ZSM-5 zeolite catalyst for preparing propylene by methanol dehydration as well as preparation method and application thereof

A ZSM-5 and zeolite catalyst technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy fluctuation of product yield and poor stability, and achieve slow decay of methanol conversion rate and excellent performance Good recovery and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0045] Embodiment 1-9: the preparation of aluminum sol

[0046] The typical raw materials, proportions and preparation conditions used in the preparation of aluminum sol are shown in Table 1 below.

[0047] Table 1. Preparation of aluminum sol

[0048]

[0049]

[0050] The preparation process is as follows:

[0051] Taking Example 1 as an example, measure a certain volume of concentrated nitric acid, dilute it to a concentration of 4mol / L with deionized water, measure a certain volume of 4mol / L nitric acid solution and a three-necked bottle, weigh an aluminum sheet of corresponding weight, and cut it into 1cm Put small pieces of the same size into the nitric acid solution in the three-necked bottle, heat the oil bath to 60°C, and keep it under stirring for 12 hours.

Embodiment 10-17

[0052] Examples 10-17: Forming of Catalysts

[0053] The typical conditions for preparing shaped catalysts with aluminum sol as a binder are shown in Table 2 below:

[0054] Formation of table 2, catalyst

[0055]

[0056] The molding process is as follows:

[0057] Taking Example 10 as an example, the zeolite powder and additive starch are mixed uniformly, the binder in the proportion is added, and an appropriate amount of water is added, and the mixture is uniformly mixed and placed in a mechanical extruder for extrusion molding.

Embodiment 18

[0058] Embodiment 18: Catalyst preparation completes and performance analysis

[0059] The catalyst particles prepared in Example 11 were calcined in a muffle furnace at 550° C. for 6 hours to obtain the prepared catalyst.

[0060] The physical and chemical properties and catalytic performance of the prepared catalyst were analyzed, the results are as follows:

[0061] figure 1 is the XRD spectrum of the catalyst. It can be seen that the catalyst is a typical MFI structure type molecular sieve with high crystallinity, and its SiO 2 / Al 2 o 3 The ratio (SAR) was 5.82. There is no obvious characteristic diffraction peak of alumina, indicating that the aluminum sol exists in the zeolite material in a highly dispersed state after high-temperature calcination, and no other crystal structure is formed.

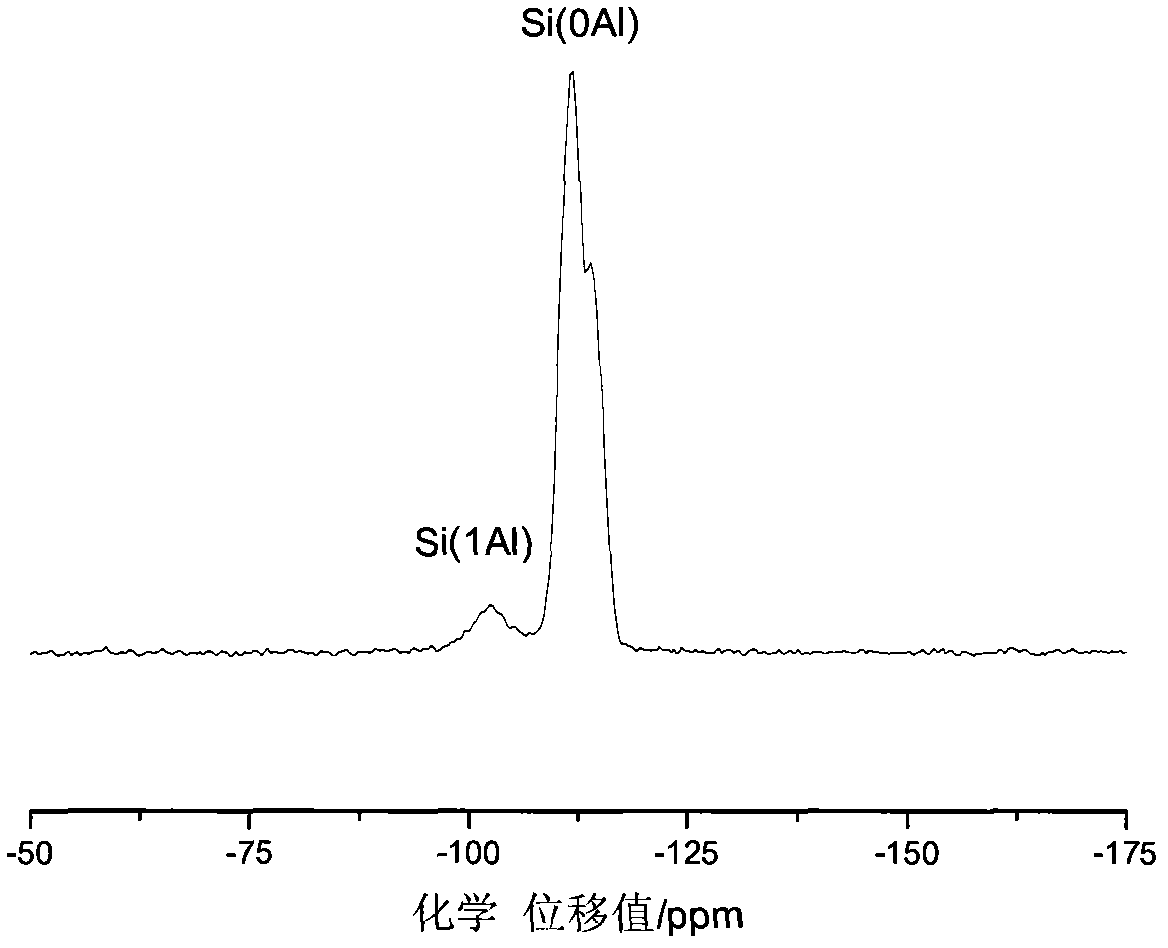

[0062] figure 2 for the catalyst 29 Si NMR spectrum. The coordination state of Si is mainly Si(0Al) and contains a small amount of Si(1Al). According to the calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com