A monolithic honeycomb structure forming method for molecular sieve catalyst

A molecular sieve and catalyst technology, applied in the field of monolithic honeycomb structural molding of molecular sieve catalysts, can solve the problems of inability to solve active components, high temperature sensitivity index, molecular sieve catalyst falling off, etc., and achieve stable and efficient catalytic performance and temperature sensitivity index. High and maintain the effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Impregnation modification: 65kg copper nitrate (Cu(NO 3 ) 2 ·3H 2 0) crushed and dissolved in 1000kg of deionized water to prepare a copper ion impregnating solution, and pour the prepared impregnating solution into the reaction kettle. Turn on the stirring device of the reactor, and set the rotating speed to 80rpm. Then slowly add 800kg of microporous molecular sieve ZSM-5 carrier into the impregnation solution, and the speed of adding the molecular sieve should be gradually slowed down to ensure that the stirring paddle of the reactor can rotate smoothly. After the mixing was completed, the mixture was uniformly stirred for 24 hours while maintaining the temperature of the water bath in the reactor at 80°C.

[0042] (2) Drying: after stirring for 24 hours, turn off the stirring paddle. The output is packed in a stainless steel drying tray (1m×0.5m×0.1m), and the height of the material layer does not exceed 3cm. Put the wet material contained in the drying tra...

Embodiment 2

[0054] For the preparation of the powdered molecular sieve catalyst, the process steps are basically the same as the steps (1) to (4) in Example 1, mainly because the preparation of each material and the parameters of the control conditions are different. That is, the following steps are:

[0055] (5) Dry mixing: take 50kg of Cu-ZSM-5 molecular sieve, 17kg of SB powder, and 4kg of safflower powder, put them into a mixer and mix until uniform, the time is 20 minutes, and the temperature is controlled at 30°C.

[0056] (6) Kneading: Add 38kg of water and 7kg of nitric acid to the above-mentioned mixed materials at a rate of 5 kg / min. During the addition, keep the stirring device turned on. After the addition is complete, continue to stir and knead for 20 to 30 minutes. Control the temperature at 35°C, and the stirring speed is 60 rpm.

[0057] (7) Mud refining: Put the evenly stirred muddy billet into the mud mixer for repeated mixing and extrusion. The temperature of the mud m...

Embodiment 3

[0064] In embodiment 3, the concrete steps are basically the same as in embodiment 1, the difference is the selection of the mould, i.e. the extrusion molding process, the step (8) in embodiment 3 is as follows

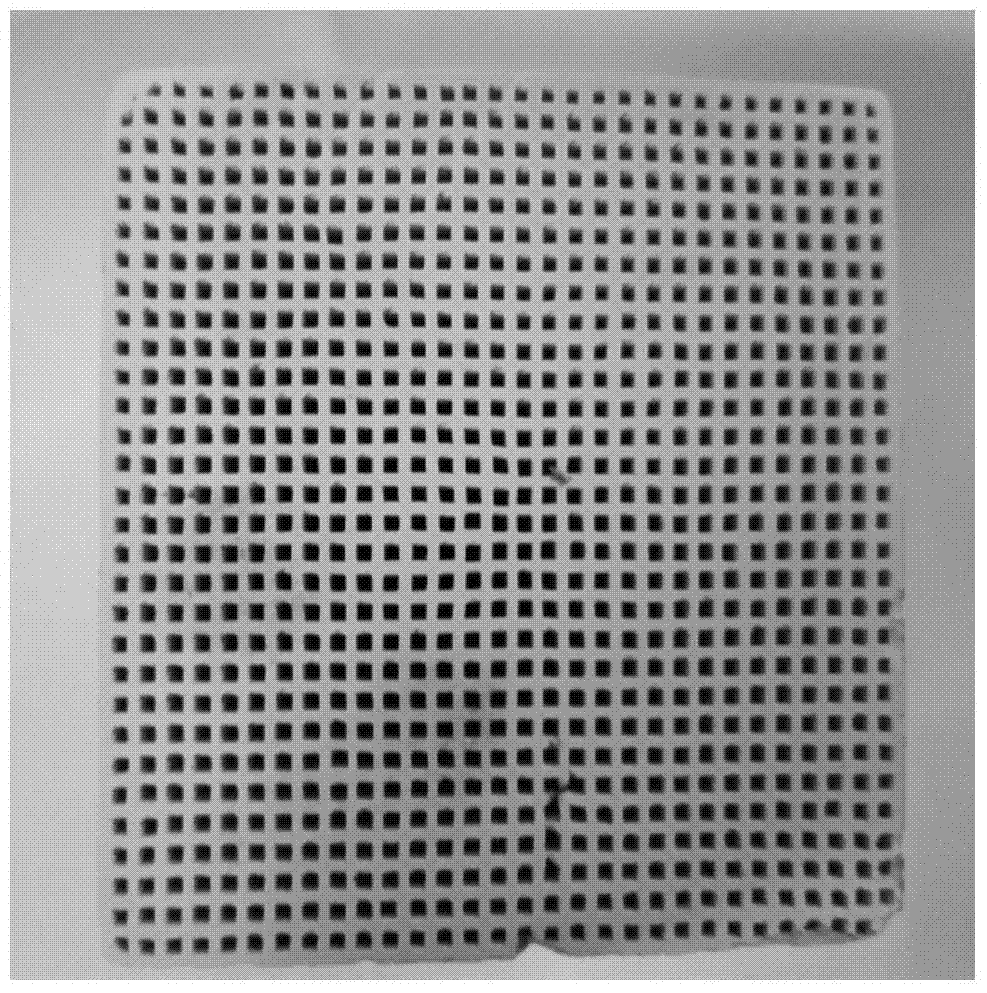

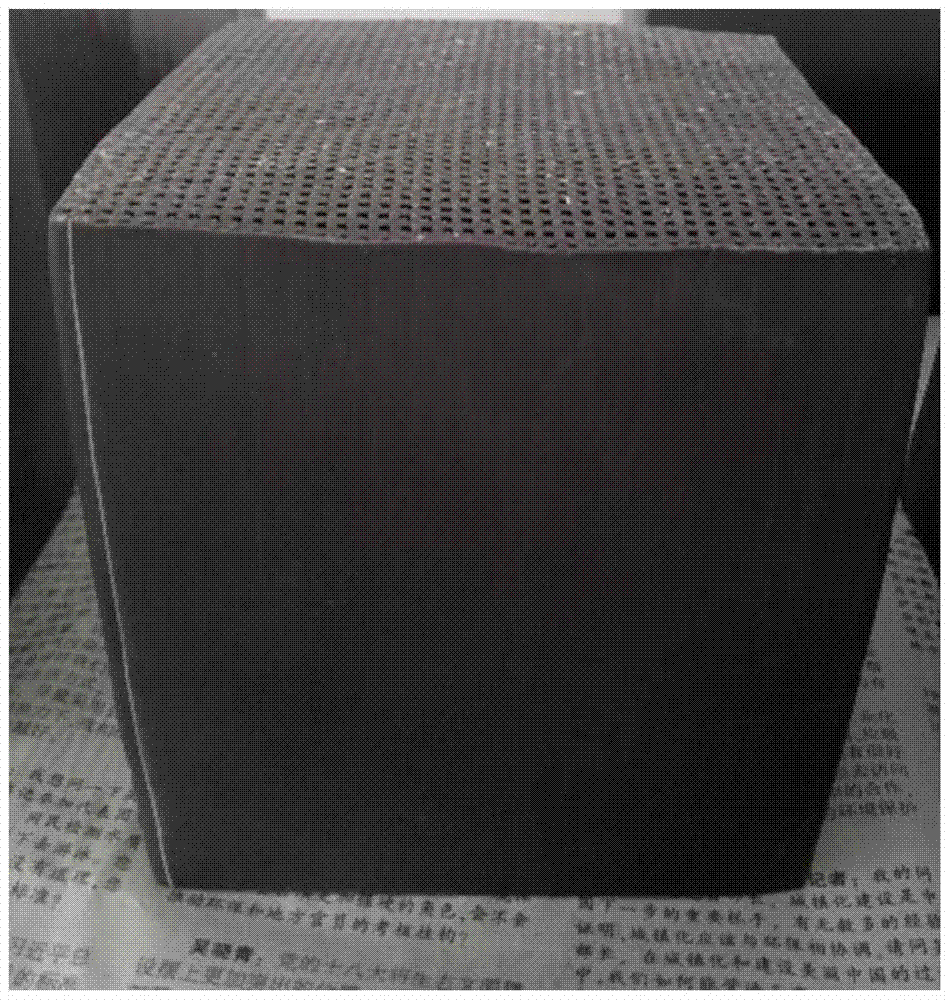

[0065] (8) Extrusion molding: Put the refined mud into a high-pressure vacuum extruder for molding and extrusion. During extrusion, the temperature is controlled at 30°C, the extrusion rate is 20mm / s, the extrusion pressure is 15MPa, and the vacuum degree is 8KPa. The extrusion die is a square specification of 100mm×100mm, the channel structure is a regular quadrilateral, the aperture is 1.4mm, the wall thickness is 1.0mm, and the cutting length of the green body is 110mm, that is, the formed honeycomb molecular sieve catalyst wet-based green body is obtained, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com