Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Unobstructed channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

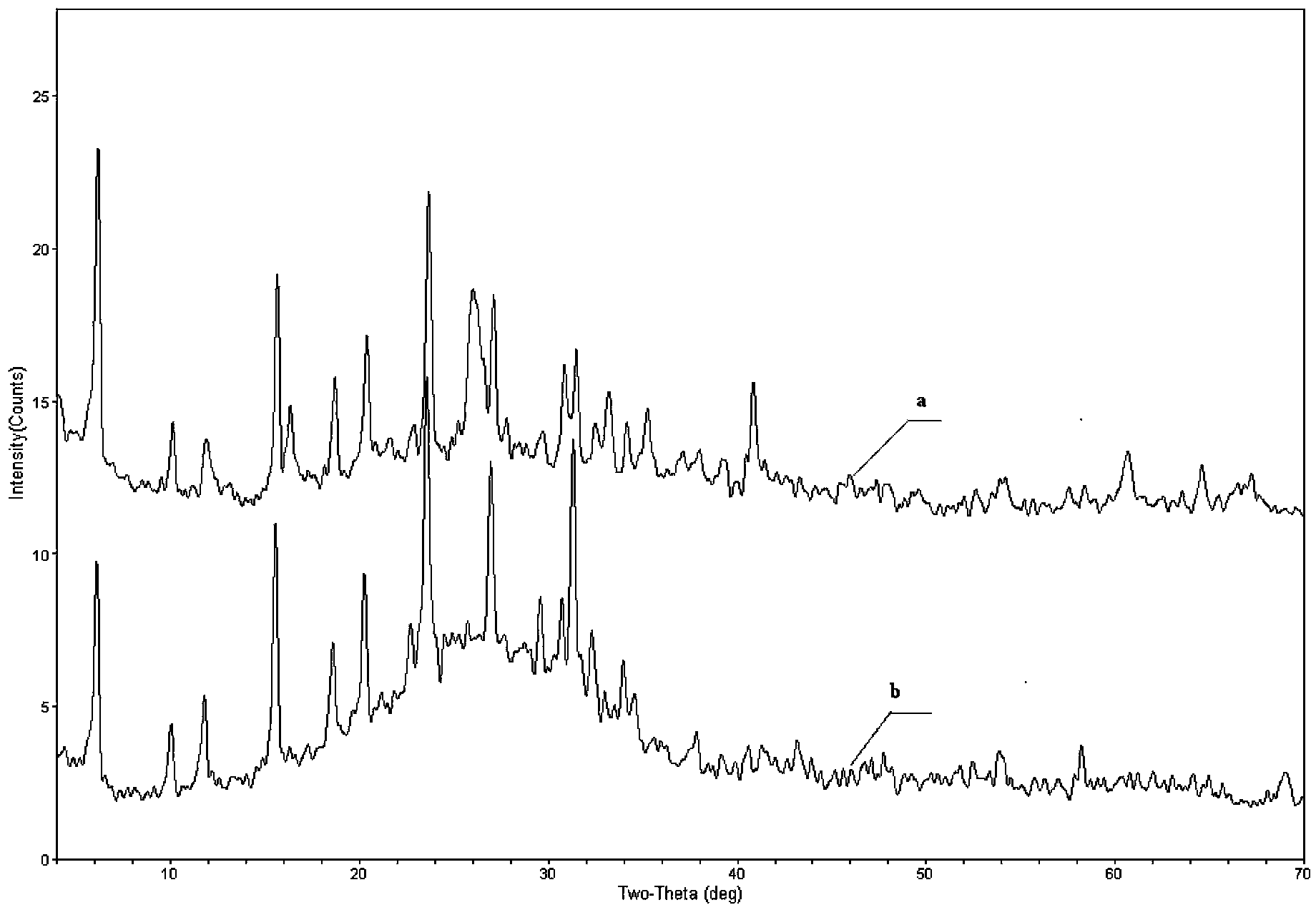

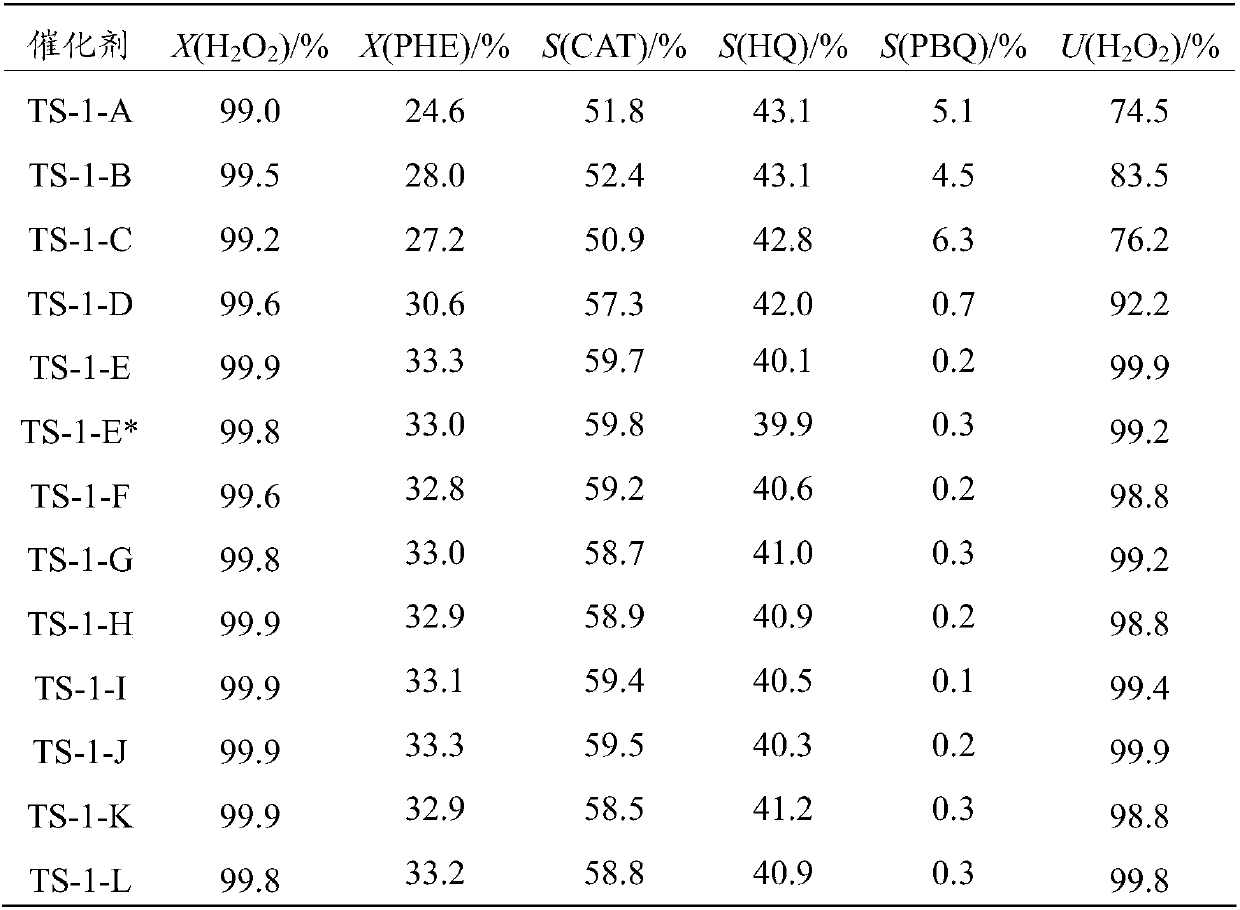

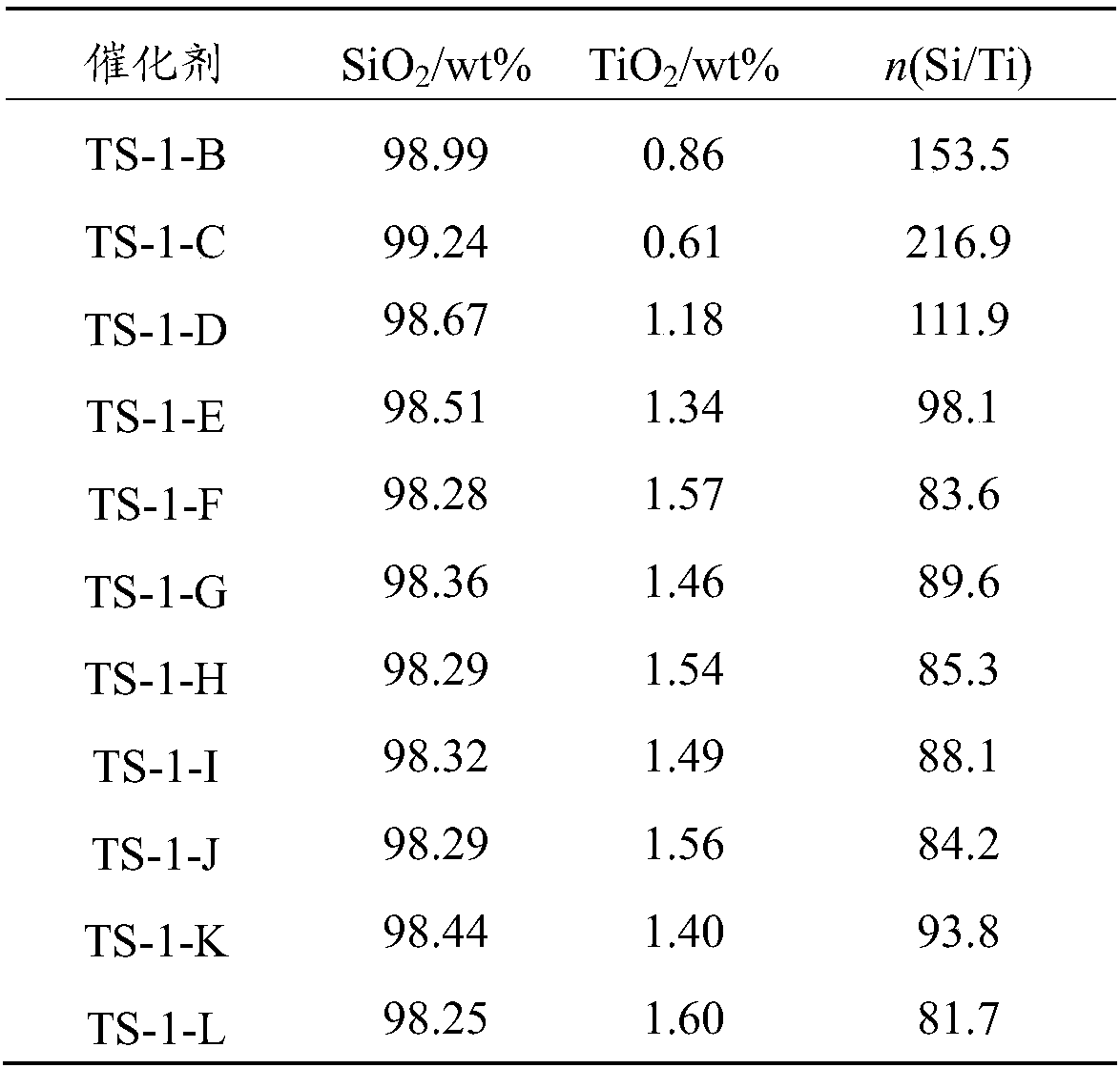

Titanium silicalite TS-1 catalyst preparation method

InactiveCN101767036AHigh activityLow costMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMicrometer

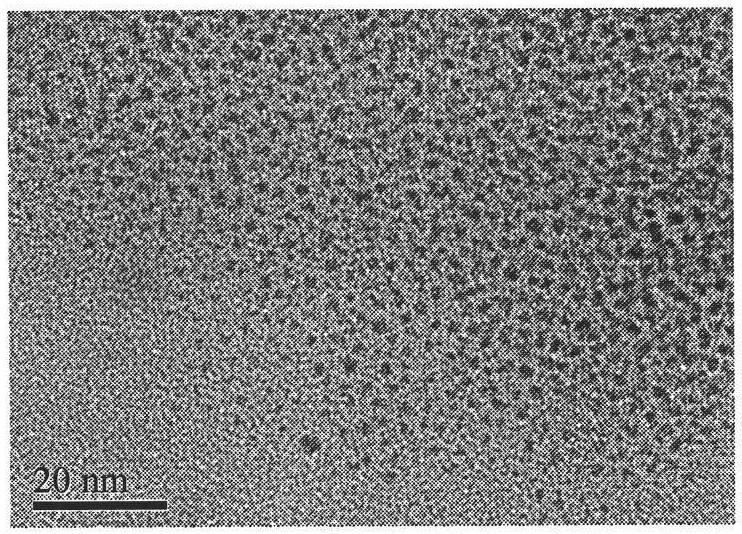

The invention discloses a titanium silicalite TS-1 catalyst preparation method. Cheap inorganic Titanium silicalite is used as raw material, low quantity of tetrapropylammonium hydroxide or tetrapropylammonium bromide is adopted as template agent, and inorganic alkali such as ammonia water is used as alkali source so that the raw materials for preparation have low price and the production cost isgreatly reduced. The precursor preparation process is simple and easy to control, seed crystal is added to reduce the crystallization time and the repeatability is good. As secondary crystallization is adopted, the non-framework titanium is further reduced, and the acid site of the molecular sieve is reduced, the grain size is controllable within certain range, the molecular sieve channel becomessmoother to facilitate direct membrane separation of micrometer crystalline grains, and the obtained Titanium silicalite TS-1 catalyst has large grains, high activity, stable catalytic performance and broad industrial application prospect.

Owner:XIANGTAN UNIV

Light oil type hydrocracking catalyst with composite molecular sieve as well as preparation method and application thereof

ActiveCN103394368BGood catalytic cracking performanceGood catalyticMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

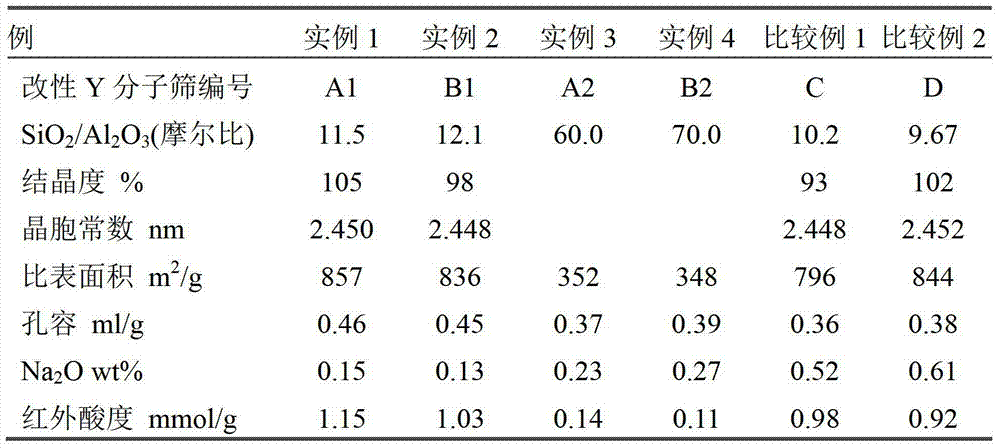

The invention discloses a light oil type hydrocracking catalyst with a composite molecular sieve. The hydrocracking catalyst comprises the composite molecular sieve consisting of a modified Y-molecular sieve and a modified ZSM-23 molecular sieve, a carrier composed of micropore aluminum oxides, and a hydrogenation activity component composed of a VIB group metal and a VIII group metal. The hydrocracking catalyst is characterized in that the composite molecular sieve comprises the modified Y-molecular sieve and the modified ZSM-23 molecular sieve, and the Y-molecular sieve is modified and dealuminized, so that heat stability and hydrothermal stability are stably enhanced, the hydrophobicity is enhanced, the absorption and desorption properties of the molecular sieve are improved, and the catalyst achieves a high catalytic cracking property. The pore passages of the modified SM-23 molecular sieve are unobstructed, the number of the acid sites is small, the isomerism property is outstanding, and the octane value of the molecular sieve is increased because of light naphtha components. The modified Y-molecular sieve and the modified ZSM-23 molecular sieve are mixed and used according to a formula ratio of the hydrocracking catalyst, so that both the cracking activity and the isomerism property are considered, and the final catalyst achieves an ideal catalytic effect.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Dimethyl benzyl alcohol hydrogenolysis catalyst and preparation method thereof

ActiveCN110075857AImprove mechanical stabilityEvenly distributedHeterogenous catalyst chemical elementsCatalyst activation/preparationCopper oxideSlurry

The invention discloses a dimethyl benzyl alcohol hydrogenolysis catalyst and a preparation method thereof. The catalyst comprises 35-70wt% of copper oxide, 5-25wt% of zinc oxide, 15-40wt% of silicondioxide, 0.5-15wt% of alkaline earth metal oxide and 0.1-5wt% of bismuth oxide and lead oxide. The preparation method comprises the following steps: (a) adding a mixed solution containing a Cu compound, a Zn compound, an alkaline earth metal compound, a Bi compound and a Pb compound and an alkaline precipitant solution into a silica sol aqueous solution for precipitation reaction and heating aging; (b) filtering, washing, drying and roasting the aged slurry to obtain complex compound powder; and (c) adding a binder, a forming assistant and the like into the complex compound powder, fully mixing, extruding and forming, drying and roasting to obtain the catalyst. When used for preparing cumene by hydrogenolysis of dimethylbenzyl alcohol, the method not only has good activity and selectivity,but also has good liquid resistance and high mechanical stability.

Owner:WANHUA CHEM GRP CO LTD

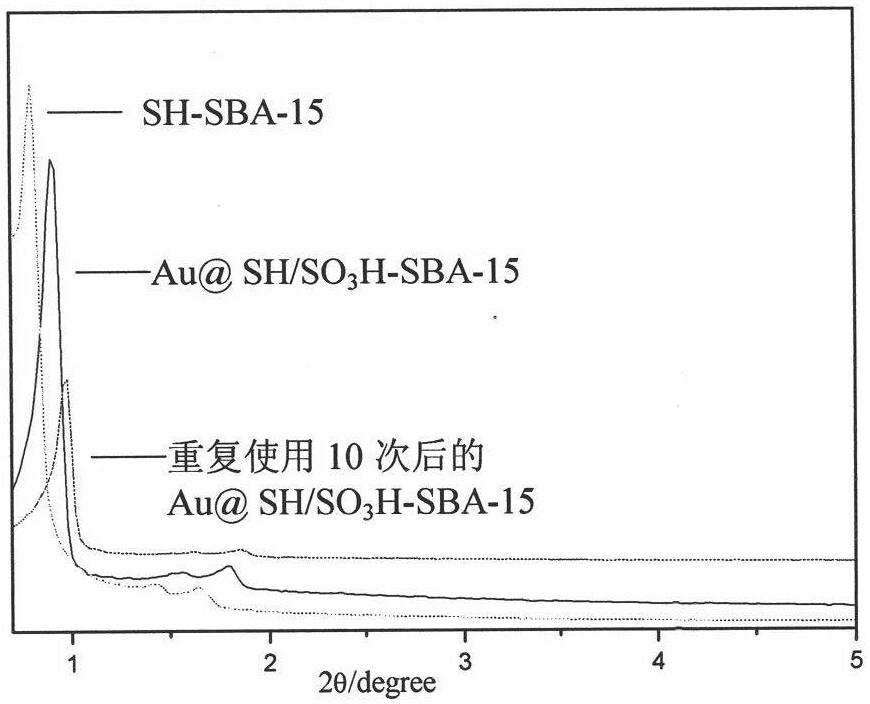

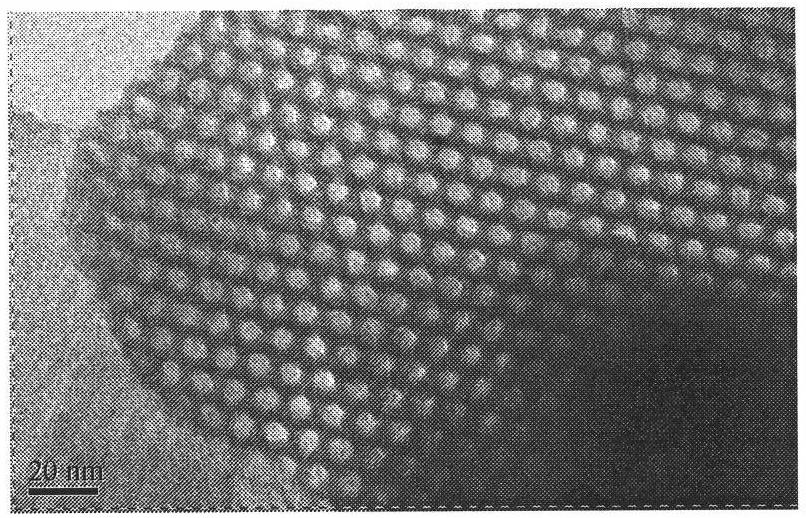

Sulfydryl functionalized ordered mesoporous silicon-immobilized Au heterogeneous catalyst and preparation method and application thereof

InactiveCN101785998AHigh catalytic activityRegular and ordered two-dimensional hexagonal mesoporous structurePreparation by C-C triple bond hydrationMetal/metal-oxides/metal-hydroxide catalystsSilanesStrong acids

The invention relates to sulfydryl functionalized ordered mesoporous silicon-immobilize Au heterogeneous catalyst and a preparation method and application thereof. The preparation method is as follows: mixing surfactant, strong acid, water, ethyl orthosilicate and sulfhydryl silane under heating condition, continuously stirring the reactant mixture, filtering the reactant mixture to get white solid, and sequentially washing and drying the white solid to get a sulfydryl functionalized ordered mesoporous silicon carrier; mixing the carrier with ethanol and HAuCl4 solution, stirring for 24h under room temperature, pump filtering and washing the mixture, and vacuum drying overnight. In this way, the ordered mesoporous sulfydryl functionalized SBA-15-immobilize Au heterogeneous catalyst can be formed. The preparation process is simple and the heterogeneous catalyst prepared through the method has efficient and long-lasting catalytic activity, can improve the reaction speed, reduce the production cost and improve the quality of the product, and can be recycled for use, thereby reducing environment pollution.

Owner:SHANGHAI NORMAL UNIVERSITY

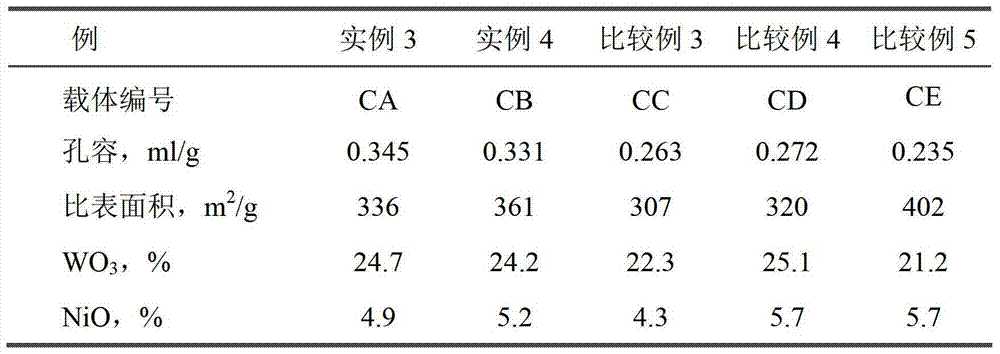

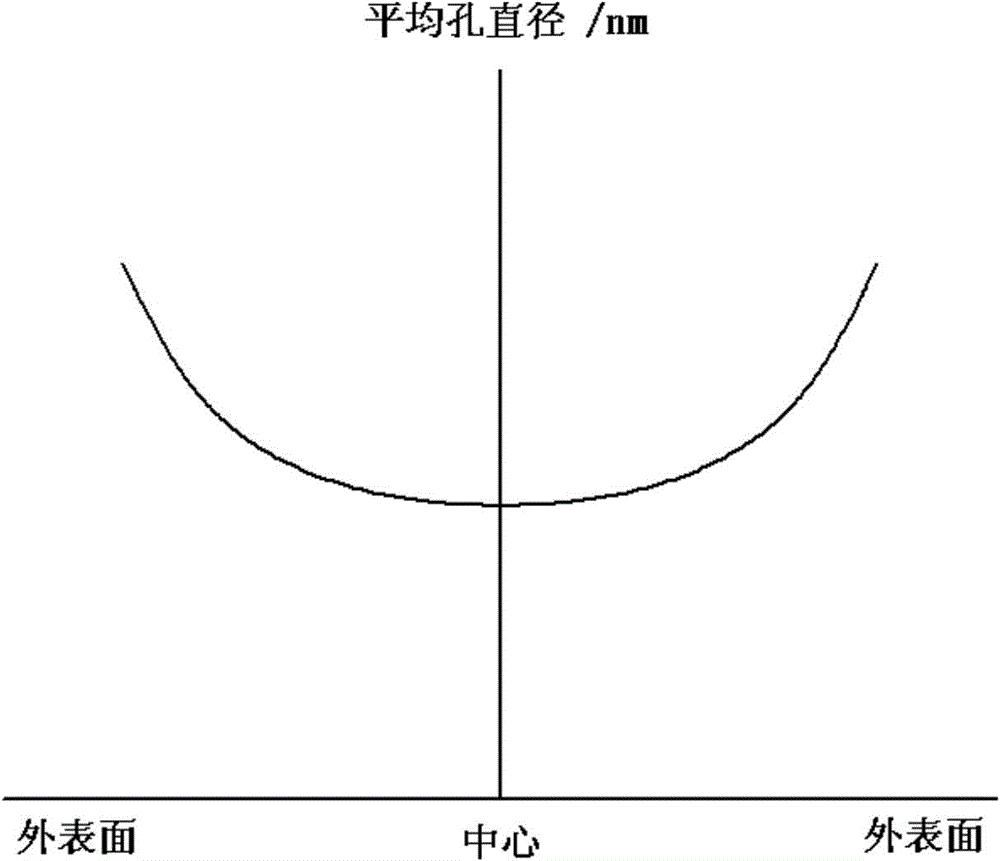

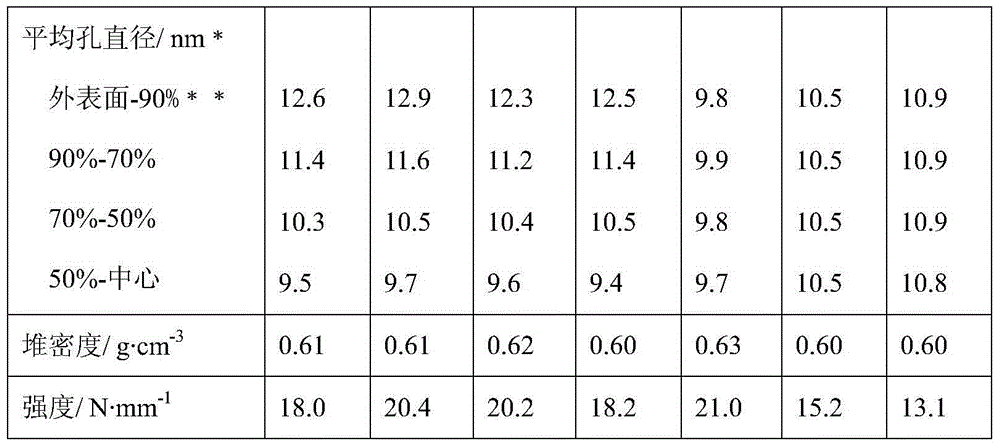

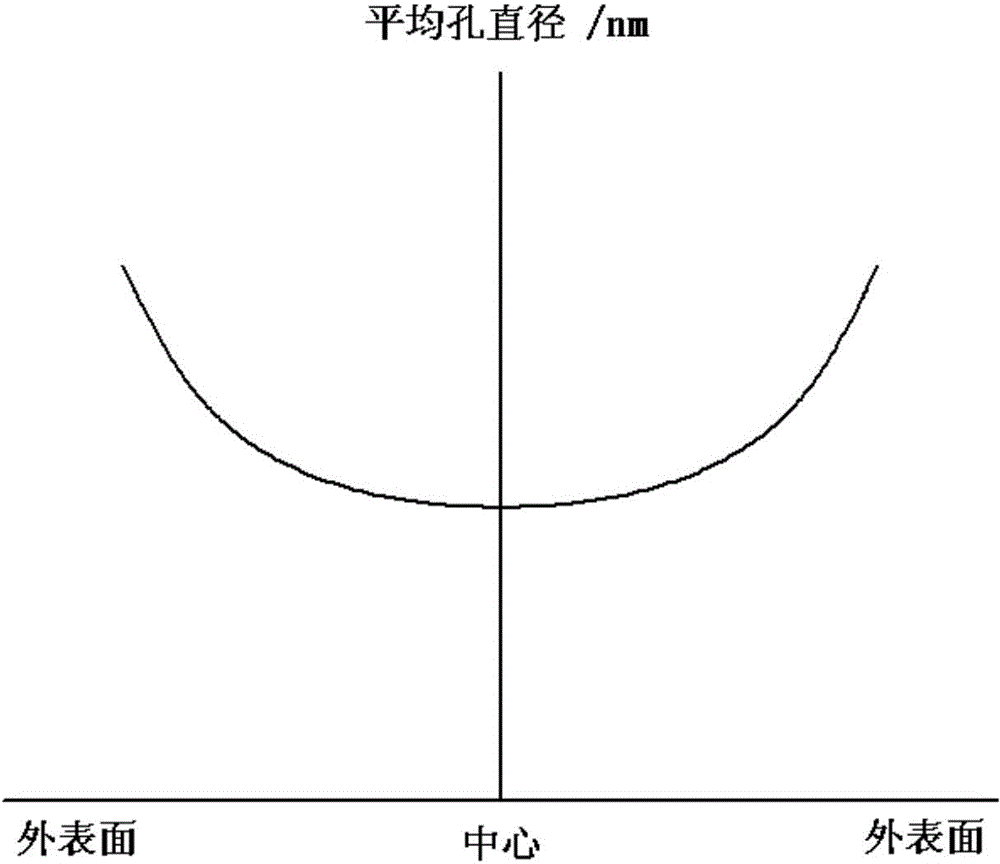

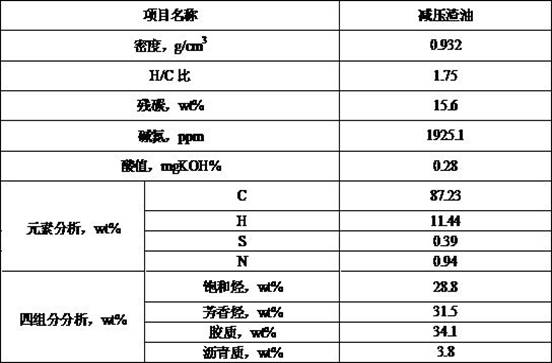

Inferior heavy oil hydrodesulfurization demetalization catalyst and preparation method thereof

ActiveCN104646008AImprove desulfurizationHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsActive componentHydrodesulfurization

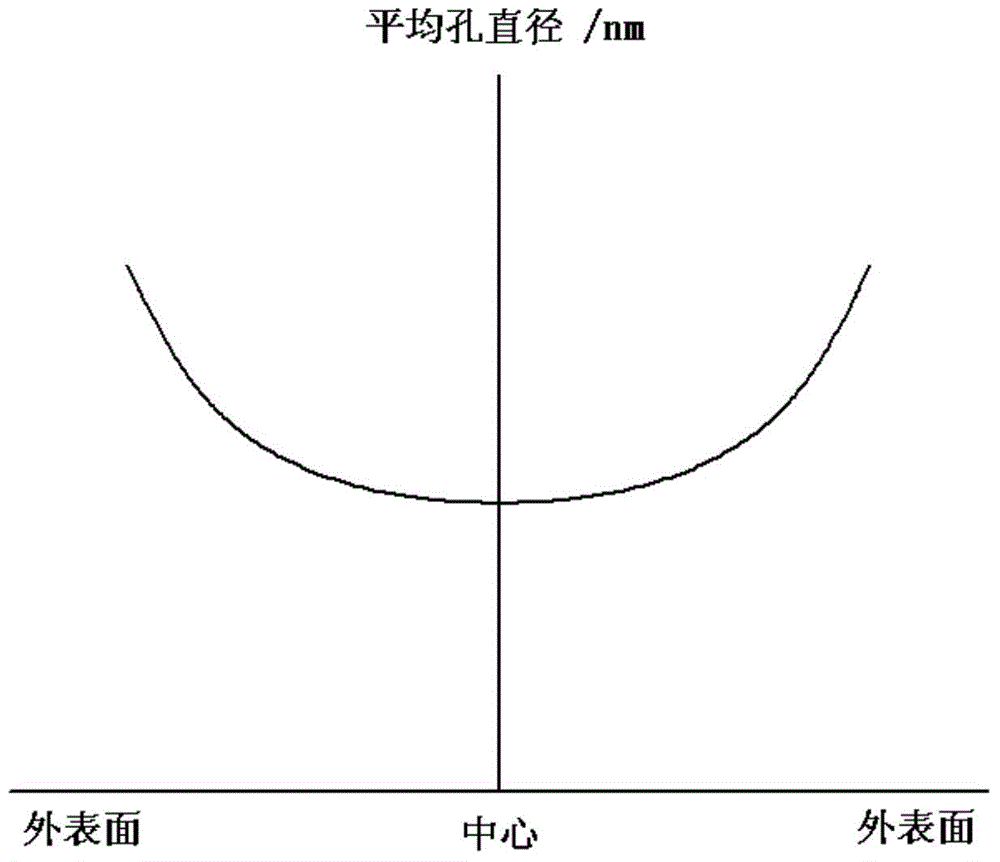

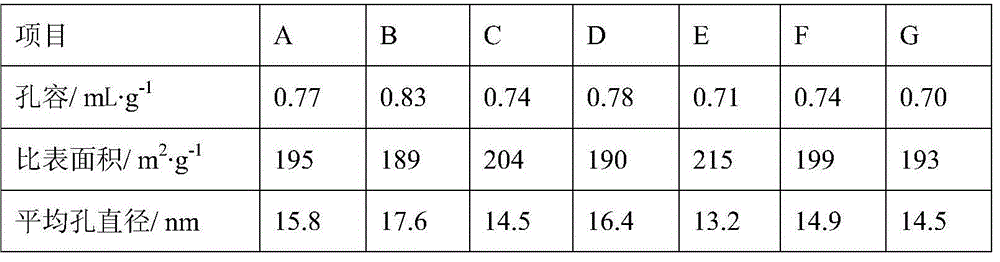

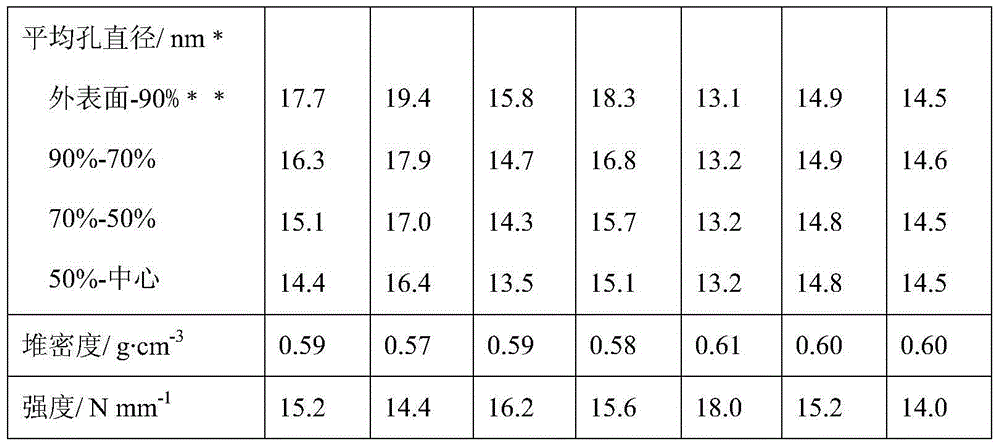

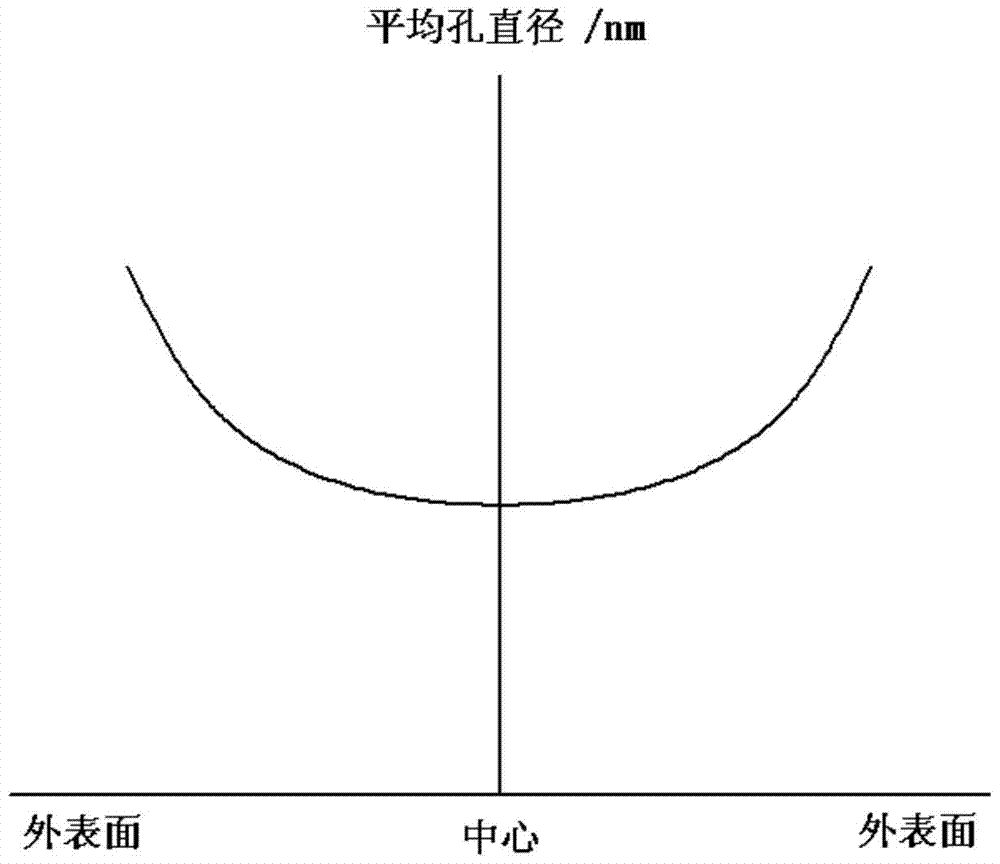

The invention puts forward an inferior heavy oil hydrodesulfurization demetalization catalyst and a preparation method thereof. The catalyst takes aluminum oxide as the carrier, and adopts group VIII and group VIB elements especially Ni-Mo as the active components, the catalyst pore volume is 0.61-0.70mL / g, the specific surface area is 155-200m<2> / g, the average pore diameter is 13.0-18.0nm, and the average pore diameter gradually increases from the center to the outer surface along the radial direction of the catalyst particles. According to the preparation method of the catalyst, a concentration continuously increasing acid solution is employed to treat molded and roasted carrier particles. The catalyst provided by the invention has large surface aperture, wide pore channel, excellent diffusion performance, high hydrodesulfurization and demetalization activity and high activity stability.

Owner:PETROCHINA CO LTD

Preparation method of catalyst for improving yield of gasoline produced by catalytic cracking

ActiveCN104275206AHigh yieldRefine grain sizeCatalytic crackingMolecular sieve catalystsSodium silicateMolecular sieve

The invention discloses a preparation method of a catalyst for improving the yield of gasoline produced by catalytic cracking. The preparation method comprises the following steps: with a mixture of kaolin and diatomite subjected to acid treatment as a raw material, adding chemical water, structural auxiliaries, a dispersing agent and / or a reinforcing agent into the mixture, and performing mixed pulping and spraying to obtain microspheres; roasting the sprayed microspheres, mixing the roasted microspheres with a guiding agent, sodium silicate and sodium hydroxide in a certain ratio, and performing a crystallization reaction under hydrothermal conditions, thereby obtaining a crystallization product with a pore structure and excellent abrasion resistance and with a 30%-60% NaY molecular sieve, wherein the crystallization product, namely the in-situ crystallized microspheres, can be taken as a precursor for preparing the catalytic cracking catalyst; and exchanging the in-situ crystallized microspheres with ammonium salt and rare earth to obtain the catalytic cracking catalyst for improving the yield of gasoline.

Owner:PETROCHINA CO LTD

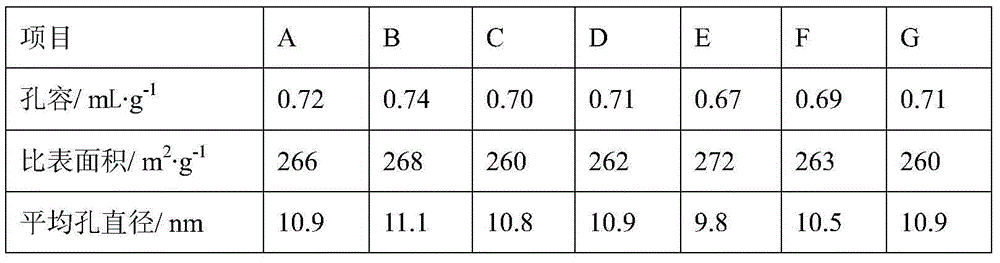

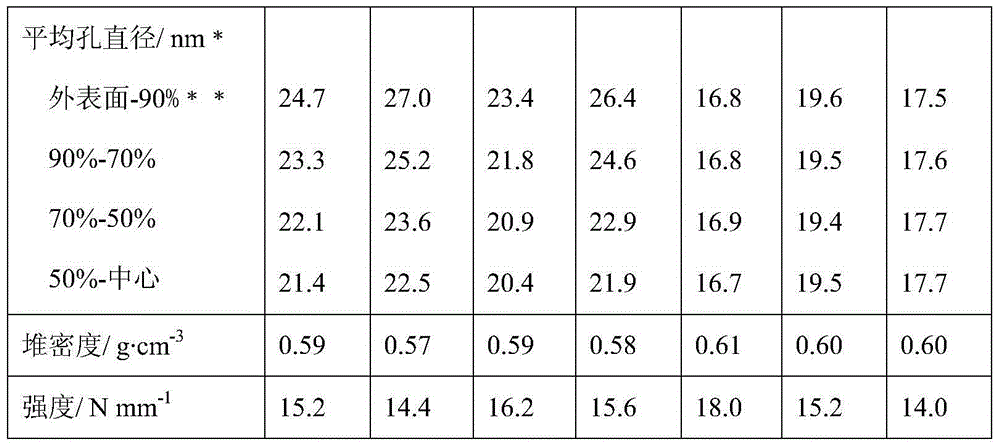

Inferior heavy oil hydrodesulfurization catalyst and preparation method thereof

ActiveCN104646009AUnobstructed channelHigh desulfurization activity and stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminium oxidesPtru catalyst

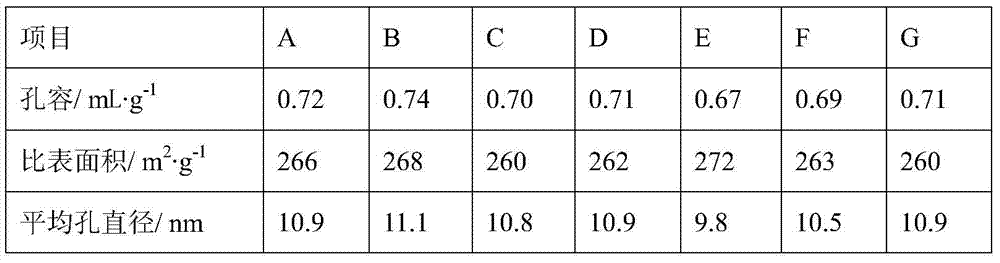

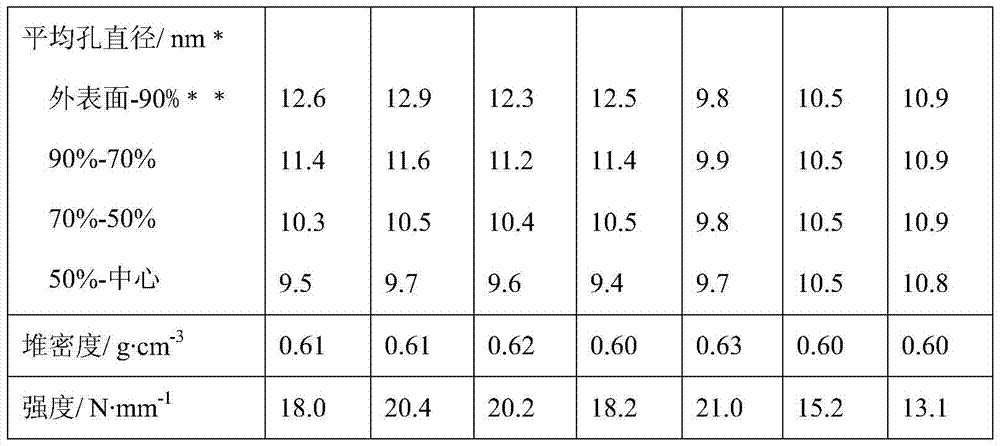

The invention relates to an inferior heavy oil hydrodesulfurization catalyst and a preparation method thereof. The catalyst takes aluminum oxide as the carrier, and adopts group VIII and group VIB elements especially Ni-Mo as the active components, the catalyst pore volume is 0.45-0.60cm<3> / g, the specific surface area is 205-260m<2> / g, the average pore diameter is 7.0-12.0nm, and the average pore diameter gradually increases from the center to the outer surface along the radial direction of the catalyst particles. According to the preparation method of the catalyst, a concentration continuously increasing acid solution is employed to treat molded and roasted carrier particles. The catalyst provided by the invention has large surface aperture, wide pore channel, excellent diffusion performance, high hydrodesulfurization activity and activity stability.

Owner:PETROCHINA CO LTD

Preparation method of catalyst for improving yield of diesel oil produced by catalytic cracking

ActiveCN104275205AImprove pore structureWell-developed pore structureMolecular sieve catalystsMicrosphereRare earth

The invention discloses a preparation method of a catalyst for improving the yield of diesel oil produced by catalytic cracking. The preparation method comprises the following steps: with a mixture of kaolin and diatomite subjected to acid treatment as a raw material, adding chemical water, structural auxiliaries, a dispersing agent and / or a reinforcing agent into the mixture, and performing mixed pulping and spraying to obtain microspheres; roasting the sprayed microspheres, mixing the roasted microspheres with a guiding agent, sodium silicate and sodium hydroxide in a certain ratio, and performing a crystallization reaction under hydrothermal conditions, thereby obtaining a crystallization product with a pore structure and excellent abrasion resistance and with a 20%-30% NaY molecular sieve, wherein the crystallization product, namely the in-situ crystallized microspheres, can be taken as a precursor for preparing the catalytic cracking catalyst; and exchanging the in-situ crystallized microspheres with ammonium salt and rare earth to obtain the catalytic cracking catalyst for improving the yield of diesel oil.

Owner:PETROCHINA CO LTD

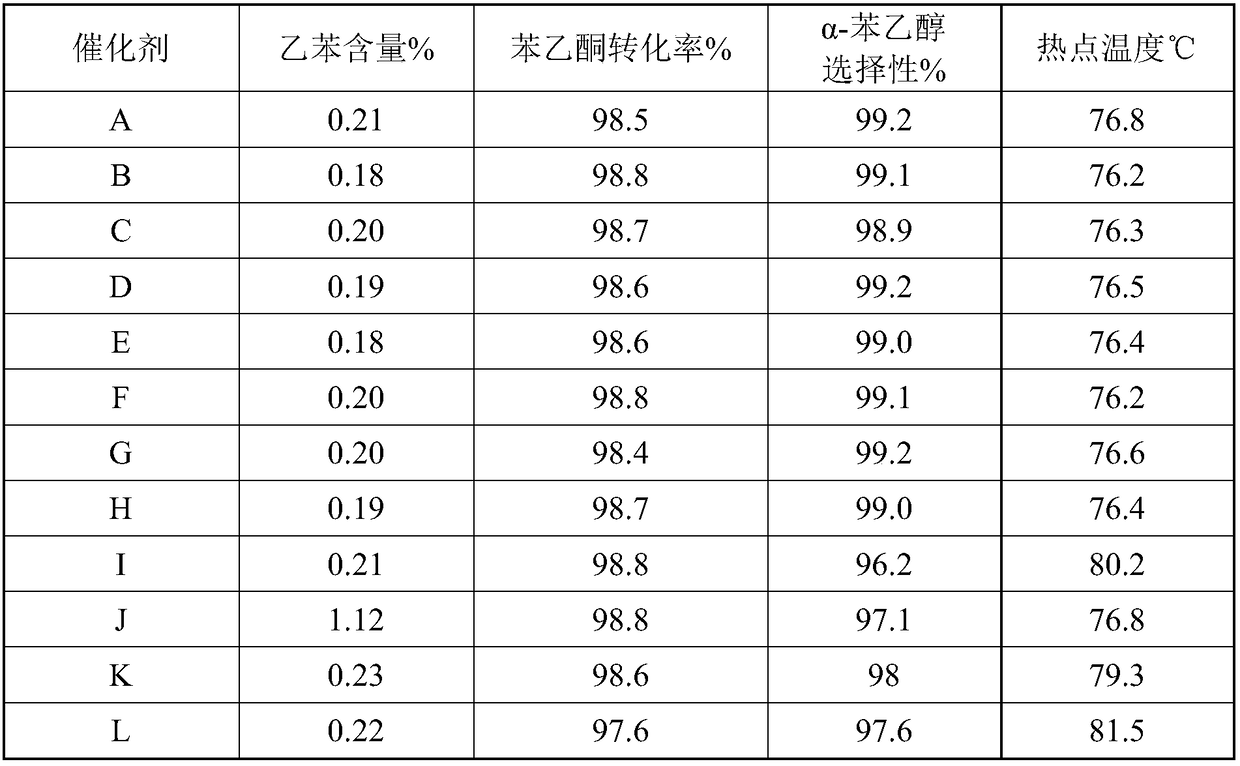

Method for preparing alpha-phenylethanol catalyst through hydrogenation of acetophenone and application

ActiveCN109482192AHigh activityAvoid filter effectsOrganic compound preparationHeterogenous catalyst chemical elementsPhenethyl alcoholSlurry

The invention relates to a method for preparing an alpha-phenylethanol catalyst through hydrogenation of acetophenone and application. The catalyst contains copper oxide, zinc oxide, silicon dioxide and bismuth oxide. The method of the catalyst is realized by virtue of a sub-step precipitation method and comprises the following steps: precipitating zinc salt and a precipitator at a certain temperature, and aging, so as to obtain slurry (1); adding a mixed solution of copper salt and bismuth salt as well as the precipitator into the slurry (1), carrying out coprecipitation, and aging, so as toobtain slurry (2); adding carrier silicon into the slurry (2), and uniformly stirring and mixing, so as to obtain slurry (3); filtering, washing, drying and roasting the slurry (3), so as to obtain catalyst powder; adding a certain amount of pore forming agents into the catalyst powder, and carrying out piece formation; and carrying out secondary roasting on the formed catalyst, so as to obtain the final catalyst. The catalyst prepared by virtue of the method is large in pore volume and aperture, good in mass transfer property and heat transfer property and high in activity and selectivity.

Owner:WANHUA CHEM GRP CO LTD

Acetophenone hydrogenation catalyst and preparation method thereof

ActiveCN109529870AIncrease the outer surface areaImprove active site utilizationOrganic compound preparationHeterogenous catalyst chemical elementsMicrospherePolymethyl methacrylate

The invention relates to an acetophenone hydrogenation catalyst and a preparation method thereof, which comprises the following steps: (1) hydrochloric acid, F127, KCl, 1,3,5-trimethylbenzene and polymethyl methacrylate microspheres are mixed evenly, then tetraethylorthosilicate is added to the mixture, and 4-12 hour later, a sol is obtained; (2) a mixed metal salt solution containing Cu, Mn, Bi and Pb is prepared, a solution of an alkaline precipitant is prepared, the two kinds of solutions are allowed to contact with the obtained sol for precipitation reaction, heating and aging to obtain aslurry; (3) the slurry is subjected to filtering, washing, drying and roasting to obtain composite compound powder; (4) the composite compound powder is mixed with a binder, an alkaline auxiliary agent and a forming auxiliary agent and extruded to obtain the catalyst. The catalyst active component copper prepared by the method has high dispersion, the acidity is weak and mass transfer performanceis good, side reactions such as hydrogenolysis and the like are effectively inhibited, and good activity and selectivity are obtained.

Owner:WANHUA CHEM GRP CO LTD +1

Inferior heavy oil hydrodemetallization catalyst and preparation method thereof

ActiveCN104646005AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystAluminium oxides

The invention relates to an inferior heavy oil hydrodemetallization catalyst and a preparation method thereof. The catalyst adopts aluminum oxide as the carrier, and takes group VIII and group VIB elements, especially Ni-Mo as the active components, the catalyst pore volume is 0.71-0.85mL / g, the specific surface area is 90-150m<2> / g, the average pore diameter is 19.0-30.0nm, and the average pore diameter gradually increases from the center to the outer surface along the radial direction of the catalyst particles. According to the preparation method of the catalyst, a concentration continuously increasing acid solution is employed to treat molded and roasted carrier particles. The catalyst provided by the invention has large surface aperture, wide pore channel, excellent diffusion performance, high hydrodemetallization activity and activity stability.

Owner:PETROCHINA CO LTD

Catalytic cracking catalyst

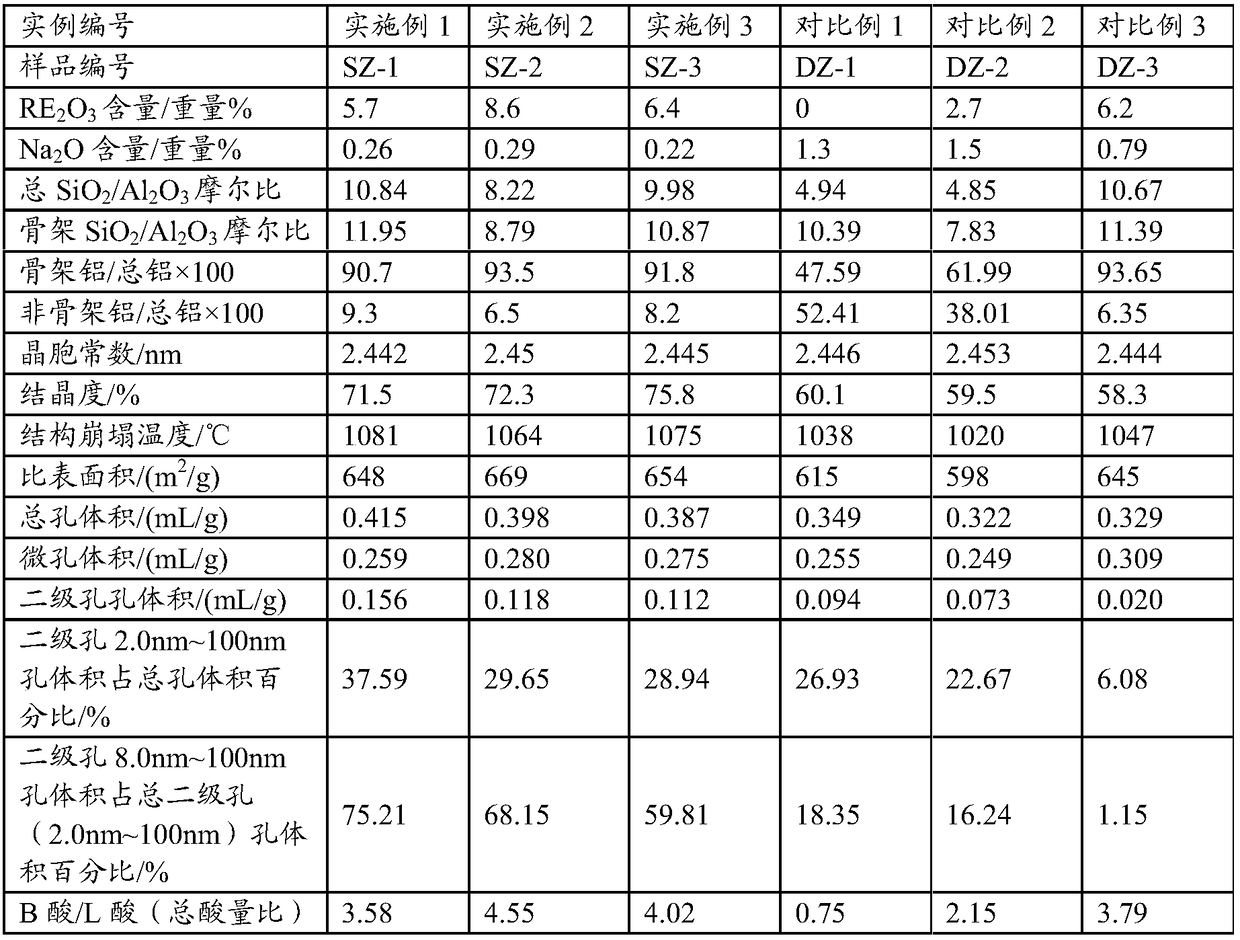

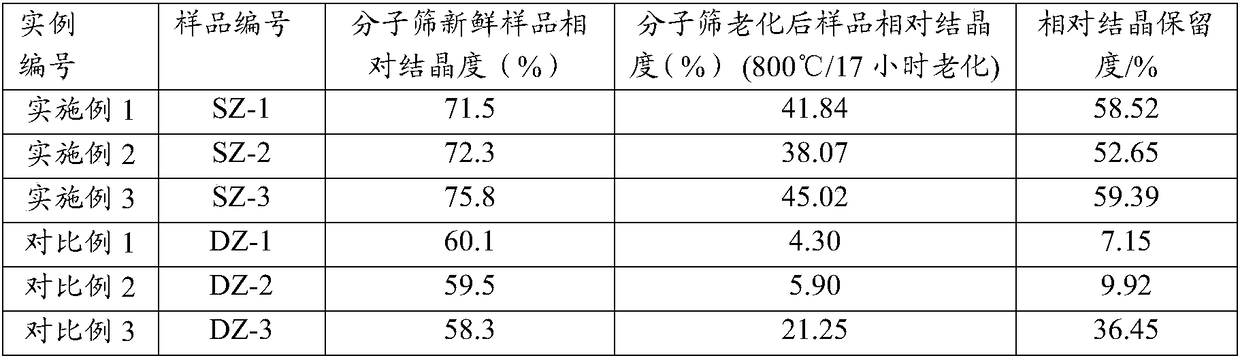

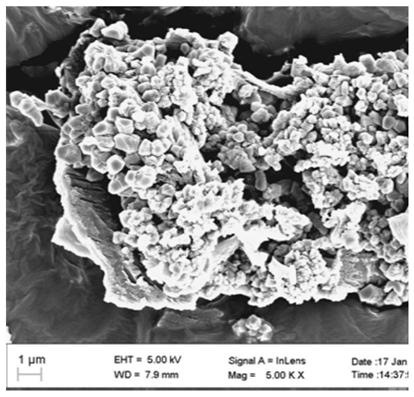

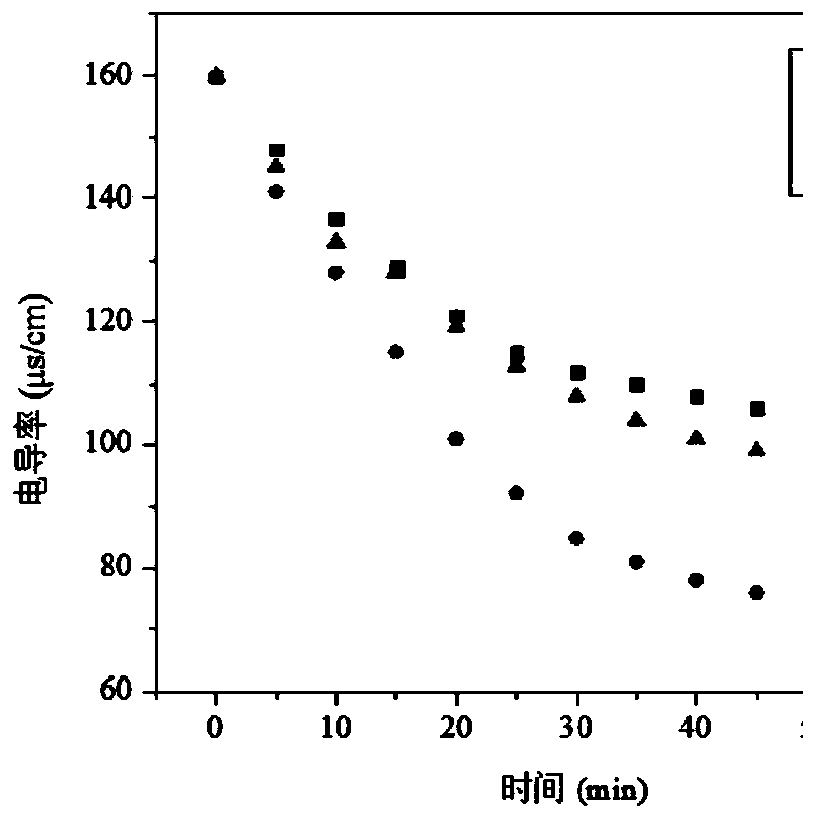

ActiveCN108452838AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, alumina containing an additive and a modified Y type molecular sieve. The modified Y type molecularsieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of thetotal pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEGC; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7h; carrying out a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalytic cracking catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chitin-based biomass charcoal double-sided electrode slice for electroadsorption and preparation method thereof

InactiveCN109694120ASimple production processLow costDispersed particle separationWater/sewage treatmentFreeze-dryingInternal resistance

The invention relates to a chitin-based biomass charcoal double-sided electrode slice for electroadsorption and a preparation method thereof. The preparation method comprises the steps: cleaning chitin powder, drying and sieving, and carrying out heat preservation for 1-2 h in a nitrogen atmosphere at the temperature of 400-500 DEG C, to obtain pre-carbonized powder; mixing the pre-carbonized powder and potassium hydroxide powder, then placing the mixture in a vacuum tube furnace, and carrying out heat preservation for 2-3 h at the temperature of 800 DEG C-900 DEG C to obtain biomass charcoalpowder I; adding the biomass charcoal powder I into a 10 wt% HCl solution, stirring and cleaning, to obtain biomass charcoal powder II; mixing an electrically conductive agent, the biomass charcoal powder II and polyvinylidene fluoride, dissolving the mixture in dimethylacetamide, and mixing; and uniformly coating both sides of a current collector titanium slice with the obtained mixed slurry, drying, and freeze-drying to prepare the chitin-based biomass charcoal double-sided electrode slice for electroadsorption. The production cost is low, and the prepared product has small internal resistance of the electrodes, high capacitance and good adsorption performance, and is suitable for treating different water qualities.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of copper-containing catalyst

ActiveCN111686739AEvenly dispersedGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-containing catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallel flow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein a quaternary ammonium salt compound is added before the gelling reaction in the step (1), wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst has characteristics of uniform active metal copper distribution, good synergistic effect, large active metal active center number, catalyst activity improving, catalyst selectivity improving, catalyst thermal stability improving, and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating nickel-containing wastewater by using composite adsorbent

ActiveCN111170501AReduce concentrationHigh pore volumeOther chemical processesWater contaminantsAluminium chlorideSodium chlorate

The invention discloses a method for treating nickel-containing wastewater by using a composite adsorbent. The method comprises the following steps: mixing the nickel-containing wastewater with the composite adsorbent, carrying out oscillating at room temperature, carrying out solid-liquid separation to obtain preliminarily-treated wastewater, adjusting the pH value of the preliminarily-treated wastewater to 4-5, adding sodium hypochlorite, carrying out a stirring reaction, adding the composite adsorbent, conducting oscillating at room temperature, and carrying out solid-liquid separation to obtain secondarily-treated wastewater; adjusting the pH value of the secondarily-treated wastewater to 10.5-11.5, performing standing for precipitation, taking supernatant liquid, adding polyaluminum chloride, conducting stirring, adding polyacrylamide, performing stirring and standing, and carrying out solid-liquid separation to obtain tertiarily-treated wastewater; and mixing the tertiarily-treated wastewater with the composite adsorbent, conducting oscillating at room temperature, and carrying out solid-liquid separation, wherein the composite adsorbent is prepared by uniformly mixing modified sepiolite, acid-modified fly ash and cross-linked chitosan. The method for treating the nickel-containing wastewater by using the composite adsorbent provided by the invention is simple in process,has a better treatment effect on various forms of nickel in a water body, and is high in nickel removal rate.

Owner:ANHUI DEQI ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of amido bridged regular mesoporous organic base heterogeneous catalyst

InactiveCN101823001AUnobstructed channelHigh reactivityOrganic chemistryOrganic compound preparationOrganic baseHomogeneous catalysis

The invention belongs to an organic base heterogeneous catalyst, in particular to a preparation method of an amido bridged regular mesoporous organic base heterogeneous catalyst. A homogeneous organic base catalyst in the prior art is separated and recycled difficultly from a reaction system, so that the production cost is increased, and environmental pollution is brought. The method comprises the following steps of: mixing P123, KCl, NaF or NaCl and HCl with water to prepare a surfactant; adding 1,2-bis(triethoxy silicon)ethane and amido bridged silicane; aging at the temperature of 90-110 DEG C for 26-36 hours and getting a deposit; grinding the deposit; adding a mixed solution of hydrochloric acid and ethanol and extracting at the temperature of 70-80 DEG C for 24-48 hours; washing a product with base; carrying out extraction filtration and vacuum dying at the temperature of 80 DEG C to obtain the amido bridged regular mesoporous organic base heterogeneous catalyst. The invention has the advantages of high catalytic activity, simple preparation process, catalyst recycle, cost saving and environmental pollution reduction.

Owner:SHANGHAI NORMAL UNIVERSITY

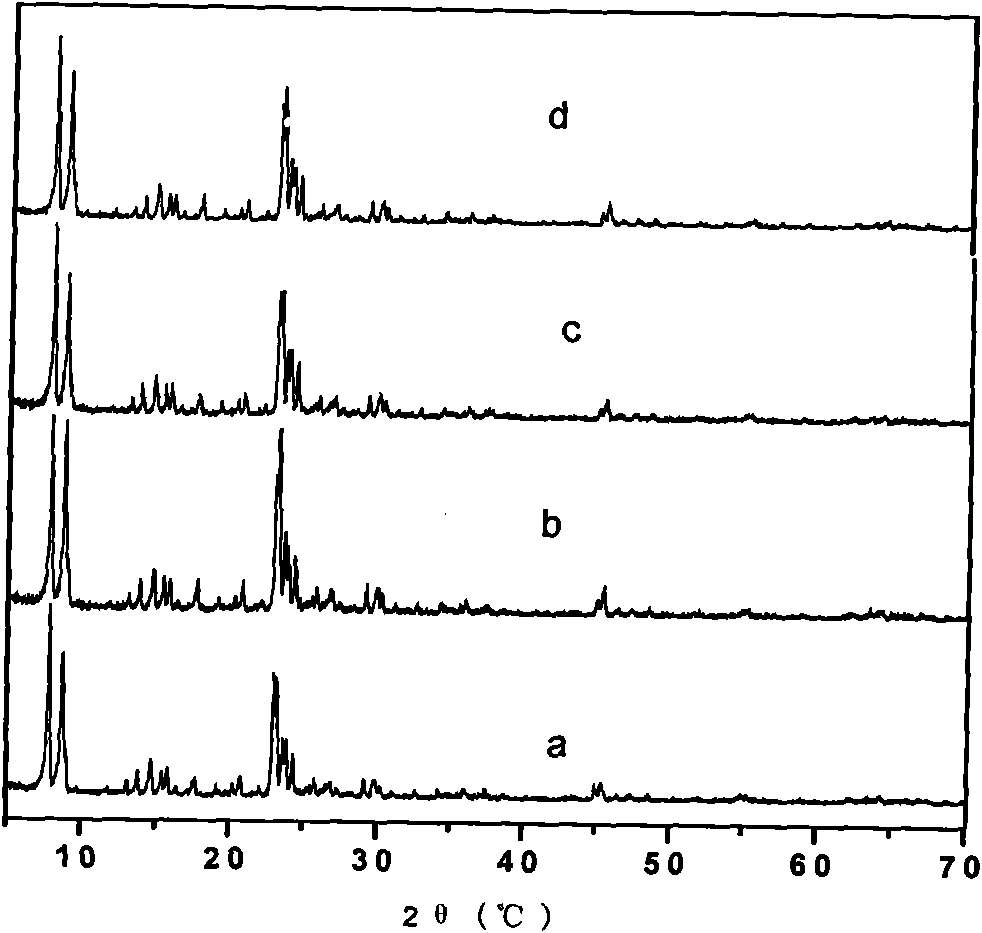

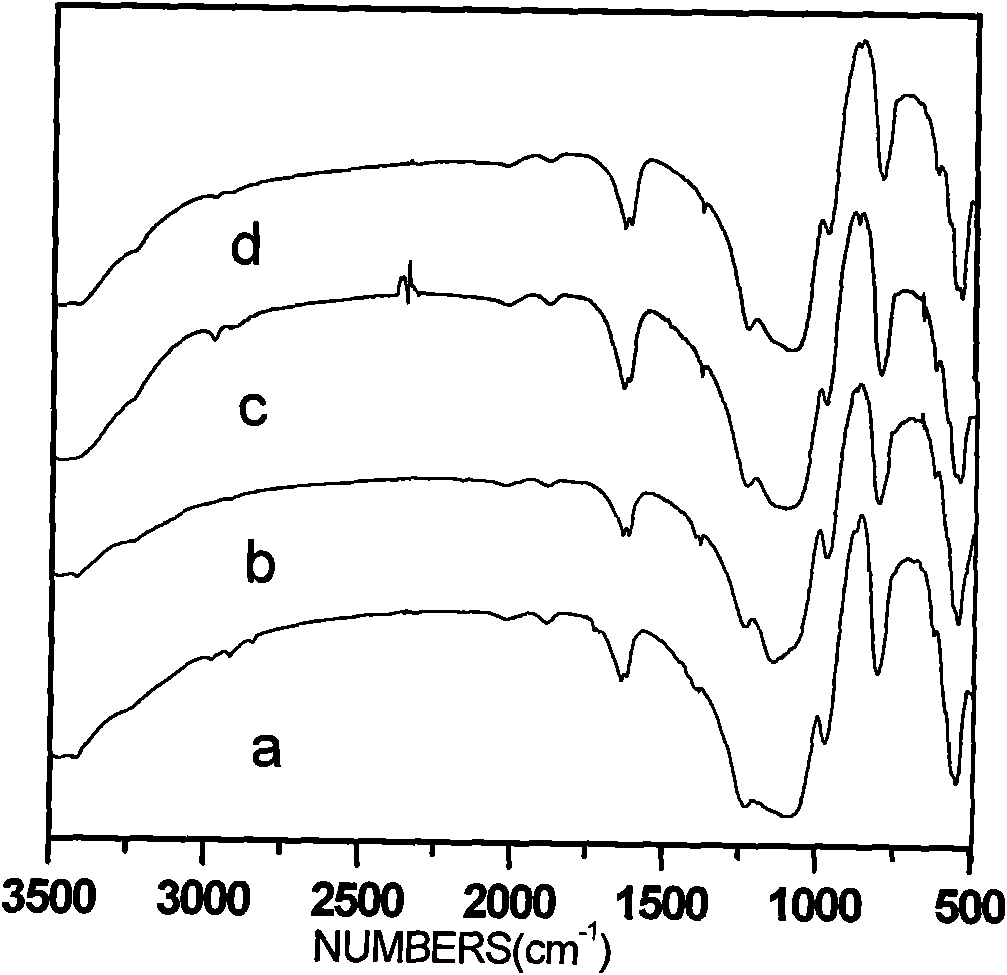

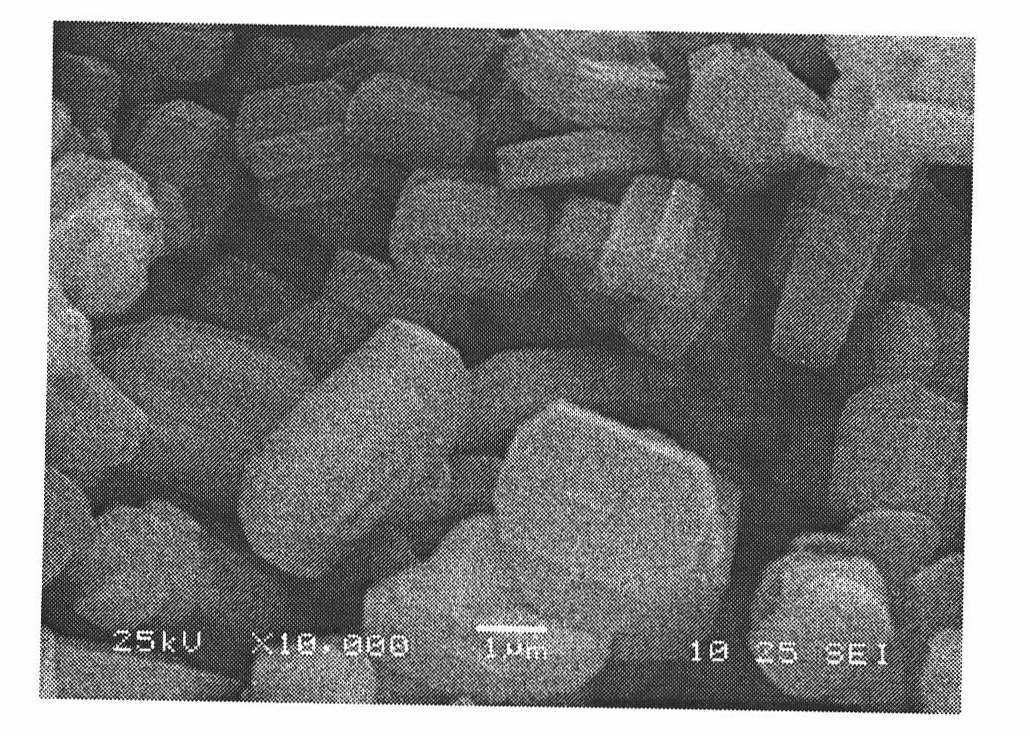

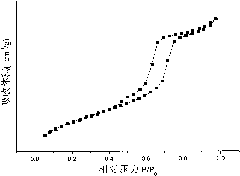

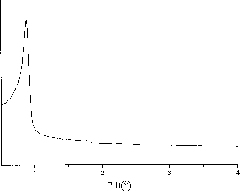

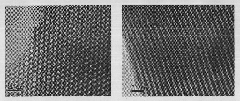

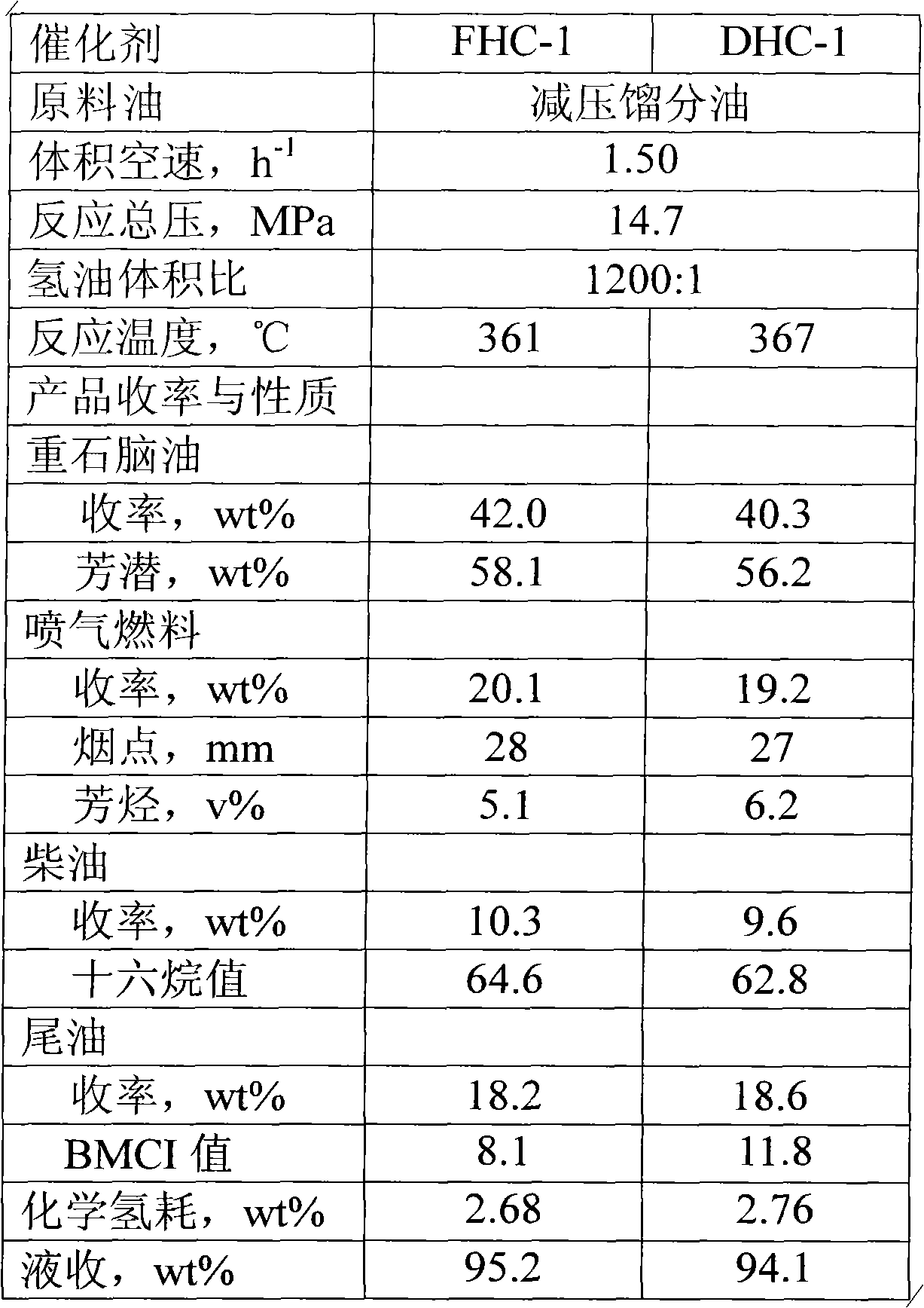

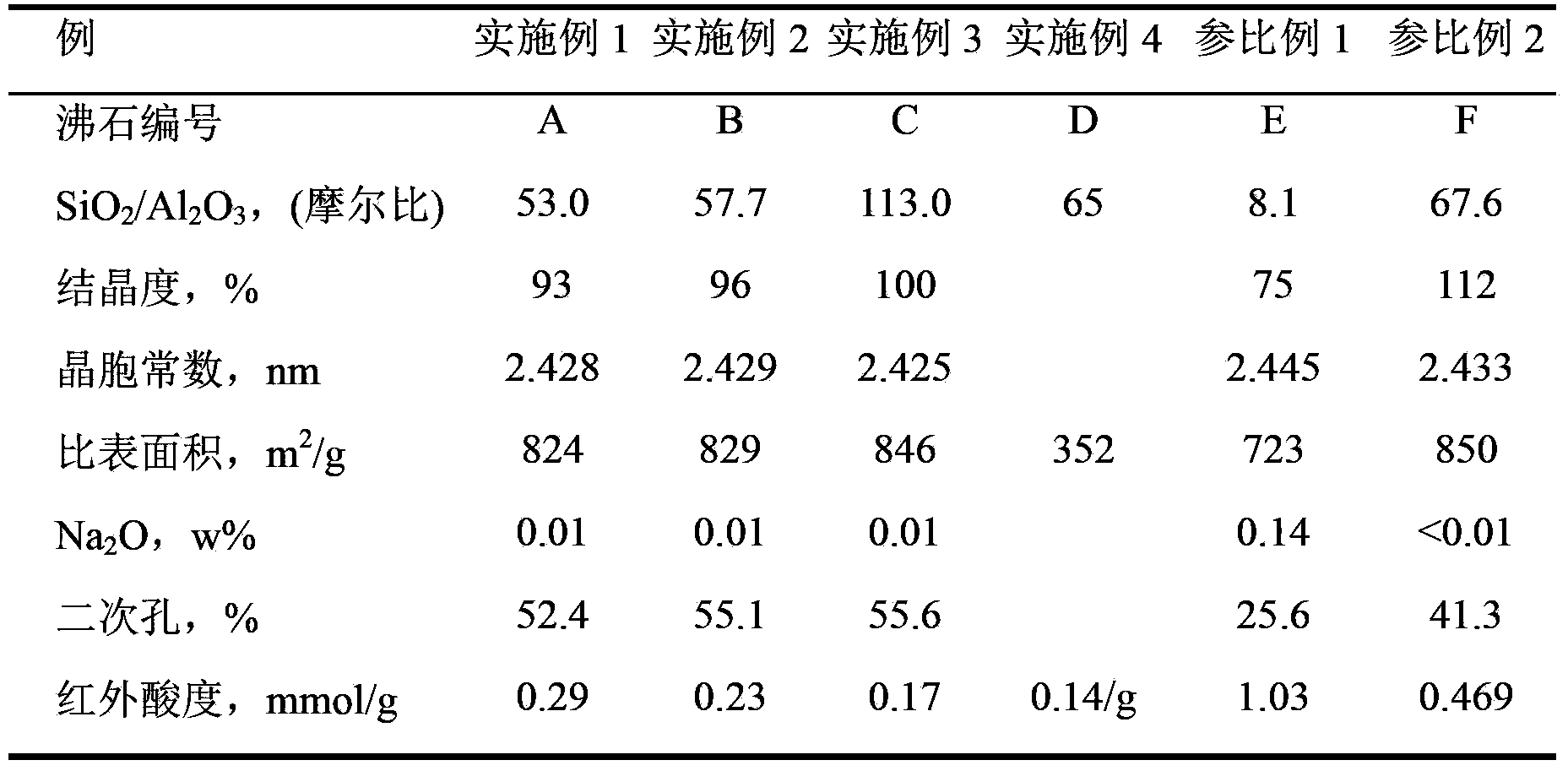

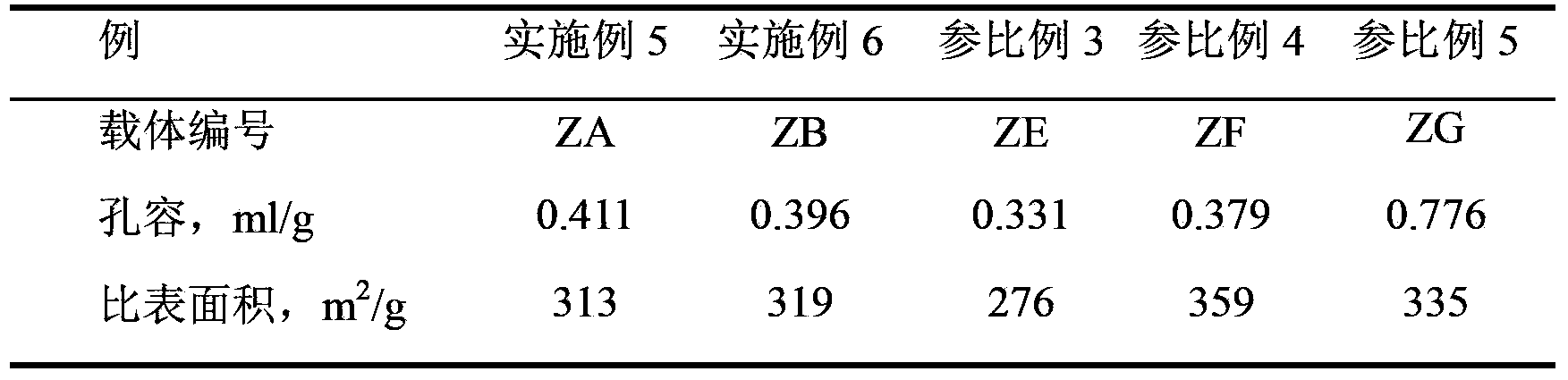

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN102049307AHigh crystallinityPreserve integrityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The carrier consists of a small crystal particle Y-shaped molecular sieve and alumina, wherein the small crystal particle Y-shaped molecular sieve has high crystallinity, high ratio of silicate to aluminium, continuous and stable framework structure and smooth pores. A hydrocracking catalyst prepared from the carrier has the characteristics of high catalytic activity, high heavy naphtha selectivity, high potential aromatic hydrocarbon content, low bureau of mines correlation index (BMCI) value of hydrocracking tail oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-dielectric constant nano silicon oxide molecular sieve thin film

InactiveCN101712478APromote decomposition and volatilizationFlat surfaceMolecular-sieve and base-exchange compoundsMolecular sieveNano silicon

The invention discloses a method for preparing a low-dielectric constant nano silicon oxide molecular sieve thin film, comprising the preparation of pure silicon molecular sieve nano particles, the synthesis of a pure silicon molecular sieve thin film and the preparation of the low-dielectric constant nano silicon oxide molecular sieve thin film by ultra-violet photolysis. The method of the invention has convenient operation, low energy consumption, short preparation time, low cost and less pollution, and can ensure that the structure of a mesoporous material can not be damaged. The dielectric constant epsilon of the thin film prepared by the method of the invention is less than or equal to 2.4.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

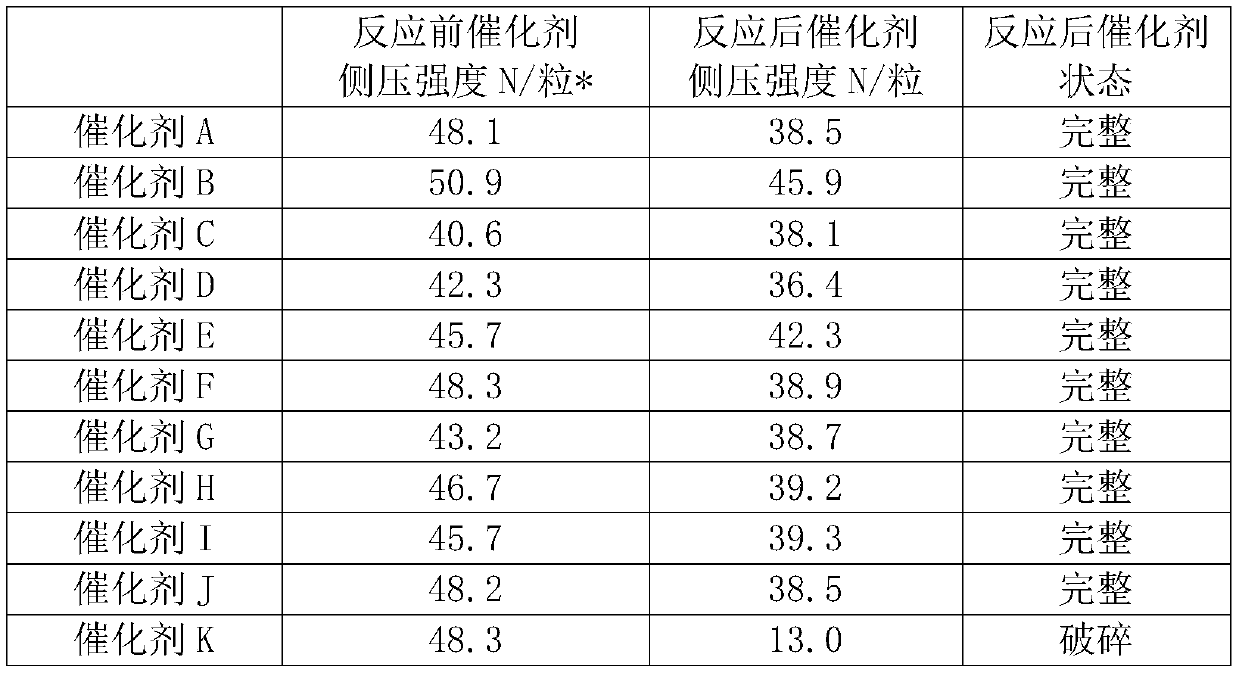

Hydrogenation catalyst and preparation method and application thereof

ActiveCN111715238AUnobstructed channelWeak acidOrganic compound preparationHeterogenous catalyst chemical elementsAlkaline earth metalPtru catalyst

The invention discloses a catalyst for preparing trimethylolpropane through hydrogenation of 2,2-dimethylolbutyraldehyde and a preparation method of the catalyst. The catalyst comprises 35 to 70 wt% of copper oxide, 5 to 25 wt% of zinc oxide, 5 to 35 wt% of aluminum oxide, 10 to 30 wt% of silicon dioxide, 0.5 to 5 wt% of alkaline earth metal oxide, 0.05 to 1.0 wt% of palladium oxide, 0.01 to 1.0 wt% of iridium oxide and 0.01 to 1.0 wt% of tin oxide. When the catalyst is used for preparing trimethylolpropane by a hydrogenation method, the catalyst not only has good activity and selectivity, butalso has strong formate conversion capability and high mechanical stability.

Owner:WANHUA CHEM GRP CO LTD

Solid base catalyst and preparation method thereof

ActiveCN113509925AHigh proportion of mesoporesUnobstructed channelCatalyst carriersCatalytic crackingPolycyclic aromatic hydrocarbonPtru catalyst

The invention discloses a solid base catalyst and a preparation method thereof. The solid base catalyst is composed of an active component, an auxiliary agent, a molding auxiliary agent and a solid base catalyst carrier. The solid base catalyst carrier is a highly mesoporous catalytic carrier, and the solid base catalyst carrier is subjected to pore channel thickening treatment, transition metal doping and surface modification treatment, so that the hydrothermal stability of the catalyst is improved, parts of polar centers are eliminated, the adsorption capacity of the catalyst on polycyclic aromatic hydrocarbon and non-hydrocarbon impurities in heavy oil is reduced, and the service life of the catalyst is prolonged. The invention also provides a preparation method of the solid base catalyst, and microsphere, strip and spherical catalysts are prepared and used for fluidized bed catalytic cracking, fixed bed, moving bed and other reaction processes. When the solid base catalyst is used for treating heavy oil with the residual carbon content larger than 10 wt% and in the residual oil catalytic cracking process, the coke yield is smaller than 10 wt%, and the selectivity of low-carbon olefin in liquefied gas is larger than 80%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

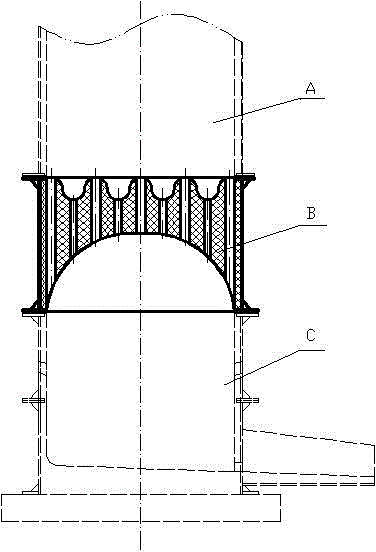

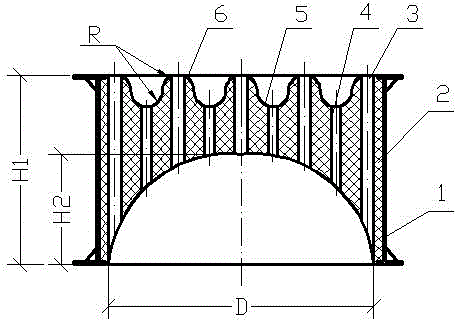

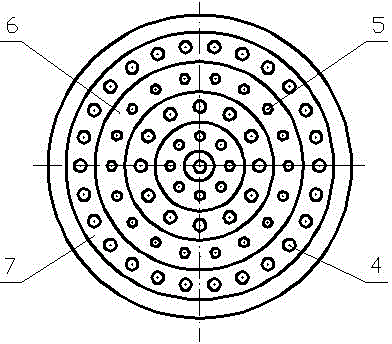

Integral cellular fire-resistant hearth for fuel gas cupola furnace

The invention relates to an integral cellular fire-resistant hearth for a fuel gas cupola furnace. According to the hearth, the high-temperature fire-resistant castable integral forming and normal-temperature hardening burn-free technology is adopted, by means of the cellular runner structure, the structural design of an annular round boss and a groove, and optimization of the bottom arch-shaped structure, fuel gas, molten iron and slag are ascended and descended through respective runways, direction contact between the fuel gas and the molten iron is reduced, and the burning loss of an alloy element is reduced. The fire-resistant hearth can effectively replace a water-cooling grate bar and a fire-resistant ball in the modern fuel gas cupola furnace, a large amount of water resources can be saved, the energy consumption can be reduced by 10-15%, the operation safety is improved, and the tapping temperature is increased.

Owner:李明弟

Physical aspergillus favus removing rice dumpling powder production technology

ActiveCN106819794ARub each other quicklyImprove qualityGrain millingFood scienceAspergillusFood technology

The invention belongs to the technical field of food, and particularly relates to a physical aspergillus favus removing rice dumpling powder production technology. According to the physical aspergillus favus removing rice dumpling powder production technology disclosed by the invention, a galvanized pipe which is 55 to 60 mm in diameter and 2 to 3 mm in pipe wall thickness is used for sucking washed sticky rice, and the sticky rice in the galvanized pipe is in mutual friction, so that aspergillus favus on the surface of the sticky rice can fall off through friction, and the quality of the sticky rice is increased; the washed sticky rice is sucked to a third-stage filter sieve for filtering, so that impurities and small particles in the sticky rice can be respectively removed, and the whole processing technology is capable of solving the problem that the haspergillus favus on the surface of the sticky rice is not easy to remove.

Owner:重庆源源龙脉食品有限公司

A kind of inferior heavy oil hydrogenation desulfurization catalyst and preparation method thereof

ActiveCN104646009BChange shapeSuitable for hydrodesulfurizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationActive component

The invention relates to an inferior heavy oil hydrodesulfurization catalyst and a preparation method thereof. The catalyst takes aluminum oxide as the carrier, and adopts group VIII and group VIB elements especially Ni-Mo as the active components, the catalyst pore volume is 0.45-0.60cm<3> / g, the specific surface area is 205-260m<2> / g, the average pore diameter is 7.0-12.0nm, and the average pore diameter gradually increases from the center to the outer surface along the radial direction of the catalyst particles. According to the preparation method of the catalyst, a concentration continuously increasing acid solution is employed to treat molded and roasted carrier particles. The catalyst provided by the invention has large surface aperture, wide pore channel, excellent diffusion performance, high hydrodesulfurization activity and activity stability.

Owner:PETROCHINA CO LTD

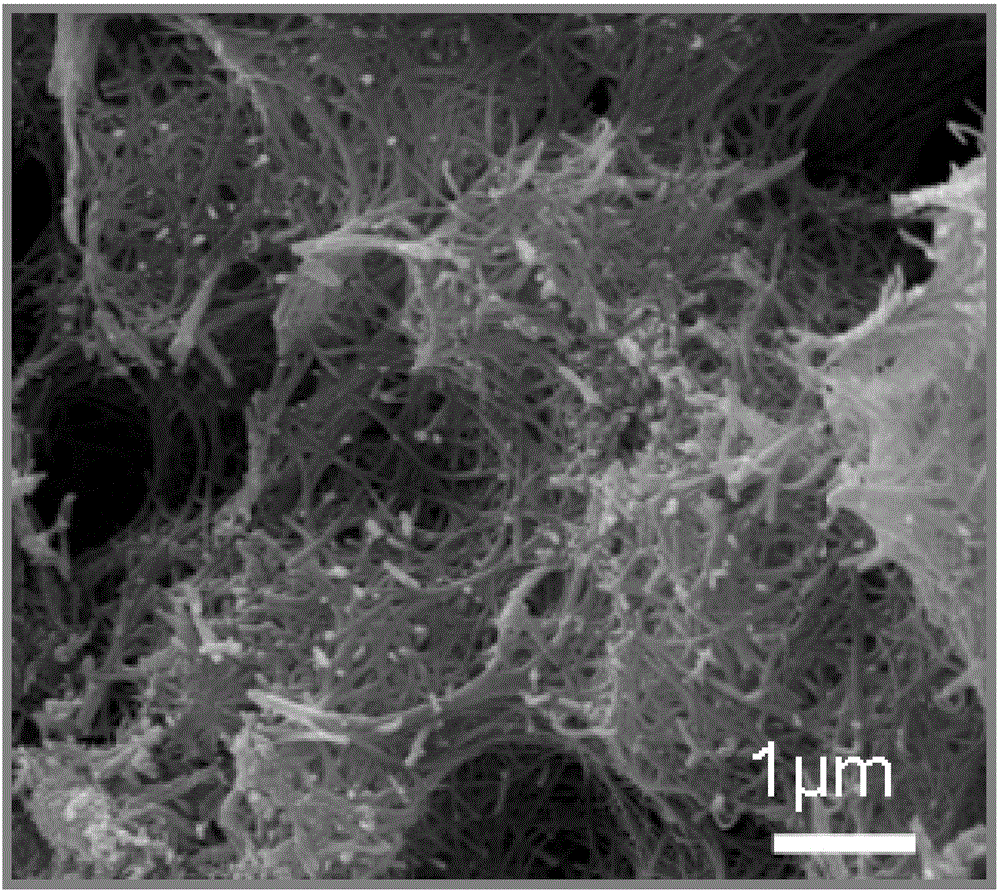

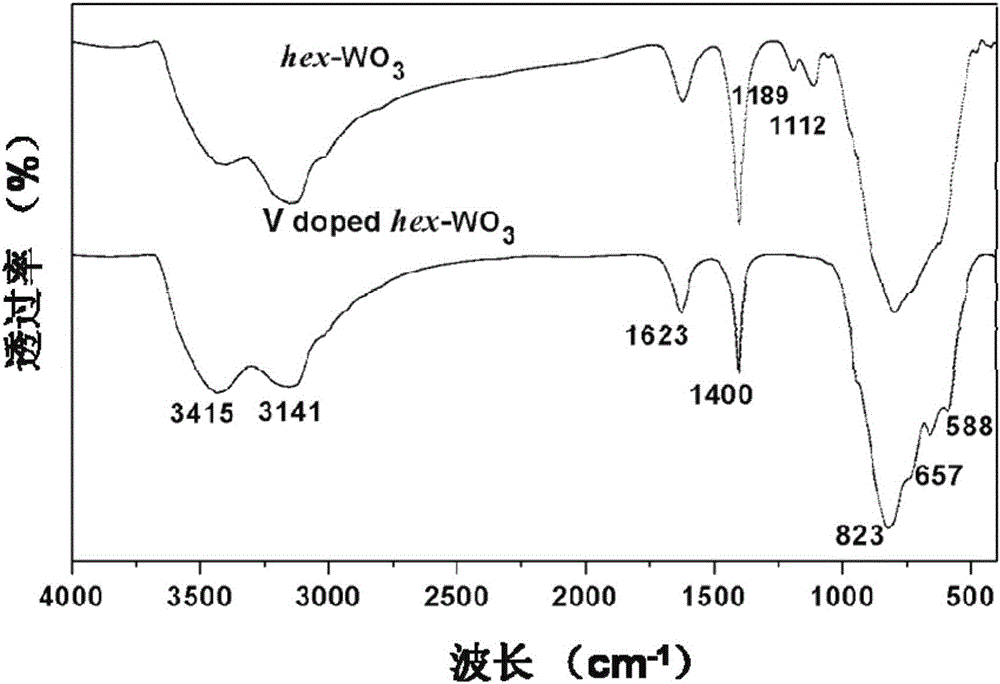

Preparation method of vanadium-doped nanometer tungsten oxide material and application of preparation method

InactiveCN106548817AImprove adsorption capacitySimple processMaterial nanotechnologyRadioactive decontaminationVanadium dopingRoom temperature

The invention discloses a preparation method of a vanadium-doped nanometer tungsten oxide material and application of the preparation method. The preparation method is characterized by comprising the following steps: putting 4-10 parts of a tungsten hexachloride solution with the concentration being 0.2-0.3mol / L in a polytetrafluoroethylene reactor, adding 12-20 parts of secondary distilled water, and stirring to enable the tungsten hexachloride solution and the secondary distilled water to be fully dissolved; adding 1-10 parts of a sodium metavanadate solution with the concentration being 0.06-0.6mmol / L in the solution, continuously stirring, and fully mixing; then adding 1-5 parts of a hydrochloric acid solution with the concentration being 2-4mol / L and 28-35 parts of an ammonium sulfate solution with the concentration being 0.4-0.5mol / L in the polytetrafluoroethylene reactor, and stirring for 0.5-1h; sealing the polytetrafluoroethylene reactor, putting in a program oven with the temperature raising rate and the temperature falling rate being 1-2 DEG C / min, and carrying out hydro-thermal treatment at the temperature of 150-200 DEG C for 24-48h; taking out the reactor, and cooling to room temperature; and washing reaction products with distilled water until neutral, putting the reaction products in an oven with the temperature being 80-100 DEG C, and drying the reaction products for 24-48h to obtain the vanadium-doped nanometer tungsten oxide material.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Hydrogenating and condensation point depressing catalyst and its preparing method

ActiveCN100496729CControl contentUnobstructed channelMolecular sieve catalystsRefining to eliminate hetero atomsAdhesiveImpurity

The invention discloses a hydro dewaxing catalyst and the preparation method. In the method, compound with hydrogen active component is mixed with aluminum dry gel to prepare adhesive; and then the adhesive is mixed with shape-selective cracked zeolite and is pinched in shape; after drying and roasting, catalyst carrier is yielded; then the catalyst carrier is impregnated in the impregnating solution containing the rest active component and promoter; and after drying and roasting again, the catalyst of the invention is yielded. The invention is capable of taking full advantage of the alumina used as adhesive in the catalyst carrier under low hydrogen active component content conditions to prepare adhesive containing all the molybdenum and tungsten and part of the nickel, thereby keeping a certain amount of nickel oxide in the zeolite. The rest of the active metal component is distributed in the alumina, keeping the zeolite passage unobstructed with good hydro dewaxing effect and effectively improving the hydrogen addition and purification performance of the catalyst. The catalyst is especially suitable for hydro dewaxing of raw material containing wax and with high nitrogen impurity content and suitable for hydrogen addition and purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

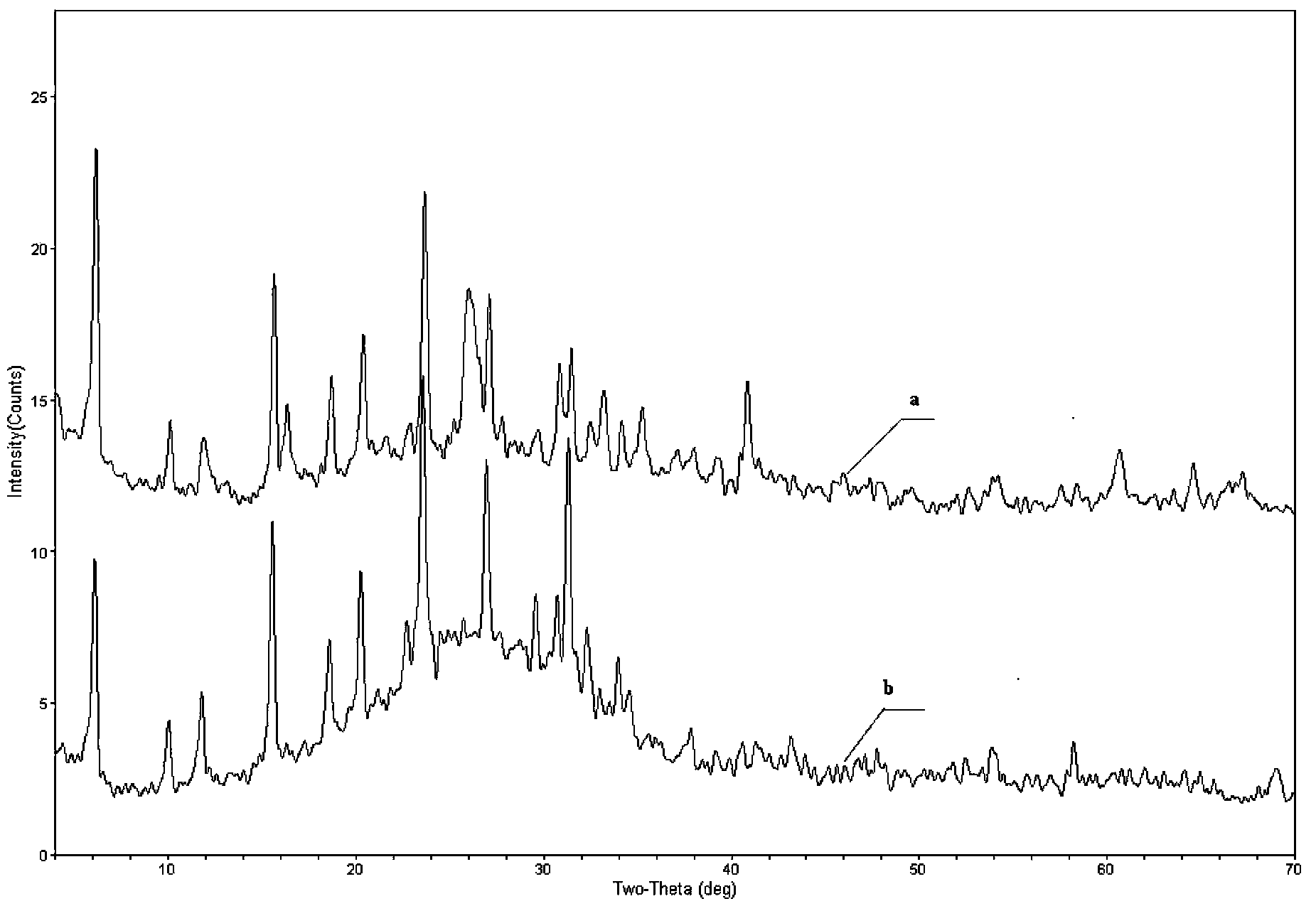

A kind of method for modification of extruded titanium-silicon molecular sieve

ActiveCN106238094BImprove solubilityPromote secondary crystallizationMolecular sieve catalystsMolecular sieveTitanium

The invention provides a method for modifying an extrusion moulding titanium silicalite molecular sieve. The method comprises the following specific steps: adding a titanium source into an alcohols solvent dropwise, sequentially adding a quaternary ammonium base, water and a protective agent, reacting for 10-60 minutes at the temperature of 20-30 DEG C to obtain a modified solution, mixing the modified solution and a strip titanium silicalite molecular sieve TS-1 obtained through extrusion moulding, putting the mixture in a crystallization kettle, processing for 12-48 hours at the temperature of 100-190 DEG C, separating a solid, washing the solid, and carrying out drying and roasting to obtain the strip titanium silicalite molecular sieve with high titanium content on the outer surface. The method solves the problems that the titanium content of a framework on the outer surface of the extrusion moulding titanium silicalite molecular sieve TS-1 is low and the large molecule is difficult to diffuse, the TS-1 with high titanium content of the framework on the outer surface is prepared, then the diffusion path of a reactant is shortened, the activity of the TS-1 in catalysis of a macromolecule reaction is improved, and the application of the TS-1 is further expanded.

Owner:DALIAN UNIV OF TECH

Silicon-aluminum carrier containing two modified molecular sieves, preparation method and application thereof

ActiveCN104250010ASmall cell constantImprove stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silicon

The invention relates to a silicon-aluminum carrier containing two modified molecular sieves. The silicon-aluminum carrier includes a modified Y molecular sieve, a modified ZSM-23 molecular sieve, and amorphous silicon-aluminum. The modified Y molecular sieve adopted by the carrier is a deep dealuminated Y molecular sieve, which has the characteristics of integral crystal form, high silicon-aluminum ratio, low acid center density, high medium-strong acid proportion and abundant secondary pores, and is suitable to serve as the acidic cracking component of a medium oil type hydrocracking catalyst. The high specific surface and developed secondary pores not only promote exertion of the hydrogenation activity, but are also conducive to spread of the reaction product, the secondary pores are numerous, and the acid center density is low, so that the probability of excessive cracking and secondary cracking can be reduced. Therefore, the catalyst can have excellent medium oil selectivity, high silicon-aluminum ratio, small lattice constant and stable structure, and has very good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Composite flocculant for municipal sewage treatment and use method thereof

InactiveCN111807489AUnobstructed channelImprove adsorption capacityWater contaminantsWater/sewage treatment by flocculation/precipitationCelluloseAluminium chloride

The invention provides a composite flocculant for municipal sewage treatment and a use method thereof. The composite flocculant is prepared from the following raw materials in parts by weight: 10-15 parts of kaolin powder, 15-25 parts of hydroxyethyl cellulose, 3-7 parts of sodium hypochlorite, 10-15 parts of lignosulfonate, 0.5-1.5 parts of a catalyst, 10-20 parts of acrylamide, 7-13 parts of polyaluminum chloride, 0.5-1.5 parts of a stabilizer, 30-35 parts of diluted hydrochloric acid and 150-180 parts of deionized water. The composite flocculant for municipal sewage treatment has a good adsorption effect on heavy metal ions in industrial wastewater, is good in biodegradability and does not easily cause secondary pollution.

Owner:中科乐美科技集团有限公司

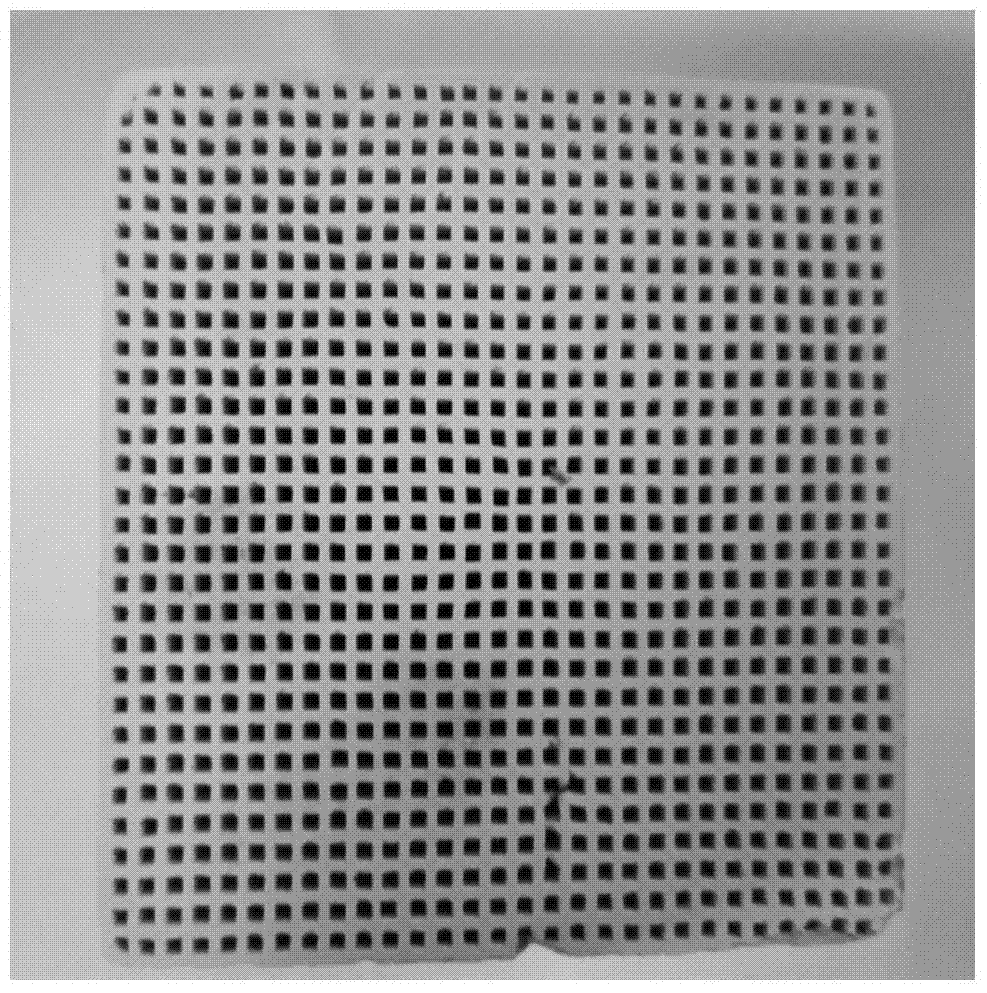

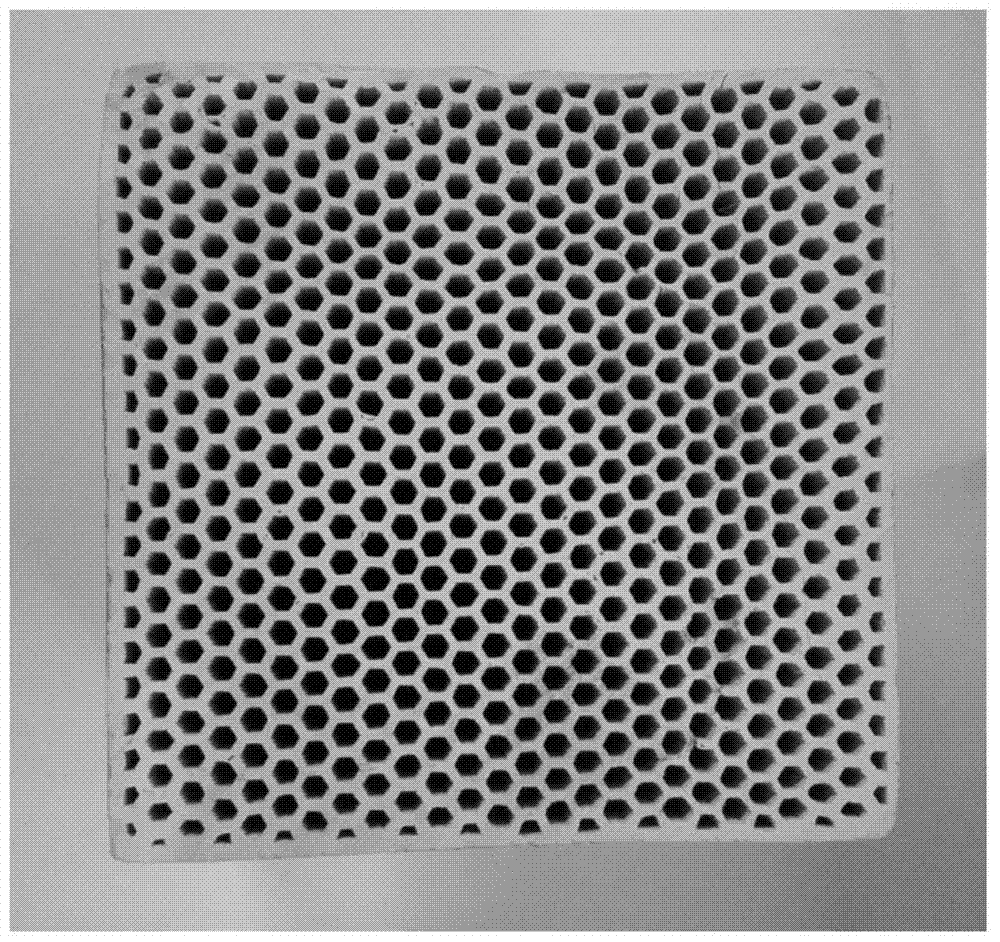

A monolithic honeycomb structure forming method for molecular sieve catalyst

ActiveCN105618159BHigh strengthLimit the rate of water lossMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention provides an integral honeycomb structured forming method of a molecular sieve catalyst, which includes the following steps: 1) impregnating the molecular sieve with a metal solution, stirring, drying, and calcining it at high temperature to prepare a powdered molecular sieve catalyst; 2) adding sticky The binder, extrusion aid, acid solution and water are mixed and kneaded to obtain a wet mass; 3) The wet mass is roughed, vacuumed and refined, and extruded under high-pressure vacuum to be extruded into a honeycomb integral wet base. 4) The green body is dried, cut, polished, and calcined at a temperature of 500 to 550°C for 6 to 10 hours to prepare a honeycomb monolithic molecular sieve catalyst. The molding method proposed by the invention precisely controls key parameters in the drying process and limits the rate of water loss of the green body, ensuring high strength and neat shape of the green body. The method of the present invention can be applied to industrial large-scale production. It adopts equipment in the existing technology and reasonably arranges the process route to obtain qualified industrial application products.

Owner:BEIJING UNIV OF CHEM TECH

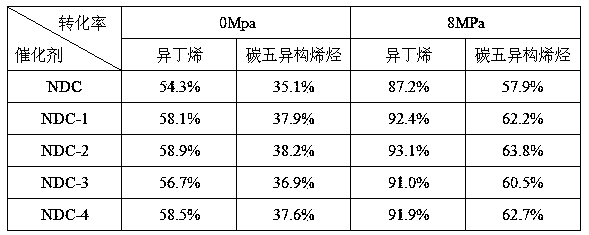

Catalyst for synthesizing methyl tertiary butyl ether (MTBE) and methyl isoamyl ether, and preparation method

InactiveCN103143382BLong overall regeneration lifeSimple regeneration methodMolecular sieve catalystsEther preparation by compound additionMolecular sievePtru catalyst

Owner:天津市南天新材料研究中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com