Inferior heavy oil hydrodesulfurization demetalization catalyst and preparation method thereof

A technology for hydrodesulfurization and low-quality heavy oil, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of reduced carrier strength and unfavorable inner and outer surfaces of particles , to achieve the effect of unobstructed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

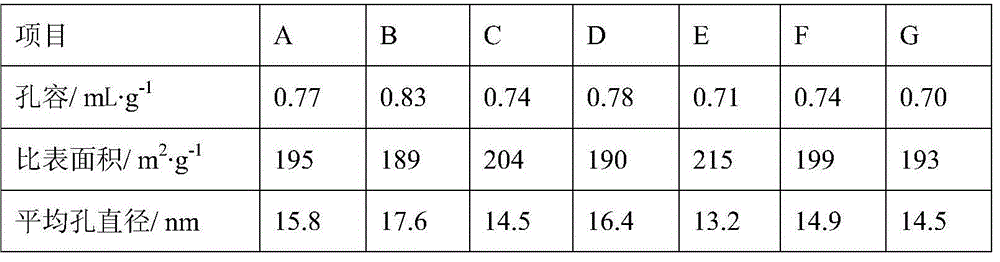

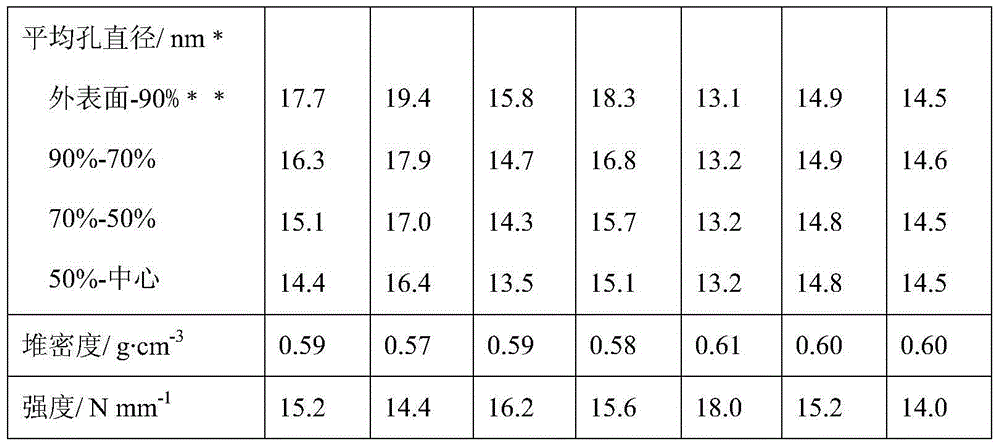

Embodiment 1

[0023] (1) Preparation of carrier

[0024] Weigh 500 g of pseudo-boehmite dry rubber powder (dry basis content 69.8 wt%) produced by Shandong Zibo Xingdu Petrochemical Technology Co., Ltd., add 14 g of Sesame powder, add 15 g of polyethylene glycol, and mix well. Add 415 g of acetic acid solution with a concentration of 3.0 wt % into the aforementioned materials, knead for 35 minutes, and then extrude into a cylindrical shape with a diameter of 1.4 mm on a front-extrusion single-screw extruder. Dry at 120°C for 3 hours, then place it in a roasting furnace, raise it to 810°C at a rate of 150°C / hour, and roast for 3 hours.

[0025] (2) Handling of the carrier

[0026] Weigh 300 grams of the obtained carrier from (1) and place it in a rotating vessel, spray 250 g of deionized water evenly on the obtained alumina carrier at a speed of 30 mL / min, and spray water to the aforementioned deionized water at a speed of 5.0 g / min. Add glacial acetic acid evenly to deionized water. Afte...

Embodiment 2

[0030] Add 500 g of the above-mentioned pseudo-boehmite dry rubber powder, add 14 g of safflower powder, add 7.0 g of hydroxypropyl methylcellulose, and mix well. Add 420 g of acetic acid solution with a concentration of 2.5 wt % into the aforementioned materials, and knead for 35 minutes. The same method as in Example 1 was extruded, dried, and calcined at 830° C. for 3 hours. 250g of deionized water was evenly sprayed on the obtained alumina carrier at a speed of 30mL / min, and glacial acetic acid was uniformly added to the aforementioned deionized water at a speed of 7.0g / min while spraying water. After spraying to the saturated water absorption rate of the carrier, airtight treatment at 60°C for 2.0 hours, and washing with clean water 3 times. Dry at 200°C for 3.0 hours. Catalyst B was obtained using the same catalyst preparation conditions as in Example 1.

Embodiment 3

[0032] The carrier calcination temperature in Example 1 was changed to 790° C., the adding rate of acetic acid was changed to 2.5 g / min, and other conditions were the same as in Example 1 to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com