Method for recycling zinc, indium, iron and gallium from iron vanadium slag

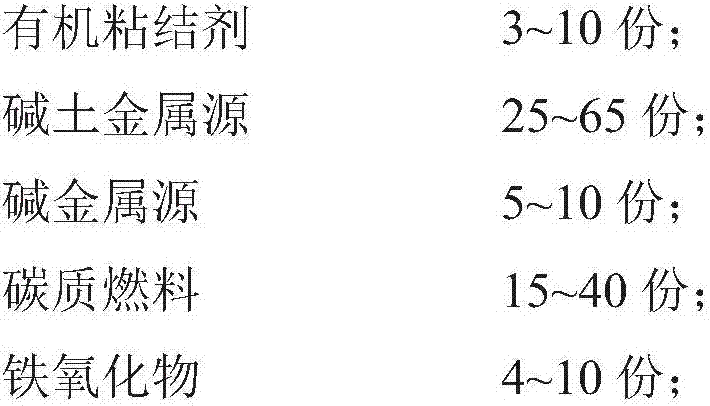

A technology of jarosite slag and alkaline earth metal, applied in the field of metallurgy, can solve the problems of difficult utilization of by-product gypsum, low comprehensive utilization, long process, etc., to improve green ball strength and thermal stability, improve fluidity and desulfurization ability. , The effect of reducing the reduction expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

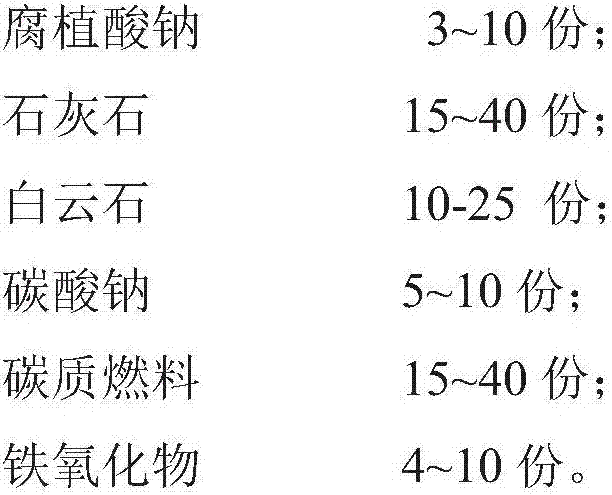

Embodiment 1

[0136] The dried alum slag has a water content of 7.2%, and the addition of a multifunctional additive with a mass ratio of 2% (the mass ratio is 15% of blue charcoal powder, 40% of limestone powder, 15% of dolomite powder, 10% of sodium humate dry powder, iron oxide powder 10%, sodium carbonate powder 10%), mix in a strong mixer for 1min (1200-1800rpm), mix in a moist mill (moisture water is 6-8%) for 2min, and then mix in a disc pelletizer Make pellets inside, and prepare green pellets with a particle size of 8-16mm and a water content of 9.5%. The drop strength of green balls is 5.1 times / 0.5m, and the compressive strength of green balls is 15.3N / piece.

[0137] Green pellets are dried at 450°C for 3 minutes, preheated at 650°C for 10 minutes, and oxidized and roasted at 1150°C for 80 minutes on a belt roaster (the height of the green pellet layer is 70 mm). The residual sulfur content of the roasted pellets is 1.0%, and the desulfurization rate is It reaches 92.2%, and th...

Embodiment 2

[0143] The dried alum slag contains 8.3% water, and the addition of multifunctional additives with a mass ratio of 5% (the mass ratio is 30% of blue charcoal powder, 40% of limestone powder, 15% of dolomite powder, 5% of sodium humate dry powder, iron oxide powder 5%, sodium carbonate powder 5%), mix in a strong mixer for 1min (1200-1800rpm), mix in a moist mill (moisture water is 6-8%) for 2min, mix well, and then Pelletizing is carried out in the disc pelletizer to prepare green pellets with a particle size of 8-16mm and a water content of 10.5%. The drop strength of green balls is 5.6 times / 0.5m, and the compressive strength of green balls is 16.0N / piece.

[0144] Green pellets were dried at 350°C for 5 minutes, preheated at 850°C for 8 minutes and oxidized and roasted at 1200°C for 60 minutes on a belt roaster (the height of the green pellet layer is 90mm). The residual sulfur content of the roasted pellets was 0.63%, and the desulfurization rate It reaches 96.2%, and the...

Embodiment 3

[0150] The dried alumina slag has a water content of 9.0%, and the alumina slag is added with a mass ratio of 7% multifunctional additives (the mass ratio is 15% of blue charcoal powder, 40% of limestone powder, 15% of dolomite powder, and 10% of sodium humate dry powder , iron oxide powder 10%, sodium carbonate powder 10%), mix in a strong mixer for 1min (1200-1800rpm), mix in a moist mill (moisture water is 6-8%) for 2min, fully mix, Then pelletize in a disc pelletizer to prepare green pellets with a particle size of 8-16 mm and a water content of 12.0%. The drop strength of green balls is 7.3 times / 0.5m, and the compressive strength of green balls is 15.0N / piece.

[0151] Green pellets were dried at 250°C for 6 minutes, preheated at 1100°C for 9 minutes, and oxidized and roasted at 1300°C for 20 minutes on a belt roaster (the height of the green pellet layer was 110mm). The residual sulfur content of the roasted pellets was 0.56%, and the desulfurization rate It reaches 98...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com