A pulsating two-way impactor

A technology of impactor and impact valve, which is applied in the direction of drilling driving device, drilling equipment, earthwork drilling and production in the wellbore, can solve the problems of no axial impact, achieve the vibration of the drill string, prolong the service life, and the technology Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

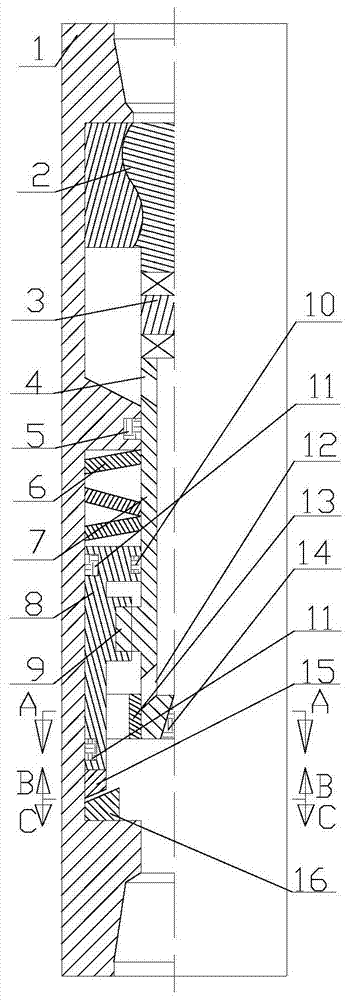

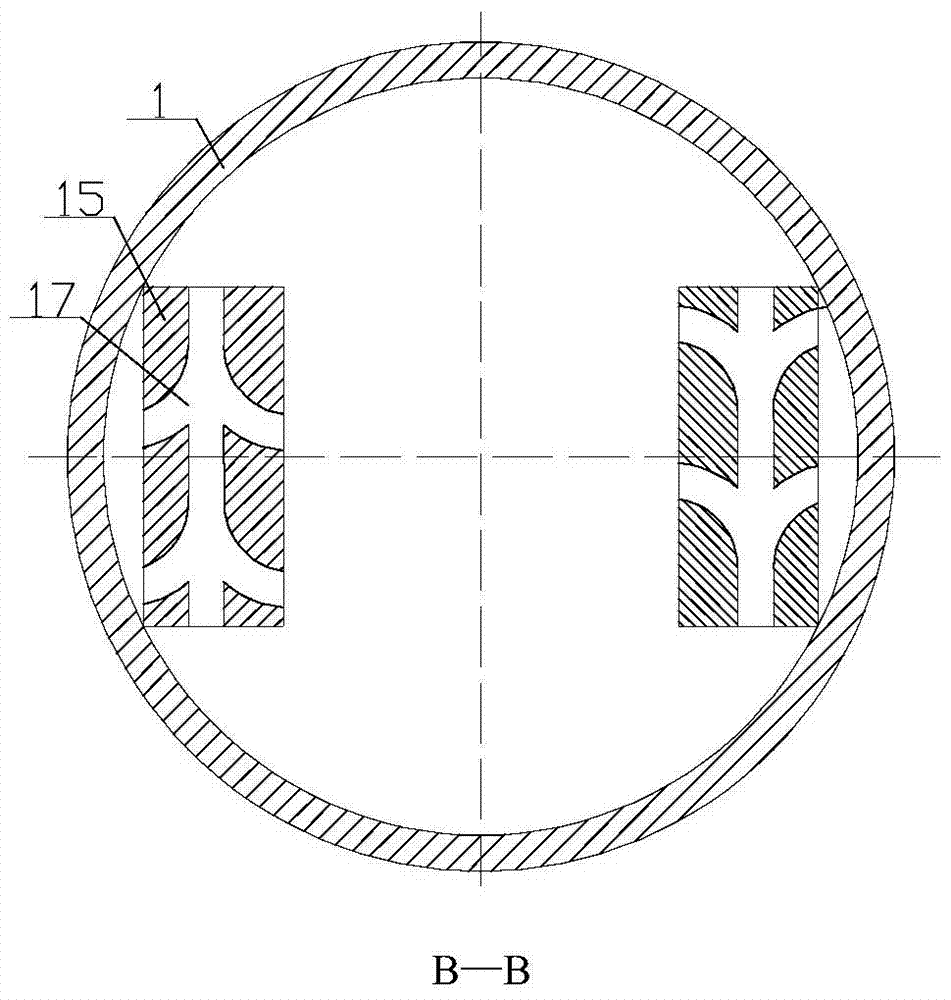

[0022] Such as figure 1 , the power mechanism 2 is installed in the upper part of the housing 1, and is connected with the central shaft 7 through the coupling 3, the upper part of the central shaft 7 is processed with a bypass hole 4, the lower part is processed with a bypass hole 12, and the lower end of the central shaft 7 is installed with a check valve 14. A sealing device 5 is installed between the housing 1 and the central shaft 7, a sealing device 11 is installed between the impact valve 8 and the housing 1, a sealing device 10 is installed between the impact valve 8 and the central shaft 7, and the impact valve 8 and the housing A spring 6 is installed between 1, the central shaft 7 is connected with the impact valve 8 through a spline group 9, the sliding sleeve 13 is installed at the bottom of the impact valve 8, the upper impact block 15 is installed at the lower end of the impact valve 8, and the lower impact block 16 is installed at the shell 1 lower end, the upp...

Embodiment 2

[0024] On the basis of Embodiment 1, the following simplification measures can also be made to the above embodiment.

[0025] One is that the installation of the sealing device 11 can be omitted under the premise of satisfying the workpiece machining accuracy between the housing 1 and the central shaft 7 and between the shock valve 8 and the housing 1 and the central shaft 7 .

[0026] The 2nd, can directly utilize impact valve 8 lower ends and housing 1 lower annular groove inner convex edge to form impact fit and omit upper and lower impact blocks.

[0027] The third is that the sliding sleeve 13 and the shock valve 8 can be of an integral structure, or of a split combined structure.

[0028] Fourth, the inclination angle and direction of the impact contact surfaces of the upper impact block and the lower impact block should be adjusted as needed to achieve the best axial and rotational impact effects.

[0029] The drain groove of the upper impact block 15 has dual function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com