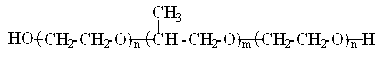

Method for directly synthesizing multi-stage ordered mesoporous molecular sieve

A technology of mesoporous molecular sieve and molecular sieve, which is applied in the directions of eight-sided crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of complex synthesis and high cost of multi-stage ordered mesoporous molecular sieves, and achieves high heat and water efficiency. Good thermal stability, high mechanical strength, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 5.13g tetraethyl orthosilicate, 2g water and 4g tetrapropyl ammonium hydroxide are mixed, at 25 o After C was stirred for 3 hours, 3.5ml of 6% NaOH solution was added thereto, and 2.36g of cetyltrimethylammonium bromide (CTAB) was added to obtain a gel mixture. The gel mixture was moved into a stainless steel synthesis kettle and sealed. at 155 o C crystallized for 24 hours to obtain the product after washing, drying and 550 o After calcination of C for 6 hours, a multi-level ordered mesoporous Silicalite-1 molecular sieve was obtained.

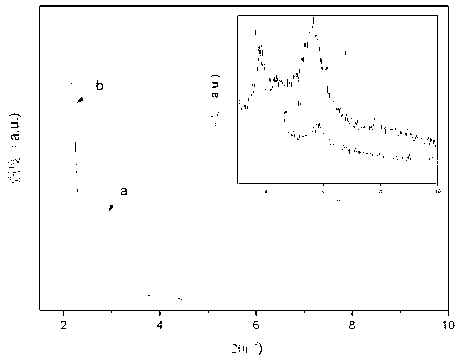

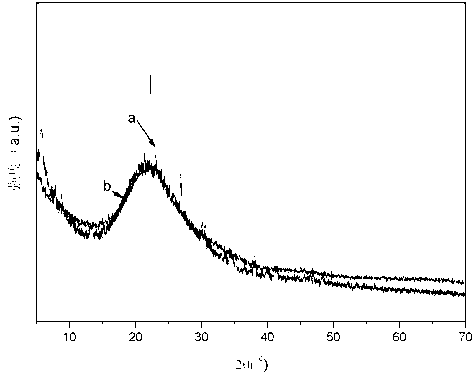

[0024] XRD characterization results ( figure 1 a and figure 2 a), Low-temperature nitrogen adsorption-desorption isotherm ( image 3 , Figure 4 ), SEM ( Figure 5 ) proves that the product is a Silicalite-1 molecular sieve with highly ordered mesoporous, high hydrothermal stability and hierarchical channels.

Embodiment 2

[0026] The sol (2.8 wt% Al 2 o 3 ), 2g of water and 4g of tetrapropylammonium hydroxide mixed at 25 o After C was stirred for 3 hours, 3.5ml 6% NaOH solution was added thereto, and then 5.1g CTAB was added to obtain a gel mixture. o C crystallized for 48 hours to obtain molecular sieve product after washing, drying and 550 o After calcination of C for 6 hours, a multi-level ordered mesoporous ZSM-5 molecular sieve was obtained.

Embodiment 3

[0028] 5.13g tetraethyl orthosilicate, 2g water and 4g tetrapropyl ammonium hydroxide are mixed, at 25 o After C was stirred for 3 hours, 3.5ml 6% NaOH solution was added thereto, and then 0.9g CTAB was added to obtain a gel mixture, and the gel mixture was moved into a stainless steel synthesis kettle for sealing, and o C crystallized for 48 hours to obtain the whole product of molecular sieve after washing, drying and 550 o After calcination of C for 6 hours, the whole of multi-level ordered mesoporous Silicalite-1 molecular sieve (now figure 1 b and 2b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com