Preparation method of amido bridged regular mesoporous organic base heterogeneous catalyst

A heterogeneous catalyst and organic base technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve difficult separation and recycling, limited industrial application prospects, Increased production costs and other issues, to achieve the effect of simple preparation process, uniform distribution of active sites, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the following steps, the amino-bridged ordered mesoporous organic base heterogeneous catalyst is prepared.

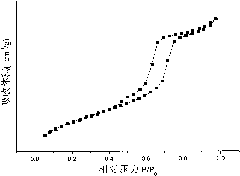

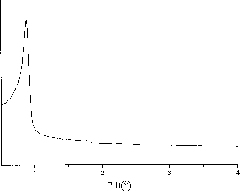

[0042] 2.0g P123 (EO 20 PO 70 EO 20 ) (0.034mmol), 8.0g KCl (0.11mol) and 62mL 0.5M HCl solution were mixed and stirred for 3.5h at 40°C in a jacketed jacket; then 5.0mmol1,2-bistriethoxysilylethane ( BTES), after BTES prepolymerization for 120min, add 5.0mmol bis[3-(trimethoxysilyl)propyl]amine (BTMA), continue to stir for 24h, age at 100°C for 28h, filter and wash, 80°C A white solid was obtained after drying in vacuo. Grind the above materials with an agate mortar, and then use HCl / C 2 h 5OH mixed solution extracts and removes surfactant, and the mass volume ratio of solid and liquid is 1.0g: 900mL; In the described mixed solution of hydrochloric acid and ethanol, the content of hydrochloric acid is 1.0mol / L, and the content of ethanol is 800g / L. Then alkali washing: add the obtained product to saturated Na at 30°C 2 CO 3 After the solutio...

Embodiment 2

[0046] The amino-bridged ordered mesoporous organic base heterogeneous catalyst was prepared according to the following steps.

[0047] 1.9g P123 (EO 20 PO 70 EO 20 ) (0.33mmol), 8.2g KCl (0.11mol) and 30mL 0.5M HCl solution were mixed, stirred at 40°C for 3h in a jacketed jacket, and then 4.5mmol 1,2-bistriethoxysilylethane ( BTES), after BTES prepolymerization for 130min, add 5.5mmol bis[3-(trimethoxysilyl)propyl]amine (BTMA), continue to stir for 24h, age at 100°C for 28h, filter, wash, and vacuum dry After obtaining a white solid;

[0048] Grind the above materials with an agate mortar, and finally with HCl / C 2 h 5 OH carries out extraction except surfactant, and the mass volume ratio of solid and liquid is 1g: 1000mL; In the described mixed solution of hydrochloric acid and ethanol, hydrochloric acid content is 1.2mol / L, and the content of ethanol is 780g / L. The resulting product was added to saturated Na at 25°C 2 CO 3 After the solution was stirred for 18 hours,...

Embodiment 3

[0050] Prepare the ordered mesoporous organic base heterogeneous catalyst of amino bridge, the steps are as follows:

[0051] 2.1g P123 (EO 20 PO 70 EO 20 ) (0.36mmol), 8.6g KCl (0.12mmol) and 66mL 0.50M HCl solution were mixed, stirred at 38°C for 3h in a jacketed jacket, and then added 6.0mmol 1,2-bistriethoxysilylethane (BTES ), after BTES prepolymerization for 130min, add 4.0mmol bis[3-(trimethoxysilyl)propyl]amine (BTMA), continue to stir for 24h, age at 110°C for 26h, filter, wash and vacuum dry A white solid was obtained;

[0052] Grind the above materials with an agate mortar, and finally with HCl / C 2 h 5 OH is extracted to remove surfactant, the mass volume ratio of solid and liquid is 1g:900mL; in the mixed solution of hydrochloric acid and ethanol, the content of hydrochloric acid is 0.9mol / L, and the content of ethanol is 600g / L. The resulting product was added to saturated Na at 25°C 2 CO 3 After the solution was stirred for 15 hours, it was suction-filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com