Cooling piece for circuit board and display panel employing cooling piece

A technology for heat sinks and circuit boards, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of unbalanced heat dissipation effect, high cost, poor chip heat dissipation effect, etc., and achieve the effect of convenient production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

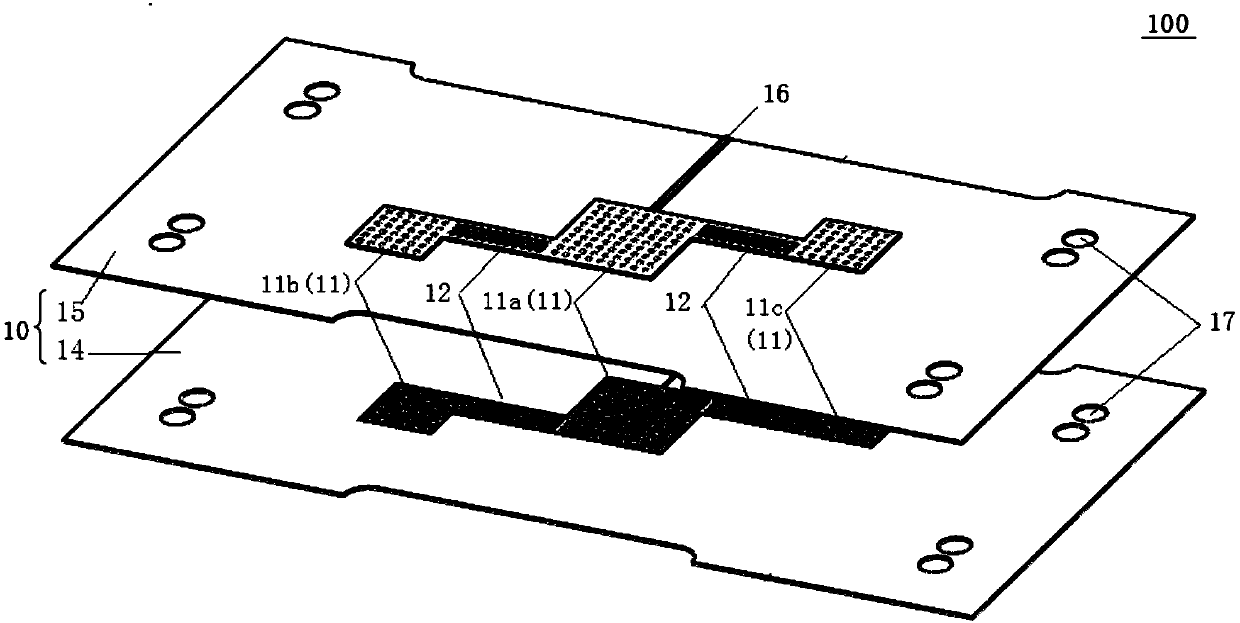

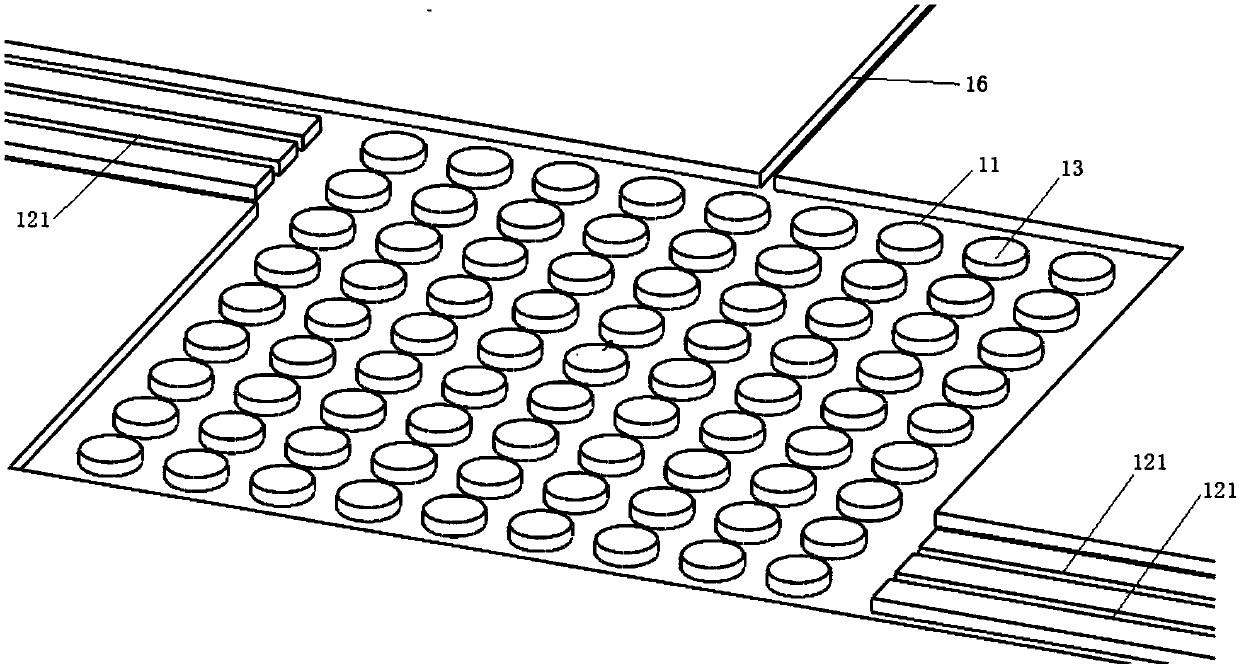

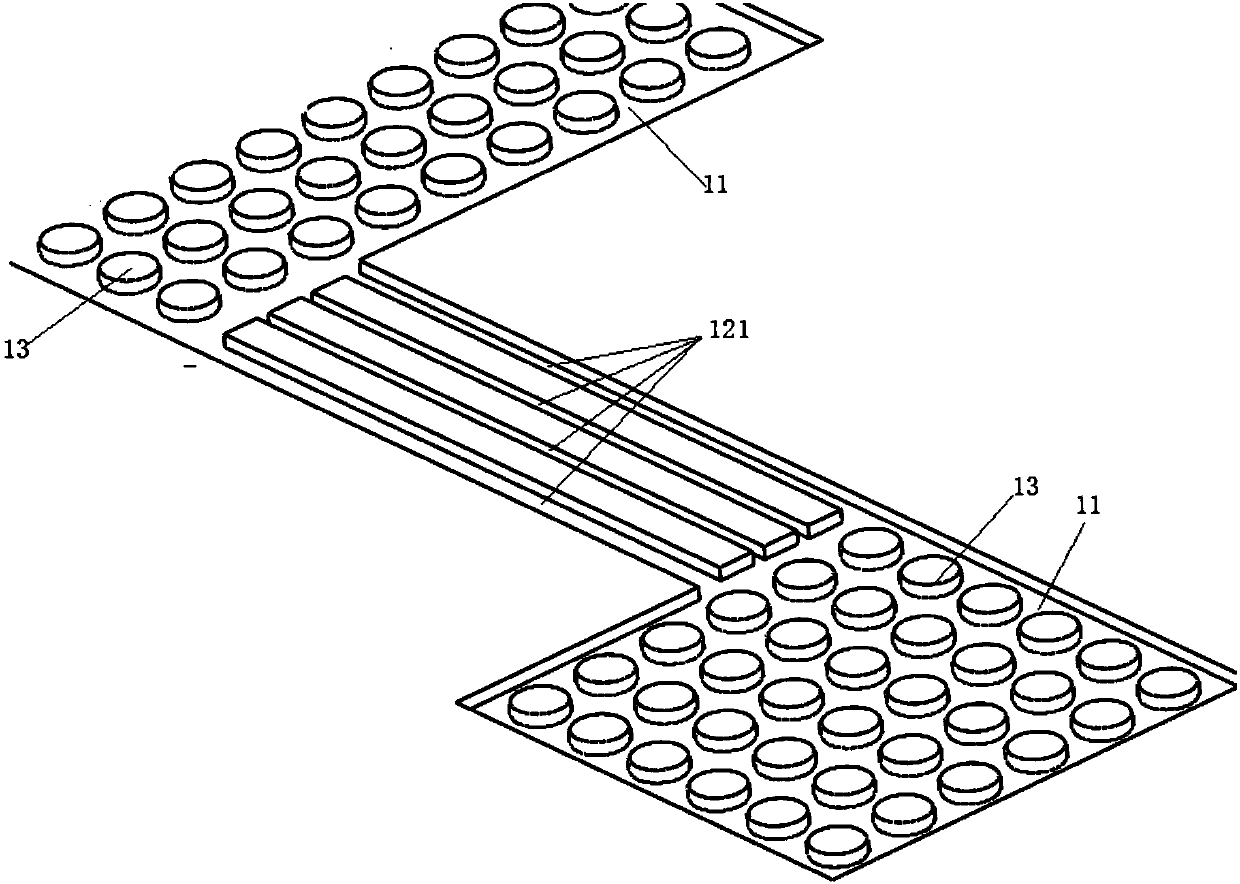

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0038] This application is made by the inventor based on the following cognitions:

[0039] For the heat dissipation of the multi-chip circuit board, although the existing circuit board is provided with a heat dissipation device, when the circuit board continues to work for a long time, insufficient heat dissipation will still occur, which will cause the circuit failure caused by the excessive temperature of the chips on the current board. In the end, when the operating temperature of one or more chips on the circuit board exceeds the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com