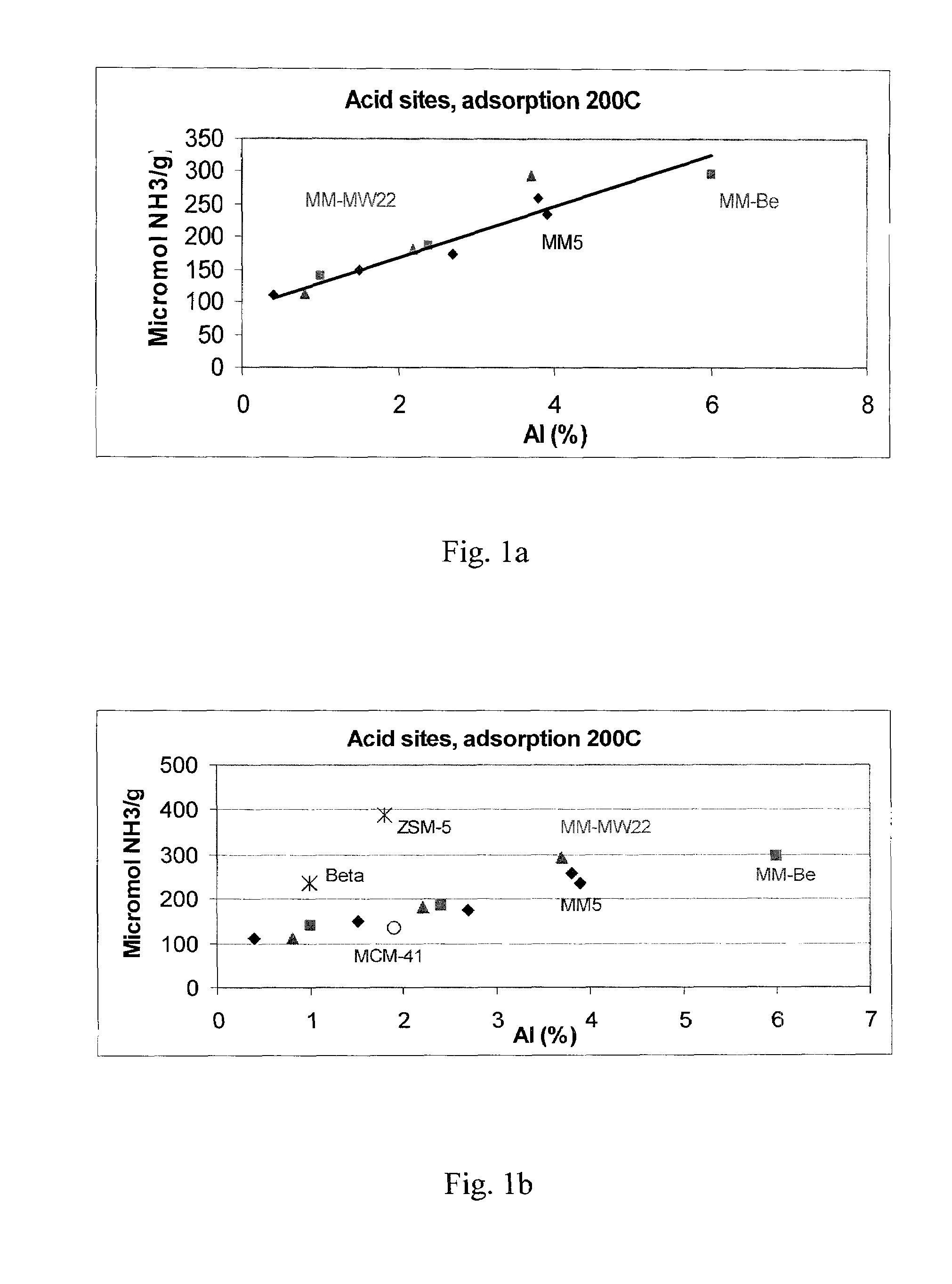

Novel zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:LUMMUS TECH INC

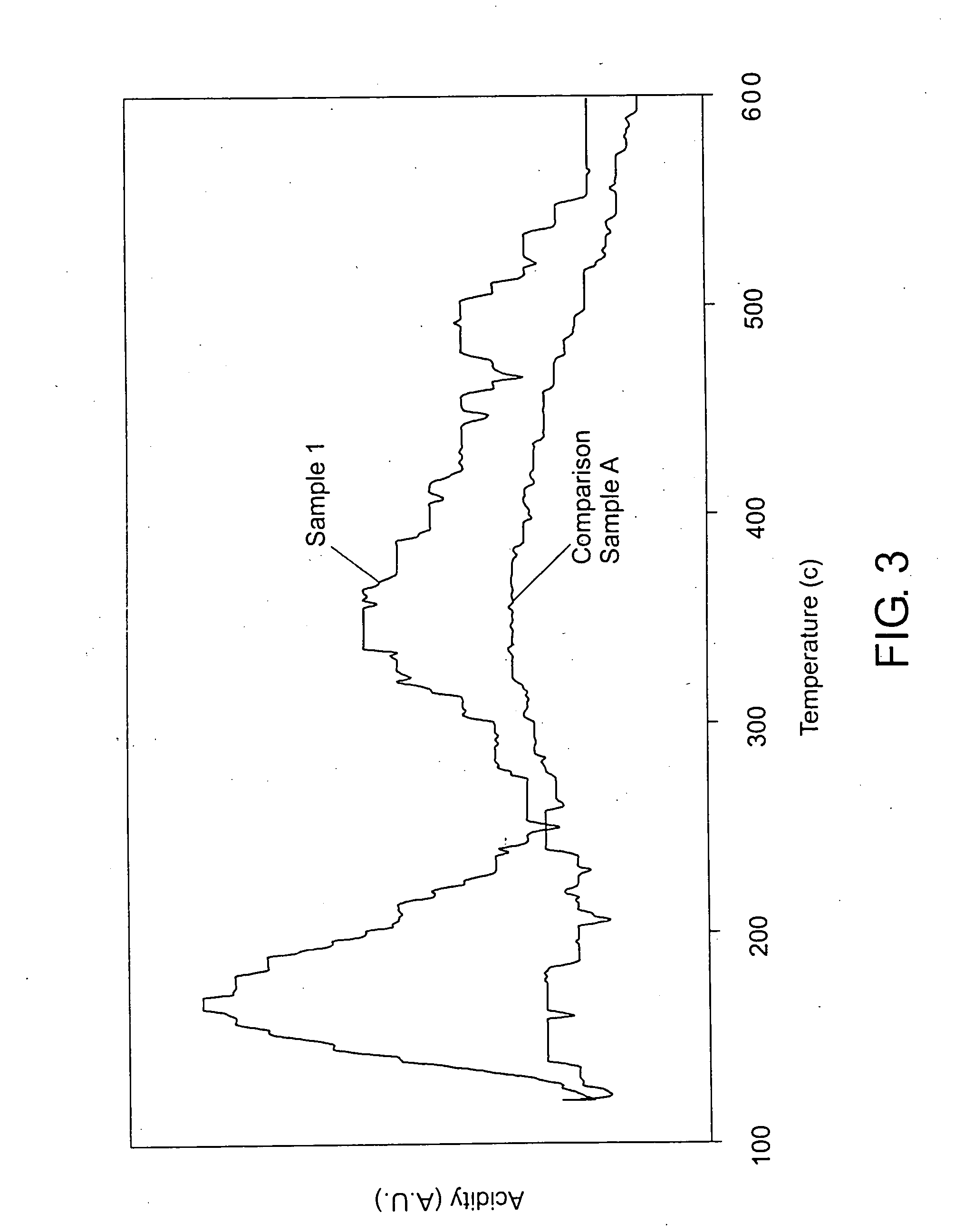

Catalytic materials and method for the preparation thereof

InactiveUS20090270245A1High catalytic activityEasy to synthesizeMolecular sieve catalystsMolecular-sieve silicatesMolecular sieveHydrocarbon

The invention is related to catalytic materials and particularly to mesoporous molecular sieves embedded with a zeolite, which are thermally stable at a temperature of at least 900° C., and to a method for the preparation of the catalytic materials. Said catalytic materials are suitable for applications in the field of hydrocarbon processing.

Owner:KUMAR NARENDRA +3

Process for preparing a nanosized zeolitic material

ActiveUS20060239906A1Easy to controlAluminium compoundsMolecular-sieve silicatesMother liquorZeolite

A process for preparing a zeolitic material, comprising (i) preparing a mixture comprising the at least one silicon containing precursor compound from which the zeolitic framework is formed, at least one pore forming agent, and at least one polymer which has an essentially spheroidal geometry in the mixture; (ii) crystallizing the zeolitic material from the mixture obtained in (i) to obtain the crystallized zeolitic material in its mother liquor.

Owner:BASF AG

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of refractory oxide containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2 theta (θ). The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:LUMMUS TECH INC

Titanium silicalite molecular sieve, synthetic method and application of titanium silicalite molecular sieve, and cyclic ketone oxidation method

ActiveCN107879354AFacilitated DiffusionImprove filtering effectMolecular sieve catalystsOrganic compound preparationMolecular sieveFiltration

The invention relates to the field of catalytic materials and in particular provides a titanium silicalite molecular sieve, a synthetic method and application of the titanium silicalite molecular sieve. The titanium silicalite molecular sieve is composed of the following elements in percentage by mass: 0.01-5% of precious metals, silicon, 0.02-8% of titanium and oxygen, wherein the I960 / I550 valueis 0.6-0.9; the U480 / U330 value is 0.5-5; and the N-116 / N-112 value is 0.01-0.2. The invention further provides a cyclic ketone oxidation method. The cyclic ketone oxidation method comprises the following step: contacting cyclic ketone, an oxidizing agent and a catalyst, wherein the catalyst contains the titanium silicalite molecular sieve disclosed by the invention. Compared with the prior art,the titanium silicalite molecular sieve disclosed by the invention has the advantages that diffusion of the reactants and product is facilitated in an oxidation reaction, so that oxidative activity isfully achieved, and the selectivity is improved. For example, when applied to a reaction in which ring molecules, particularly cyclic ketone molecules, participate or are produced, the titanium silicalite molecular sieve can achieve excellent catalytic effects. Moreover, filtration and separation of the catalyst after the reaction can be further facilitated, and industrialized application is easily realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Molecular-sieve silica-polymorphs Molecular-sieve and base-exchange phosphates Pentasil aluminosilicate zeolite Crystalline aluminosilicate zeolites Silicon compounds Molecular-sieve and base-exchange compounds Liquid hydrocarbon mixture production Carbonyl compound preparation by condensation Hydrocarbon oils treatment products Refining to eliminate hetero atoms

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com