Titanium silicon molecular sieve, and preparation method and application thereof

A titanium-silicon molecular sieve and titanium source technology, applied in molecular sieve compounds, molecular sieve catalysts, molecular sieve characteristic silicates, etc., can solve the problems of restricting mesoporous materials, unable to achieve satisfactory results, and poor hydrothermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

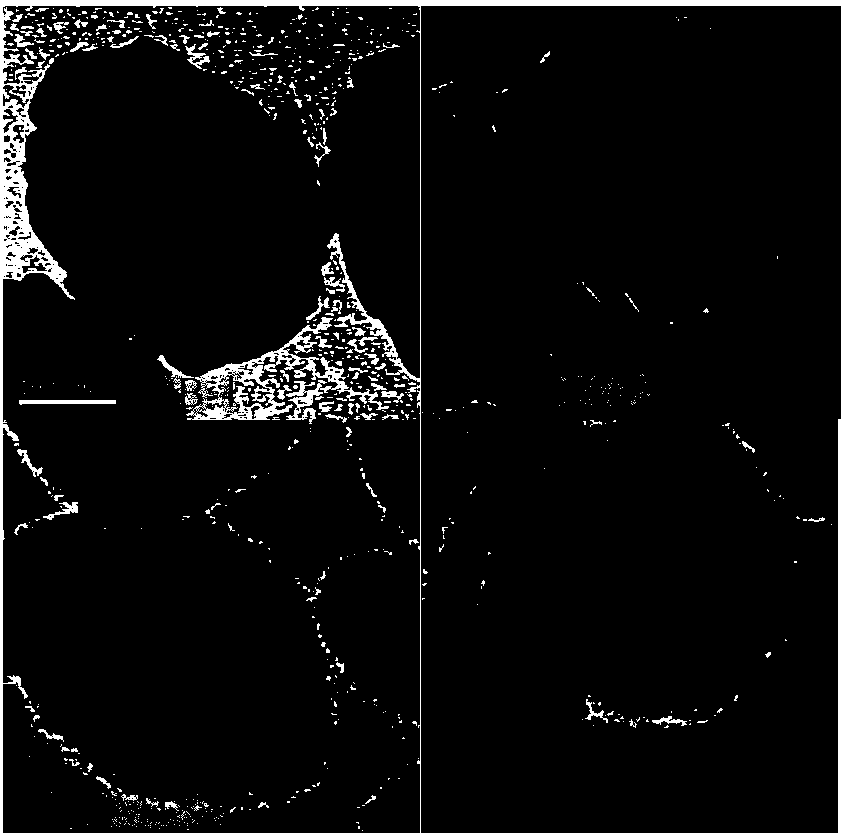

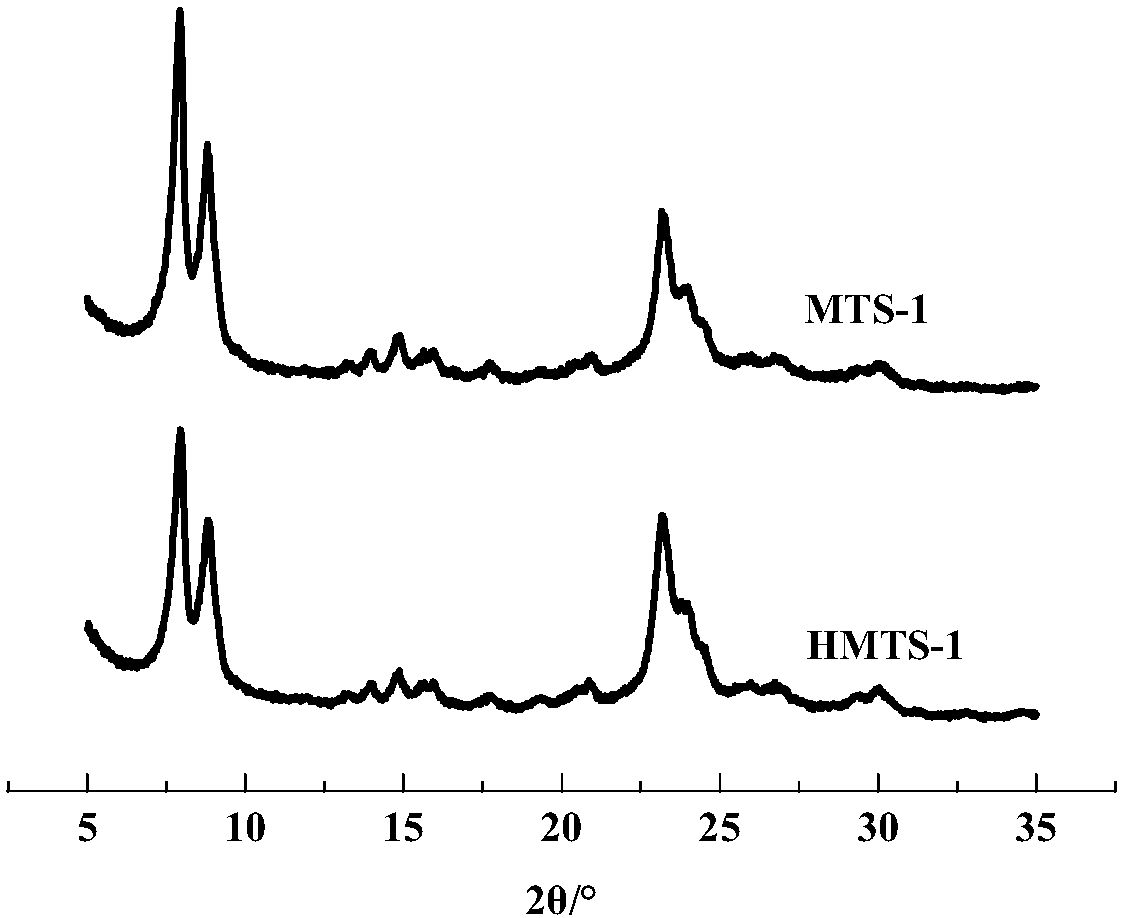

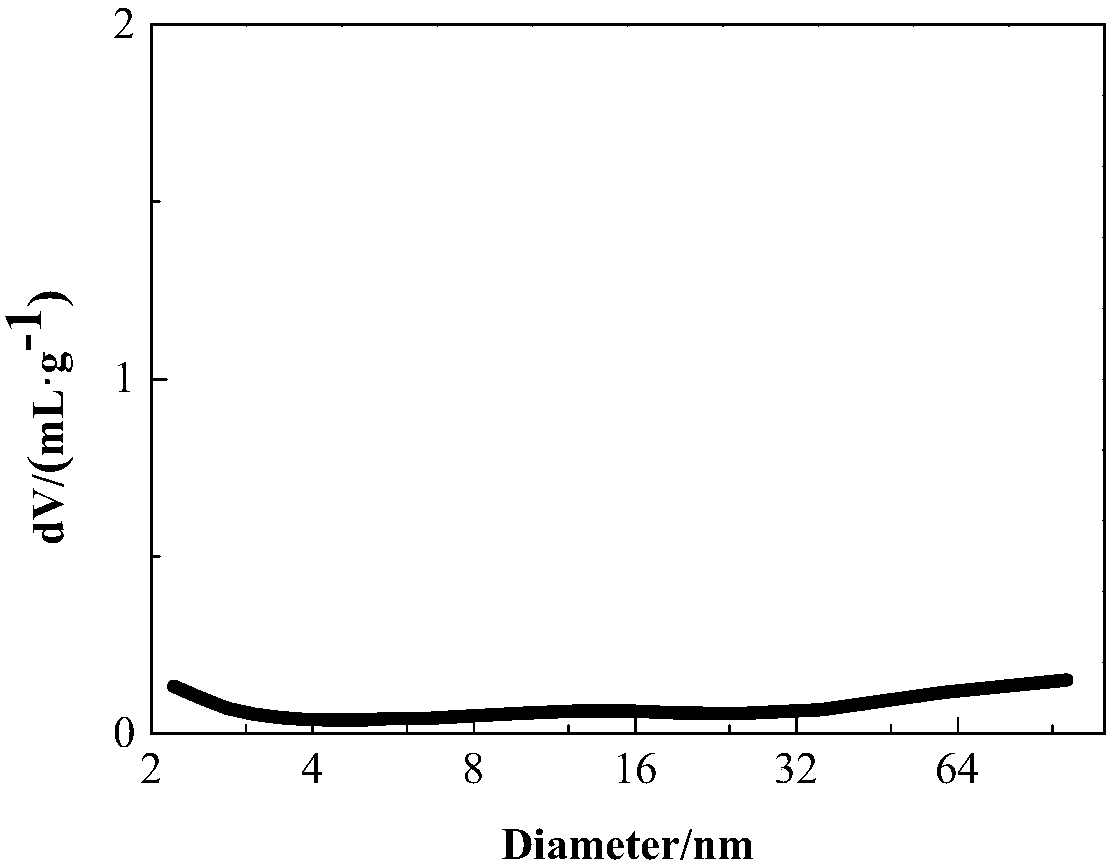

Image

Examples

Embodiment 1

[0074] (1) Mix 31.0 g tetraethyl silicate, 1.8 g tetrabutyl titanate and 15 g tetrapropyl ammonium hydroxide solution (mass concentration 24.4%), add 25 g deionized water under stirring, and Hydrolyze and remove the alcohol for 4 hours while supplementing the evaporated water to obtain a slightly yellow transparent aqueous solution;

[0075] (2) Put the product obtained in step (1) into a closed stainless steel reaction kettle, and let it stand at 80° C. for 24 hours to obtain a precrystallized product;

[0076] (3) Add 2.0 g of the compound represented by formula (III) to the above pre-crystallized product, stir at room temperature for 2 hours to form a transparent viscous liquid, transfer the above liquid to a stainless steel airtight reaction kettle, and keep the temperature at 90°C After 12 hours, slowly raise the temperature to 165°C at a rate of 1°C / min, keep the temperature for 2 days, then filter, wash, dry at 120°C for 12 hours, and roast at 550°C for 6 hours to obtai...

Embodiment 2

[0082] (1) Mix 31.0 g tetraethyl silicate, 1.8 g tetrabutyl titanate and 15 g tetrapropyl ammonium hydroxide solution (mass concentration 24.4%), add 25 g deionized water under stirring, and Hydrolyze and remove the alcohol for 4 hours while supplementing the evaporated water to obtain a slightly yellow transparent aqueous solution;

[0083] (2) Put the product obtained in step (1) into a closed stainless steel reaction kettle, and let it stand at 100° C. for 6 hours to obtain a precrystallized product;

[0084] (3) Add 0.80 g of the compound represented by formula (IV) to the above pre-crystallized product, stir at room temperature for 2 hours to form a transparent viscous liquid, transfer the above liquid to a stainless steel airtight reaction kettle, and keep the temperature at 90°C After 48 hours, slowly raise the temperature to 165°C at a rate of 1°C / min, keep the temperature constant for 0.5 days, then filter, wash, dry at 120°C for 12 hours, and roast at 550°C for 6 hou...

Embodiment 3

[0090] (1) Mix 26.0g tetraethyl silicate, 1.27g tetrabutyl titanate and 10.4g tetrapropylammonium hydroxide solution (mass concentration 24.4%), add 26g deionized water under stirring, and Hydrolyze and remove the alcohol for 7 hours, and replenish the evaporated water at the same time to obtain a light yellow transparent aqueous solution;

[0091] (2) Put the product obtained in step (1) into a closed stainless steel reaction kettle, and let it stand at 80° C. for 24 hours to obtain a precrystallized product;

[0092] (3) Add 0.20 g of the compound represented by formula (III) to the above pre-crystallized product, stir at room temperature for 2 hours to form a transparent viscous liquid, transfer the above liquid to a stainless steel closed reaction kettle, and keep the temperature at 100°C After 24 hours, the temperature was slowly raised to 155°C at a rate of 1°C / min, and the temperature was kept constant for 3 days. Then the obtained material was filtered, washed, dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com