Catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as low activity, high silicon-aluminum ratio, and poor accessibility of active centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0071] In the preparation method of catalytic cracking catalyst provided by the present invention, in the preparation method of the modified Y-type molecular sieve, in step (4), the gas-phase ultrastable modified Y-type molecular sieve obtained in step (3) is contacted with an acid solution to react ( The present invention is called channel cleaning modification, referred to as channel cleaning, or acid treatment modification). One embodiment, the reaction of the gas-phase ultra-stable modified Y-type molecular sieve obtained in step (3) in contact with the acid solution is to react the gas-phase ultra-stable modified molecular sieve, that is, the gas-phase ultra-stable modified Y-type molecular sieve is mixed with acid solution and reacted for a period of time, then the reacted molecular sieve is separated from acid solution, for example, separated by filtration, and then optionally washed and optionally dried to obtain the modified Y-type molecular sieve provided by the inven...

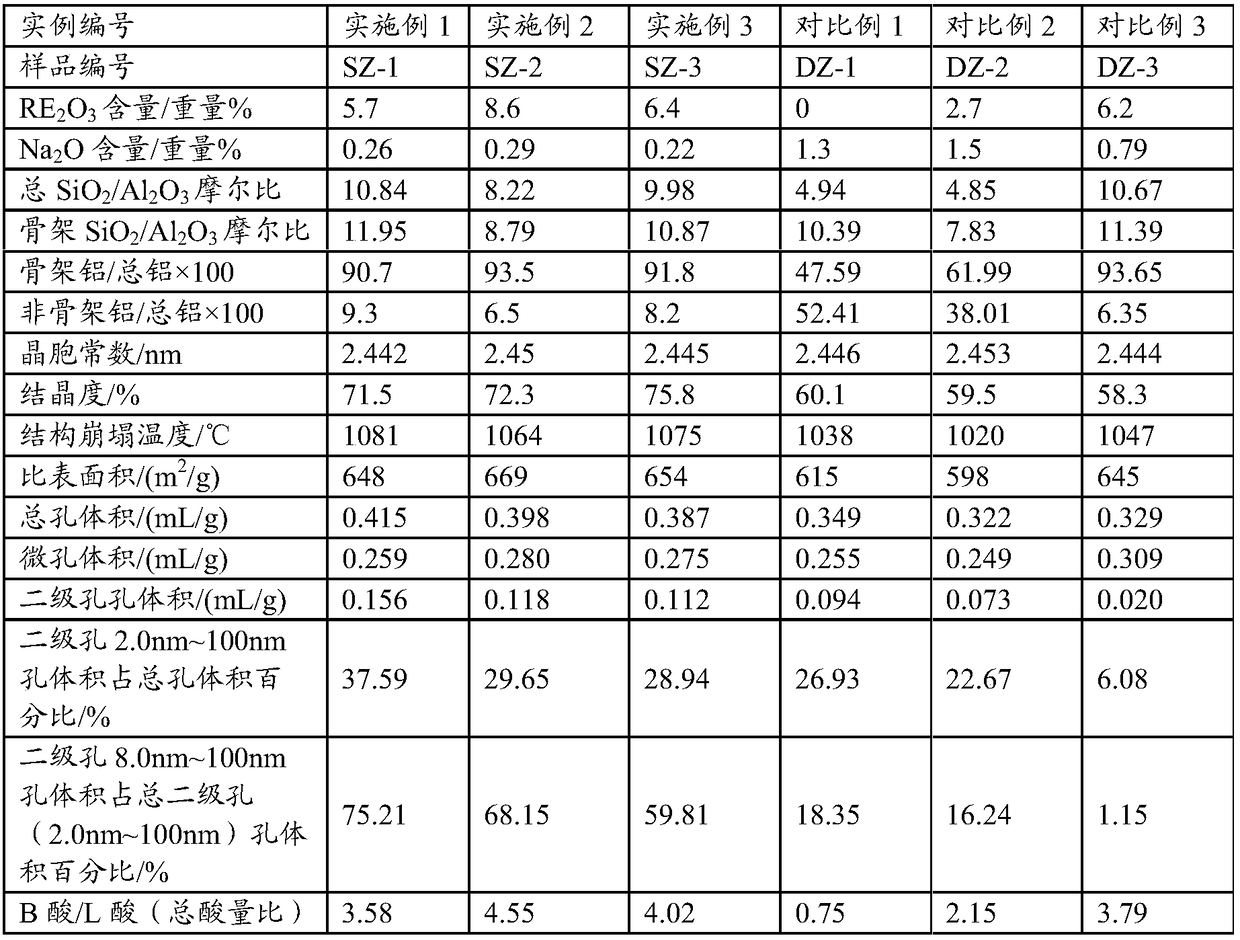

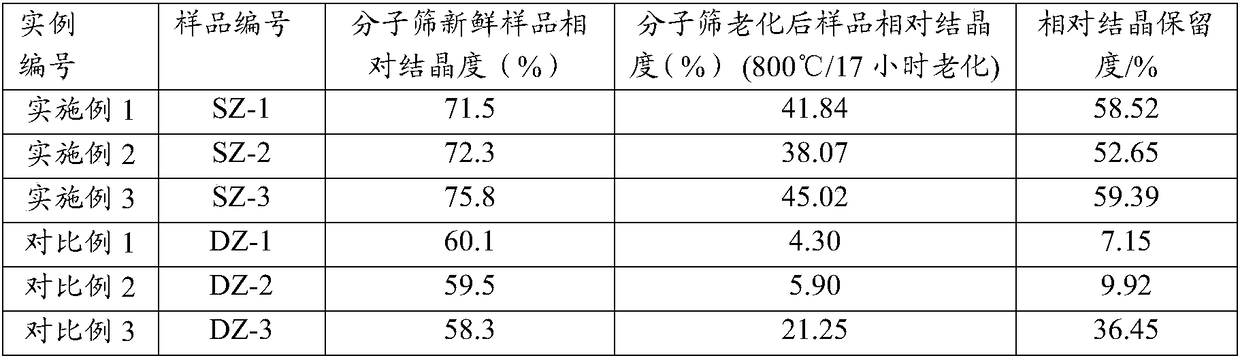

Embodiment 1

[0086] 2000Kg (dry basis weight) skeleton SiO 2 / Al 2 o 3 Be 4.6 NaY type zeolite (sodium oxide content 13.5% by weight, Sinopec Catalyst Qilu Branch Company produces) joins and is equipped with 20m 3 In the water exchange tank, stir well at 25°C and then add 600L RECl 3 Solution (RECl 3 The rare earth concentration in the solution is expressed as RE 2 o 3 Calculated as 319g / L), after continuing to stir for 60 minutes, filter, wash, and the filter cake is sent to a flash drying oven for drying; obtain a Y-type molecular sieve with a rare earth-containing conventional unit cell size with reduced sodium oxide content, and its sodium oxide content It is 7.0% by weight, and the unit cell constant is 2.471nm; then, it is sent to a roasting furnace at a temperature of 390°C, and is roasted for 6 hours under 50% water vapor (containing 50% by volume of water vapor in the atmosphere); then, at a temperature of 500°C, it is dried Air atmosphere (water vapor content is lower than ...

Embodiment 2

[0092] 2000Kg (dry basis weight) skeleton SiO 2 / Al 2 o 3 Be 4.6 NaY type zeolite (sodium oxide content 13.5% by weight, Sinopec Catalyst Qilu Branch Company produces) joins and is equipped with 20m 3 In the primary exchange tank of decationized water, at 90°C, after stirring evenly, add 800L RECl 3 Solution (RECl 3 The rare earth concentration in the solution is expressed as RE 2 o 3 Calculated as 319g / L), stirred for 60 minutes; filtered, washed, and the filter cake was sent to a flash drying oven for drying to obtain a Y-type molecular sieve with a rare earth-containing conventional unit cell size with a reduced sodium oxide content, and its sodium oxide content was 5.5 % by weight, unit cell constant is 2.471nm, then, sent to roasting furnace at temperature (atmosphere temperature) 450 ℃, roasting 5.5 hours under 80% water vapor atmosphere; ℃, the atmosphere is a dry air atmosphere, and the calcination time is 2 hours, so that the water content is lower than 1% by we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com