Catalyst for synthesizing methyl tertiary butyl ether (MTBE) and methyl isoamyl ether, and preparation method

A technology of methyl isoamyl ether and methyl tert-butyl ether, which is applied in the field of catalysts and preparations, can solve the problems of short service life of catalysts, catalysts are easily dissolved by carbon five, etc., and achieve simple regeneration methods and smooth channels , the effect of prolonging the reaction life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

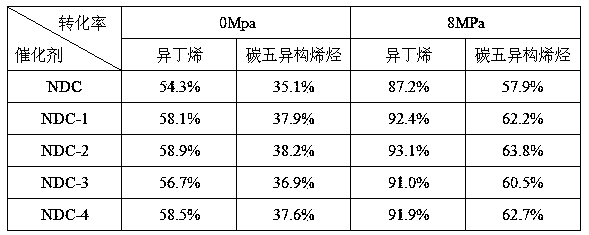

Examples

Embodiment 1

[0023] Preparation of molecular sieves containing mother liquor: put silica gel, sodium metaaluminate, pseudoboehmite and caustic soda in a reaction kettle, and control the molar ratio to SiO 2 :Al 2 o 3 : Na 2 O: H 2 O =1: (0.002~0.04): (0.03~0.05): (8~15), fully stirred and mixed, the synthesis temperature is 80~160°C, the synthesis pressure is 5~15Mpa, react for 72 hours, cool down, release from the autoclave material, which is the molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 25~500). This mother liquor also contains a large amount of sodium and small amounts of silicon and aluminum.

[0024] 1) Take the molecular sieve sample containing the mother liquor and analyze the dry basis (the mass percentage of the molecular sieve solid in the unit mass sample) is 35.6%, and take the water glass sample used to configure the adhesive to analyze SiO 2 concentration.

[0025] 2) Weigh 857g of molecular sieve containing mother liquor, and calculate the mass of solid mo...

Embodiment 2

[0035] The catalyst was prepared according to the method of Example 1, wherein the amount of nano-alumina used in step 3) was changed to 21g, and the catalyst was named NDC-2.

Embodiment 3

[0037] The catalyst was prepared according to the method of Example 1, wherein the amount of nano-alumina used in step 3) was changed to 6g, and the catalyst was named NDC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com