Plugging agent for low-pressure leakage gas well, and preparation method and application method thereof

A gas well and leakage technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as wellhead fire, gas well production reduction, and permeability reduction, so as to achieve convenient plugging and plugging removal operations, and solve serious leakage. Effect of Pollution Damage Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

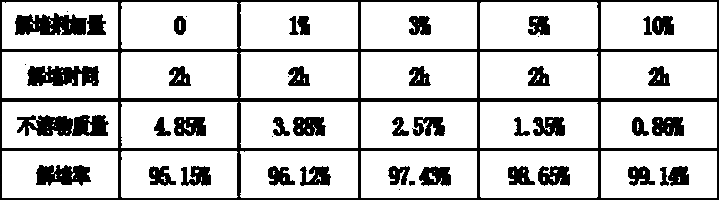

Method used

Image

Examples

Embodiment 1

[0069] The plugging agent for low-pressure leakage gas wells in this embodiment consists of the following components in mass percent:

[0070] Guar gum dry powder 0.3%;

[0071] Calcium carbonate powder 4%;

[0072] Polyvinyl alcohol fiber 1%;

[0073] Expanded particles with a particle size of 0.025mm to 0.425mm 0.3%;

[0074] Expanded particles with a particle size of 1 mm to 3 mm 0.5%;

[0075] Clear water remaining.

[0076] In this example, the method for preparing a plugging agent for a low-pressure leakage gas well is as follows:

[0077] (1) Weigh 0.3% guar gum dry powder and formula water, mix and stir to form a guar gum solution, and stir at room temperature for 45-60 min to fully dissolve the guar gum dry powder in clean water to form a guar gum solution A;

[0078] (2) Add calcium carbonate powder with a mass percentage of 4% to the guar gum solution A, and stir at room temperature for 20-30 minutes, so that the calcium carbonate powder is evenly dispersed in...

Embodiment 2

[0083] The plugging agent for low-pressure leakage gas wells in this embodiment consists of the following components in mass percent:

[0084] Guar gum dry powder 0.4%;

[0085] Calcium carbonate powder 2%;

[0086] Polyvinyl alcohol fiber 2%;

[0087] Expanded particles with a particle size of 0.025mm to 0.425mm 0.3%;

[0088] Expanded particles with a particle size of 1 mm to 3 mm 0.4%;

[0089] Clear water remaining.

[0090] In this example, the method for preparing a plugging agent for a low-pressure leakage gas well is as follows:

[0091] (1) Weigh 0.4% guar gum dry powder and formula water, mix and stir to form a guar gum solution, and stir at room temperature for 45-60 min to fully dissolve the guar gum dry powder in clean water to form a guar gum solution A;

[0092] (2) Add calcium carbonate powder with a mass percentage of 2% to the guar gum solution A, and stir at room temperature for 20-30 minutes, so that the calcium carbonate powder is evenly dispersed in...

Embodiment 3

[0097] The plugging agent for low-pressure leakage gas wells in this embodiment consists of the following components in mass percent:

[0098] Guar gum dry powder 0.5%;

[0099] Calcium carbonate powder 3%;

[0100] Polyvinyl alcohol fiber 2.5%;

[0101] Expanded particles with a particle size of 0.025mm to 0.425mm 0.5%;

[0102] Expanded particles with a particle size of 1 mm to 3 mm 0.5%;

[0103] Clear water remaining.

[0104] In this example, the method for preparing a plugging agent for a low-pressure leakage gas well is as follows:

[0105] (1) Weigh 0.5% guar gum dry powder and formula water, mix and stir to form a guar gum solution, and stir at room temperature for 45-60 min to fully dissolve the guar gum dry powder in clean water to form a guar gum solution A;

[0106] (2) Add calcium carbonate powder with a mass percentage of 3% to the guar gum solution A, and stir at room temperature for 20-30 minutes, so that the calcium carbonate powder is evenly dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com