Aluminium killed steel refined deoxidizing and desulfurizing synthetic slag

A technology of aluminum-killed steel and synthetic slag, which is applied in the field of desulfurization treatment, refining and deoxidation of aluminum-killed steel, can solve the problems of hydrogenation of molten steel, high cost, difficult removal of inclusions, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

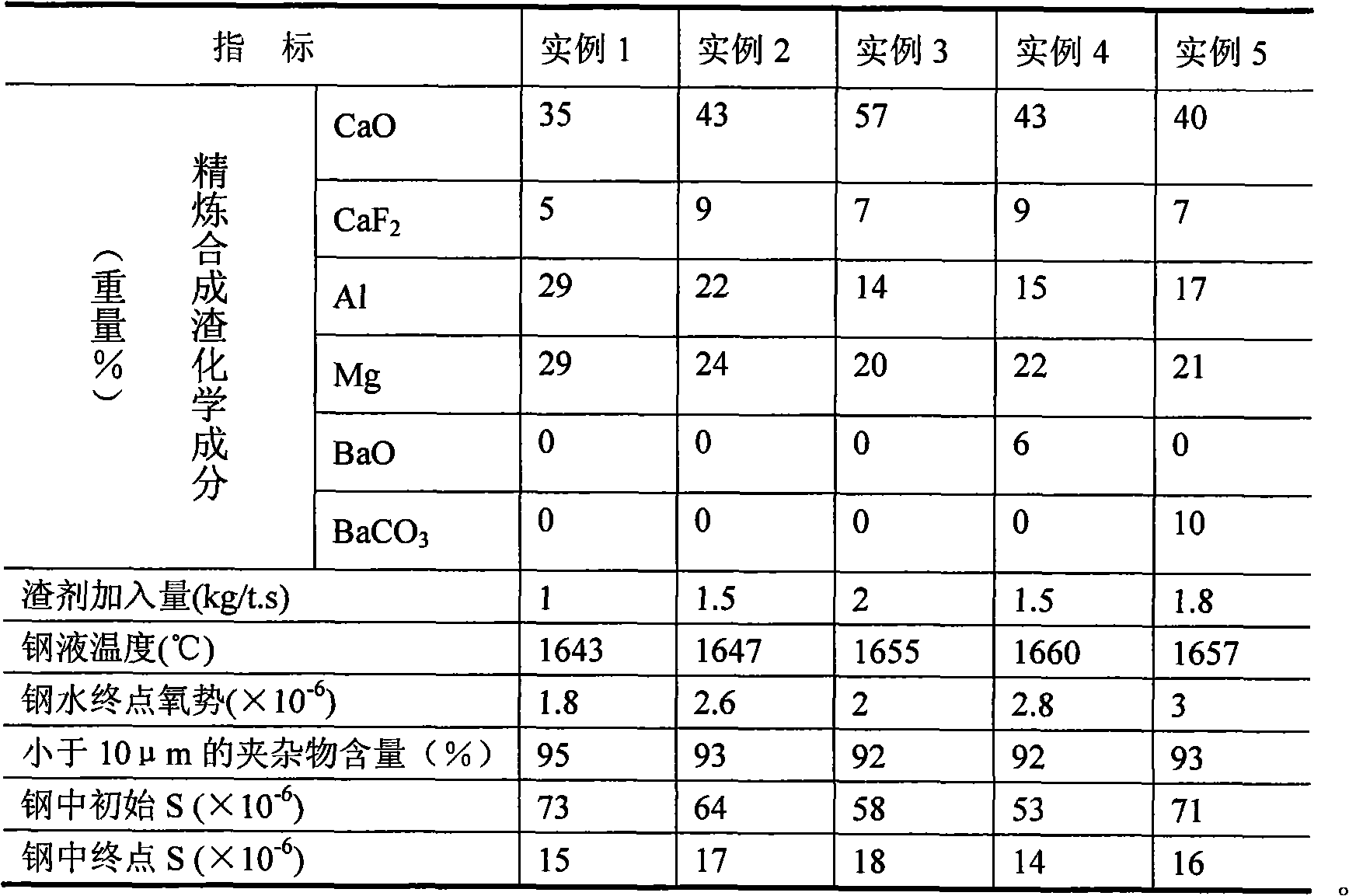

[0018] According to the proportioning of the present invention, CaO, CaF 2 After the powder is mixed, it is heated and pre-melted at high temperature, cooled and crushed into a fine powder less than 0.5mm, and then mixed with passivated Mg powder and Al powder in a corresponding proportion to obtain the refining synthetic slag of the present invention. The coated thin strip steel is made into a cored wire, which is fed into molten steel during use, or can be made into slag balls and directly added to the surface of molten steel. The present invention uses IF steel as a carrier and is tested in a vacuum induction furnace. Concrete embodiment of the present invention and test obtain effect as follows:

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com