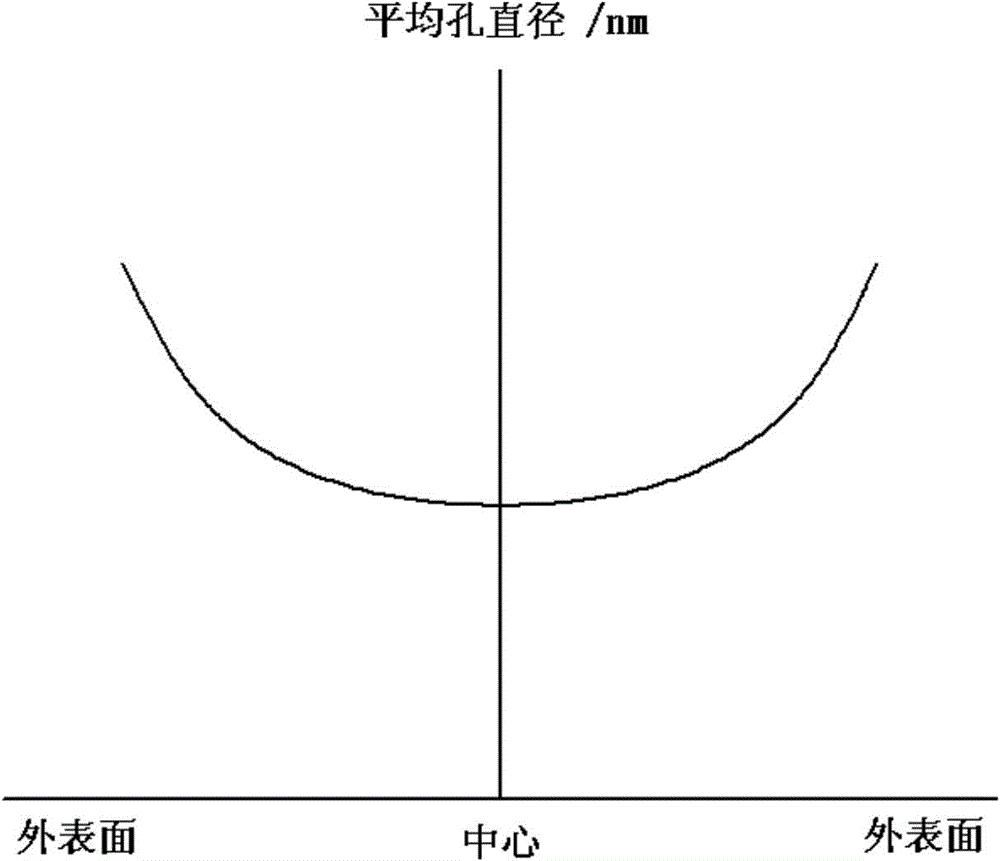

Inferior heavy oil hydrodesulfurization catalyst and preparation method thereof

A technology for hydrodesulfurization and low-quality heavy oil, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Achieve the effect of smooth pores, high desulfurization activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

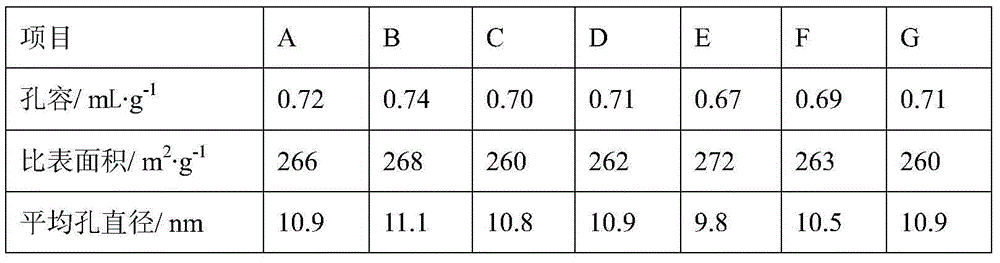

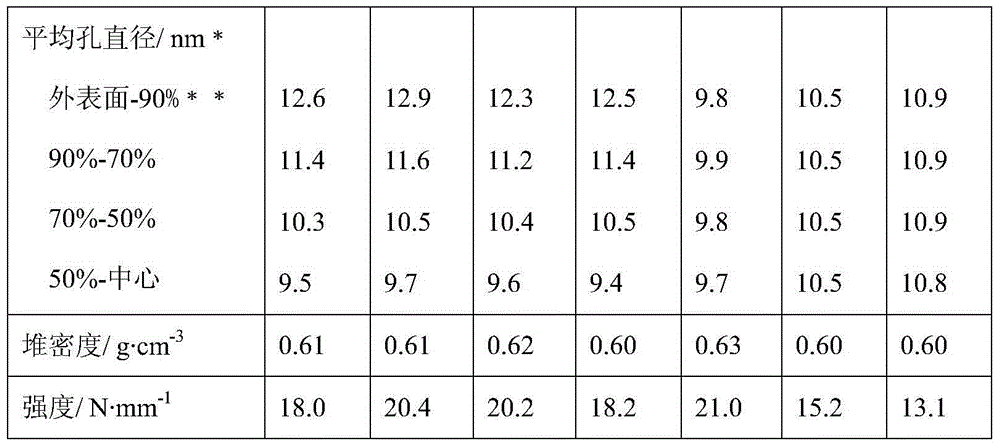

Examples

Embodiment 1

[0023] (1) Preparation of carrier

[0024] Weigh 500 g of macroporous pseudo-boehmite dry rubber powder (dry basis content 71.5 wt%) produced by Yantai Henghui Chemical Co., Ltd., add 14 g of celadon powder, and mix evenly. Add 390 g of acetic acid solution with a concentration of 4.0 wt % into the aforementioned materials, knead it into a plastic body, and then extrude it into a cylinder with a diameter of 1.4 mm on a front-extrusion single-screw extruder. Dry at 120°C for 3.0 hours, then put it into a roasting furnace, raise it to 650°C at a rate of 180°C / hour, and keep the temperature constant for 3 hours.

[0025] (2) Handling of the carrier

[0026] Weigh 300 grams of the carrier obtained in (1) and place it in a rotating vessel, spray 250 g of deionized water on the carrier evenly at a speed of 30 mL / min, and spray water evenly on the aforementioned deionized water at a speed of 3.0 g / min. Add acetic acid. After spraying to the saturated water absorption rate of the c...

Embodiment 2

[0030] Weigh 500 g of the above-mentioned pseudo-boehmite dry rubber powder, add 14 g of safflower powder, and mix evenly. Concentration is that the acetic acid solution 400g of 3.5wt% is added in the aforementioned material, kneading becomes plastic body. Extruded, dried and roasted in the same manner as in Example 1. 250g of deionized water was evenly sprayed on the obtained alumina carrier at a speed of 30mL / min, and acetic acid was evenly added to the aforementioned deionized water at a speed of 4.0g / min while spraying water. After spraying to the saturated water absorption rate of the carrier, airtight treatment at 60°C for 3.0 hours, and washing with clean water 3 times. Dry at 200°C for 3.0 hours. Catalyst B was obtained using the same catalyst preparation conditions as in Example 1.

Embodiment 3

[0032] Change the adding speed of acetic acid into 2.5g / min among the embodiment 1, other conditions are all identical with embodiment 1, obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com