Casing running auxiliary tool for petroleum drilling

A technology for oil drilling and auxiliary tools, which is used in drilling equipment, earthmoving, wellbore/well components, etc. It can solve the problem of not making full use of the time window of continuous operation, reducing the frequency of static slurry replenishment, and easily polluting the wellhead of the drilling floor, etc. It can reduce the frequency of static slurry replenishment, reduce the risk of differential pressure sticking, and improve the time utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

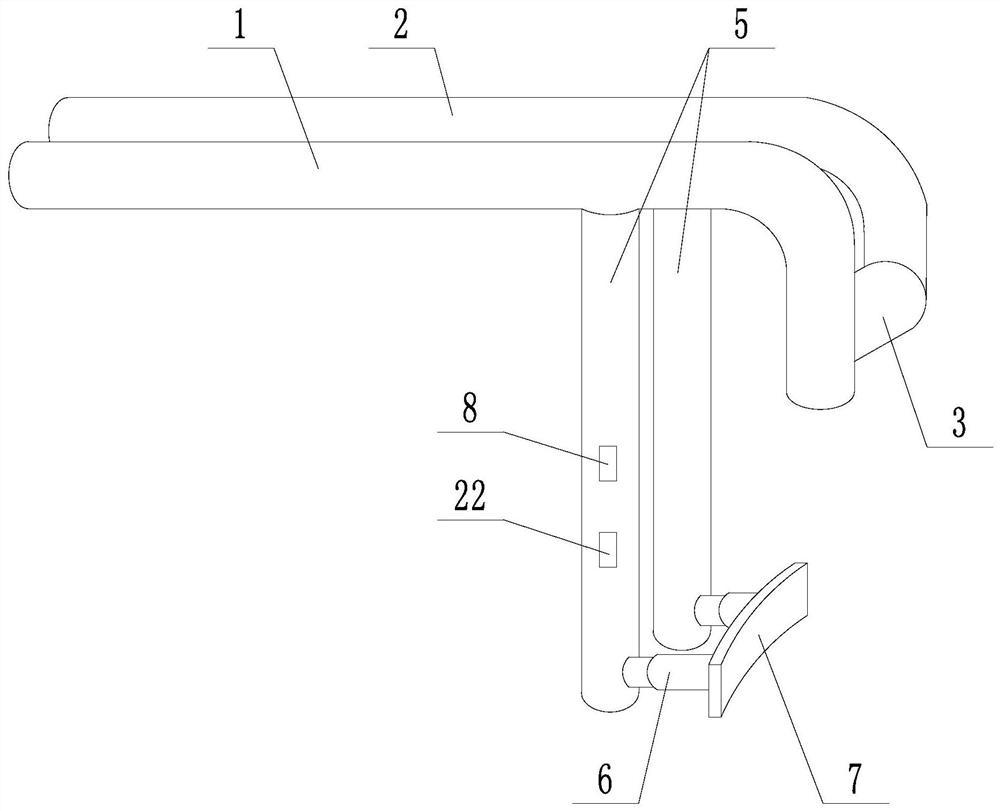

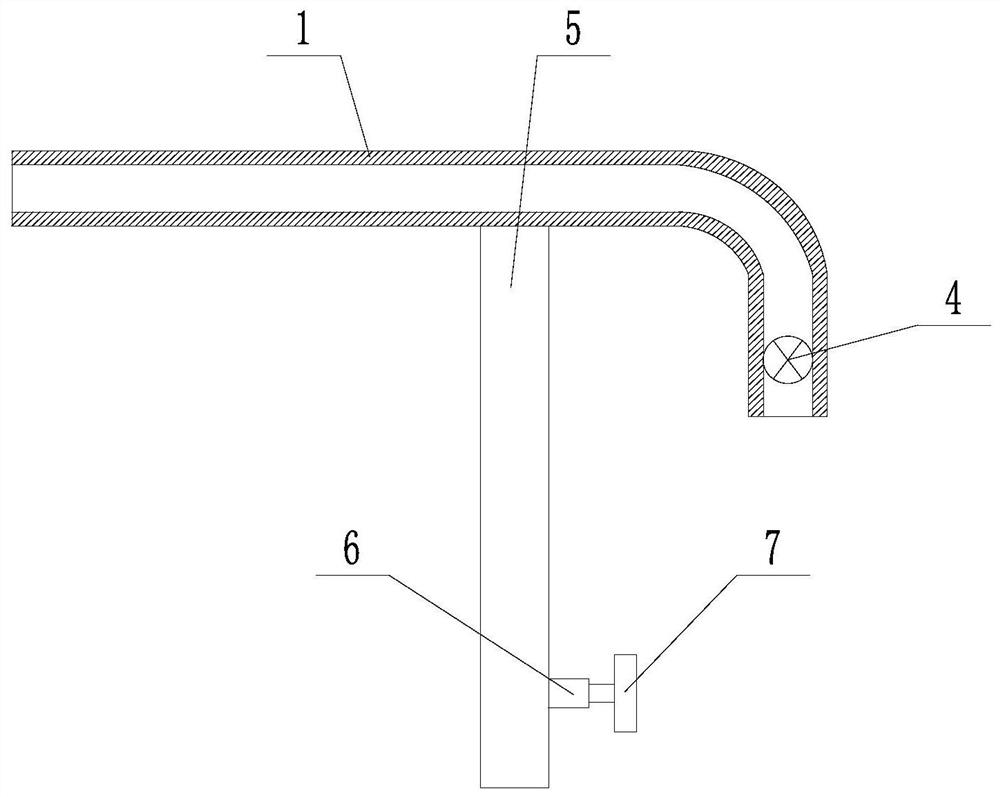

[0036] Such as Figure 1 to Figure 3 The shown casing running auxiliary tool for oil drilling includes an L-shaped grouting pipe 1 and a return pipe 2. The short sides of the grouting pipe 1 and the return pipe 2 are communicated through a bypass pipe 3. A reversing valve 4 is provided at the junction of the through pipe 3 and the grouting pipe 1, the short side end of the grouting pipe 1 is open, and the short side end of the return pipe 2 is closed; A watering system for pumping fluids. The grouting pipe 1 and the return pipe 2 are parallel to each other, and the length of the short side of the grouting pipe 1 is greater than that of the return pipe 2 ; the reversing valve 4 is located in the grouting pipe 1 .

[0037] When this embodiment is used, the drilling fluid is continuously pumped into the grouting pipe 1 by the water supply system, and the reversing valve is used to make the drilling fluid flow back through the grouting pipe, the bypass pipe, and the return pipe i...

Embodiment 2

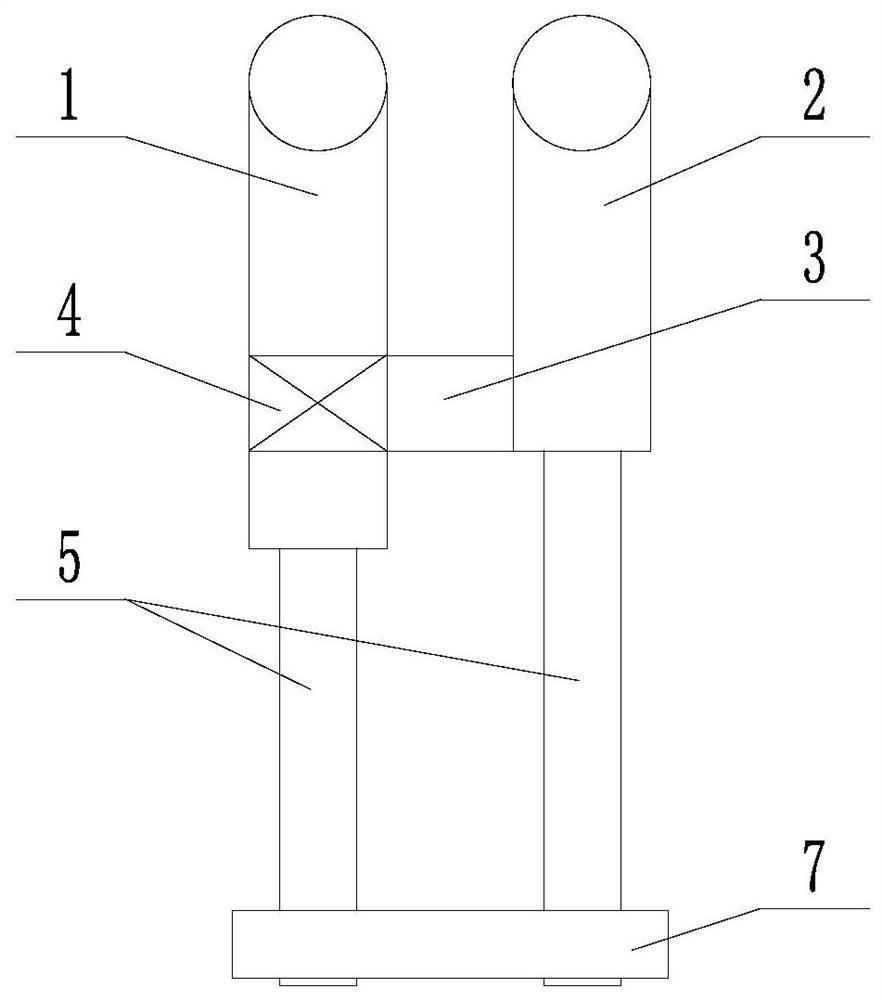

[0042] On the basis of Example 1, the auxiliary tool for running the casing, the long sides of the grouting pipe 1 and the return pipe 2 are fixedly connected with the limit rod 5, and the orientation of the limit rod 5 is consistent with that of the grout pipe 1 and the return pipe 2. The short sides are the same, and the limiting rod 5 is parallel to the short sides of the grouting pipe 1 and / or the return pipe 2 ; the length of the limiting rod 5 is greater than the length of the short side of the grouting pipe 1 . The limit rod 5 is connected with a telescopic rod 6, and one end of the telescopic rod 6 away from the limit rod 5 is detachably connected with a pusher 7, and the pusher 7 is in the shape of an arc with the center facing outward.

[0043] Such as Figure 4 As shown, the long side of the grouting pipe 1 and / or the return pipe 2 is provided with a slide rail 9, and one end of the limit rod 5 is provided with a slider 10 which is slidably matched with the slide ra...

Embodiment 3

[0048] An auxiliary tool for running casing for oil drilling, on the basis of any of the above-mentioned embodiments, the water supply system is as follows: Figure 5 and Figure 6 As shown, it includes a storage tank 12 and a water pump 13 for pumping liquid from the storage tank 12. The long side of the grouting pipe 1 communicates with the discharge port of the water pump 13 through a first flexible pipe 14. The return pipe The long side of 2 communicates with the storage tank 12 through a second hose 15 . The storage tank 12 is provided with a bearing plate 16, which is in dynamic sealing fit with the inner wall of the storage tank 12, and also includes a lifting device 23 for driving the loading plate 16 up and down; the lifting device 23 is arranged on On the installation platform 17 , a discharge hole 18 is provided at the bottom of the storage tank 12 . The water pump 13 is located at the top of the storage tank 12 , the liquid inlet of the water pump 13 extends to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com