Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

400results about How to "Low pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

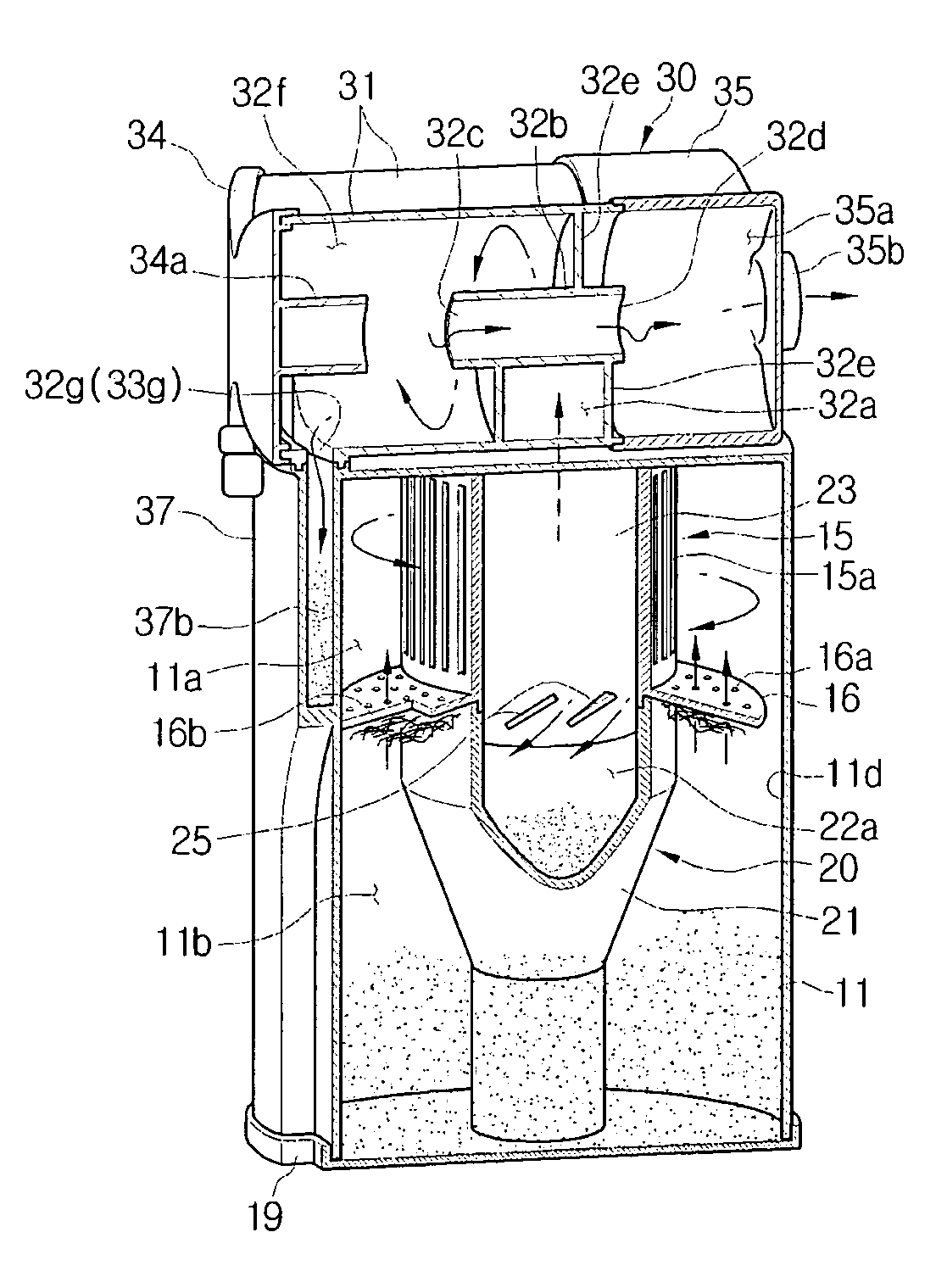

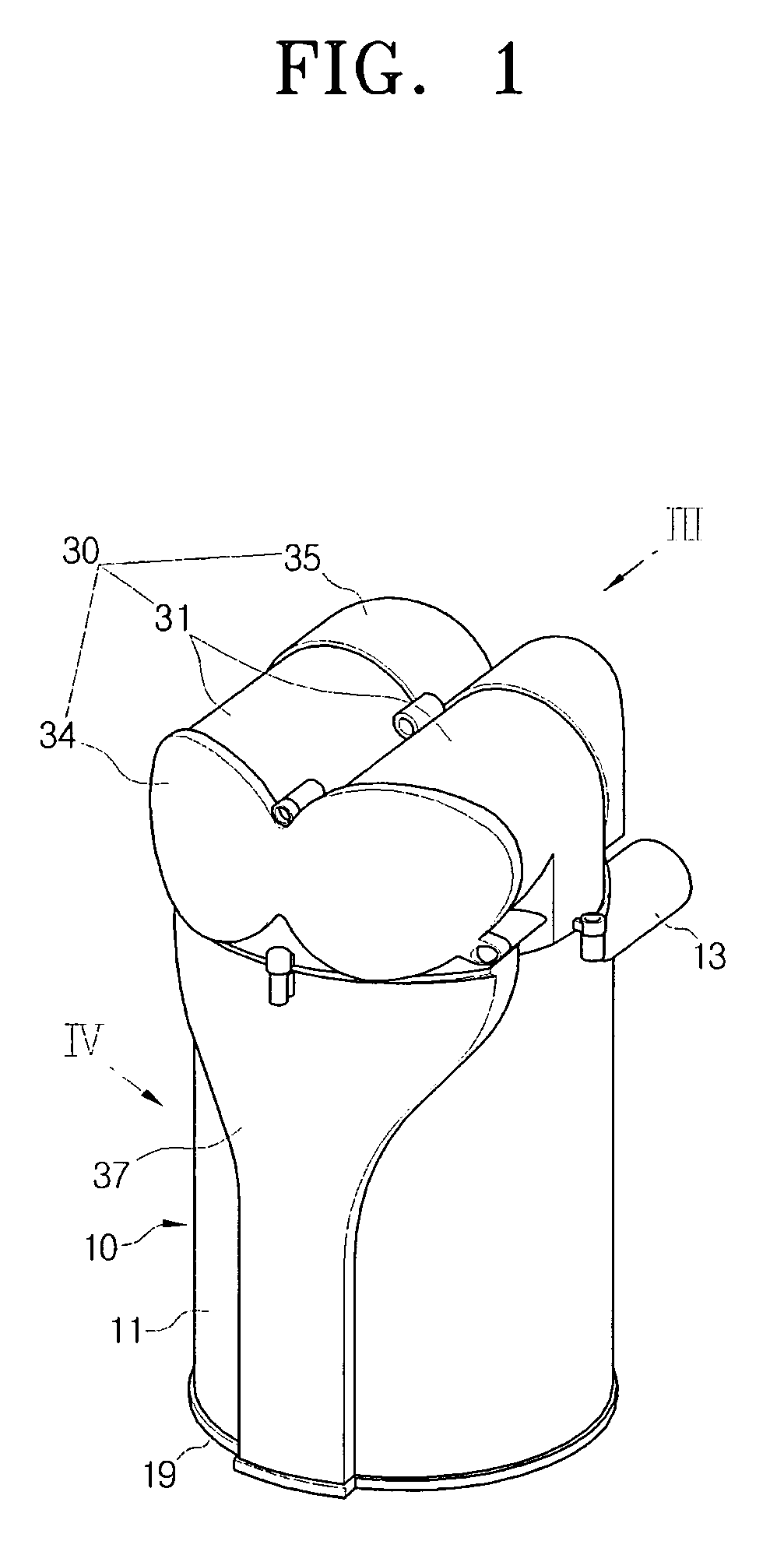

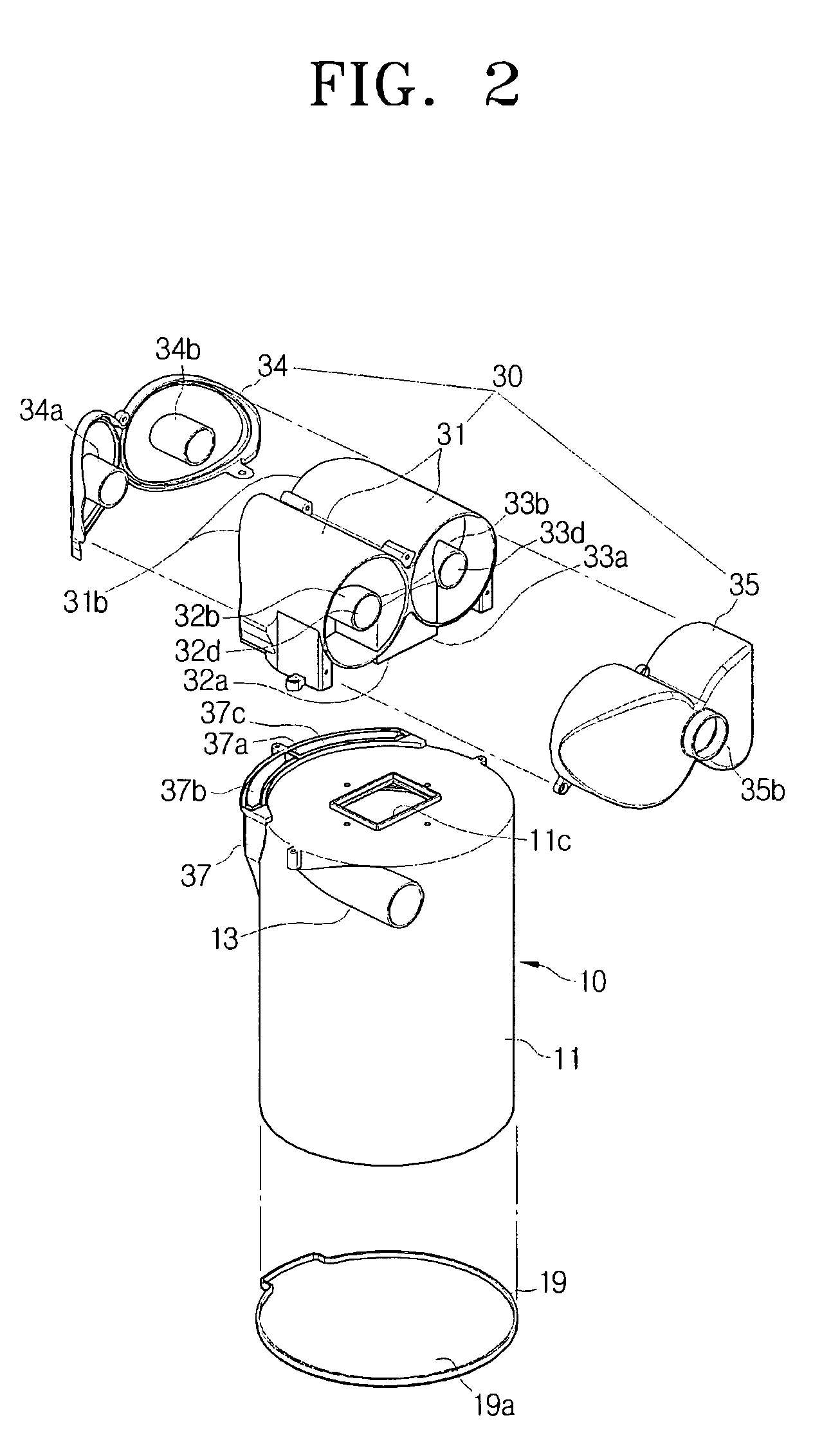

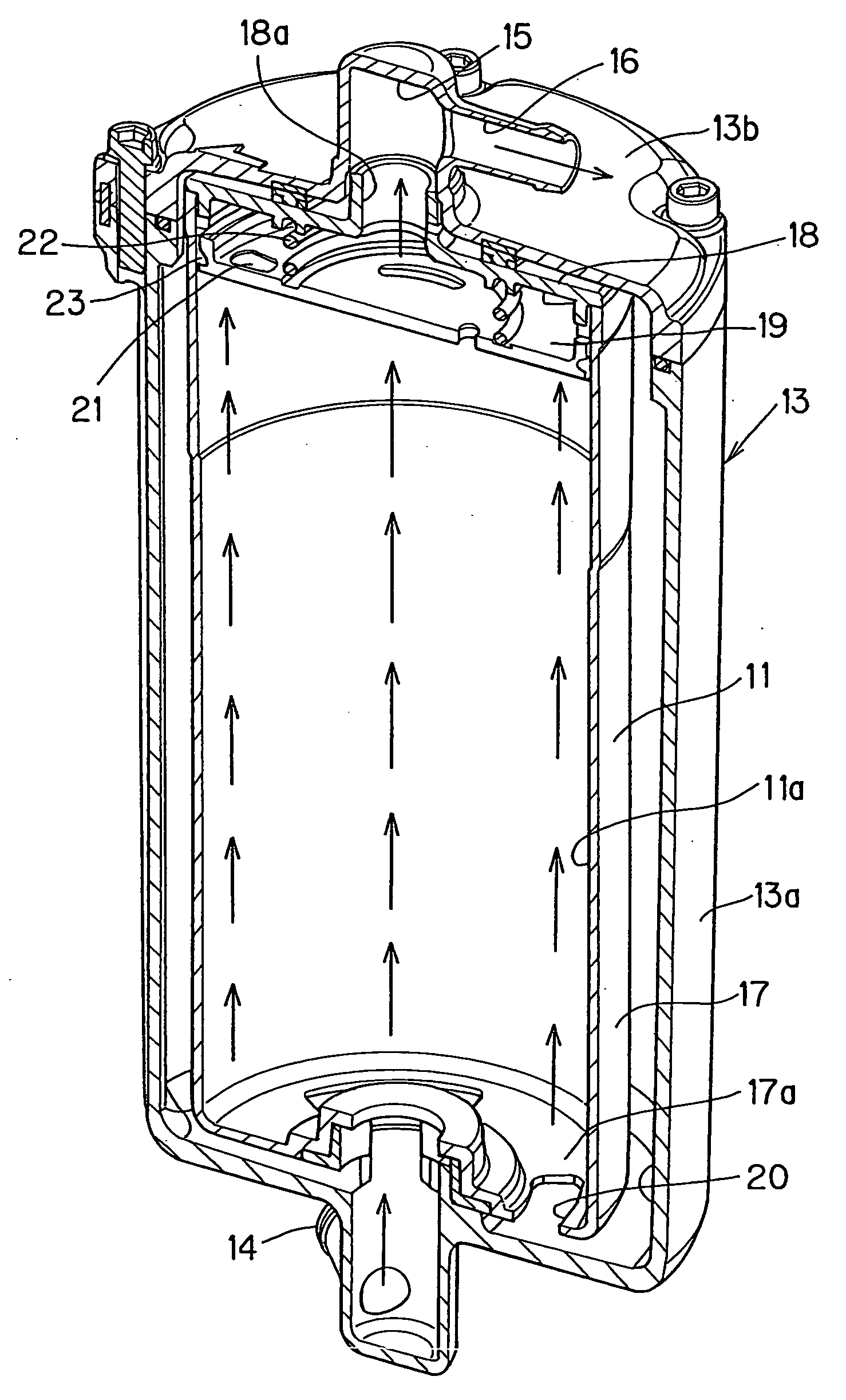

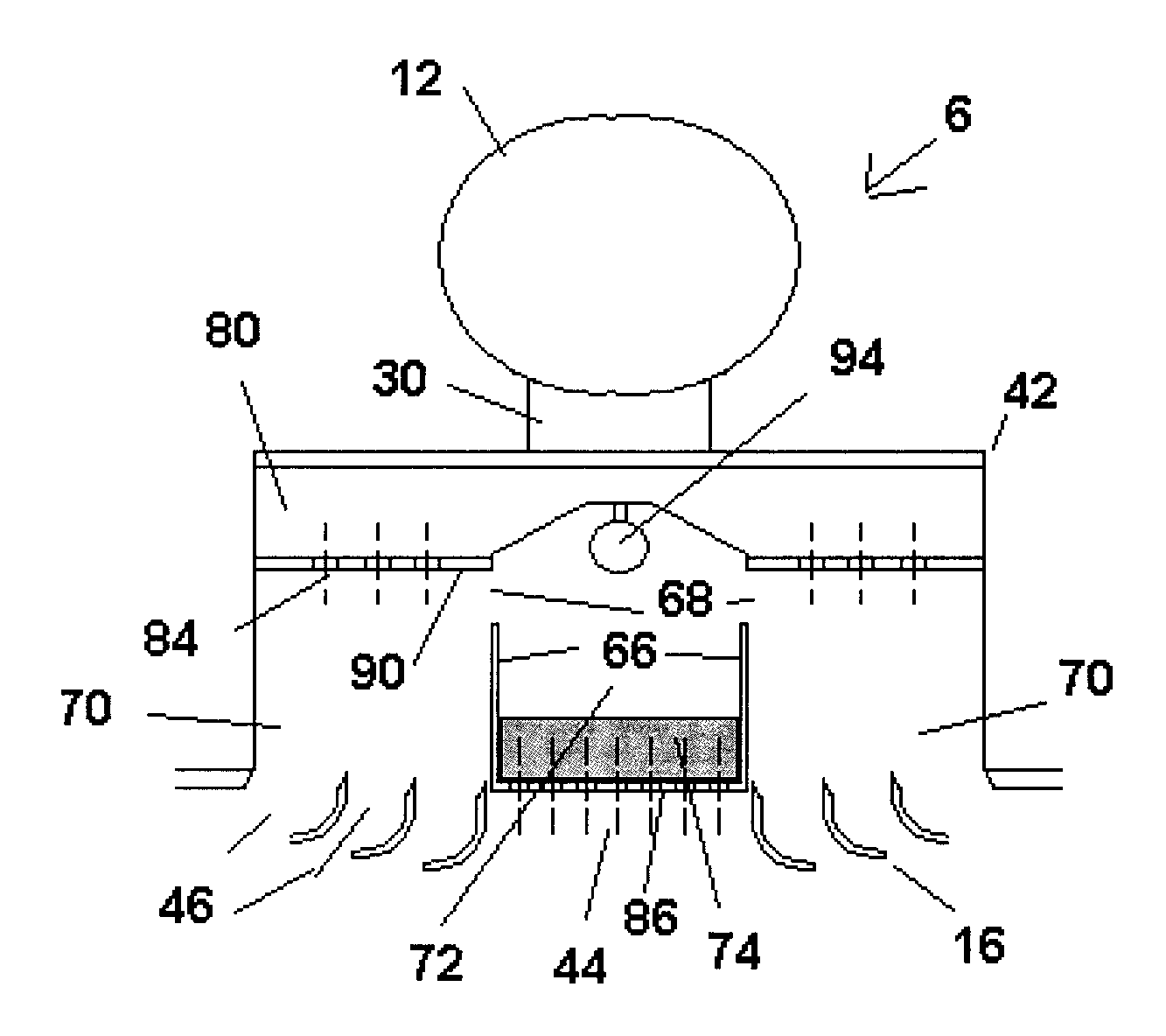

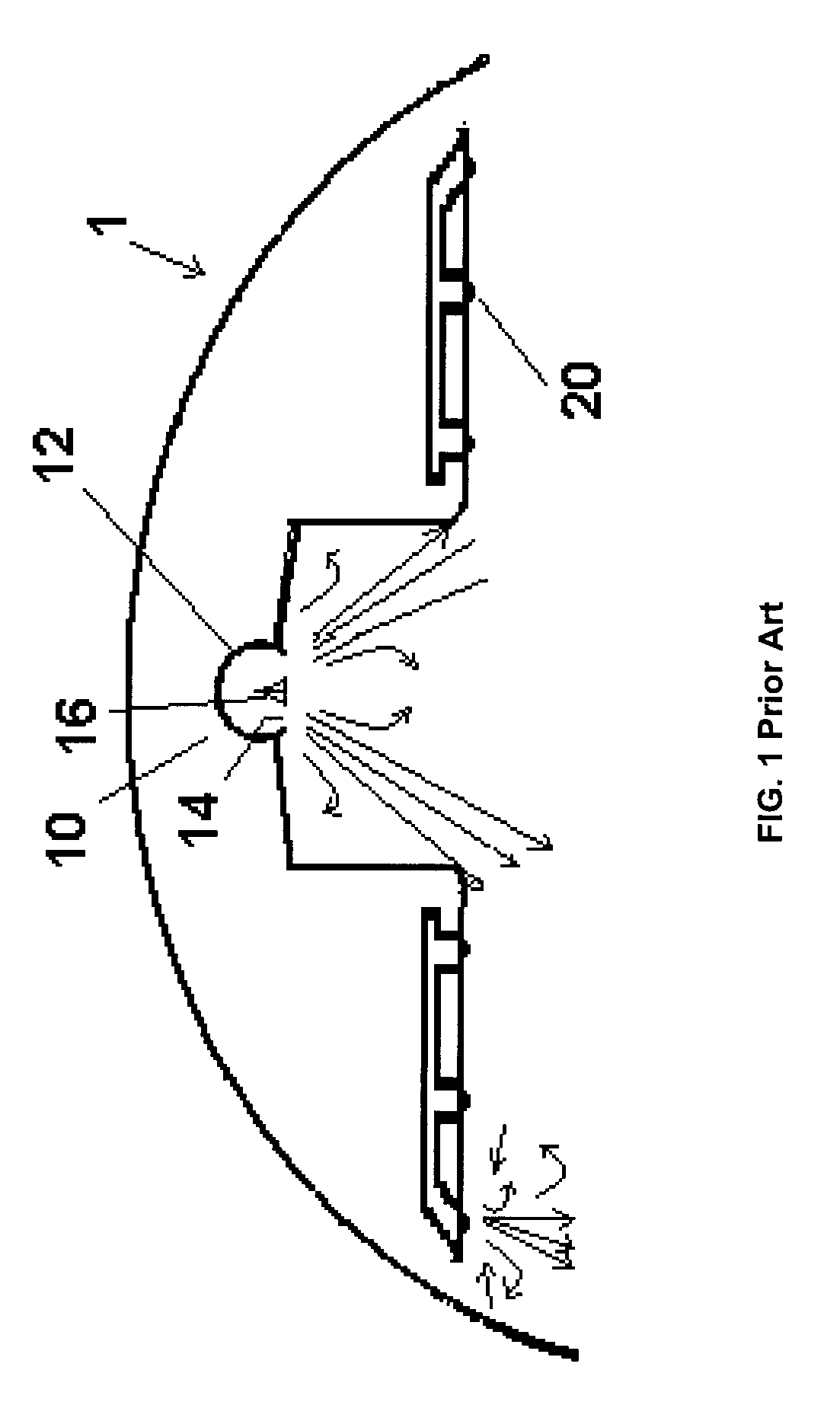

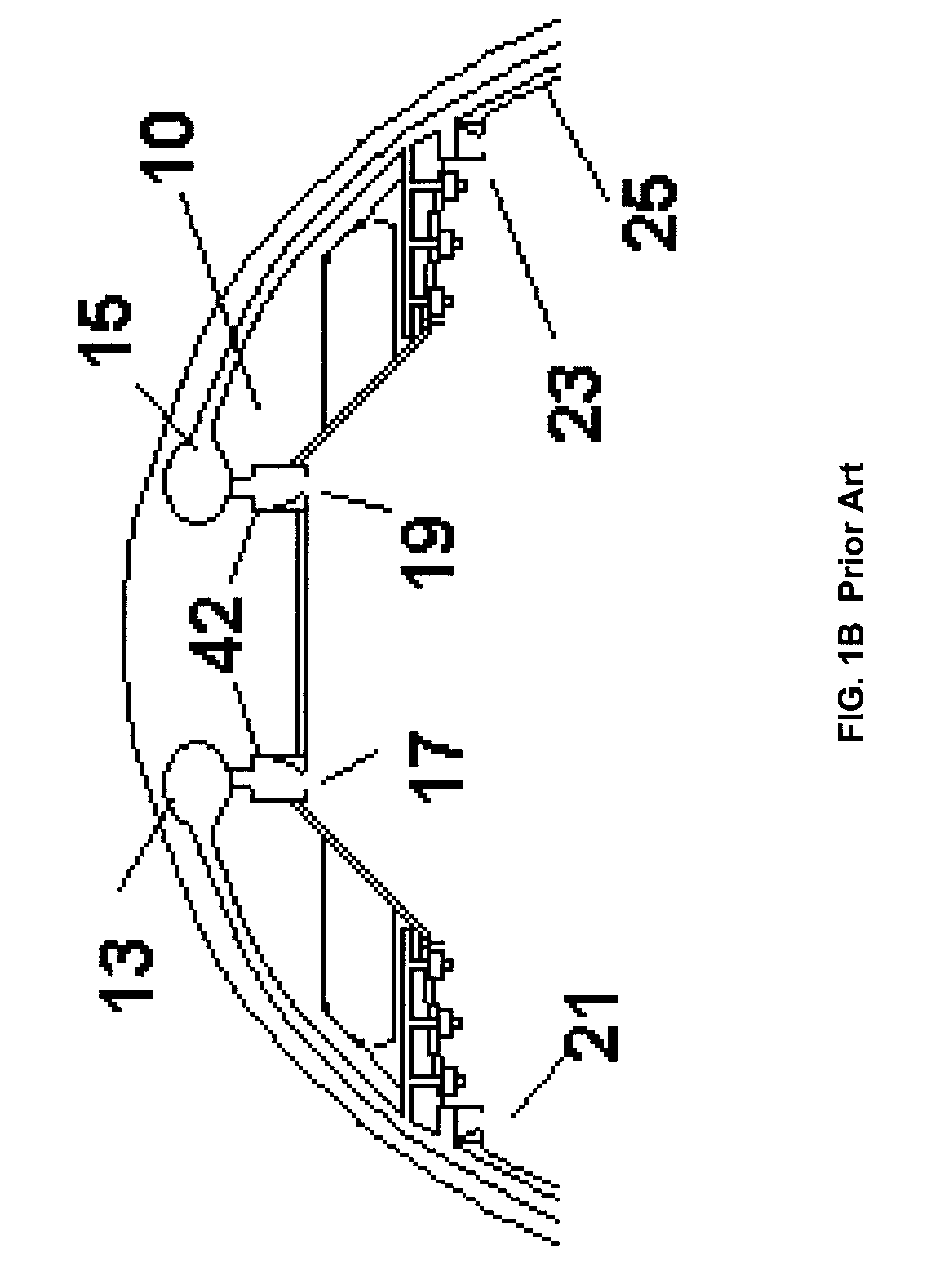

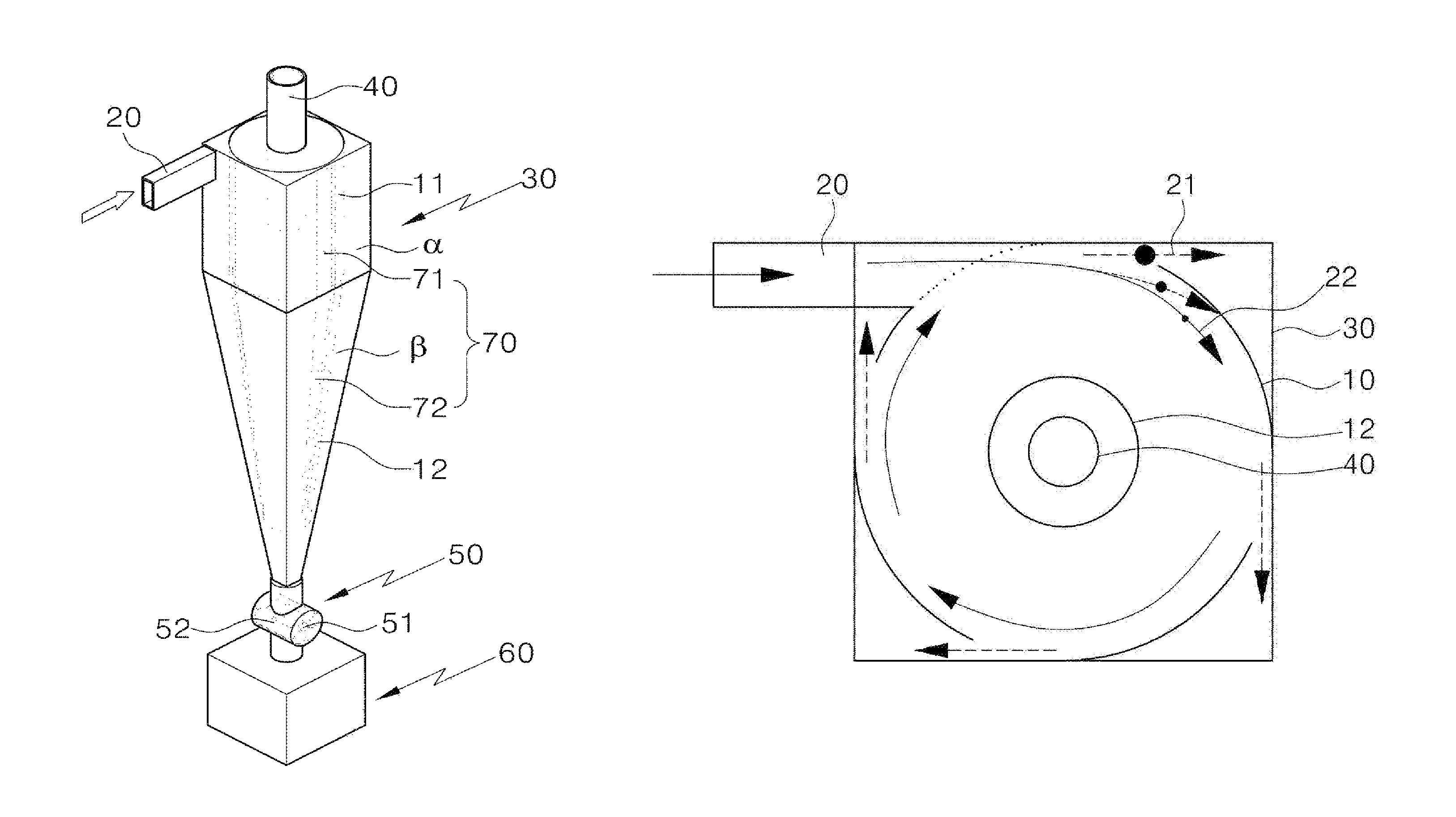

Cyclone dust-collecting apparatus

InactiveUS7691161B2High dust collecting efficiencyLow pressure lossCleaning filter meansCombination devicesCycloneCentrifugal force

A cyclone dust-collecting apparatus to separate dust from air drawn in through a suction port body of a vacuum cleaner using a centrifugal force and to collect the separated dust is provided. The cyclone dust-collecting apparatus includes a primary cyclone unit to separate dust from air drawn in through the suction port body; a secondary cyclone unit disposed inside the primary cyclone unit to separate dust from air discharged from the primary cyclone unit; and a tertiary cyclone unit disposed above the primary cyclone unit at an angle different from the primary and secondary cyclone units.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

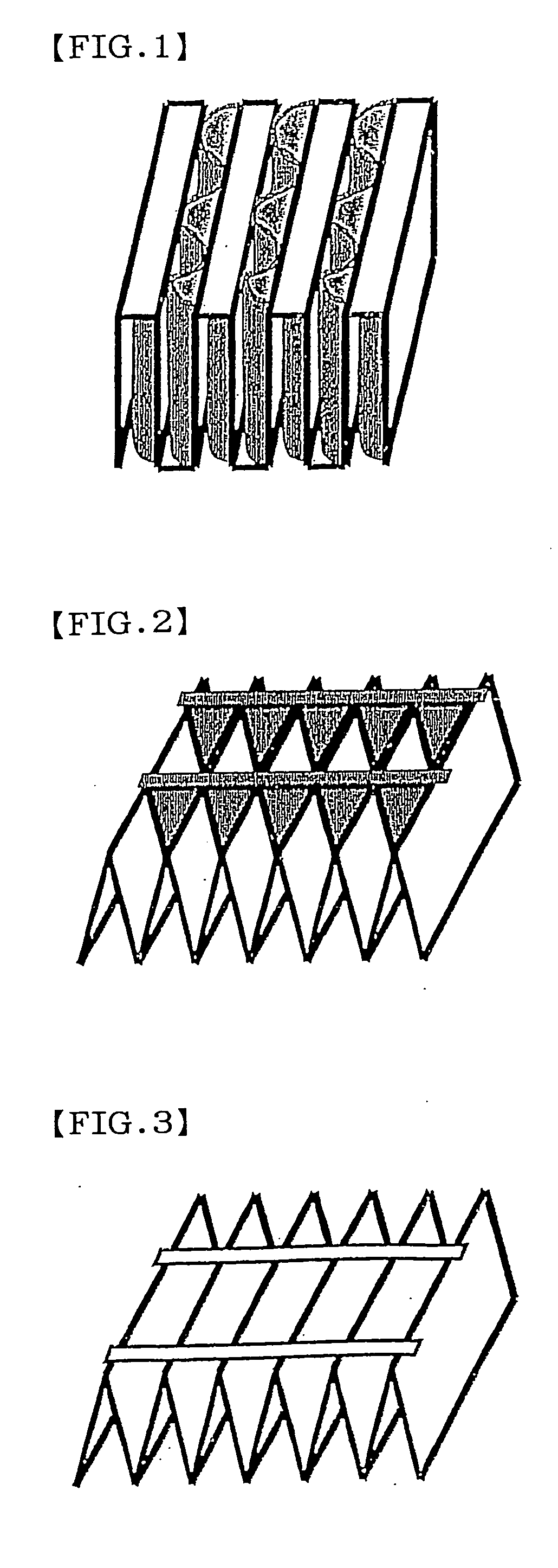

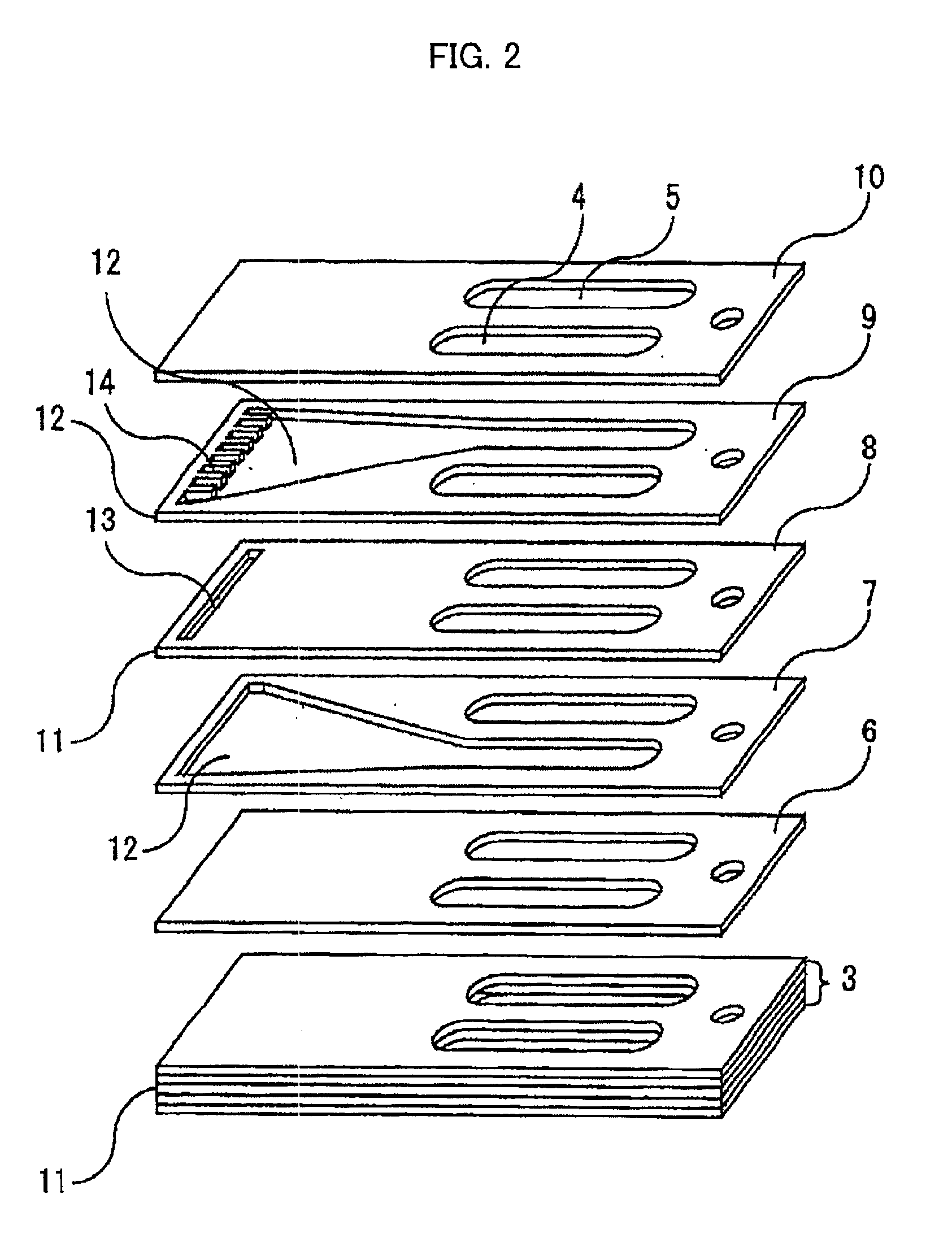

Filter

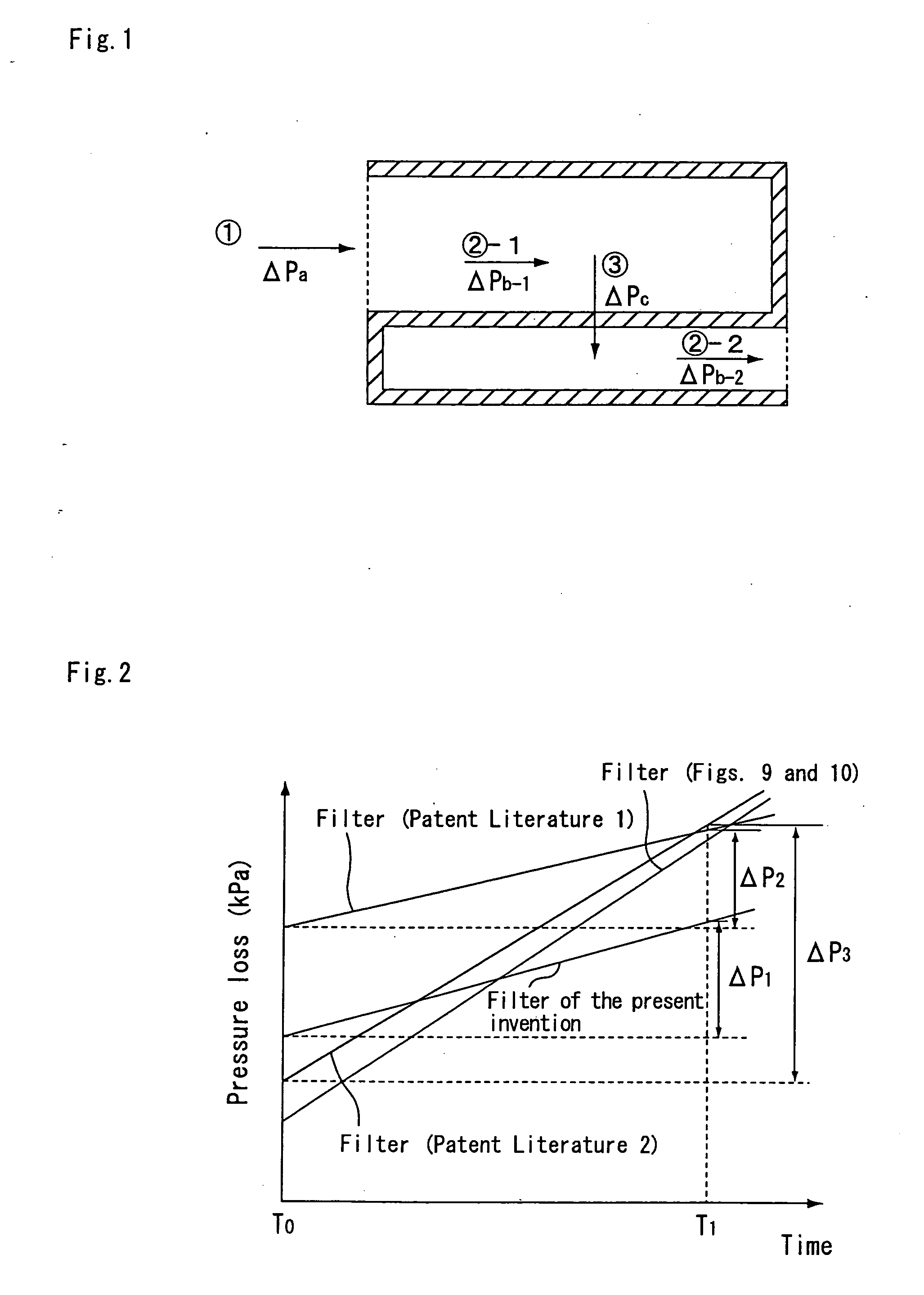

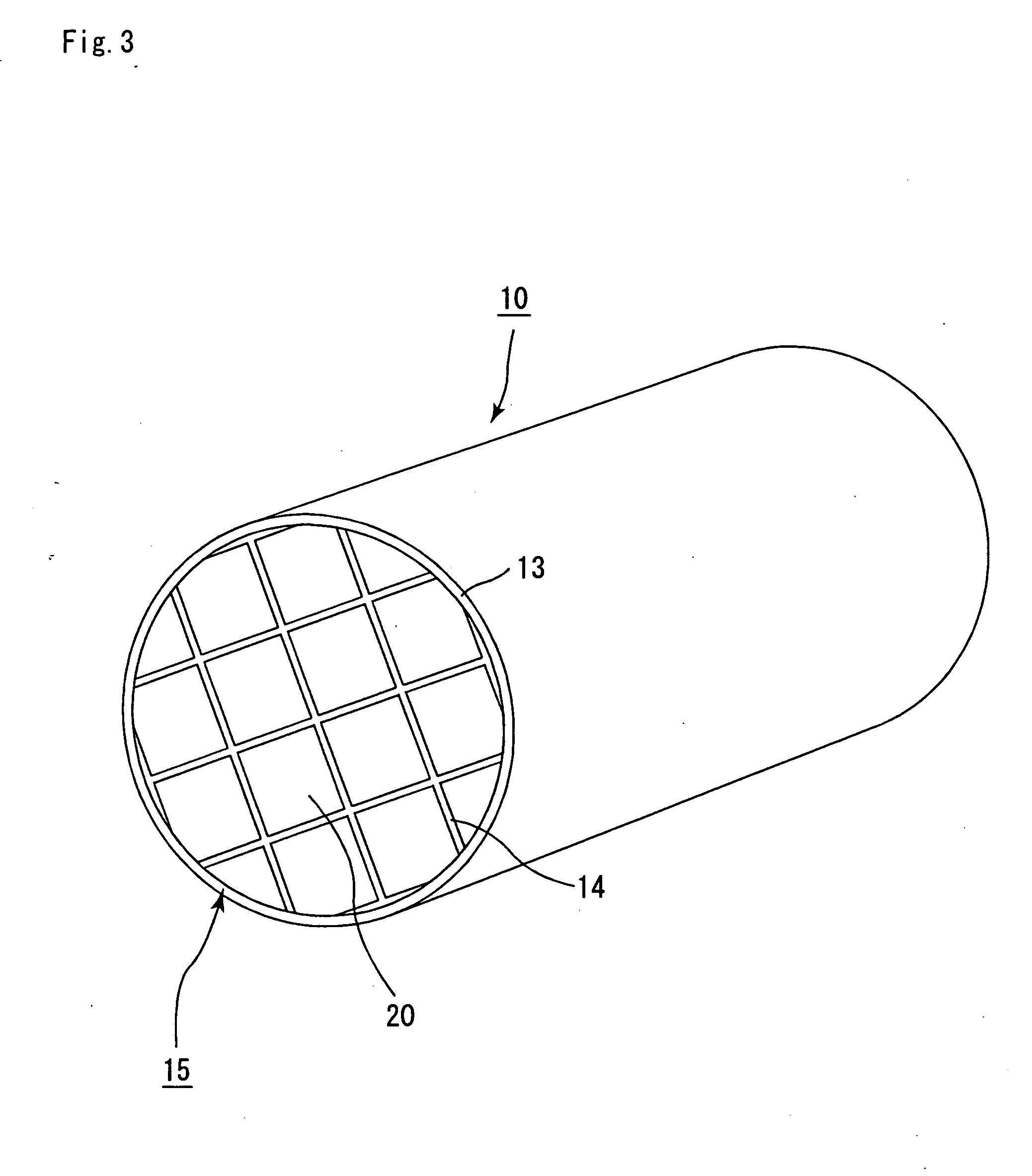

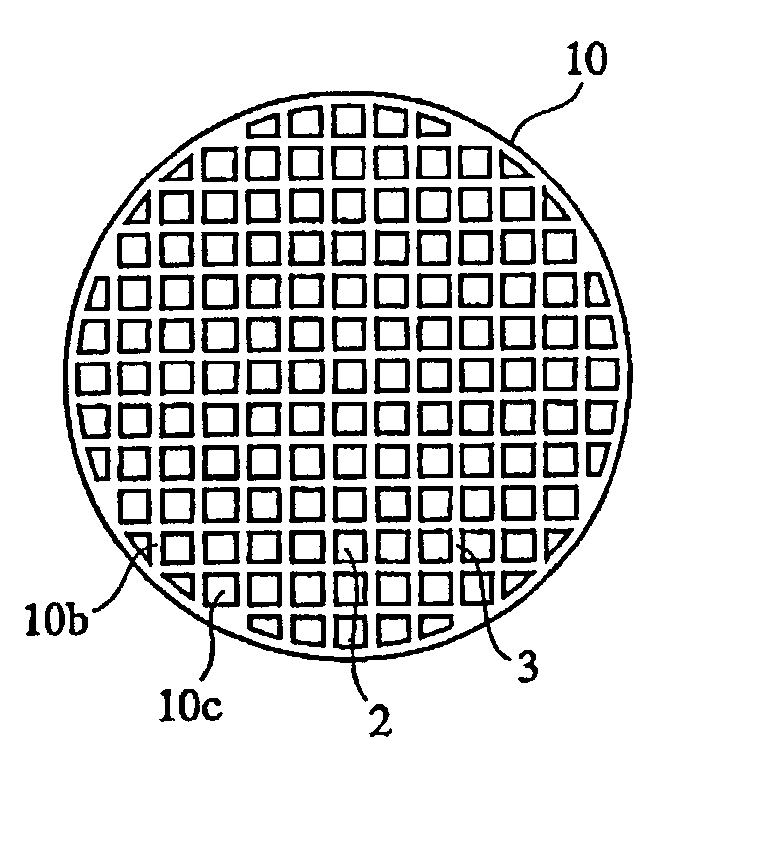

ActiveUS20050016141A1Low pressure lossImprove collection effectDispersed particle filtrationTransportation and packagingParticulatesEngineering

Owner:IBIDEN CO LTD

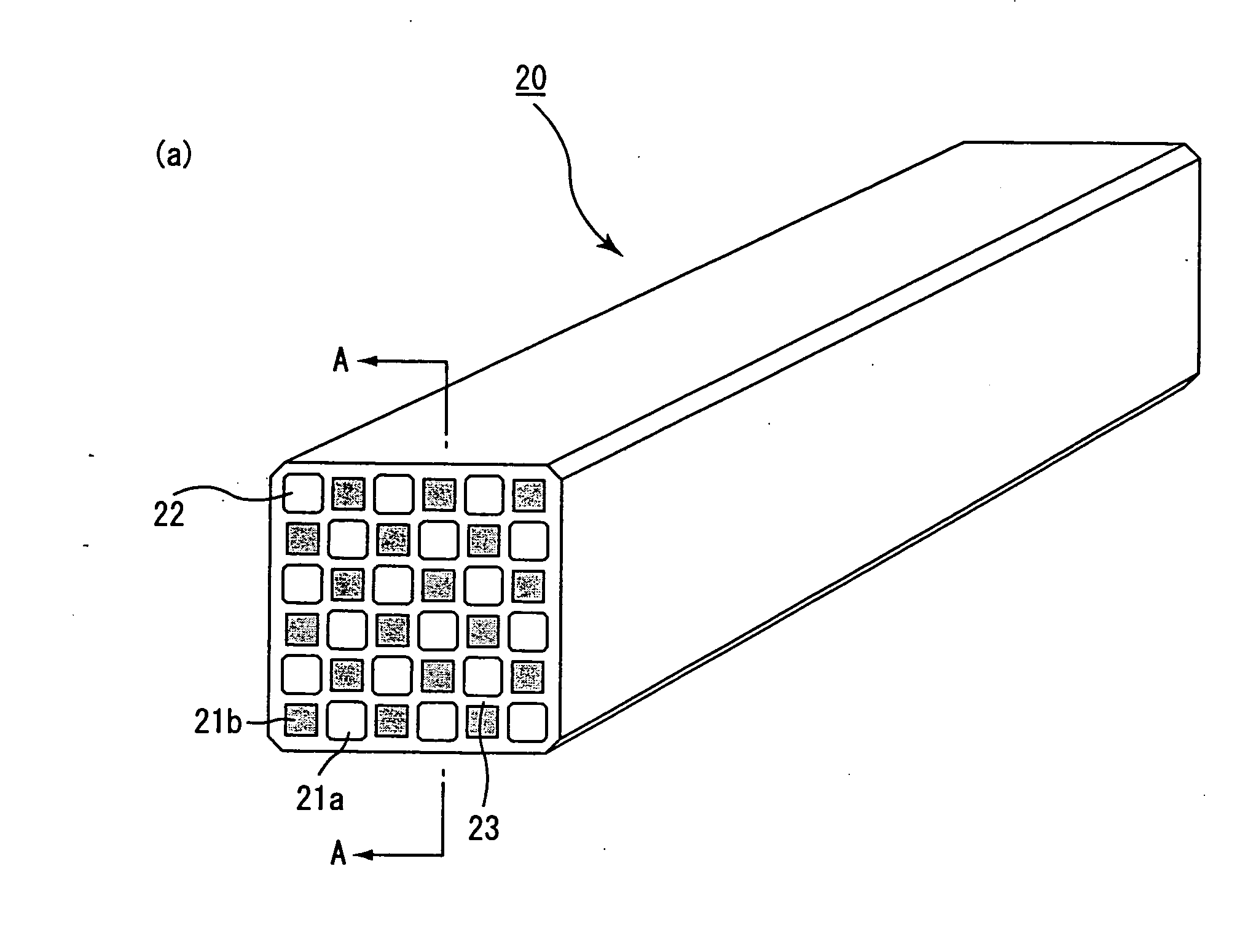

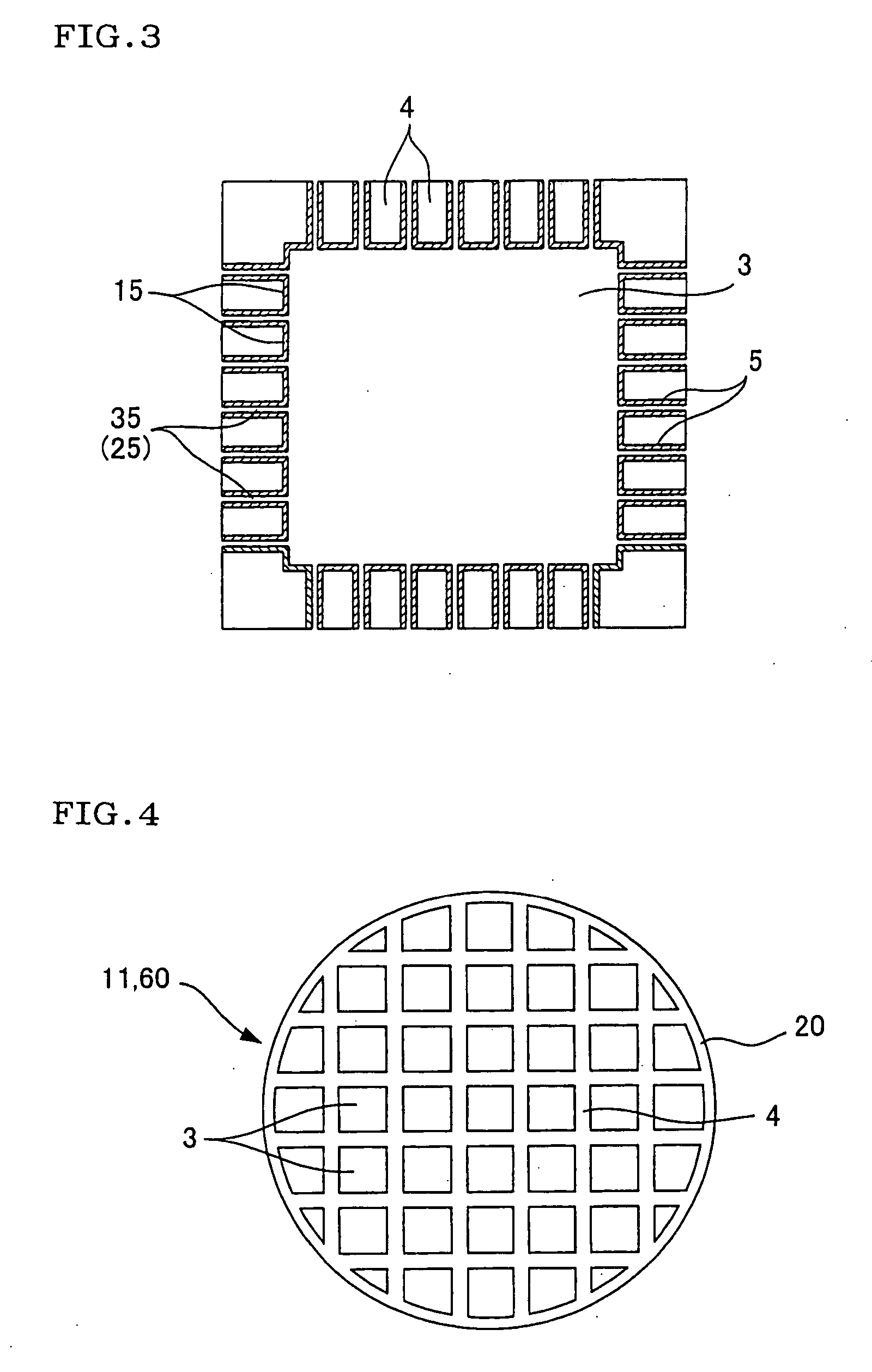

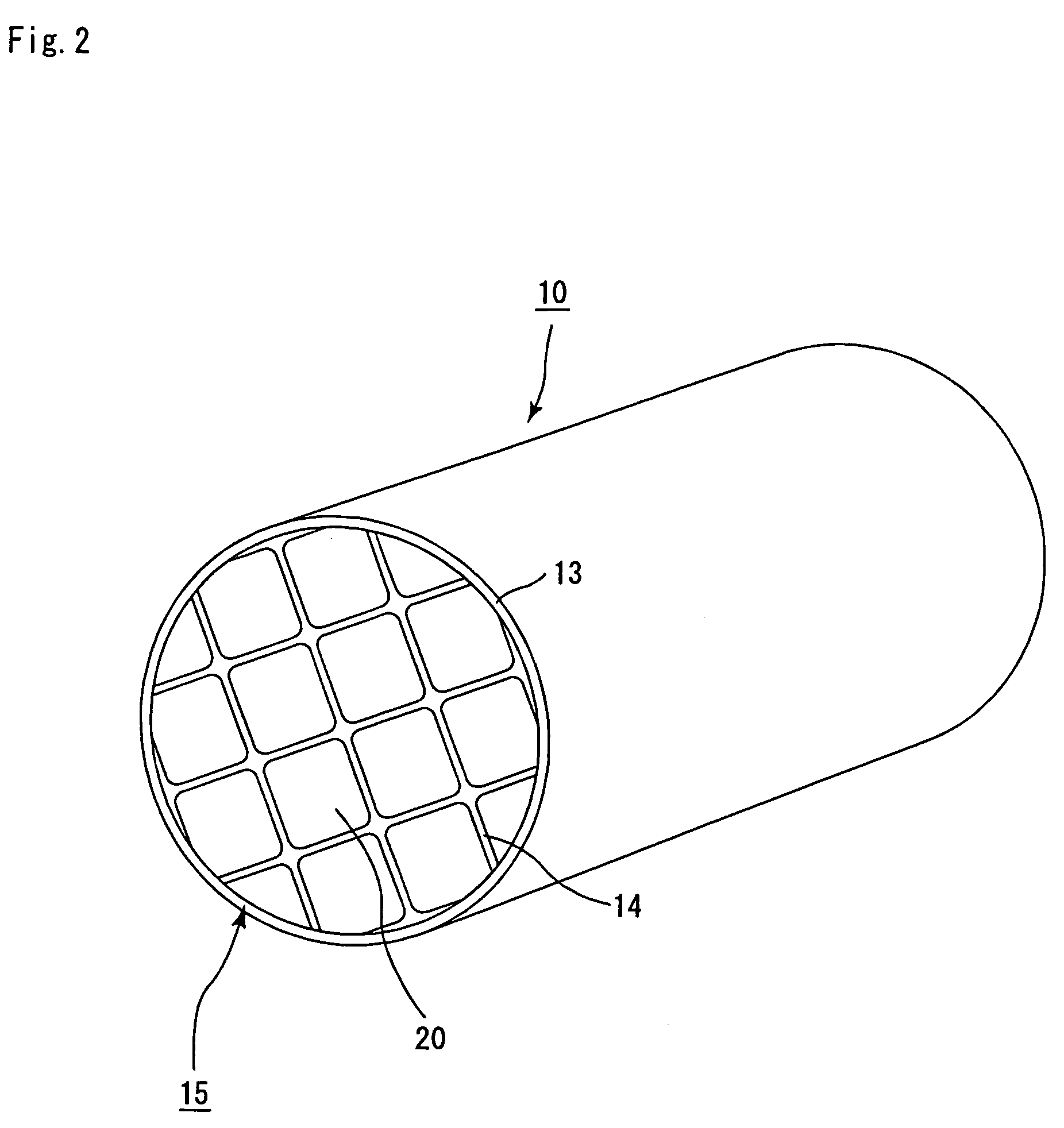

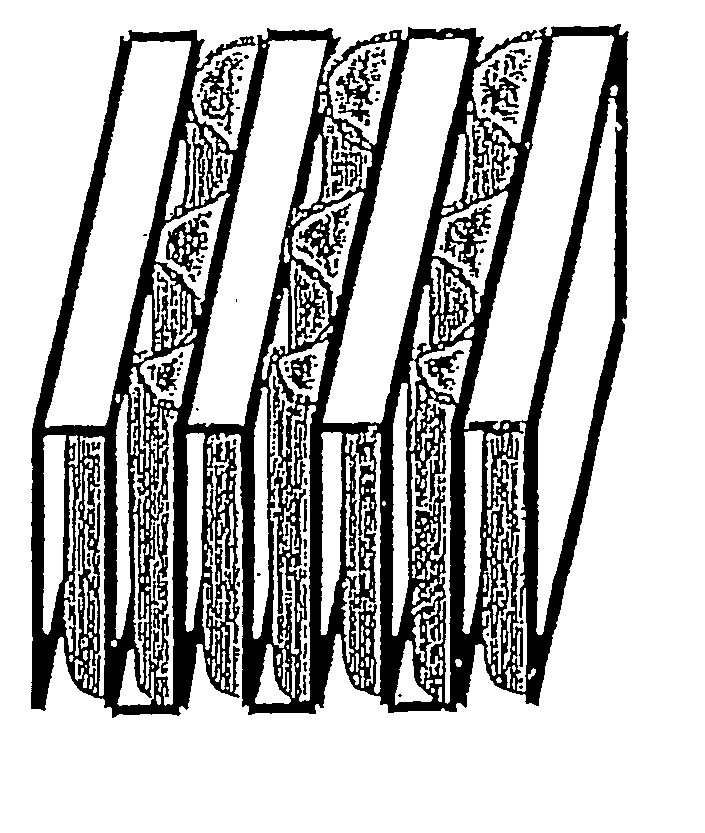

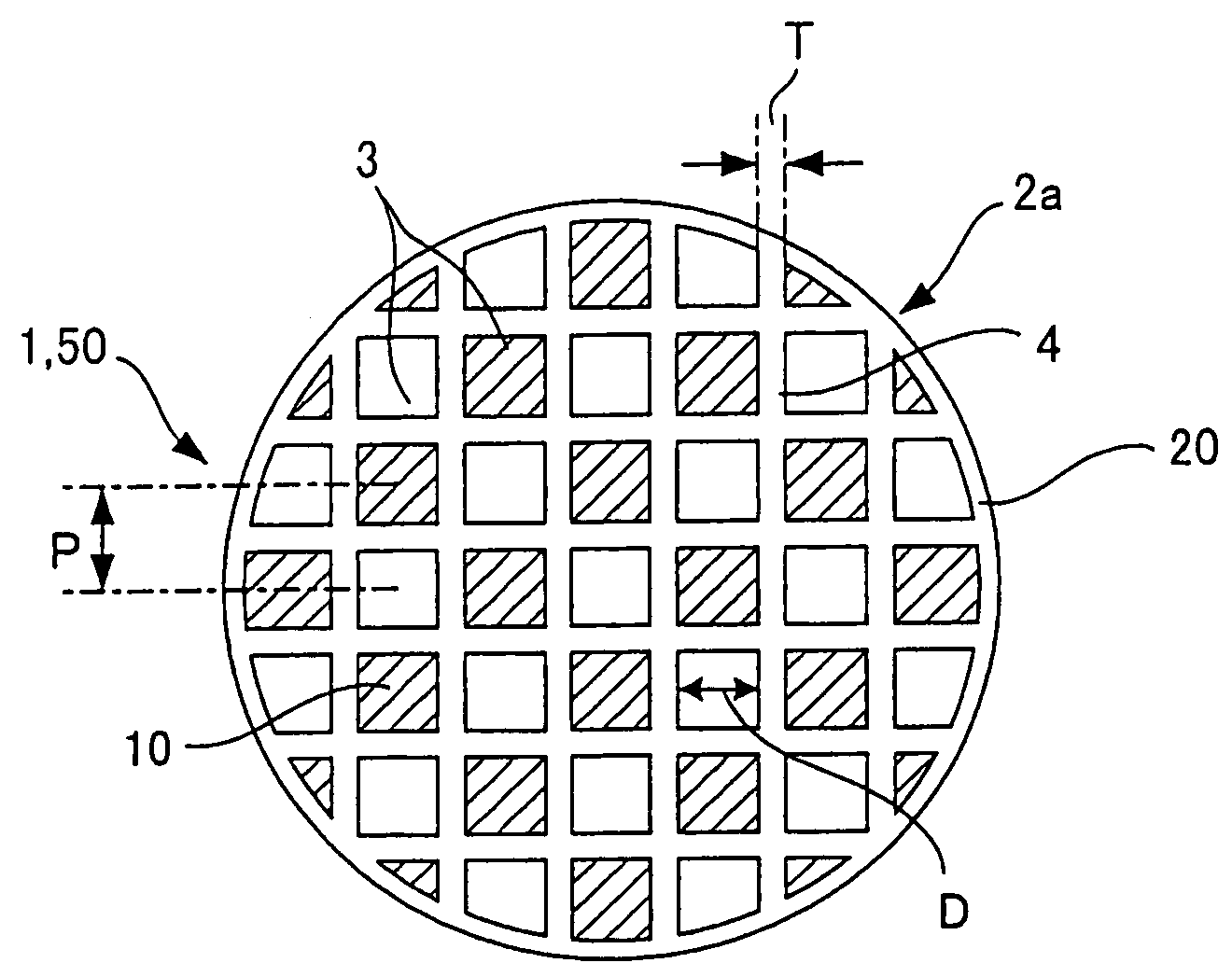

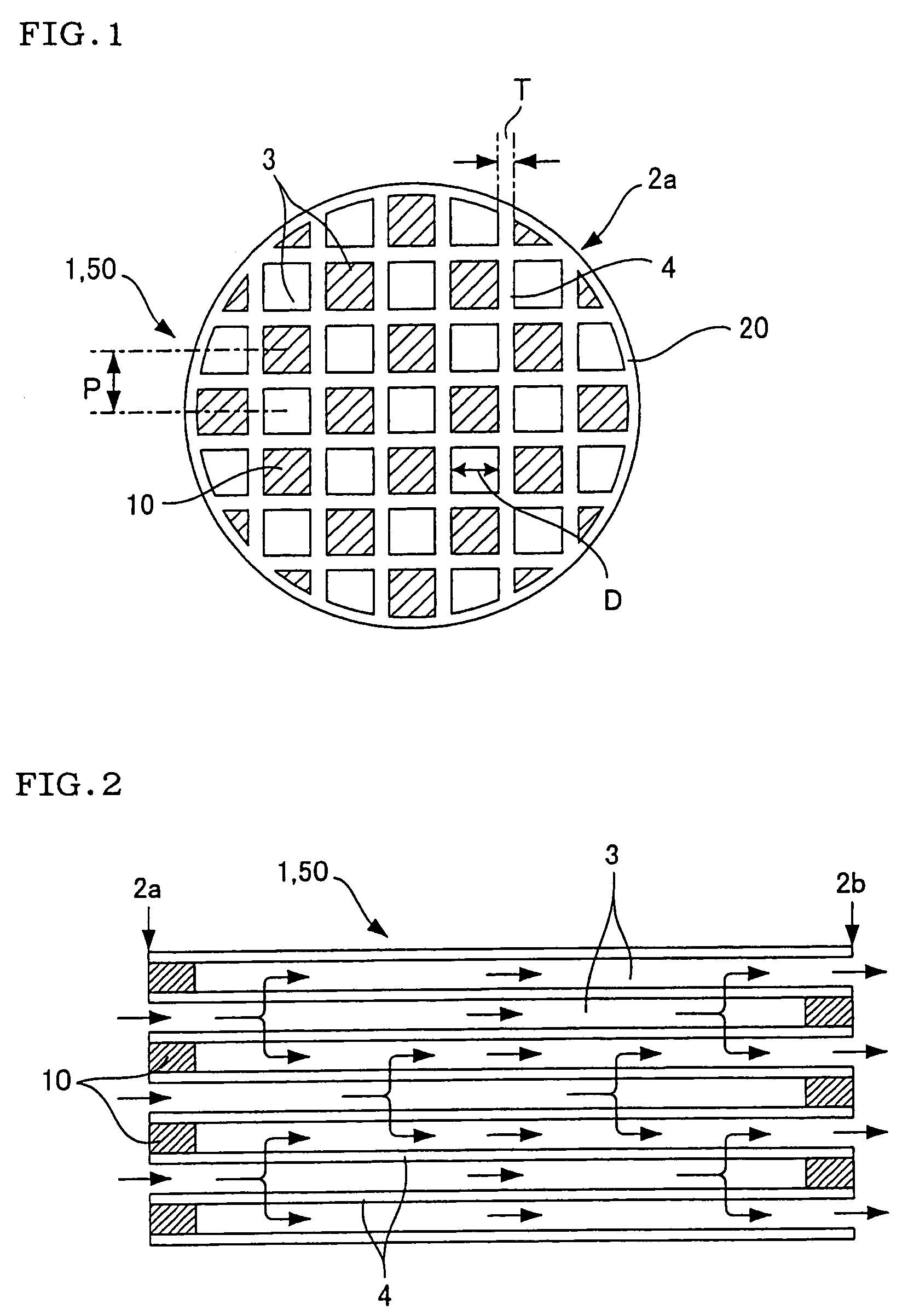

Ceramic honeycomb filter

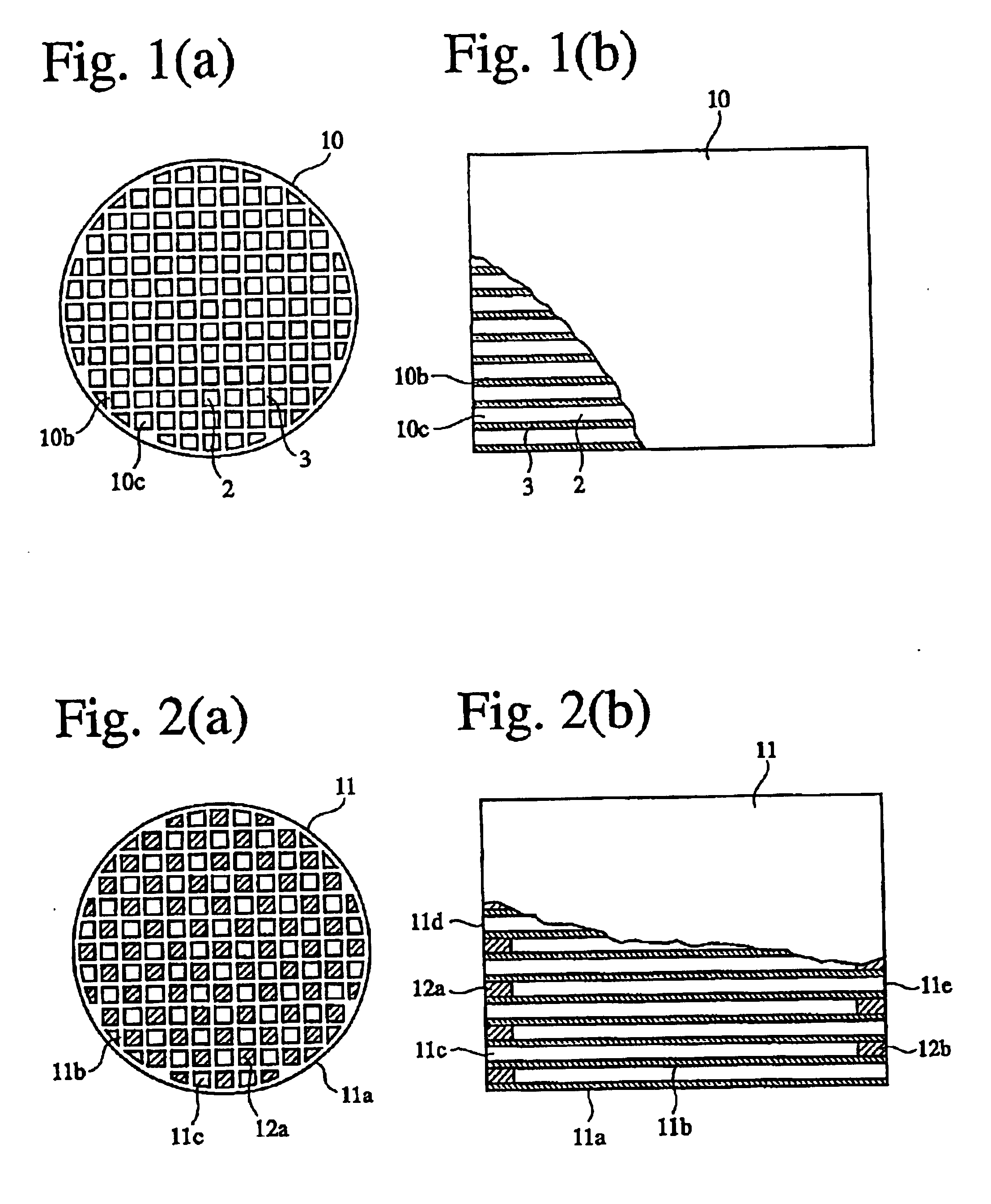

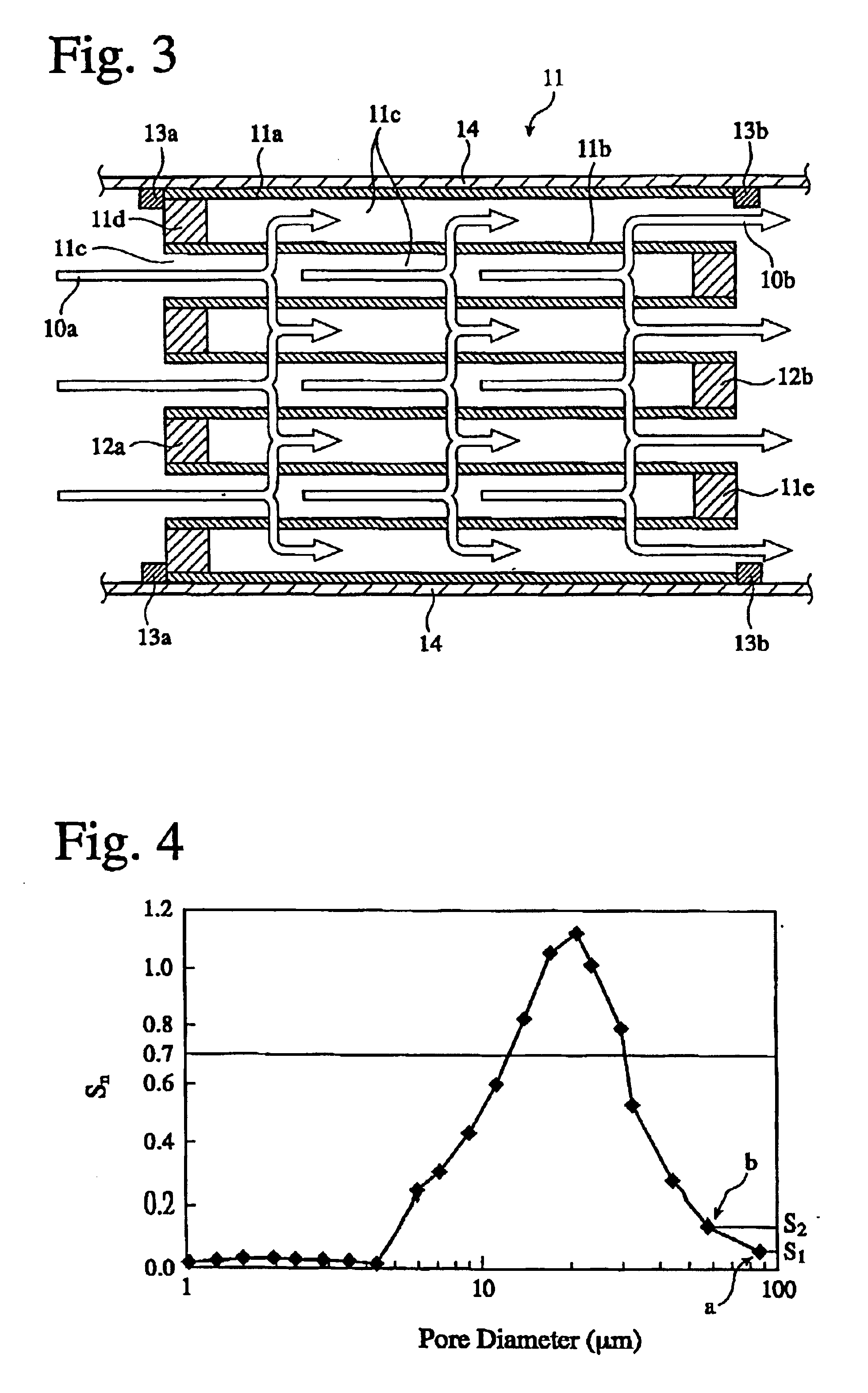

InactiveUS20030093982A1Increased durabilityHigh strengthCombination devicesAuxillary pretreatmentParticulatesMeasurement point

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, the predetermined flow paths among the flow paths being sealed at their ends, a catalyst being carried by the porous partition walls, the porous partition walls having a porosity of 60-75% and an average pore diameter of 15-25 mum when measured according to a mercury penetration method, and the maximum of a slope Sn of a cumulative pore volume curve of the porous partition walls relative to a pore diameter obtained at an n-th measurement point being 0.7 or more, the Sb being represented by the following formula (1): Sn=-(Vb-Vn-1) / [log Dn-log (Dn-1)] (1), wherein Dn is a pore diameter (mum) at an n-th measurement point, Dn-1 is a pore diameter (mum) at an (n-1)-th measurement point, Vn is a cumulative pore volume (cm3 / g) at an n-th measurement point, and Vn-1 is a cumulative pore volume (cm3 / g) at an (n-1)-th measurement point.

Owner:HITACHI METALS LTD +1

Ceramic honeycomb filter

InactiveUS6827754B2Increased durabilityHigh strengthCombination devicesAuxillary pretreatmentParticulatesMeasurement point

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, the predetermined flow paths among the flow paths being sealed at their ends, a catalyst being carried by the porous partition walls, the porous partition walls having a porosity of 60-75% and an average pore diameter of 15-25 mum when measured according to a mercury penetration method, and the maximum of a slope Sn of a cumulative pore volume curve of the porous partition walls relative to a pore diameter obtained at an n-th measurement point being 0.7 or more, the Sn being represented by the following formula (1):wherein Dn is a pore diameter (mum) at an n-th measurement point, Dn-1 is a pore diameter (mum) at an (n-1)-th measurement point, Vn is a cumulative pore volume (cm<3> / g) at an n-th measurement point, and Vn-1 is a cumulative pore volume (cm<3> / g) at an (n-1)-th measurement point.

Owner:HITACHI METALS LTD +1

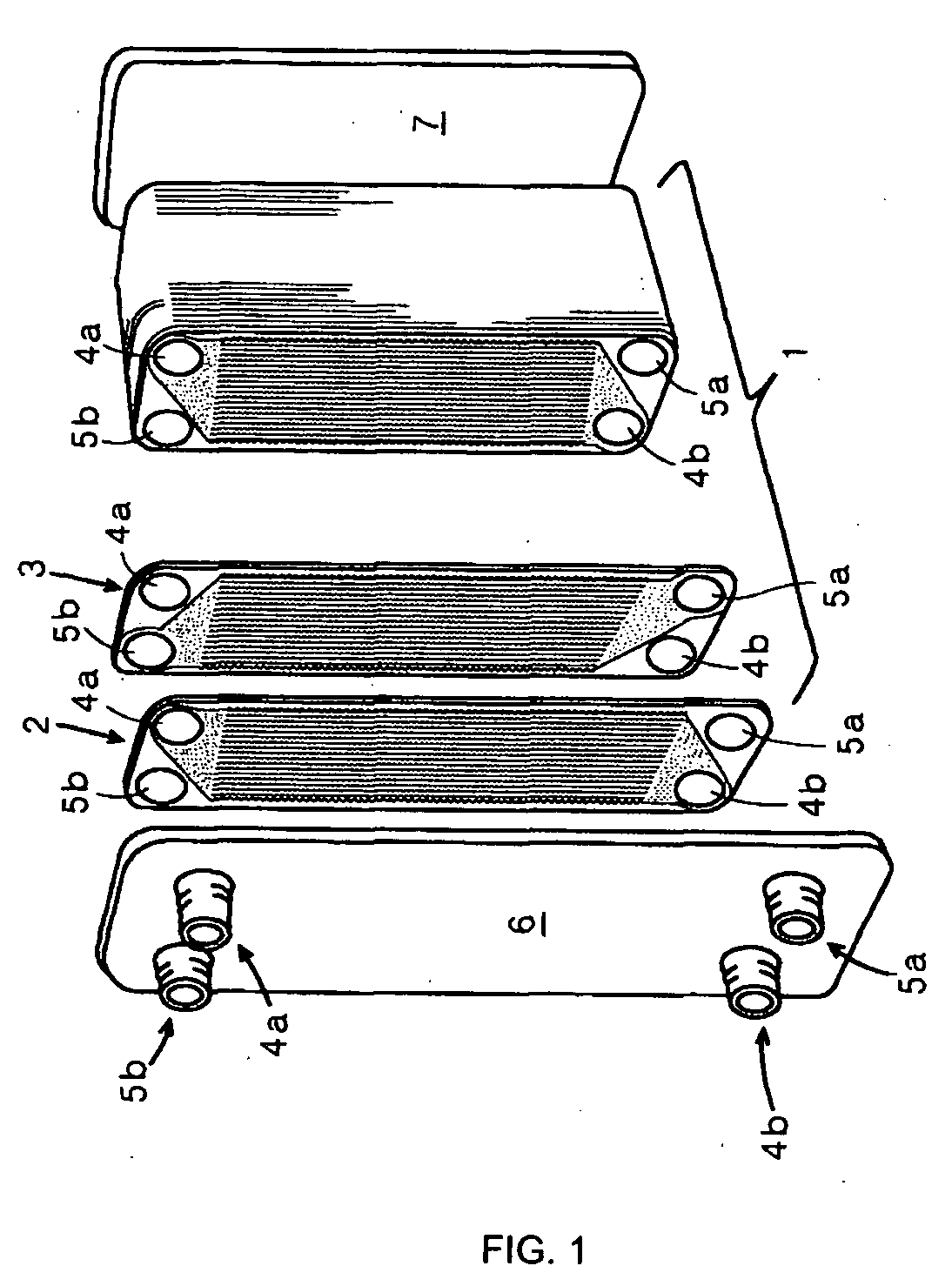

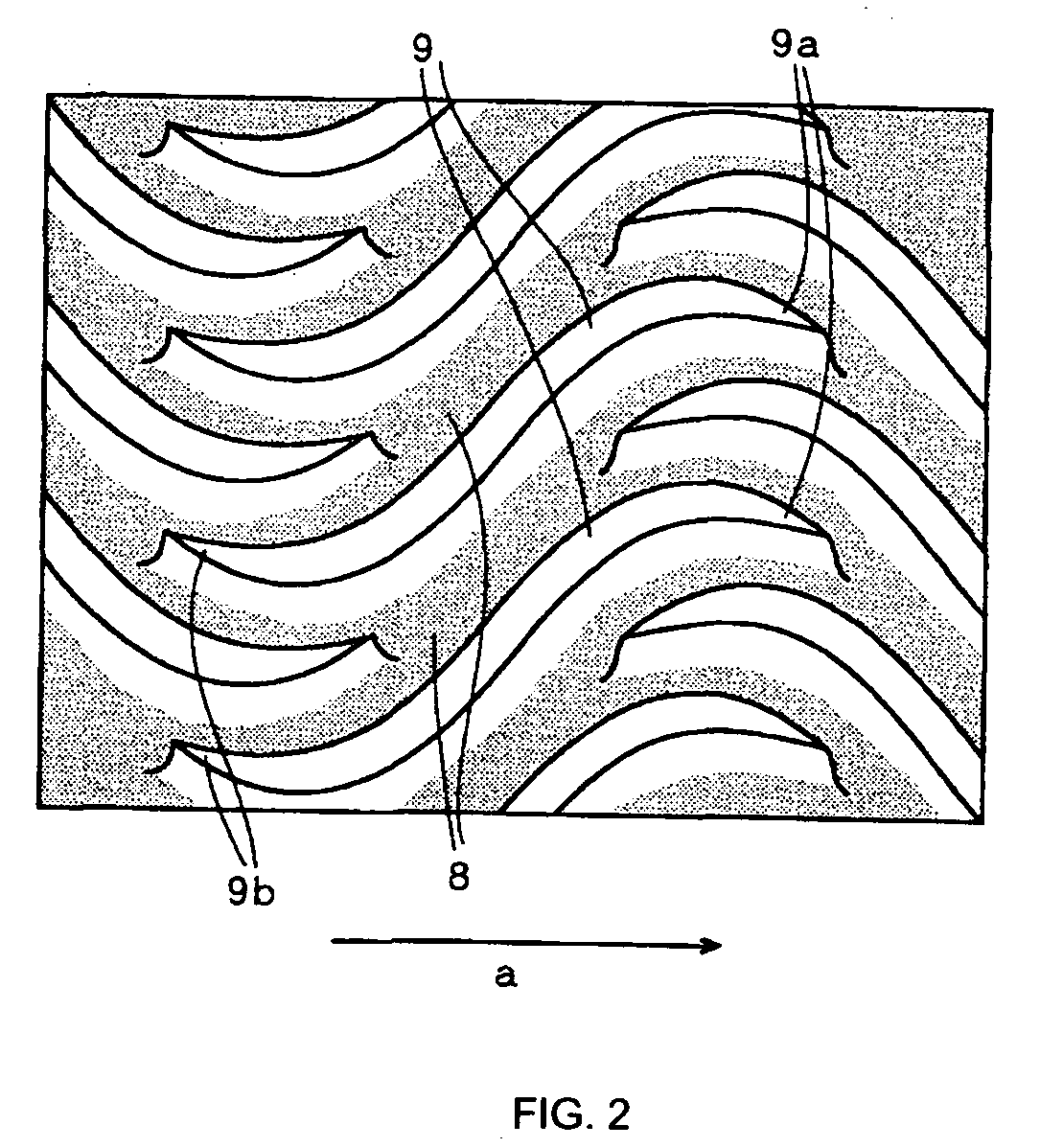

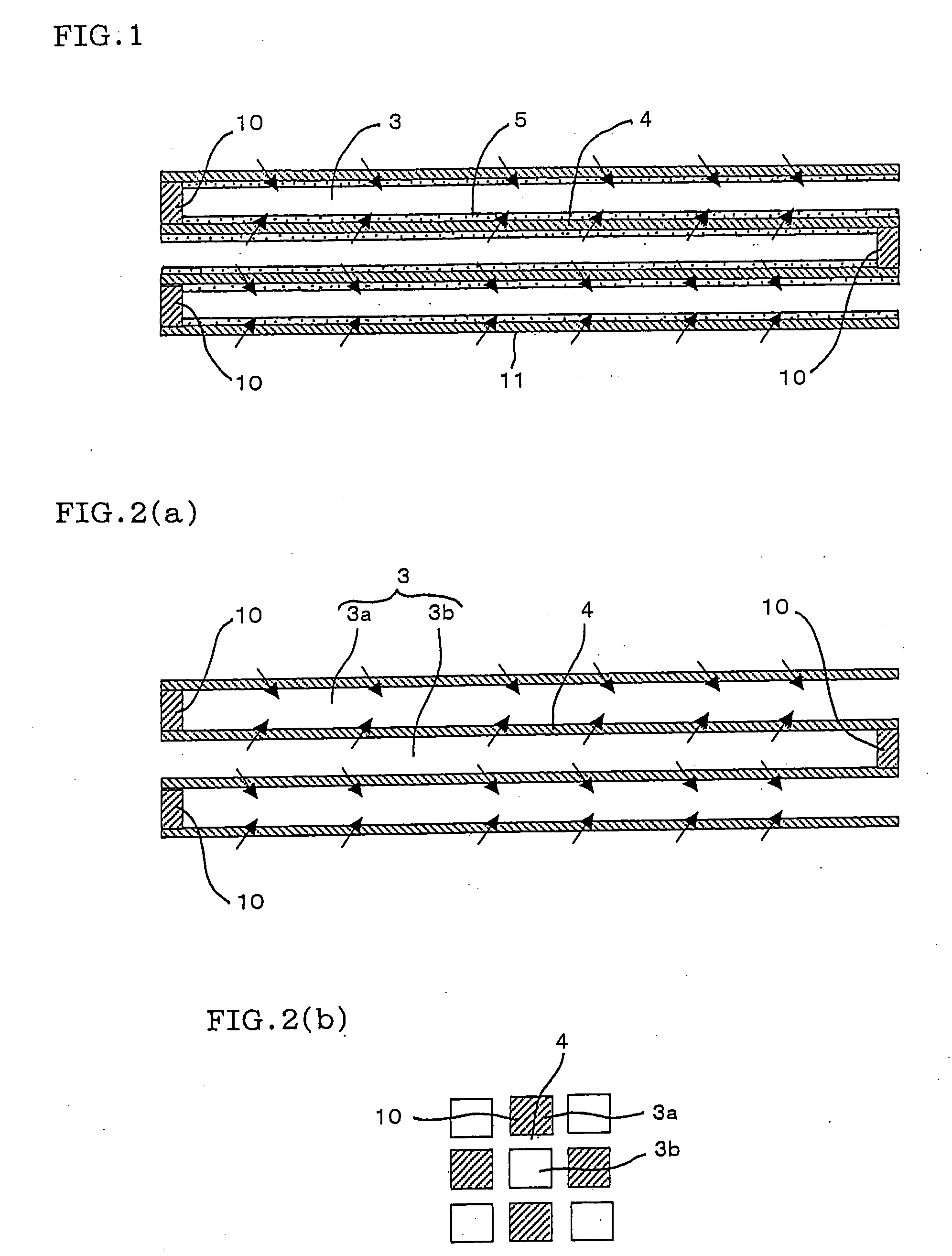

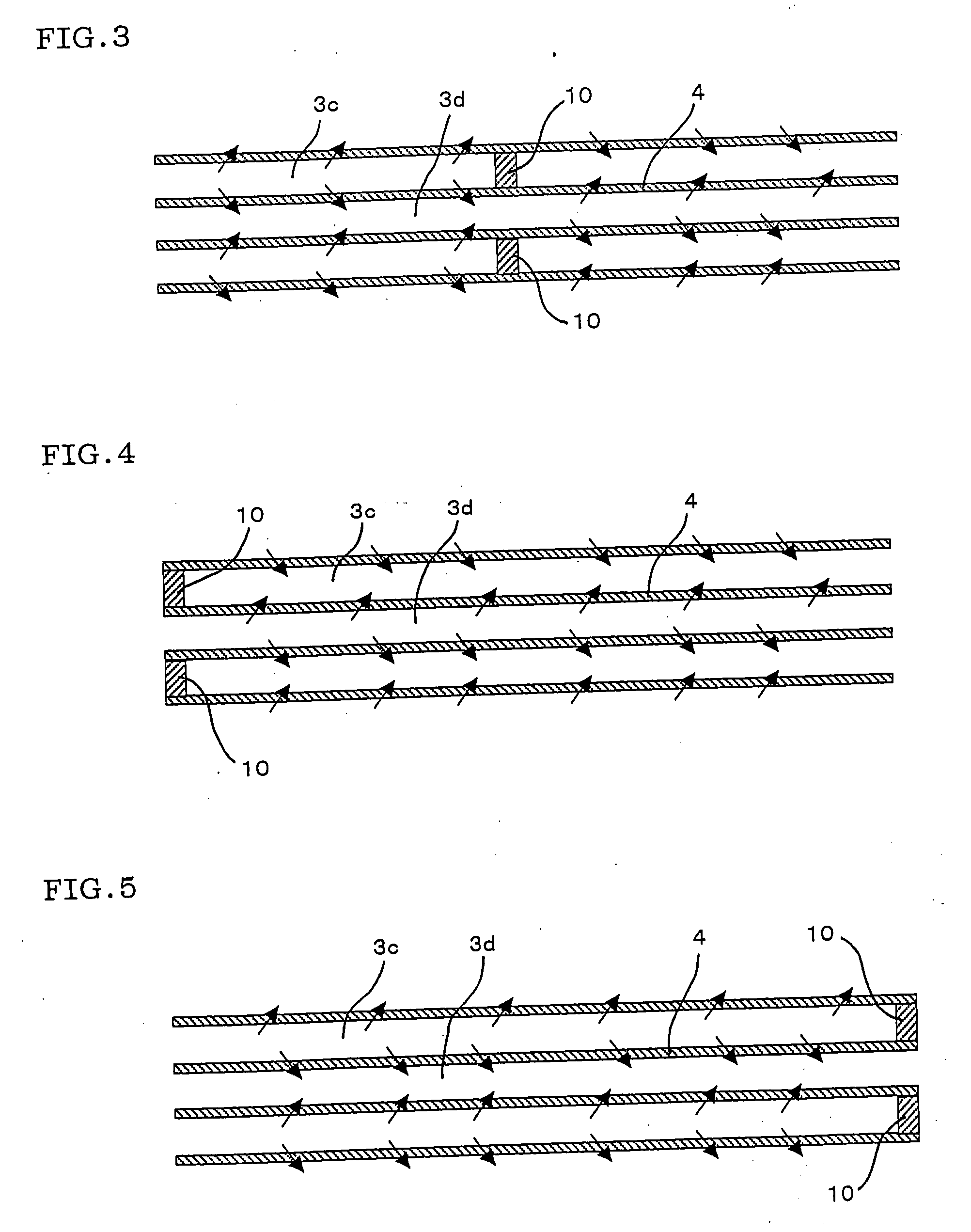

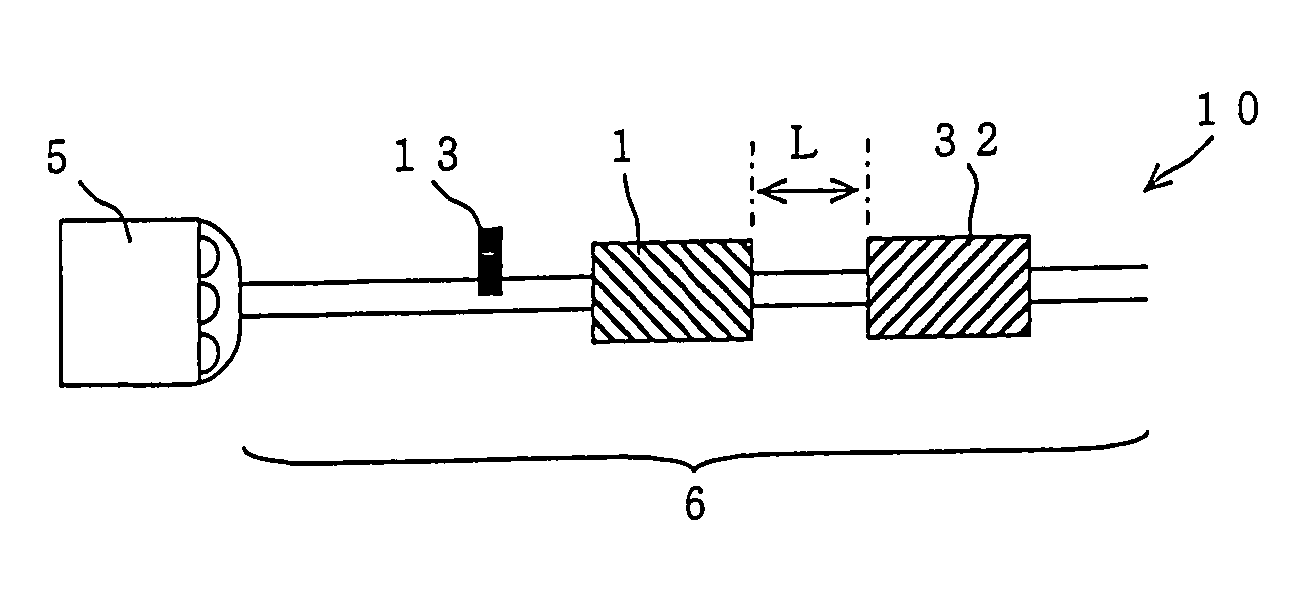

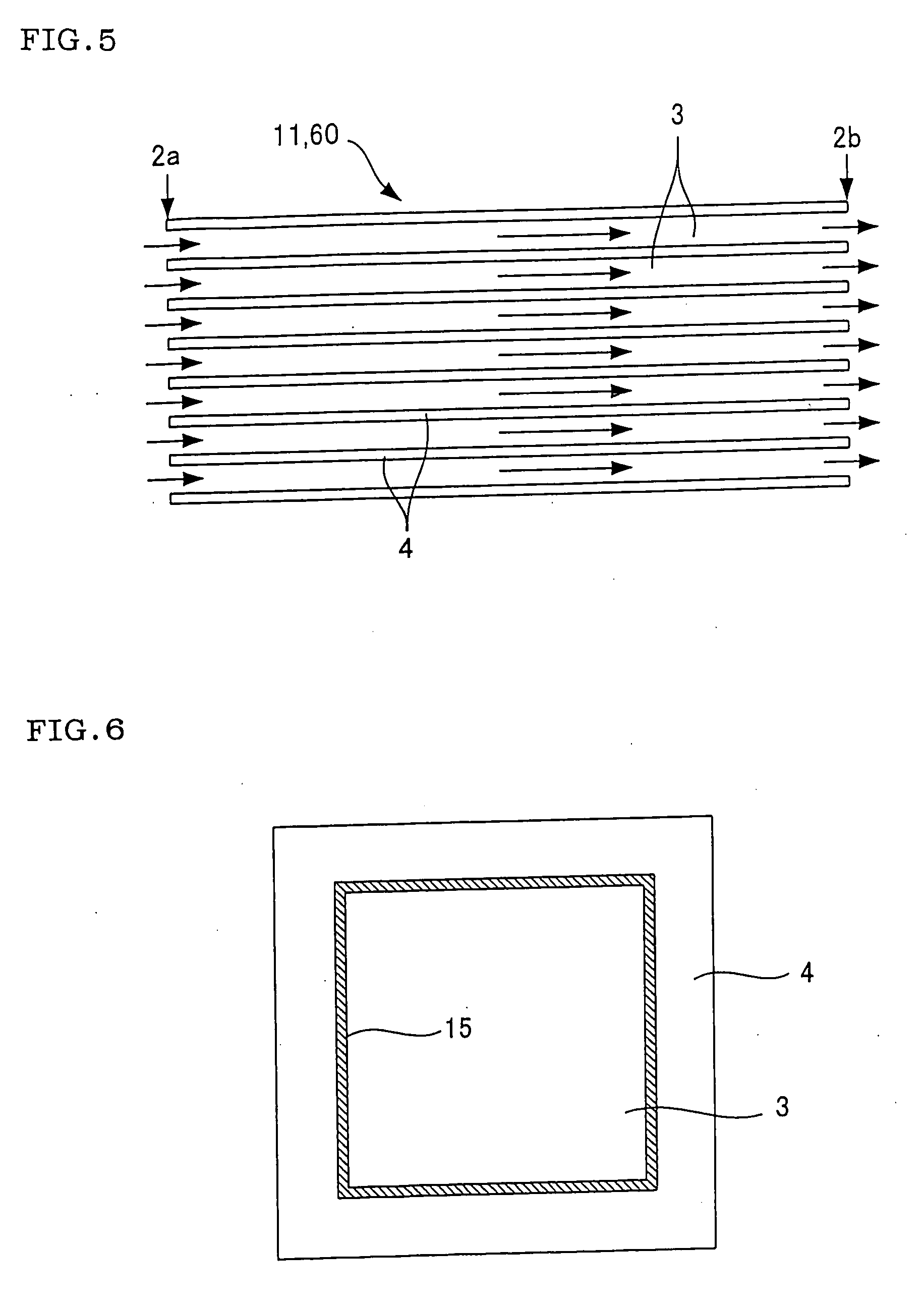

Heat exchanger

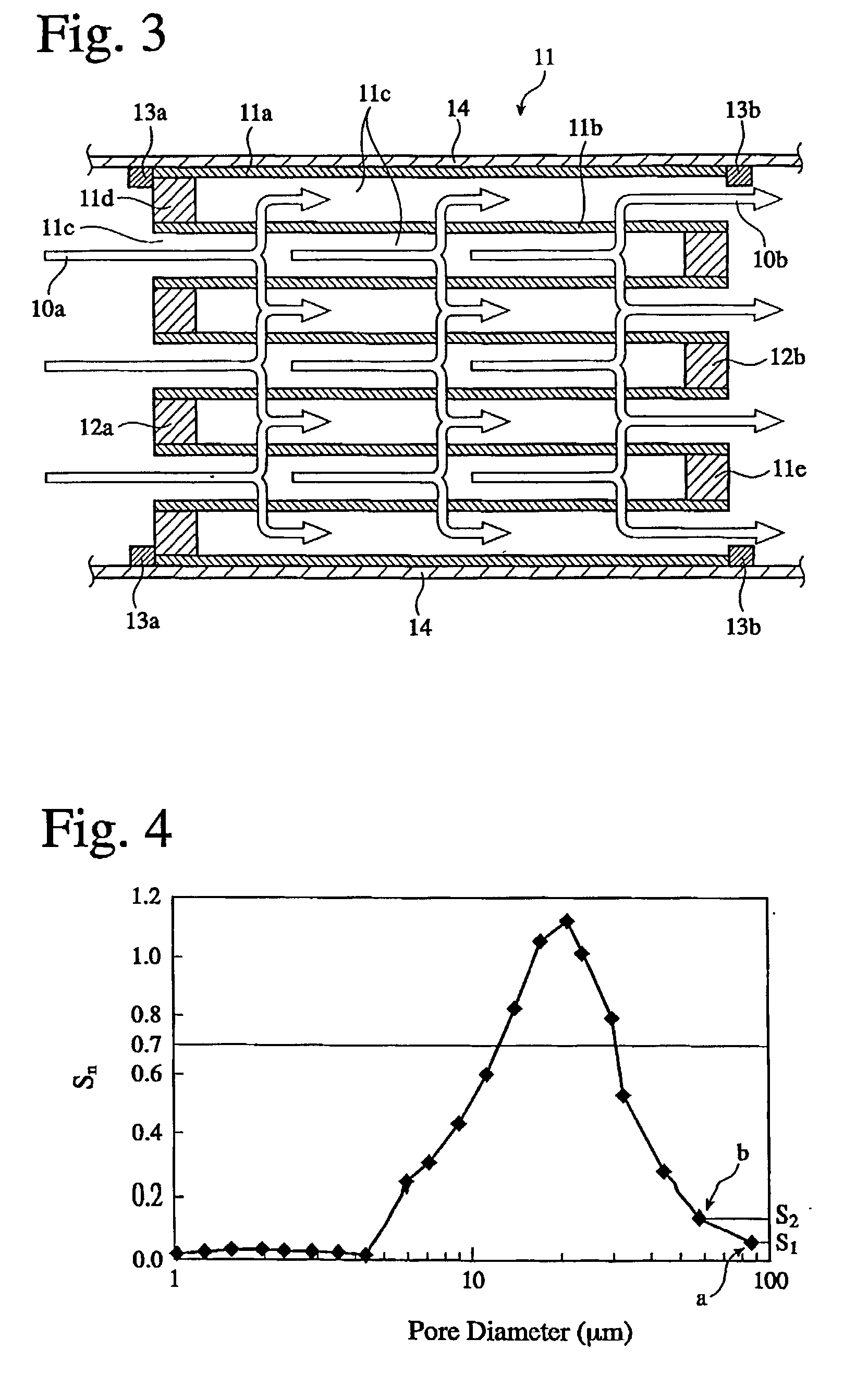

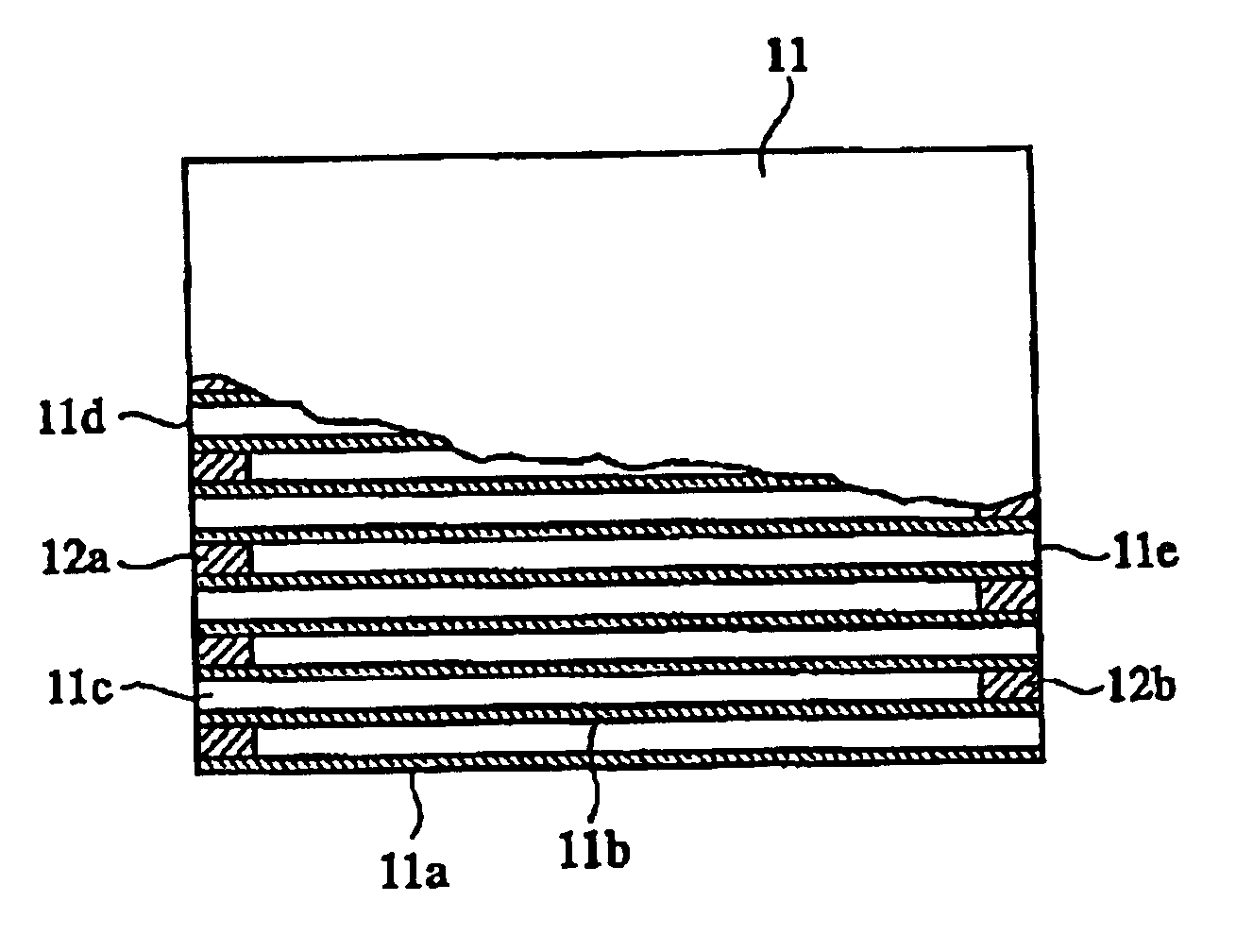

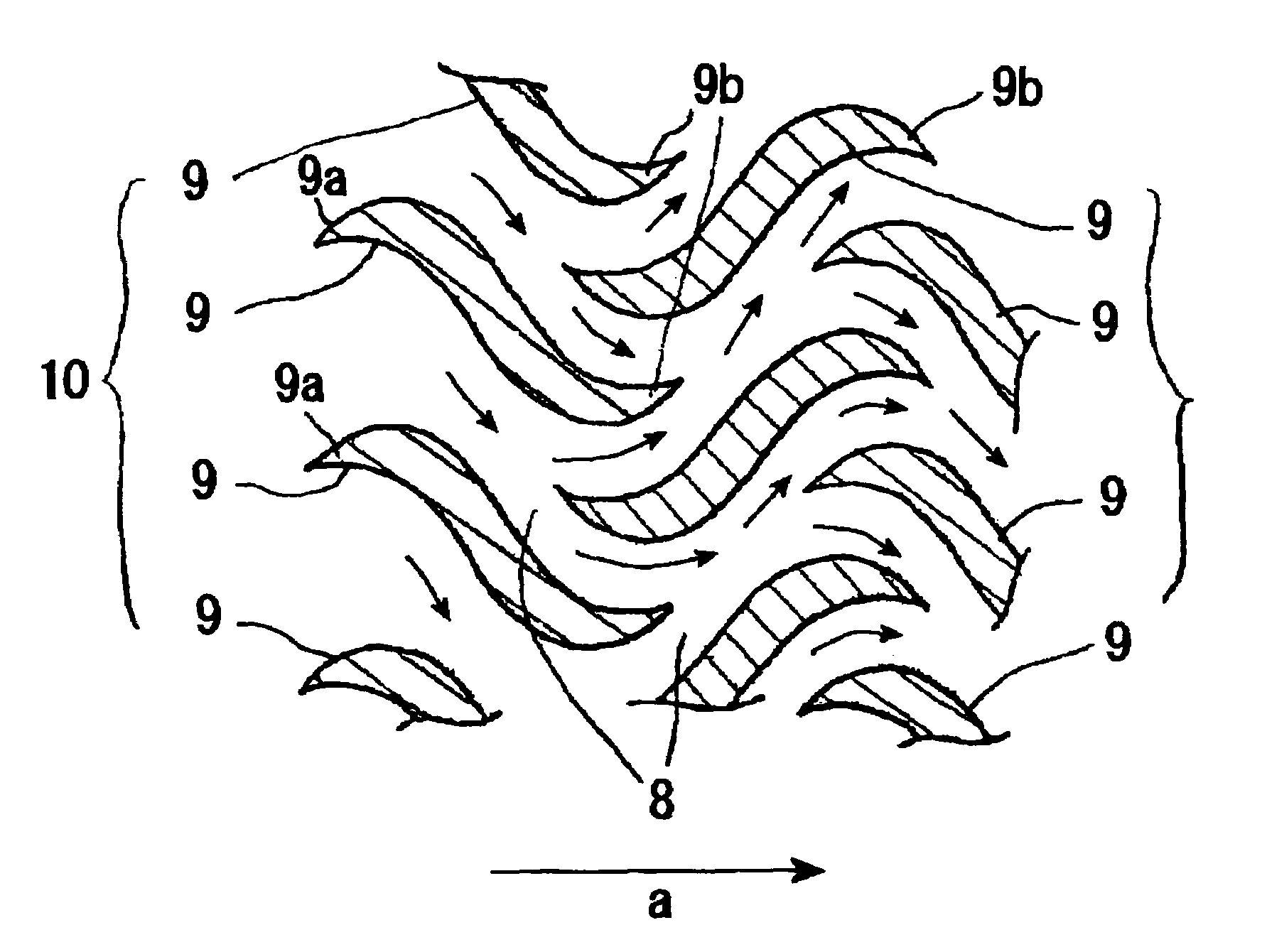

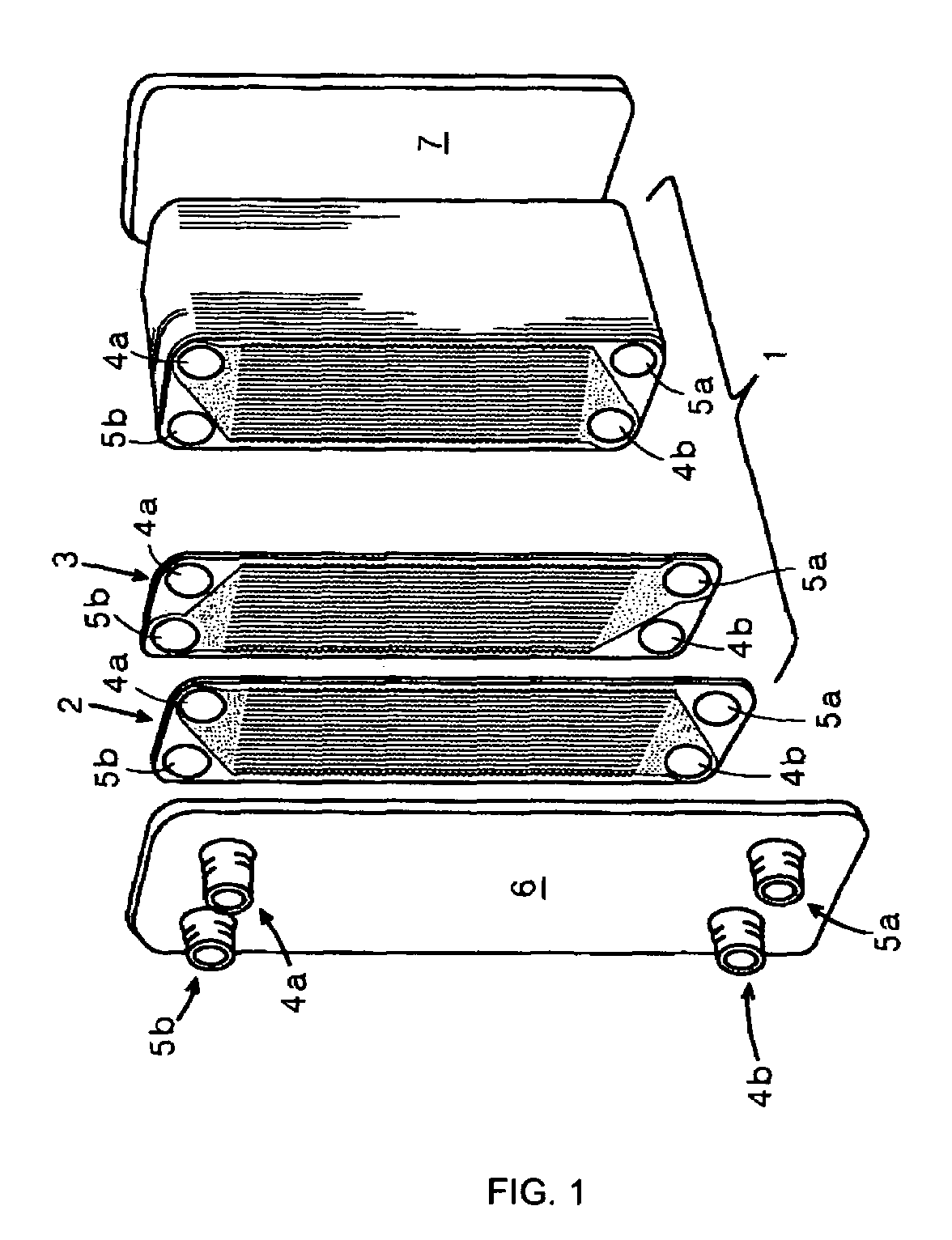

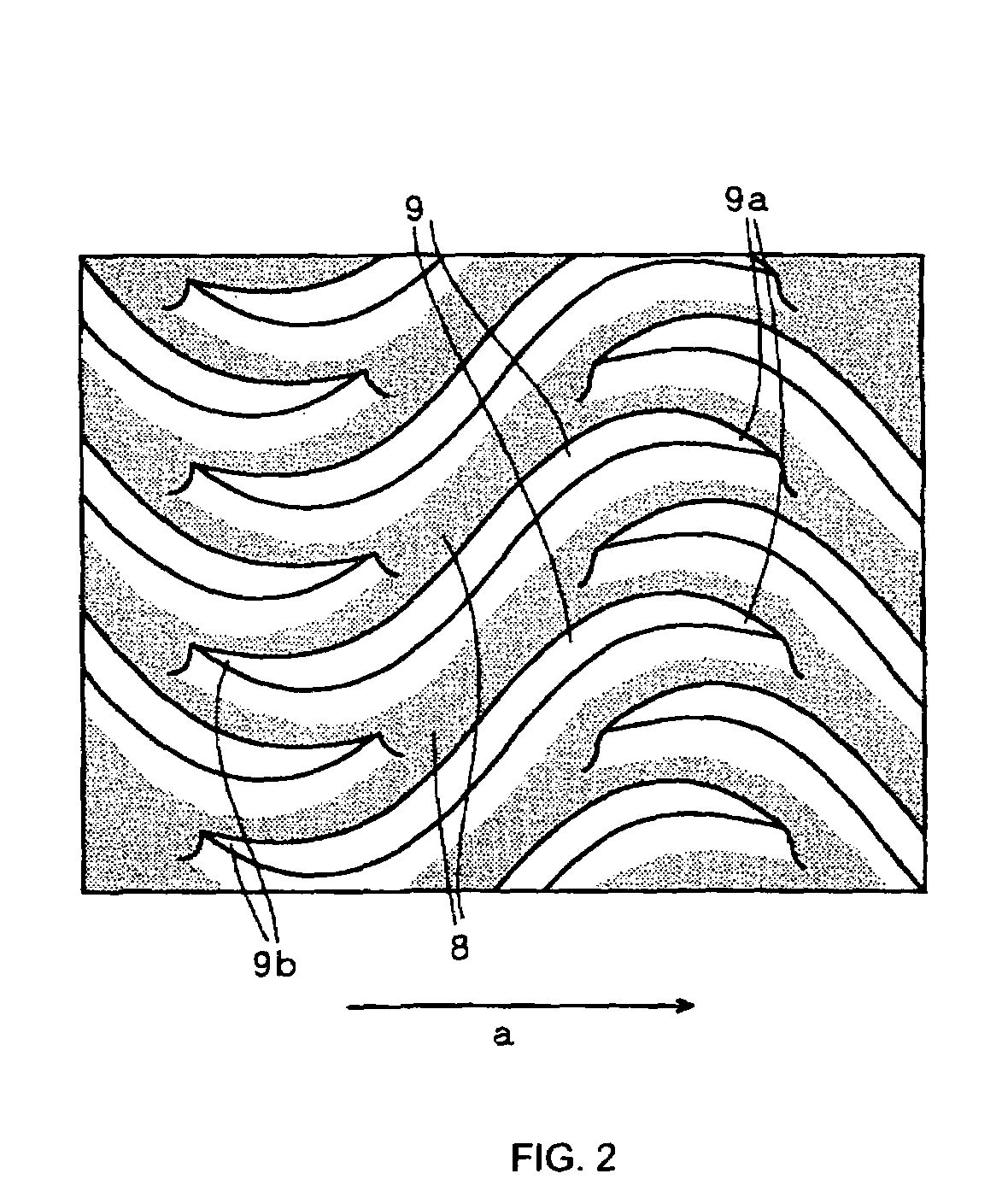

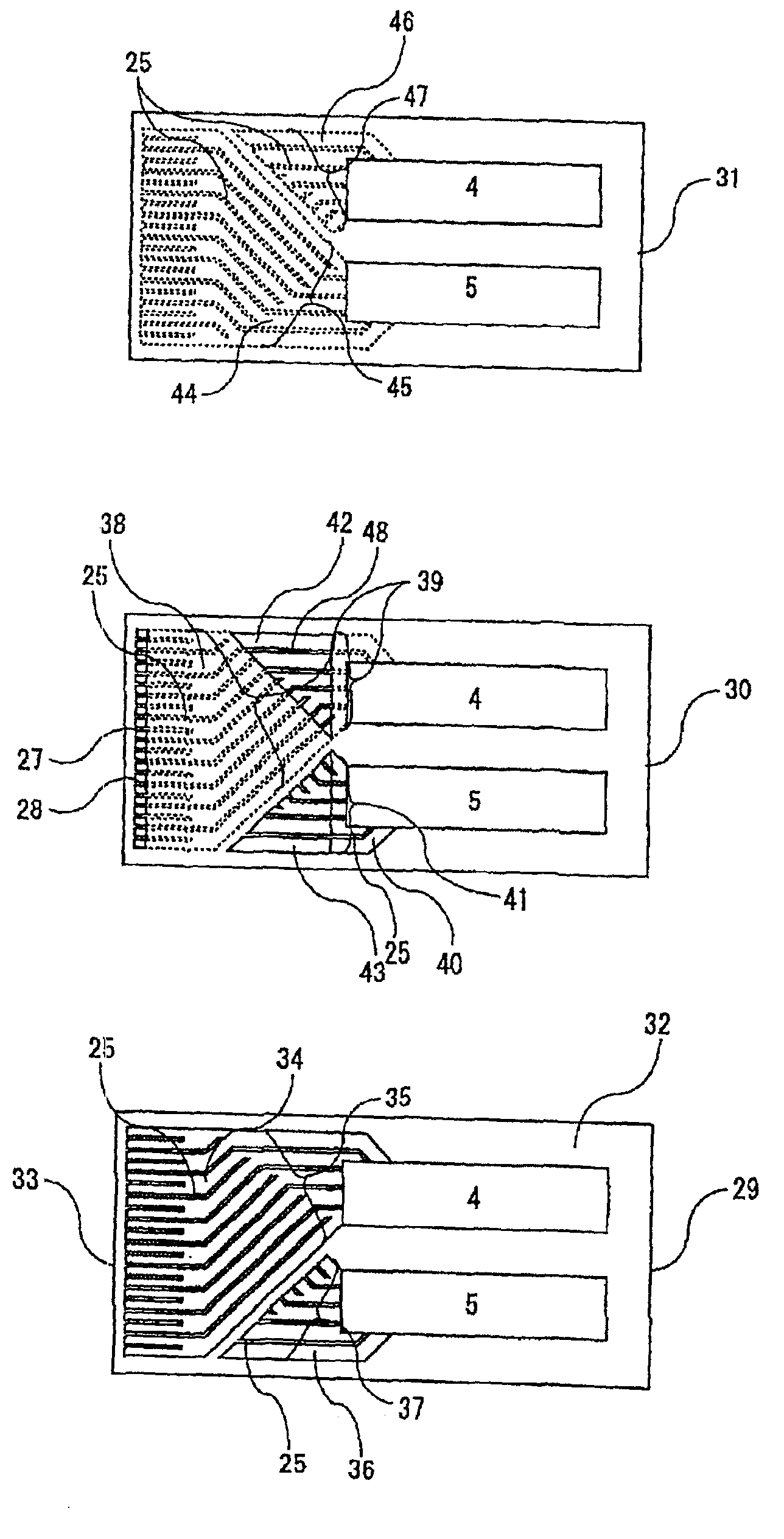

InactiveUS7334631B2Without impairment of heat transfer characteristicIncreased pressure lossHeat transfer modificationLaminated elementsThin metalPlate heat exchanger

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

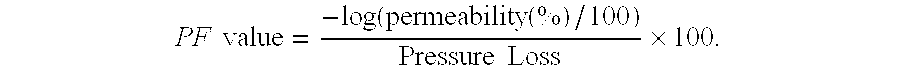

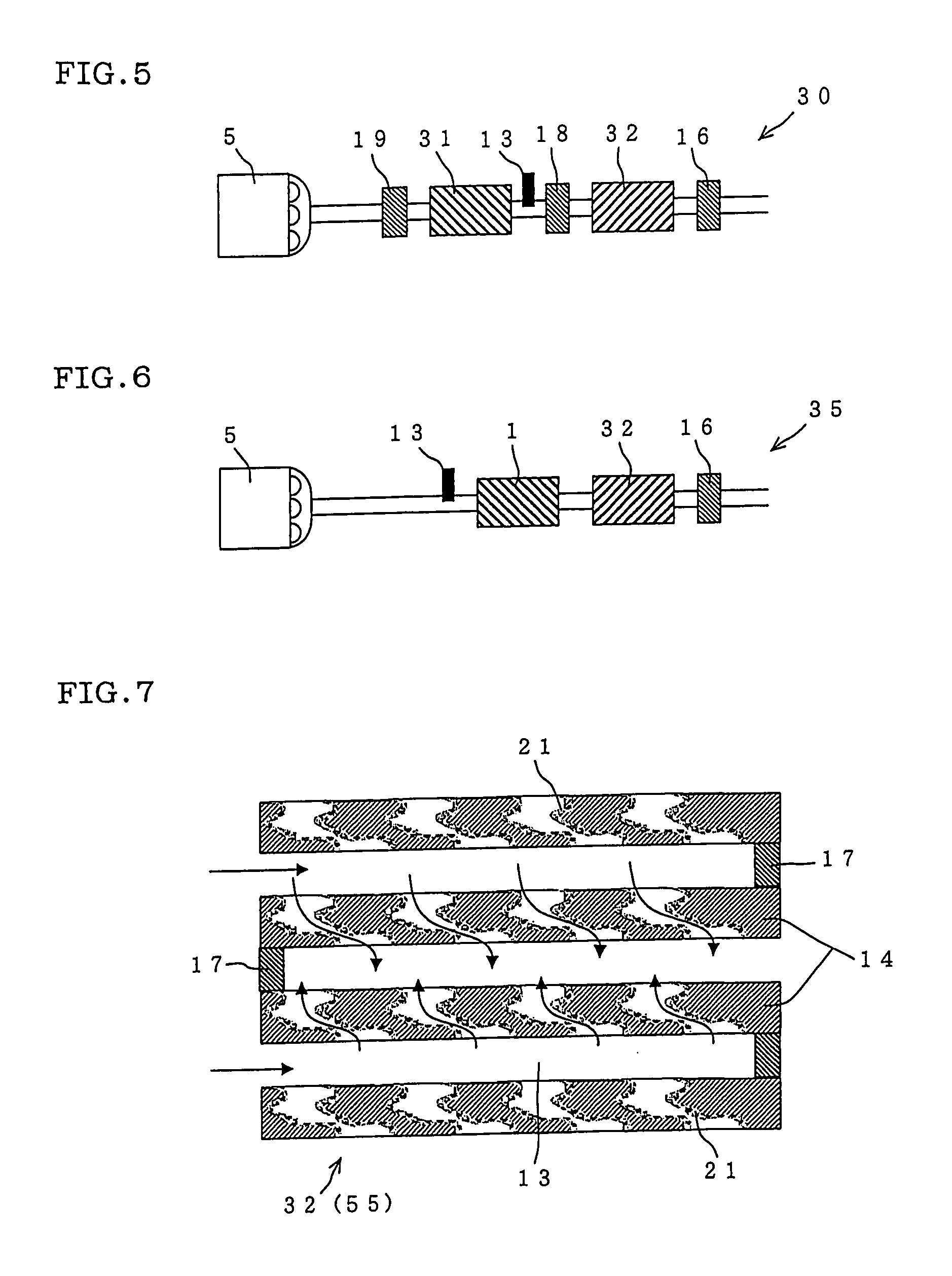

Filter medium and air filter unit using the same

InactiveUS6261979B1Low pressure lossImprove collection efficiencyMembranesSemi-permeable membranesAir filterFilter media

A filter medium which has an average pore diameter of more than 0.5 .mu.m, a pressure loss of 2-50 mmH.sub.2 O determined when air is permeated therethrough at a velocity of flow of 5.3 cm / sec, and a PF value of 18-12, which is calculated in accordance with the following equation on the basis of this pressure loss and a collection efficiency using DOP of a grain size of 0.10-0.12 .mu.m. ##EQU1##

Owner:DAIKIN IND LTD

Honeycomb structure and honeycomb catalytic body

ActiveUS20070048494A1Improve purification efficiencyLow pressure lossInternal combustion piston enginesDispersed particle filtrationEngineeringMechanical engineering

A honeycomb structure having porous partition walls having a large number of pores, formed so as to produce a plurality of cells each extending between the two ends of the honeycomb structure, and plugged portions formed so as to plug the cells at either one end of the honeycomb structure or at the insides of the cells, wherein the honeycomb structure has the partition walls of a permeability of 7×10−12 to 4×10−8 m2. The honeycomb structure can provide a honeycomb catalyst structure which is superior in purification efficiency, is low in pressure loss and can be mounted even in a limited space.

Owner:NGK INSULATORS LTD

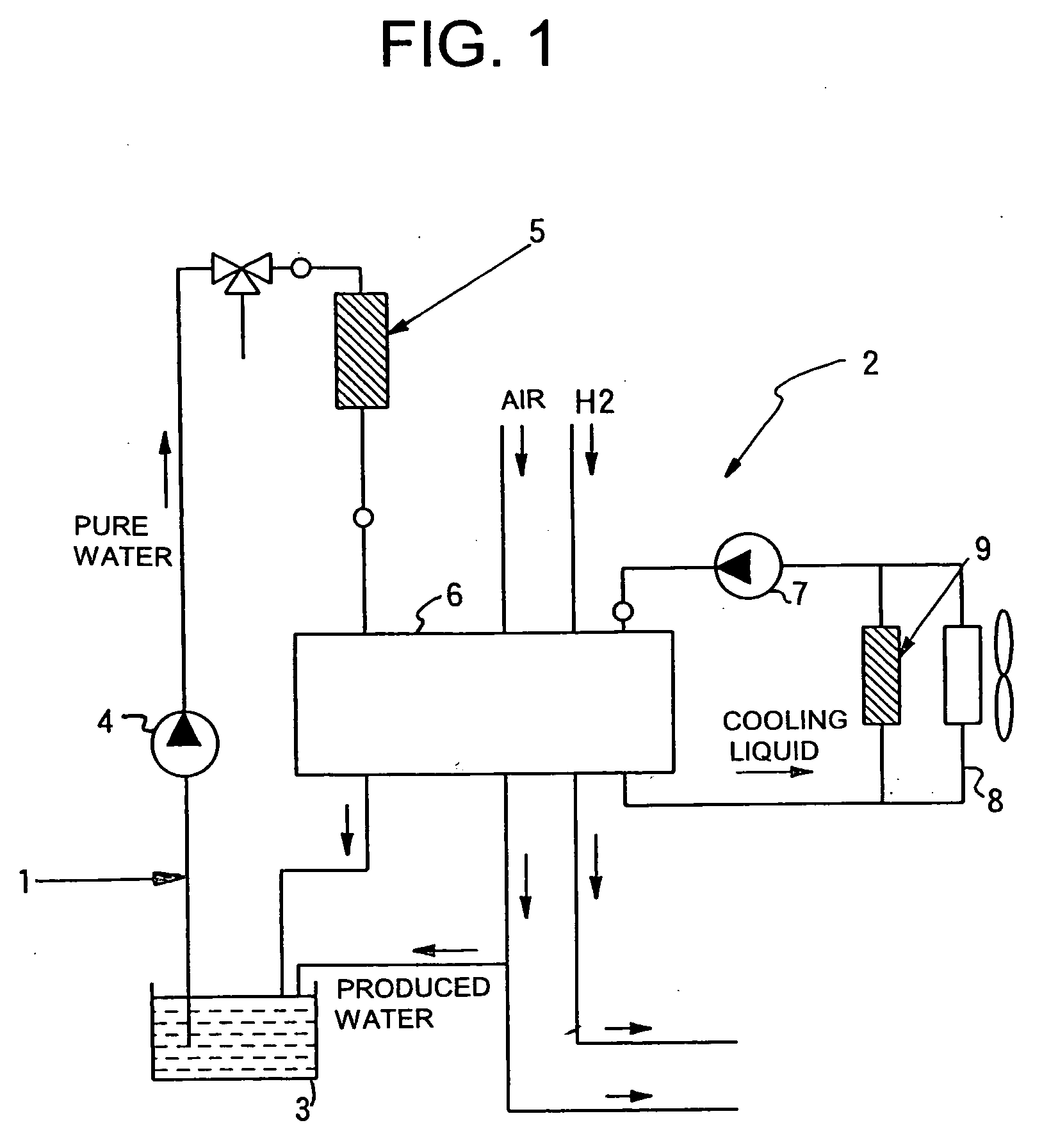

Ion-exchange filter

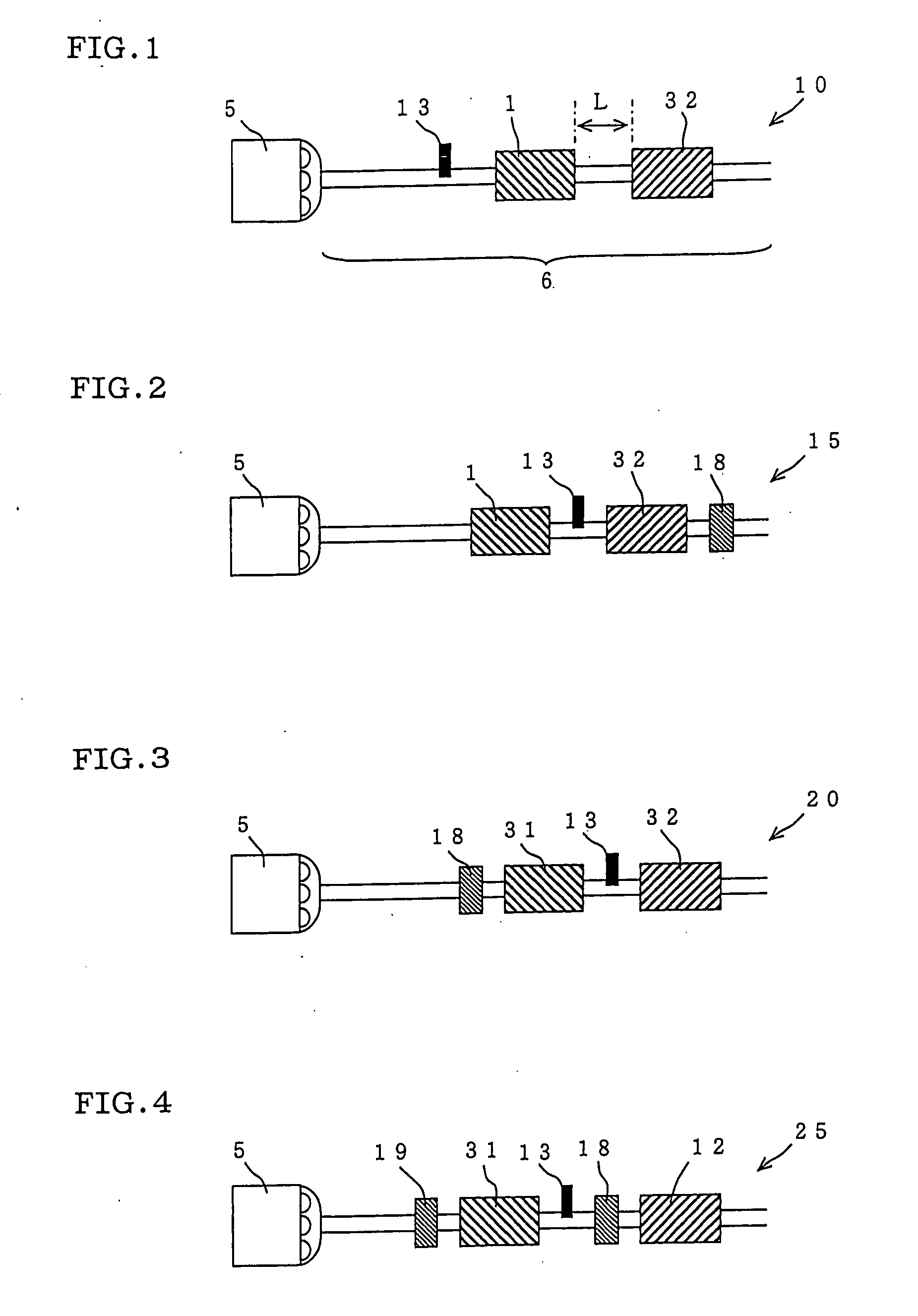

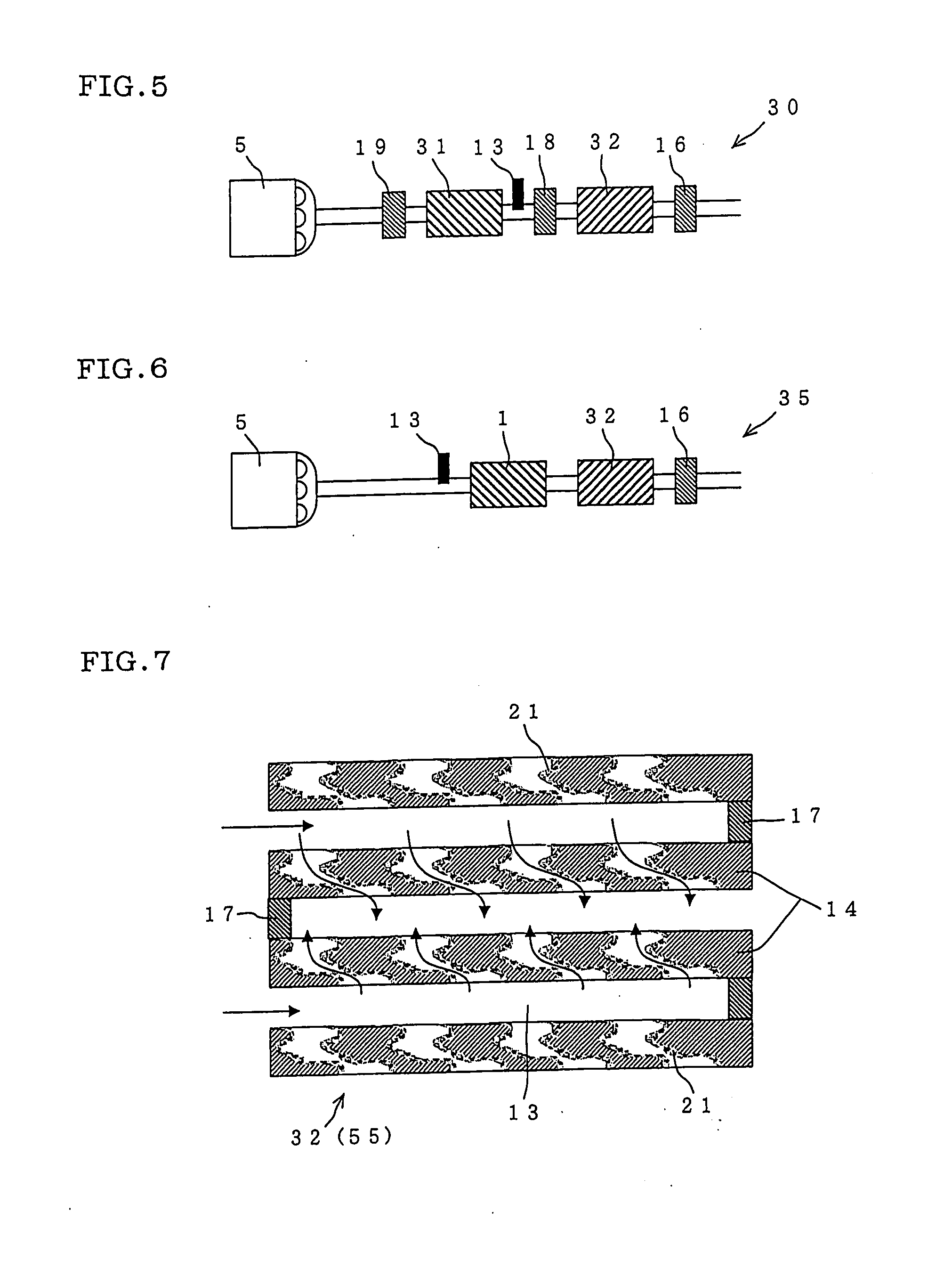

ActiveUS20050115884A1Improve exchange efficiencyLow pressure lossIon-exchange column/bed processesFuel cell auxillariesFuel cellsIon exchange

A fuel cell system includes an ion-exchange filter, which is provided with a cartridge which is filled up with an ion-exchange resin. The cartridge includes one of a pressure-loss emphasizing type cartridge and an ion-exchange efficiency emphasizing type cartridge, which are selectively exchanged with each other, for a common case of the ion-exchange filter. The ion-exchange efficiency emphasizing type cartridge is one for an ion-exchange filter having a high pressure loss and high ion-exchange efficiency and, on the other hand, the pressure-loss emphasizing type cartridge is one for an ion-exchange filter having a pressure loss lower than that of the former ion-exchange filter and an ion-exchange efficiency lower than that of the former ion-exchange filter.

Owner:TOYO ROKI MFG CO LTD +1

Entrainment air flow control and filtration devices

ActiveUS20090311951A1High energyImprove performanceCombination devicesAuxillary pretreatmentFiltrationAir treatment

Devices and systems are provided, that entrain ambient air within a primary stream of pressurised air, for use in a variety of applications including aircraft, buildings and other stationary structures. The ambient air is drawn through an air treatment such a filter before entrainment within the primary stream. The combined streams are then delivered to a ventilation system, an air curtain or other suitable recipient of treated, thermally conditioned air. The systems include air curtain systems and ventilation systems for aircraft and other vehicles.

Owner:VEFT AEROSPACE TECH

Heat exchanger

InactiveUS20060090887A1Reduce total pressure lossReduce maintenanceHeat transfer modificationLaminated elementsThin metalEngineering

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

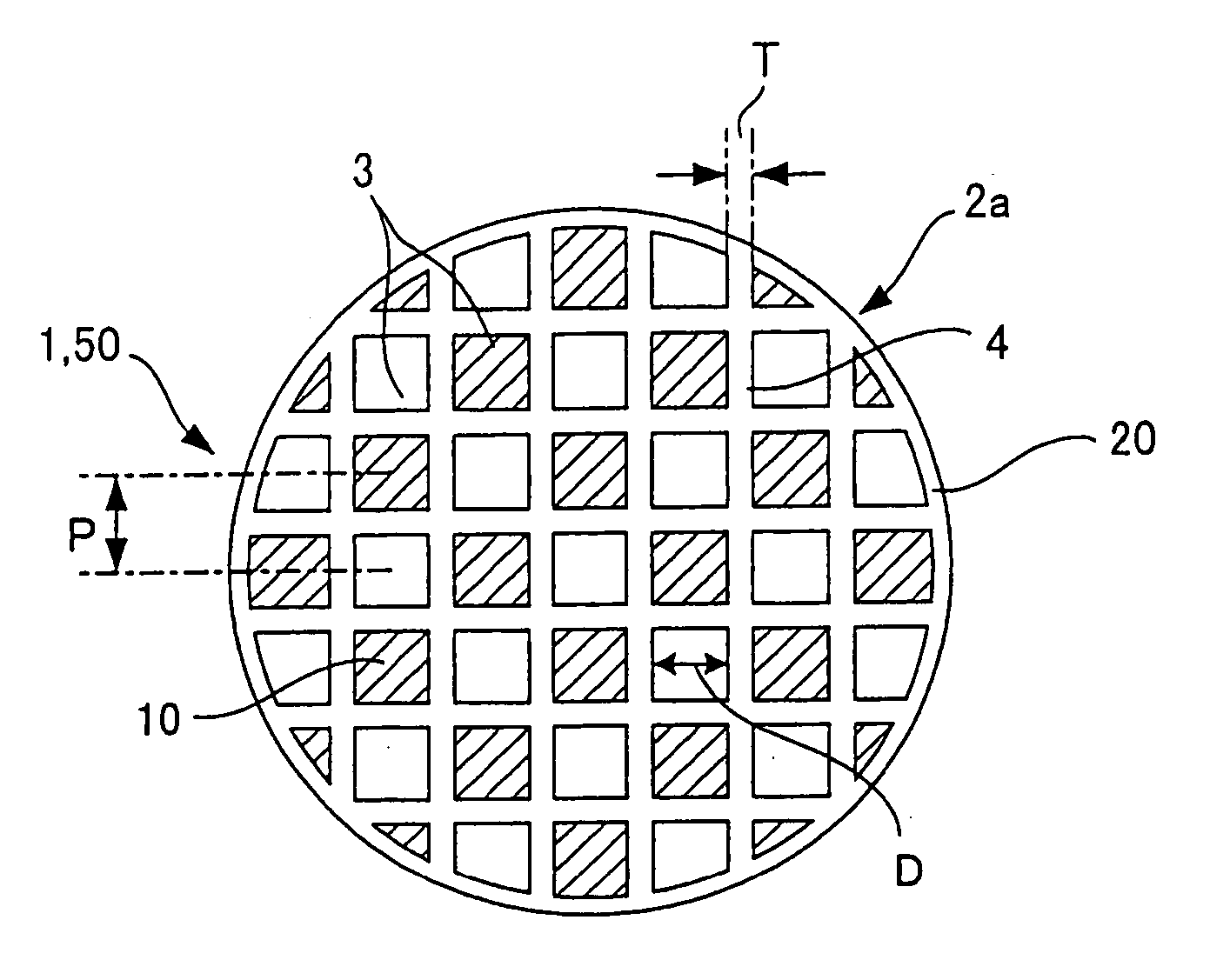

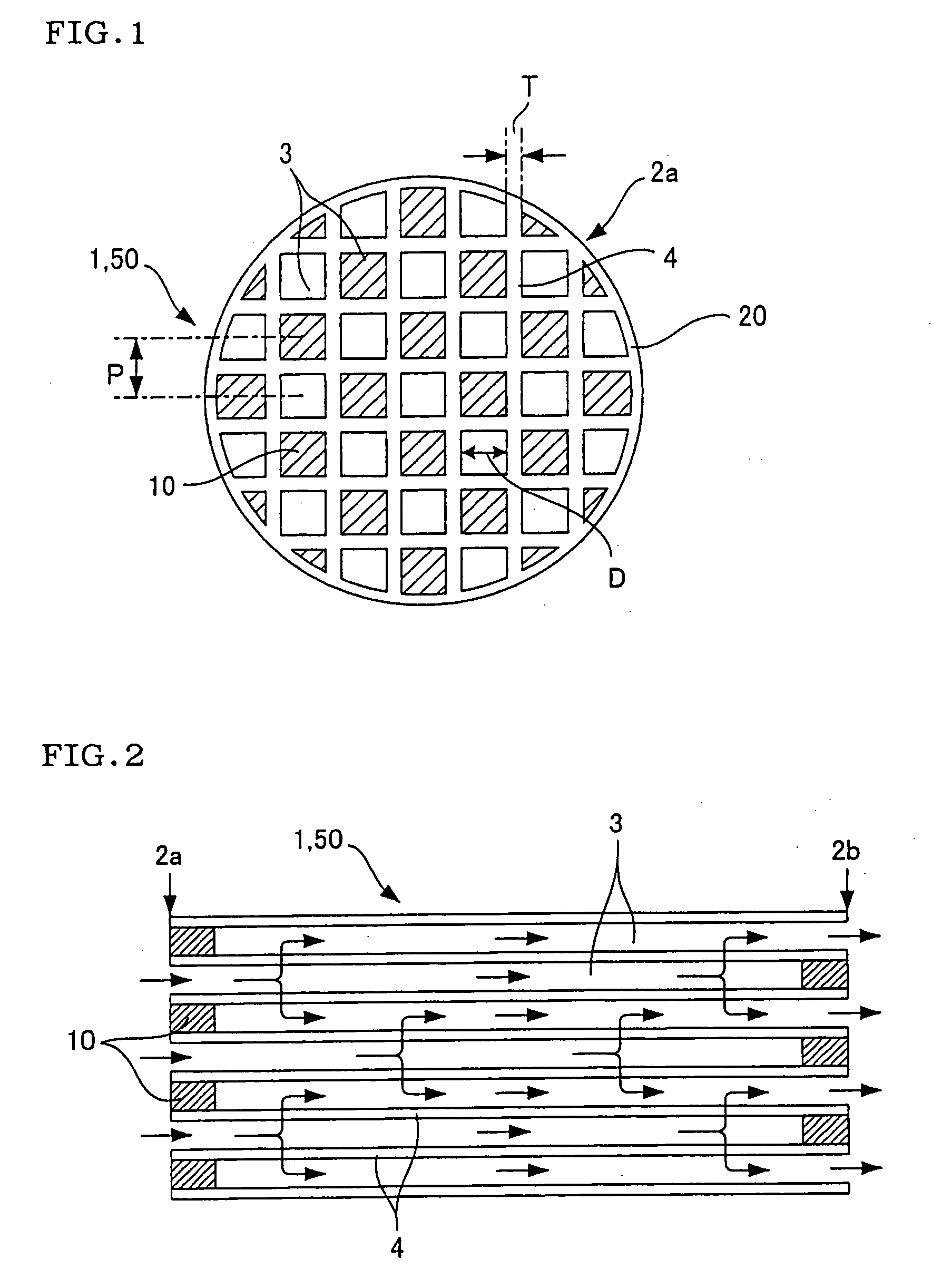

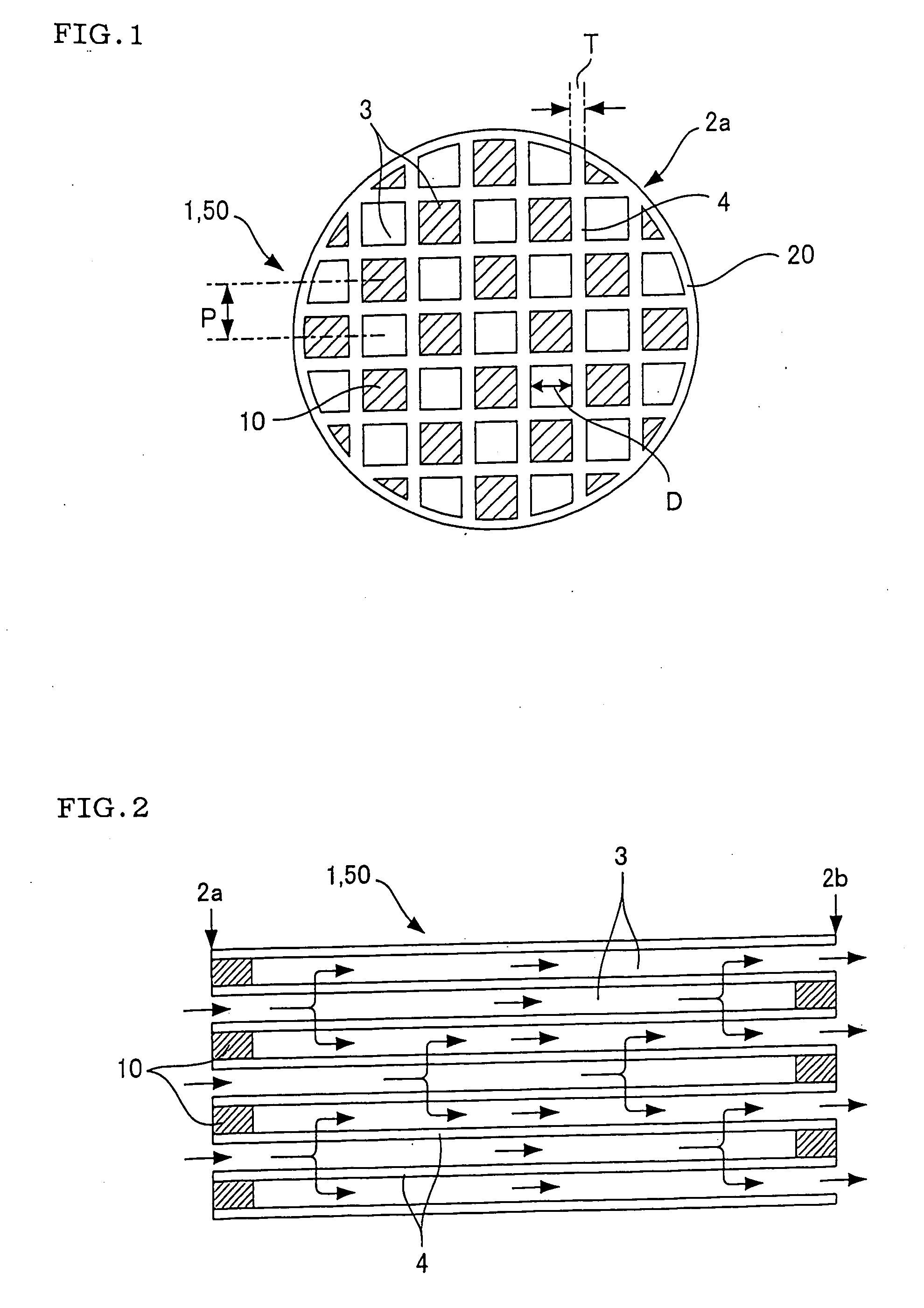

Honeycomb structure

ActiveUS7316722B2Low pressure lossGood partitionCombination devicesAuxillary pretreatmentParticulatesEngineering

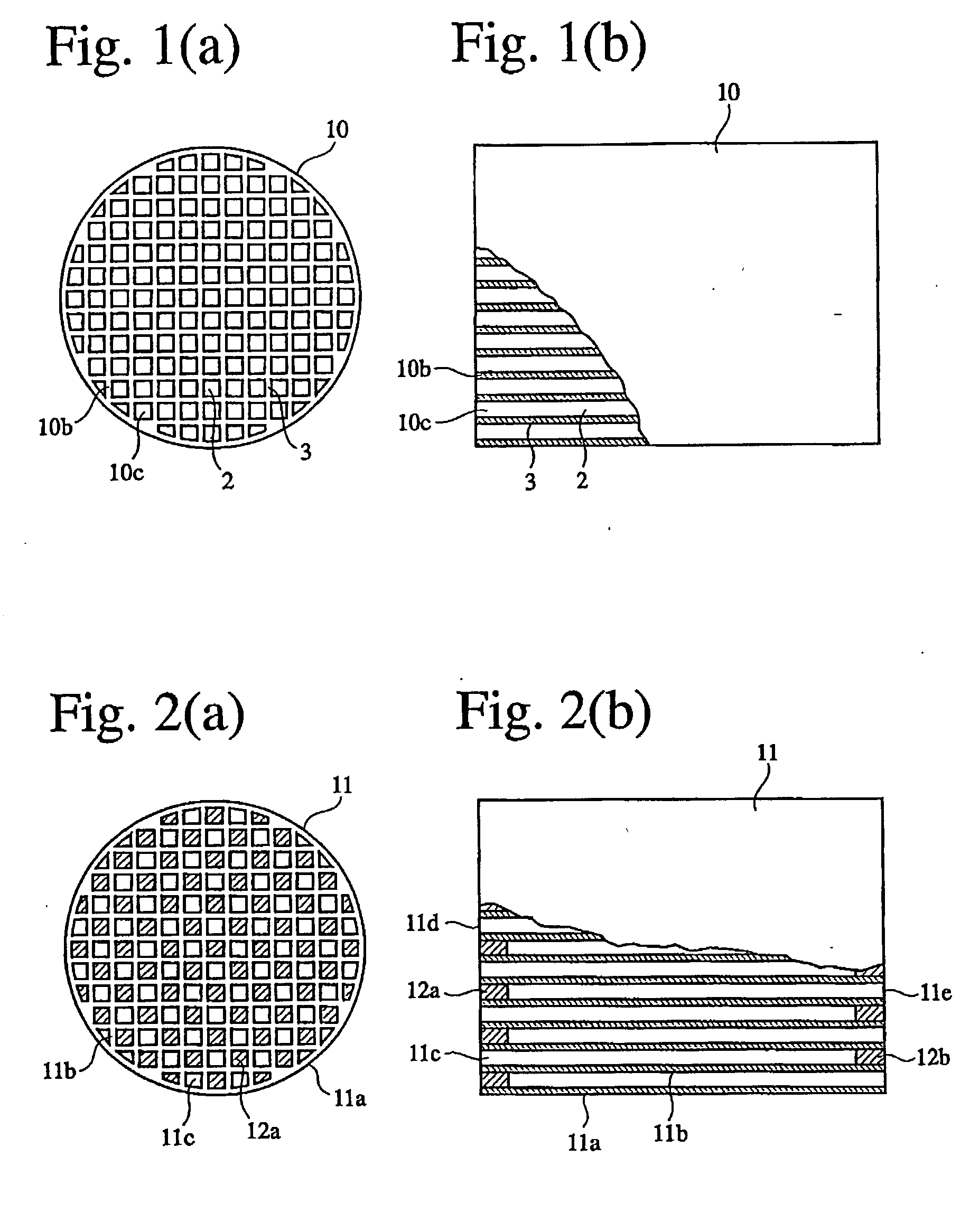

An object of the present invention is to provide a honeycomb structural body (filter) which has a low pressure loss upon collecting particulates, makes it possible to deposit a great amount of particulates and ashes, and is less likely to produce cracks. The columnar honeycomb structural body of the present invention includes a plurality of through holes placed in parallel with one another in the length direction, and wall portion that separates the plurality of through holes from one another and constitutes a circumferential face, wherein the plurality of through holes are composed of a group of large-capacity through holes, with one end thereof being sealed so as to cause the total of areas of cross-section perpendicular to the length direction to become relatively greater, and a group of small-capacity through holes, with the other end thereof being sealed so as to cause the total of areas of the above-mentioned cross-section to become relatively smaller, and the above-mentioned circumferential face of the columnar honeycomb structural body has a chamfered corner portion.

Owner:IBIDEN CO LTD

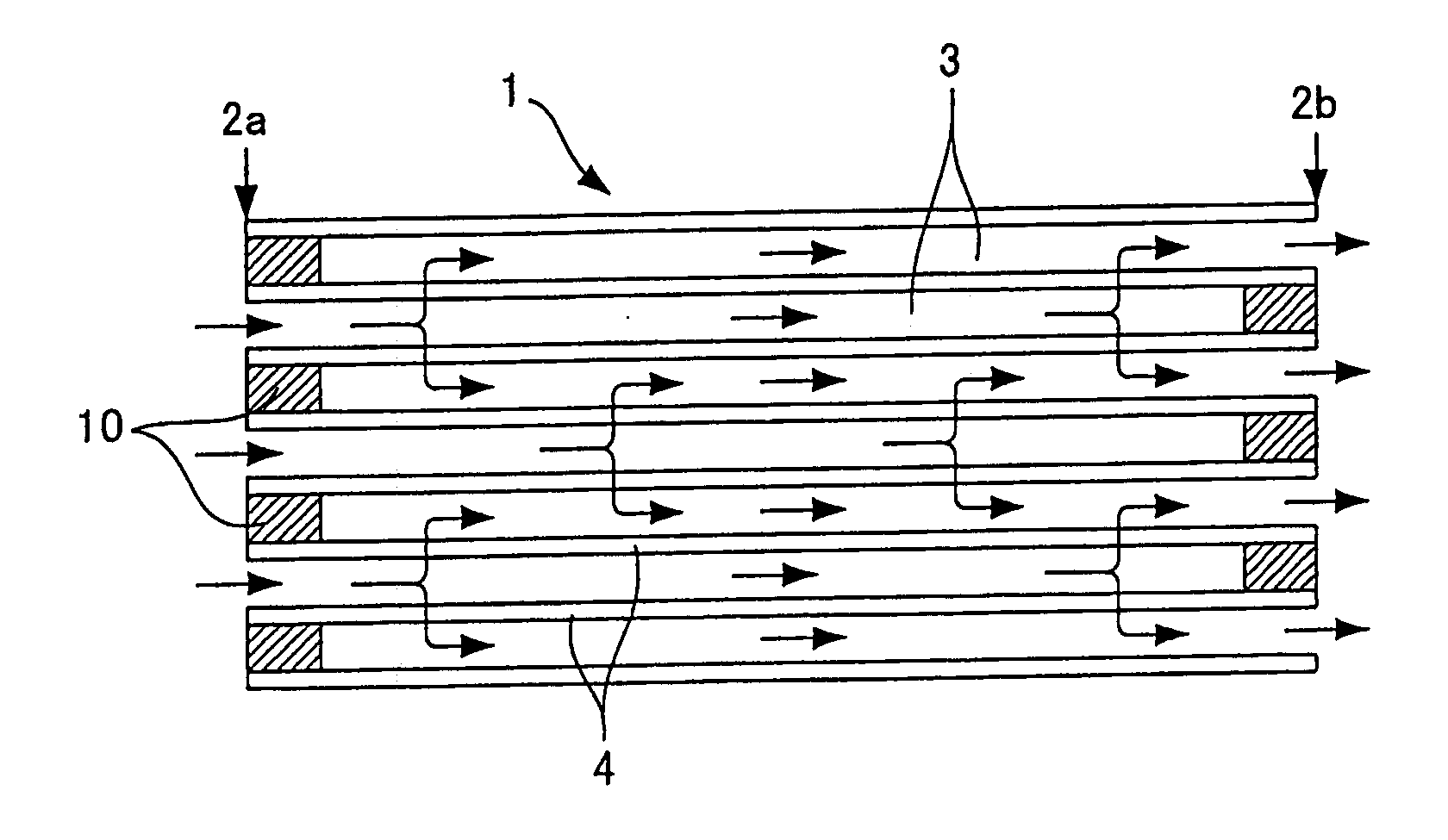

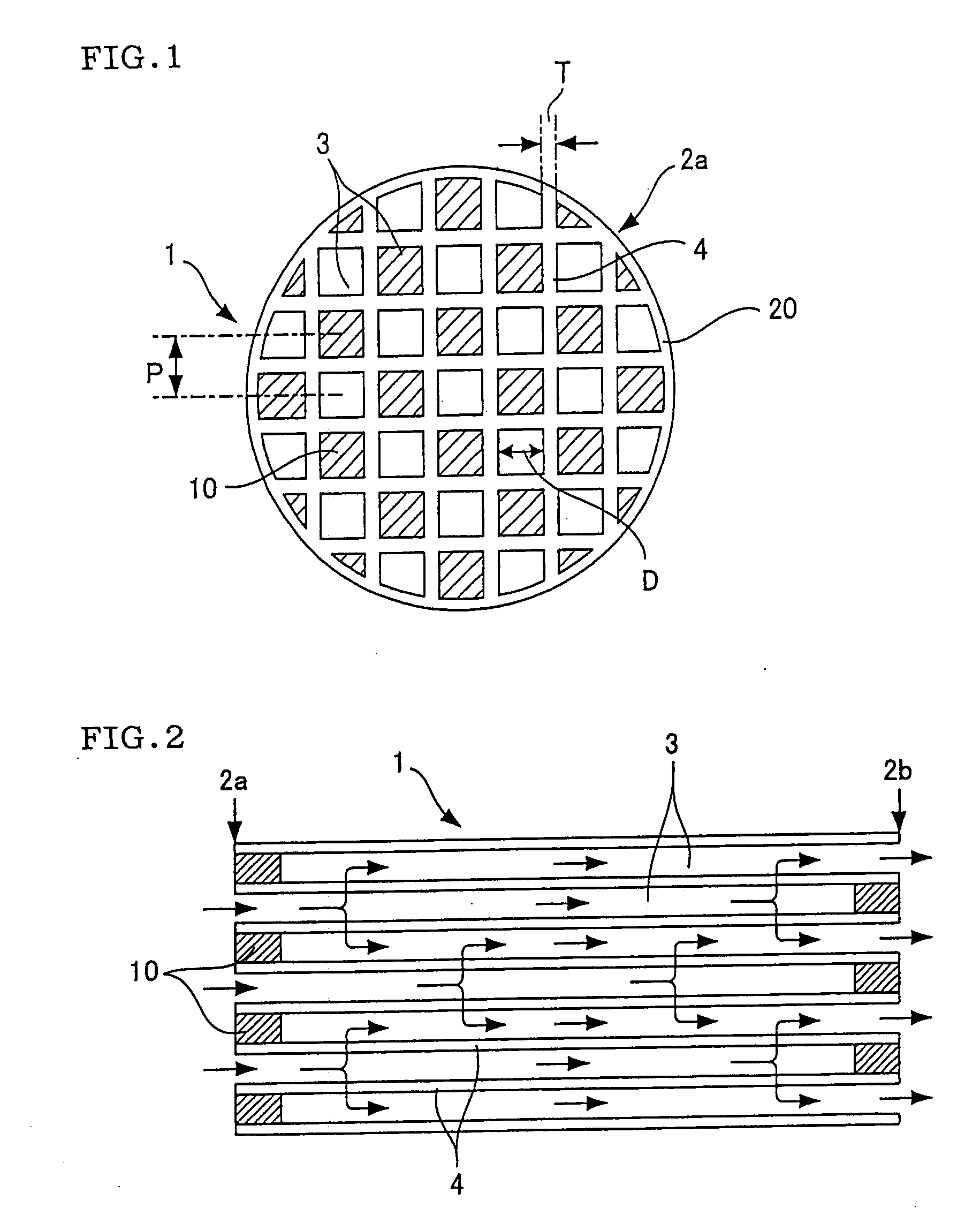

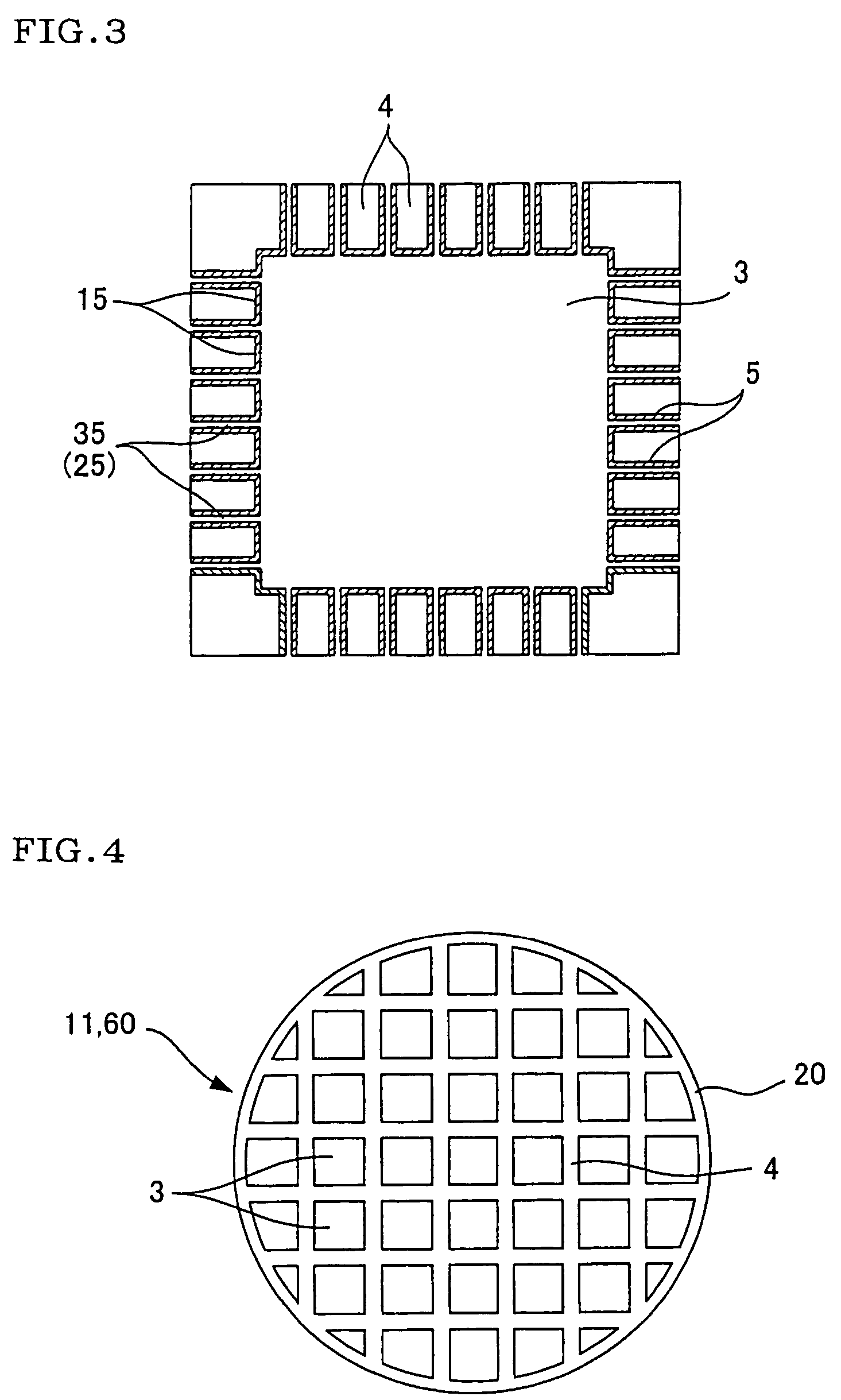

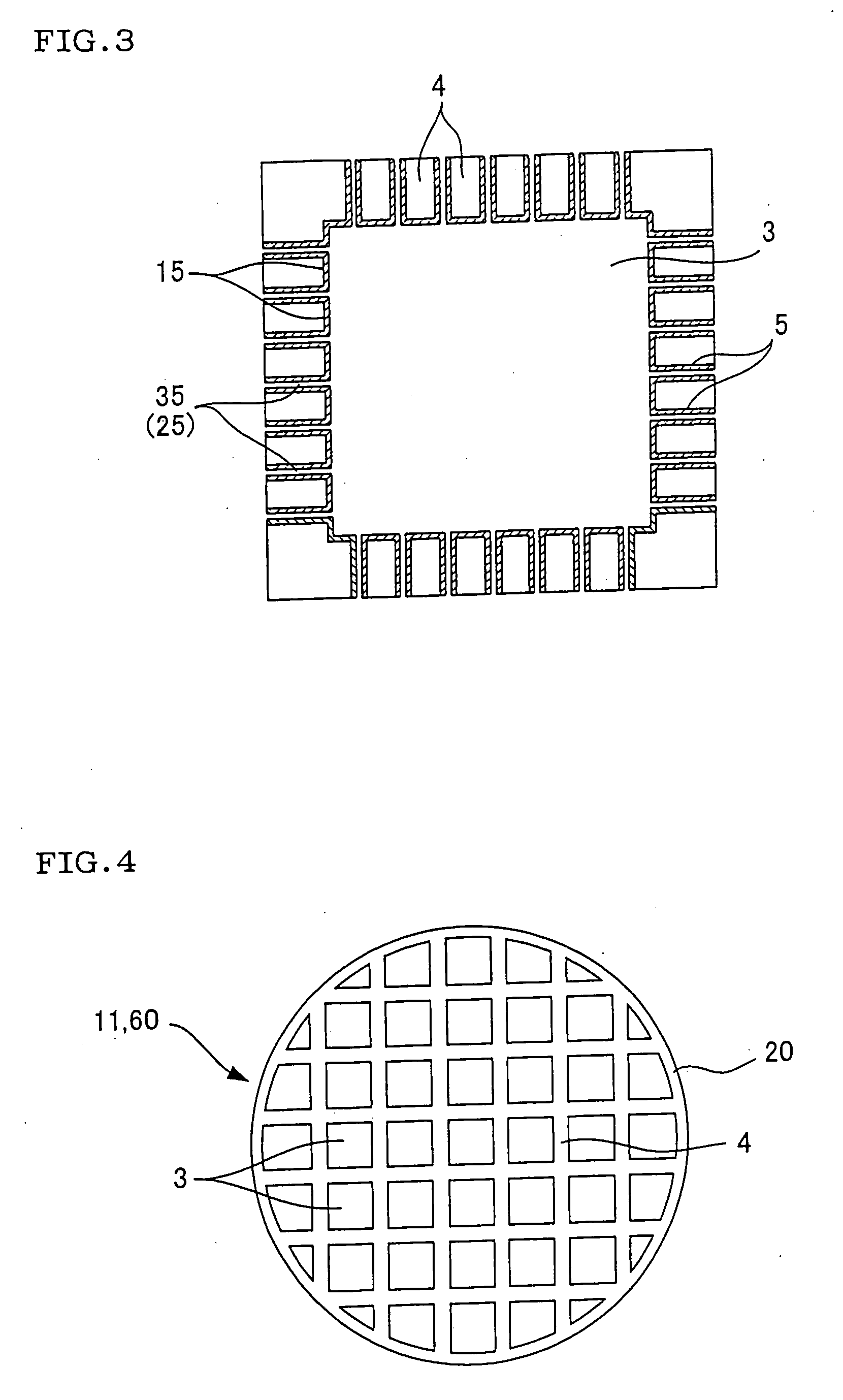

Honeycomb catalyst and manufacturing method thereof

ActiveUS20080044319A1Small pressure lossImprove purification efficiencyCombination devicesGas treatmentHoneycombEngineering

This invention provides a honeycomb catalyst having an excellent purification efficiency and a small pressure loss and can be mounted even in a limited space, the honeycomb catalyst comprising: porous partition walls 4 having plural pores 25, which are arranged to form plural cells 3 allowing communication between two end faces; plugging portions being arranged to plug the cells 3 in one of the end faces; and catalytically active components 5, 15 loaded on surfaces of partition walls 4 and inner surfaces of pores 25, wherein many catalytically active component-loading pores 35 through which a gas can pass are formed in partition walls 4, and a ratio of a mass (MW) of the catalytically active component loaded on the surfaces of partition walls 4 to a mass (MP) of the catalytically active component 5 loaded on the inner surfaces of the pores 25 is (MW):(MP)=1:3 to 3:1.

Owner:NGK INSULATORS LTD

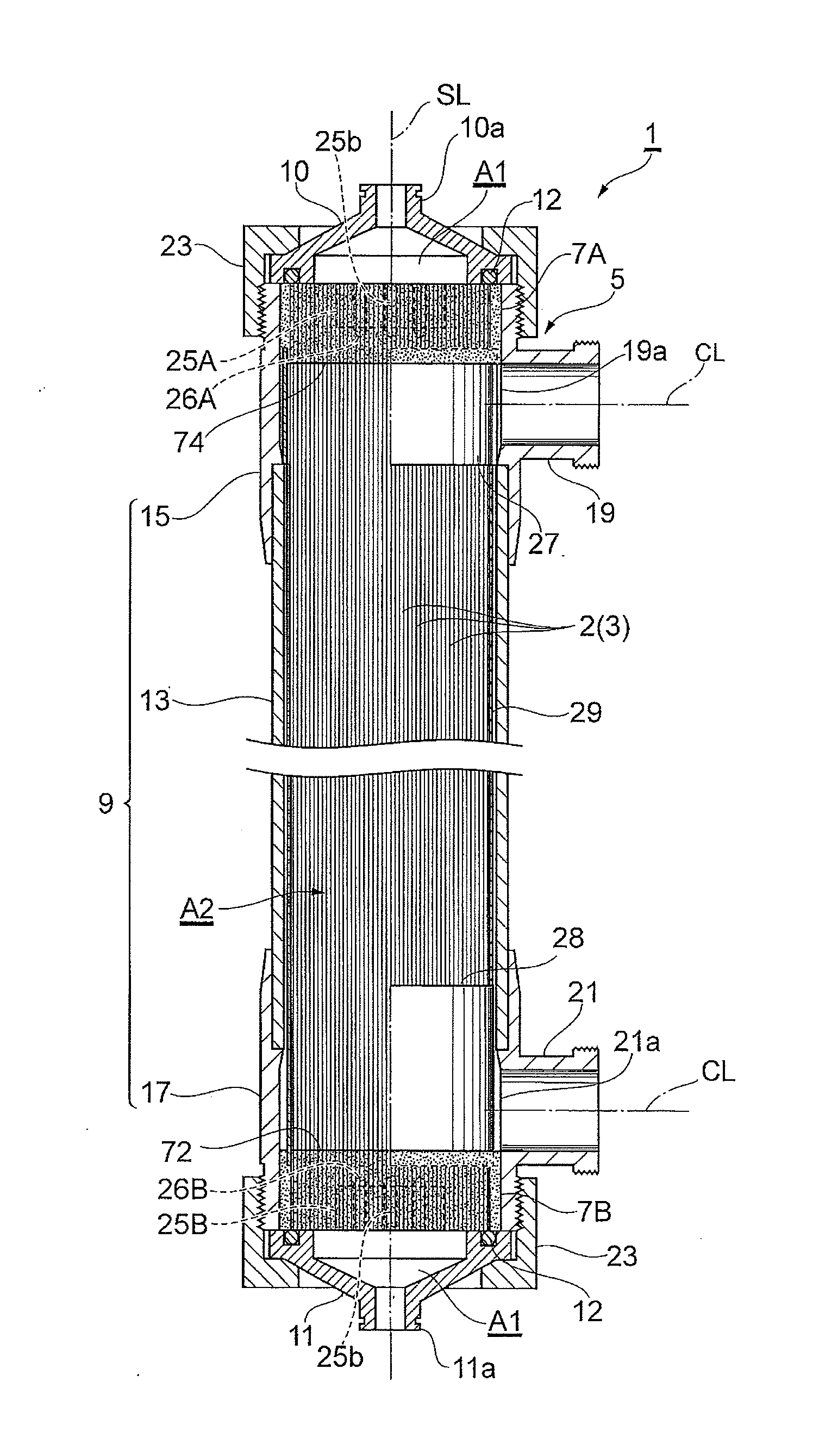

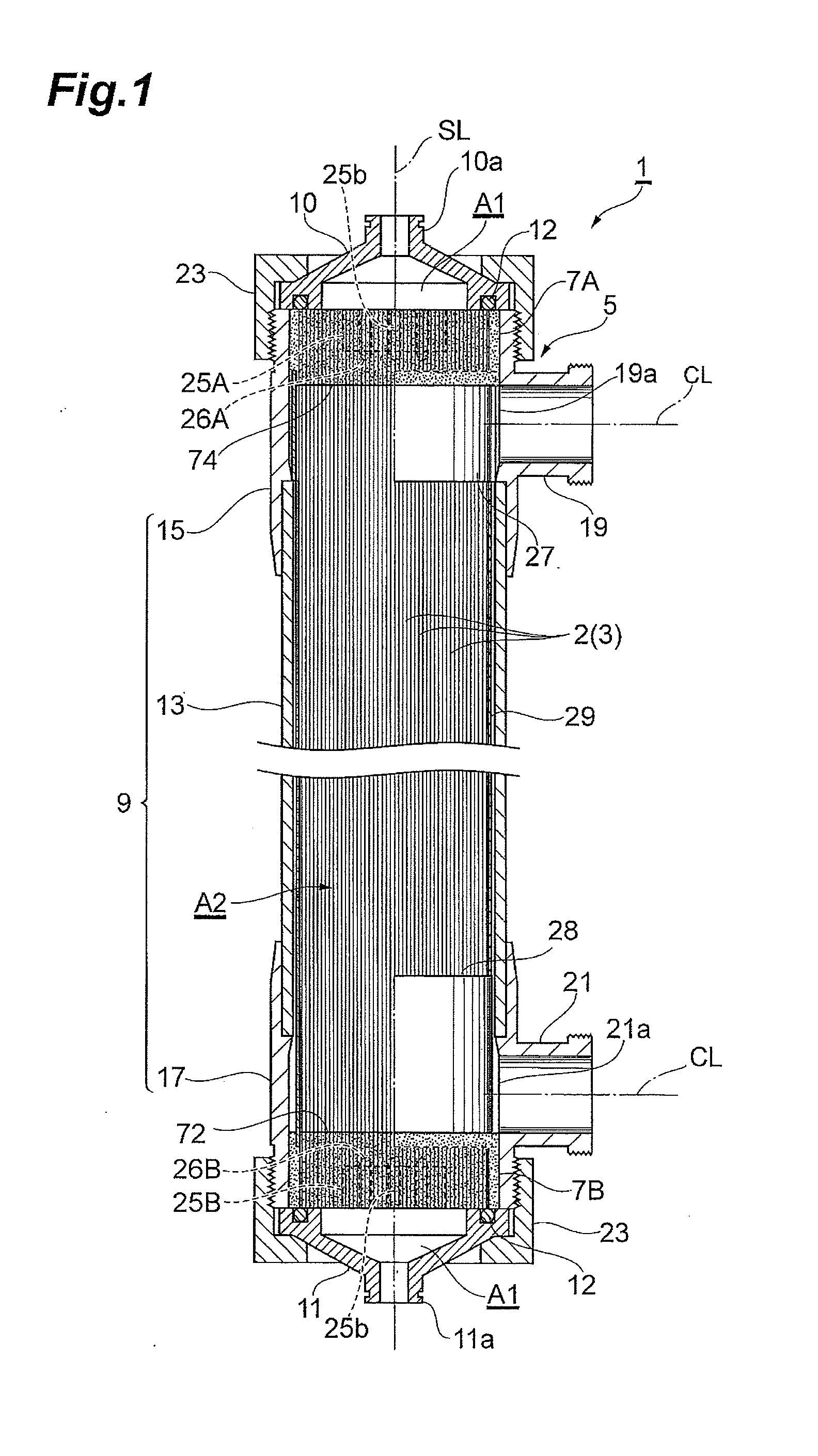

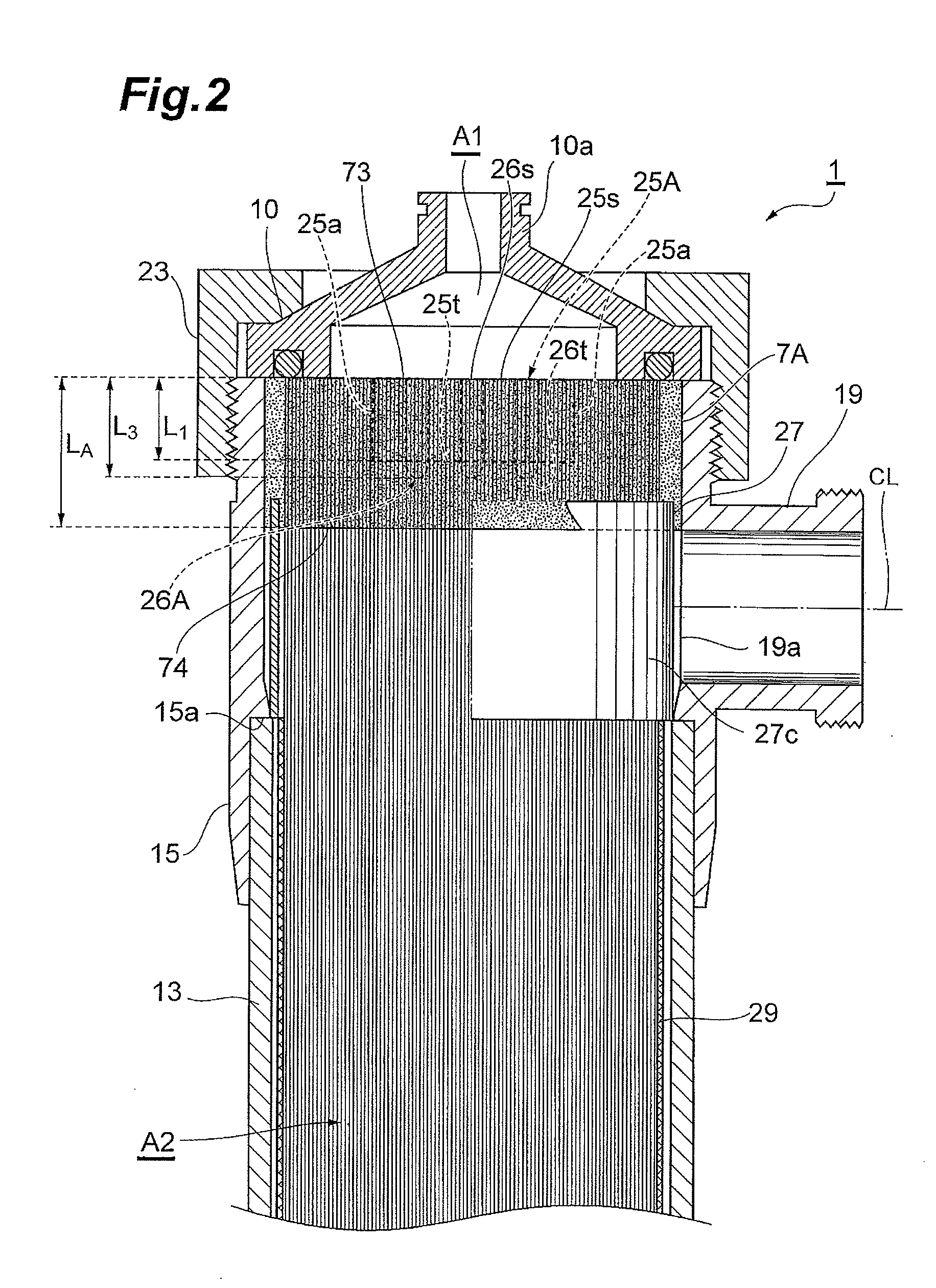

Semiconductor device and cooler thereof

ActiveUS20140376184A1Reduce pressure lossReduce power lossSemiconductor/solid-state device detailsSolid-state devicesHeat sinkCooling Units

A semiconductor device exhibits low pressure loss and is capable of cooling a plurality of power semiconductor chips evenly. This semiconductor device includes a semiconductor module and a cooler for cooling a power semiconductor element mounted in the semiconductor module. A cooling unit of the cooler has a first header part that has a first bottom surface disposed between a coolant inlet and an end portion of a first substrate on the coolant outlet side and inclined toward a bottom plane of cooling fins so that a coolant supplied from the coolant inlet flows toward the cooling fins; and a second header part that has a second bottom surface inclined from an end portion of the bottom plane of the cooling fins on the coolant outlet side so that the coolant discharged from the cooling fins flows to the coolant outlet.

Owner:FUJI ELECTRIC CO LTD

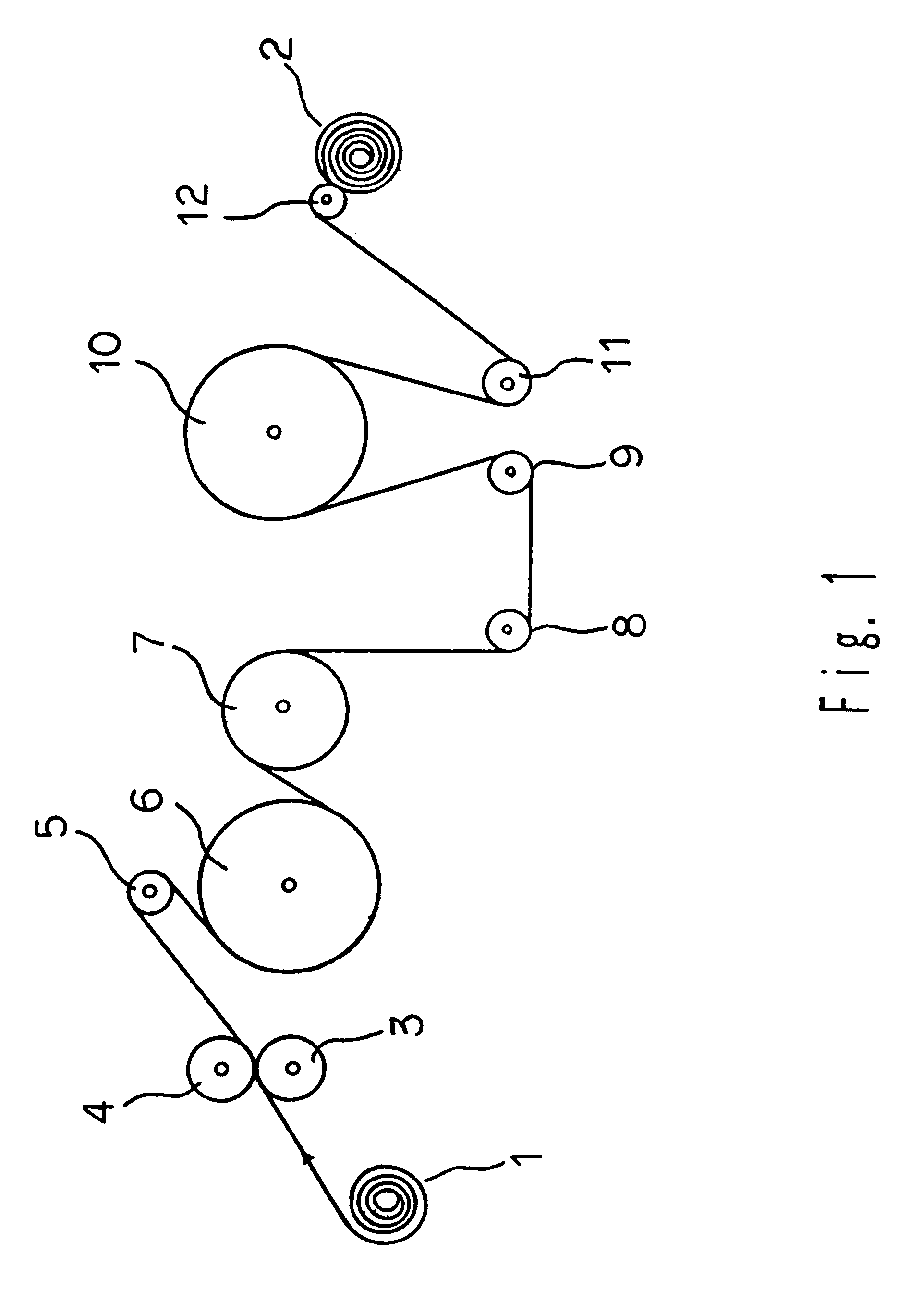

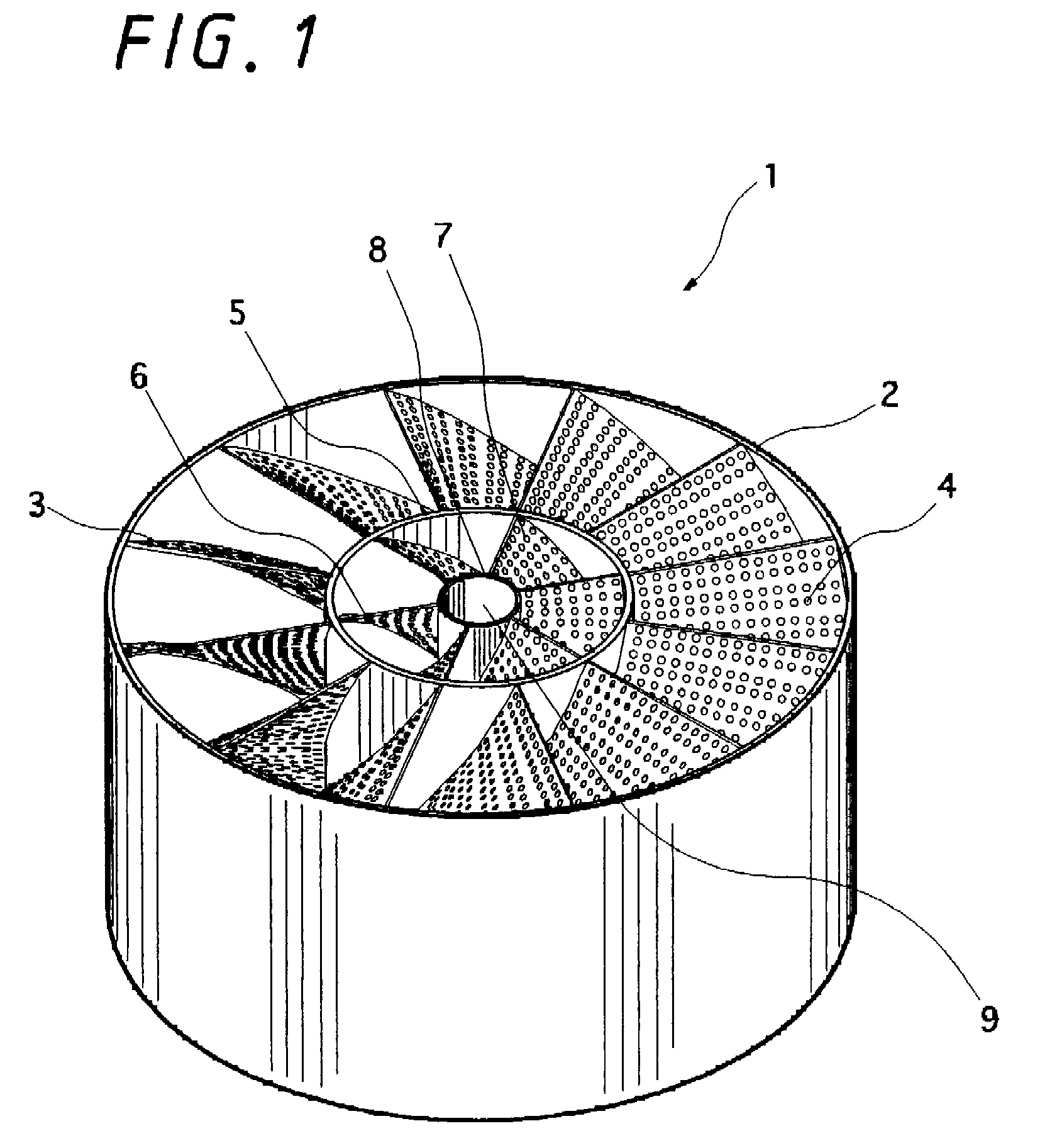

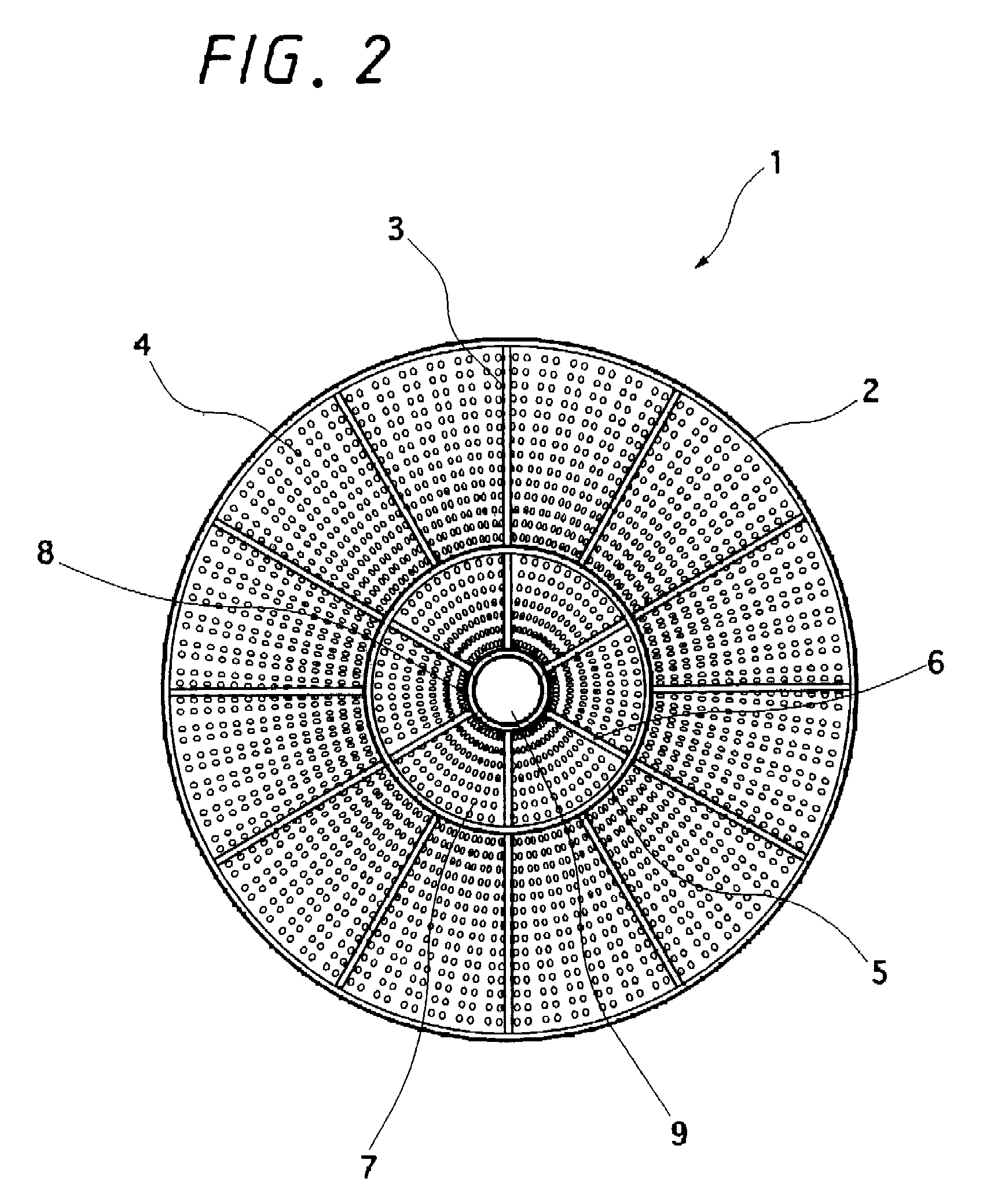

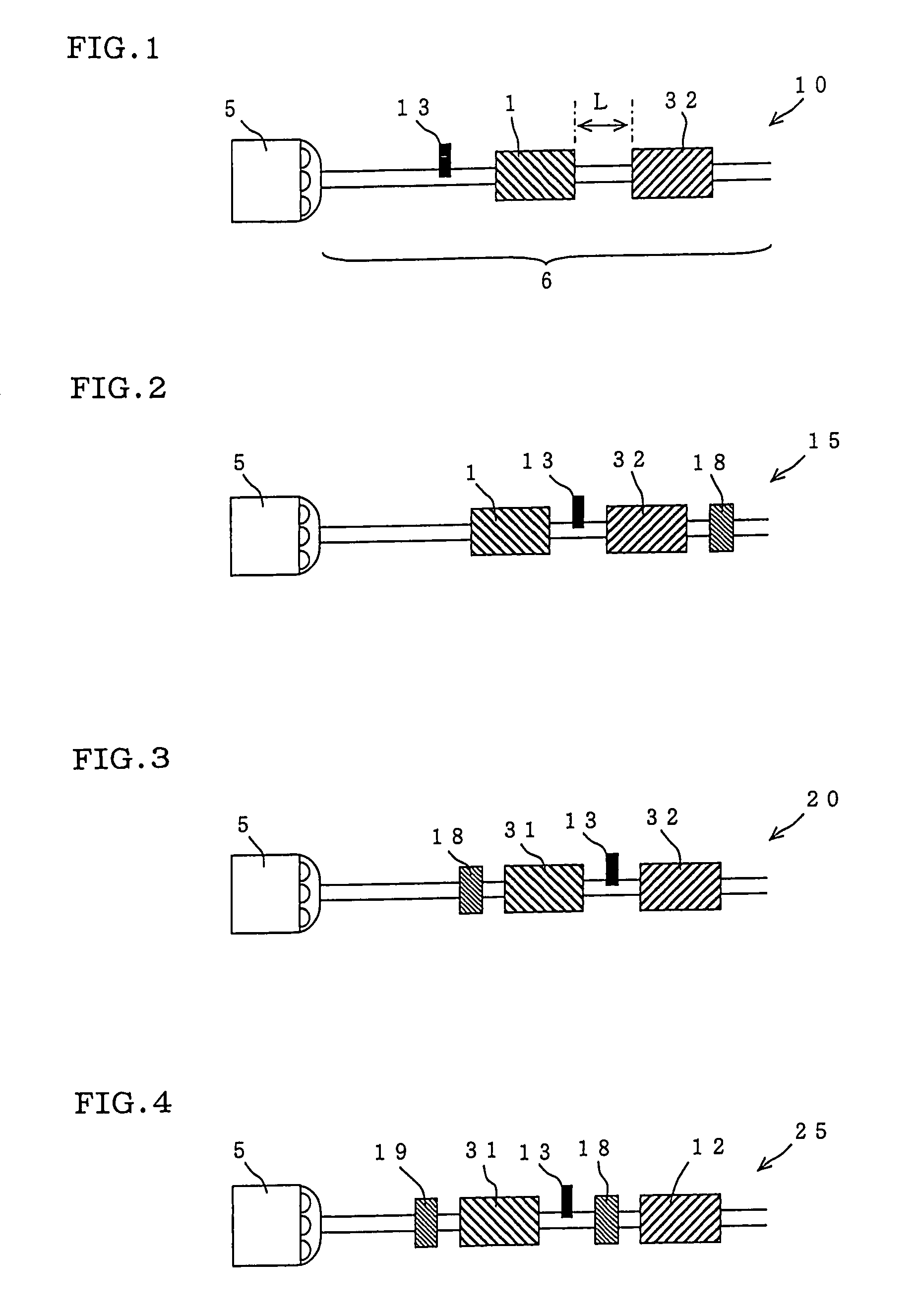

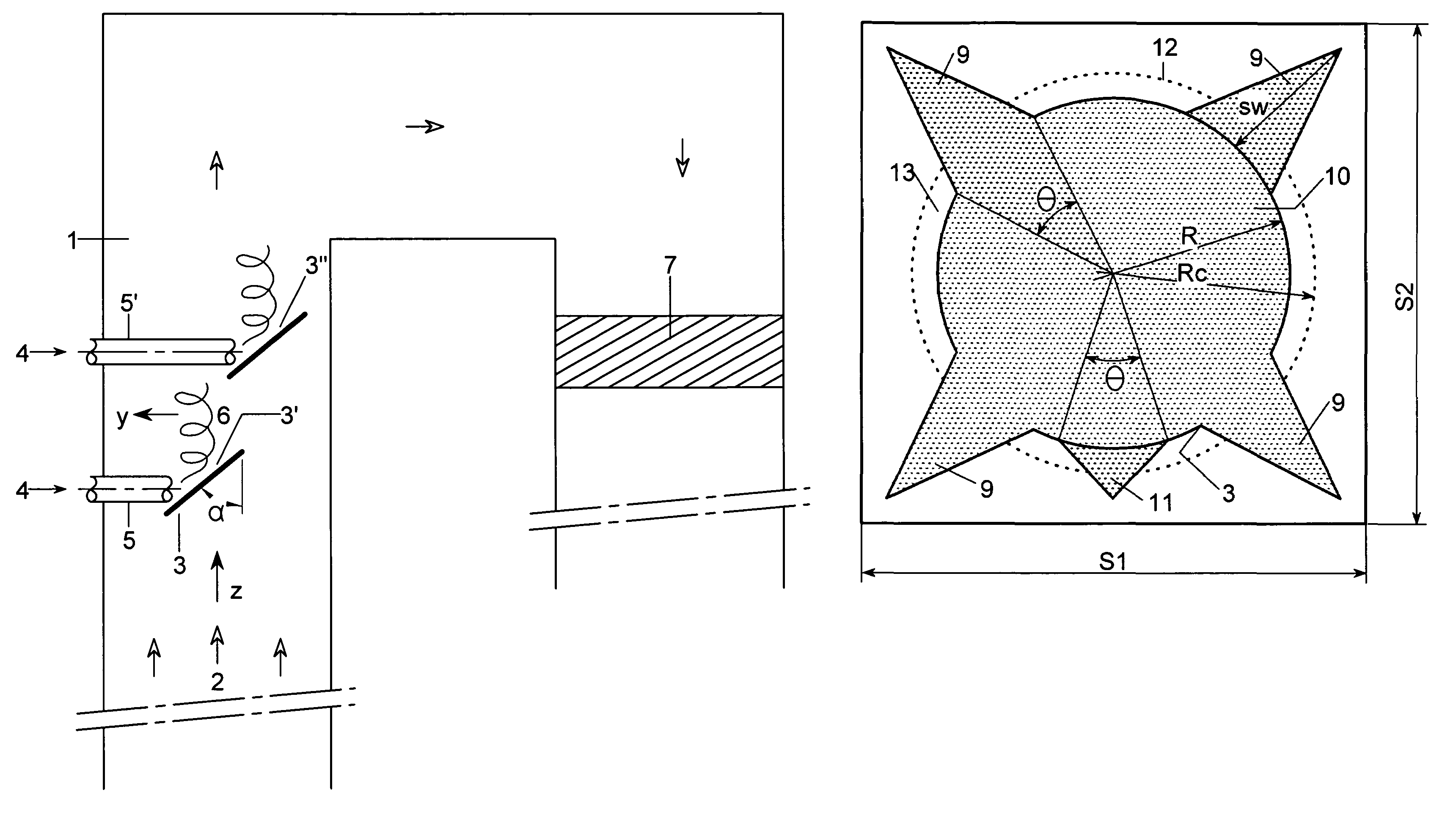

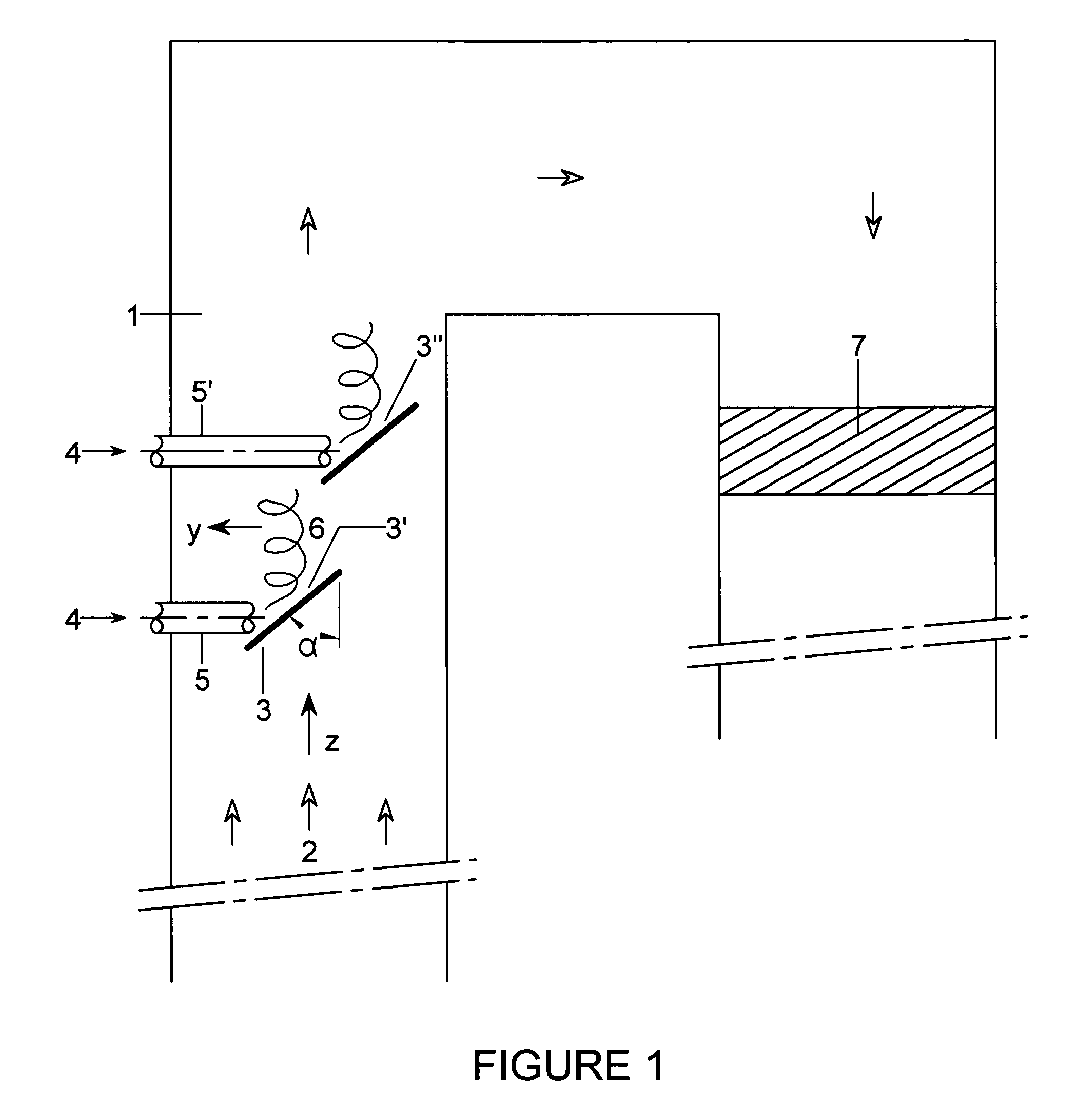

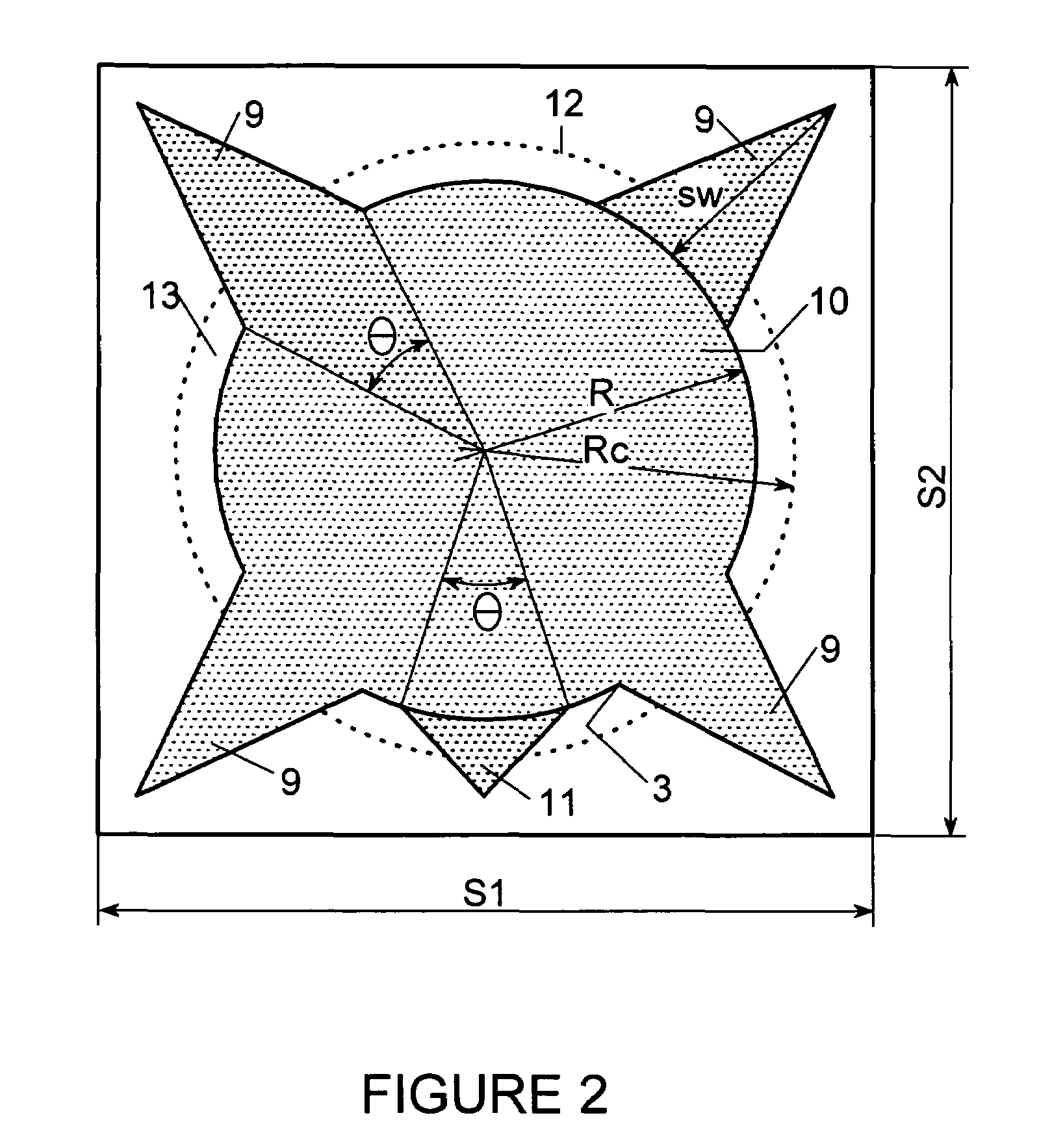

Mixing element and static fluid mixer using same

ActiveUS7510172B2Low pressure lossImprove efficiencyFlow mixersTransportation and packagingEngineeringHelix

A mixing element, which is produced at low cost, has high mixture agitation effectiveness, and is easily made large, and a static fluid mixer using the mixing element are provided. Further, a gas-liquid treatment apparatus with high treatment ability is provided. A mixing element 1 includes: a cylindrical passage tube 2 trough which fluid flows; a plurality of spiral rightward rotation type first blades 3 formed of a perforated object, which are provided in the passage tube 2; a first inner cylindrical tube 5 shaped like a cylinder and disposed inside the blades 3; a plurality of spiral rightward rotation type blades 6 provided in the inner cylindrical tube 5; and an opening 9 formed in the axial center portion of the blades 6. A static fluid mixer is formed by using at least one mixing, element 1 mentioned above.

Owner:ANEMOS CO LTD

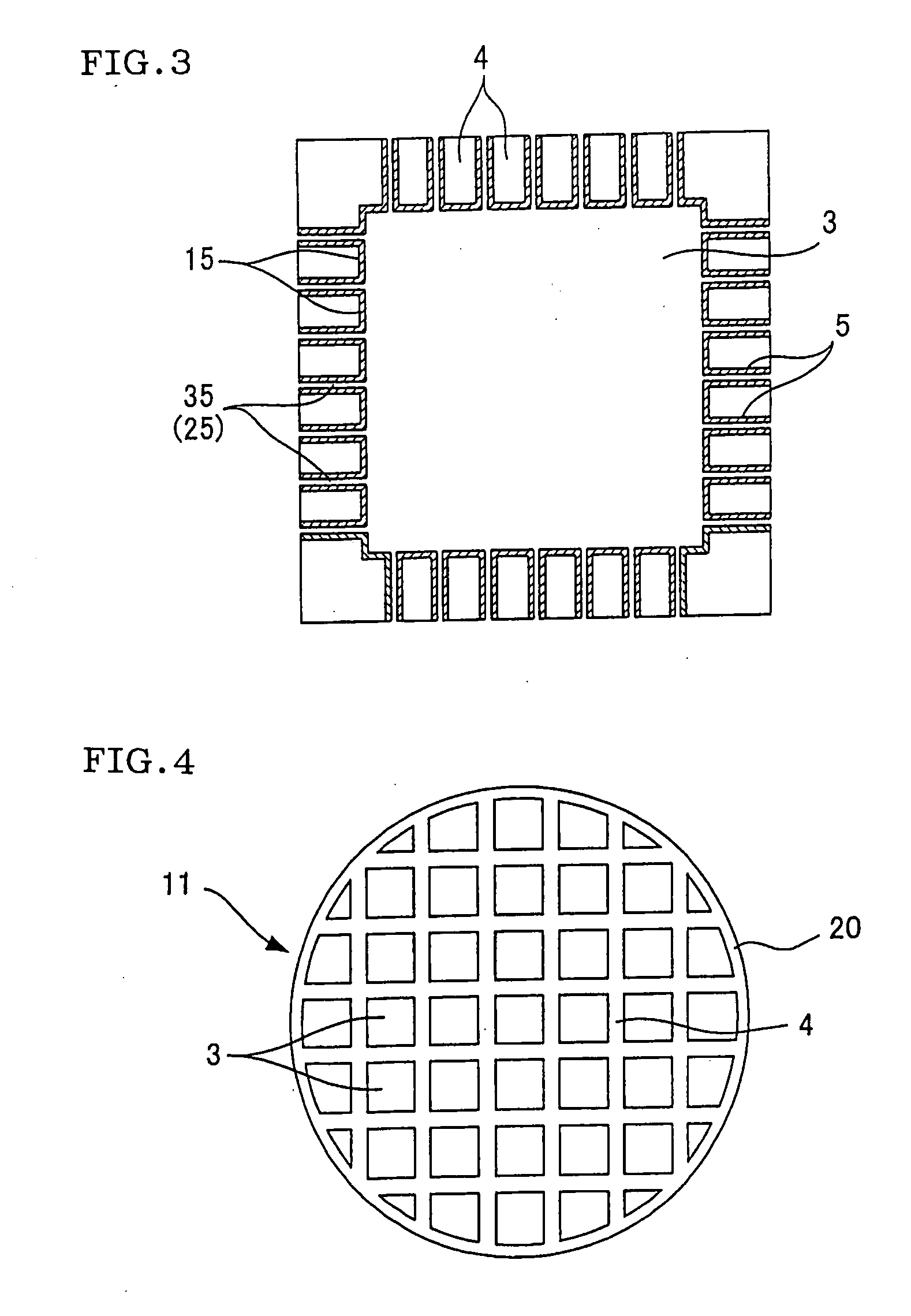

Catalytic converter and a method for producing the catalytic converter

ActiveUS20070224092A1Improve purification efficiencyReduce total pressure lossCombination devicesGas treatmentCell functionOxide

A catalytic converter having an excellent purification efficiency and small pressure loss and a method for producing the same is provided. A catalytic converter comprises a catalyst coating layer which is coated on the surface of the partition walls of the honeycomb structural body having partition walls which divide and form a plurality of cells functioning as fluid passages. 10% or more of the plurality of the cells are plugged by the plug portions which are formed at the one end or the middle of the passage, the average maximum distance of image of the honeycomb structural body is 10 μm or more and the porosity of the honeycomb structural body is 40% or more, the catalyst coating layer contains at least one oxide selected from the group consisting of alumina, ceria, titania, silica and zirconia, and also a catalyst containing at least one precious metal selected from the group consisting of platinum, rhodium and palladium, or metal exchanged zeolite or vanadium is supported in the catalyst coating layer as the catalytic active constituent, the average maximum distance of image of the catalyst coating layer is 10 μm or more, and the porosity of the catalyst coating layer is 40% or more.

Owner:NGK INSULATORS LTD

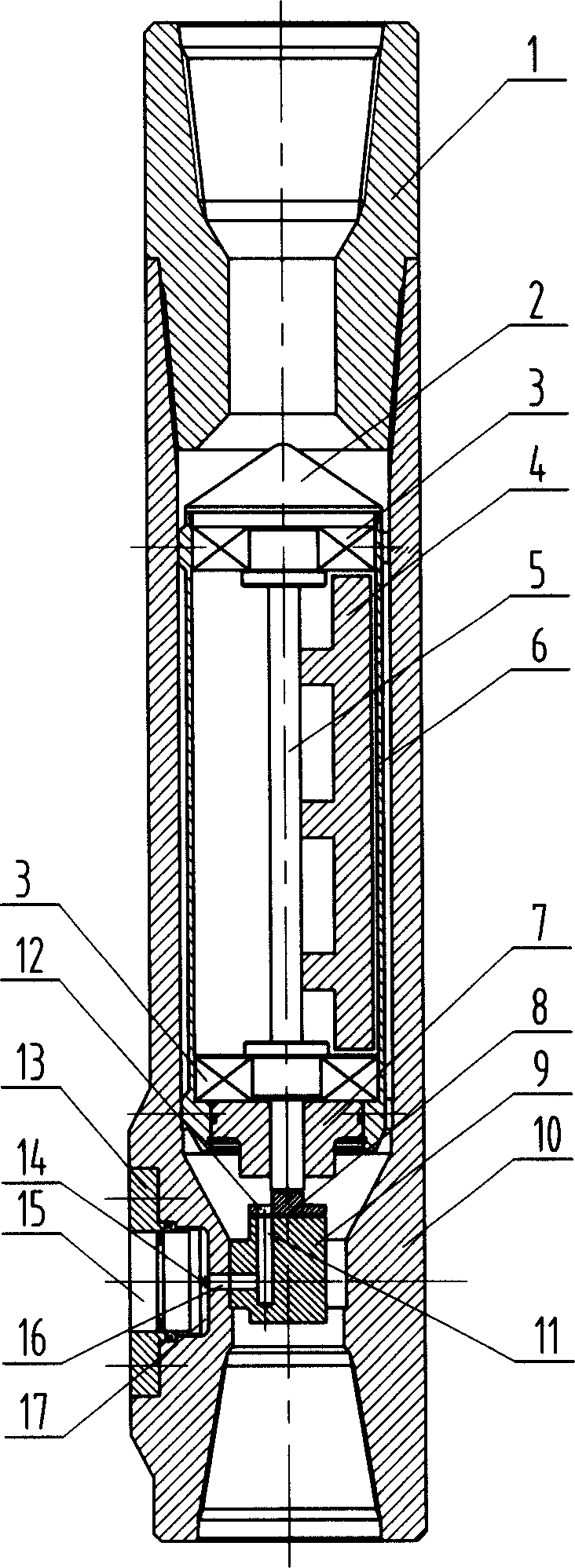

Mechanical automatic vertical drilling tool

InactiveCN1676862AIncrease drilling speedShorten the purification processDirectional drillingWell drillingDifferential pressure

One kind of mechanical type automatic vertically well-drilling tool, including turner, the conduction current head, the bearing, the counterweight, the spindle, in-tube, the back plate, above plate-valve, gets down plate-value, the shell, the piston cylinder back plate and the piston, its principle is at the right moment induces the well slanting gravity signal, by the gravity-actuates in the organization, the establishment drills inside and out the column high-low pressure channel between the fluid, uses two between the differential pressure, actuates the piston at the right moment to push depends on the wall of a well is high side, the wall of a well reacting force then pushes the drill bit to is low side, but in well-eye other positions, the piston does not push depends on the wall of a well, drills the column revolves, this process circulation reciprocation, the well is slanting namely is unceasingly induced and the revision, this invention realization is initiative, At the right moment guards against slanting at the same time, but also can effectively liberate distilling, largely enhances drills fast and well-eye the quality, reduces the construction risk, this invention has the structure is simple, reliable, is suitable to the many kinds of well drilling platform, the processing makes the maintenance cost is low and so on the characteristic.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

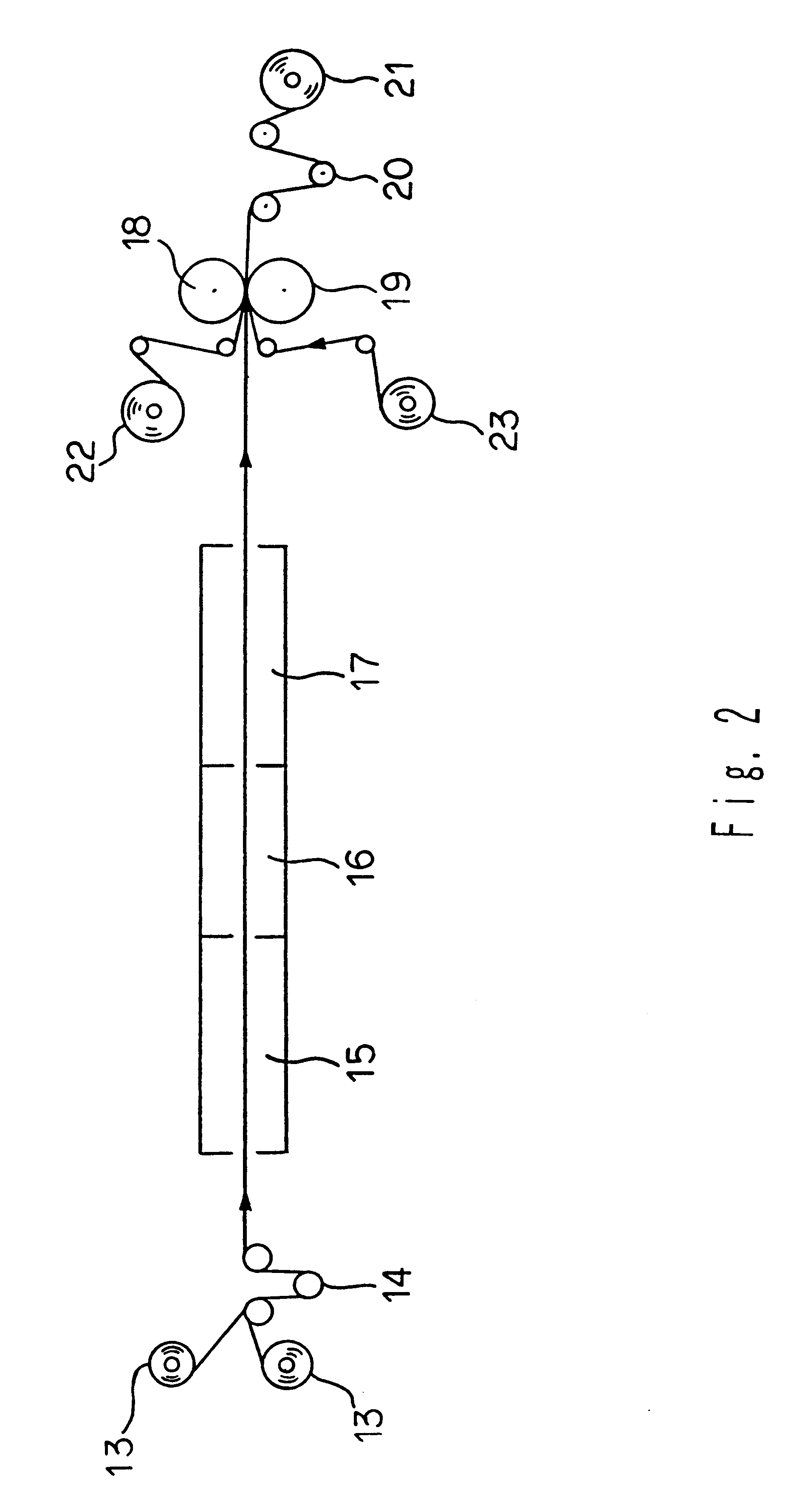

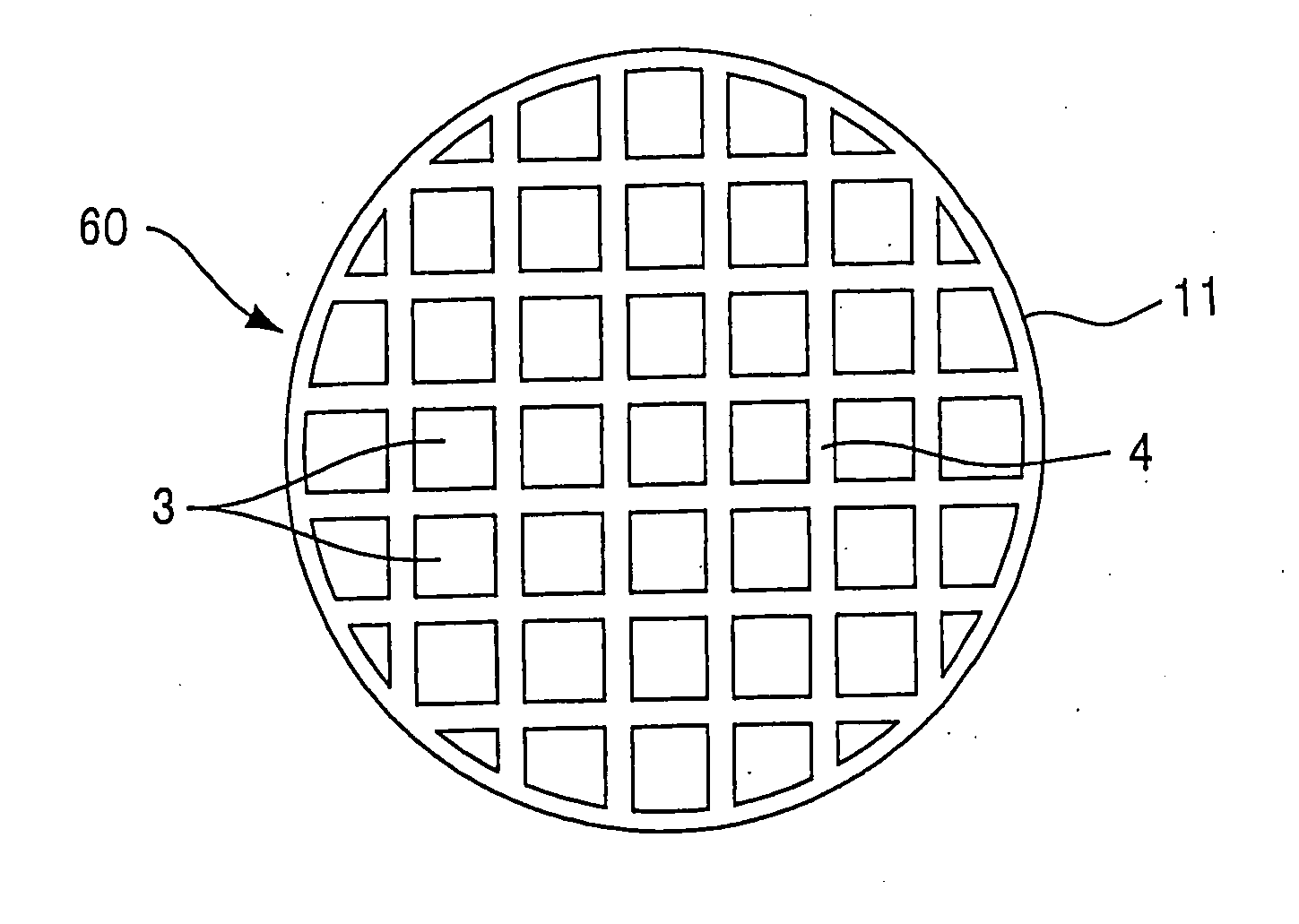

Wrought fiber sheet and filter unit

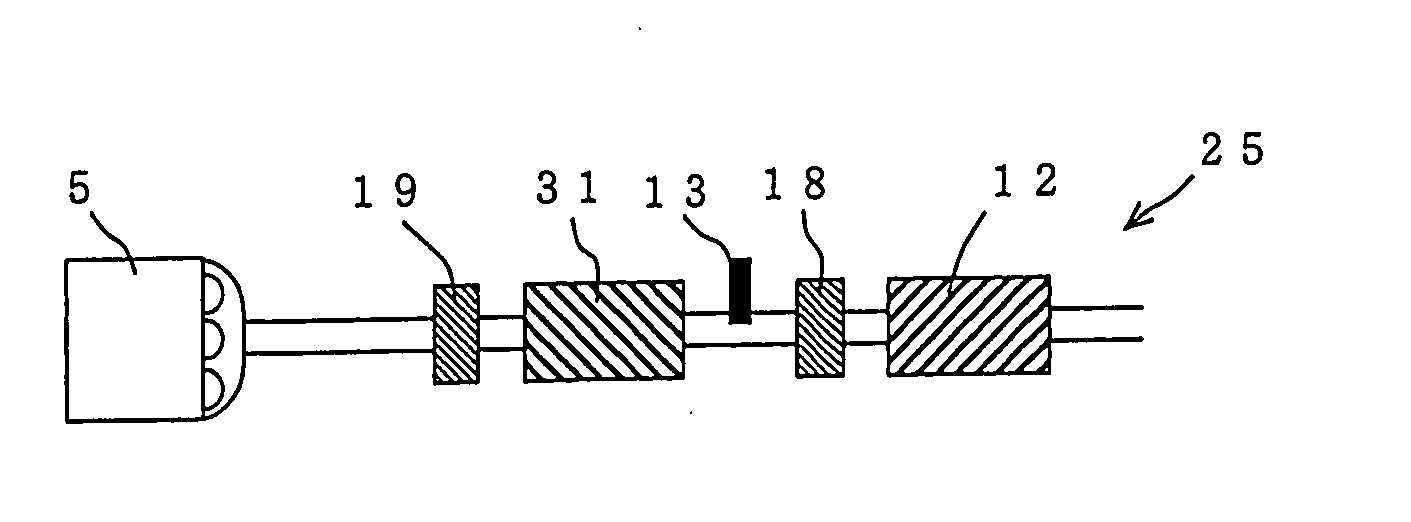

InactiveUS20050172812A1Improve stabilityHigh molecular weightDispersed particle filtrationElectrostatic separationAir cleaningElectret

A wrought fiber sheet or air cleaning filter unit that exhibits high performance and is biodegradable so as to enable reducing load upon environment. The wrought fiber sheet is produced by coupling biodegradable fiber sheets having electret properties by means of a configuration reinforcing member of a biodegradable material. Further, the frame for accommodating the wrought fiber sheet is also constituted of a biodegradable member so as to obtain an air cleaning filter unit that exerts biodegradability as a whole.

Owner:TOYO TOYOBO CO LTD

Exhaust gas purifying system

ActiveUS7763222B2Improve efficiencyLow pressure lossCombination devicesNitrogen compoundsHoneycombDiesel engine

Owner:NGK INSULATORS LTD

Filter material

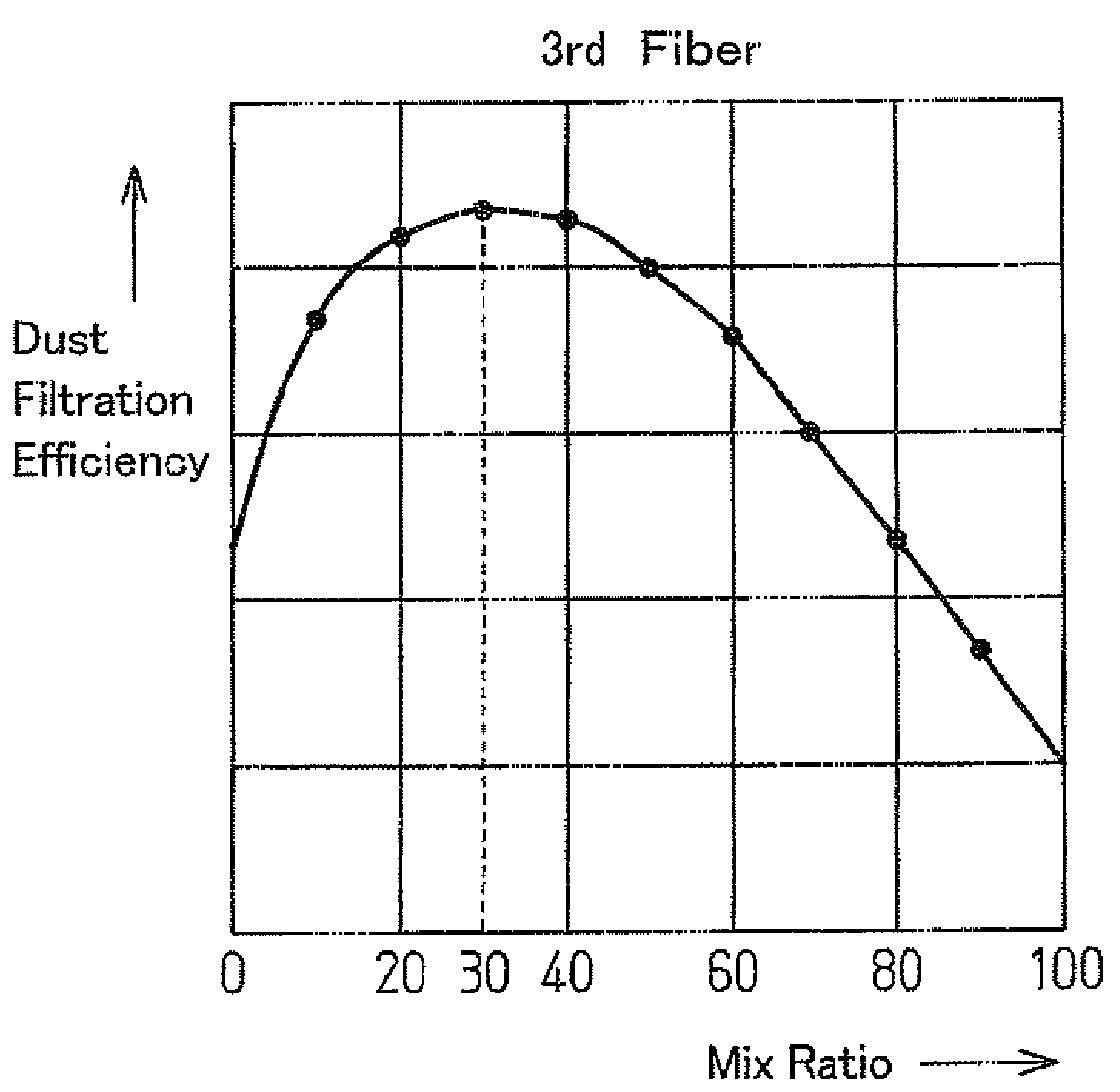

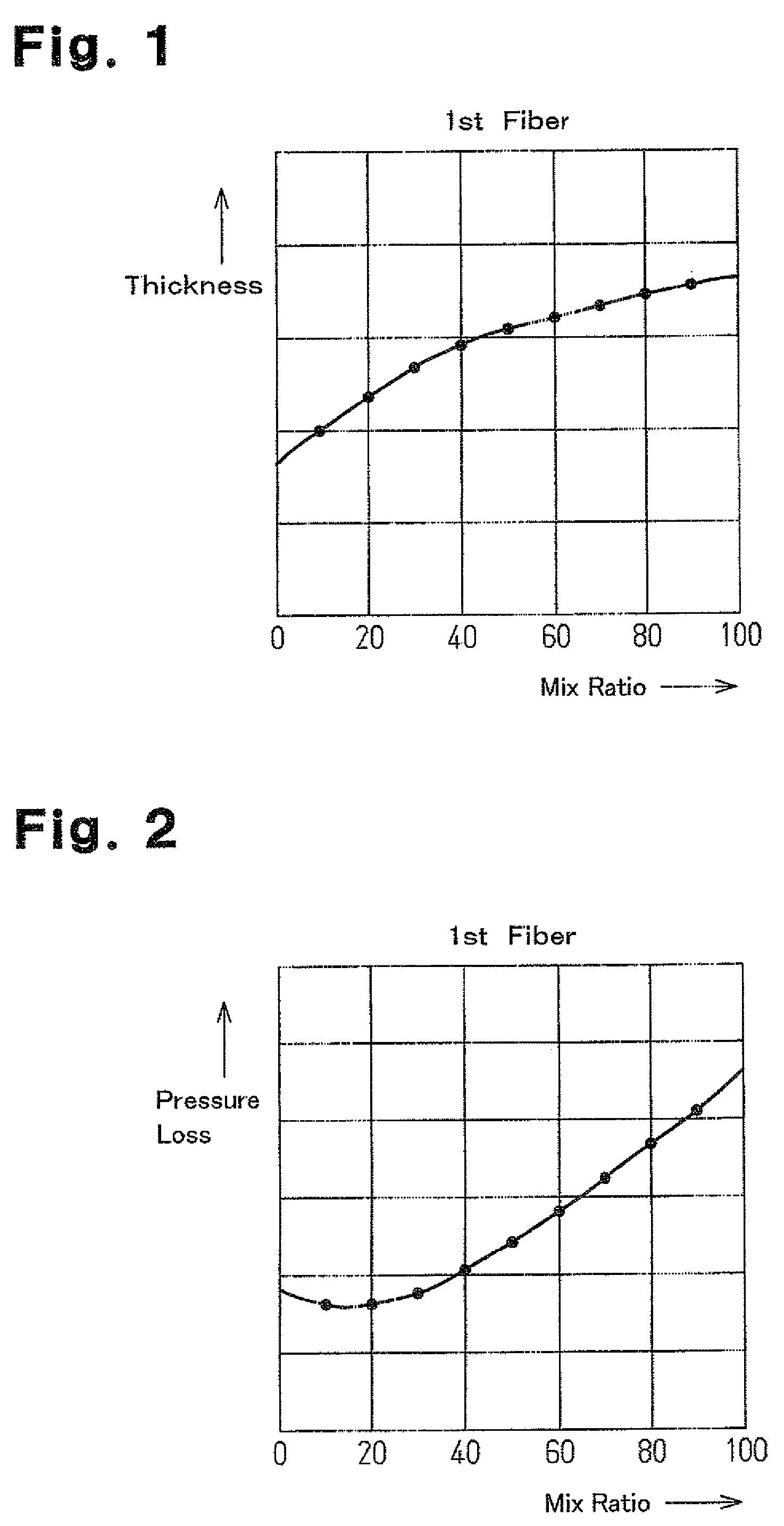

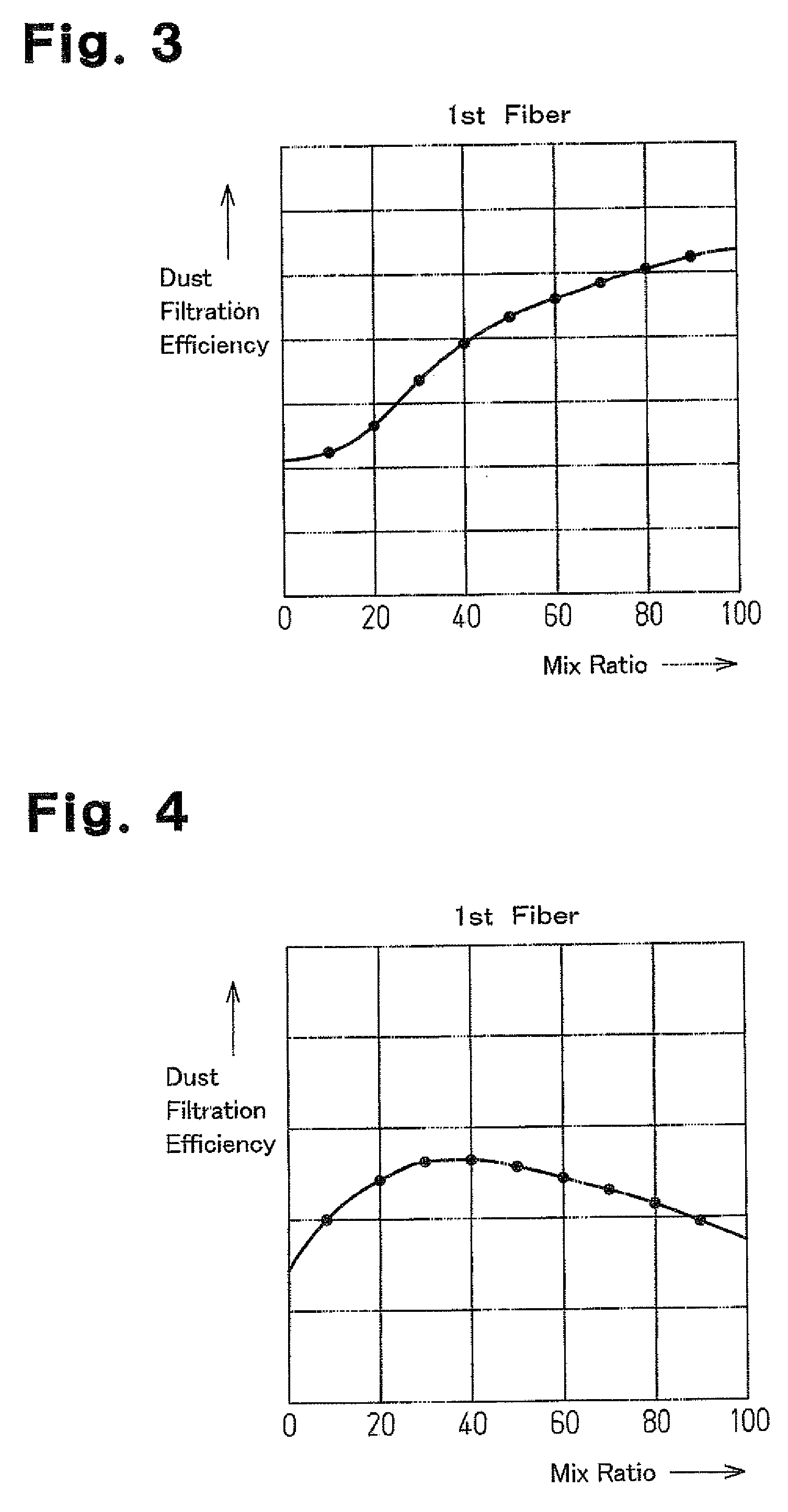

InactiveUS20090077938A1Low pressure lossHigh dust hold amountPaper/cardboardLoose filtering material filtersNatural fiberFilter material

A filter material fabricated by mixing 10 to 30% by mass of first fibers having a fiber diameter of 10 to 40 μm, 40 to 80% by mass of second fibers obtained by crimping natural fibers having a fiber diameter of 10 to 40 μm, and 10 to 30% by mass of third fibers having a fiber diameter of 5 to 10 μm. The filter material has low pressure loss a high dust holding amount, and high dust filtration efficiency.

Owner:TOYOTA BOSHOKU KK +1

Exhaust gas purifying system

ActiveUS20070224093A1Improve purification efficiencySmall pressure lossCombination devicesNitrogen compoundsExhaust fumesHoneycomb

Owner:NGK INSULATORS LTD

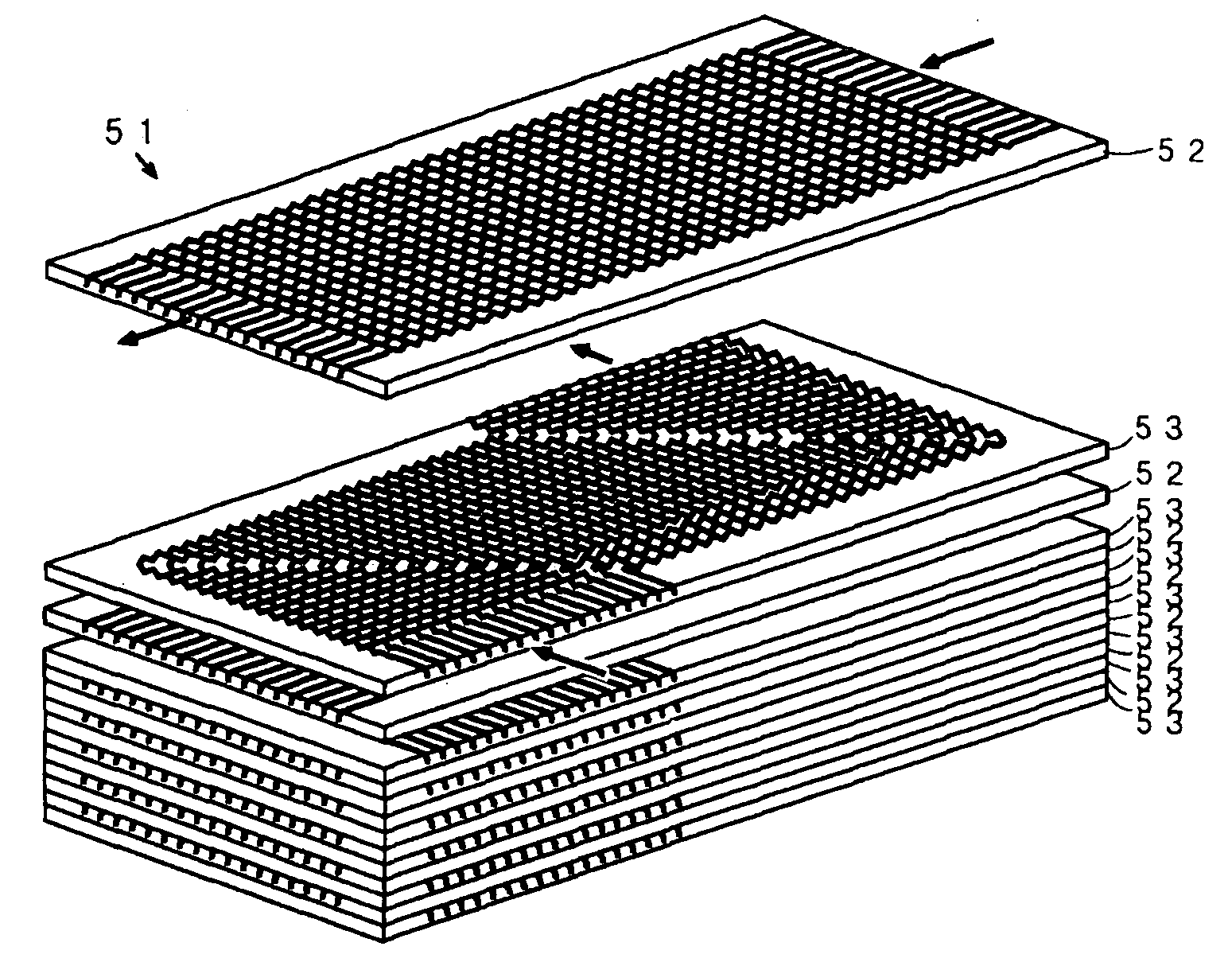

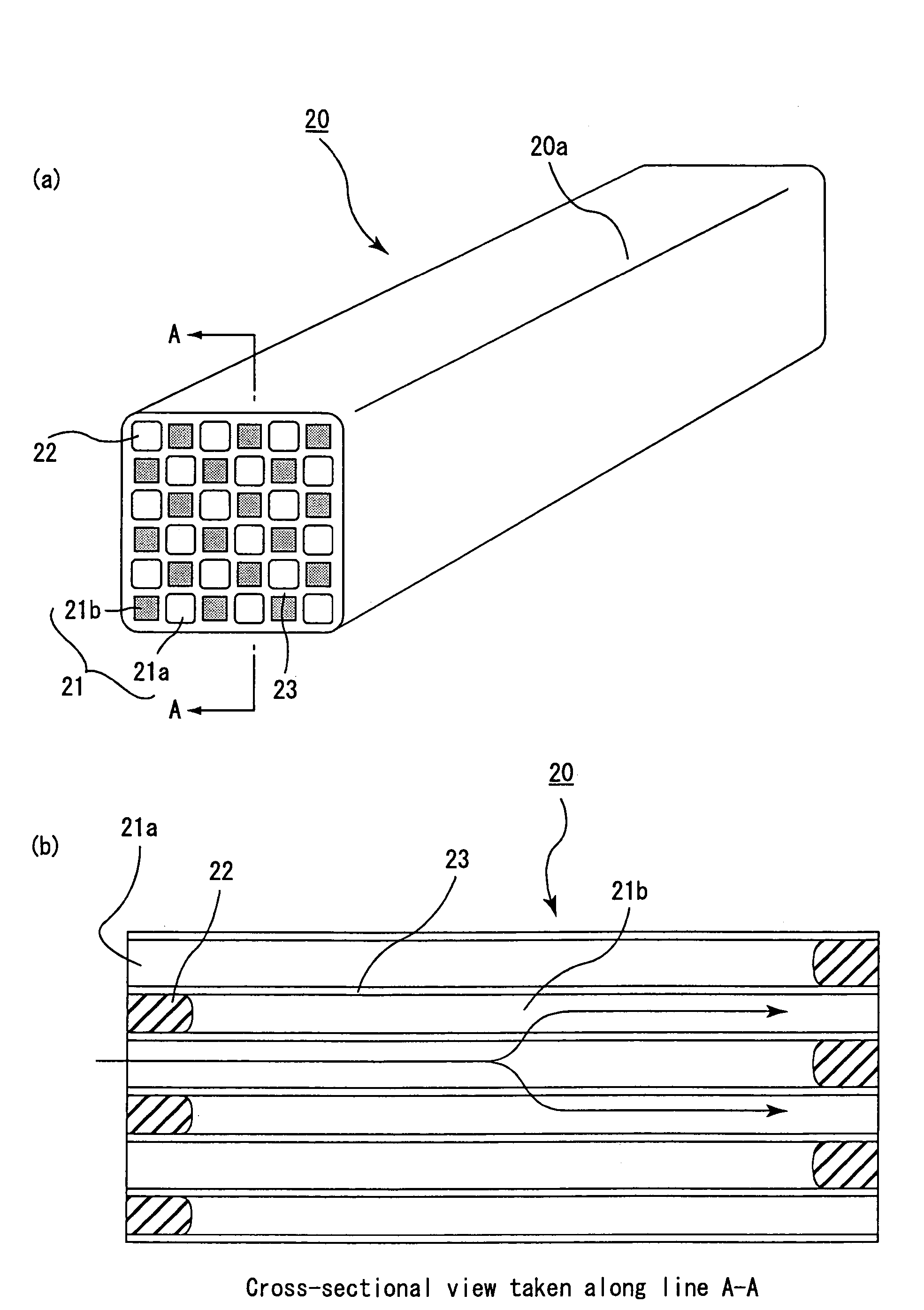

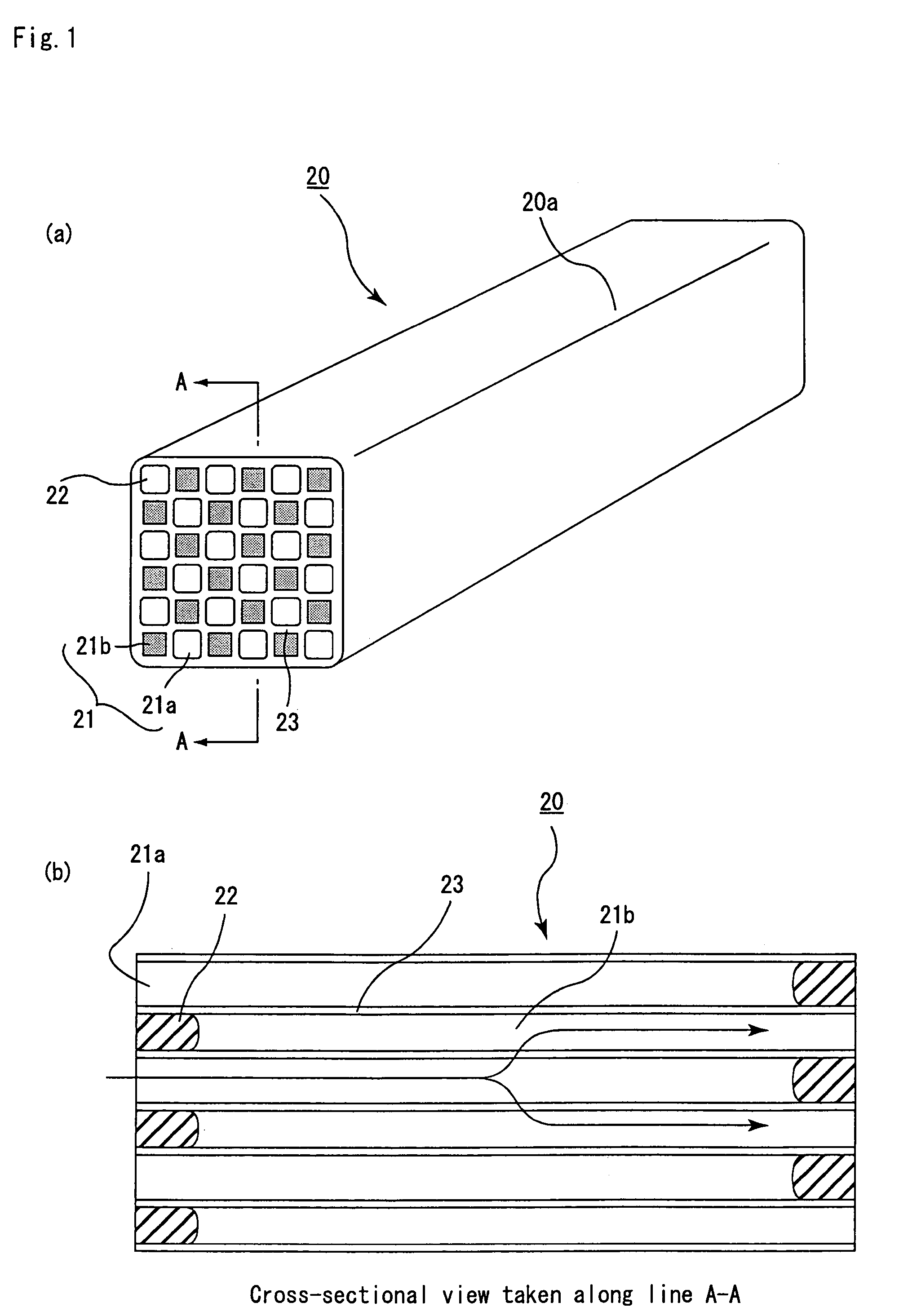

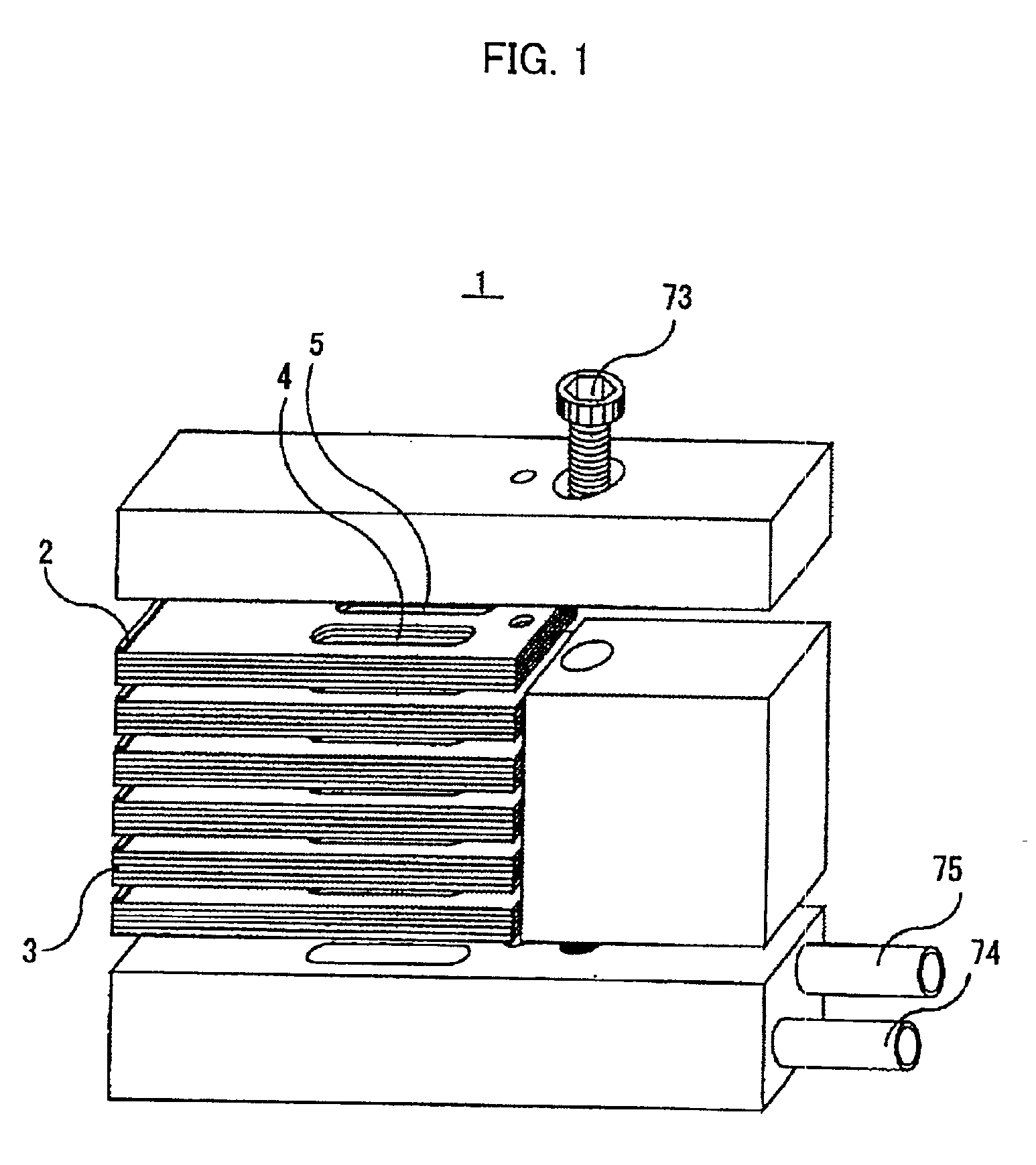

Cooling device

InactiveUS6865200B2High power outputIncreased power output densitySemiconductor laser arrangementsSemiconductor/solid-state device detailsEngineeringOpen path

A cooling device suitable for cooling a laser diode bar constituting a surface illuminating device as a light source for exciting a laser medium of a solid-state laser oscillator of high power. The cooling device is capable of flowing coolant at sufficient flow rate by reducing the pressure loss in the flow passage of the coolant in the device, to realize a light source device of small thickness with high cooling capability and high reliability. The cooling device comprises a first plate member, one or more second plate member and a third plate member to be joined together to form a laminated body. The second plate member has grooved paths formed on both surfaces thereof and having depths greater than a half of thickness of the plate member, and also opened paths for communicating grooved paths formed on the first plate member and the third plate member. The pressure loss in the flow passage of coolant is reduced by increasing a sectional area of the flow passage by the grooved paths and the opened path of the second plate member without lowering mechanical strength of the device and without increasing a manufacturing cost of the device.

Owner:FANUC LTD

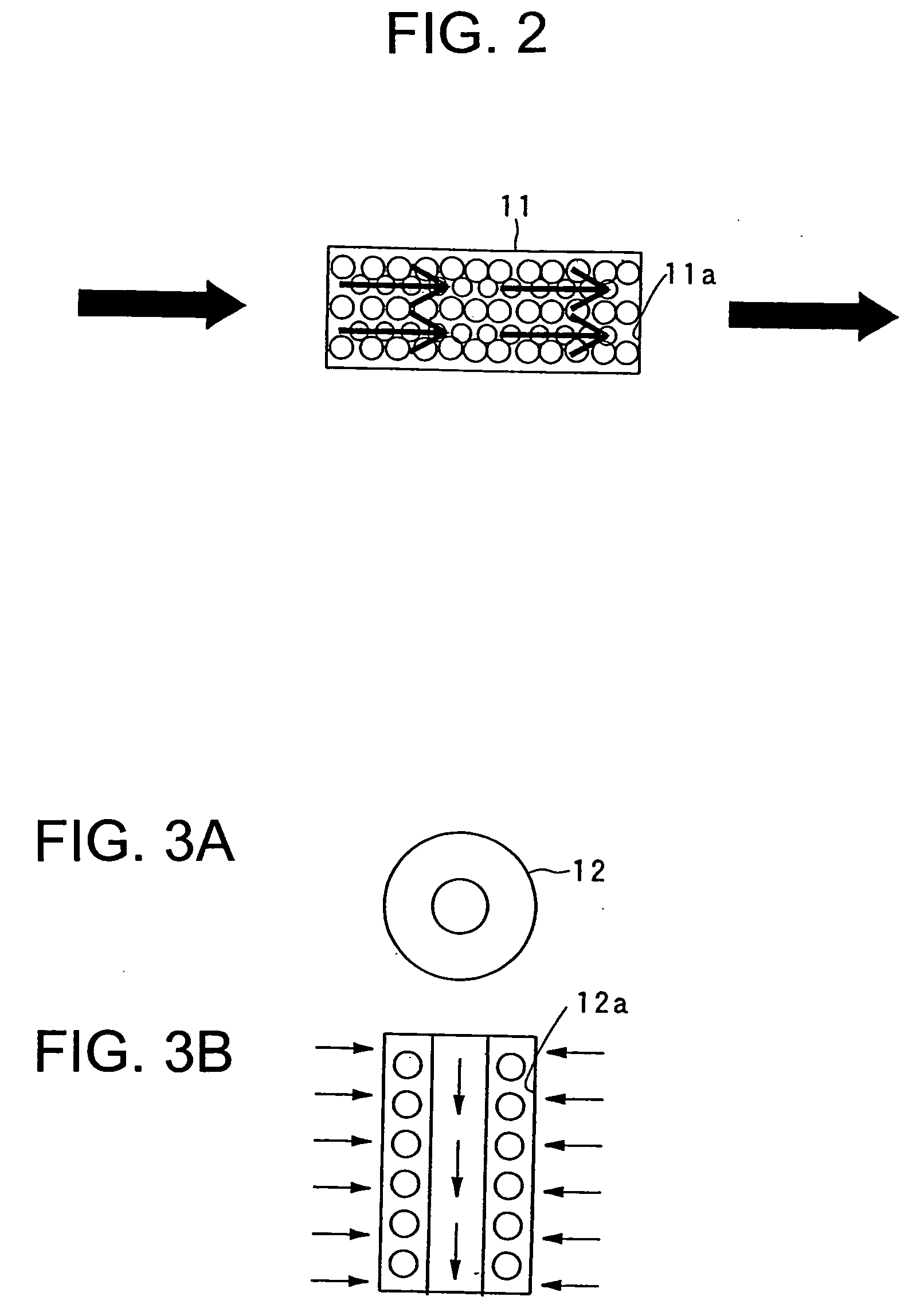

Hollow fiber membrane module and filtering method

ActiveUS20150197431A1Reliable adjustmentReduce speedMembranesReverse osmosisHollow fiber membraneBiomedical engineering

A hollow fiber membrane module comprising a bundle of hollow fiber membranes, a housing, an adhesive fixation layer, an inlet and outlet, at least one bias regulating member, and at least one straightening cylinder, in which the bias regulating member is contained in the adhesive fixation layer, the adhesive fixation layer comprises an outer end surface and an inner end surface inside the straightening cylinder, at least some of spaces between the hollow fiber membranes are at least three times as large as an outer diameter of the hollow fiber membrane on the outer end surface of the adhesive fixation layer, and the spaces between the hollow fiber membranes and a space from the hollow fiber membranes to the straightening cylinder are all less than three times as large as the outer diameter of the hollow fiber membrane on the inner end surface of the adhesive fixation layer.

Owner:ASAHI KASEI CHEM CORP

Honeycomb structure and honeycomb catalytic body

ActiveUS7867598B2Improve purification efficiencyLow pressure lossInternal combustion piston enginesDispersed particle filtrationEngineeringMechanical engineering

A honeycomb structure having porous partition walls having a large number of pores, formed so as to produce a plurality of cells each extending between the two ends of the honeycomb structure, and plugged portions formed so as to plug the cells at either one end of the honeycomb structure or at the insides of the cells, wherein the honeycomb structure has the partition walls of a permeability of 7×10−12 to 4×10−8 m2. The honeycomb structure can provide a honeycomb catalyst structure which is superior in purification efficiency, is low in pressure loss and can be mounted even in a limited space.

Owner:NGK INSULATORS LTD

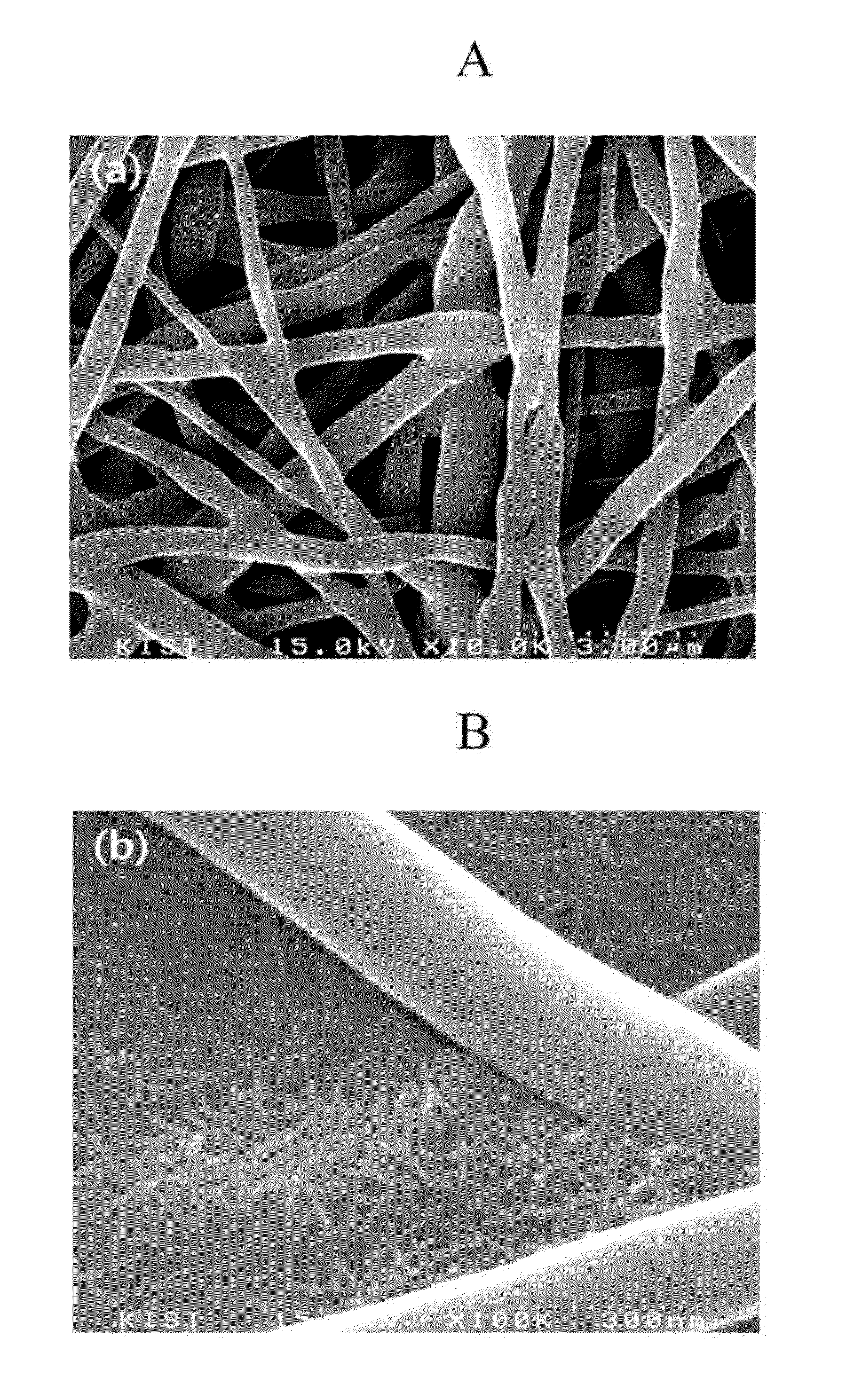

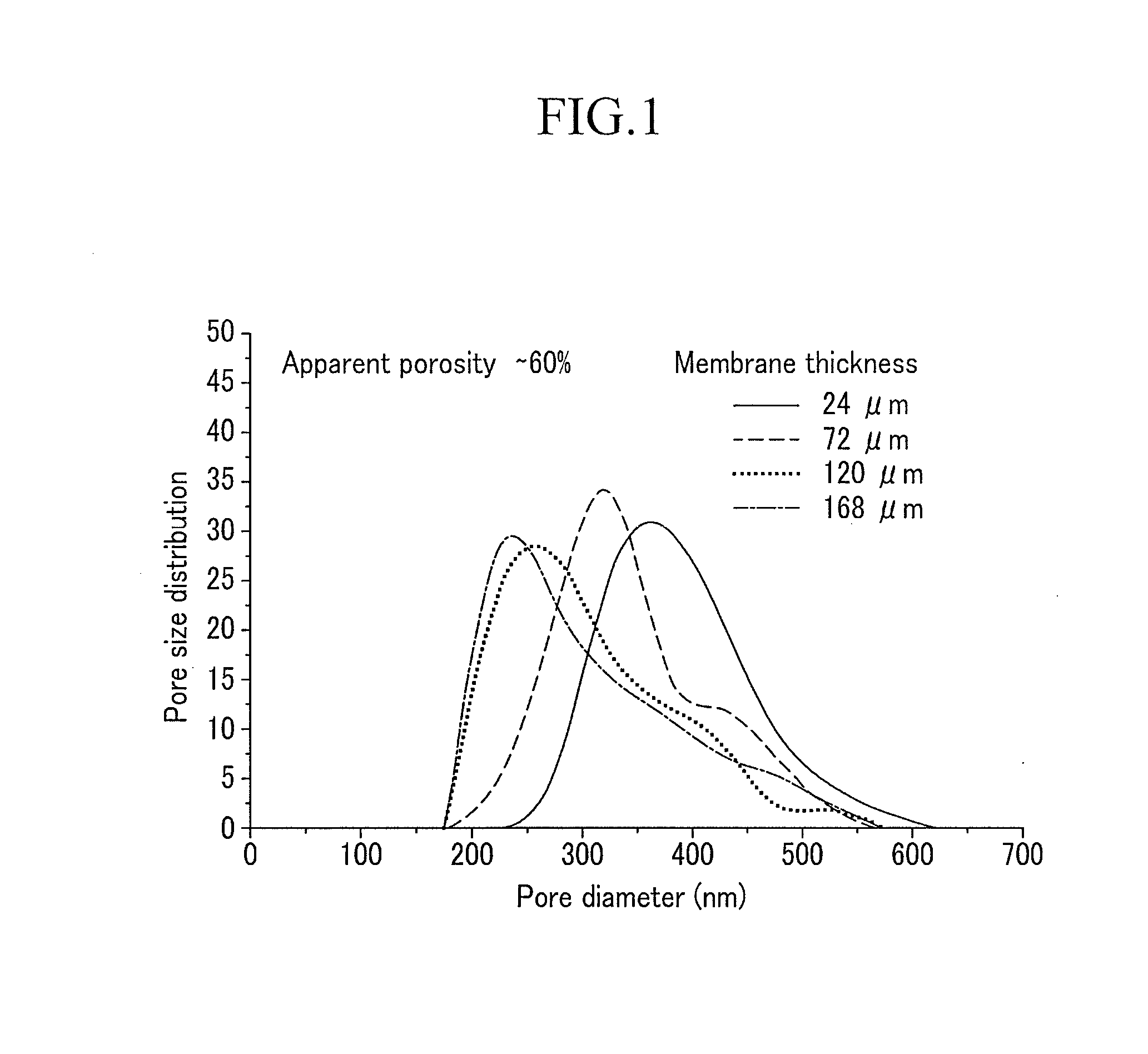

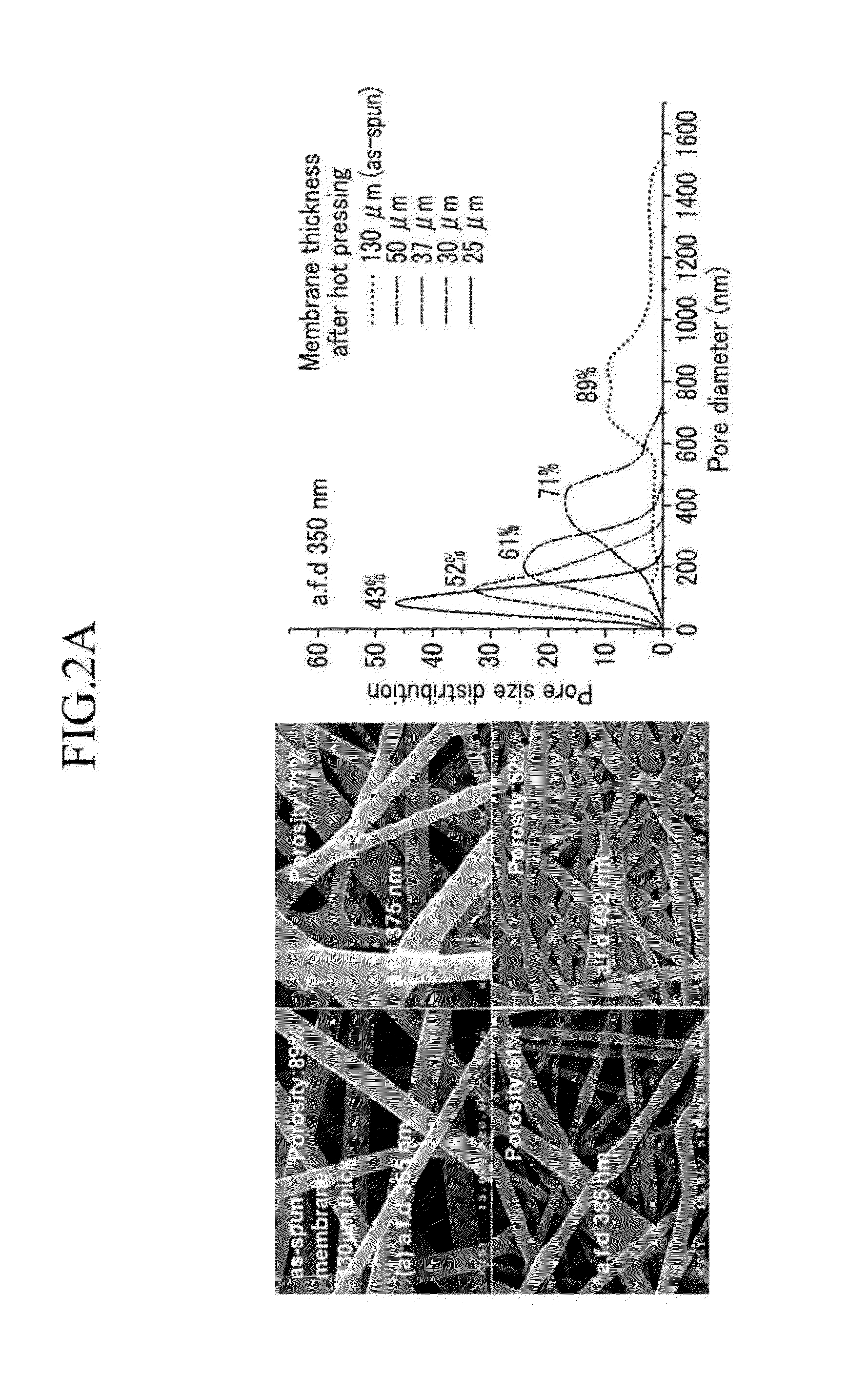

Fiber-based filter with nanonet layer and preparation method thereof

InactiveUS20140076797A1Improve filtration efficiencyImprove throughputSemi-permeable membranesMembrane filtersFiberFiltration

A fiber-based filter includes a filter-based porous body having a most frequent pore size from 0.1 μm to 2 μm in a pore size distribution, in which a ultra-fine fiber is continuously and randomly disposed, and a filtration layer having a nanonet layer having a most frequent pore size from 1 nm to 100 nm in the pore size distribution, in which an anisotropic nanomaterial is disposed. The fiber-based filter may have excellent filtration efficiency capable of removing even super-fine particles such as virus and heavy metal, and may show high permeation flow rate due to low loss of pressure during the filtration, and may be usefully used as an air and water-treatment filter.

Owner:KOREA INST OF SCI & TECH

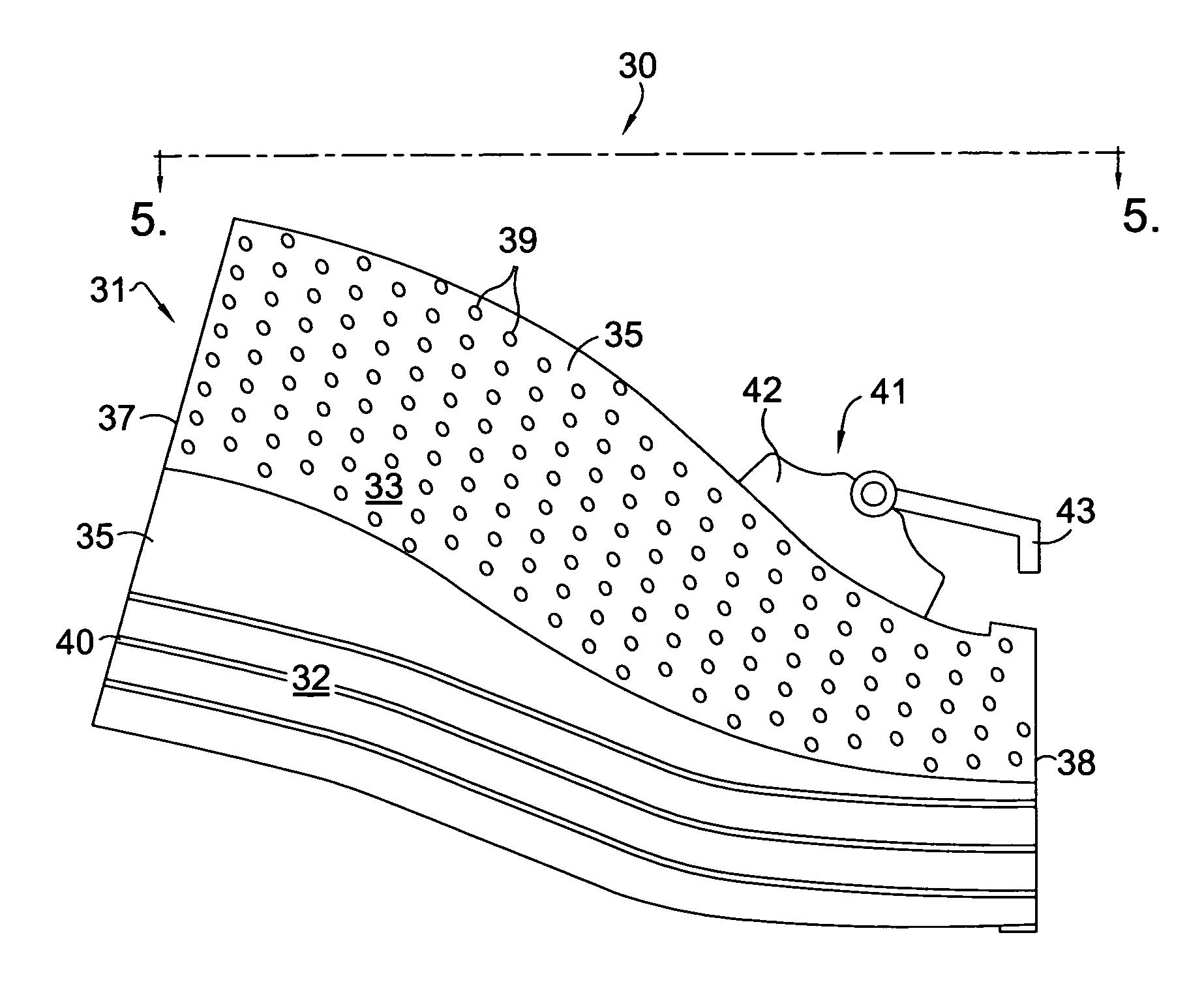

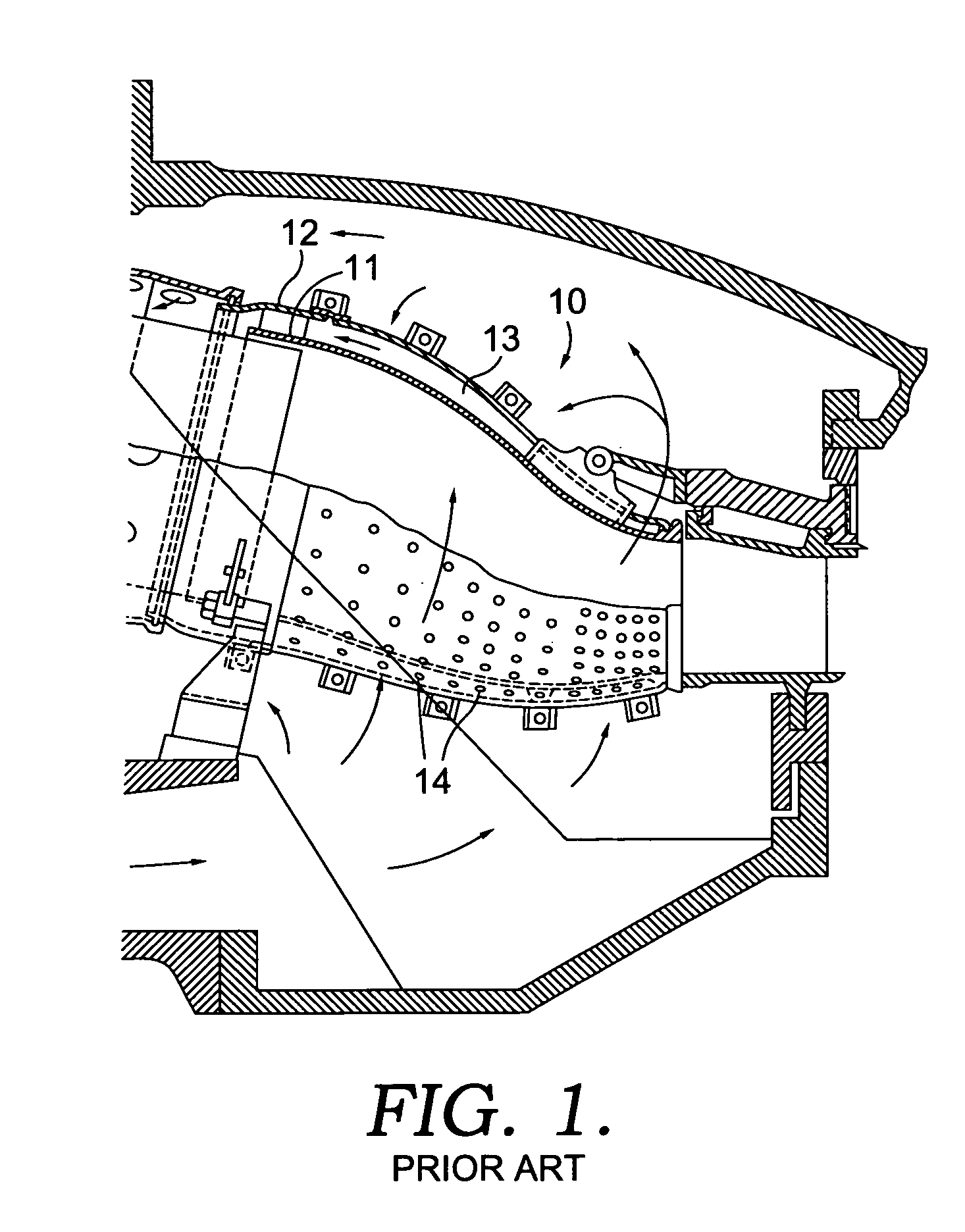

Transition duct apparatus having reduced pressure loss

ActiveUS7137241B2Low pressure lossContinuous combustion chamberTurbine/propulsion engine coolingTurbineGuide tube

A gas turbine transition duct having a reduced pressure loss is disclosed. The transition duct of the preferred embodiment comprises a panel assembly having a first panel fixed to a second panel and a mounting assembly for securing the transition duct to a turbine inlet. The first panel includes a means for augmenting the heat transfer from the first panel while the second panel includes a plurality of first cooling holes for directing cooling air through the second panel. Specific details are provided regarding the first cooling holes and multiple embodiments are disclosed for the heat transfer augmentation of the transition duct first panel.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Method for mixing fluid streams

A method for the mixing of fluid streams in a duct comprising positioning at least one mixing device having a front side and a back side within said duct through which a first major stream travels, the at least one mixing device determining a total cross-sectional area which is significantly lower than that of the duct so as to allow for the passage of said first major stream, whereby the at least one mixing device is a solid plate provided with one or more protrusions extending outward from the main solid plate body.

Owner:UMICORE AG & CO KG

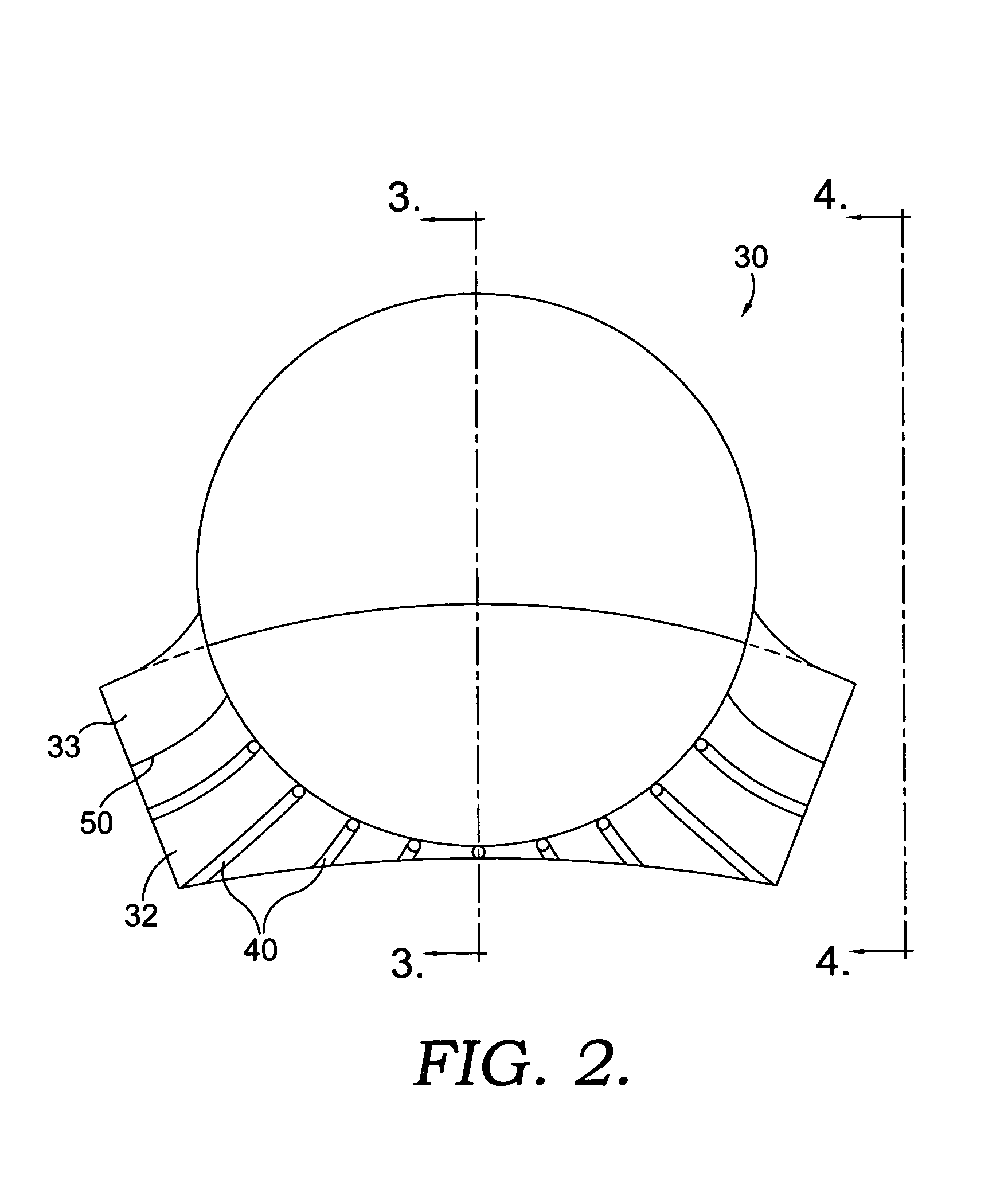

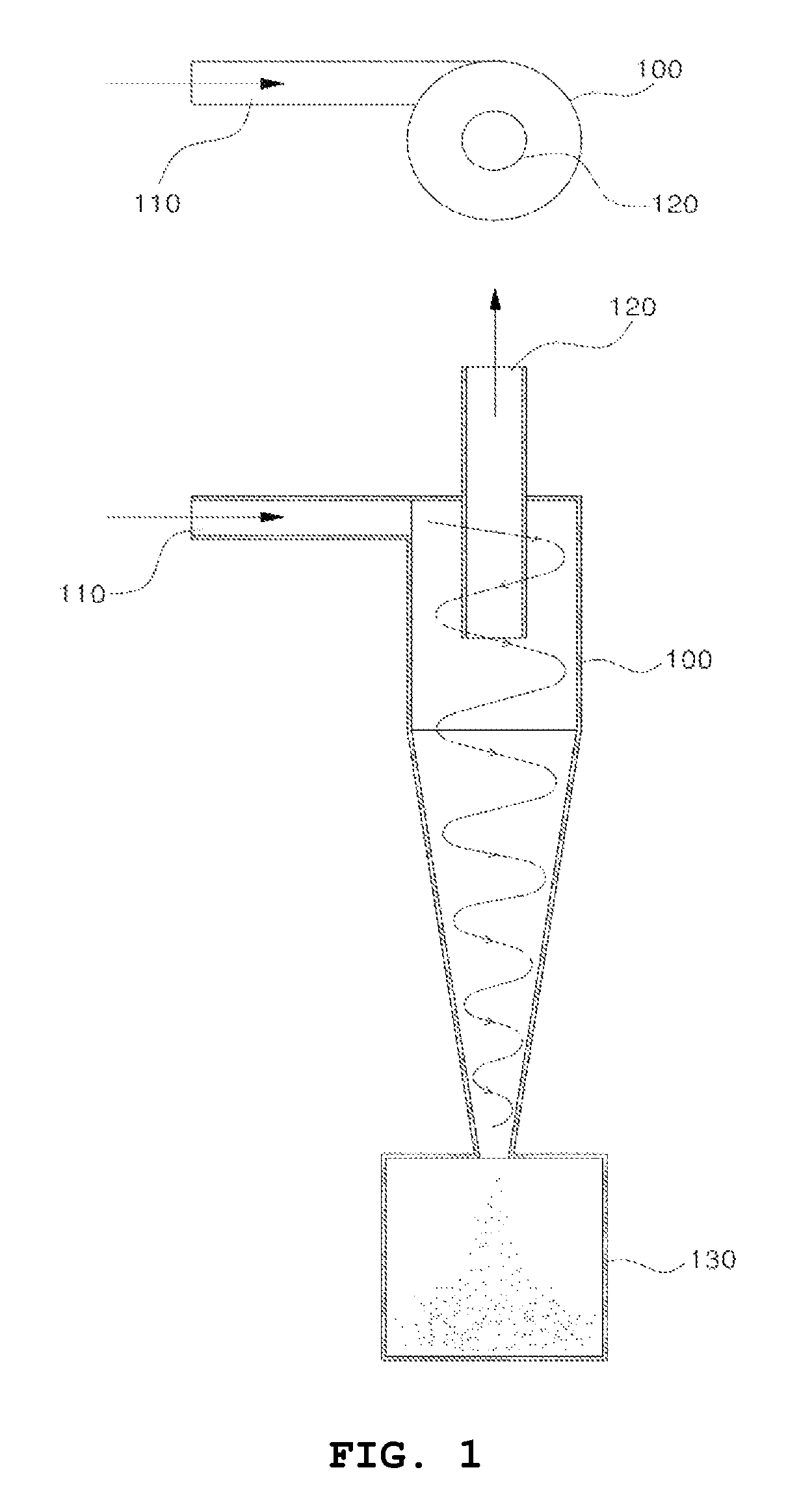

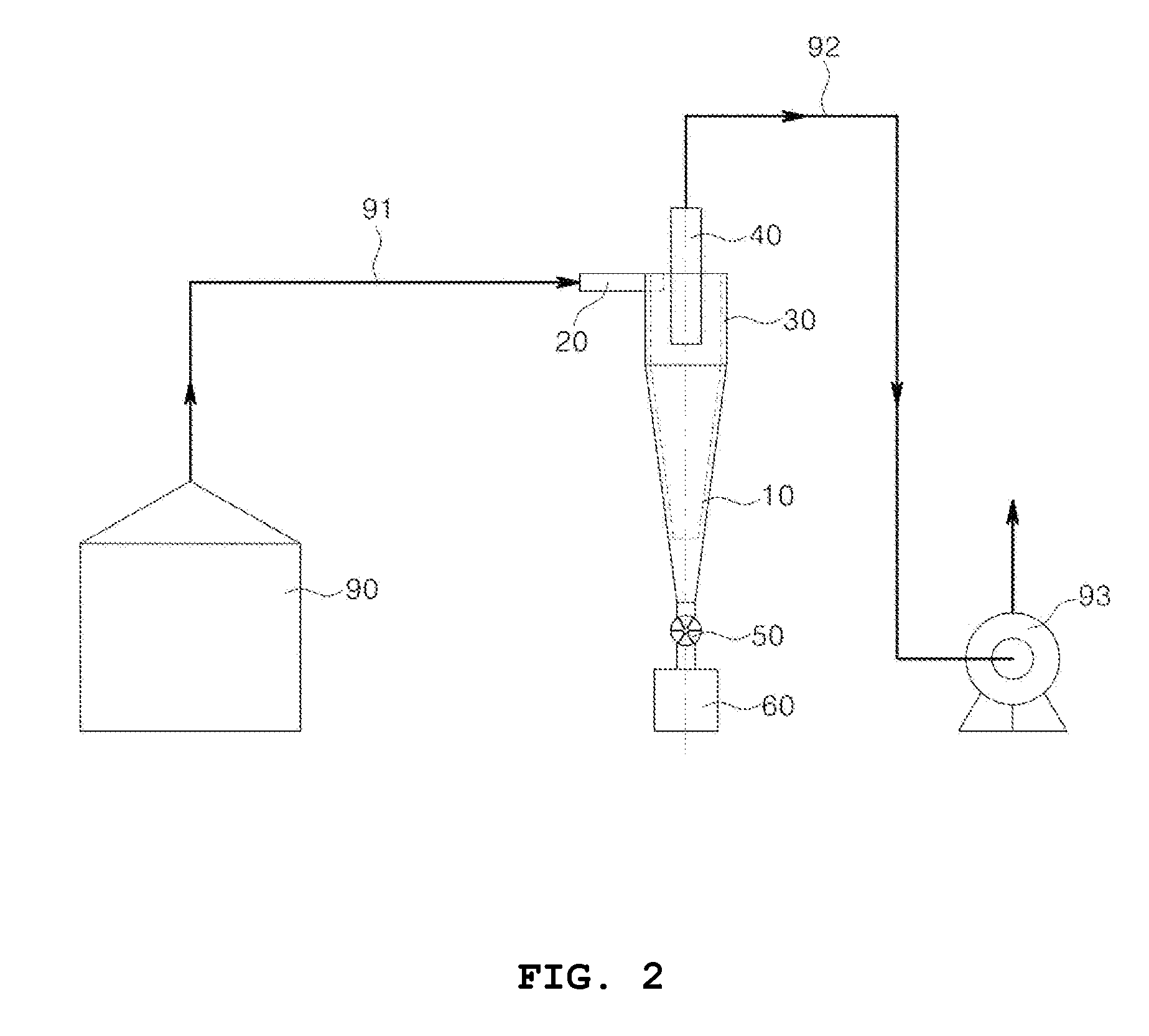

Cyclone dust collector

ActiveUS8657910B2Low pressure lossReduce flow rateCombination devicesSuction filtersCycloneCentrifugal force

Owner:KOREA INST OF ENERGY RES

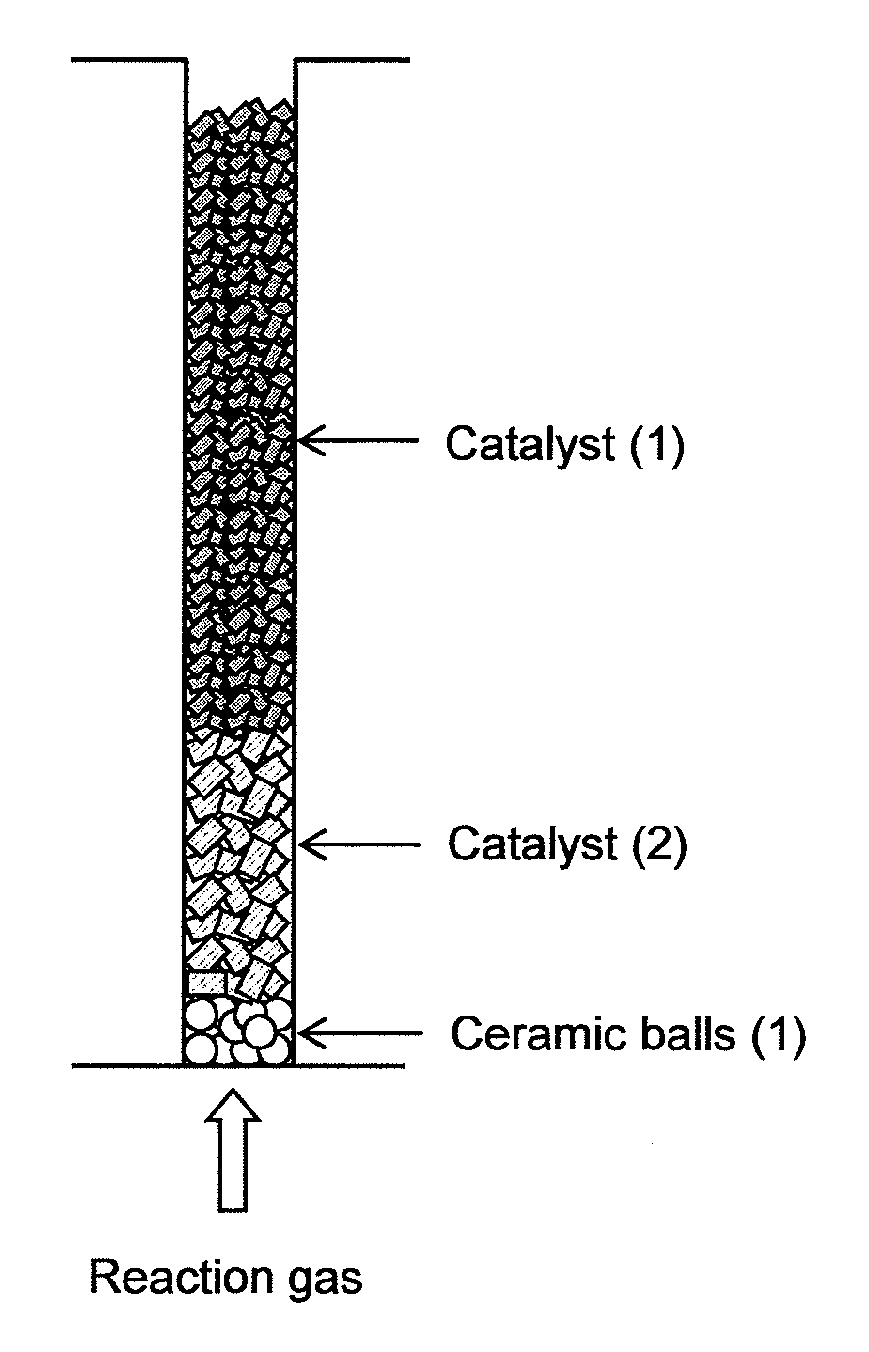

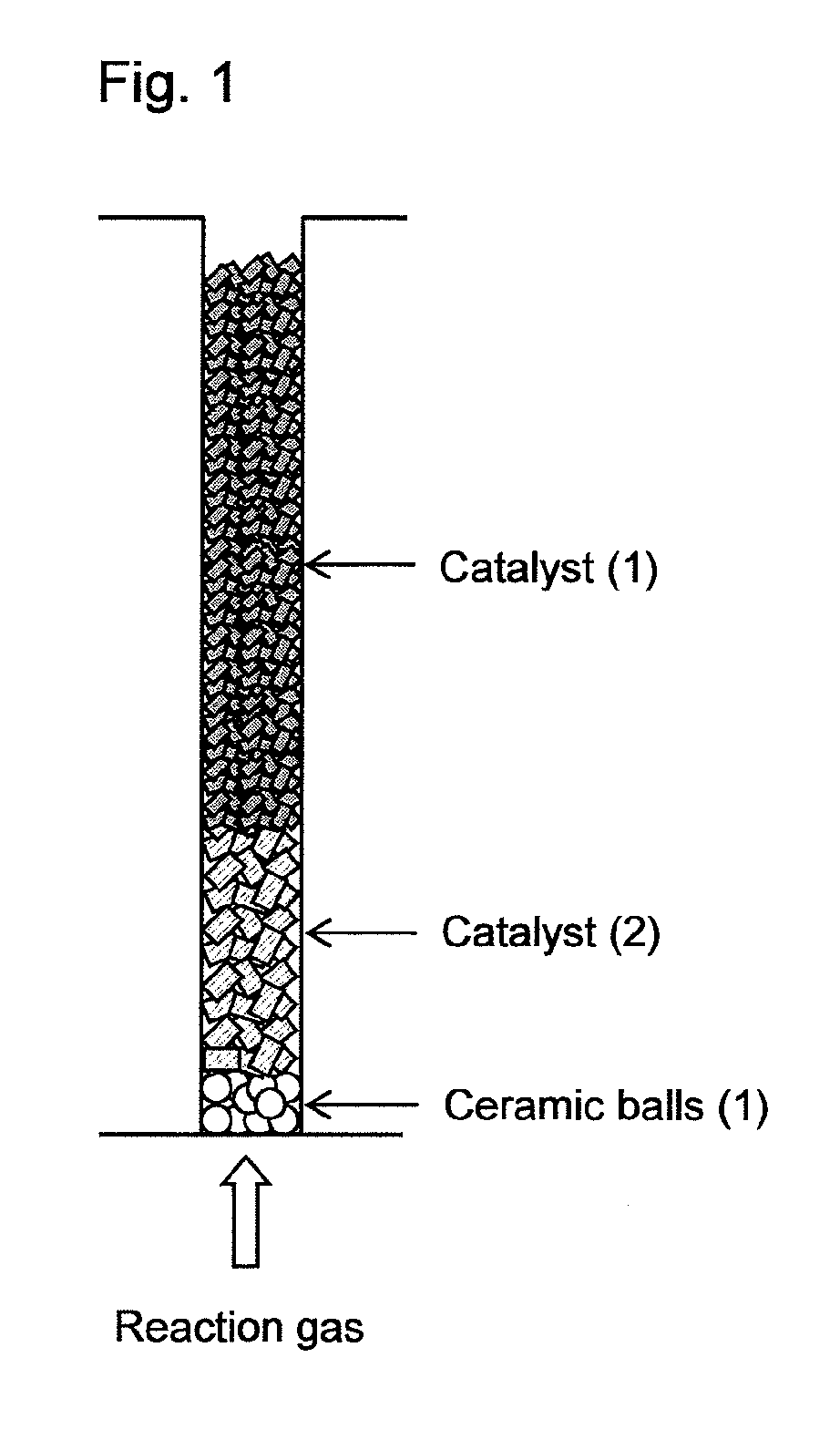

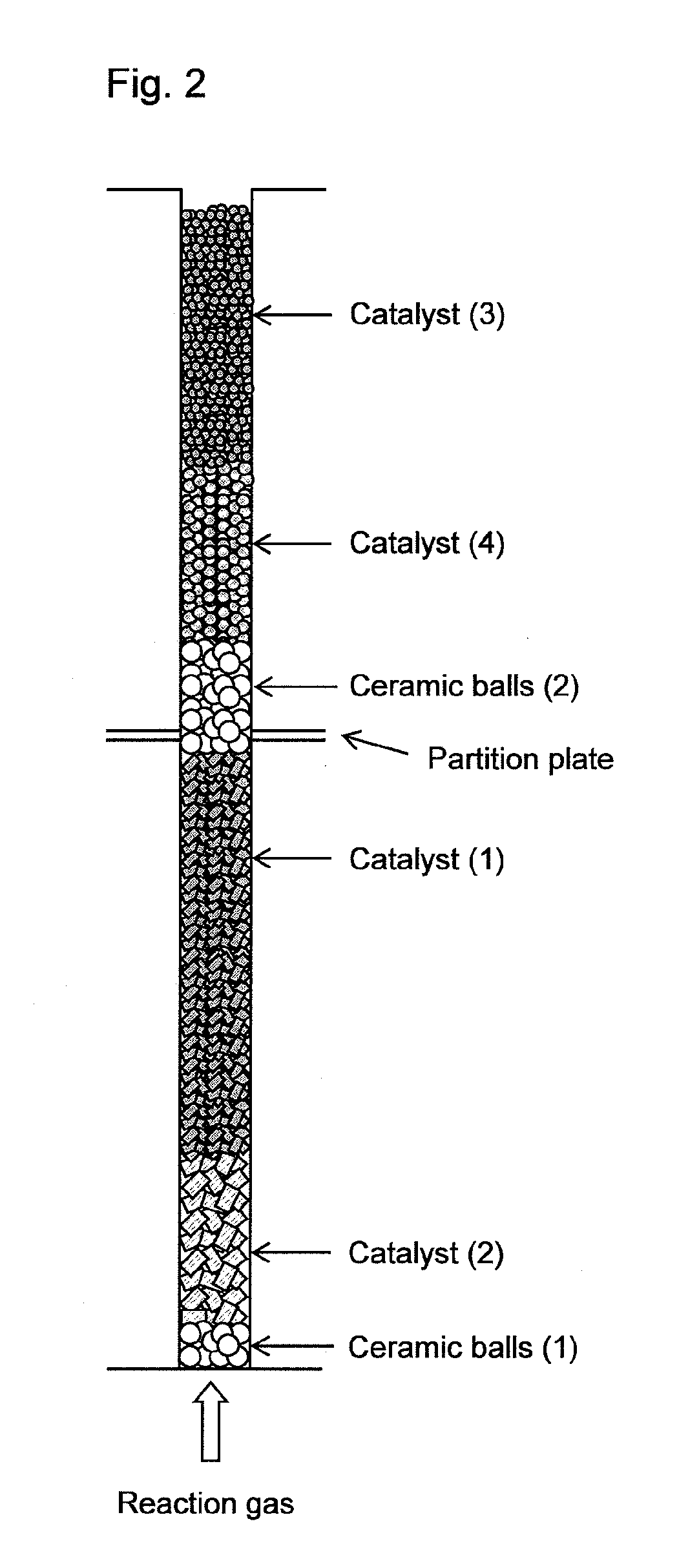

Method of loading solid particles into a fixed-bed multitubular reactor

InactiveUS20110017348A1High yieldPressure loss can be easilyOrganic compound preparationHeterogenous catalyst chemical elementsFixed bedSolid particle

A method of loading solid particles into reaction tubes of a fixed-bed multitubular reactor, comprising the step of loading two or more kinds of solid particles into each of the reaction tubes so that the respective kinds of the solid particles are stacked in layers in a direction of an axis of the tube, wherein a gaseous fluid is introduced into the reaction tubes at least once every time the each kind of the solid particles is loaded in the layer.

Owner:NIPPON SHOKUBAI CO LTD

Honeycomb structure and honeycomb catalytic body

ActiveUS20070054803A1Improve purification efficiencyLow pressure lossCombination devicesInternal combustion piston enginesParticulatesMean diameter

A honeycomb structure includes: porous partition walls having a large number of pores and disposed to form a plurality of cells communicating between two end faces, and plugged portions disposed to plug each of the cells on one of the end faces. A percentage of the number of carbon particulates contained in combustion exhaust gas satisfying the following condition (1) and passing through a honeycomb structure is 80% or more at a space velocity of 25000 / h. The condition (1) is that the carbon particulates has a mean diameter of 0.07 to 0.2 μm, a ratio of the carbon particulates having a diameter of 1 μm or more is 0.1% or less in number and that a concentration of the carbon particulates is 10 mg / m3. The honeycomb structure is excellent in purification efficiency, has low pressure loss, and is mountable even in a limited space.

Owner:NGK INSULATORS LTD

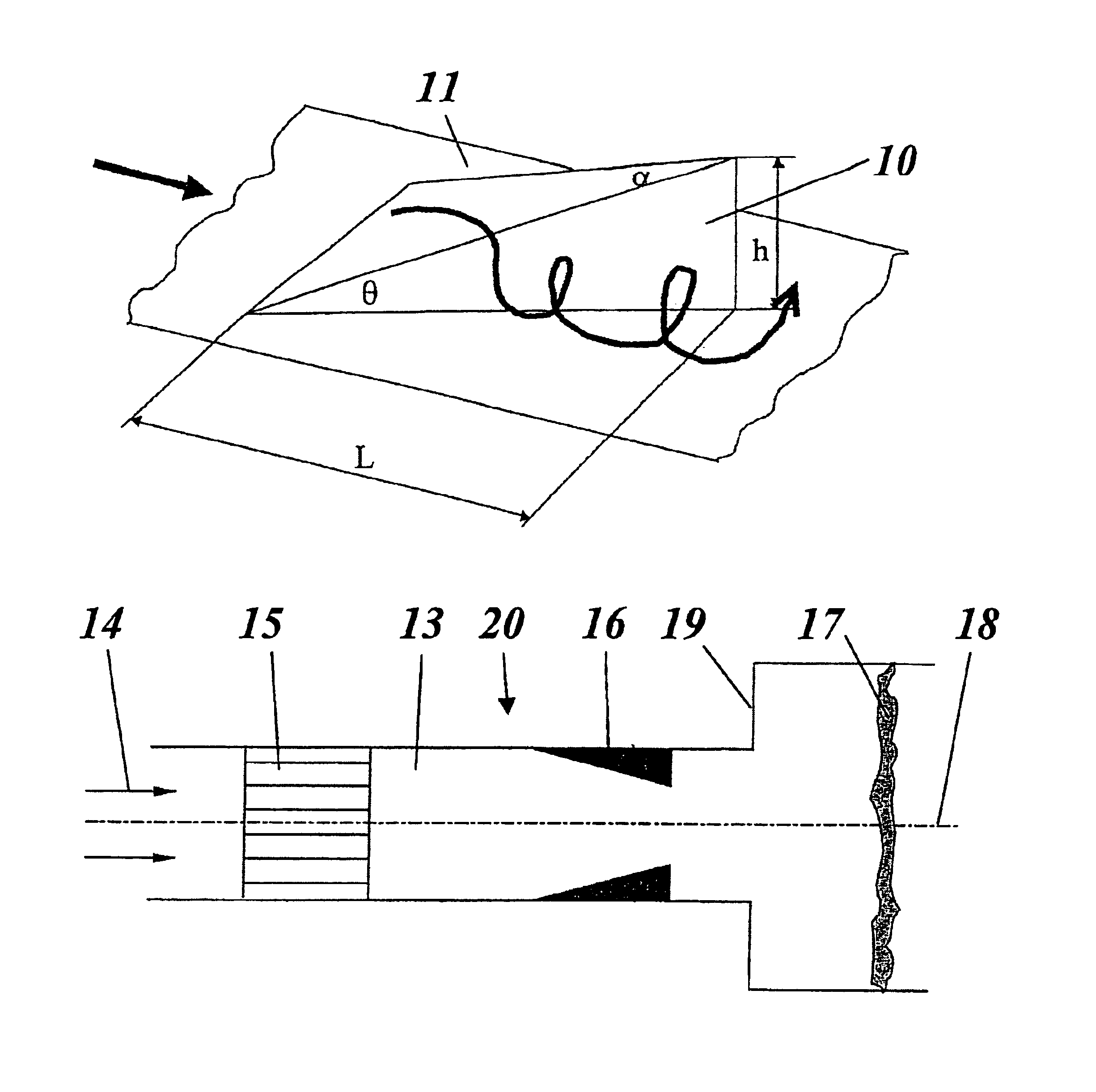

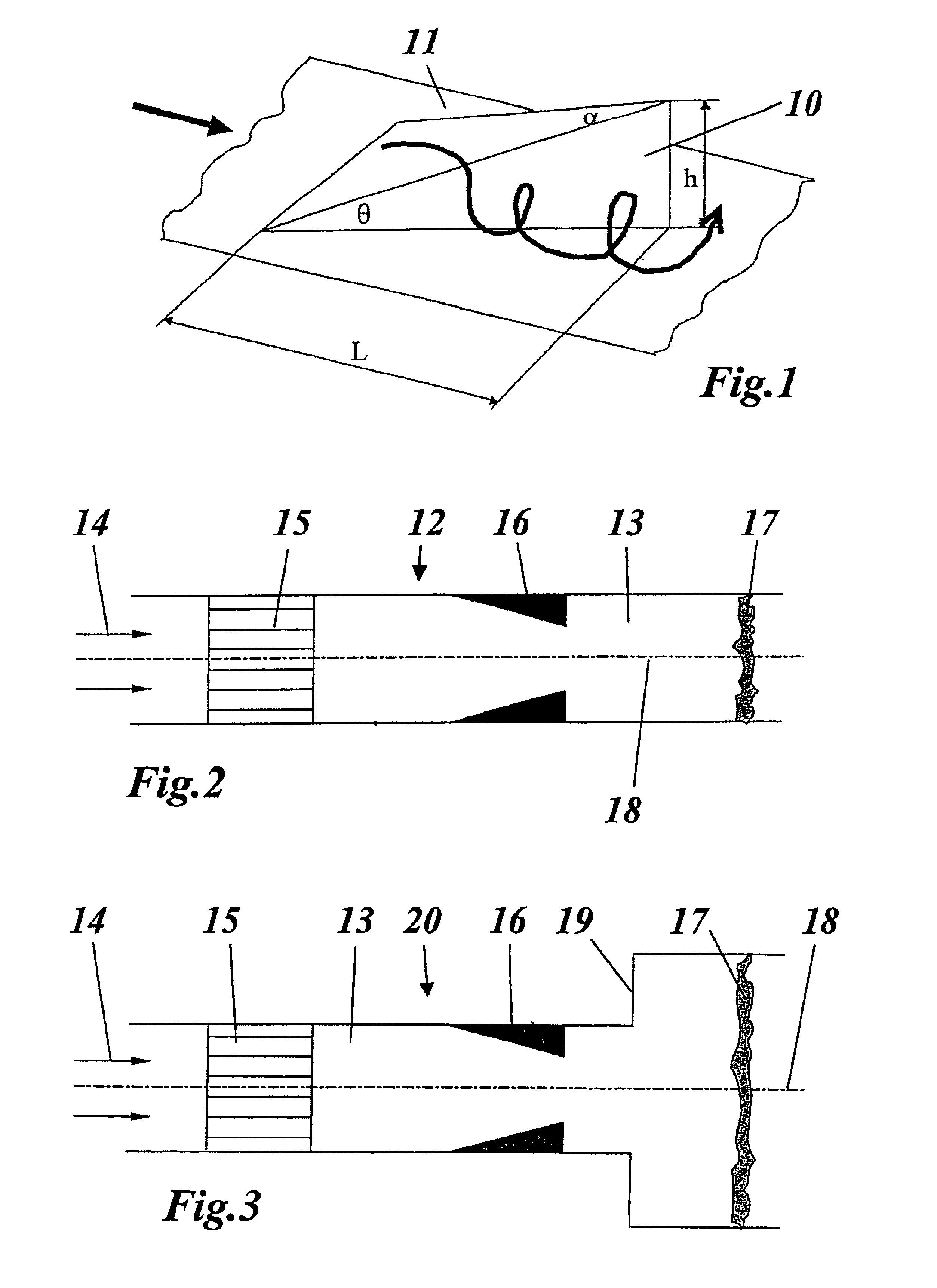

Combustion method and burner for carrying out the method

ActiveUS6896509B2Simple and reliable to carry-outLow pressure lossContinuous combustion chamberFurnace componentsCombustorProcess engineering

In a combustion method, in a burner (12, 20), a fuel / air mixture flowing through a flow passage (13) is made to react in a first combustion stage in a catalytic reactor (15), and downstream of the catalytic reactor (15) fuel is burnt together with the exhaust gas from the catalytic reactor (15) in a second combustion stage to form a homogenous flame (17) by self-ignition.If the fuel from the fuel / air mixture is only partially burnt in the first combustion stage in the catalytic reactor (15), and the unburnt remainder of the fuel is burnt in the second combustion stage, combustion can be stabilized by virtue of the fact that the fuel-containing exhaust gas from the catalytic reactor (15), between the outlet of the catalytic reactor (15) and the homogenous flame (17) is passed through devices 916, 19) which aerodynamically stabilize the homogenous flame (17).

Owner:ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com