Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduced risk of stuck pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

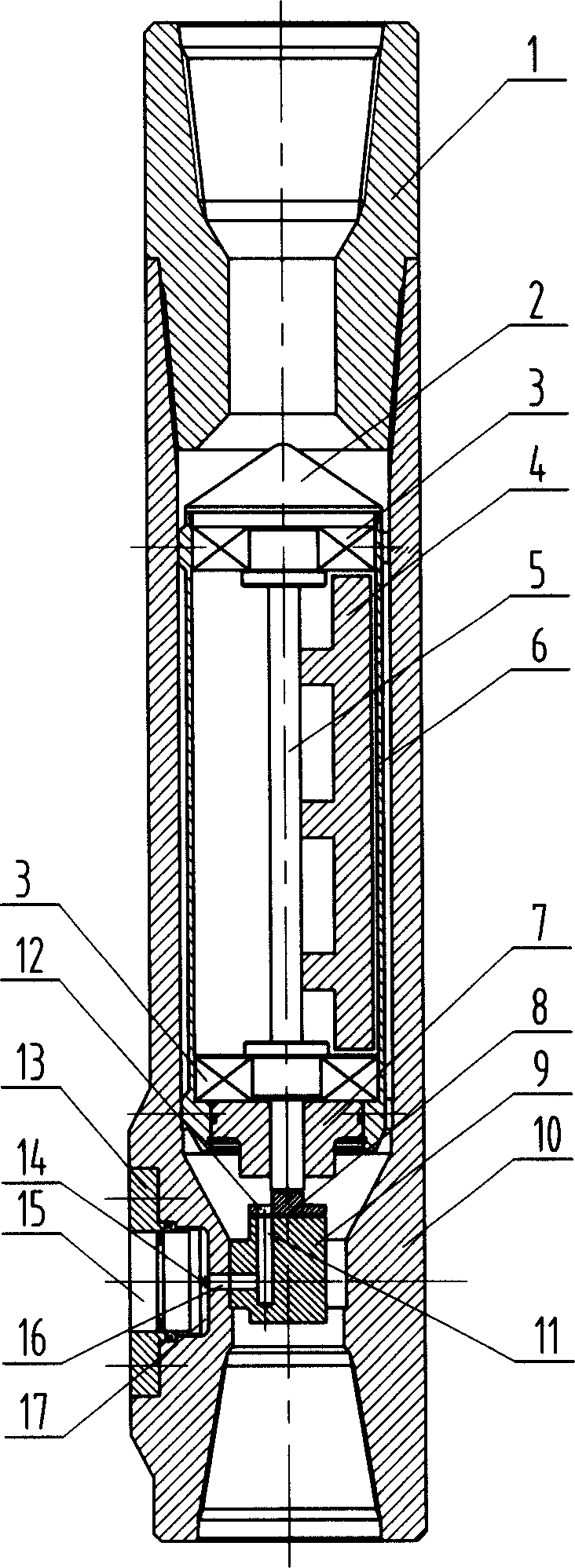

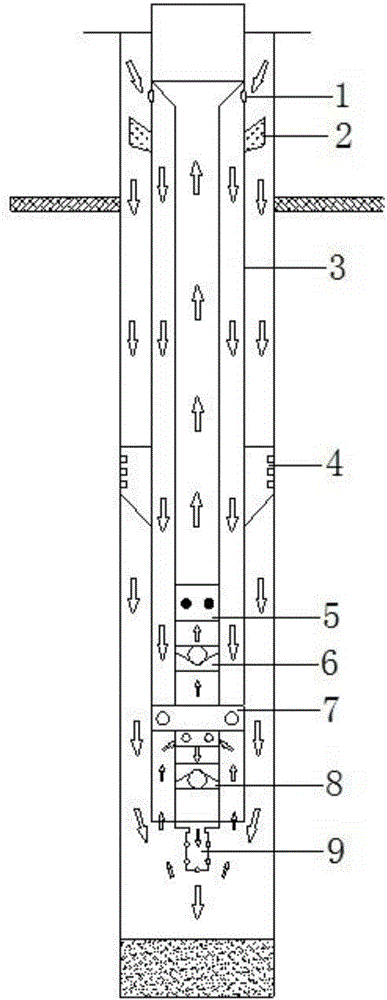

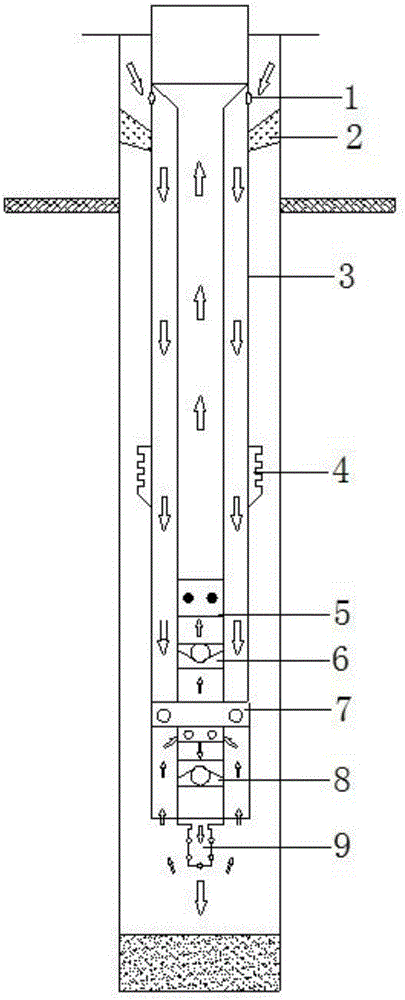

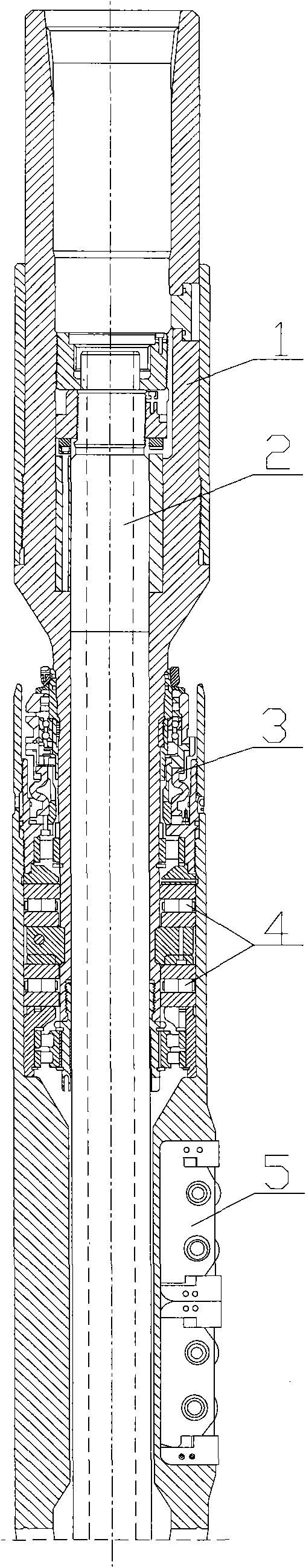

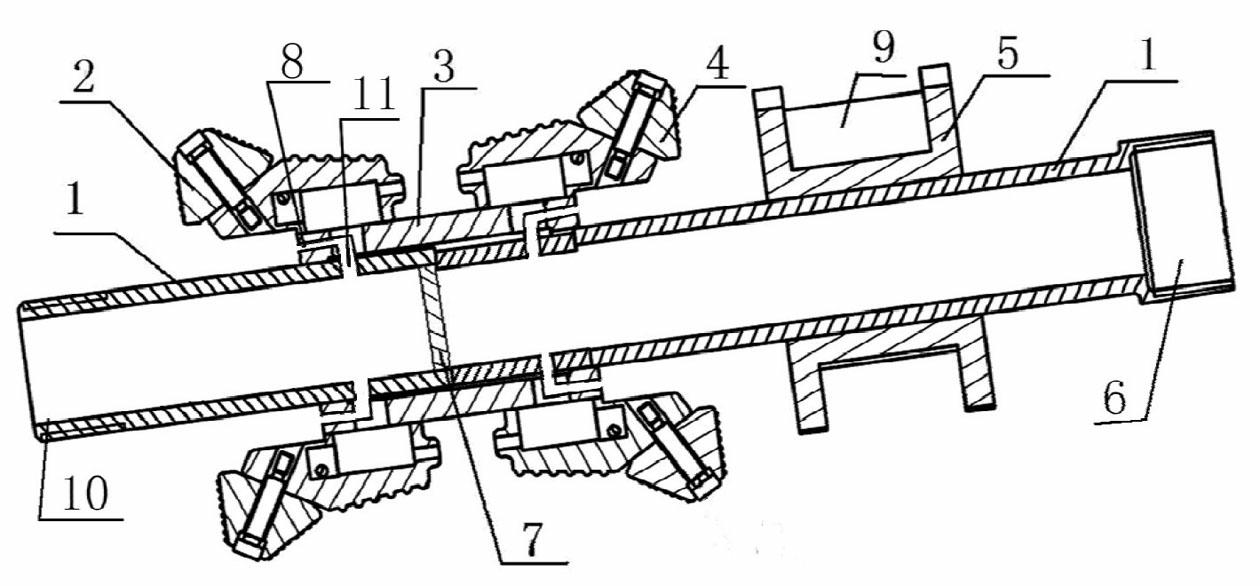

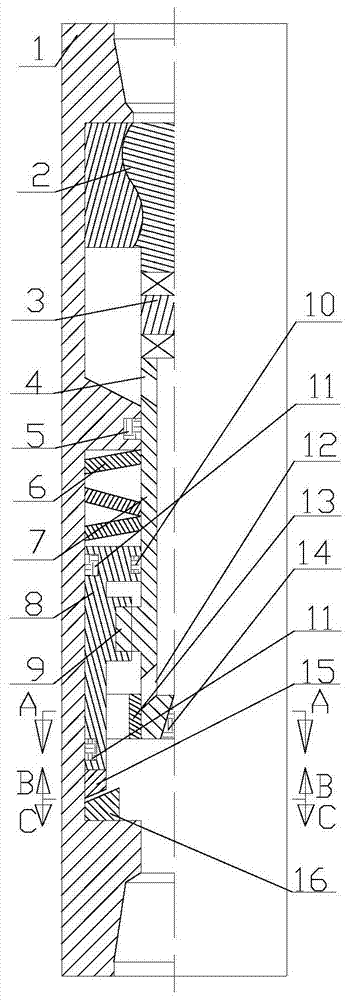

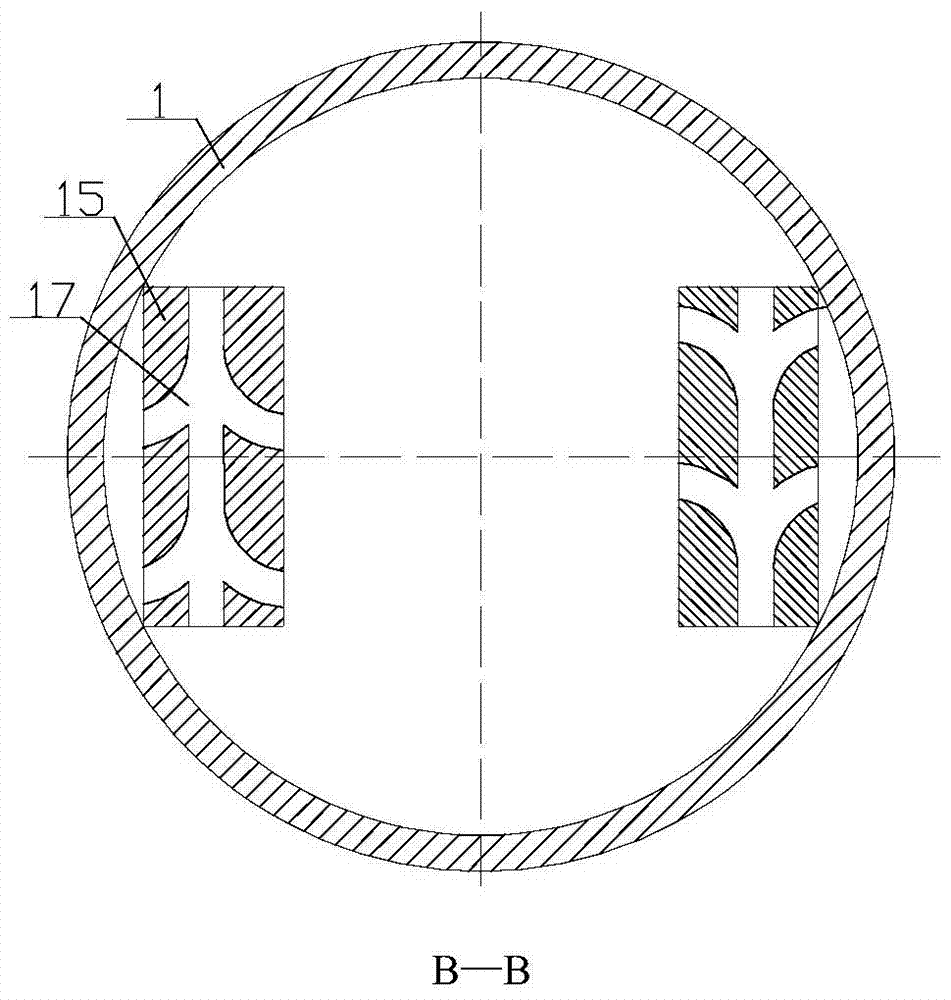

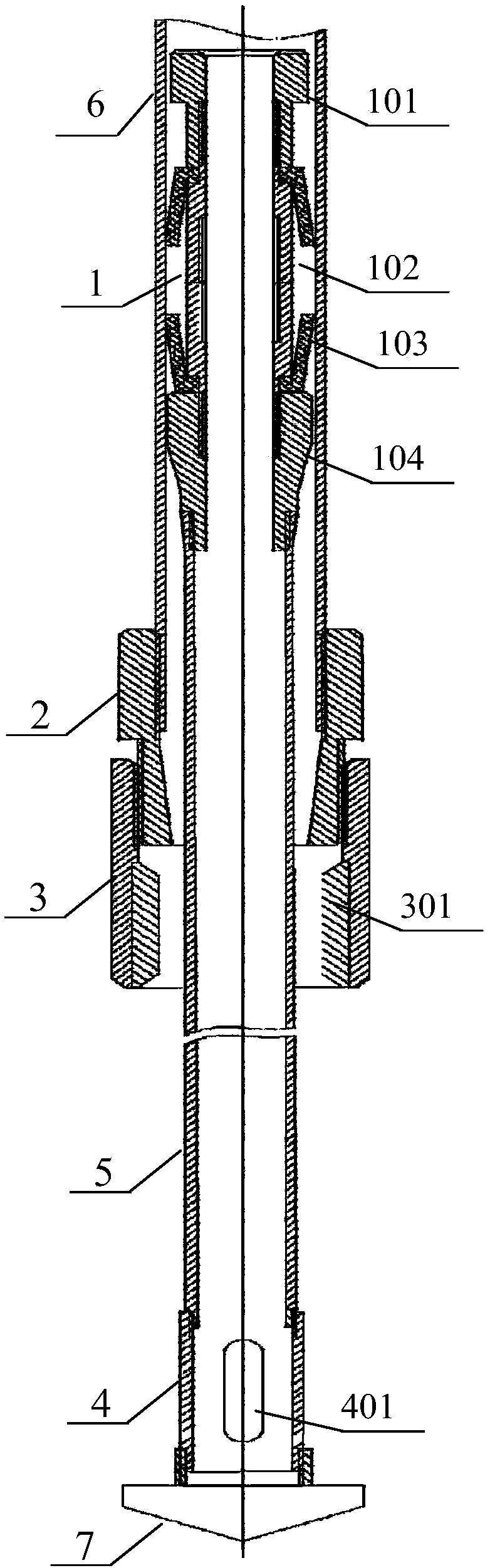

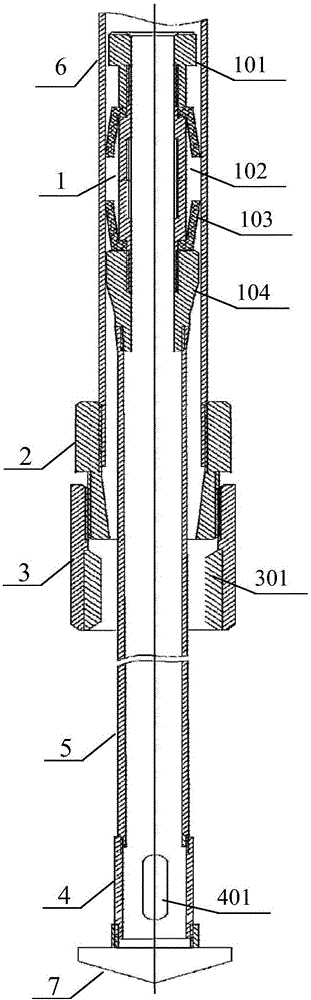

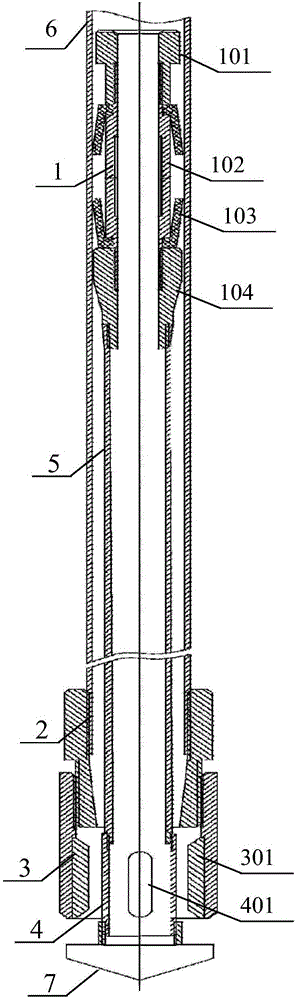

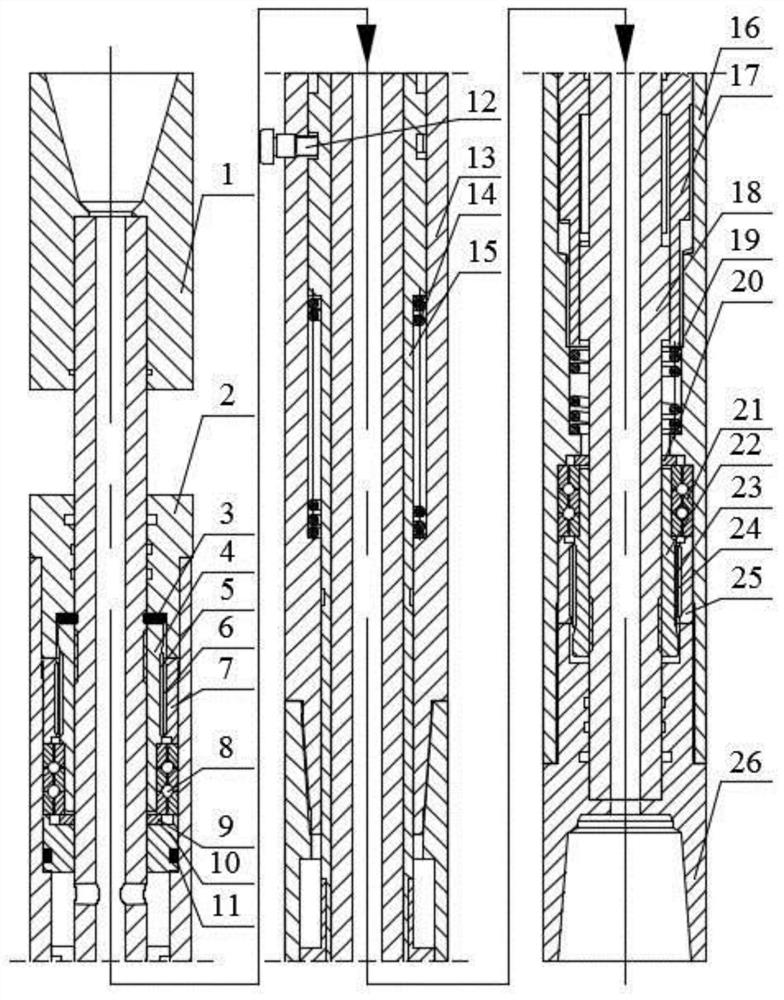

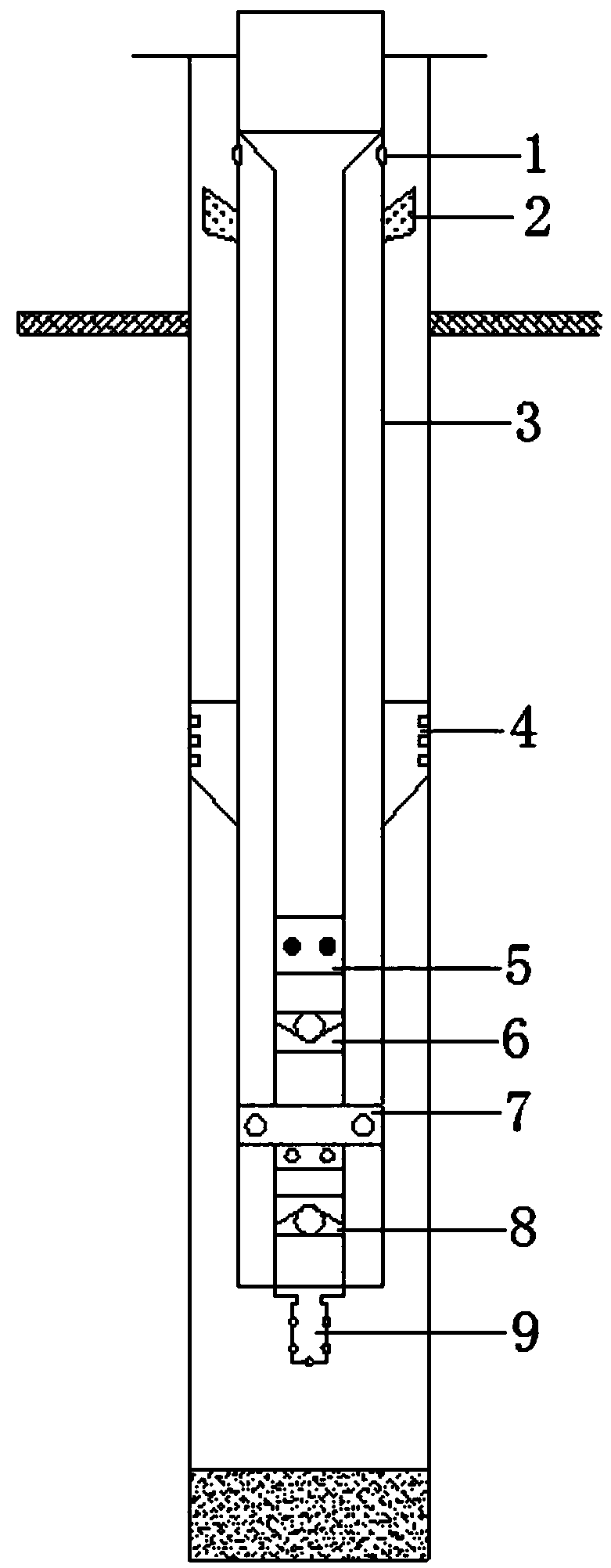

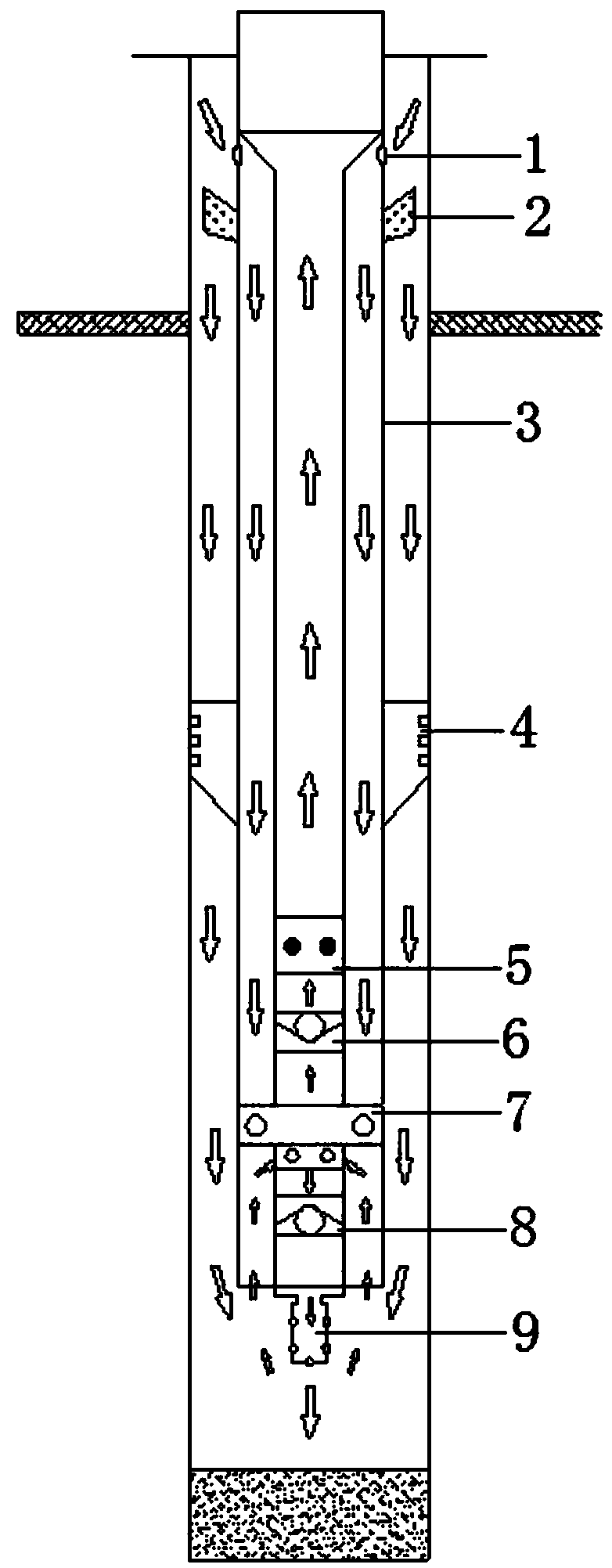

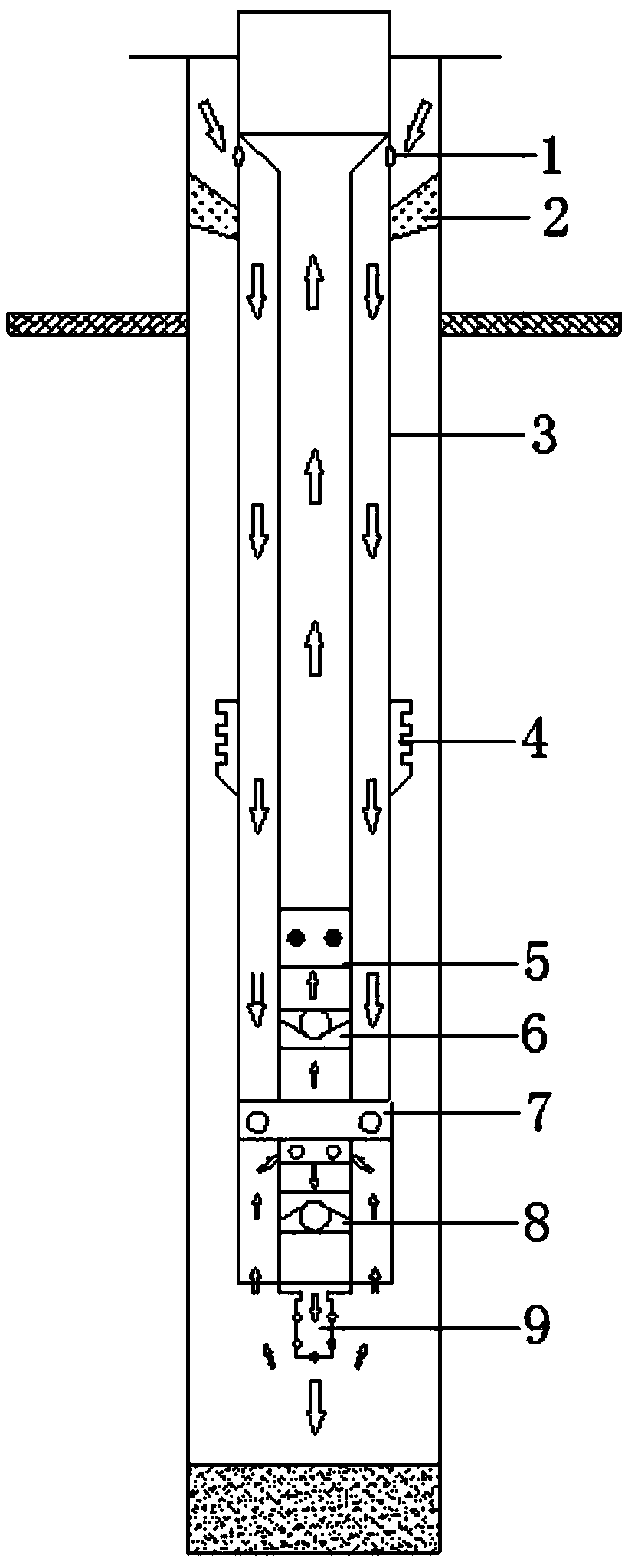

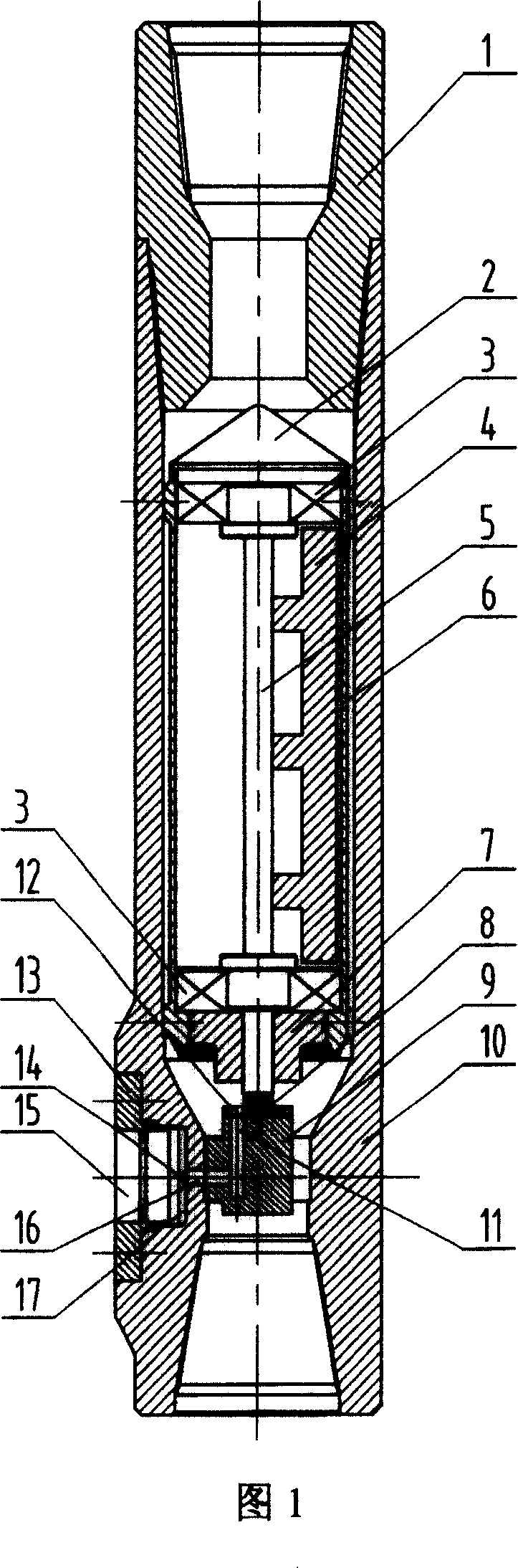

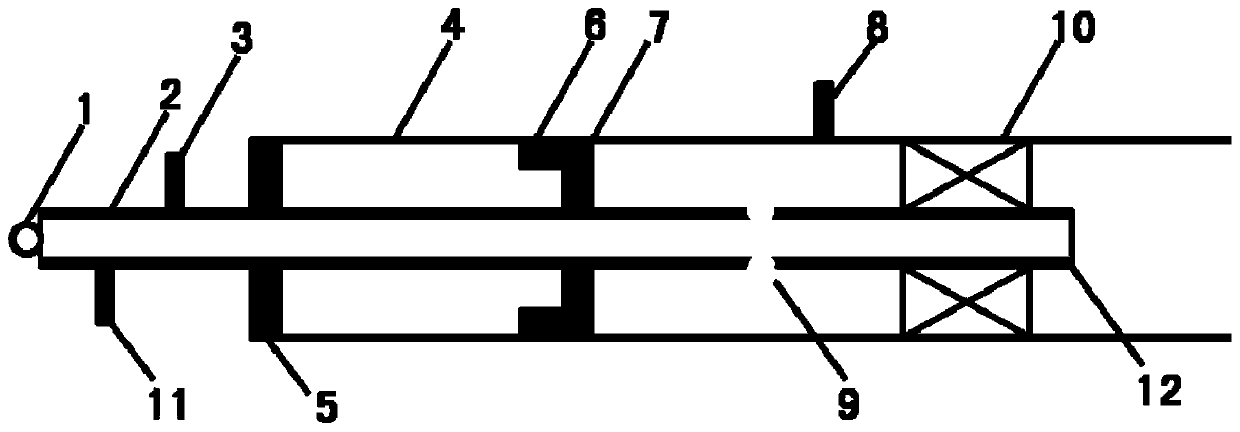

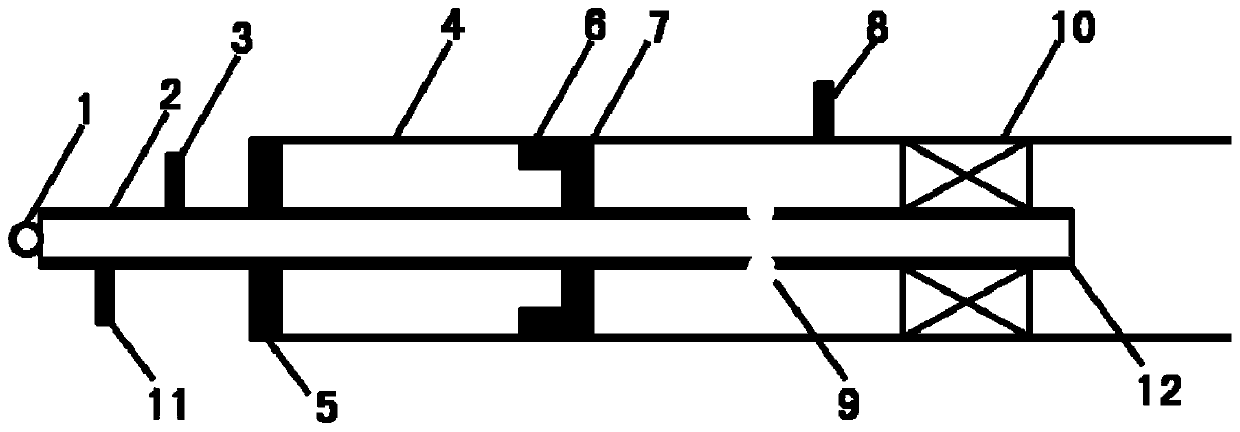

Mechanical automatic vertical drilling tool

InactiveCN1676862AIncrease drilling speedShorten the purification processDirectional drillingWell drillingDifferential pressure

One kind of mechanical type automatic vertically well-drilling tool, including turner, the conduction current head, the bearing, the counterweight, the spindle, in-tube, the back plate, above plate-valve, gets down plate-value, the shell, the piston cylinder back plate and the piston, its principle is at the right moment induces the well slanting gravity signal, by the gravity-actuates in the organization, the establishment drills inside and out the column high-low pressure channel between the fluid, uses two between the differential pressure, actuates the piston at the right moment to push depends on the wall of a well is high side, the wall of a well reacting force then pushes the drill bit to is low side, but in well-eye other positions, the piston does not push depends on the wall of a well, drills the column revolves, this process circulation reciprocation, the well is slanting namely is unceasingly induced and the revision, this invention realization is initiative, At the right moment guards against slanting at the same time, but also can effectively liberate distilling, largely enhances drills fast and well-eye the quality, reduces the construction risk, this invention has the structure is simple, reliable, is suitable to the many kinds of well drilling platform, the processing makes the maintenance cost is low and so on the characteristic.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

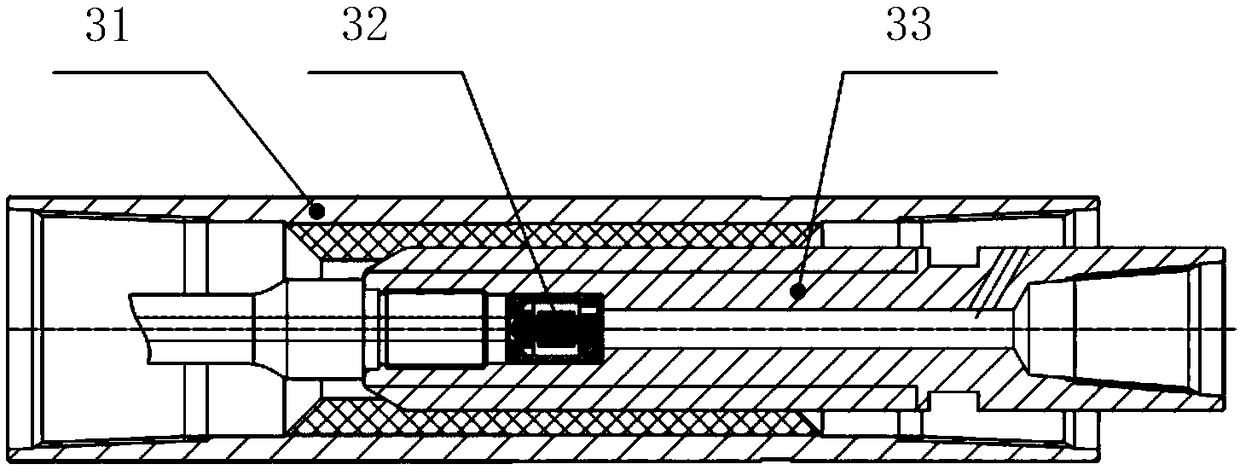

Rotation-free pawl-type sliding sleeve with ball seat capable of being taken out

InactiveCN103321608AReduce salvage costsImplement late closureFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

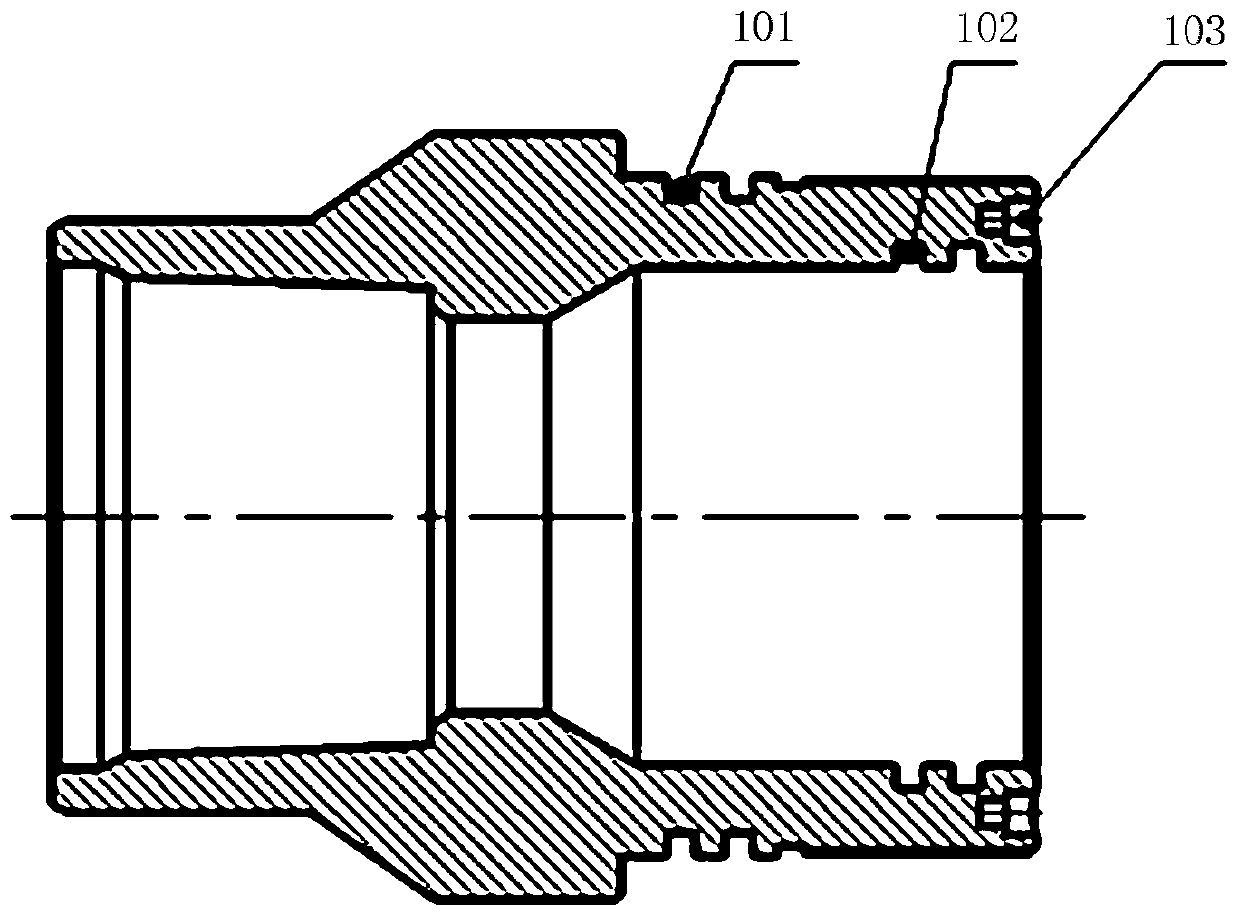

The invention discloses a rotation-free pawl-type sliding sleeve with a ball seat capable of being taken out. The sliding sleeve comprises a sliding sleeve body, an inner sliding sleeve and a ball seat cylinder, wherein the sliding sleeve body is composed of an upper connector, an outer cylinder and a lower connector. The sliding sleeve body and the inner sliding sleeve are fixed through a shear nail, the inner sliding sleeve and the ball seat cylinder are fixed through a shear nail, a fluid outlet hole is formed in the upper portion of the outer cylinder, and a clamping spring hole is formed in the lower position of the middle of the inner wall of the outer cylinder. An annular switch clamping groove is formed in the inner wall of the upper portion of the inner sliding sleeve, a plurality of split pawl clamping grooves are formed in the inner wall of the middle of the inner sliding sleeve in the peripheral direction, and a clamping spring is installed on the outer wall of the middle of the inner sliding sleeve. A plurality of male pawls are arranged at the upper end of the ball seat cylinder in the peripheral direction, a plurality of female pawls are arranged on the inner side of the lower end of the ball seat cylinder in the peripheral direction, the male pawls are clamped into the split pawl clamping grooves, and a variable diameter ball seat is arranged in the ball seat cylinder. When the inner sliding sleeve moves to the lower end of the outer cylinder, the clamping spring on the inner sliding sleeve is clamped into the clamping spring hole in the outer cylinder. All base seat cylinders can be salvaged through non-rotating type tubular columns in a disposable mode, and a full through path is achieved.

Owner:CNPC BOHAI DRILLING ENG

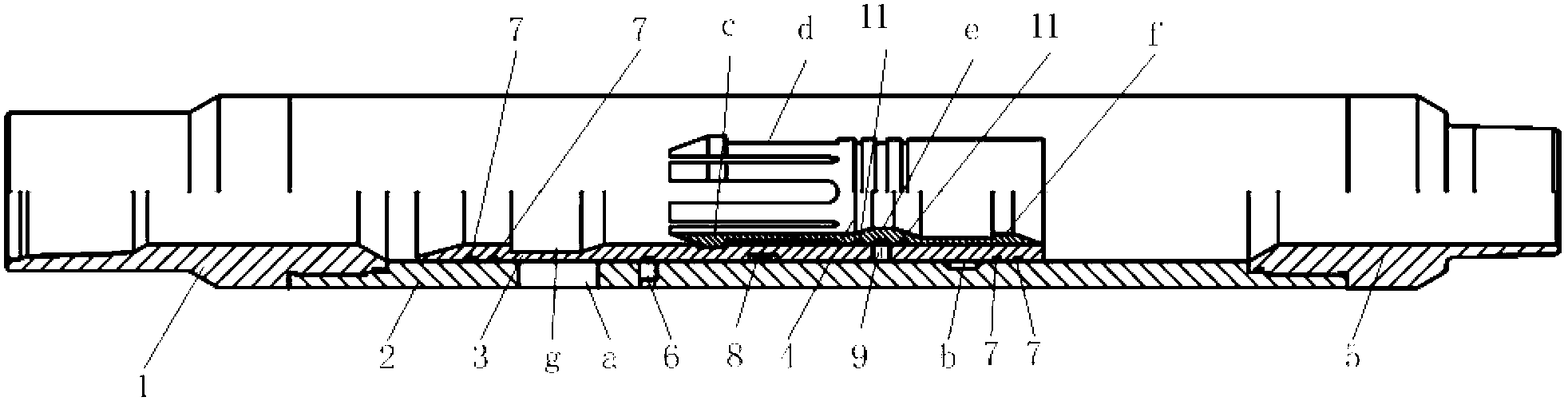

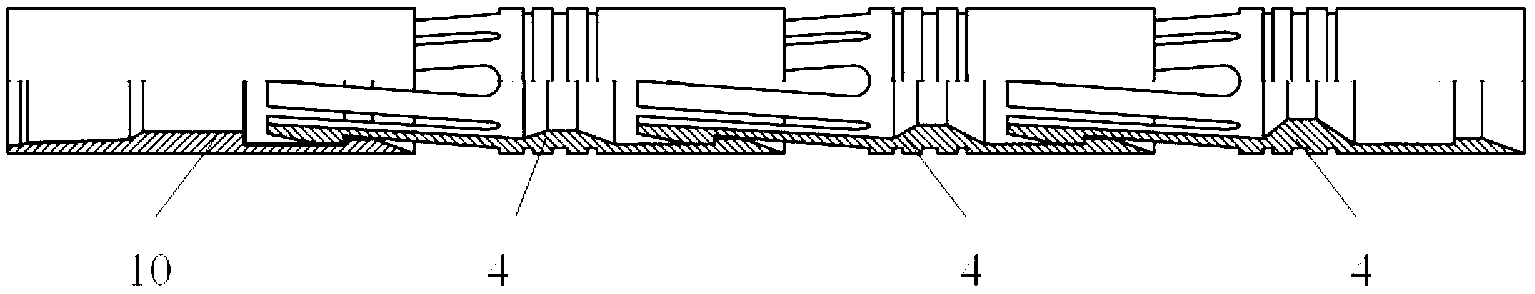

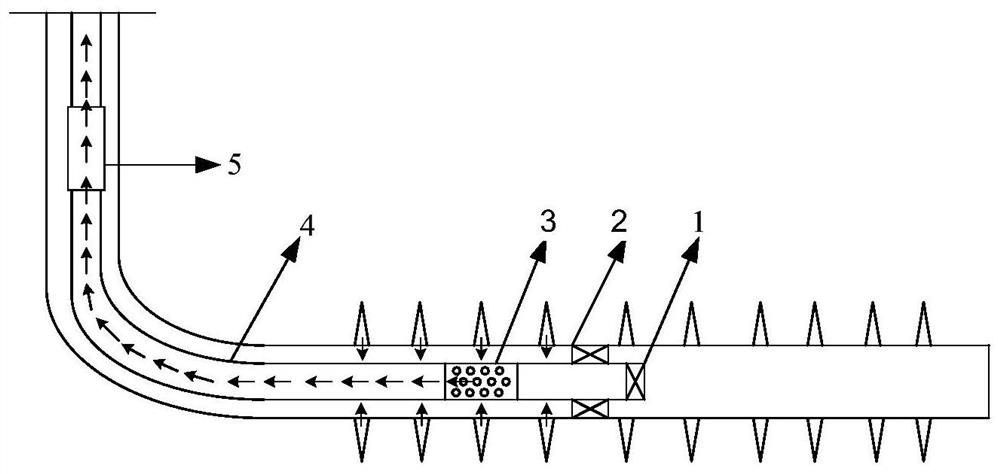

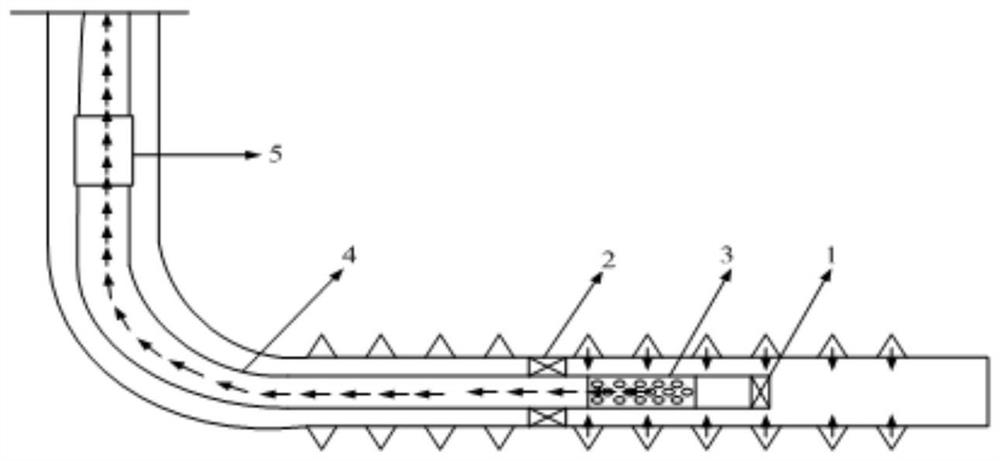

Oil well pipe cleaning and sand flushing integrated device and pipe cleaning and sand flushing method

ActiveCN106194112ARealize the technical requirements of scraper sand washing processReduced risk of stuck pipeDrilling rodsCleaning apparatusPositive pressureOil well

The invention discloses an oil well pipe cleaning and sand flushing integrated device. The device comprises a shunt nipple, a shunt packer, a double-layer pipe body, a pipe scraper and a sand flushing nipple which are mutually communicated and are each of a double-layer pipe structure; the pipe cleaning and sand flushing method comprises the steps that the pipe scraper is opened, the shunt packer is recovered, the device is placed down in an oil well casing, a well cleaning fluid is injected into casing annulus, and pipe cleaning and well cleaning are completed; after the sand surface position is determined, the pipe scraper is recovered, and the shunt packer is subjected to setting; a sand cleaning fluid is injected into the casing annulus, and the bottom of a well is flushed through positive pressure sand flushing or negative pressure sand flushing; finally, the shunt packer is upset, and pulling out of the hole is conducted. According to the oil well pipe cleaning and sand flushing integrated device, pipe cleaning and sand flushing operation can be achieved at a time, for formation leakage, both positive pressure sand flushing and negative pressure sand flushing can be conducted, the risk of sticking operation is reduced, the pipe cleaning and sand flushing operation efficiency is improved, the well-completion operation cycle is shortened, and the well-completion operation cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

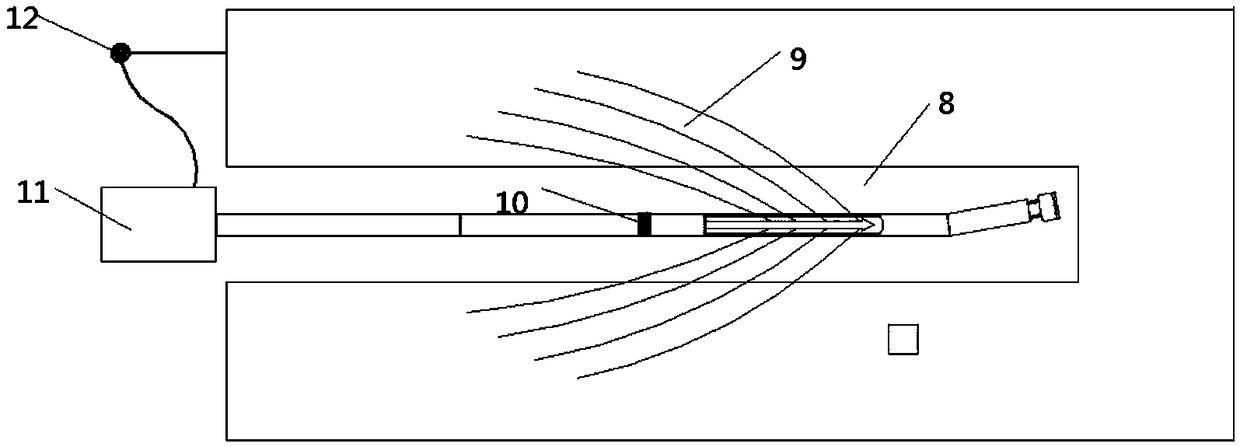

Composite oriented drilling equipment for coal mine underground complex stratum and application thereof

PendingCN108590529AStable trackingEasy to cleanSurveyConstructionsUltimate tensile strengthData transmission

The invention provides composite oriented drilling equipment for a coal mine underground complex stratum and application thereof. The composite oriented drilling equipment comprises a drilling tool, an oriented screw motor, a wireless electromagnetic wave while-drilling measuring system and a drill bit. The drill bit, the oriented screw motor, the wireless electromagnetic wave while-drilling measuring system, a normal drill stem and a water braid are connected in sequence in a screw-threading mode. Electromagnetic waves are used as a transmission medium, the depth of remote sensing is large, the transmission speed is high, the data transmission is reliable and effective, and adaptation to the underground drilling condition is high; the detected data in holes can be effectively transmittedby the normal drill stems and the stratum; compared with wired while-drilling measuring, the intensity of the drill stems is high, shearing strength and fatigue strength are better, manpower, materials and financial resources are saved; and the composite oriented drilling equipment for the coal mine underground complex stratum and the application thereof are a preferred mode and equipment for coalmine underground oriented drilling.

Owner:SHAANXI TAIHE TECH CO LTD

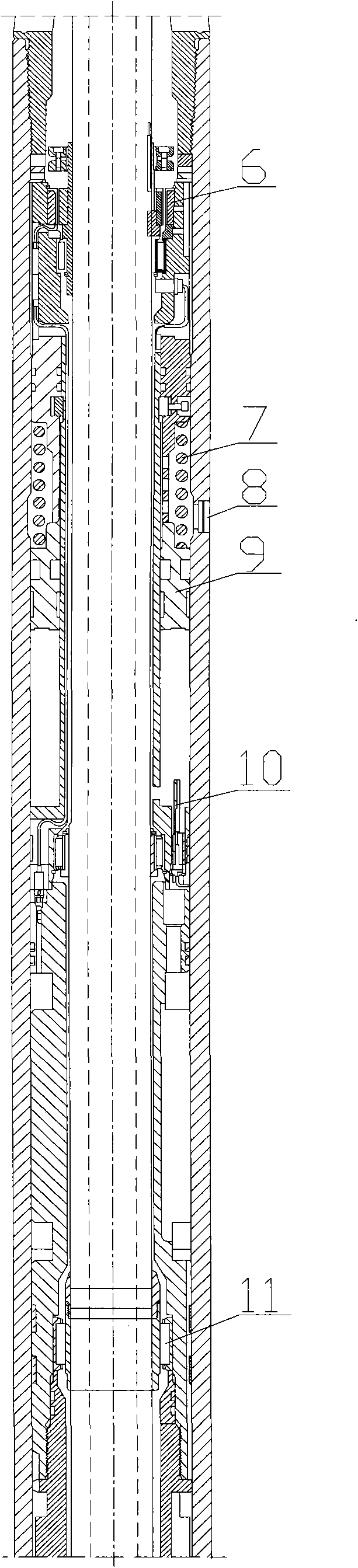

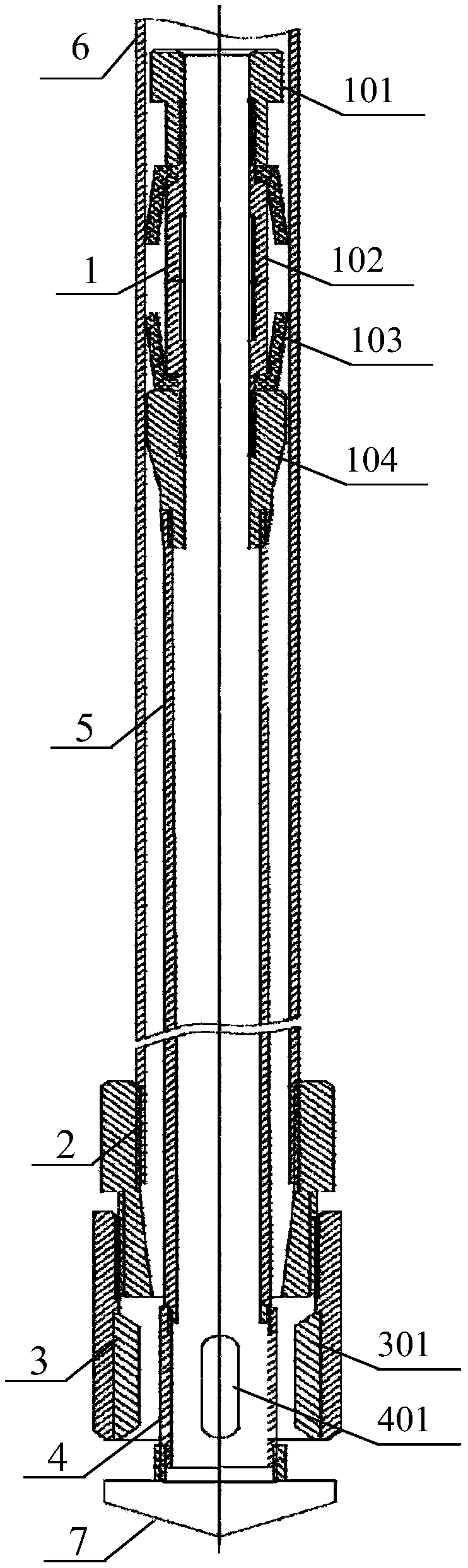

Stepless adjustable borehole trace control tool

InactiveCN102400644AShorten working timeReduced risk of stuck pipeDirectional drillingElectromagnetic clutchControl theory

The invention relates to a stepless adjustable borehole trace control tool and belongs to the technical field of design of an oil drilling tool. The stepless adjustable borehole trace control tool is characterized in that: an outer ring electromagnetic clutch (13), an outer ring harmonic transmission device (14), an eccentric mechanism (15), an inner ring harmonic transmission device (16), an inner ring electromagnetic clutch (17) and a lower end coupling (18) are sequentially arranged at the lower end of an upper end coupling (12); the installation positions of the inner ring harmonic transmission device (16), the inner ring electromagnetic clutch (17) and the lower end coupling (18) and the installation positions of the outer ring harmonic transmission device (14), the outer ring electromagnetic clutch (13) and the upper end coupling (12) are in full symmetry about the eccentric mechanism (15); and connection modes of the components are the same. By adoption of the stepless adjustable borehole trace control tool, adjustable control of a deflection angle can be realized, and stepless deflection in any direction in a circumference range of 360 DEG can be realized. The stepless adjustable borehole trace control tool has the characteristics of high trace control accuracy, high quality of a well bore, high purification capacity of a borehole and high displacement extension capacity.

Owner:YANGTZE UNIVERSITY

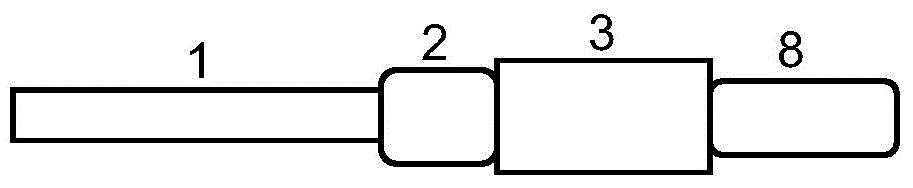

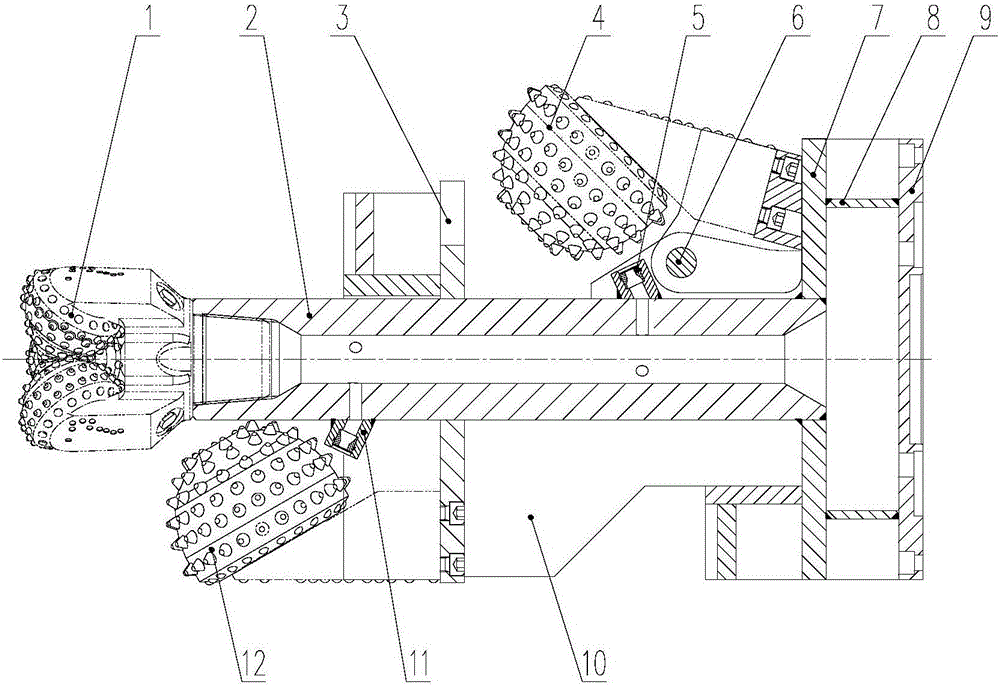

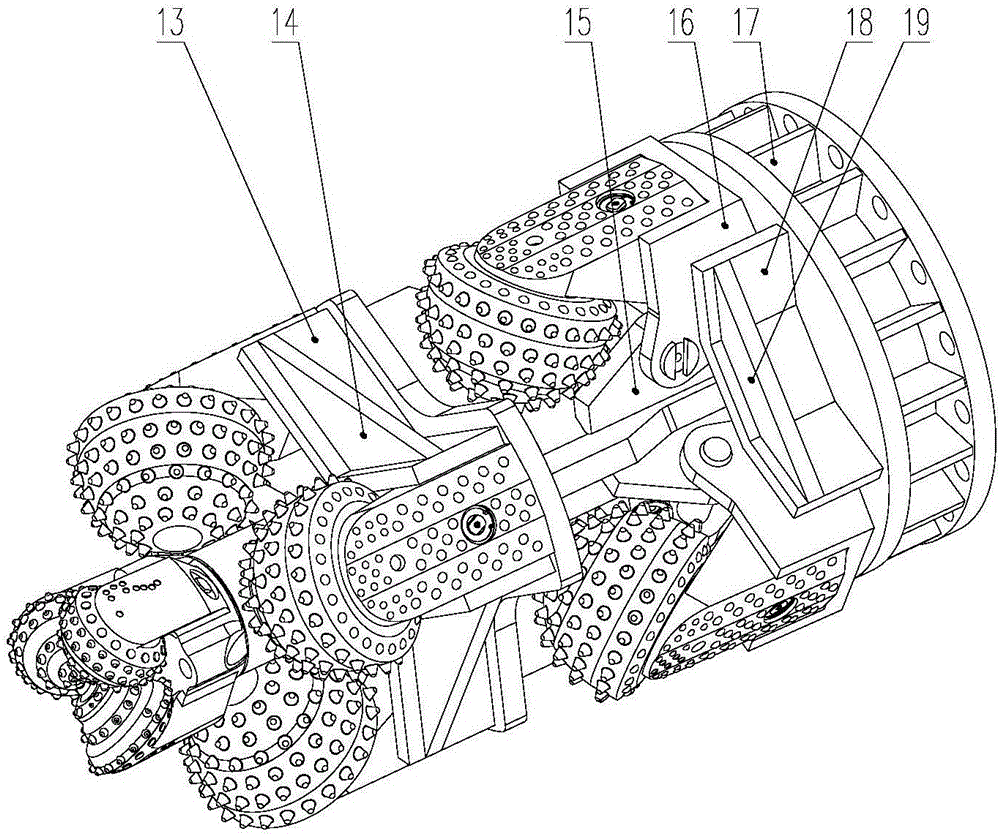

Two-way reamer

InactiveCN102587836AReduced risk of stuck pipeAvoid the problem of stuck drillDrill bitsDrive shaftEngineering

The invention relates to a two-way reamer, belonging to the technical field of special tools for horizontal directional drilling crossing engineering. The two-way reamer consists of a hollow transmission shaft, a roller bit and a centralizer, wherein one end of the hollow transmission shaft is a joint, and the other end of the hollow transmission shaft is provided with connecting threads; a baffle is welded in a central hole of the hollow transmission shaft; an installation base is welded on an outer pipe wall of the hollow transmission shaft corresponding to the baffle; a positive roller and a negative roller are welded on the installation base; and a through hole communicated with water holes of the positive roller and the negative roller and the central hole of the hollow transmission shaft is arranged on the installation seat. Due to the positive roller and the negative roller, the two-way reamer is controlled by a primary drilling machine and a secondary drilling machine respectively; when the hole cannot be extended in a positive direction, the hole can be extended in a negative direction by a secondary roller group; the hole can be extended for several times in a section in which the hole is difficult to form, therefore, the problem that the drilling machine is clamped during the negative hole extension is avoided, the construction difficulty is reduced, and the working efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

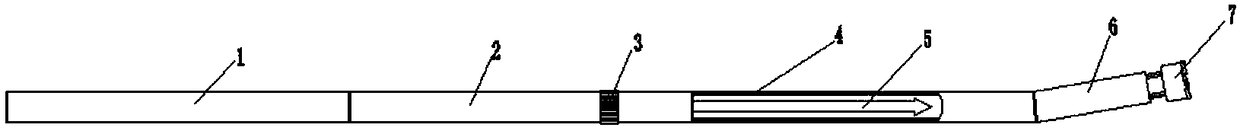

Coiled tubing drilling polishing horizontal section cement plug downhole tool combination and technology

InactiveCN104563936ADrilling and grinding meetIncrease displacement extensionSurveyCoiled tubingHigh pressure

The invention discloses a coiled tubing drilling polishing horizontal section cement plug downhole tool combination, comprising a coiled tubing, a coiled tubing connector, a plug detecting tool string or a drilling polishing tool string. When using the coiled tubing drilling polishing horizontal section cement plug downhole tool combination provided by the invention, the size of the tool string can be changed flexibly according to the size of the well, so as to meet the drilling polishing requirement of small well. Meanwhile, the tool combination can penetrate through the well section with large dogleg degree and steps and can be used for the drilling polishing of the cement plug with long horizontal section, therefore the application range is wider. The continuous drilling is realized, the drill blocking risk during the drilling polishing process is reduced effectively, and the working efficiency is improved. In addition, by utilizing the coiled tubing, the drilling polishing works of well with pressure, in particular to the well with higher pressure after being drilled can be implemented. The invention further discloses a coiled tubing drilling polishing horizontal section cement plug technology using the coiled tubing drilling polishing horizontal section cement plug downhole tool combination.

Owner:JEREH ENERGY SERVICES

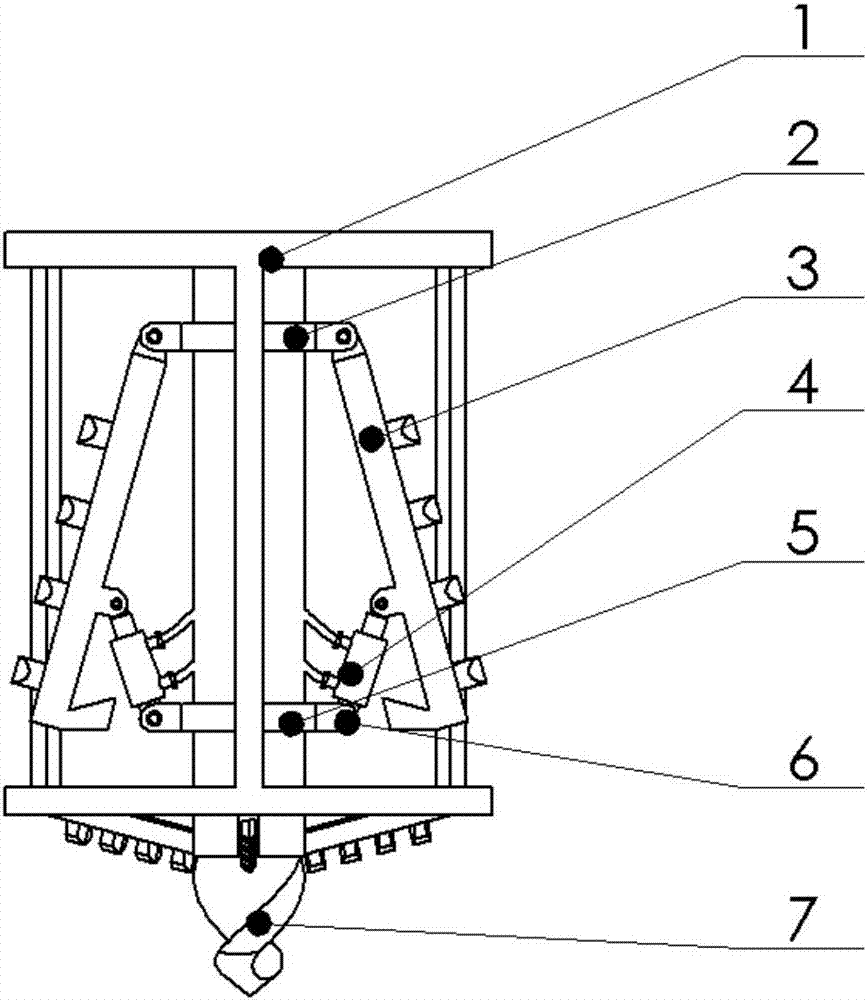

Drill bit device for variable diameter drilling and construction method

PendingCN107882510AReduce drilling resistanceReduced risk of stuck pipeDrill bitsServomotorsDrill bitPetroleum engineering

The invention belongs to drilling tools for pile foundation engineering, and relates to a drill bit for variable diameter drilling. The device is modified and optimized on the basis of a traditional drill bit. The device comprises a drill pipe, a movable knife row mounting base, a movable knife row, an oil cylinder, an oil cylinder mounting base, a pin, a spiral drill bit, the movable knife row isinstalled on the movable knife row base and tightened by the oil cylinder, and the size of opening of movable knife row blades can be controlled by controlling telescoping of the oil cylinder so as to achieve the variable diameter effect. Compared with the prior art, the drill bit has the advantages that drilling and hole expanding are conducted simultaneously, the hole collapse probability is effectively lowered, drilling resistance can be reduced, the drilling efficiency is high, the drilling sticking risk is reduced, and the drilling safety is guaranteed.

Owner:SHANGHAI CHENGDI CONSTR +1

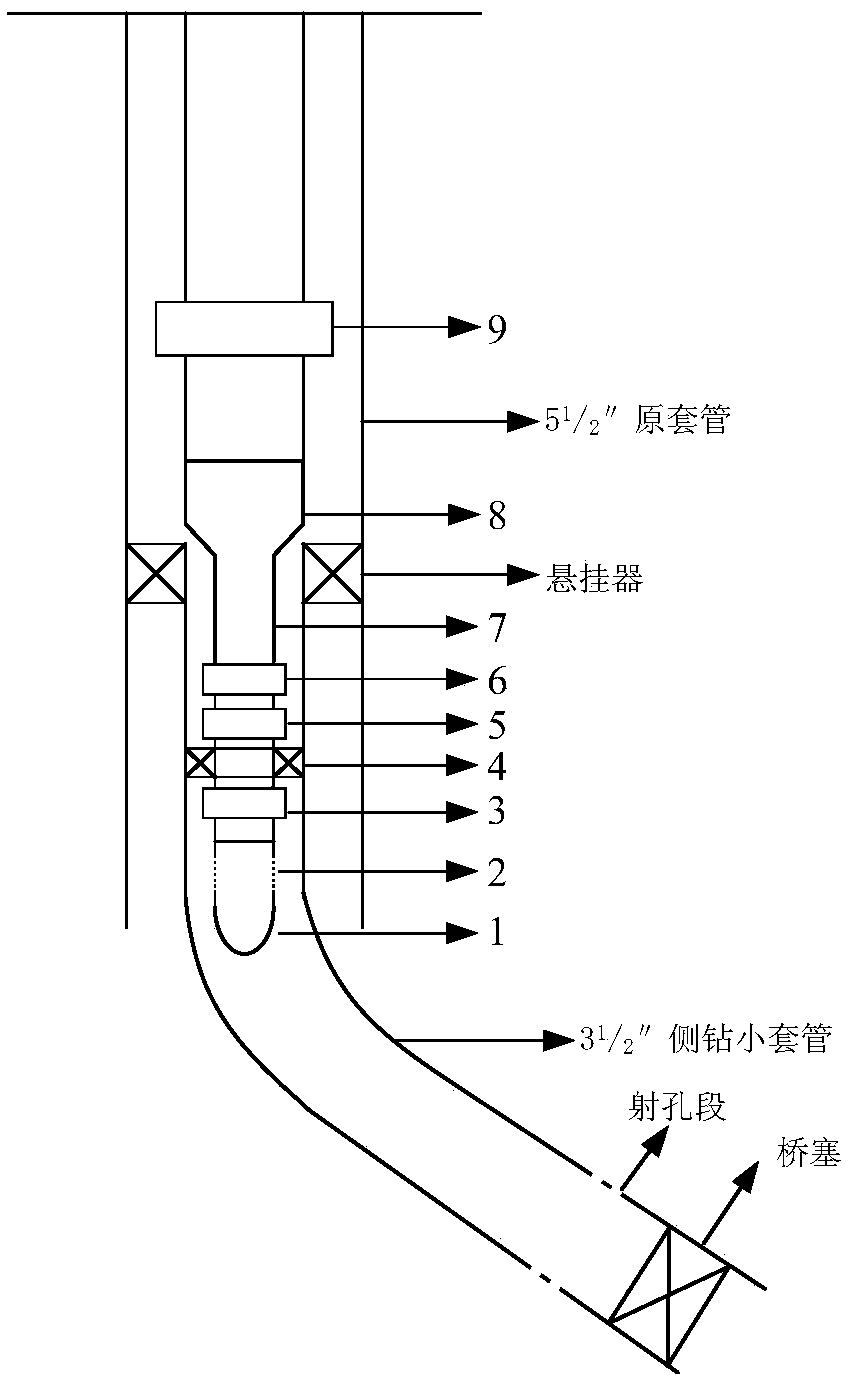

3.5-inch sidetracked slim hole sectioned fracturing pipe column

The invention discloses a 3.5-inch sidetracked slim hole sectioned fracturing pipe column. The 3.5-inch sidetracked slim hole sectioned fracturing pipe column comprises an oil tube, a strengthening nipple, a hydraulic anchor, a backwash valve, a packer, a setting ball seat, a sandblaster, a ball receiving basket, a 3.5-inch sidetracking small casing and an original casing. Windowing is conducted in the original casing for drilling a slim hole; then, the 3.5-inch sidetracking small casing is used for well cementing and completion; the strengthening nipple, the hydraulic anchor, the backwash valve, the packer, the setting ball seat, the sandblaster and the ball receiving basket are all located in the 3.5-inch sidetracking small casing, the oil tube, an adapter nipple and a safe releasing subare all located in the original casing, and the oil tube, the safe releasing sub, the adapter nipple, the strengthening nipple, the hydraulic anchor, the backwash valve, the packer, the setting ballseat, the sandblaster and the ball receiving basket communicate sequentially from top to bottom; and fire perforating and reperforating, fracturing, and plugging through sanding filling or through a run bridge plug are carried out sequentially in the 3.5-inch sidetracking small casing from bottom to top till fracturing of all layer sections is completed, wherein a perforated section is located below the ball receiving basket. Through the pipe column, sectioned fracturing can be achieved, and the drilling tool jamming risk is small.

Owner:PETROCHINA CO LTD

Horizontal well rapid water exploration method

The invention provides a horizontal well rapid water exploration method. A screwed plug is connected with a Y211 packer, the upper end of the Y211 packer is connected with a screen pipe, and the upper end of the screen pipe is connected with an oil pipe. The upper end of the oil pipe is connected with an oil-well pump. According to the golden section principle, horizontal well packer setting position layouts with different spraying point numbers are established, and the setting position of the Y211 packer is determined from the layouts. According to the water containing fluctuation judgment rules, the pumping and sucking results are diagnosed, the spraying point water breakthrough possibility of the upper end or the lower end of the Y211 packer is excluded, and the like, the suspected water breakthrough spraying point range is decreased step by step till the water breakthrough spraying points are determined finally. According to the horizontal well rapid water exploration method, through upward lifting and downward putting for setting and unsetting, airtightness is good; the pumping and sucking liquid quantity of every time is the liquid quantity of the spraying points of the upper portion of the packer, and the problem that in single-section testing, the low liquid quantity is large in water containing fluctuation and difficult in dereferencing is solved; a down-hole testing pipe string structure is simple, reliable in overall performance, low in cost and small in drilling jamming risk; and the diagnosis method is scientific and reasonable, section-by-section testing is not needed, the water exploration speed is high, the period is short, and the cost is low.

Owner:PETROCHINA CO LTD

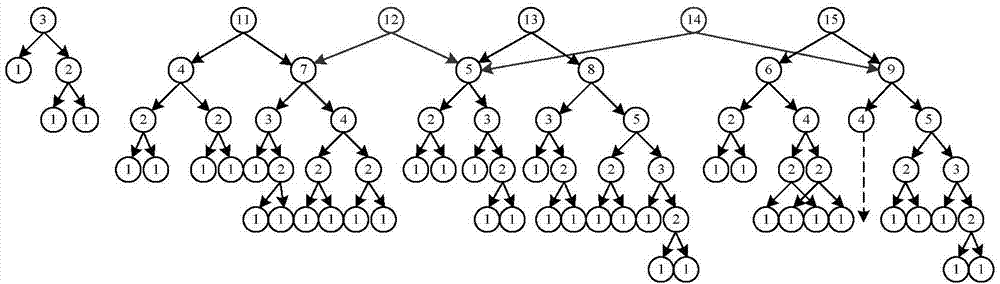

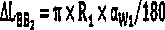

Method for determining medium-and-large-radius track of two-dimensional small-pre-target-displacement horizontal well

ActiveCN103993830AAdd counter-displacementIncrease drilling footageDirectional drillingTrue vertical depthWellhead

The invention relates to a method for determining a medium-and-large-radius track of a two-dimensional small-pre-target-displacement horizontal well. The method sequentially comprises the following steps that the position of a first target spot, the position of a second target spot and the position of a wellhead are determined, the displacement and the true vertical depth of the first target spot and the displacement and the true vertical depth of the second target spot are obtained, a third-part horizontal segment rail is determined, and the third horizontal segment track extends along a connecting line between the first target spot and the second target spot; a second-part angle-gain landing track is determined upwards with the first target spot as a terminal point, and the second-part angle-gain landing track comprises a first angle-gain circular-arc segment, an angle-holding linear segment and a second angle-gain circular-arc segment; a reverse angle-building track is determined with the wellhead as a starting point and the track midpoint as a terminal point, the reverse angle-building track comprises a plumb shaft segment, a reverse angle-building circular-arc segment, an angle-holding linear segment and an angle-dropping circular-arc segment, and the radius values of all the circular-arc segments range from 191 m to 286.5 m. According to the method for determining the medium-and-large-radius track of the two-dimensional small-pre-target-displacement horizontal well, the pre-target displacement is increased through reverse angle building, and the contradiction between the complex ground conditions and well location optimization of the horizontal well with the medium-and-large-radius track can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

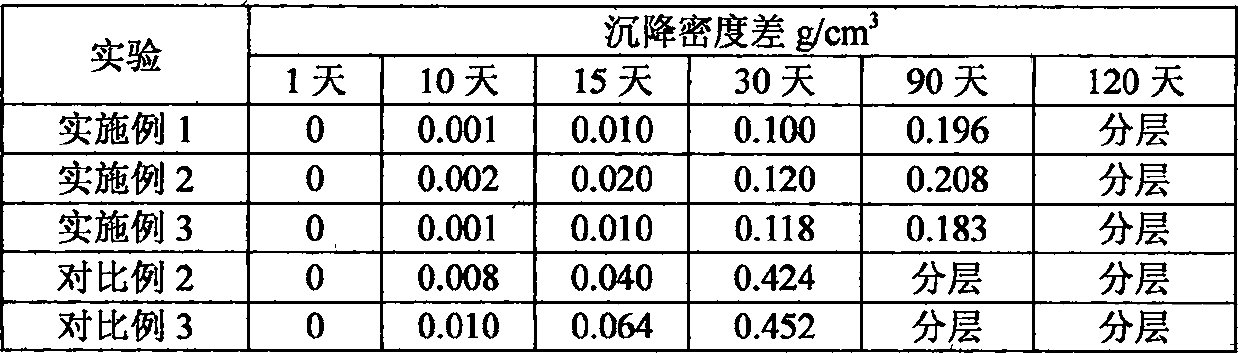

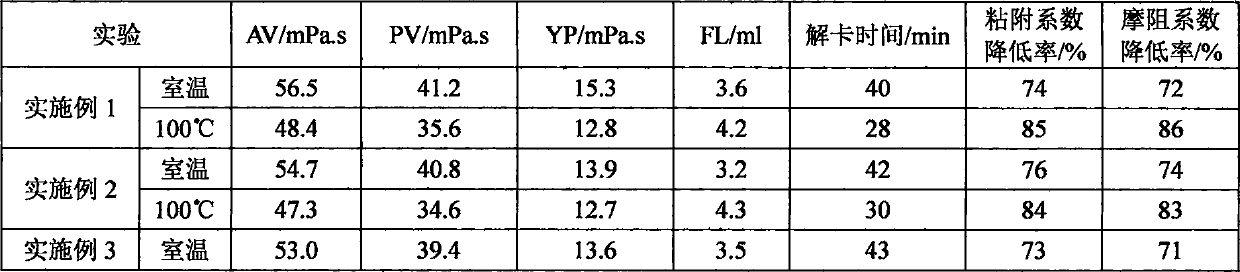

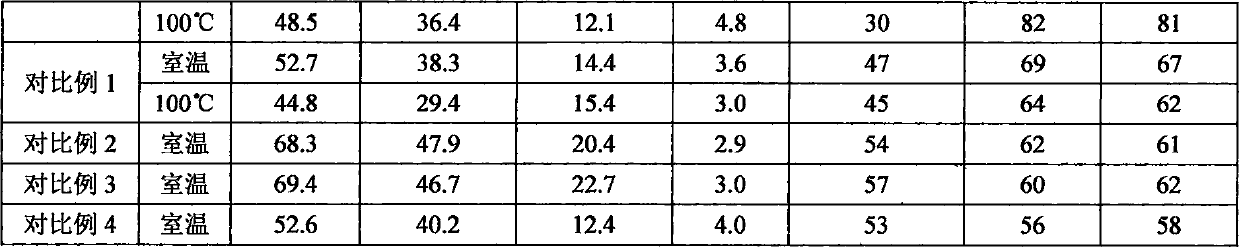

Oil-based lubricating anti-seize agent used in well drilling, and preparation method and applications thereof

InactiveCN107629767ALow surface tension propertiesImprove stabilityDrilling compositionWell drillingNanoparticle

The invention relates to an oil-based lubricating anti-seize agent used in well drilling, and a preparation method and applications thereof. The oil-based lubricating anti-seize agent used in well drilling is prepared from 80 to 100 parts of a base oil, 10 to 20 parts of low fluorescence sulfonated bitumen, 10 to 20 parts of sodium succinate, 10 to 15 parts of a lubricant, 3 to 5 parts of a wetting dispersant, 2 to 4 parts of a promoter, 3 to 6 parts of nanoparticles, and 4 to 6 parts of a formate via mixing and stirring at a certain sequence. Compared with conventional products, the oil-basedlubricating anti-seize agent possesses following advantages: the stability is high, the lubricating performance is excellent, seizing resolving speed is high, preparation is convenient, the oil-basedlubricating anti-seize agent is more suitable for anti-seize and seizing resolving under high temperature stratum, and is convenient for on-site construction.

Owner:NORTHWEST UNIV(CN)

Plugging agent for low-pressure leakage gas well, and preparation method and application method thereof

InactiveCN110041903AGood compatibilityReduced risk of stuck pipeDrilling compositionChemistryCalcium carbonate

The invention discloses a plugging agent for a low-pressure leakage gas well, and a preparation method and an application method thereof. The plugging agent is prepared through the following steps: 1)stirring 0.3-0.7wt% of guanidine gum dry powder and clear water for mixing to form a mixture, and stirring at a constant temperature for 45-60 min; 2) adding 2-5% of calcium carbonate powder of whichthe particle size is 1000-2000 meshes into formed guanidine gum liquid after mixing, and stirring at the constant temperature for 20-30 min; 3) adding 1-3% of a polyvinyl alcohol fiber of which the length is 6-10 mm and the diameter is 20 Am into mixed liquid, and stirring at the constant temperature for 20-30 min; 4) adding 0.3-0.5% of an expanded particle of which the particle size is 1-3 mm into the mixed liquid, and stirring at the constant temperature for 1-3 min; 5) adding 0.3-0.5% of an expanded particle of which the particle size is 0.025-0.425 mm into the mixed liquid, and stirring at the constant temperature for 1-3 min to obtain the plugging agent for the low-pressure leakage gas well. The plugging agent can be directly used for the well repairing and leaking stoppage construction of the leakage gas well, and technical support is provided for a well repairing field well control operation; in addition, the plugging agent is simple in plug removal measure, and plug removal can be carried out through the injection of a plugging remover.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

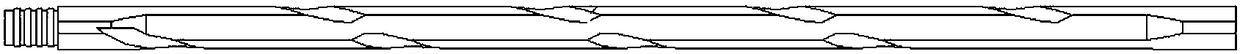

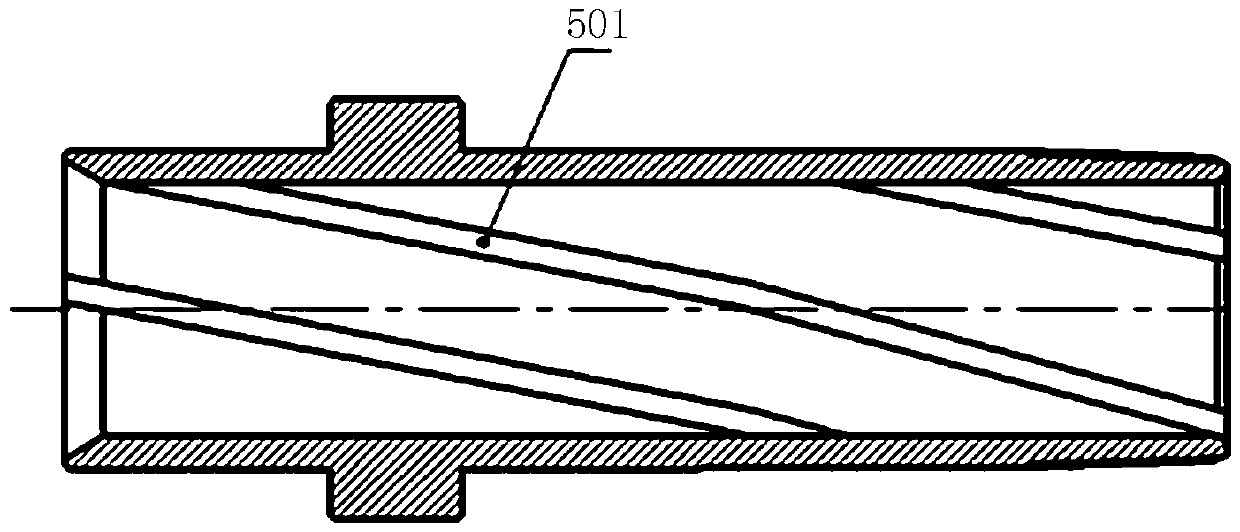

Bidirectional screw-type while-drilling well wall shaper

ActiveCN109403885ANo increase in drilling operation timeReduce wearDrill bitsDrilling rodsSpiral bladeWell drilling

The invention discloses a bidirectional screw-type while-drilling well wall shaper. The bidirectional screw-type while-drilling well wall shaper comprises a shaper body and further comprises a femalethread and a male thread which are arranged at the two ends of the shaper body correspondingly, at least three sets of spiral bodies are arranged on the shaper body at intervals, spiral structureson the positions, close to the two ends of the shaper body correspondingly, of the two sets of spiral bodiesin the at least three sets of spiral bodies are arranged in reverse, each set of spiral bodies is composed of at least three spiral bladeswhich are distributed in parallel and have spiral angles of 10 to 45 degrees with the center line of the shaper body, the outer diameters of one of the spiralblades on the corresponding set of the spiral bodies are larger than those of other spiral blades on the corresponding set of the spiral bodies to show the eccentric structures, and diameter retaining teeth and cutting teeth are arranged at the centers of the tops of the spiral blades and the edges of the tops of one sides of the spiral blades, at the eccentric positions, on the spiral bodies atintervals correspondingly. According to the bidirectional screw-type while-drilling well wall shaper, while-drilling downwards can be achieved, a well wall is shaped while drilling operation is conducted, the drilling operation time is not increased, and the well wall can be shaped once again when back reaming is conducted.

Owner:深圳越海工程技术有限公司

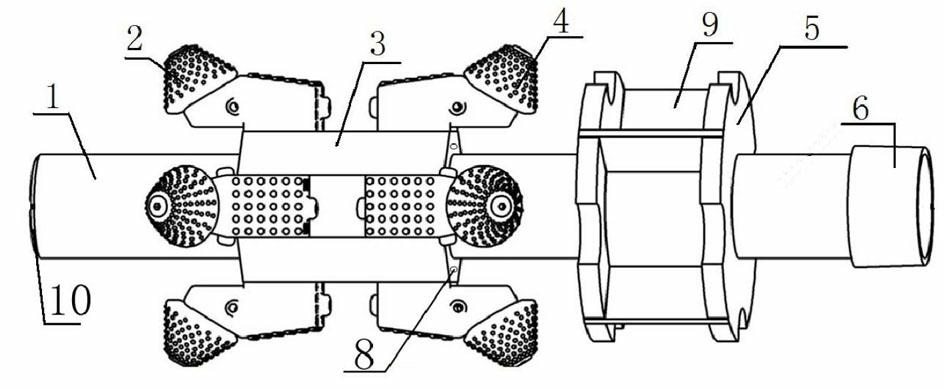

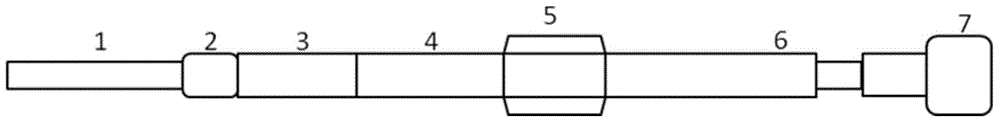

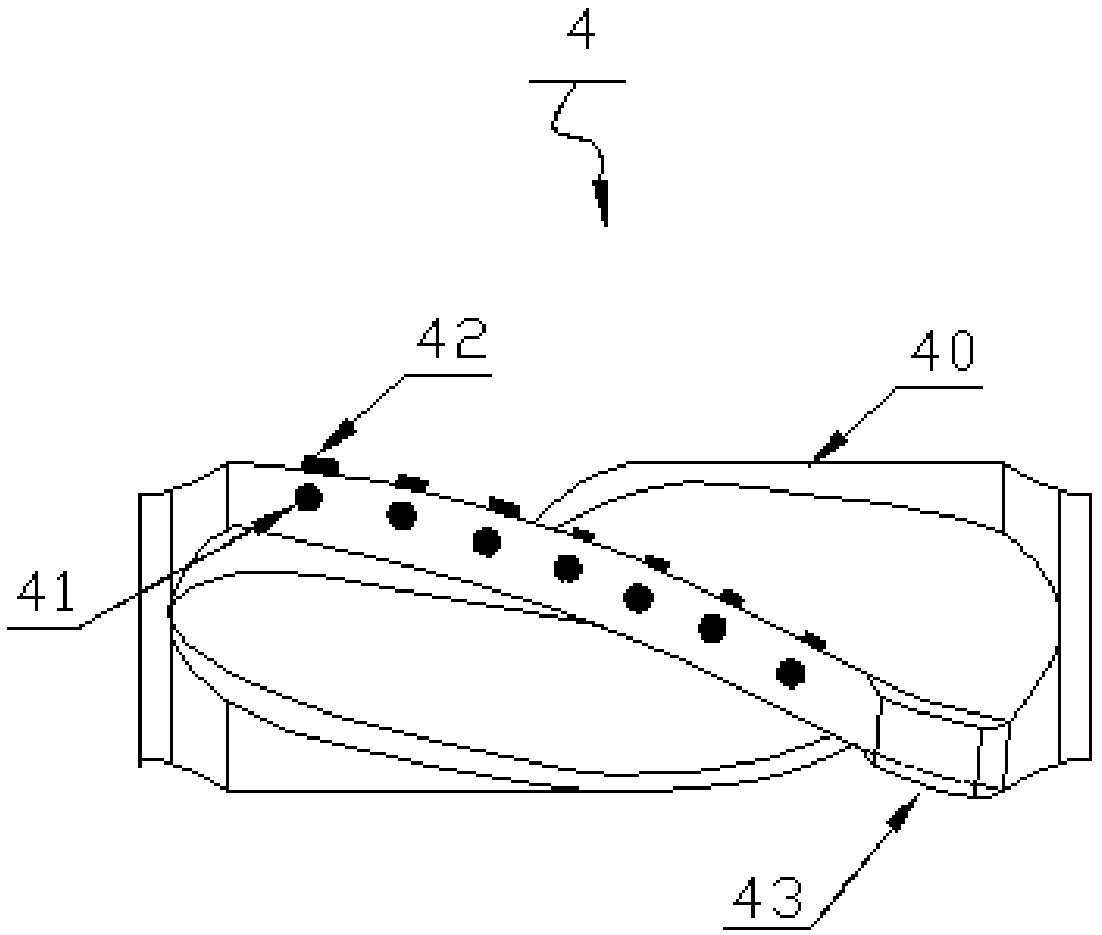

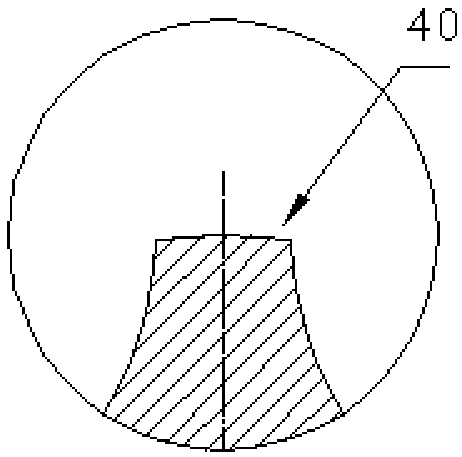

Reducing reamer

ActiveCN105781423AReduced risk of stuck pipeExtended service lifeDrill bitsAgricultural engineeringReamer

The invention discloses a reducing reamer which comprises a reamer body, a tricone bit, a fixed cone and a turnover cone, wherein the tricone bit is connected with the front end of the reamer body; the fixed cone is arranged at the middle part of the reamer body through a connecting seat plate; the turnover cone is arranged at the tail part of the reamer body through a seat plate; the tail end of the turnover cone is fixedly connected with a turning plate; the turning plate extends to form downward wing plates corresponding to the two sides of the turnover cone; the two wing plates are separately in hinge joint with fixing plates arranged on the two sides of the turnover cone in advance; a positioning plate is arranged on the seat plate corresponding to the turning plate of the turnover cone; and a connecting disc is arranged on one side of the seat plate corresponding to the tail part of the reamer body. In the invention, during pipeline crossing with complex formation and limited construction site, the turnover cone in reaming drilling rotates around the hinge pin of the turning plate under the effect of rock-soil resistance in the advancing direction, and the cutting diameter is increased; and for retreating, the turnover cone rotates to the initial position under the frictional resistance of the hole wall rock and soil, the diameter of the reducing reamer is reduced, and thus the risk of tool sticking in the retreating process is lowered.

Owner:河北华元科工股份有限公司

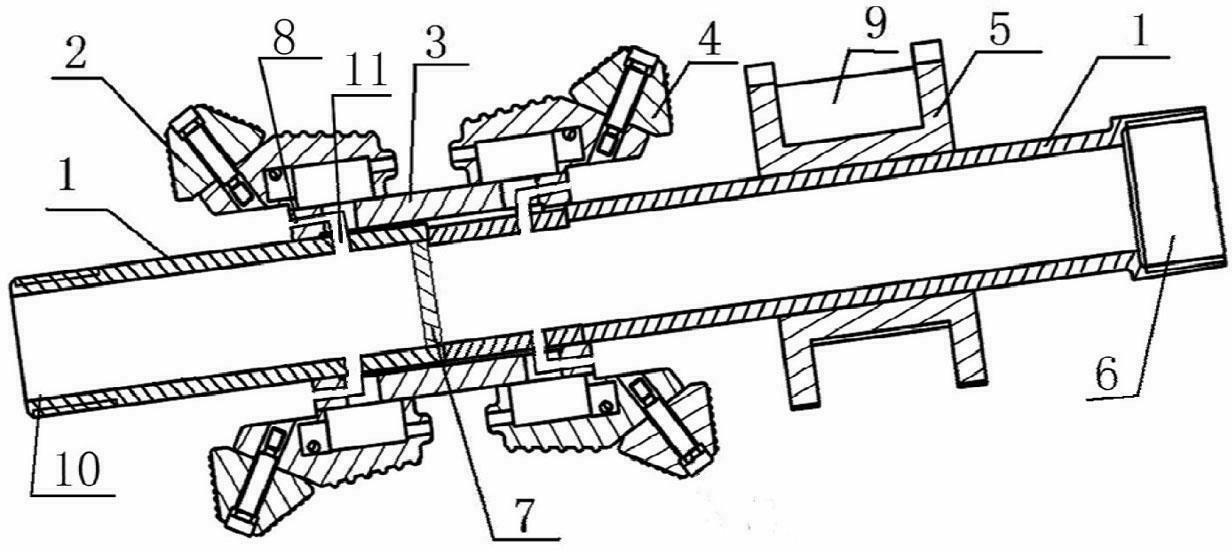

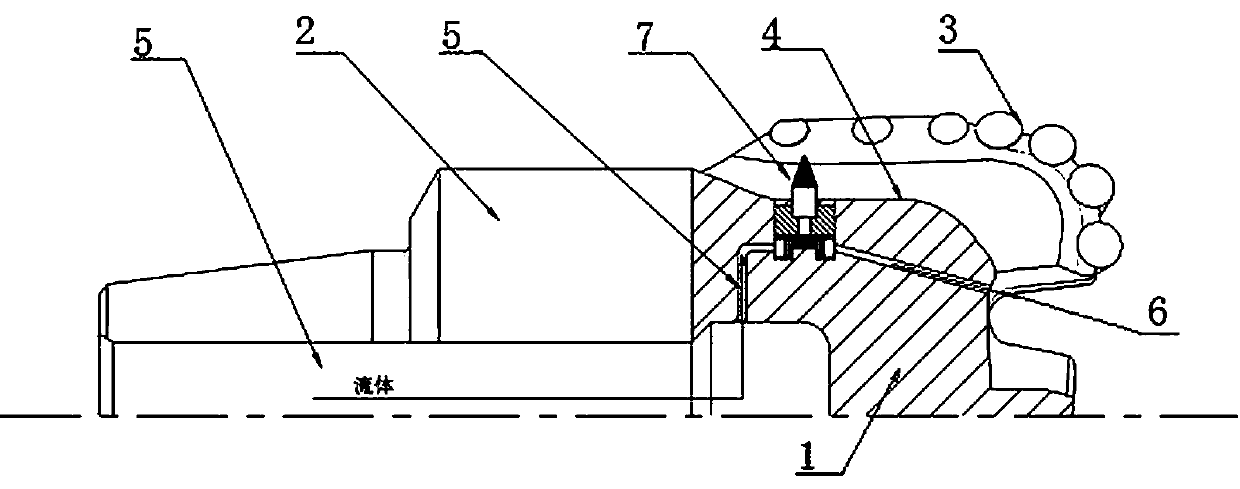

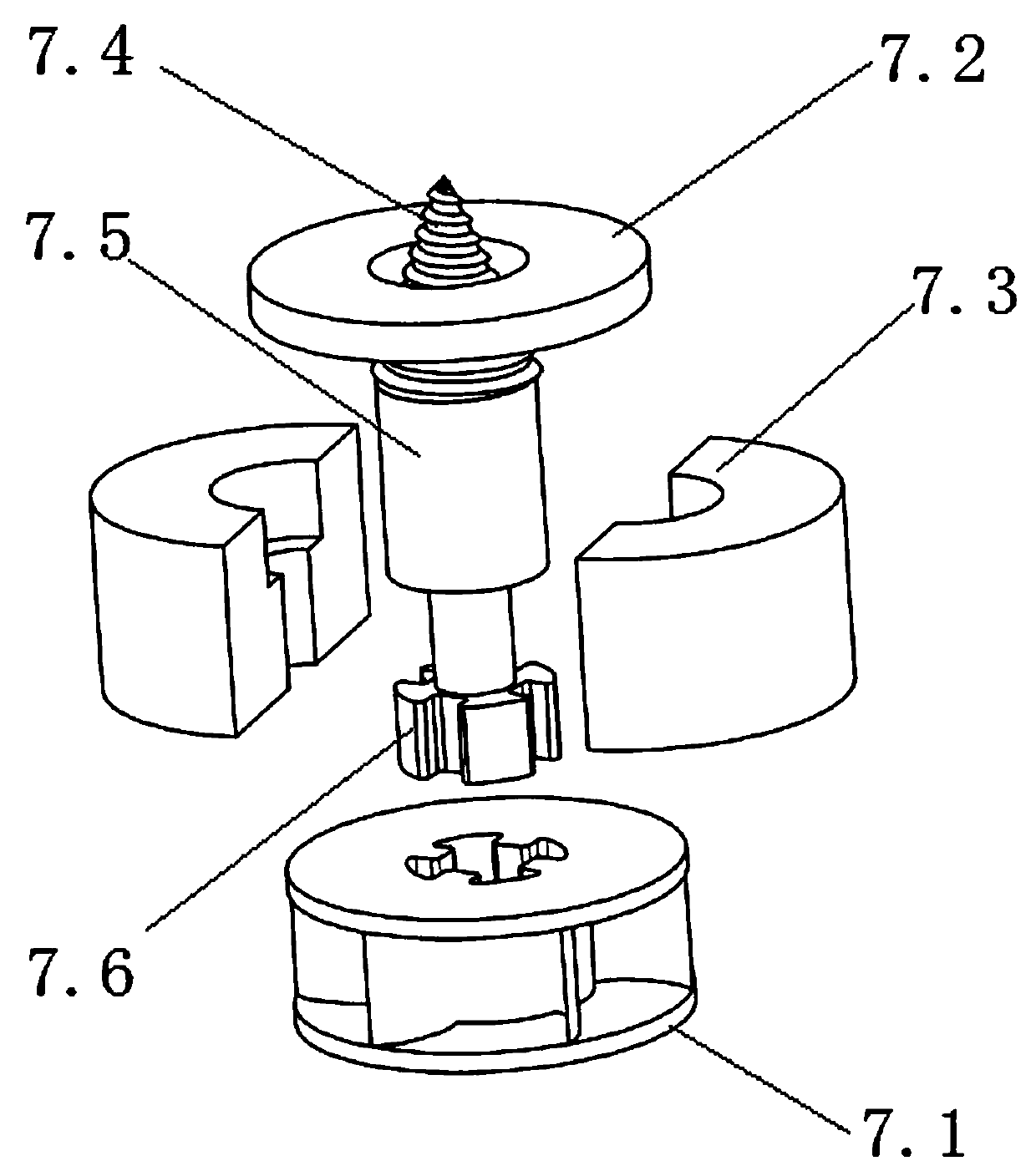

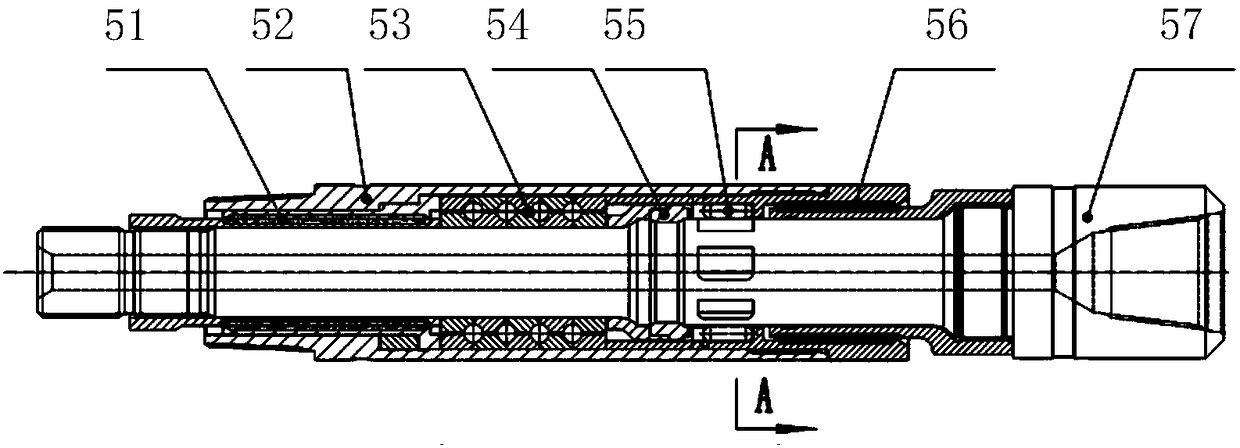

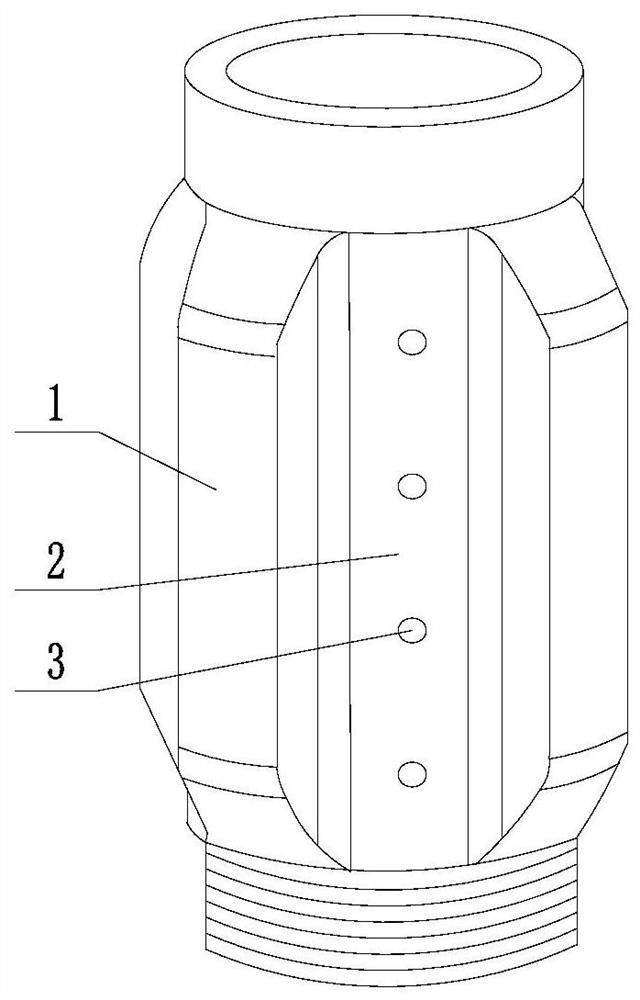

A pulsating two-way impactor

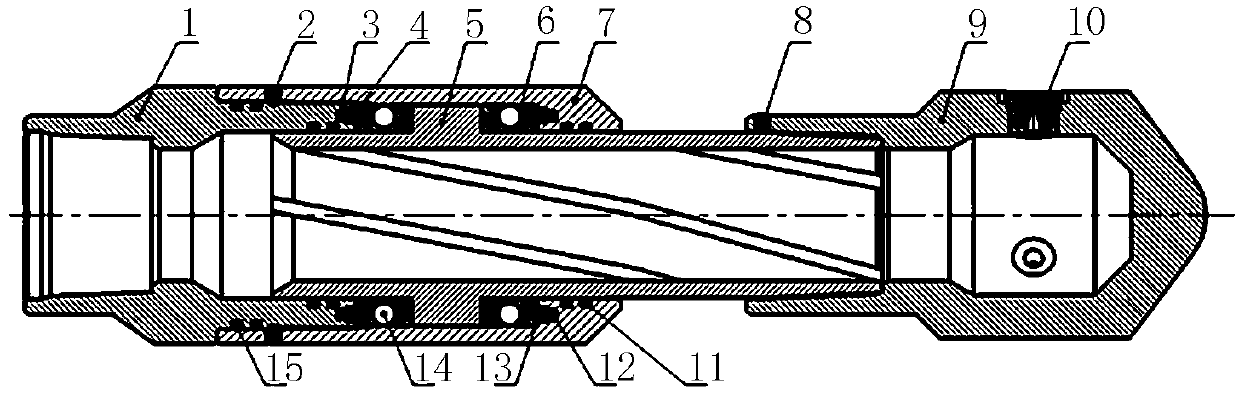

ActiveCN105525868BHigh cutting forceIncrease instantaneous cutting forceBorehole drivesDifferential stickingSleeve valve

The invention discloses a pulsating two-way impactor. The pulsating two-way impactor comprises a shell power mechanism and an impact mechanism, wherein the impact mechanism includes a coupling, a central shaft, a spring, a sliding sleeve and an impact valve, and the central shaft There is a radial bypass hole connected with the upper and lower annular grooves built in the housing. The lower part of the central shaft forms an axial sliding fit connection with the impact valve through a spline group. The impact valve and the spring above it are arranged in the lower annular groove of the housing. Inside, the sliding sleeve is arranged on the impact valve, and the lower end of the impact valve forms an impact fit with the inner convex edge of the lower annular groove of the housing. The pulsating two-way impactor can simultaneously produce the dual effects of axial impact and torsional impact. The combination of axial impact and torsional impact can not only induce axial vibration of the drill string, reduce frictional resistance during sliding drilling, reduce the risk of drill sticking due to differential pressure, and increase The pressure on bit can weaken the impact of decompression, and can increase the instantaneous cutting force of the drill bit to prevent stick-slip vibration. It also has the advantages of simple structure, convenient operation, convenient installation, safety and reliability.

Owner:CHINA PETROCHEMICAL CORP +1

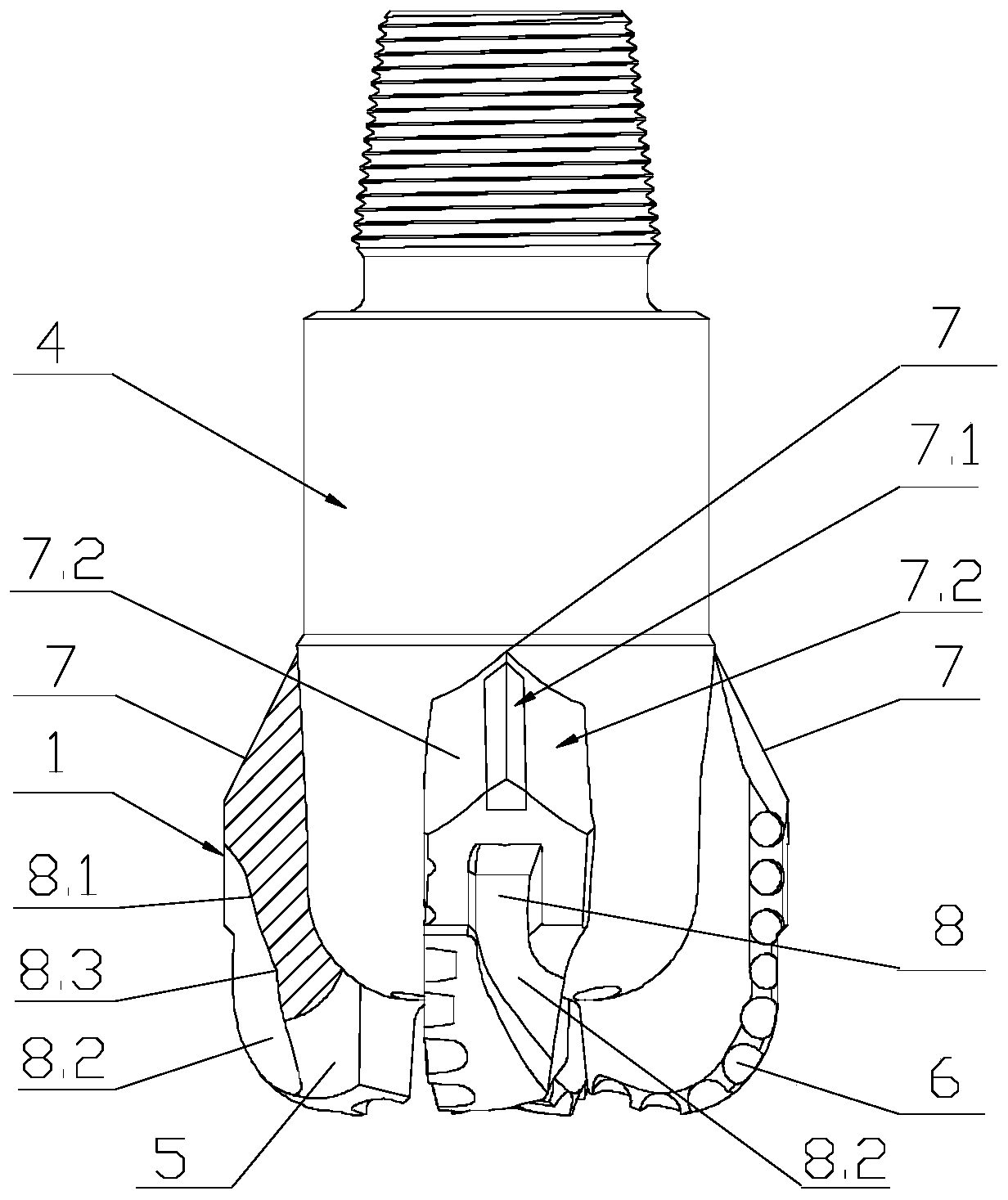

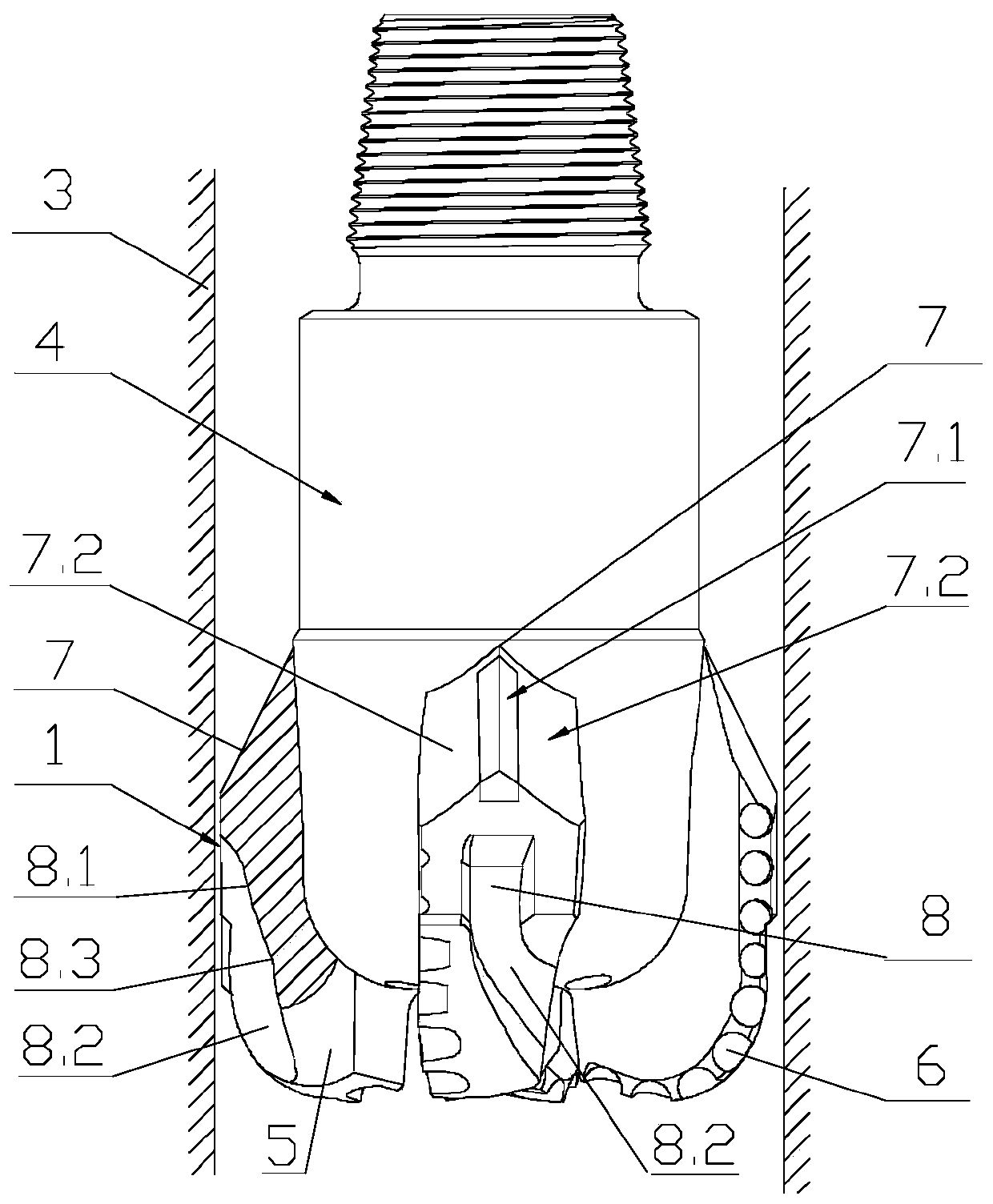

Active anti-sticking PDC drill bit with rotary rock breaking device

ActiveCN111395970AReduced risk of stuck pipeSave design spaceDrill bitsConstructionsTool bitImpeller

The invention relates to the technical field of rock drilling PDC drill bits, in particular to an active anti-sticking PDC drill bit with a rotary rock breaking device. The active anti-sticking PDC drill bit comprises a drill bit body with a cutter head, wherein a plurality of drill bit blades are arranged on the cutter head; an outer flowing channel on the side edge of the cutter head is formed among the drill bit blades; a communicating inner flowing channel for fluid to pass through is arranged in the cutter head and the drill bit body; the fluid flows into the inner flowing channel from the tail end of the drill bit body, passes through the drill bit body and the cutter head, and then flows out from an outlet at the front end of the cutter head; the rotary rock breaking device is arranged in the outer flowing channel of the cutter head; the rotary rock breaking device comprises an impeller and a rotating part; the impeller is arranged in the inner flowing channel of the cutter head; the rotating part penetrates through the side edge of the cutter head; the tail of the rotating part is inserted into the impeller; the head of the rotating part is exposed out of the outer flowingchannel; and the rotating part is driven to rotate by the impeller when the fluid flows through the inner flowing channel of the cutter head.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Sand washing method and special tool

ActiveCN106368630BAchieving an annulus sealMeet construction requirementsFlushingSealing/packingEngineeringWater well

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for quickly finding water in horizontal wells

Owner:PETROCHINA CO LTD

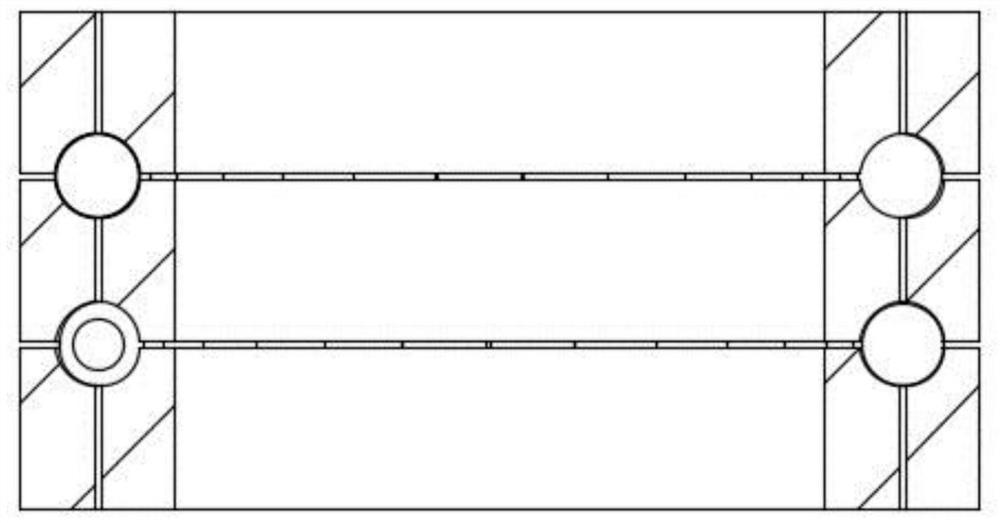

Method and special tool for sand flushing

ActiveCN106368630AAchieving an annulus sealMeet construction requirementsFlushingSealing/packingEngineeringWater well

The invention relates to a method and special tool for sand flushing, and belongs to the technical field of well repairing work. The method and special tool for sand flushing are suitable for sand flushing construction of a pitshaft of an oil-gas well. The special tool for sand flushing comprises an outer pipe and a sand flushing inner pipe. The outer pipe is formed by sequentially connecting an oil pipe, a suspension pup joint and a rotary outer cylinder in a threaded mode. The sand flushing inner pipe is formed by sequentially connecting a sealing pup joint, a flushing pipe, a rotary inner cylinder and a drill bit in a threaded mode. According to the method and special tool for sand flushing, the annular space between the flushing pipe and the outer pipe is sealed through the sealing pup joint, a sand flushing fluid circulating channel between the outer pipe and the sand flushing inner pipe is established, and direct-circulating and reverse-circulating sand flushing construction in the sliding state of the flushing pipe is achieved; and rotating power for matching between the outer pipe and the ground is transmitted through the rotary inner cylinder and the rotary outer cylinder, the sand flushing drill bit is driven to rotate, and thus the rotary-drilling sand flushing construction requirement under a complex well condition is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

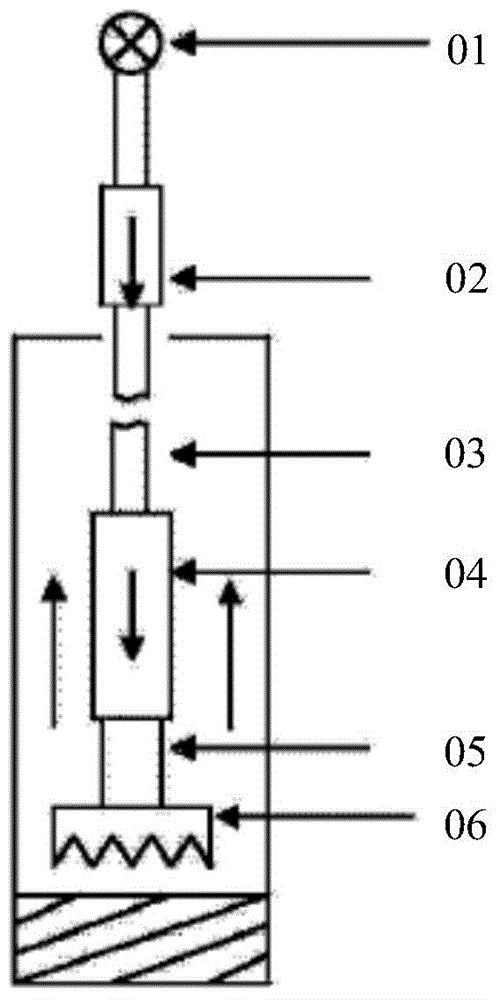

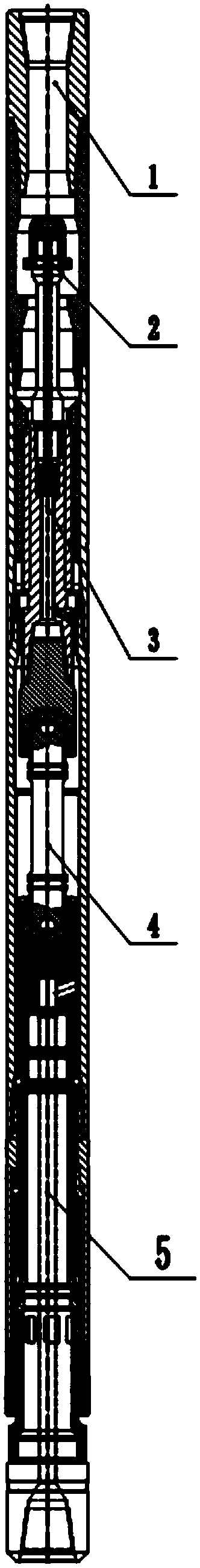

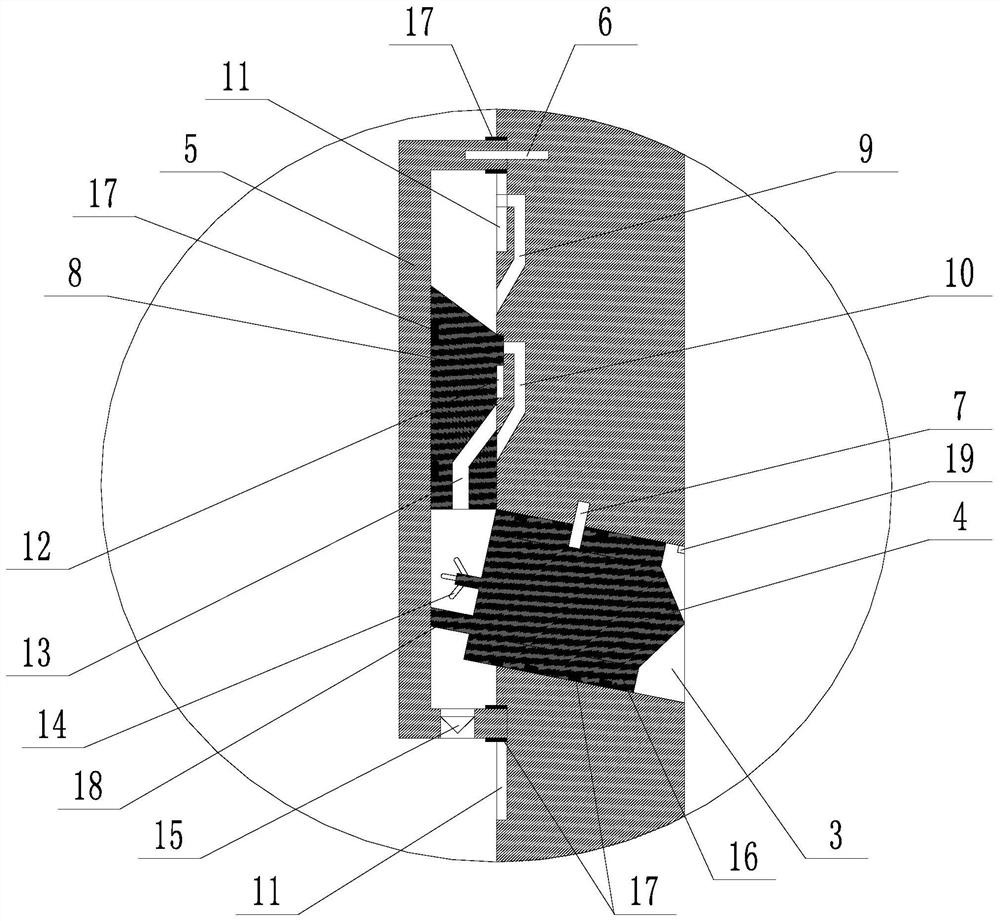

Transmission shaft overturning prevention positive displacement motor with overload protection

The invention relates to the technical field of positive displacement motors, in particular to a transmission shaft overturning prevention positive displacement motor with overload protection. The positive displacement motor comprises a bypass valve assembly, an anti-falling assembly, an overload protection motor assembly, a universal shaft assembly and an anti-overturning transmission shaft assembly which are connected in sequence. The overload protection motor assembly comprises a stator, a hollow rotor and a high-pressure one-way overflow valve, the hollow rotor is assembled into the stator, and the high-pressure one-way overflow valve is installed inside the hollow rotor; the anti-overturning transmission shaft assembly comprises an upper radial bearing set, a transmission shaft shell,a thrust bearing set, a transmission shaft anti-falling mechanism, a transmission shaft anti-overturning mechanism, a lower radial bearing set and a transmission shaft. By adopting the one-way high-pressure overflow valve structure, the transmission mechanism of the positive displacement motor is safer and more reliable; by adopting the anti-overturning transmission shaft assembly, the phenomenonthat the transmission shaft overturns relative to the body due to the fact that rotation of a drill bit is clamped in the using process of the positive displacement motor is avoided, and therefore the risk caused by clamping of bricks is lowered.

Owner:TIANJIN LILIN GASOLINEEUM MACHINERY

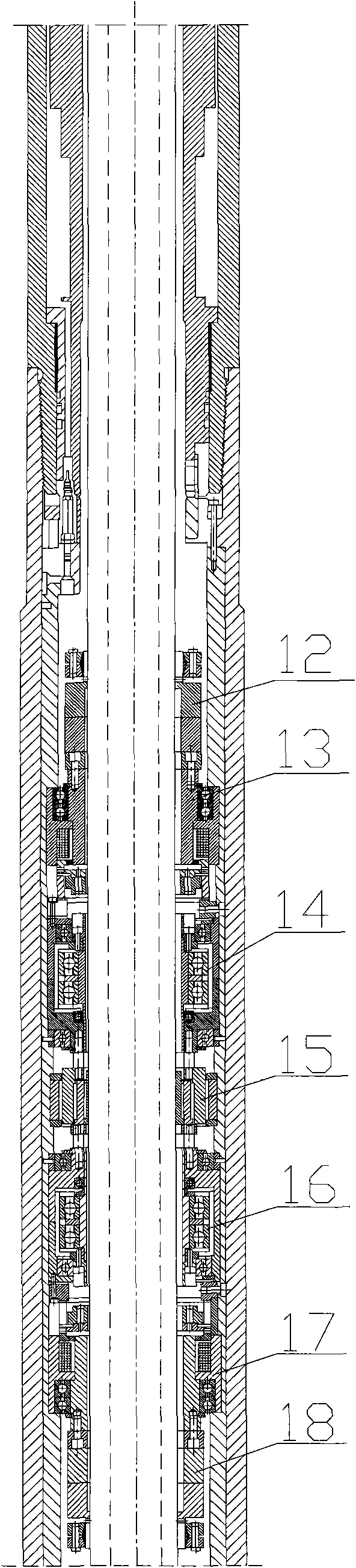

Controller for realizing full-rotation composite orientation of drill string

PendingCN114109250AReduced risk of stuck pipeGood for borehole cleaningDrilling rodsDirectional drillingPhysicsClutch

The invention relates to a controller for realizing full-rotation composite orientation of a drill stem, which comprises an upper joint, an upper cylinder, an upper TC bearing sealing retainer ring, an upper TC bearing moving component, an upper string bearing, an upper string bearing inner retainer ring, an upper string bearing outer retainer ring, a sealing ring, a control screw, a clutch shell, a reset spring A, a clutch conversion cylinder, a spline shell, a spline sleeve, a mandrel and a reset spring B, the lower TC bearing moving assembly comprises a lower TC bearing inner retainer ring, a lower string bearing, a lower TC bearing moving assembly and a lower end cover. A circumferential sliding groove is formed in the outer wall of the upper end of the clutch conversion cylinder, and the control screw is matched with the sliding groove of the clutch conversion cylinder to control the clutch state and the clutch state of the clutch conversion cylinder. When the clutch conversion cylinder is in a closed state, the clutch conversion cylinder is matched with the spline housing, the drilling tool conducts composite drilling, when the clutch conversion cylinder is in a separated state, the clutch conversion cylinder is matched with the spline housing in a separated mode, and the drilling tool conducts sliding drilling.

Owner:SOUTHWEST PETROLEUM UNIV +1

Anti-drill-sticking PDC drill bit

The invention provides an anti-drill-sticking PDC drill bit, and belongs to a rotary-drilling drill bit structure for petroleum and geology. The anti-drill-sticking PDC drill bit includes a drill bitbody and a joint, wherein the drill bit body includes blades and a gauge, and PDC teeth are brazed to the blades. According to the key technology points, a ridge-shaped slope is arranged on the frontend surface of the gauge, a debris discharging groove is formed in a gauge body, and a small platform is arranged between the debris discharging groove and the ridge-shaped slope. The anti-drill-sticking PDC drill bit has the beneficial effects that the ridge-shaped slope structure on the front end surface of the gauge can push a large amount of falling blocks and rock debris to the two sides of the gauge and discharge the falling blocks and the rock debris to free space between the blades, and the risk of drill sticking is greatly reduced; and the gauge body is provided with the debris discharging groove structure with a one-way outlet, when the falling blocks and the rock debris are stacked and squeezed in the debris discharging groove, the open slope structure enables the falling blocksand the rock debris to be discharged to a deeper opening position along with the slope under the action of squeezing force and enter the free space between the blades of the drill bit, and the drillsticking caused by accumulation of the rock debris and the falling blocks on the surface of the gauge is further avoided.

Owner:四川川石金刚石钻头有限公司

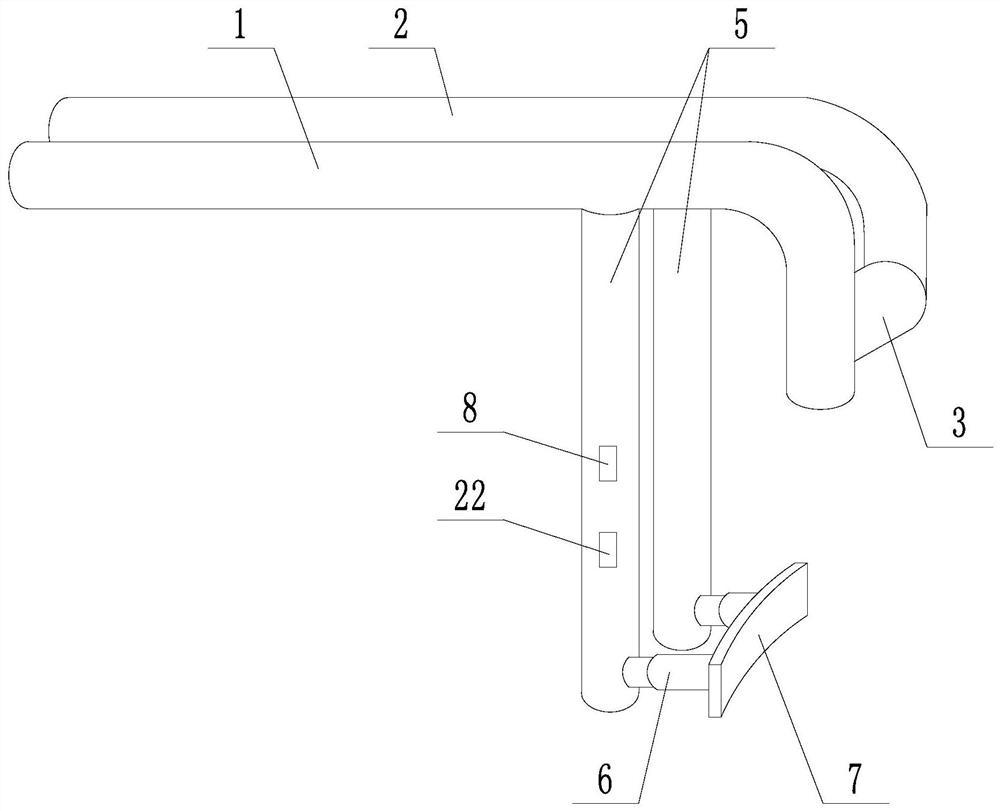

Casing running auxiliary tool for petroleum drilling

InactiveCN112554796ARealize self-circulationOvercome timeSealing/packingDrilling machines and methodsMining engineeringWell drilling

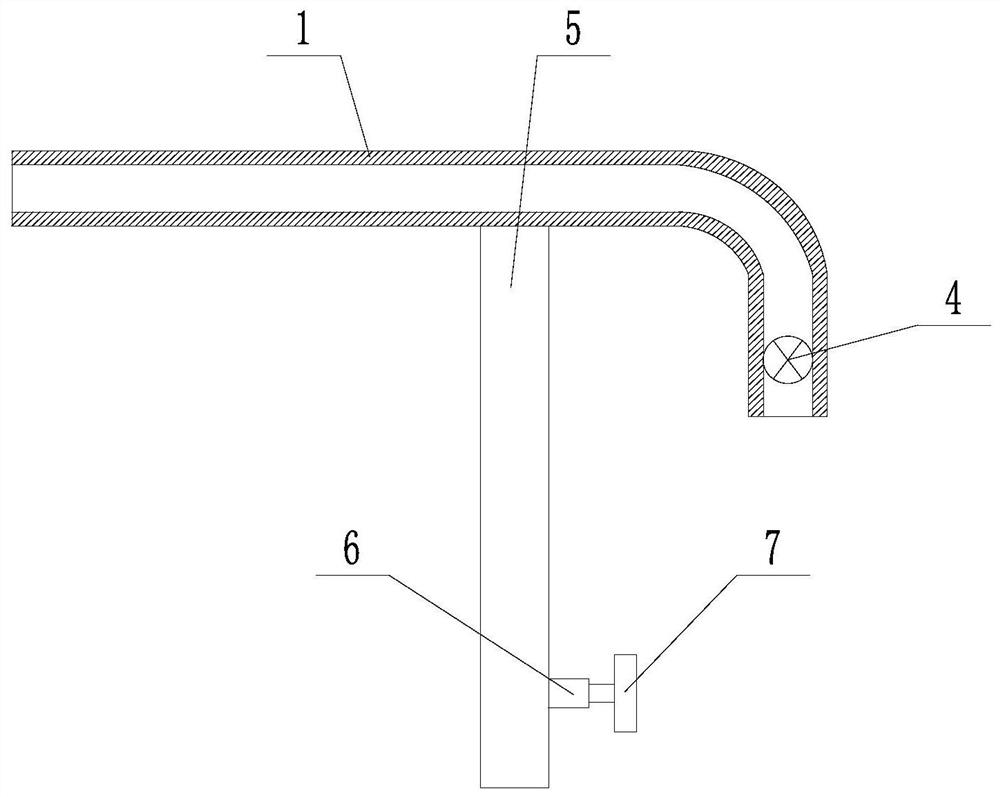

The invention discloses a casing running auxiliary tool for petroleum drilling. The casing running auxiliary tool comprises an L-shaped grouting pipe and a return pipe; the grouting pipe is in communication with the short edge of the return pipe through a bypass pipe, a reversing valve is arranged at the joint of the bypass pipe and the grouting pipe, the end of the short edge of the grouting pipeis open, and the end of the short edge of the return pipe is closed; and the casing running auxiliary tool further comprises a water feeding system used for pumping fluid into the grouting pipe. According to the casing running auxiliary tool for petroleum drilling, the problems that in the prior art, a direct grouting mode does not make full use of a time window of continuous operation, and meanwhile a wellhead of a drill floor is prone to being polluted are solved; and the purposes that interval windows are fully used for grouting in the continuous casing running operation process, static slurry supplementing frequency is reduced, and the wellhead of the drill floor is prevented from being polluted can be achieved.

Owner:熊勇

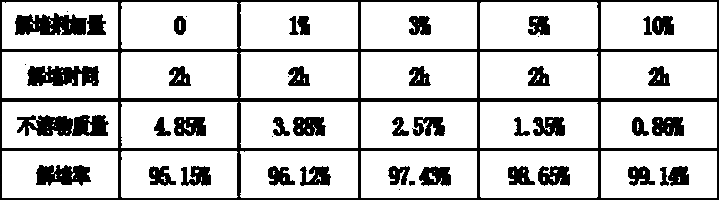

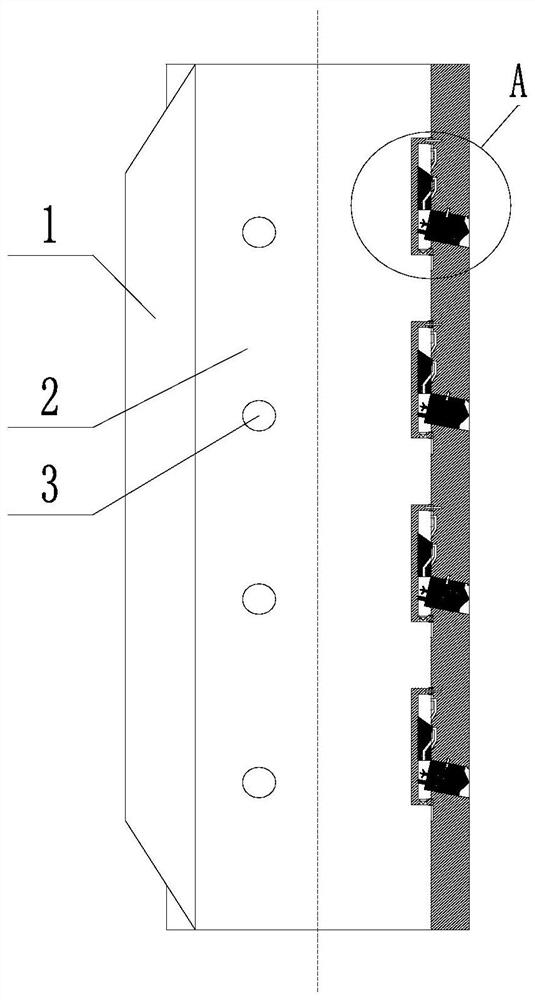

A rotary hydraulic jet cutting casing tool and its construction method

ActiveCN110552646BImprove cutting efficiencyEasy to flow backBorehole/well accessoriesUpper jointWell cementing

The invention relates to a rotary type hydraulic jet cutting sleeve tool and a construction method thereof. The rotary type hydraulic jet cutting sleeve tool comprises an upper joint (1), a rotary sleeve (5), an outer sleeve (7) and a rotary head (9); one end of the upper joint (1) is connected with an oil pipe (18), the other end of the upper joint (1) is sleeved with the rotary sleeve (5) and inserted into the outer sleeve (7), the rotary sleeve (5) penetrates through the outer sleeve (7) and is inserted into the rotary head (9), the rotary sleeve (5) is connected with the outer sleeve (7) through a bearing, and the rotary sleeve (5) and the rotary head (9) are fixedly connected through screws. According to the rotary type hydraulic jet cutting sleeve tool, the sand-carrying liquid withdifferent pressure and displacement is injected into a well mouth, the rotary head of the hydraulic cutting sleeve tool is driven to rotate so as to complete operation of the hydraulic cutting sleeveand the well cementation cement ring, and the rotary type hydraulic jet cutting sleeve tool has the advantages of being high in hydraulic cutting efficiency, small in chip particle size, easy to return, small in drilling risk, free of application of drilling pressure and the like.

Owner:PETROCHINA CO LTD +1

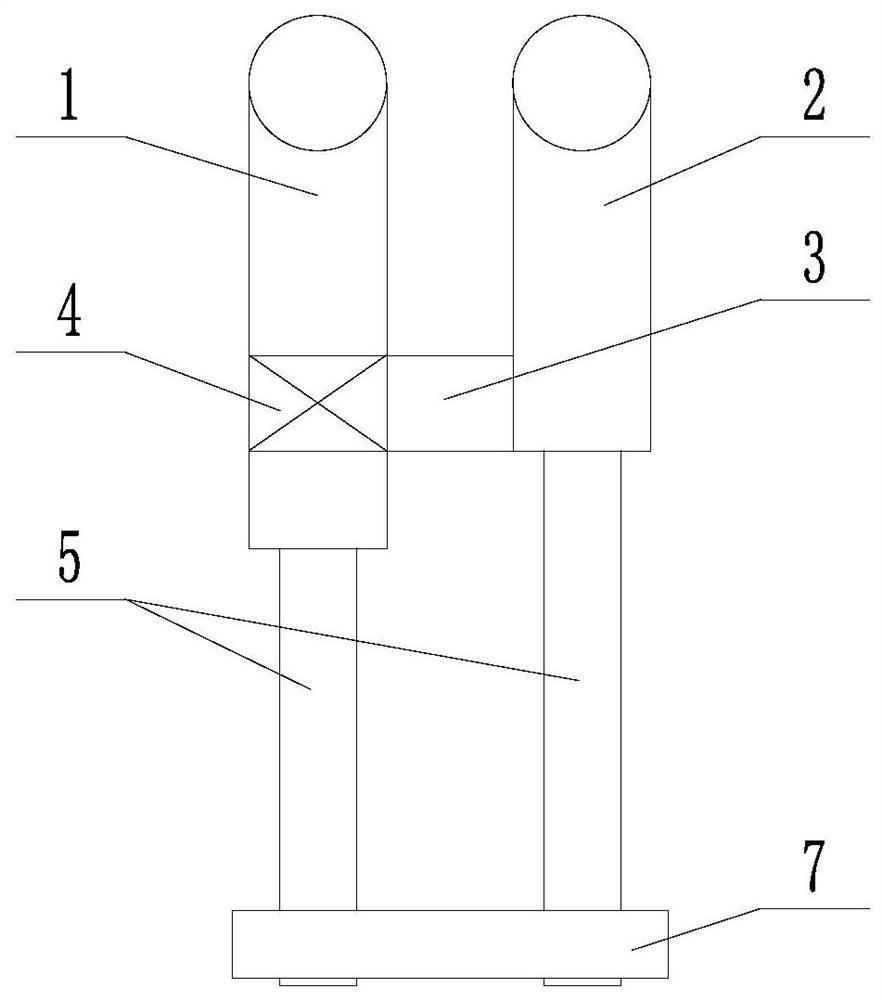

Drill rod centralizer

The invention discloses a drill rod centralizer. The drill rod centralizer comprises a centralizing wing, an upward flow channel and a through hole, wherein a conical part is arranged in the through hole in a sealing fit mode, and the conical part is connected with the hole wall of the through hole through a first shear pin; the drill rod centralizer further comprises a sliding sleeve, the slidingsleeve is connected to the inner wall of the centralizer in a sealing mode, a one-way valve is arranged at the bottom of the sliding sleeve, and the sliding sleeve is connected with the centralizer through a second shear pin; a first pressurizing flow channel and a second pressurizing flow channel are formed in the inner wall of the centralizer, and a third pressurizing flow channel is further formed in a sliding push block; when the sliding sleeve moves downwards to a low stroke position, the upper end of the first pressurizing flow channel is located outside the sliding sleeve; when the sliding push block moves downwards to the low stroke position, the second pressurizing flow channel communicates with the third pressurizing flow channel; and a plurality of spiral blades are further arranged at the end, away from the pointed cone end, of the conical part. The drill rod centralizer is used for solving the problem that in the prior art, a drill rod centralizer is prone to mud drum andthen underground accidents are induced, and the purposes of providing a self-unblocking function for the drill rod centralizer and reducing the risk of jamming of a drill by the mud drum of the centralizer are achieved.

Owner:熊朝柱

A kind of elastic graphite and preparation method thereof

ActiveCN108793150BImprove the lubrication effectIncrease pressureProductsReagentsEngineeringPetroleum oil

The invention provides a method for preparing elastic graphite. The preparation method includes the following steps: using petroleum coke and petroleum pitch as raw materials, crushing the raw materials, mixing and kneading them and molding them at one time; crushing the raw materials after molding them at one time, and adding them to facilitate kneading The secondary molding is completed after the auxiliary materials are used; high-temperature graphitization roasting is carried out at a temperature of 1900°C-2700°C; the elastic graphite raw material is obtained after crushing and screening; the elastic graphite raw material is added to the mixer for mixing, and the fineness is qualified. Package. The advantages and positive effects of the present invention are: the elastic graphite prepared by the present invention is used to prevent the leakage of porous and fractured formations in water-based or oil-based mud systems, and to help seal porous and wide-cracked formations for water Or oil-based mud leak-proof design.

Owner:天津渤海中联石油科技有限公司

An oil well scraper pipe sand washing integrated device and scraper pipe sand washing method

ActiveCN106194112BRealize the technical requirements of scraper sand washing processReduced risk of stuck pipeDrilling rodsCleaning apparatusPositive pressureOil well

The invention discloses an oil well pipe cleaning and sand flushing integrated device. The device comprises a shunt nipple, a shunt packer, a double-layer pipe body, a pipe scraper and a sand flushing nipple which are mutually communicated and are each of a double-layer pipe structure; the pipe cleaning and sand flushing method comprises the steps that the pipe scraper is opened, the shunt packer is recovered, the device is placed down in an oil well casing, a well cleaning fluid is injected into casing annulus, and pipe cleaning and well cleaning are completed; after the sand surface position is determined, the pipe scraper is recovered, and the shunt packer is subjected to setting; a sand cleaning fluid is injected into the casing annulus, and the bottom of a well is flushed through positive pressure sand flushing or negative pressure sand flushing; finally, the shunt packer is upset, and pulling out of the hole is conducted. According to the oil well pipe cleaning and sand flushing integrated device, pipe cleaning and sand flushing operation can be achieved at a time, for formation leakage, both positive pressure sand flushing and negative pressure sand flushing can be conducted, the risk of sticking operation is reduced, the pipe cleaning and sand flushing operation efficiency is improved, the well-completion operation cycle is shortened, and the well-completion operation cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Mechanical automatic vertical drilling tool

InactiveCN100378289CIncrease drilling speedShorten the purification processDirectional drillingWell drillingDifferential pressure

One kind of mechanical type automatic vertically well-drilling tool, including turner, the conduction current head, the bearing, the counterweight, the spindle, in-tube, the back plate, above plate-valve, gets down plate-value, the shell, the piston cylinder back plate and the piston, its principle is at the right moment induces the well slanting gravity signal, by the gravity-actuates in the organization, the establishment drills inside and out the column high-low pressure channel between the fluid, uses two between the differential pressure, actuates the piston at the right moment to push depends on the wall of a well is high side, the wall of a well reacting force then pushes the drill bit to is low side, but in well-eye other positions, the piston does not push depends on the wall of a well, drills the column revolves, this process circulation reciprocation, the well is slanting namely is unceasingly induced and the revision, this invention realization is initiative, At the right moment guards against slanting at the same time, but also can effectively liberate distilling, largely enhances drills fast and well-eye the quality, reduces the construction risk, this invention has the structure is simple, reliable, is suitable to the many kinds of well drilling platform, the processing makes the maintenance cost is low and so on the characteristic.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

A test method for unpacking ability of k344 packer under repeated stimulation conditions of horizontal wells

ActiveCN107702901BReduced risk of stuck pipeRealize quantitative simulationMachine part testingHorizontal wellsDifferential pressure

The present invention discloses a device and a method for a releasing capability test of a K344 packer under a condition of repeat reconstruction of a horizontal well. The test device comprises a plugwith a pull ring, a test oil tube, an oil tube striking hole, a simulation sleeve, a first plug, a spacing ring, a piston, an annular striking hole, an orifice, a K344 packer, an explosion liquid exit channel and a second plug. The plug with the pull ring is connected with the test oil tube, and the oil tube striking hole, the orifice and the explosion liquid exit channel are arranged on the testoil tube; the spacing ring is arranged at the inner side of the simulation sleeve; the first plug is provided with an oil tube fixing device and fitting screws; and the piston can transversely move,and contact surfaces of an inner wall and an outer wall are sealed by employing seal rings. The test method provided by the invention can simulate a releasing capability of the K344 packer when upperand lower ends of a rubber sheet of the K344 packer have a large differential pressure after repeat reconstruction of a horizontal well, the test device is simple in structure and low in cost, and a test result is reliable.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com