Mechanical automatic vertical drilling tool

A vertical drilling and mechanical technology, applied in directional drilling and other directions, can solve the problems that vertical well drilling has not been well solved, cannot meet the needs of vertical well drilling, and is difficult to popularize and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

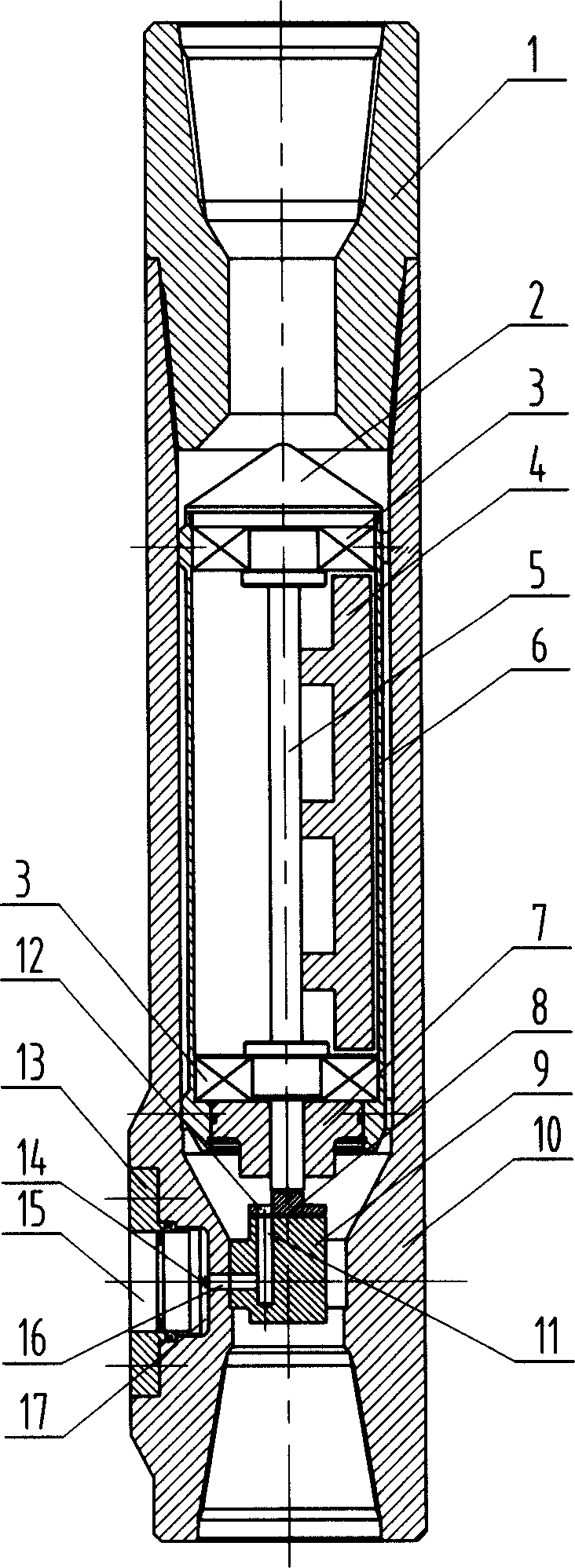

[0010] The present invention will be further described now in conjunction with the accompanying drawings of the description.

[0011] When using the present invention to carry out vertical well drilling construction, the bearings [3] are mounted on both ends of the mandrel [5], the counterweight [4] is fixed on one side of the mandrel [5] and between the bearings [3], and then the mandrel [5], the bearing [3] and the counterweight [4] are put into the inner cylinder [6] together, the guide head [2] is fixed on the upper end of the inner cylinder [6], and the inner cylinder baffle [7] is set on the mandrel [5] ], and fixed with the inner cylinder [6], the upper disc valve [8] is connected with the lower end surface of the mandrel [5], the fan-shaped eccentric flow channel [12] and the counterweight [4] of the upper disc valve [8] Located on both sides of the mandrel [5] respectively, a piston cylinder [17] is processed on the outer wall of the lower end of the housing [10], the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com