Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

543results about "Ion-exchange column/bed processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

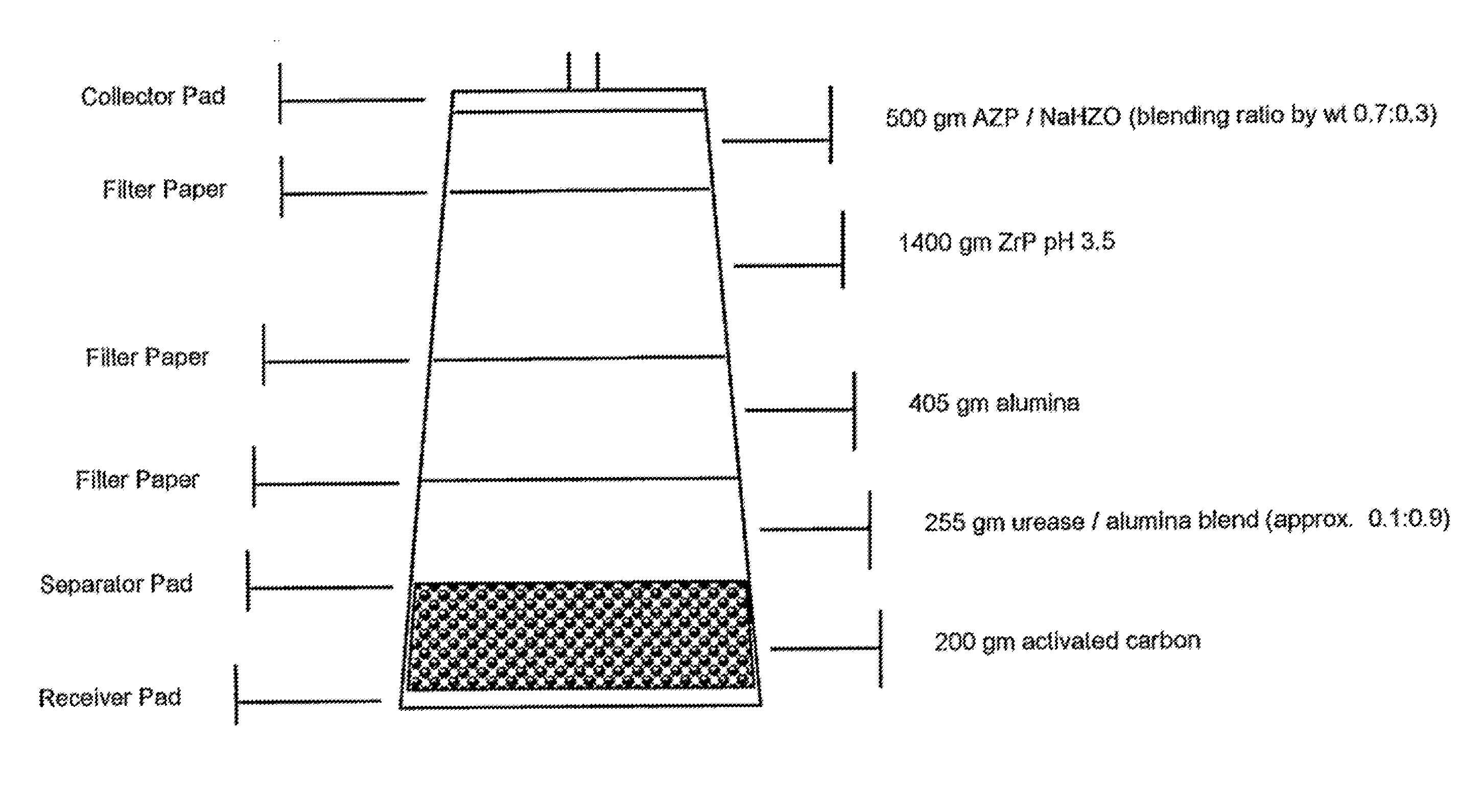

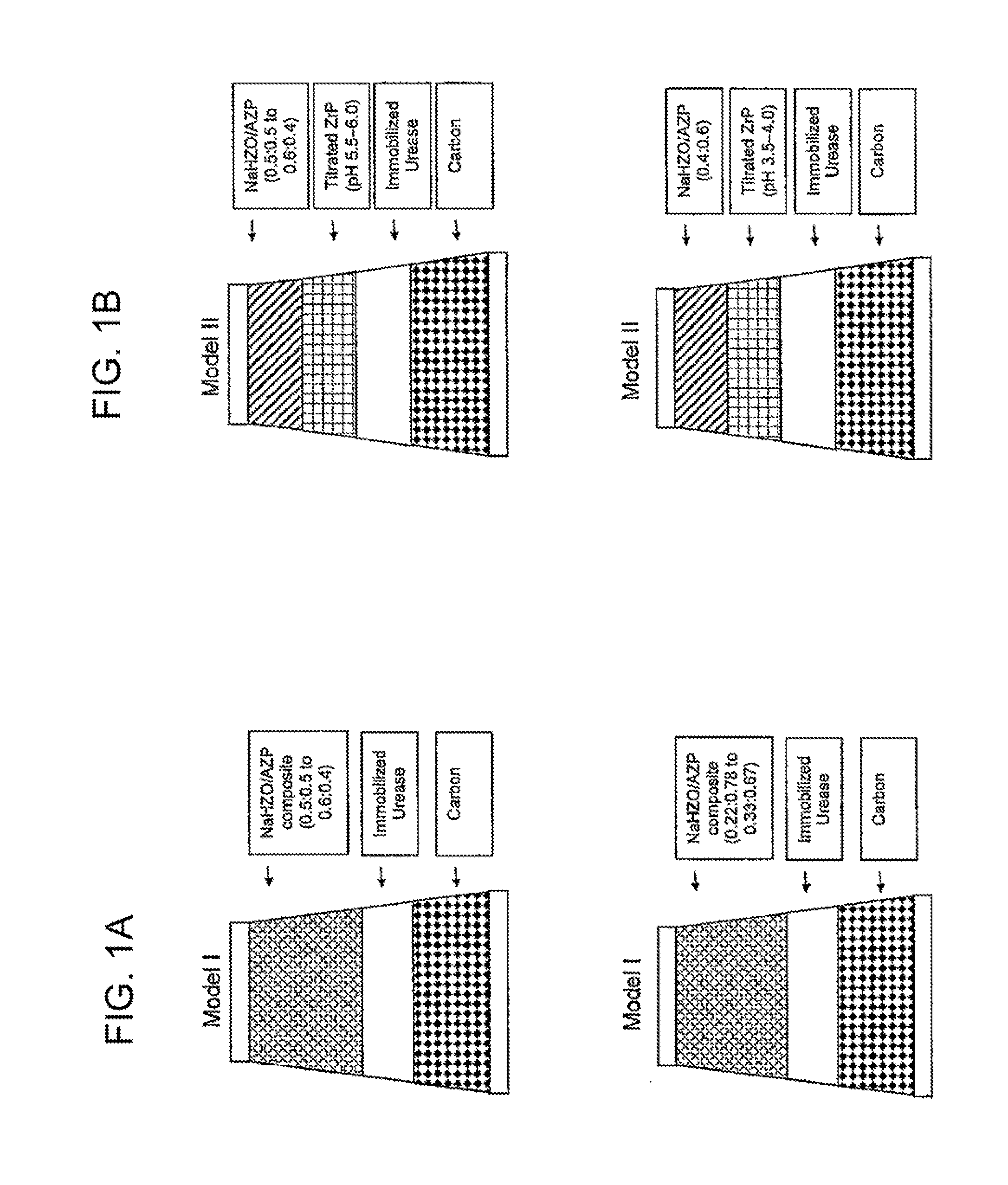

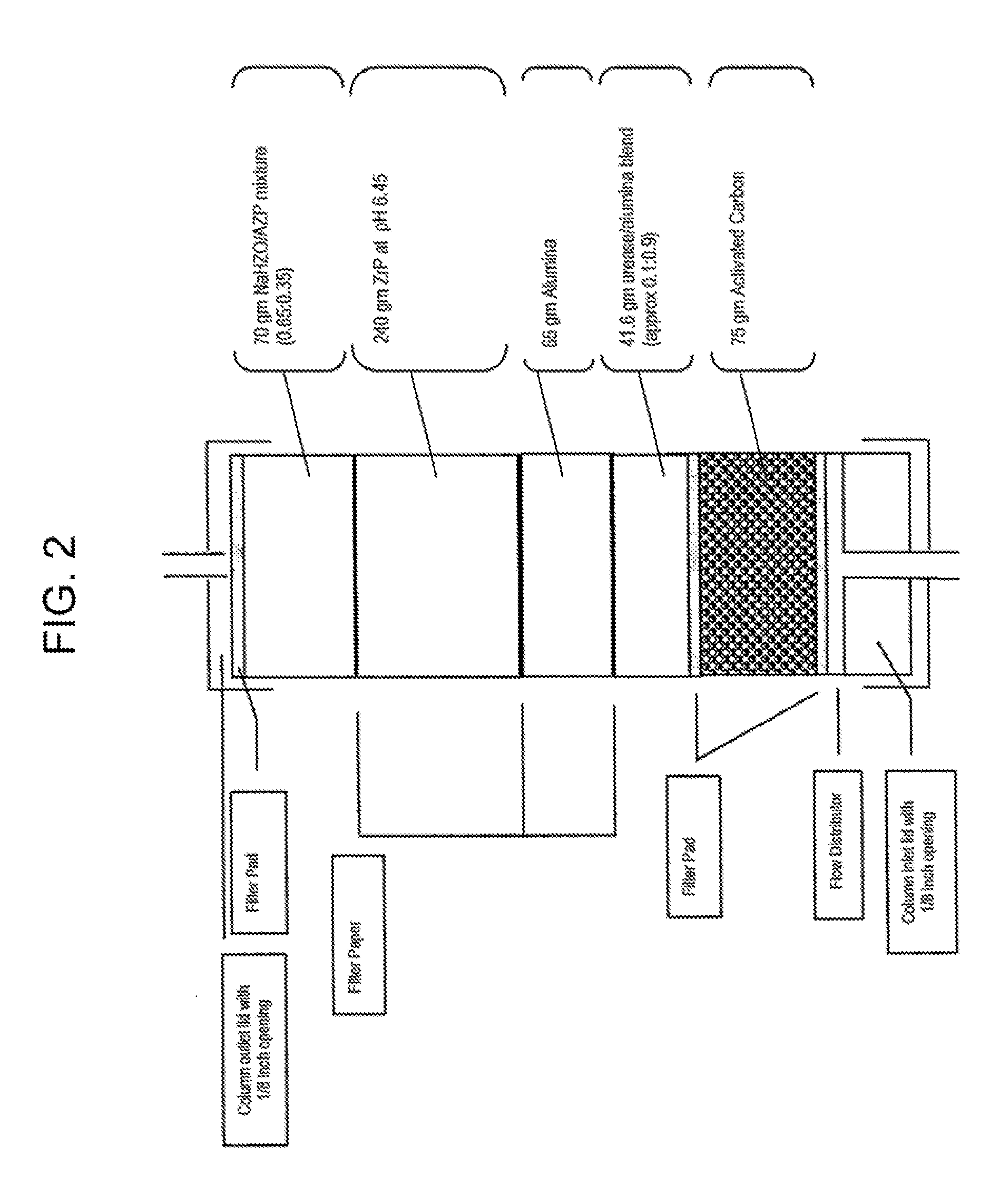

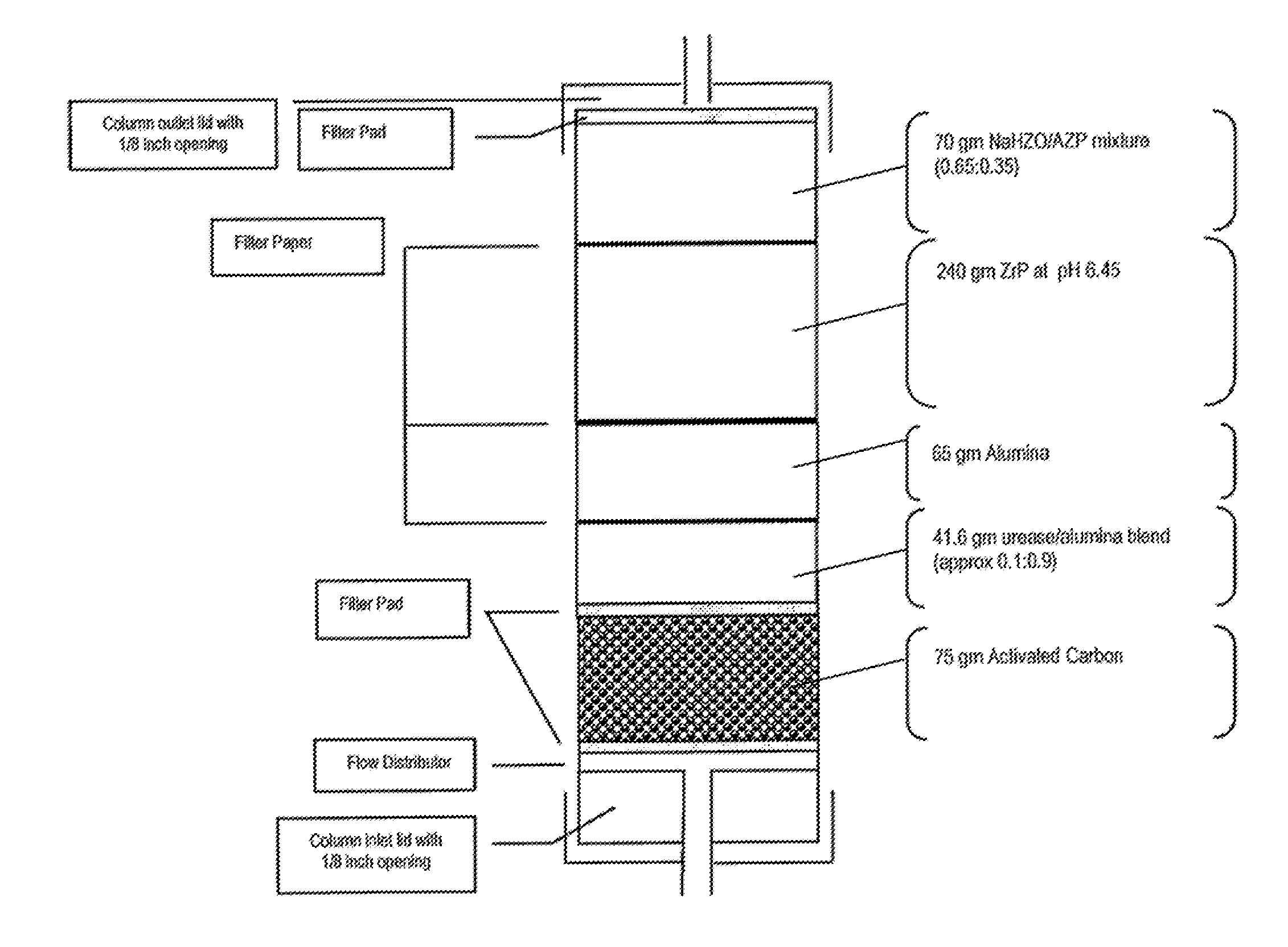

Acid Zirconium Phosphate and Alkaline Hydrous Zirconium Oxide Materials For Sorbent Dialysis

ActiveUS20100078387A1Avoid disadvantagesRestore balanceCation exchanger materialsOrganic anion exchangersIon exchangeDialysis fluid

Owner:FRESENIUS MEDICAL CARE HLDG INC

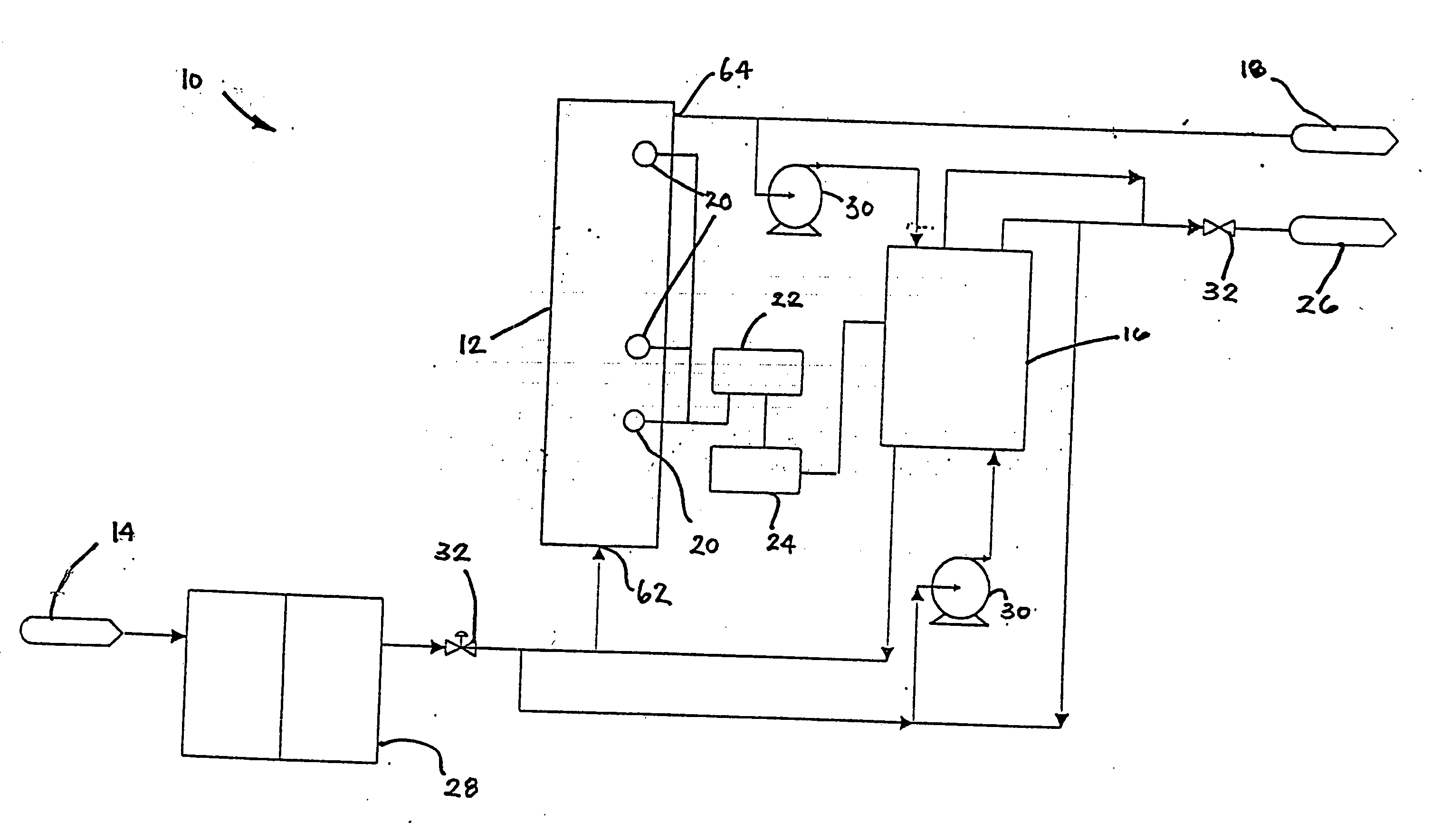

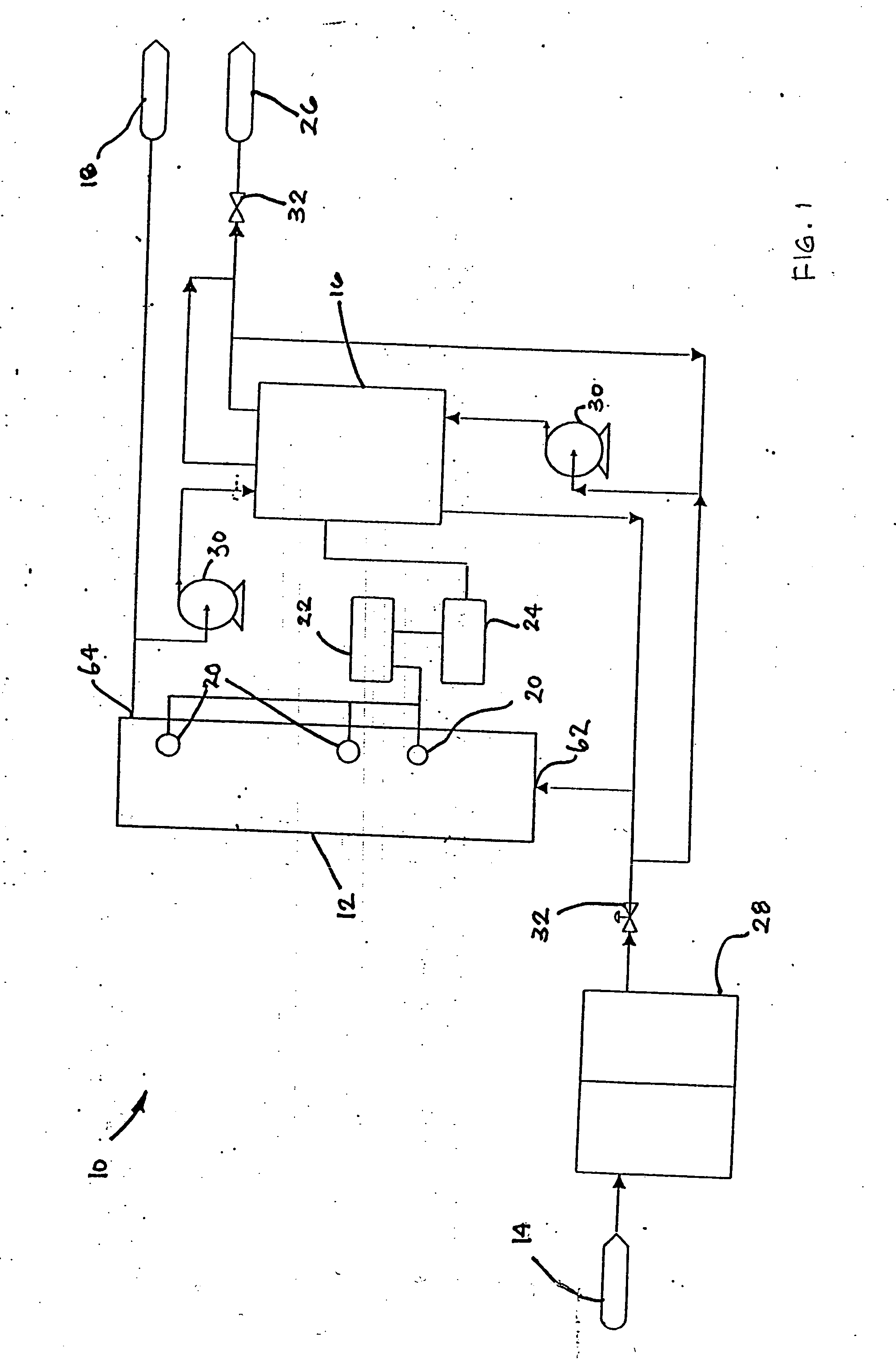

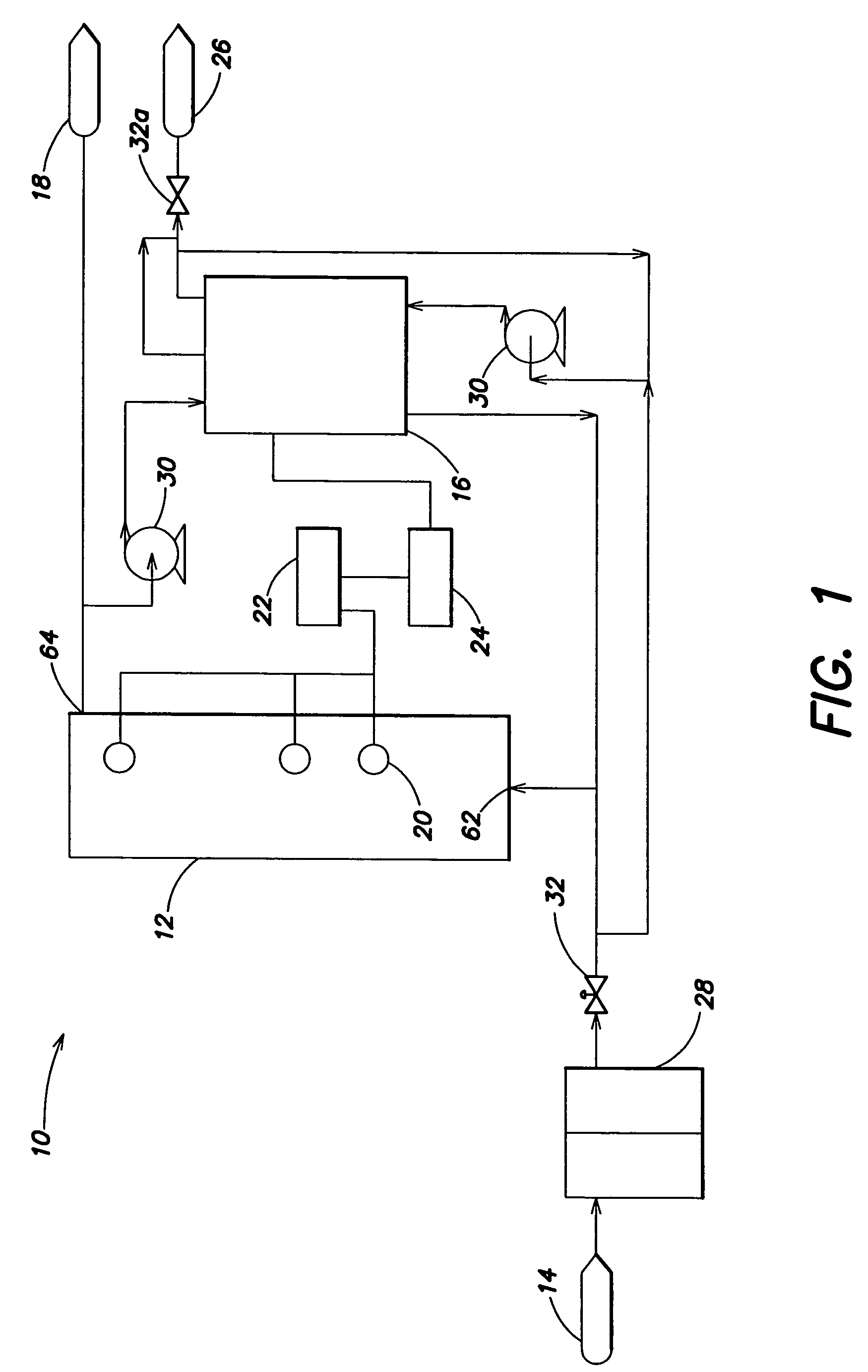

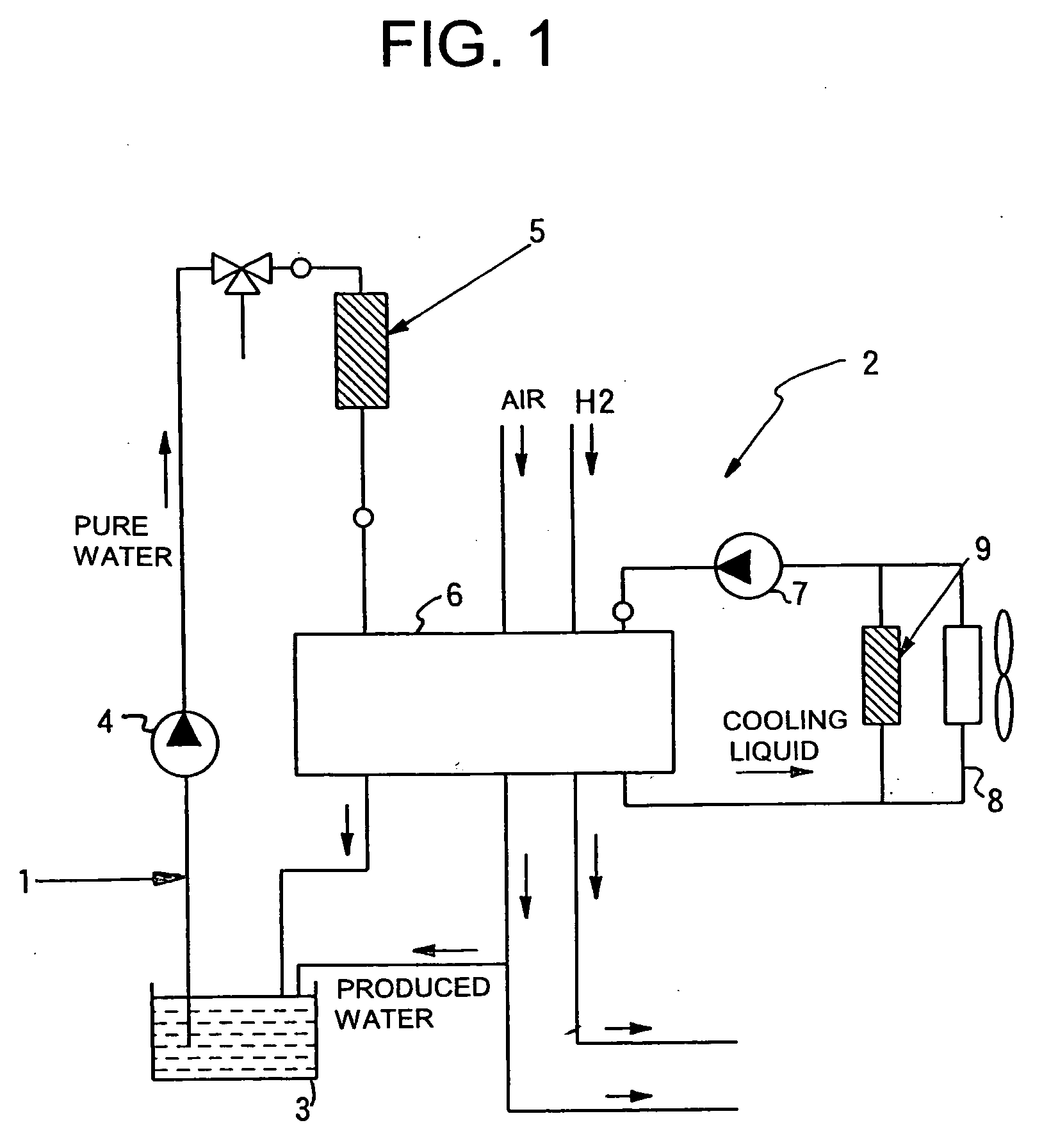

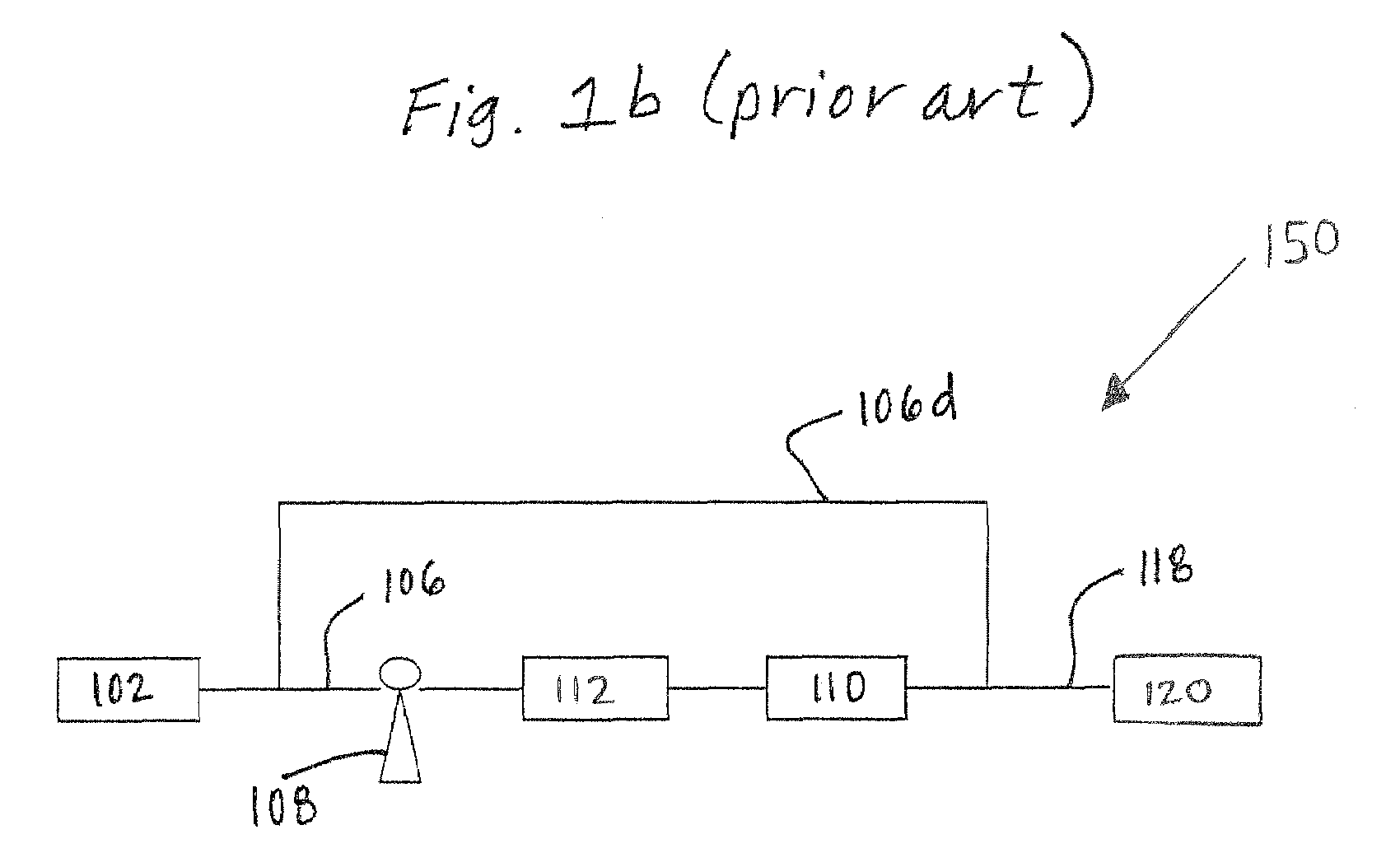

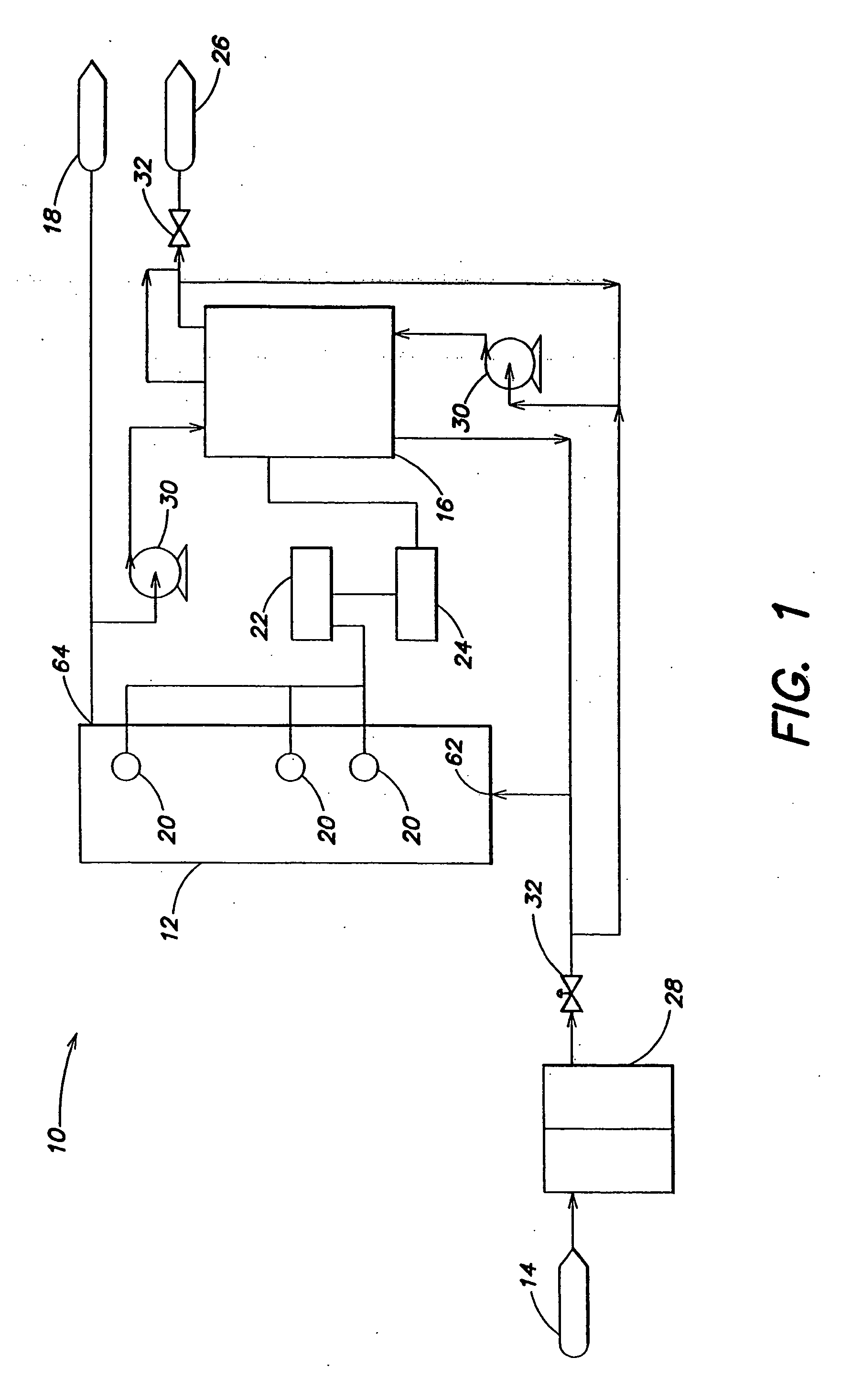

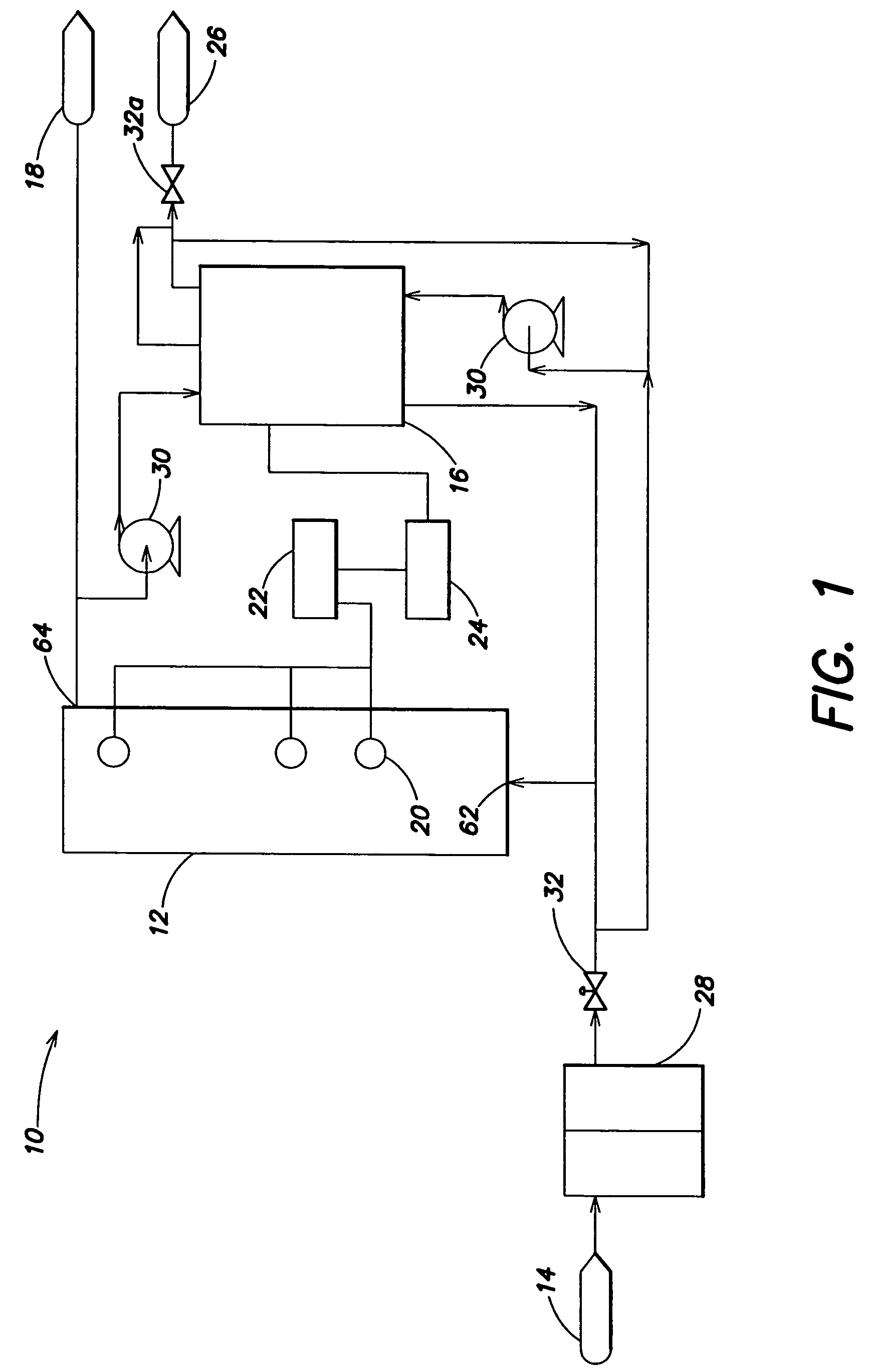

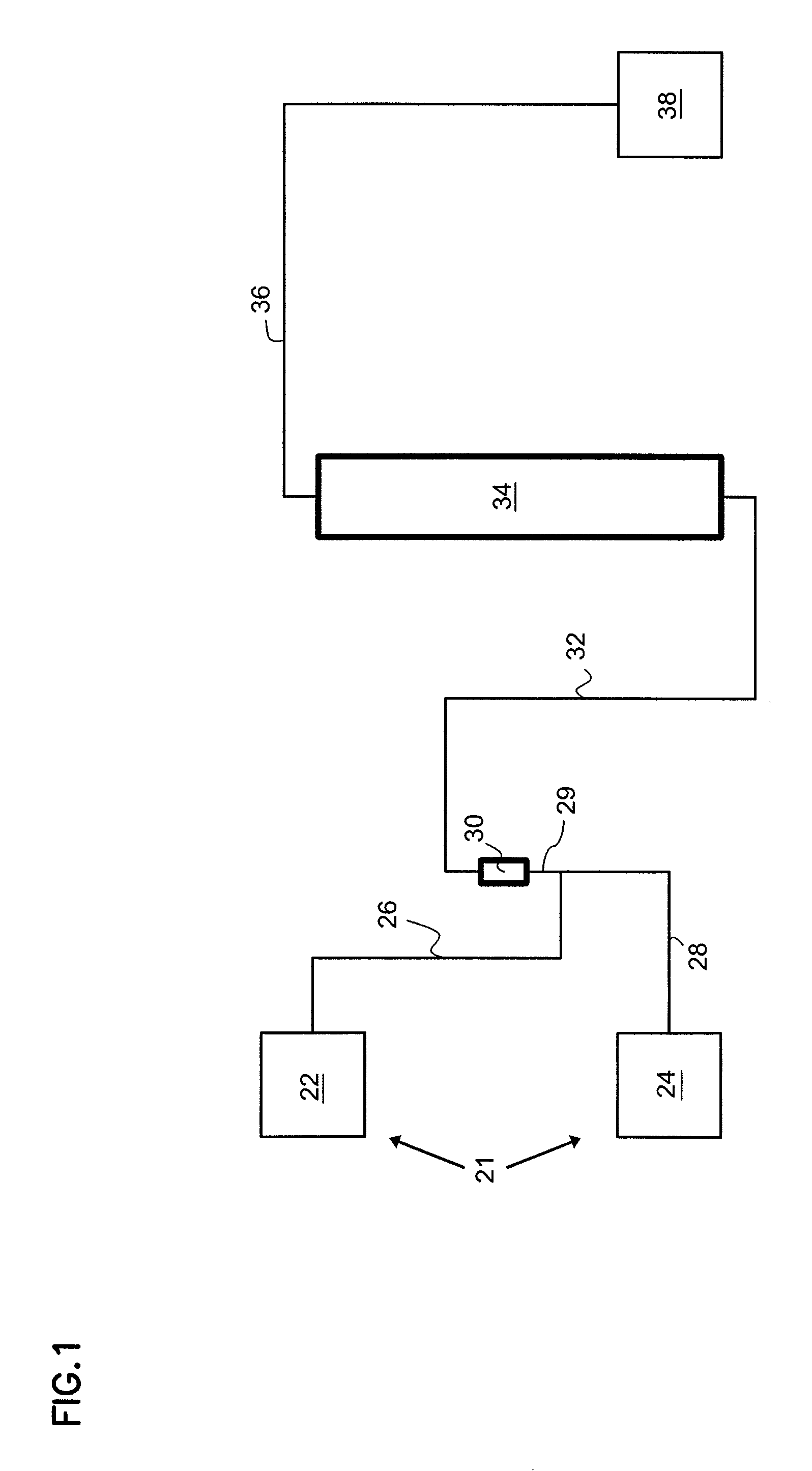

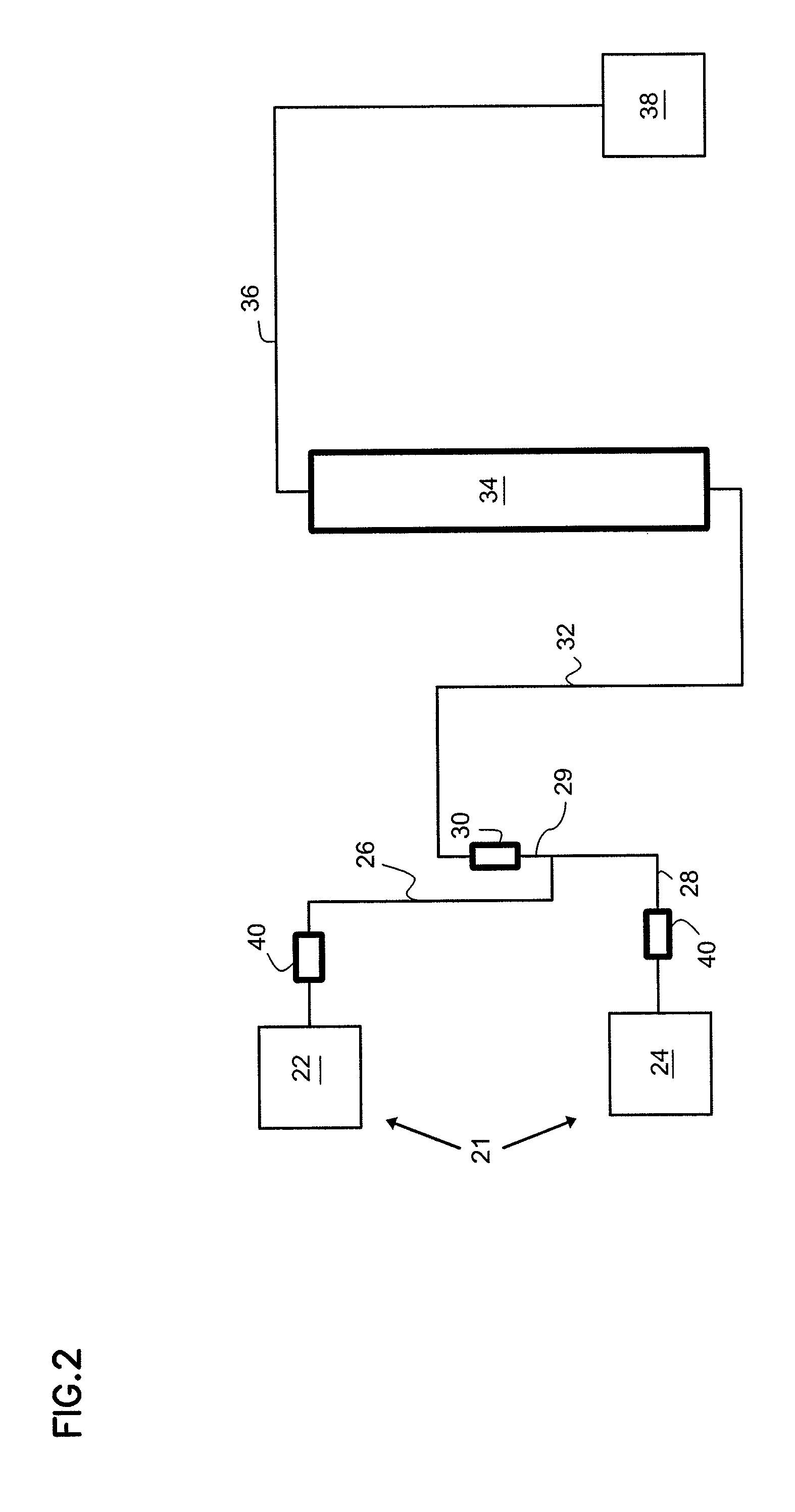

Water treatment system and method

ActiveUS20050103722A1Water treatment parameter controlIon-exchange column/bed processesWater treatment systemWater source

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

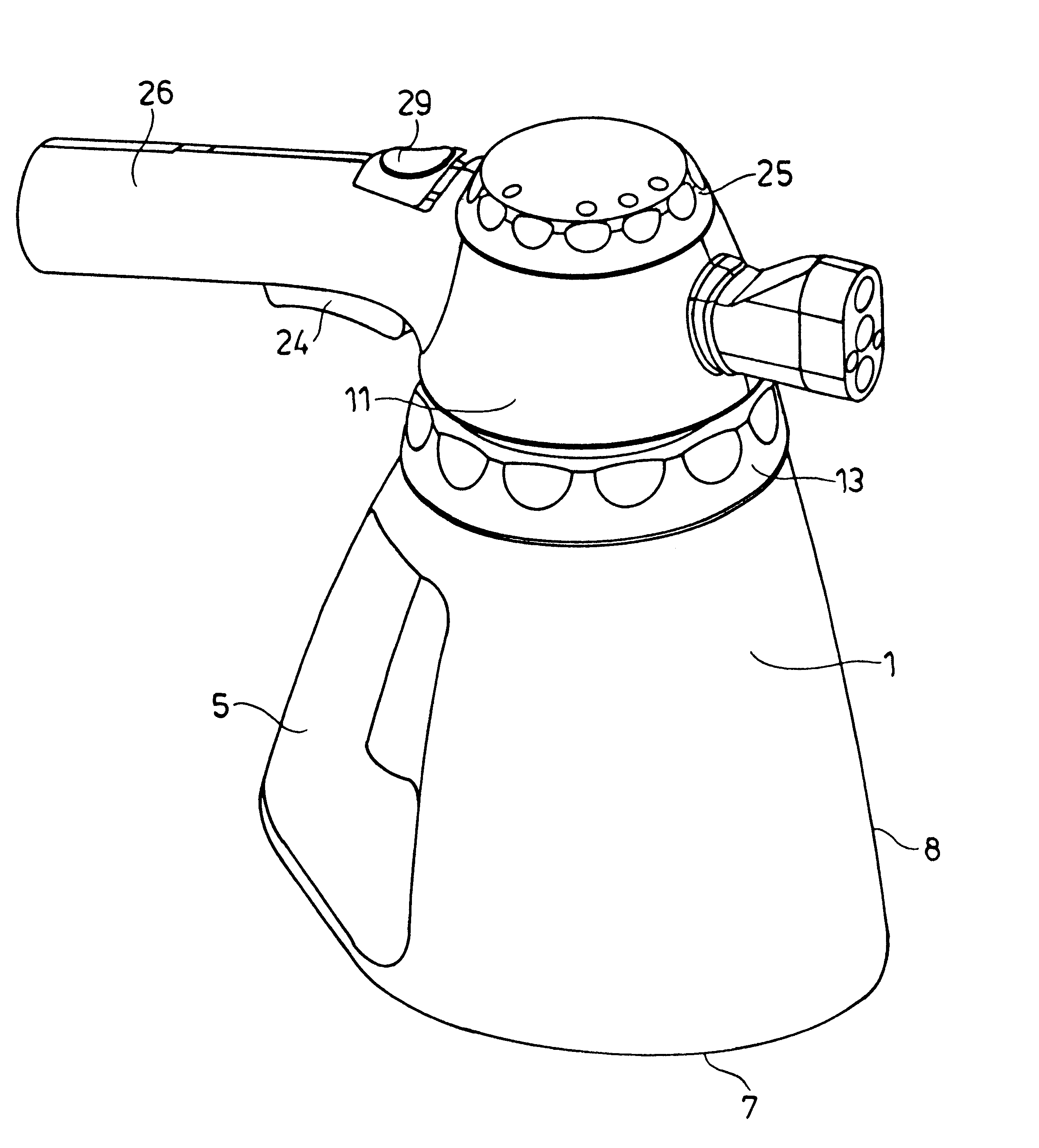

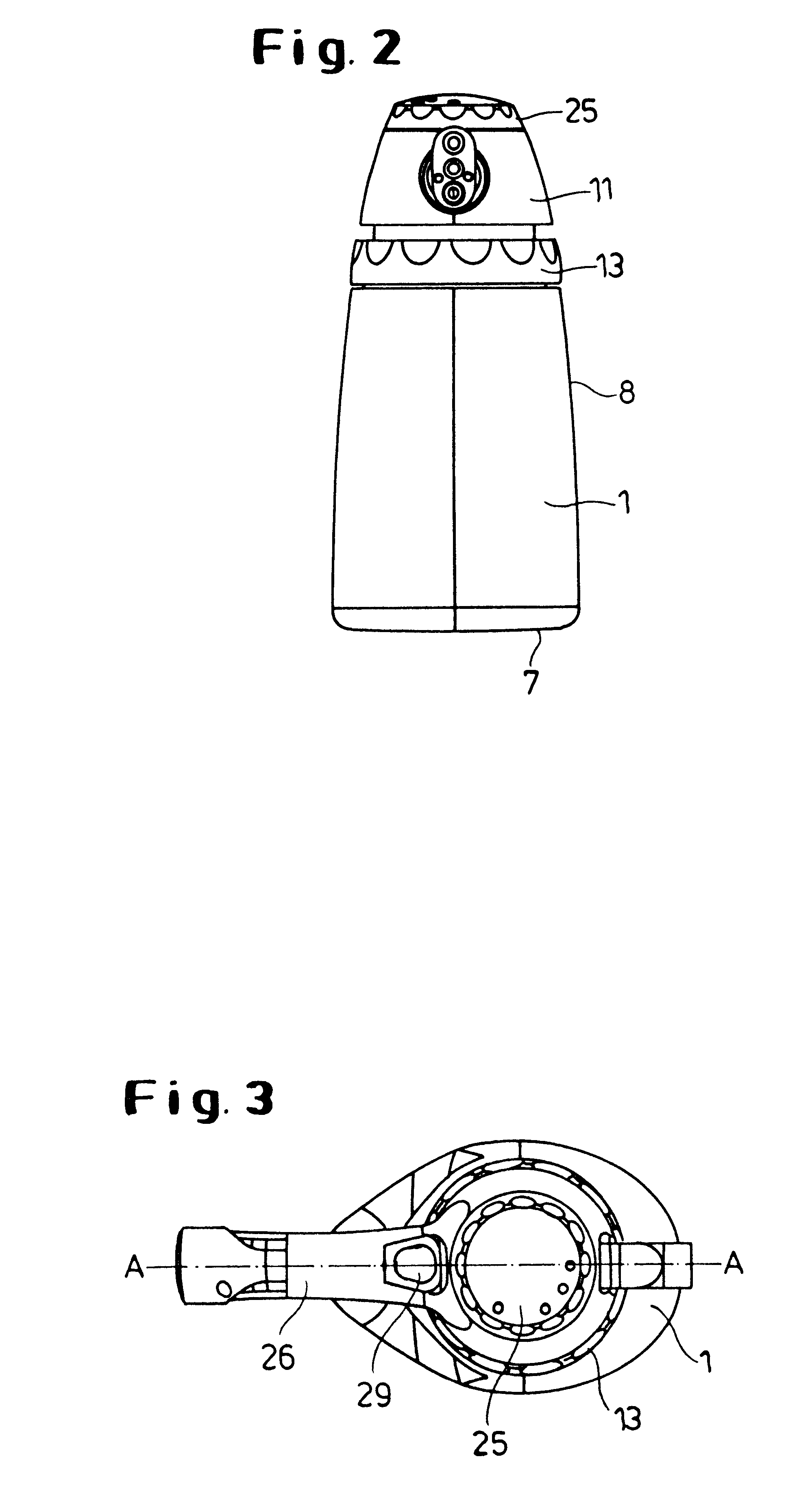

Filtration device for liquid purification

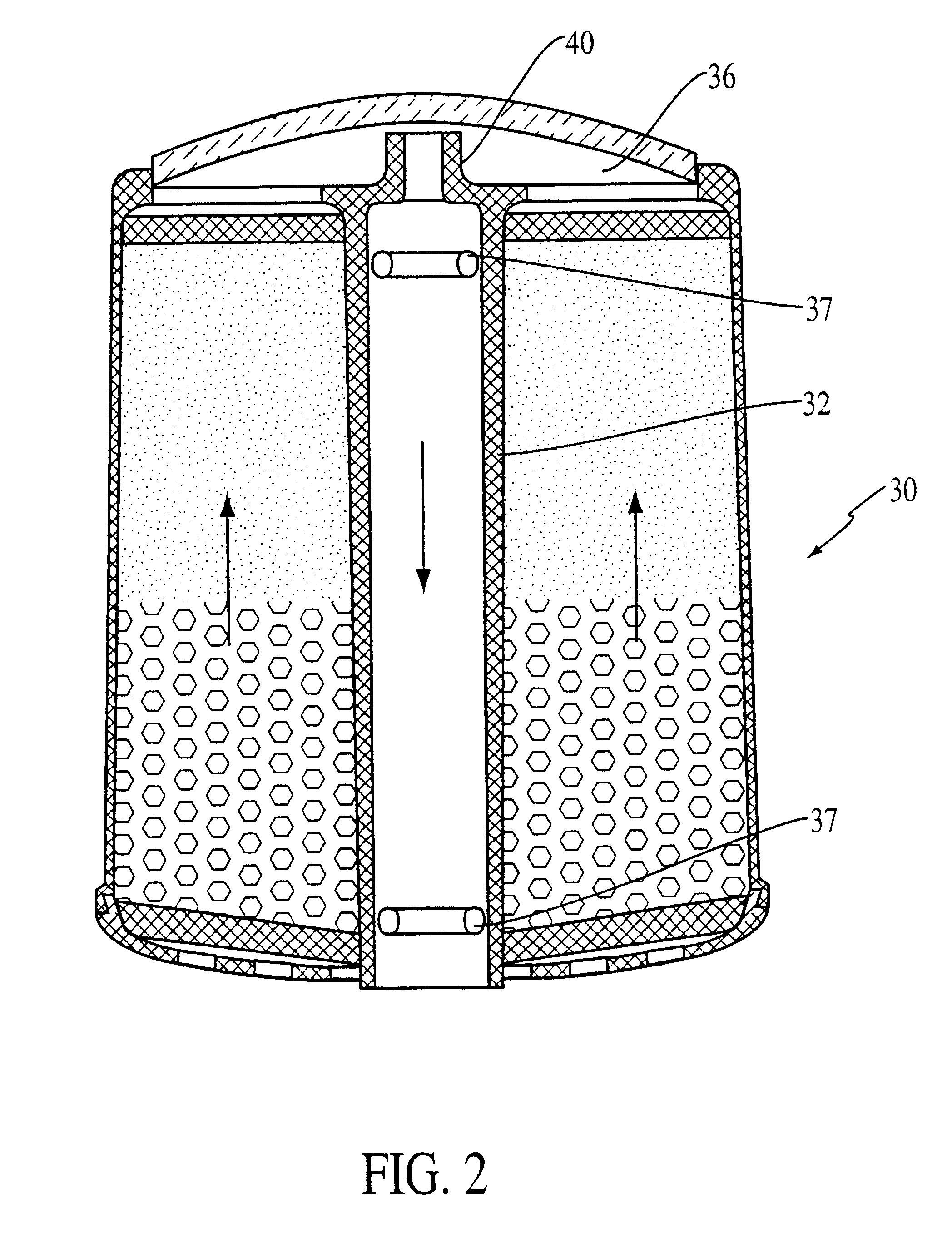

InactiveUS6387260B1Confirm its effectivenessIon-exchange column/bed processesTreatment involving filtrationInternal pressureWater use

The invention is directed to purification of liquids, such as drinking water using filters, wherein filtration is effected while the liquid flows upwardly. The invention includes both the method and a device enabling the method to be carried out. The device is constructed to intake impure liquid at the bottom of the filter and initially to effect flow by filling liquid to above the filter outlet near the top, and maintaining flow thereafter by virtue of the presence of a low internal pressure that develops as the liquid passes through the system.

Owner:ELECTROPHOR INC

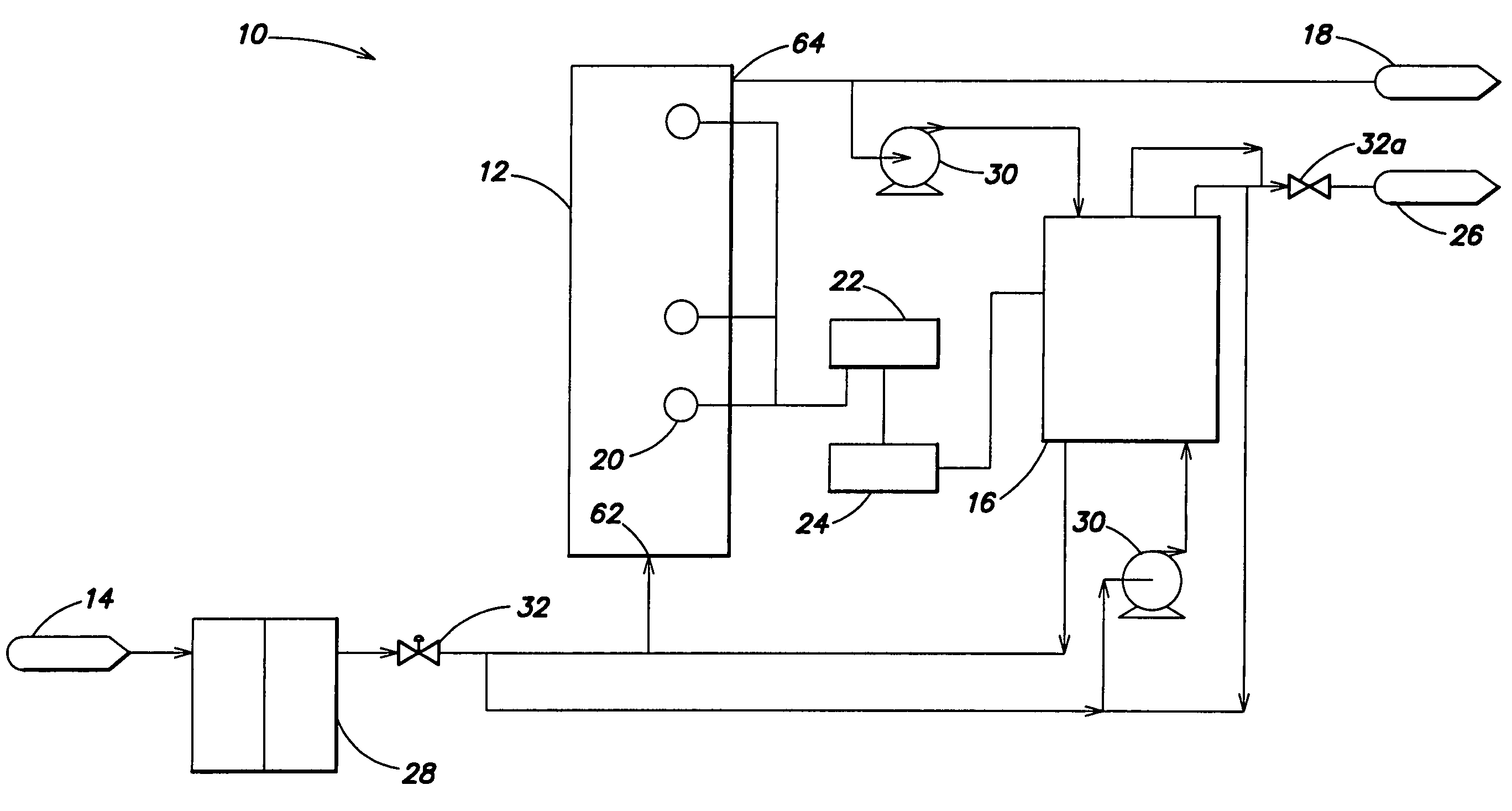

Water treatment system and method

ActiveUS20050103644A1Facilitate water treatmentSludge treatmentVolume/mass flow measurementWater treatment systemWaste stream

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point-of-entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system. A flow regulator regulates a waste stream flow to drain and can be operated to recirculate fluid through electrode or concentrating compartments of an electrochemical device and can opened and closed intermittently according to a predetermined schedule or based on an operating parameter of the water treatment system. The flow regulator can also be charged so that ionic species can be generated in the surrounding fluid, which, in turn, can lower the pH of the surrounding fluid.

Owner:EVOQUA WATER TECH LLC

Acid zirconium phosphate and alkaline hydrous zirconium oxide materials for sorbent dialysis

ActiveUS8409444B2Avoid disadvantagesRestore balanceCation exchanger materialsSolvent extractionIon exchangeDialysis fluid

Owner:FRESENIUS MEDICAL CARE HLDG INC

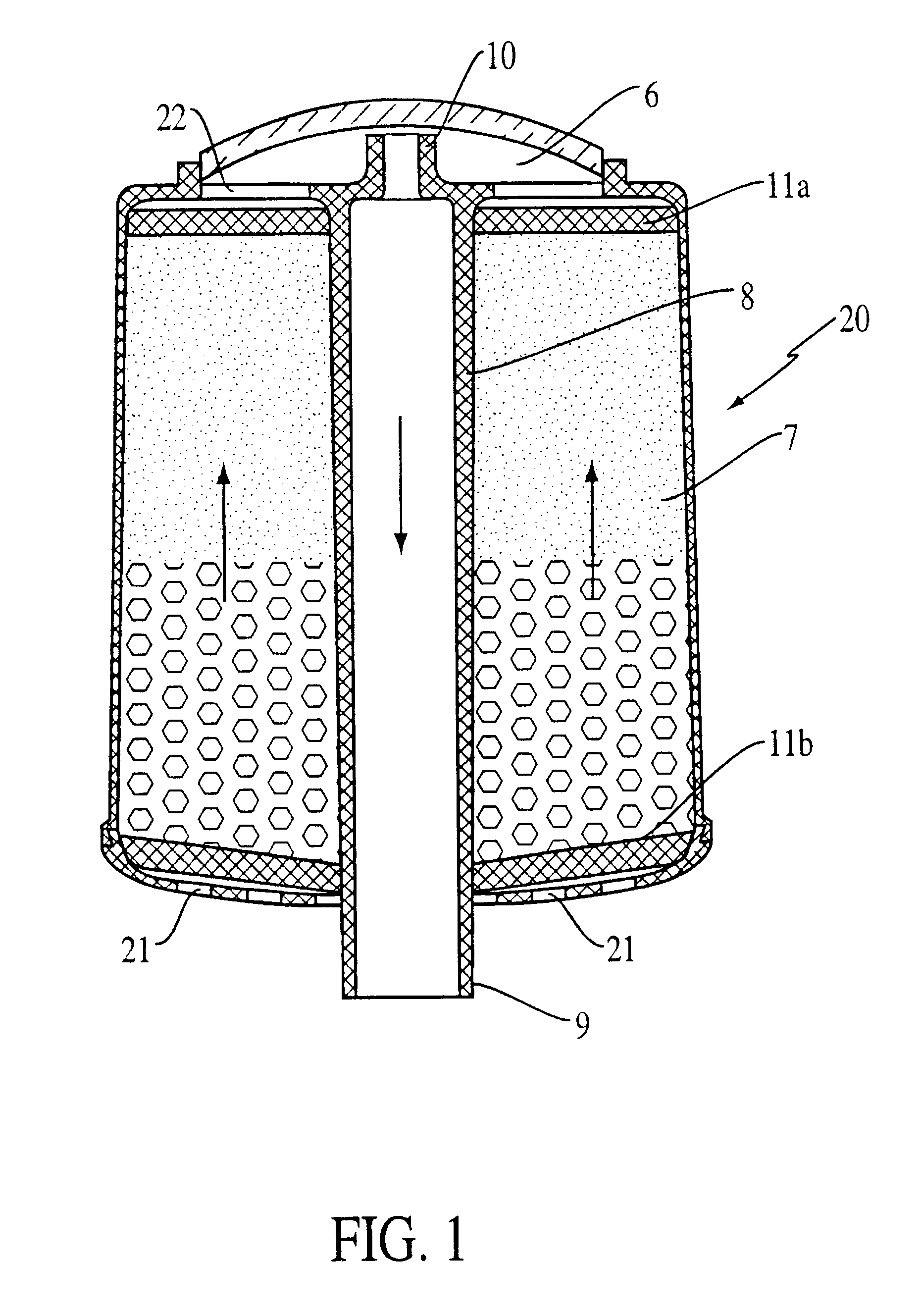

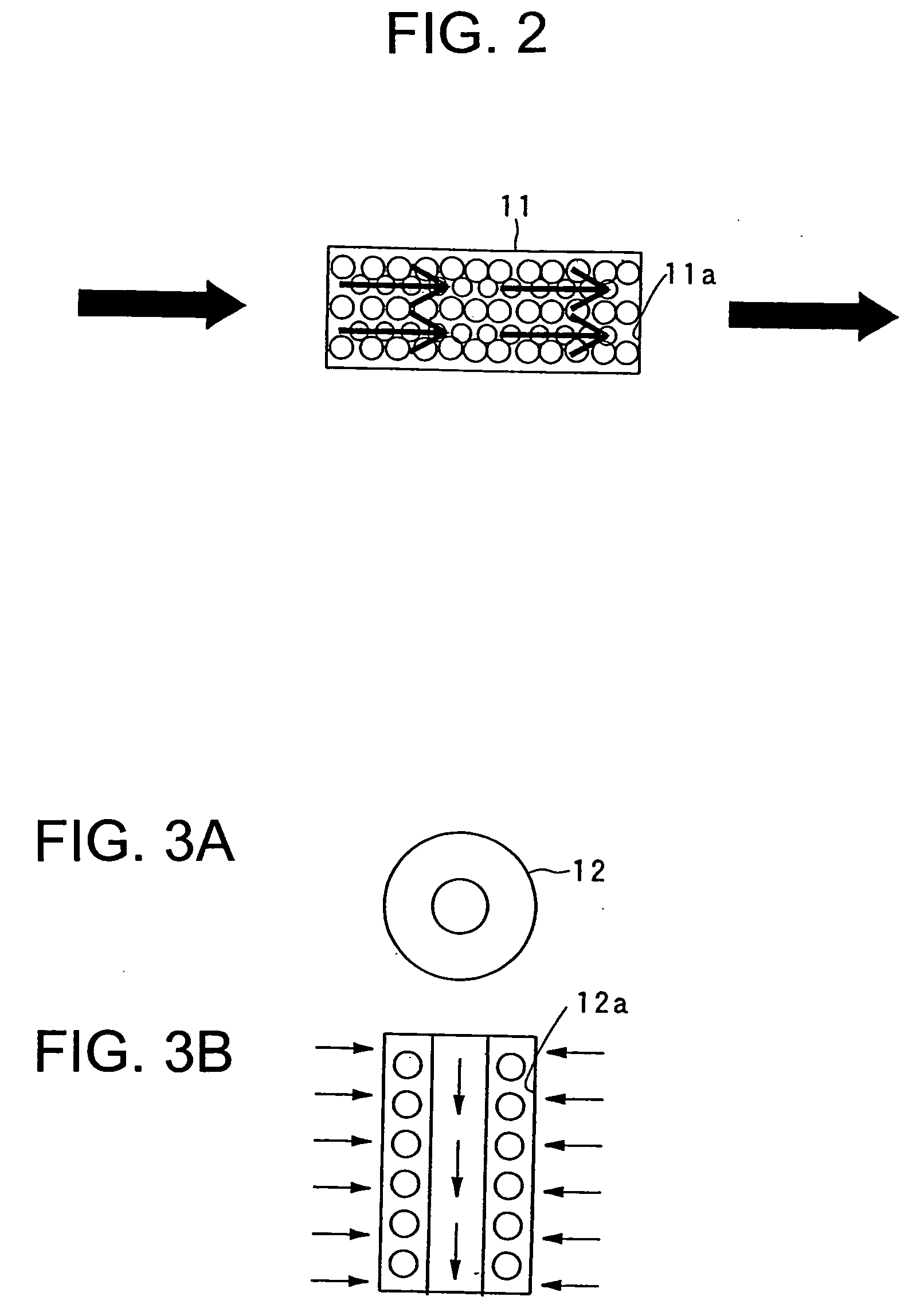

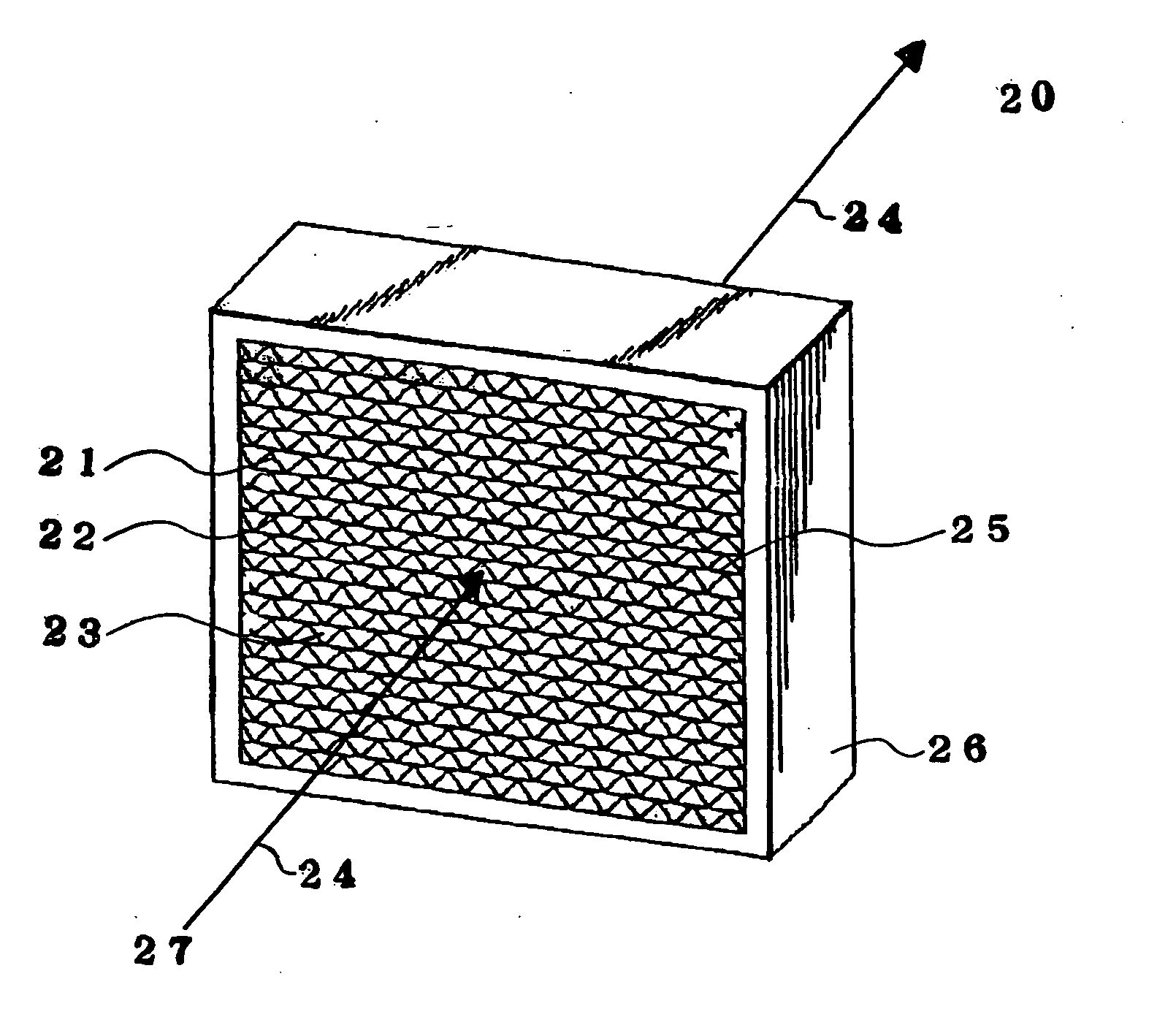

Ion-exchange filter

ActiveUS20050115884A1Improve exchange efficiencyLow pressure lossIon-exchange column/bed processesFuel cell auxillariesFuel cellsIon exchange

A fuel cell system includes an ion-exchange filter, which is provided with a cartridge which is filled up with an ion-exchange resin. The cartridge includes one of a pressure-loss emphasizing type cartridge and an ion-exchange efficiency emphasizing type cartridge, which are selectively exchanged with each other, for a common case of the ion-exchange filter. The ion-exchange efficiency emphasizing type cartridge is one for an ion-exchange filter having a high pressure loss and high ion-exchange efficiency and, on the other hand, the pressure-loss emphasizing type cartridge is one for an ion-exchange filter having a pressure loss lower than that of the former ion-exchange filter and an ion-exchange efficiency lower than that of the former ion-exchange filter.

Owner:TOYO ROKI MFG CO LTD +1

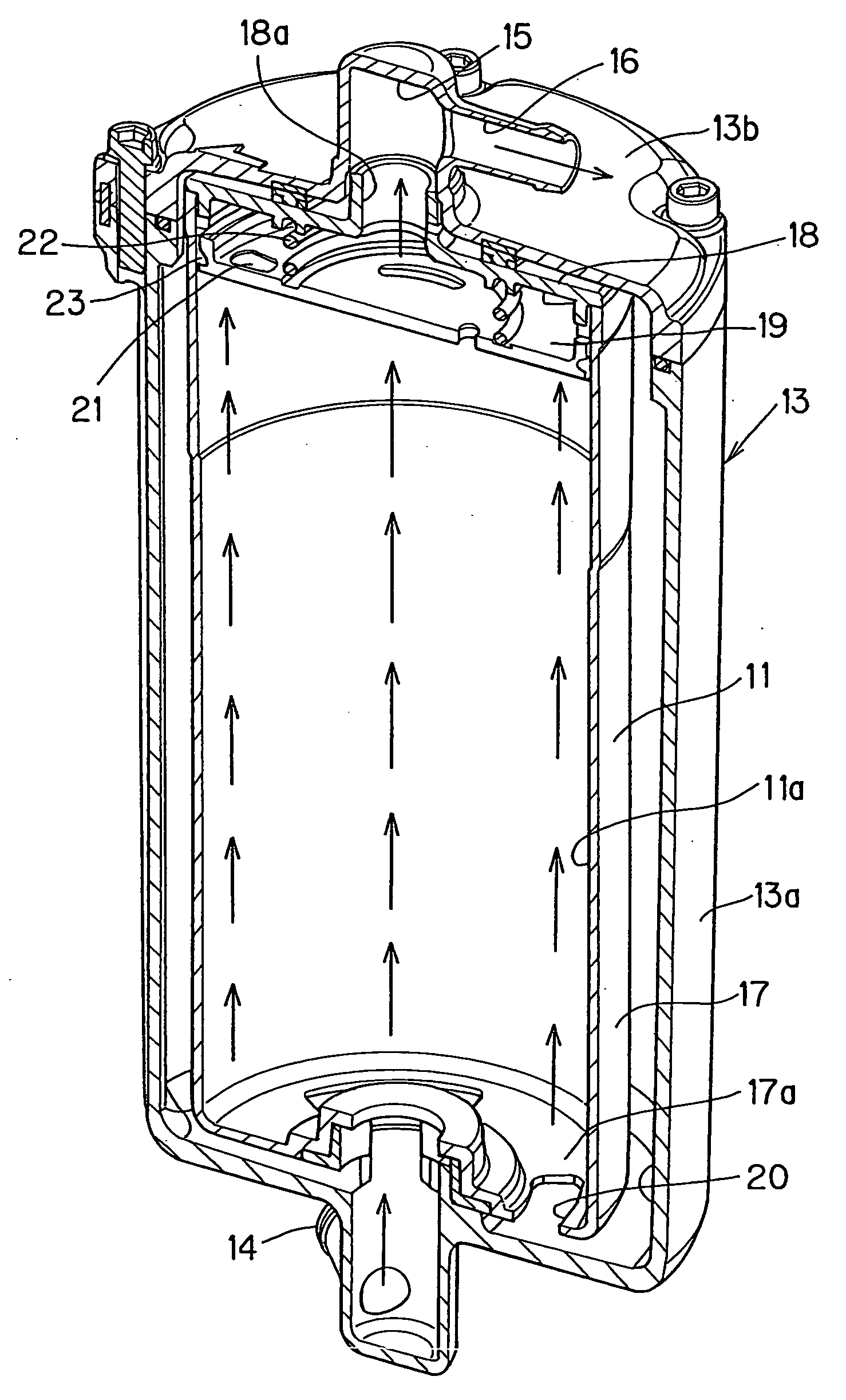

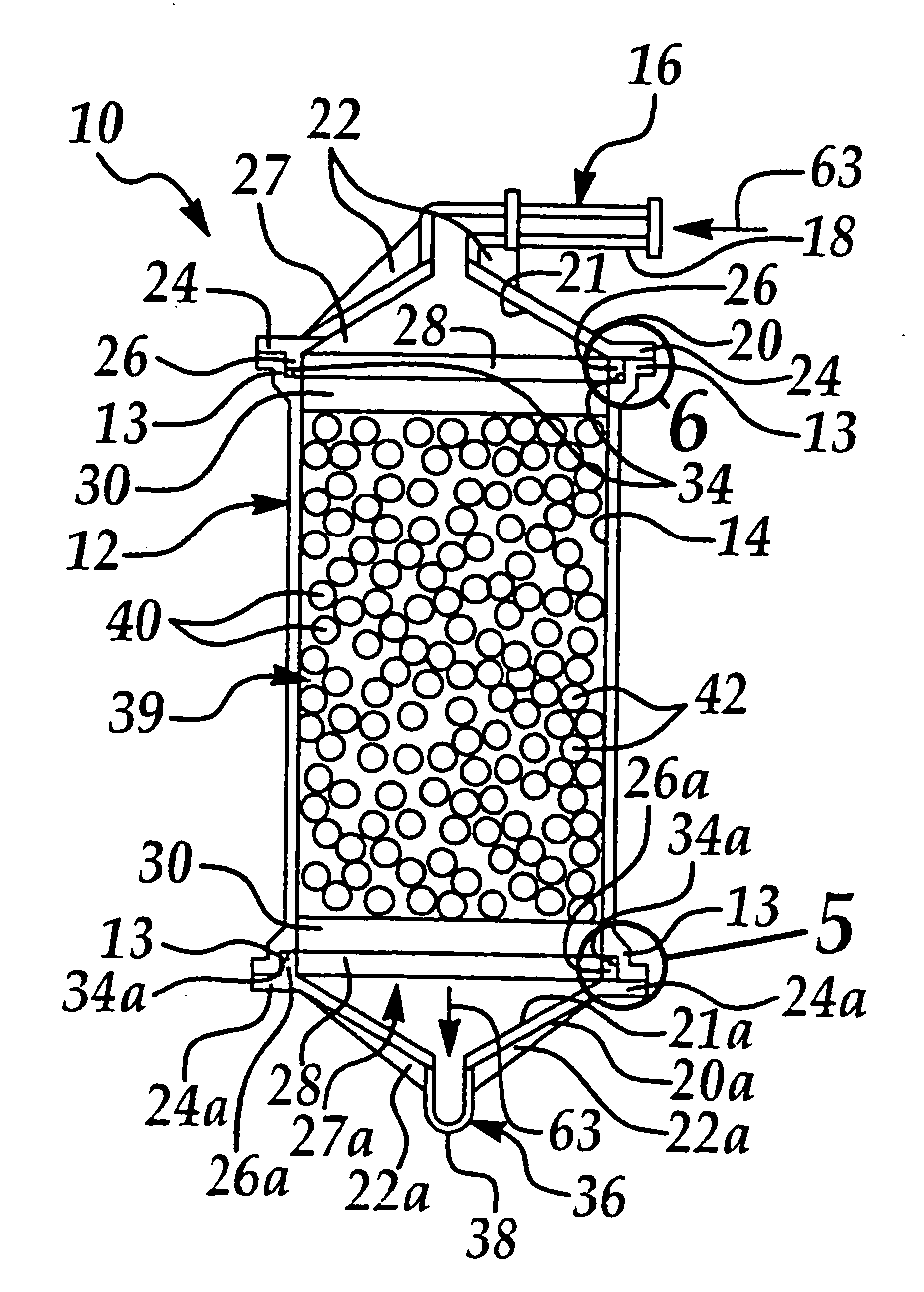

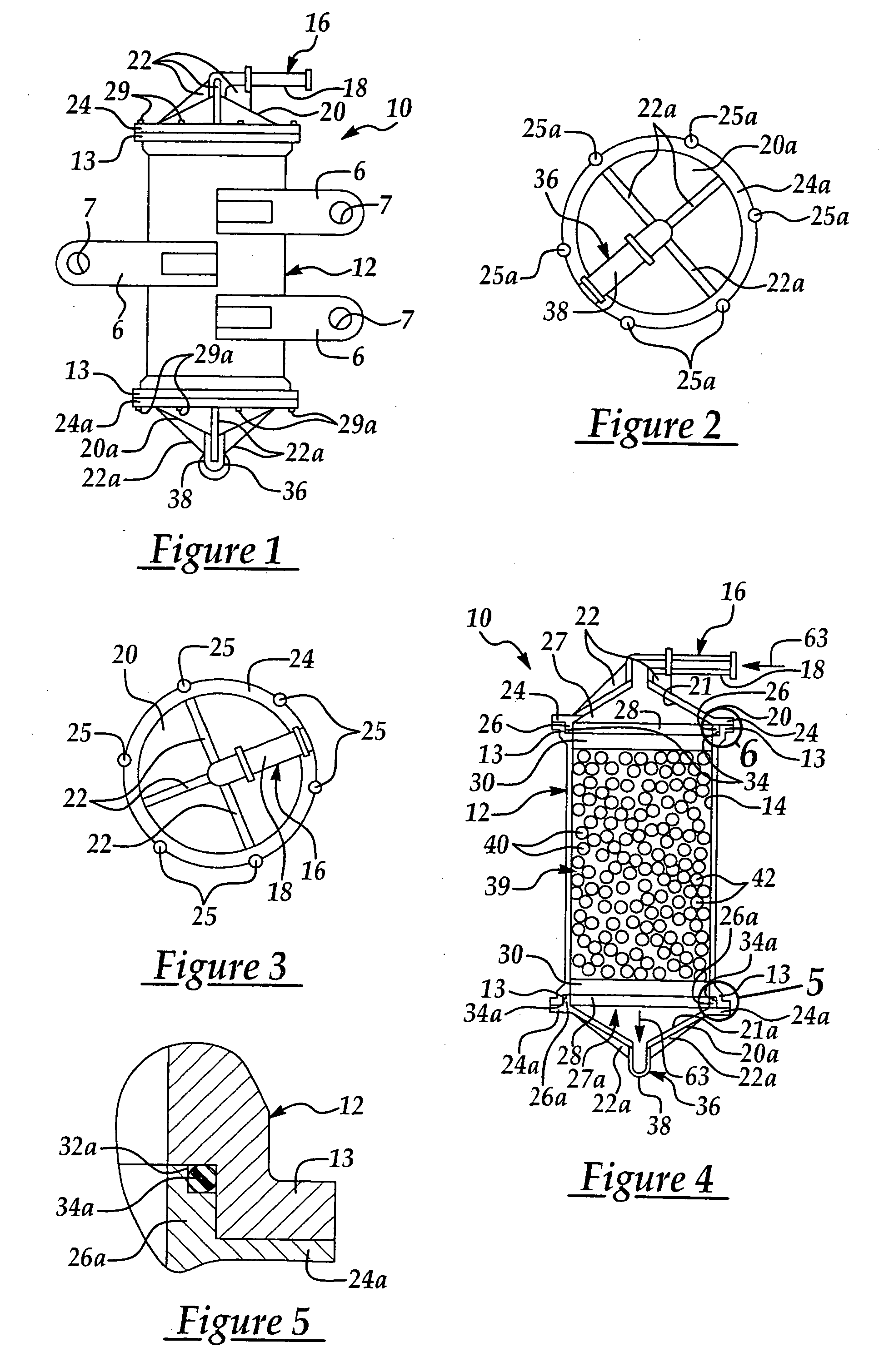

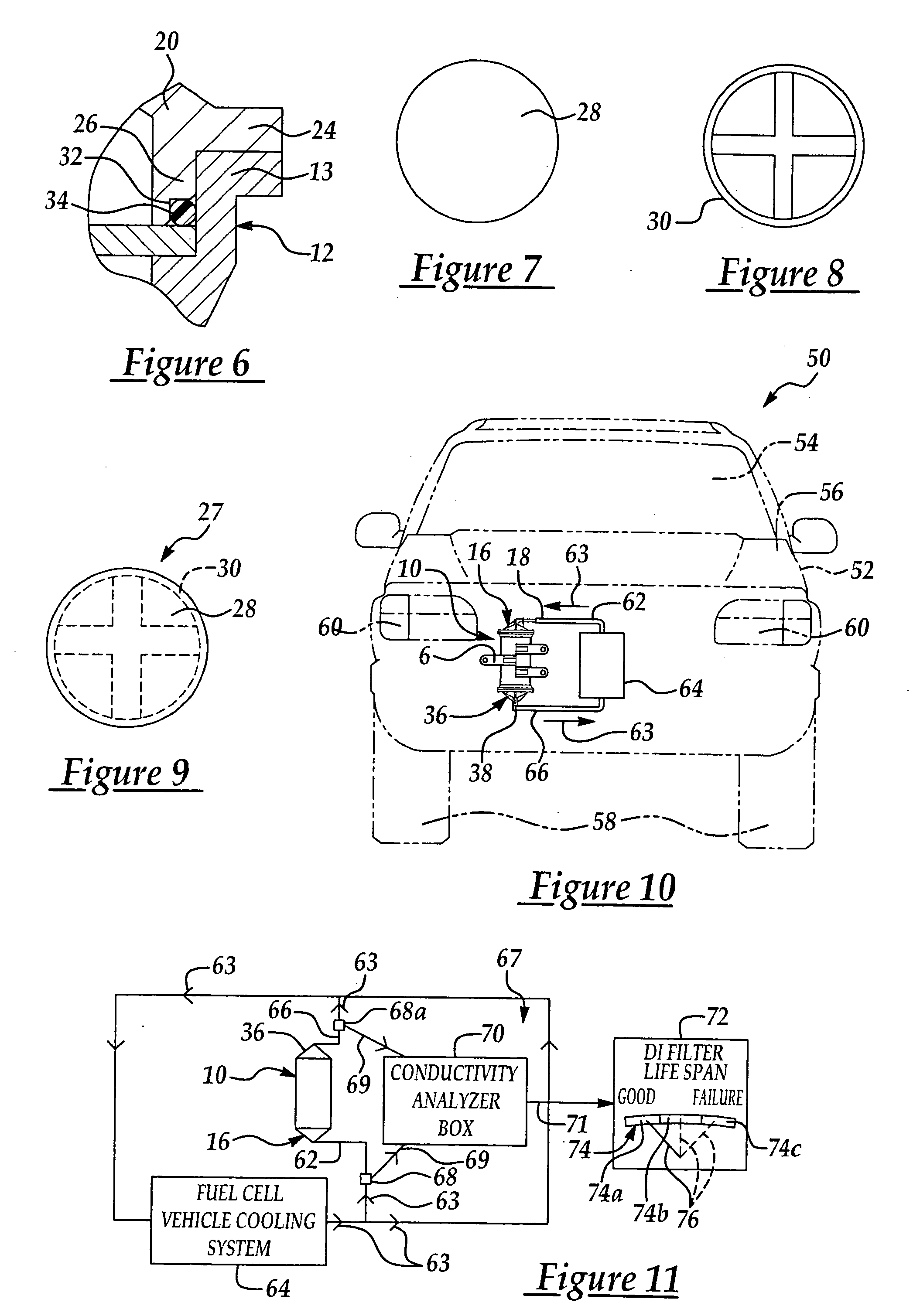

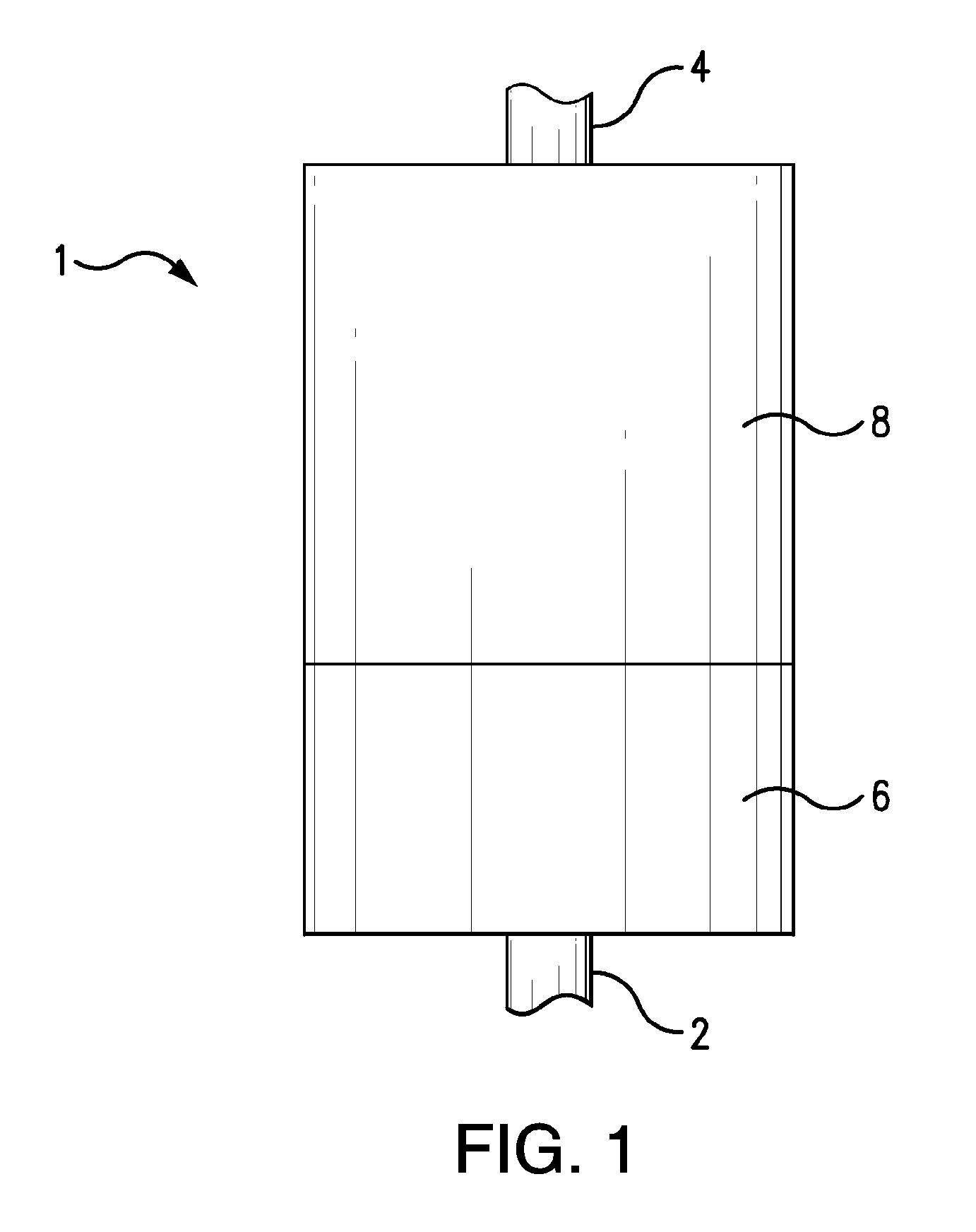

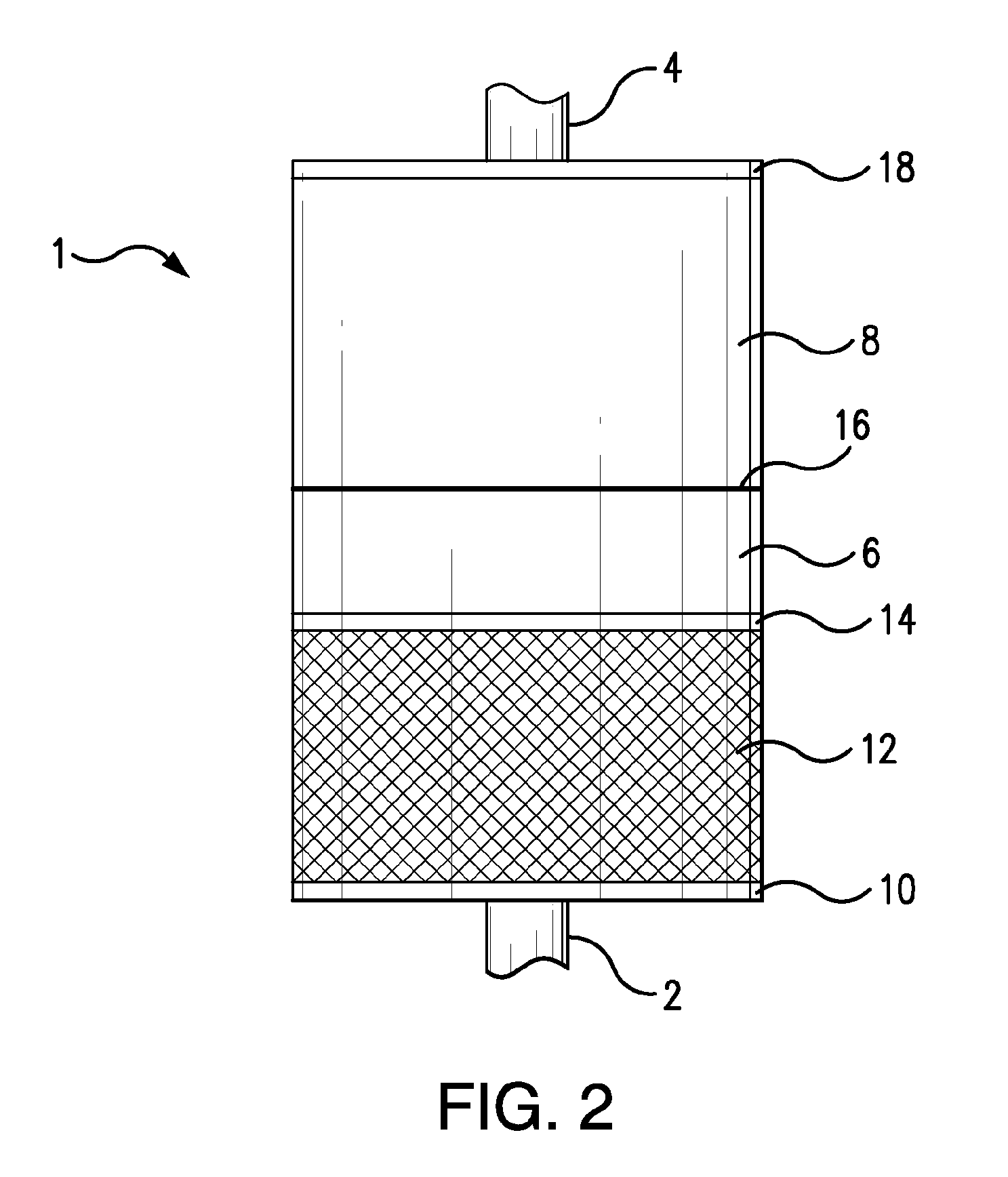

Deionization filter for fuel cell vehicle coolant

A novel deionization filter for removing ions from a coolant in an electric fuel cell vehicle cooling system is disclosed. The deionization filter includes a filter housing having a coolant inlet port, through which the coolant enters the filter housing; and a coolant outlet port, through which the coolant exits the filter housing. An ion exchange bed having positively-charged and negatively-charged ion exchange resin beads is provided in the filter housing for removing negative and positive ions, respectively, from the coolant. At least one filter assembly is typically provided in the filter housing for filtering particles from the coolant.

Owner:FORD MOTOR CO

Regeneration of adsorption media within electrical purification apparatuses

The present disclosure generally relates to methods, systems, and devices for electrically purifying liquids containing species such as minerals, salts, ions, organics, and the like. One aspect of the invention provides methods of regenerating media within an electrical purification device, for example, exposing the media to one or more eluting solutions, and / or selectively desorbing ions, organics, and / or other species from the media by exposing the media to certain eluting conditions. In yet another aspect, methods of selectively removing one or more ions, organics, and / or other species from a liquid to be purified are provided, e.g., by selective removal of one or more ions, or organics, and the like from solution that can easily precipitate, and / or cause scaling or fouling to occur. In still another aspect, the invention provides a method of treating a solution containing ions, organics, and / or other species using an electrical purification apparatus in a continuous or semi-continuous fashion, while also performing regeneration of media contained within the apparatus.

Owner:SIEMENS IND INC

Apparatus and method for making a peroxycarboxylic acid

ActiveUS7547421B2Increase life and activity and safetyProcess control/regulationExhaust apparatusCarboxylic acidReagent

Owner:ECOLAB USA INC

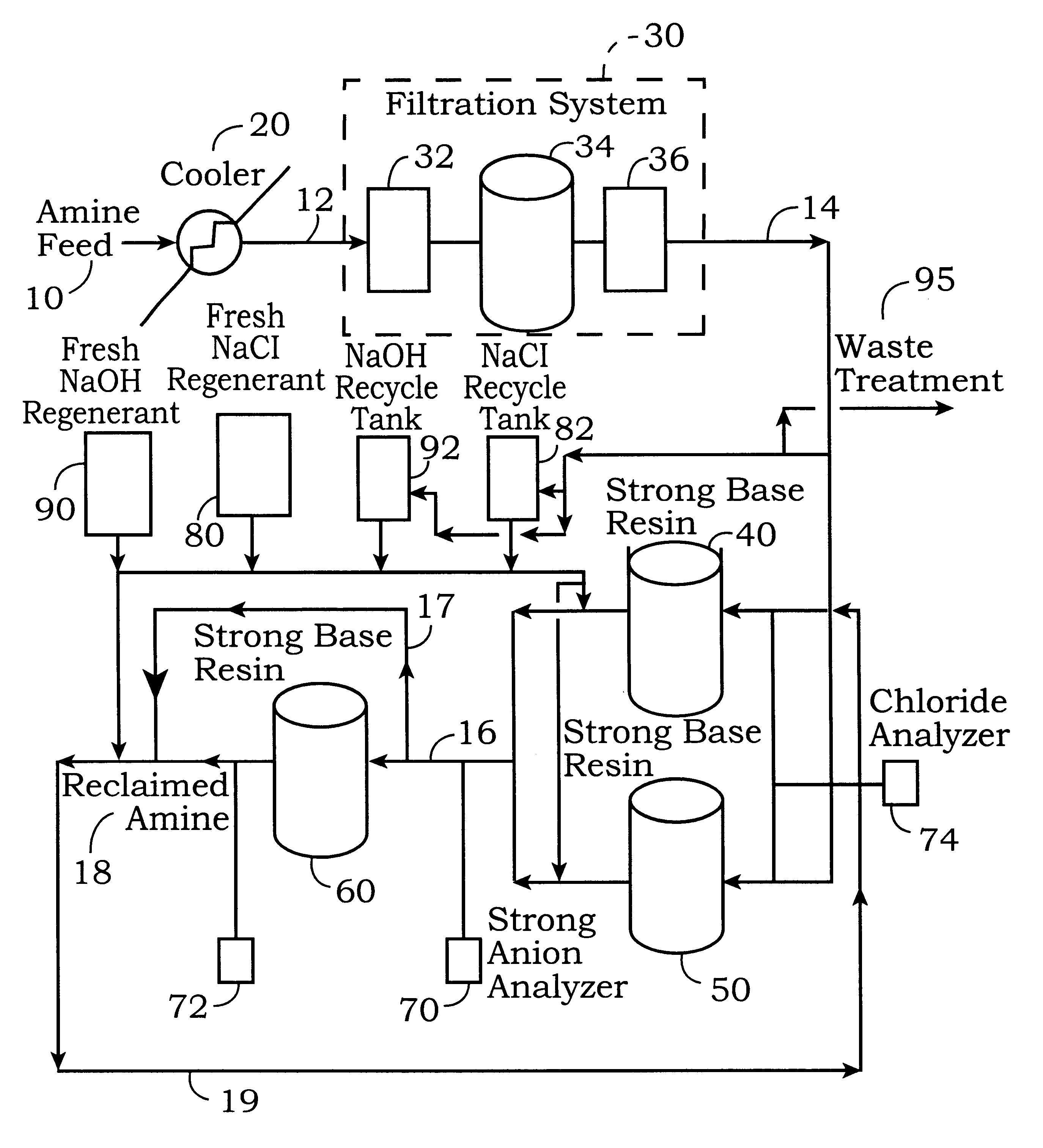

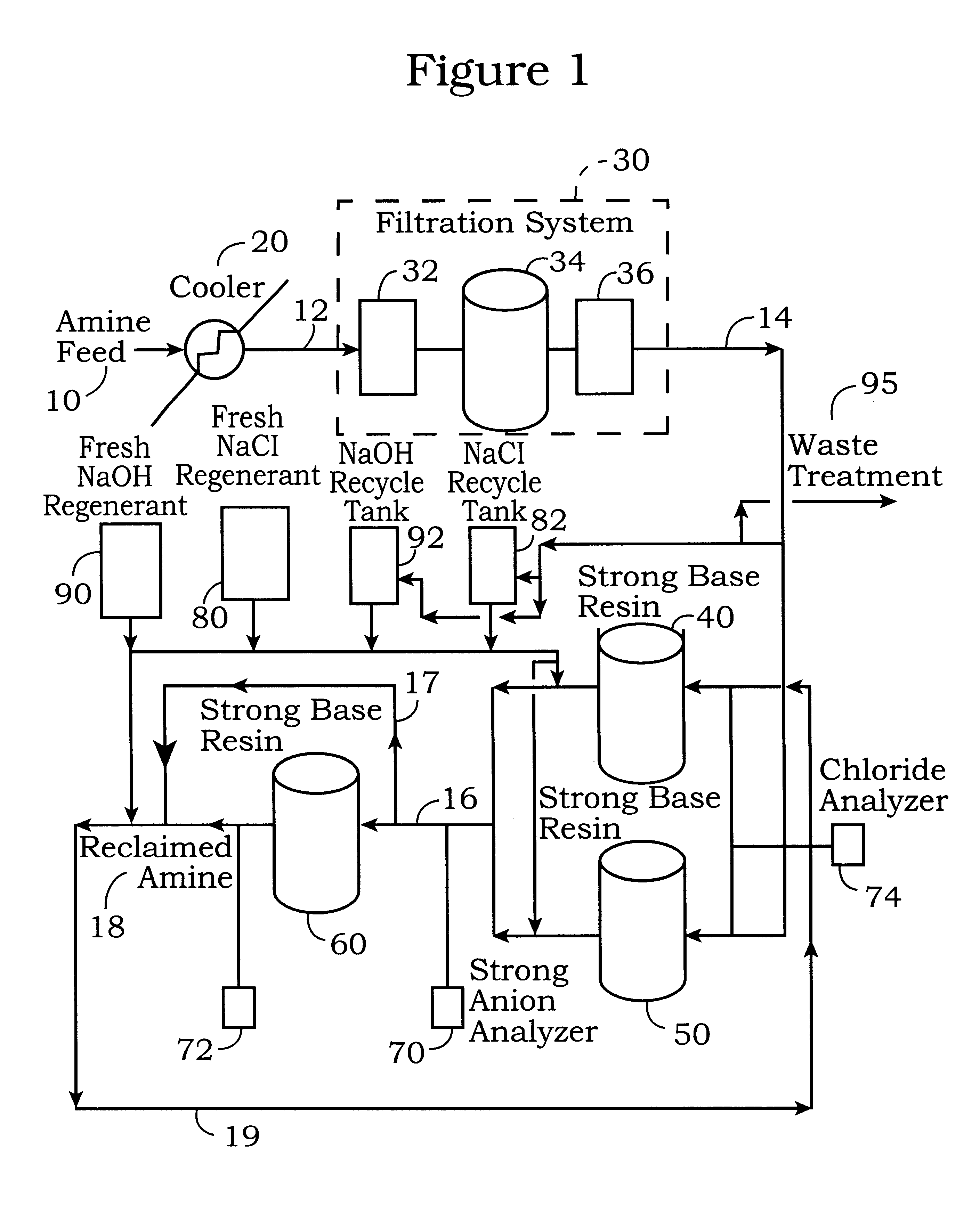

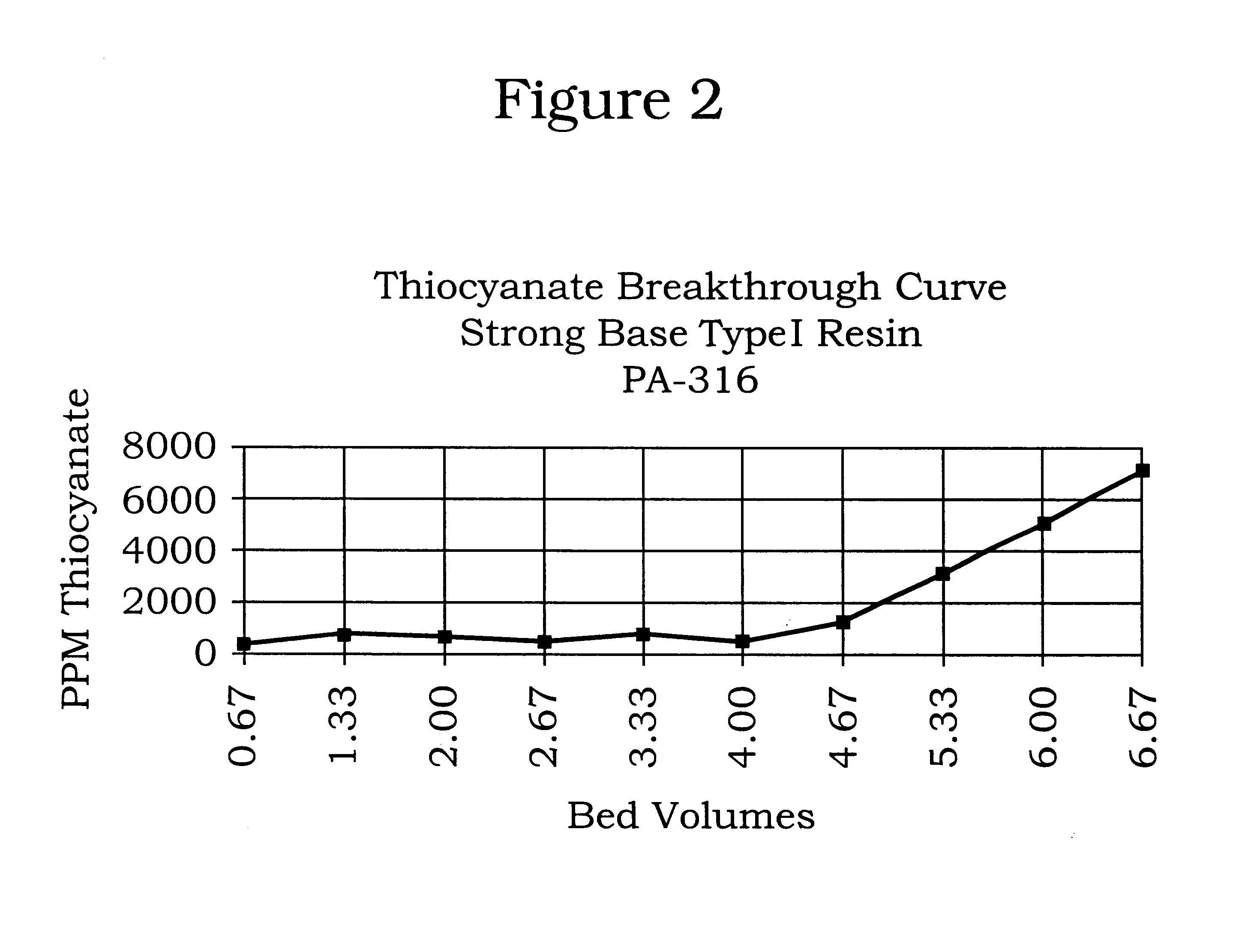

Process for the reclamation of spent alkanolamine solution

InactiveUS6245128B1Raise the potentialReduces efficiency of systemLiquid degasificationIon-exchange column/bed processesHigh concentrationNitrogen gas

A process for the reclamation of spent aqueous alkanolamine solutions by contacting a spent aqueous alkanolamine solution with a strong base ion exchange resin for time sufficient to sorb from the aqueous alkanolamine solution at least a portion of the accumulated ions and after a high concentration of ions accumulate on the resin, regenerating the strong base ion exchange resin by: a) purging the resin with water or nitrogen, b) contacting the strong base ion exchange resin with a sodium chloride solution for a time sufficient to remove the ions, c) purging the resin to remove the sodium chloride solution, d) contacting the resin with an alkali metal hydroxide solution, preferably sodium hydroxide, for a time sufficient to convert the resin to a substantially hydroxide form; and e) purging the resin, wherein the ion sorption capacity of the resin is maintained at a substantially constant value.

Owner:MOBIL OIL CORP

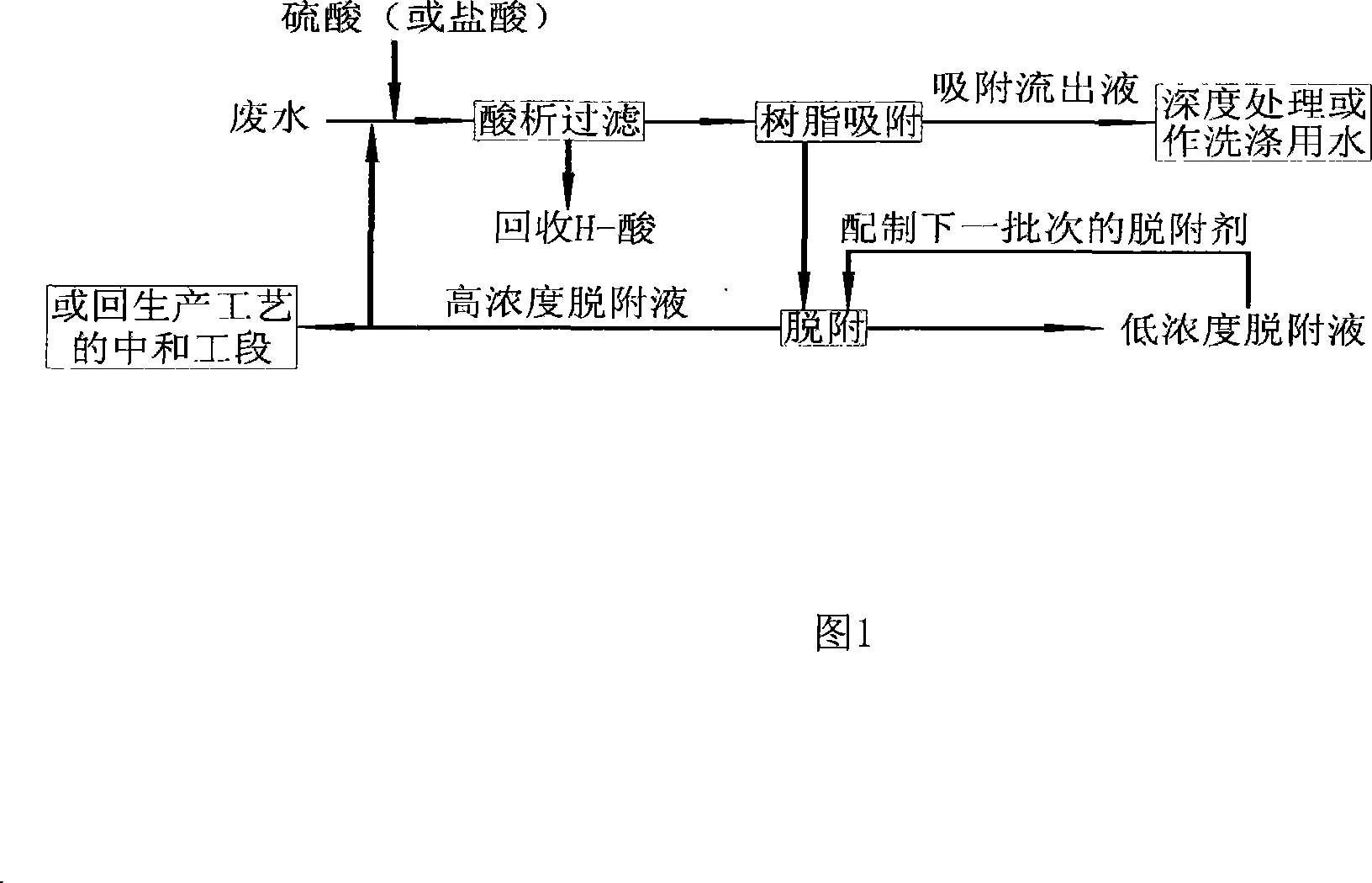

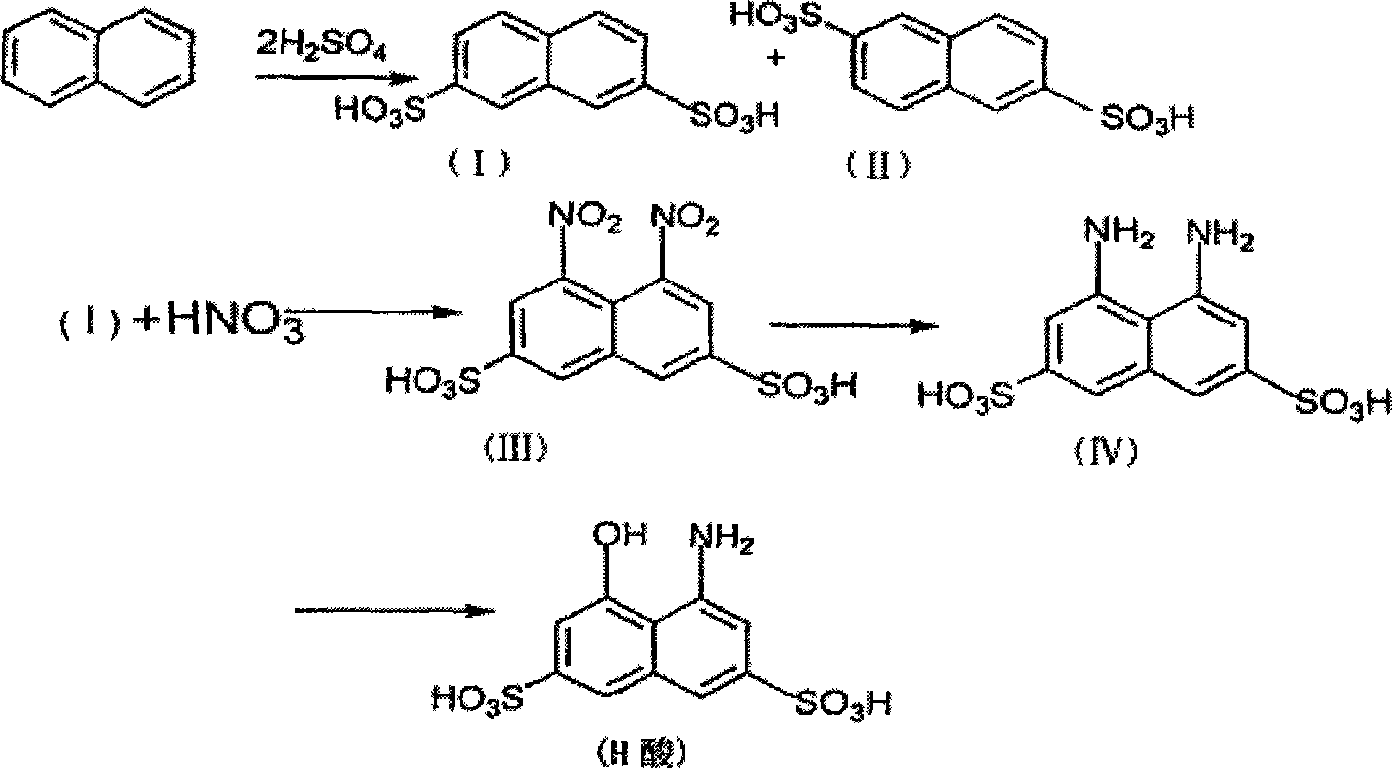

Method for treating waste water of H-acid production

InactiveCN101104533ANot affected by the adsorption effectImprove practicalityOrganic chemistryIon-exchange column/bed processesResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

Spraying device

The present invention relates to a spraying device suitable for spraying cleaning compositions and rinse water onto hard surfaces. More particularly the spraying device may be attached to a hose, for example a conventional garden hose, so that the cleaning composition and rinse water can be applied to outside surfaces, such as vehicles or the outside surface of windows. The spraying device comprises a purifier located inside the cavity of a container and a spray head.

Owner:THE PROCTER & GAMBLE COMPANY

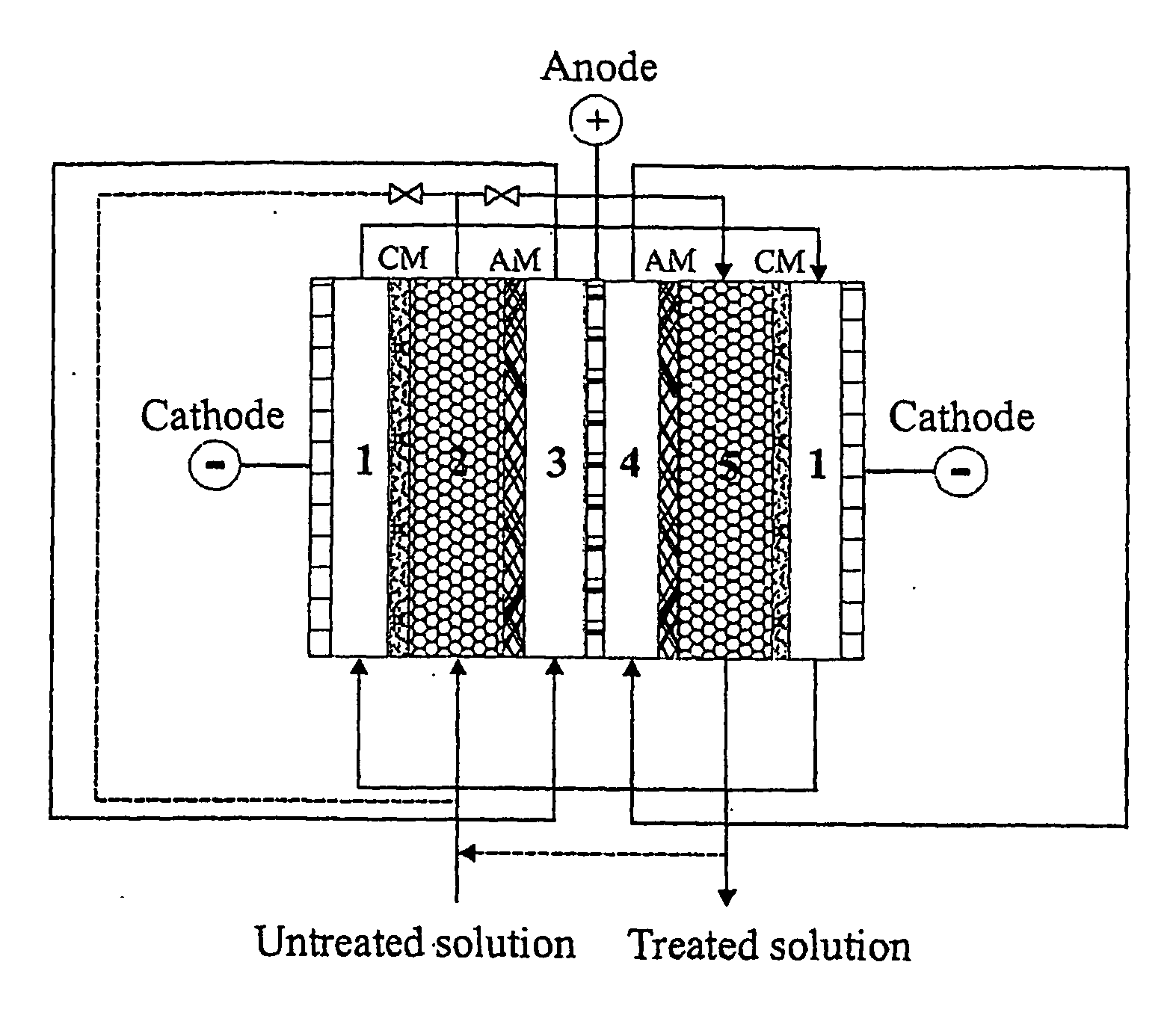

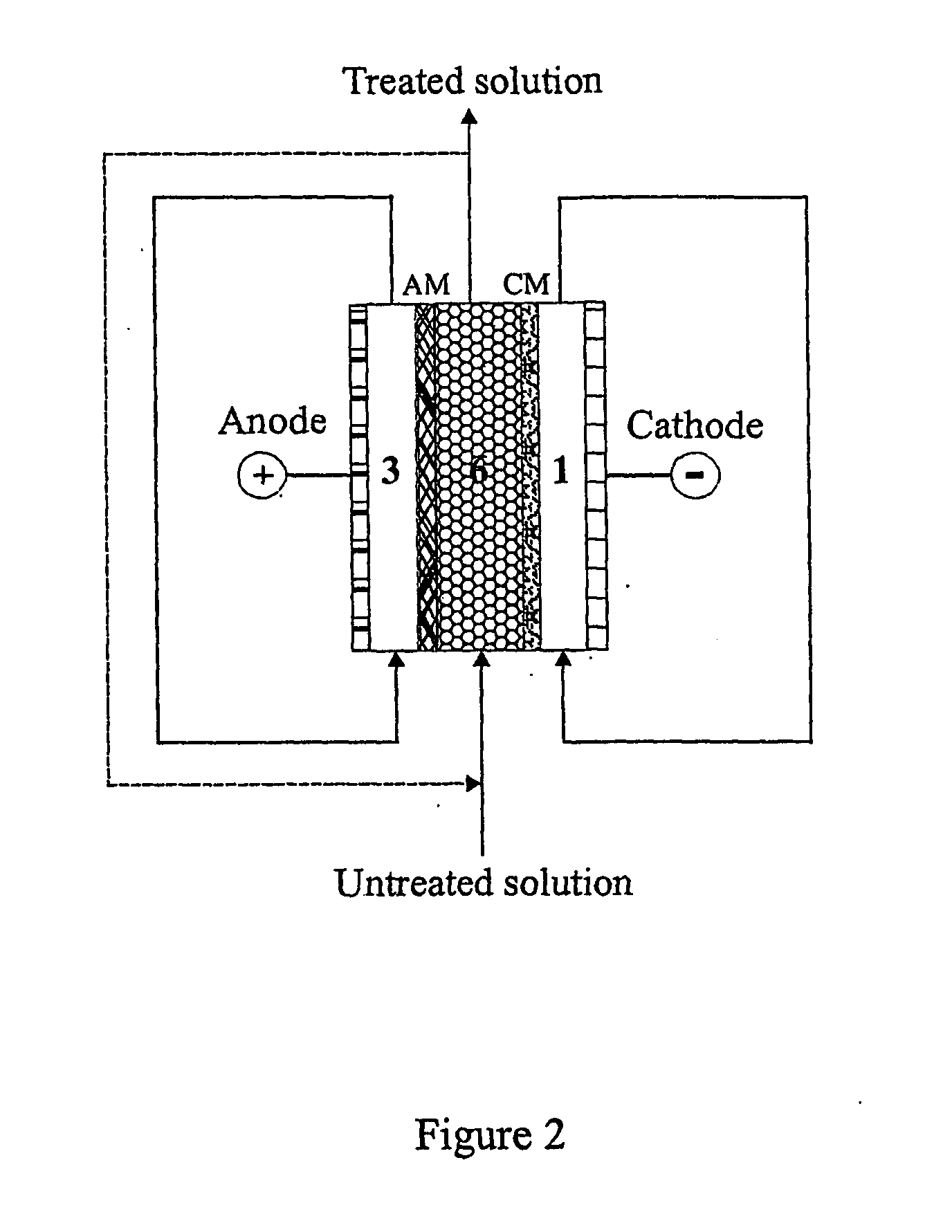

Boron separation and recovery

InactiveUS20060249390A1Efficient dissociationEasy to separateElectrolysis componentsIon-exchange column/bed processesIon exchangeEnvironmental chemistry

A process is provided for separating, concentrating and recovery of boron compound from aqueous solution containing boron, strongly dissociated anions and some cations. The process specifically integrates electrodialysis with ion exchange to selectively separate boron from aqueous solution that contains a wide concentration range of boron, strongly ionised anions such as chloride, nitrate and sulfate, and cations like lithium. The process is adapted for controlling boron concentration in an industrial process, for the recovery or purification of boron and some cations like lithium form aqueous solutions, and for wastewater treatment.

Owner:VATTENFALL

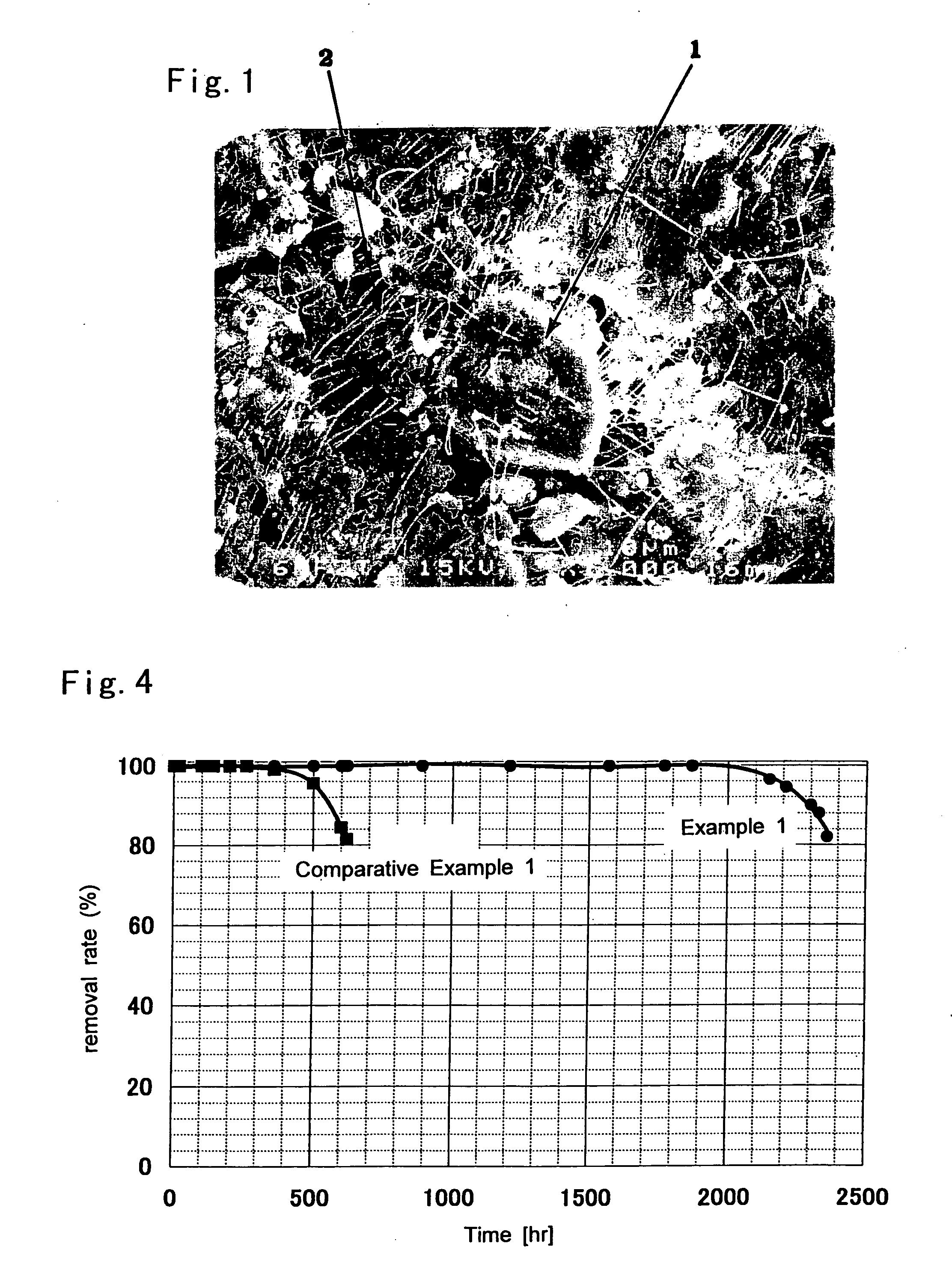

Endotoxin adsorption system

InactiveUS6132610AReduce concentrationAvoid it happening againIon-exchange column/bed processesOther blood circulation devicesCounterionToxin

An endotoxin adsorption system of the present invention comprises a combination of a cation exchange resin having sodium as a counter ion and a cation exchange resin having sodium and one or more metal ions other than sodium as a counter ion, and adsorbs an endotoxin without decreasing of the concentration of cations.

Owner:KANEKA CORP

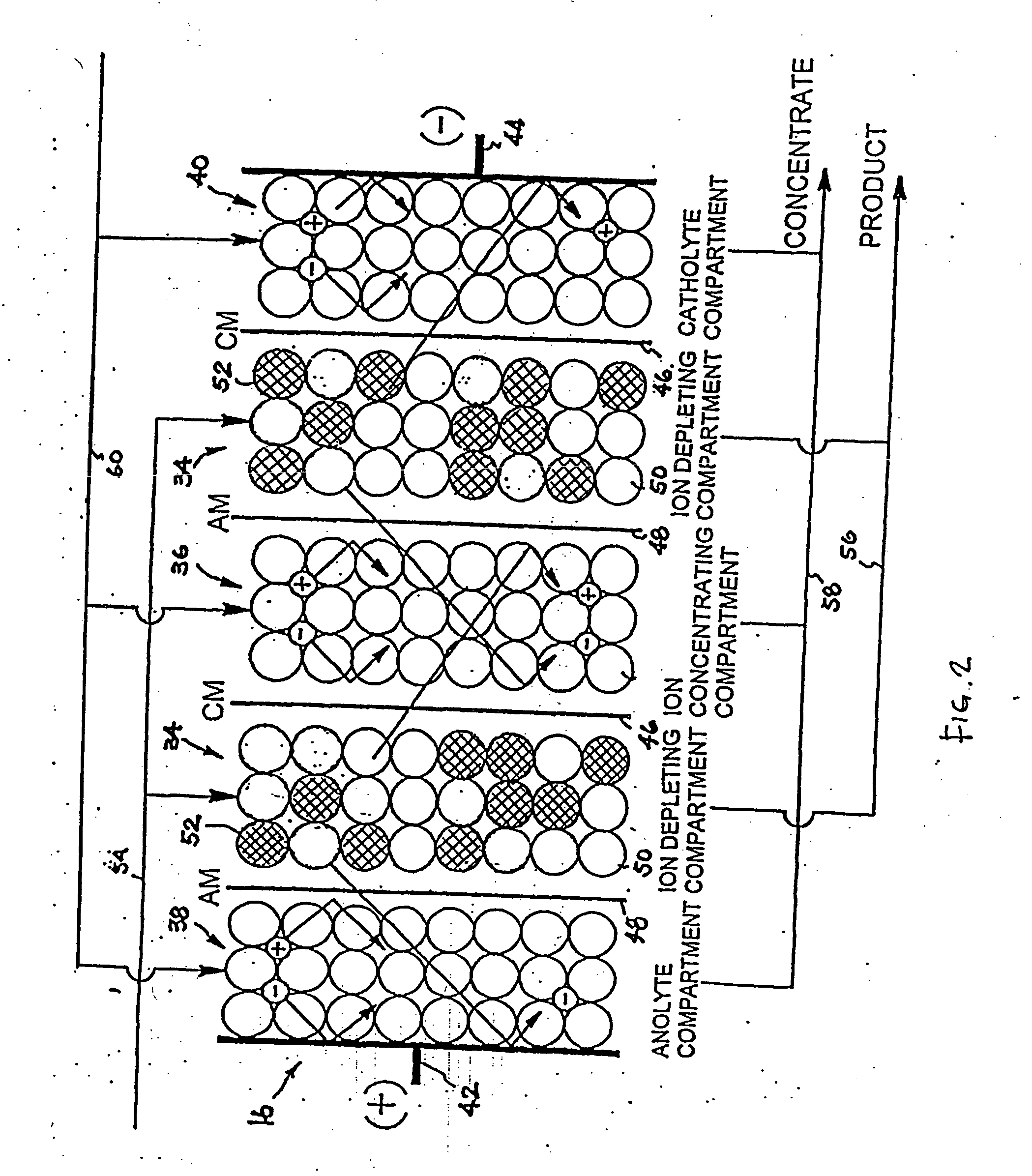

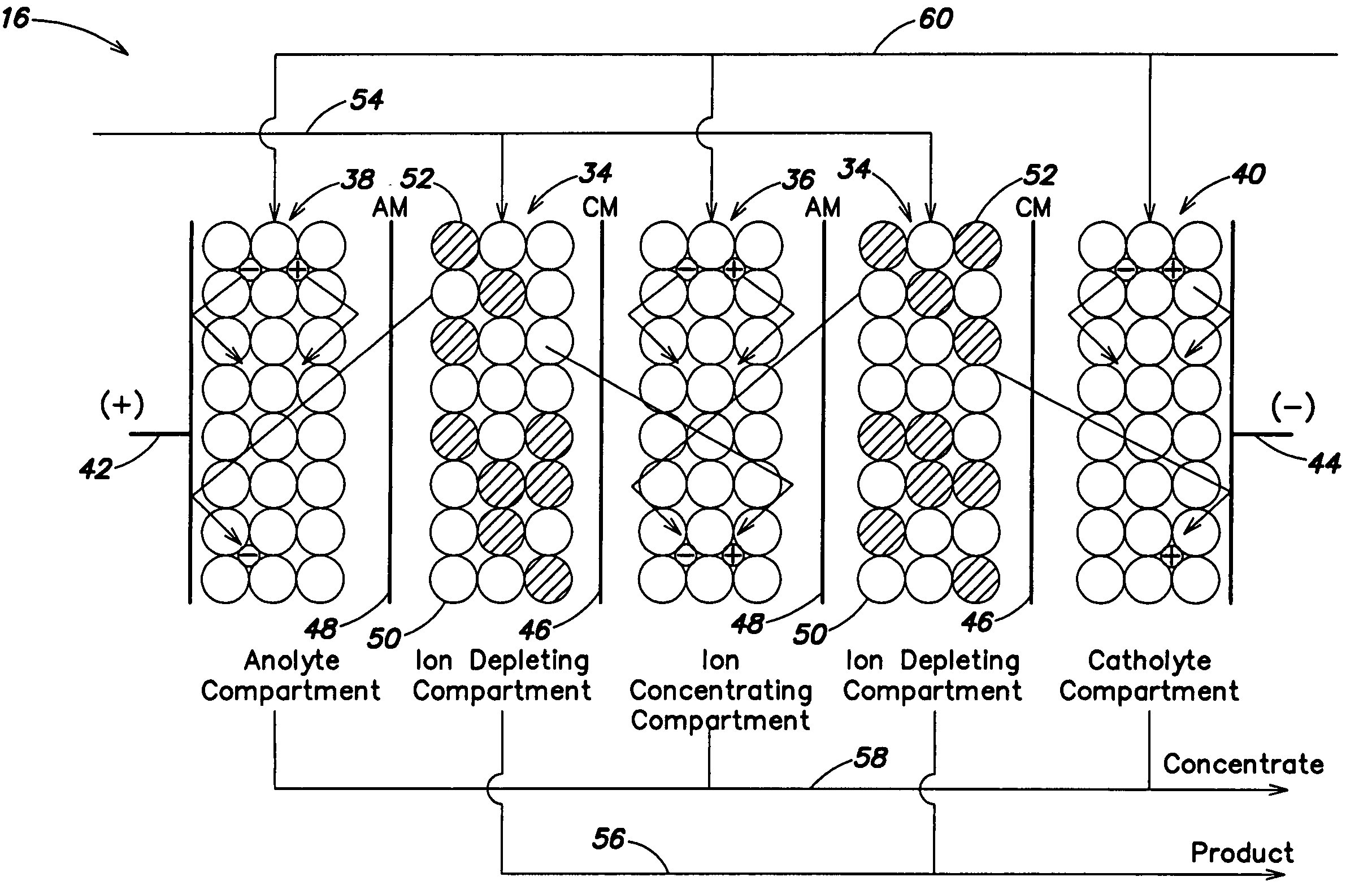

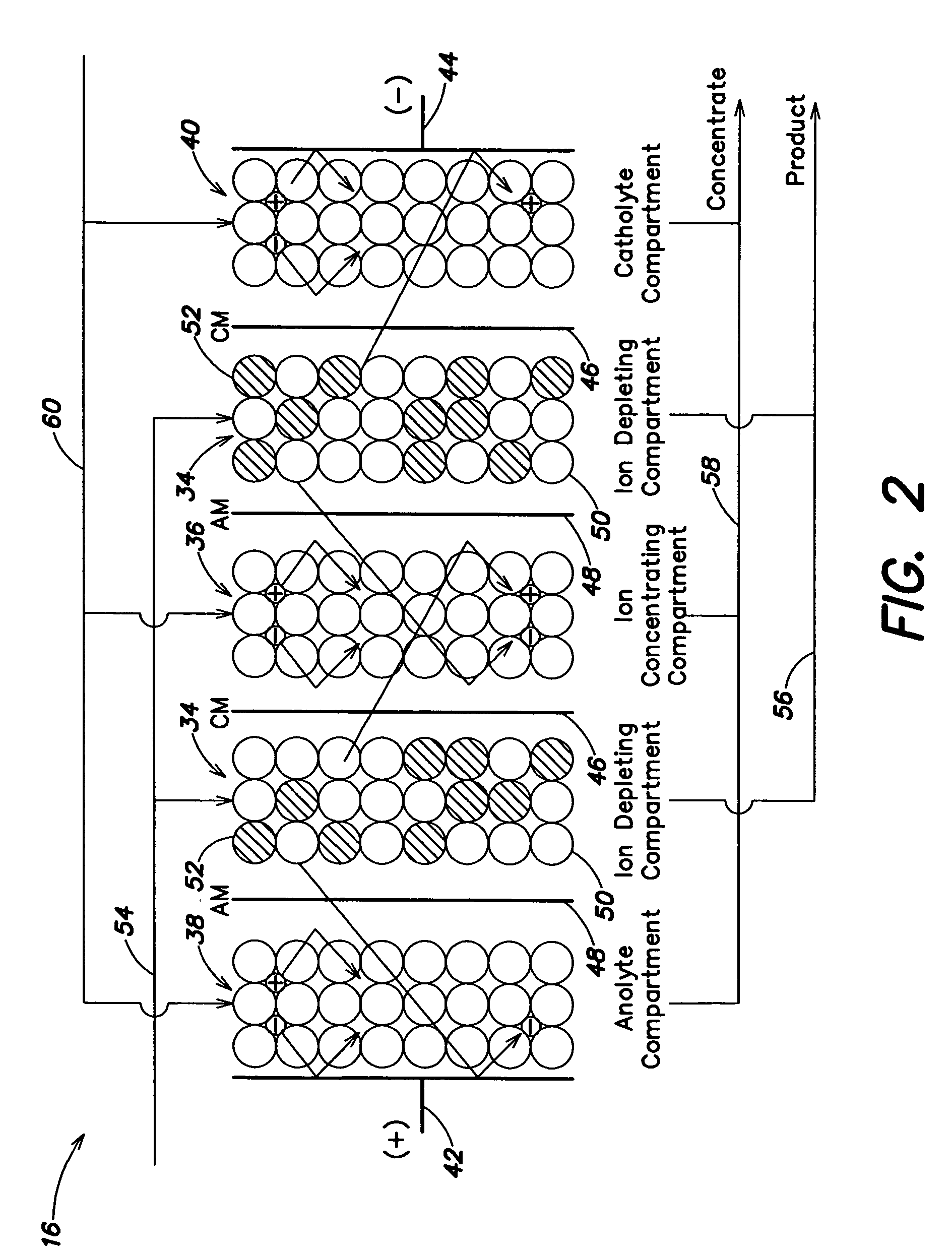

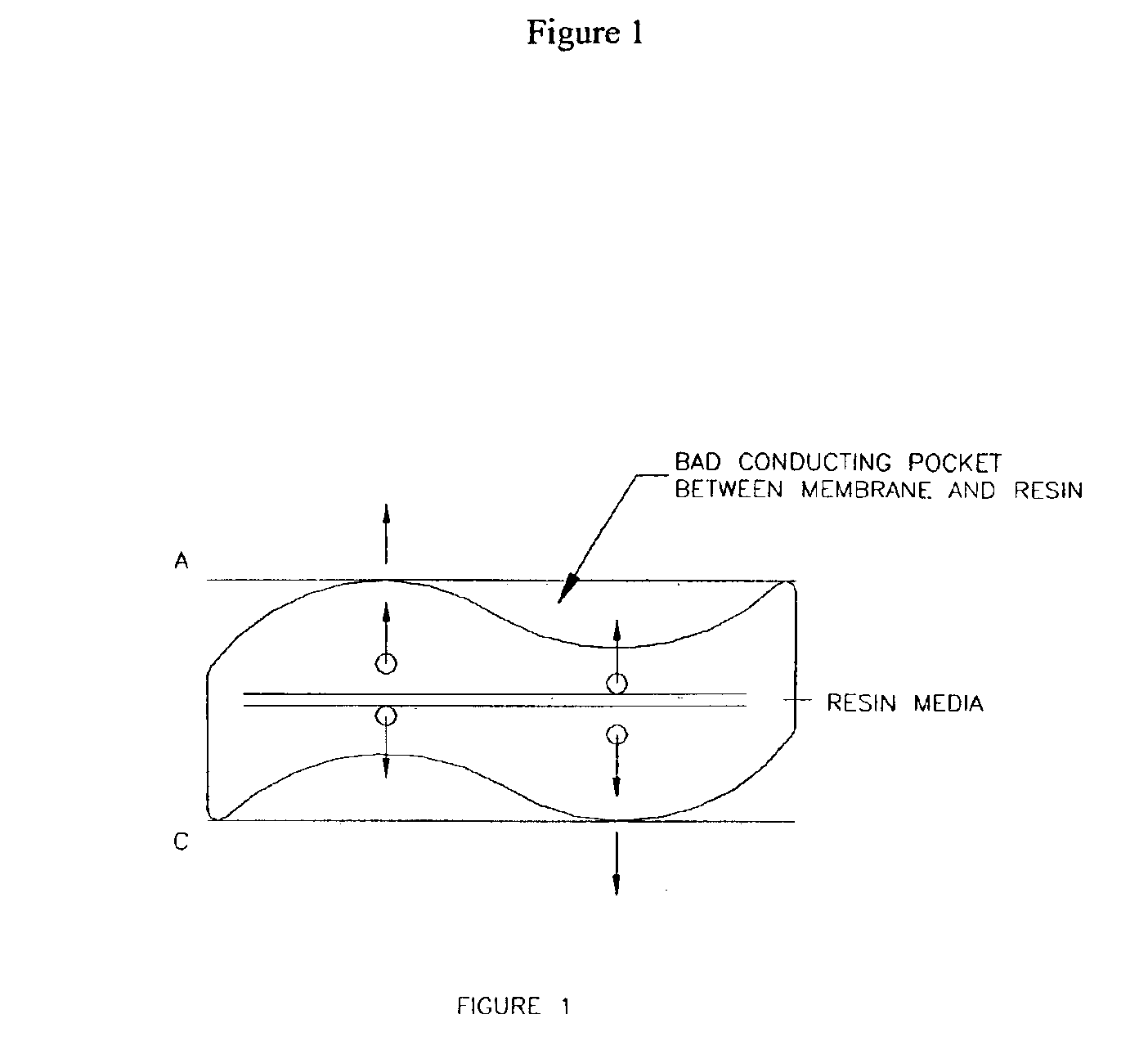

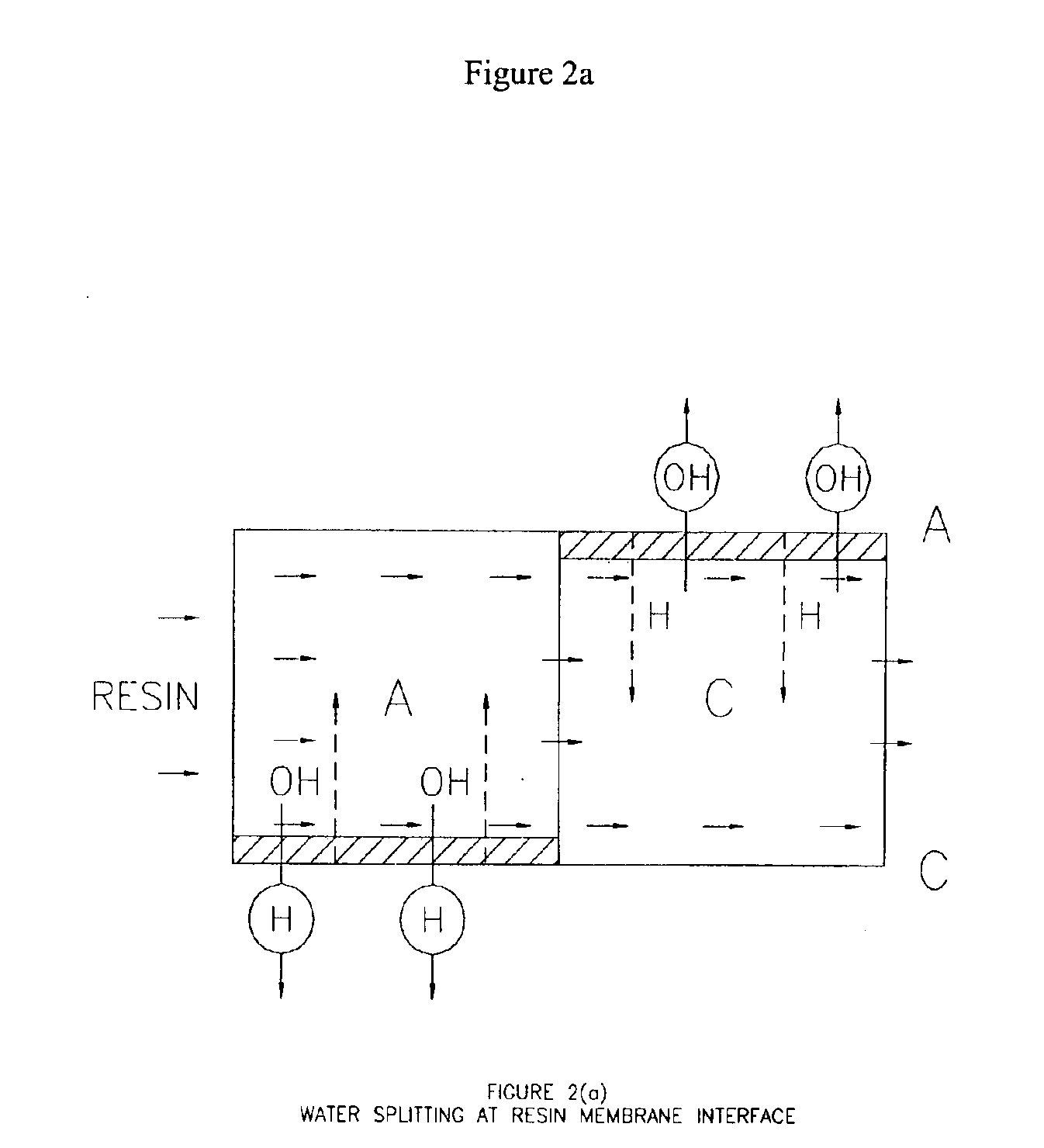

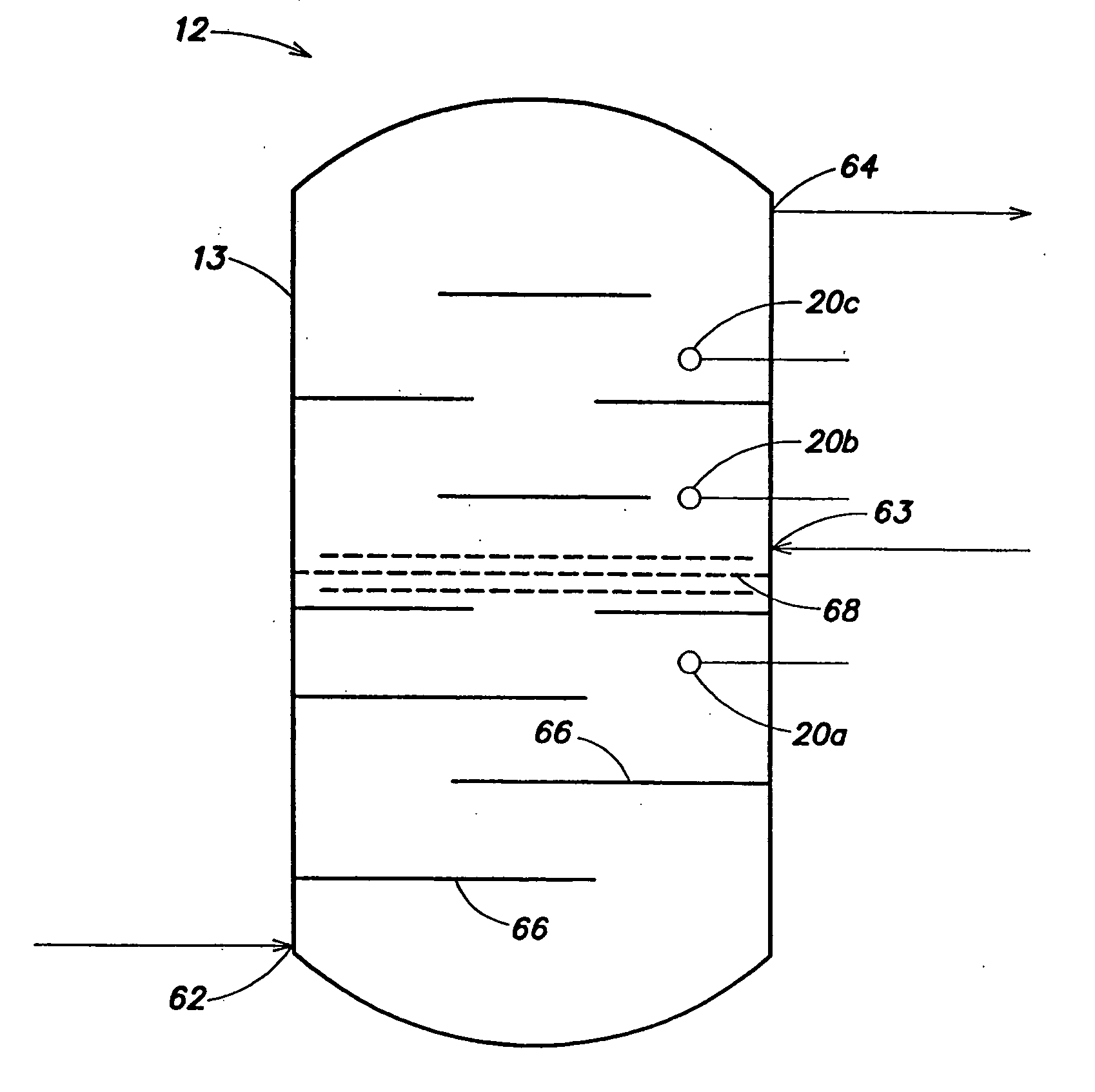

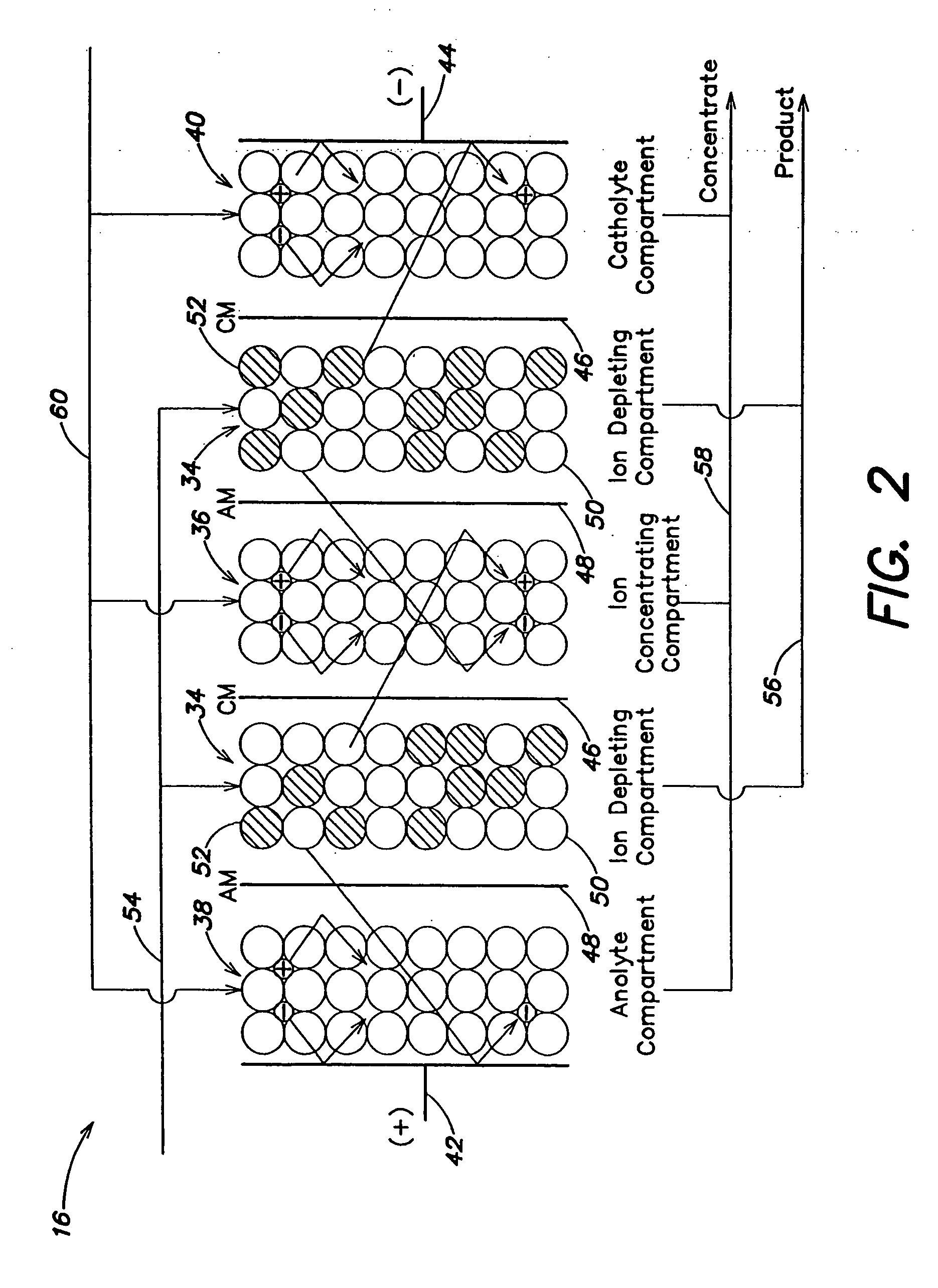

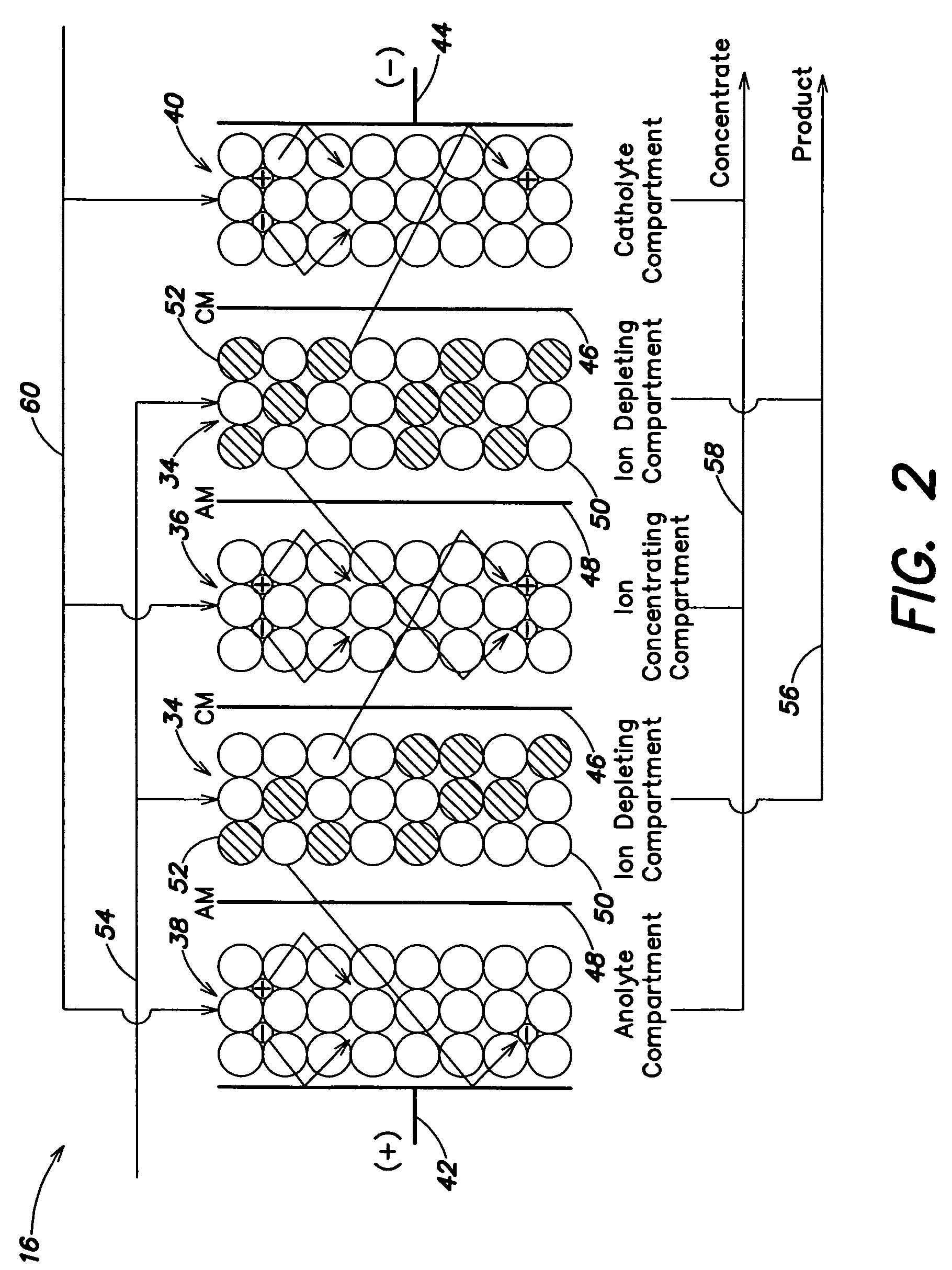

Sparse media edi apparatus and method

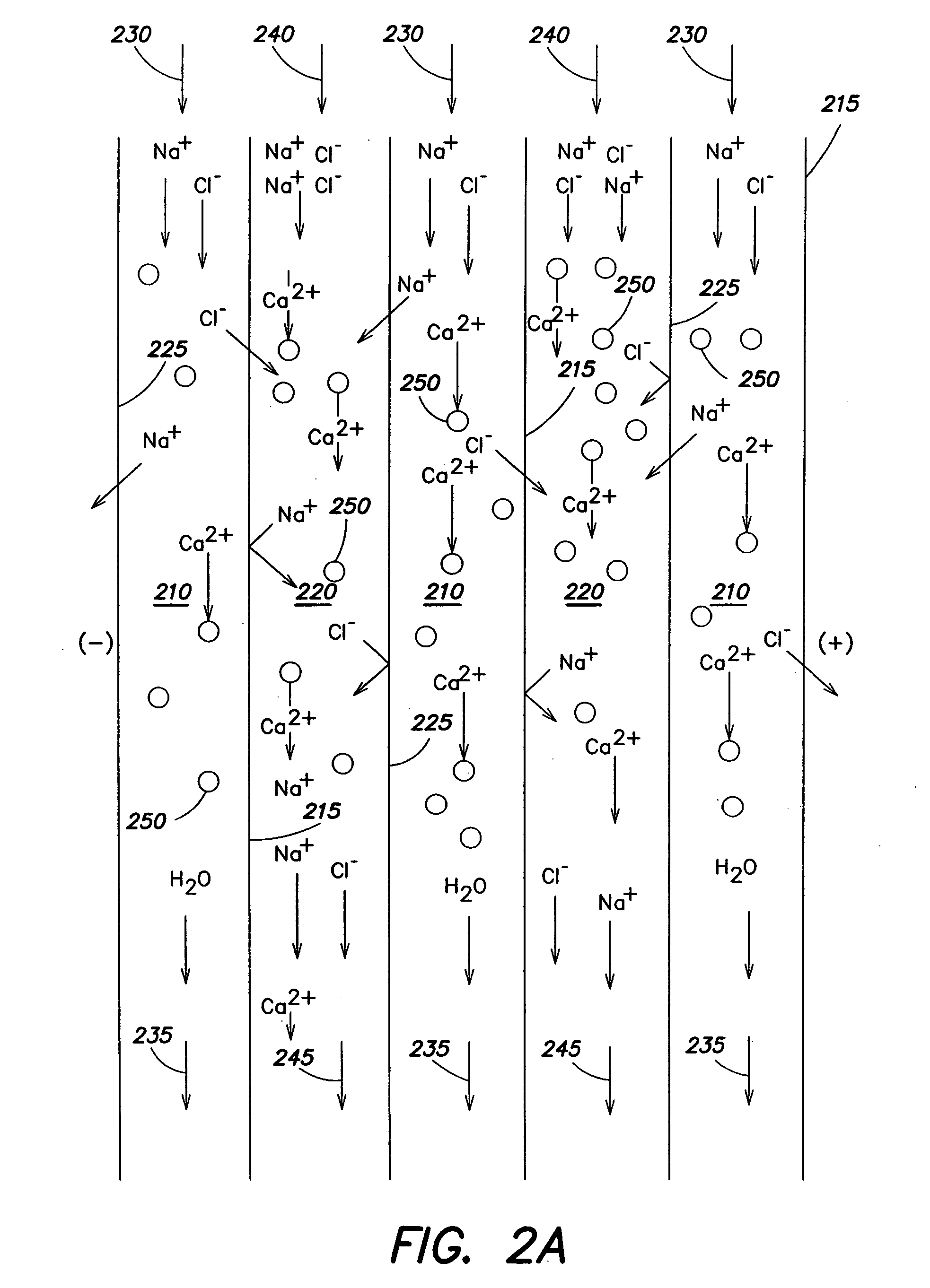

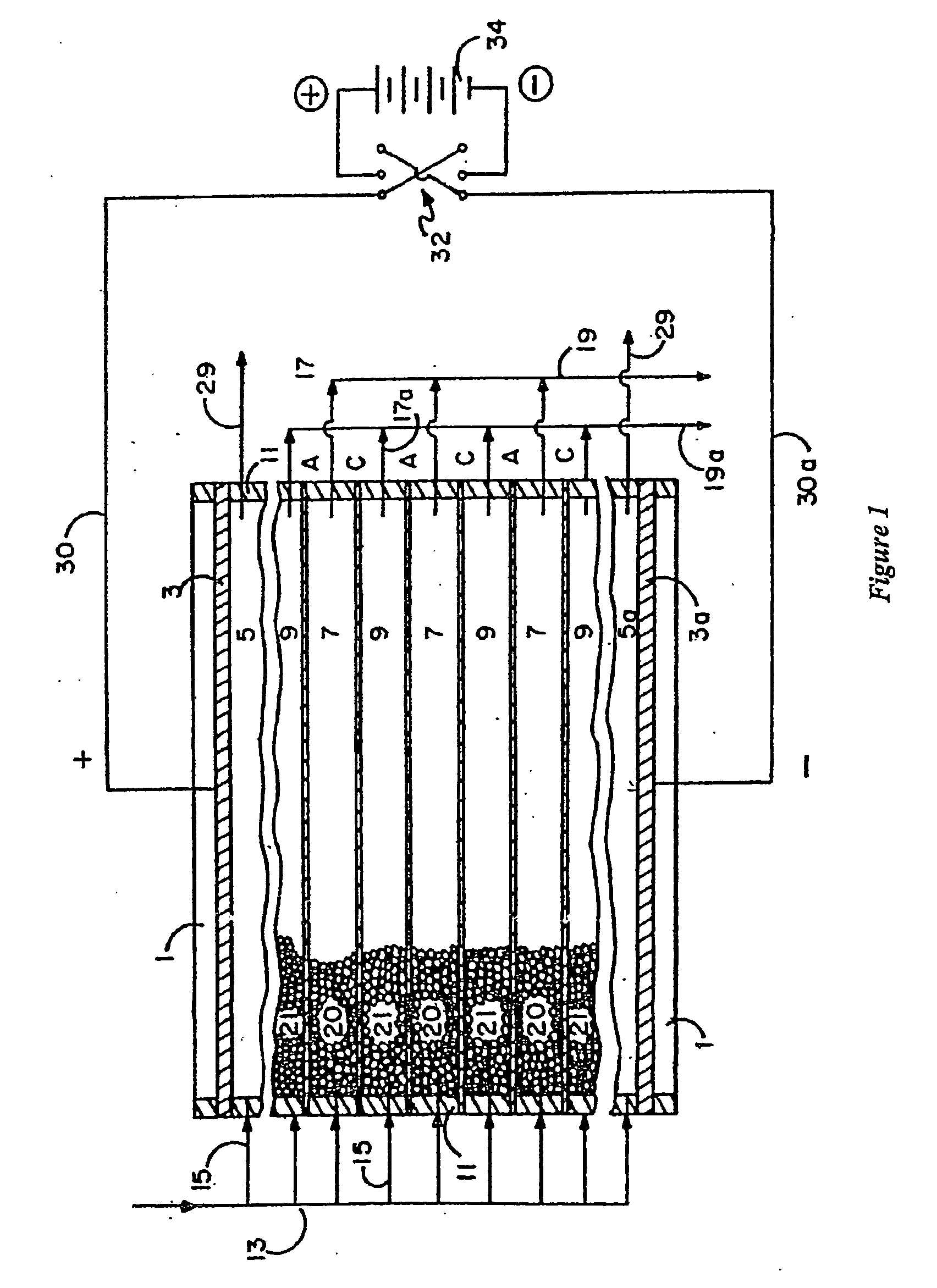

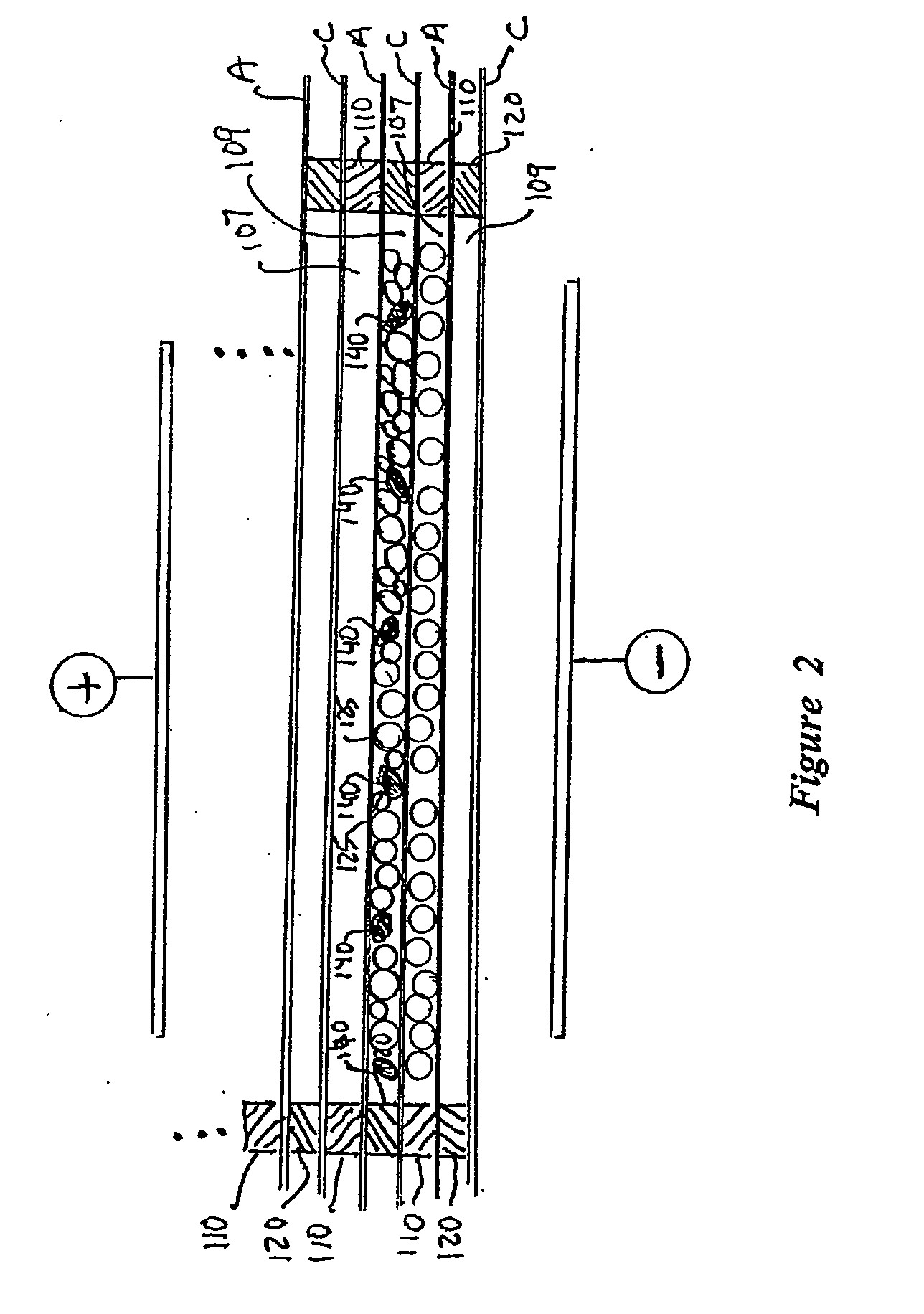

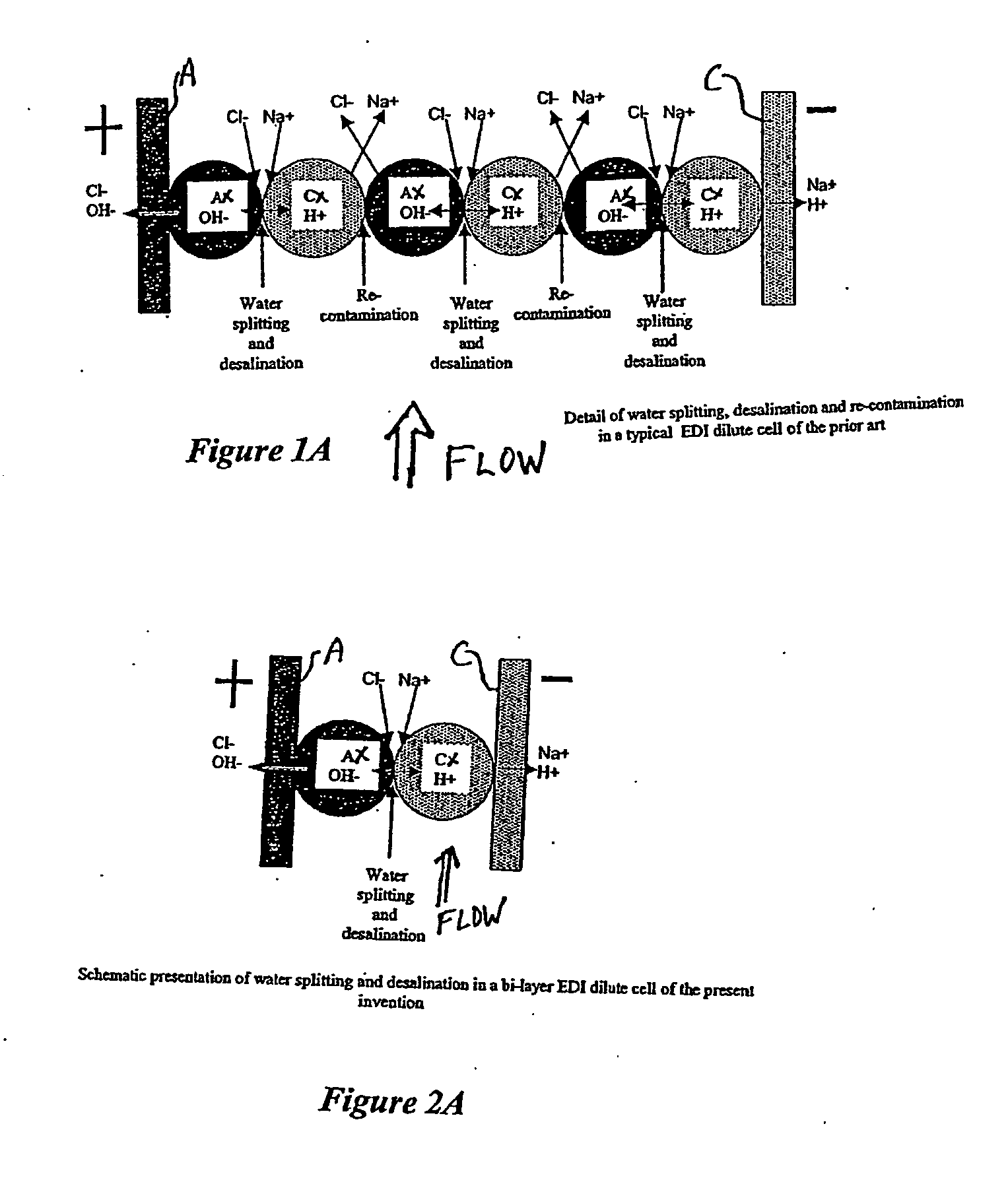

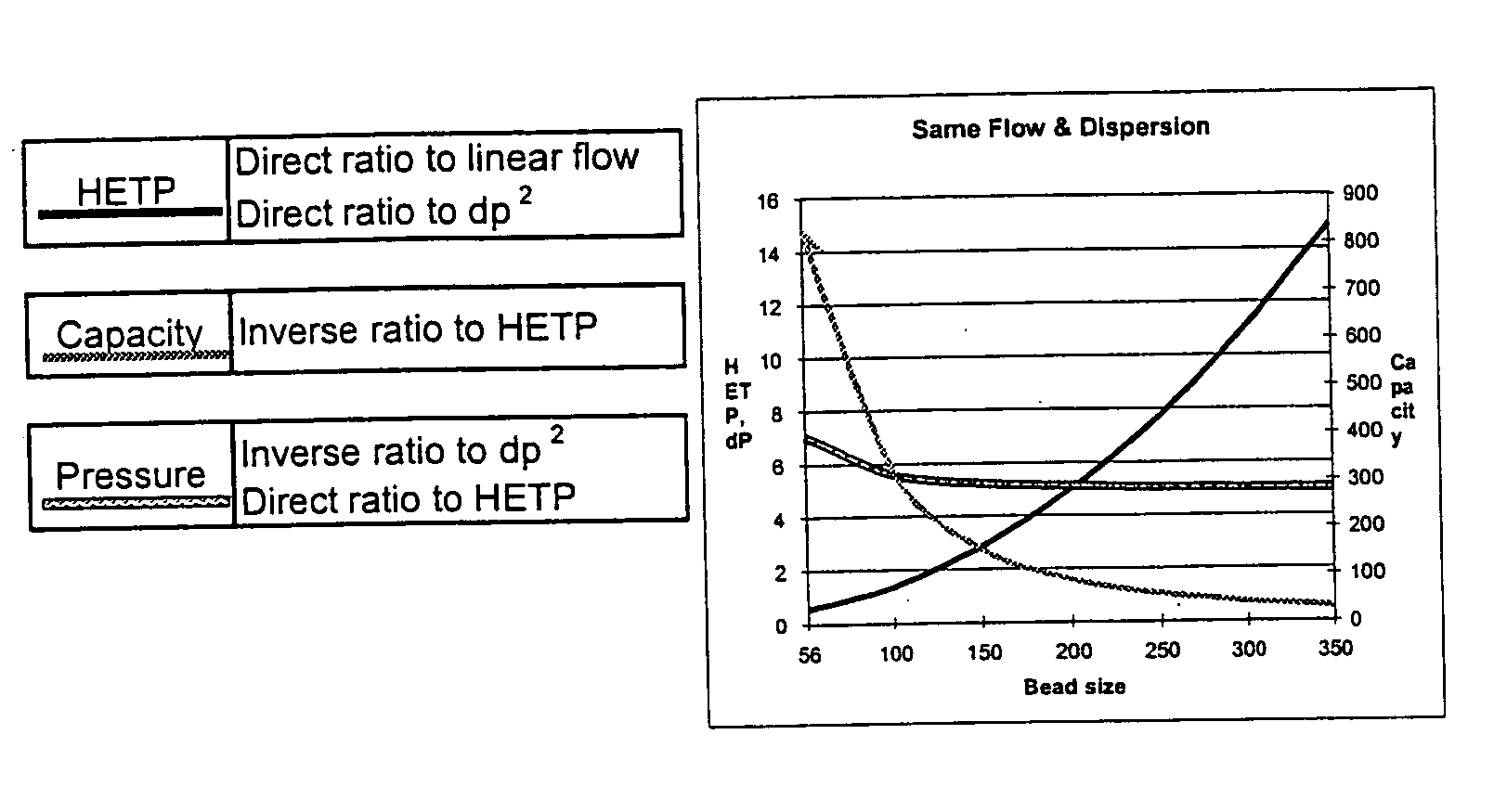

An electrodeionization, (EDI) apparatus has flow cells with a sparse distribution of ion exchange (IX) material or beads. The beads extend between membranes defining opposed walls of the cell to separate and support the membranes, and form a layer substantially free of bead-to-bead dead-end reverse junctions. The beads enhance capture of ions from surrounding fluid in dilute cells, and do not throw salt when operating current is increased. In concentrating cells, the sparse bead filling provides a stable low impedance bridge to enhanced power utilization in the stack. A monotype sparse filling may be used in concentrate cells, while mixed, layered, striped, graded or other beads may be employed in dilute cells. Ion conduction paths are no more than a few grains long and the lower packing density permits effective fluid flow. A flow cell thickness may be below one millimeter, and the beads may be discretely spaced, form a mixed or patterned monolayer, or form an ordered bilayer, and a mesh having a lattice spacing comparable to or of the same order of magnitude as resin grain size, may provide a distributed open support that assures a stable distribution of the sparse filling, and over time maintains the initial balance of uniform conductivity and good through-flow. The cells or low thickness and this resin layers relax stack size and power supply constraints, while providing treatment efficiencies and process stability. Reduced ion migration distances enhance the ion removal rate without reducing the product flow rate. The sparse resin bed may be layered, graded along the length of the path, striped or otherwise patterned. Inter-grain ion hopping is reduced or eliminated, thus avoiding the occurrence of salt-throwing which occurs at reverse bead junctions of prior art constructions. Conductivity of concentrate cells is increased, permitting more compact device construction, allowing increases in stack cell number, and providing more efficient electrical operation without ion additions. Finally, ion storage within beads is greatly reduces, eliminating the potential for contamination during reversal operation. Various methods of forming sparse beds and assembling the stacks are disclosed.

Owner:IONICS INC

Separation system and process

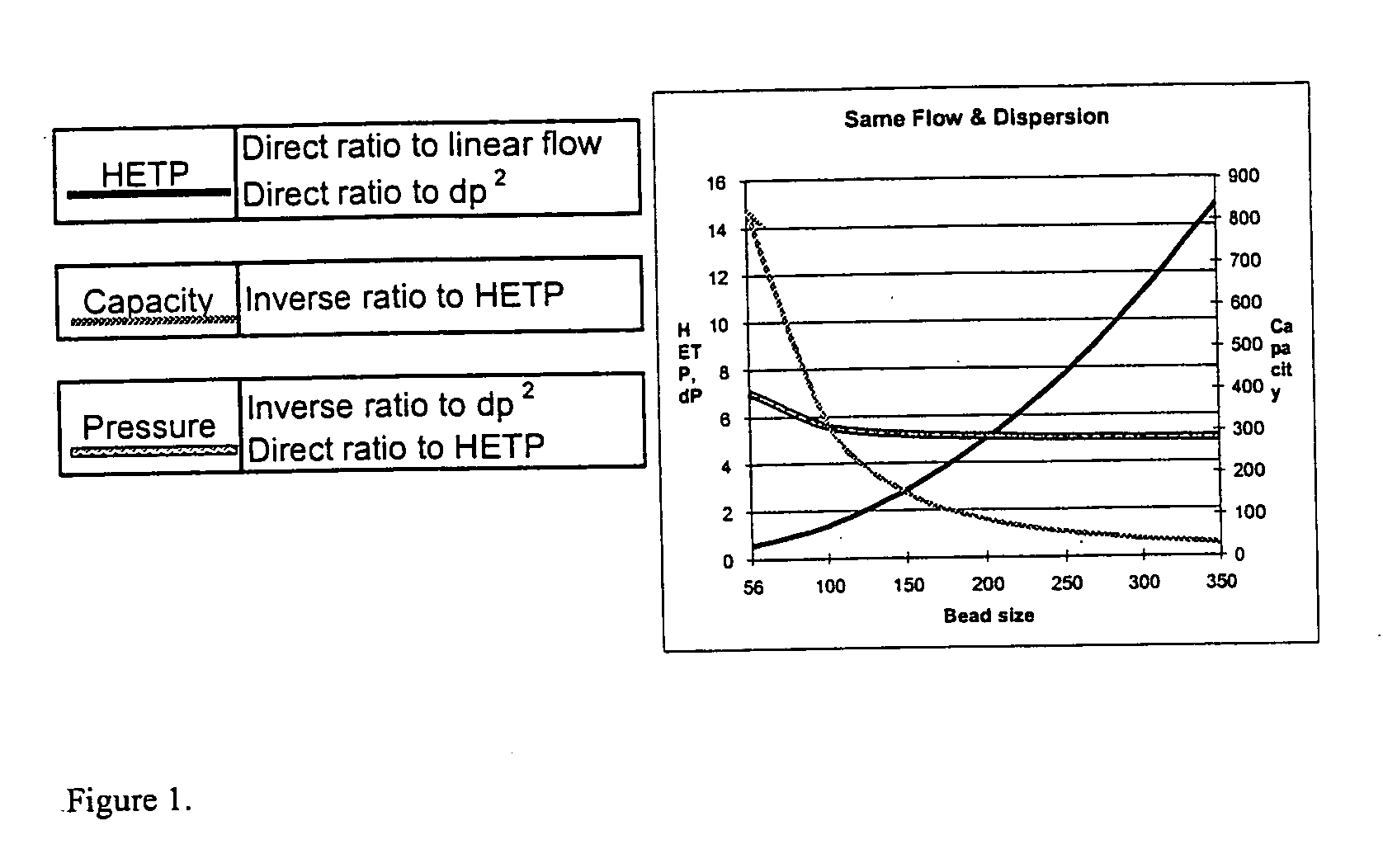

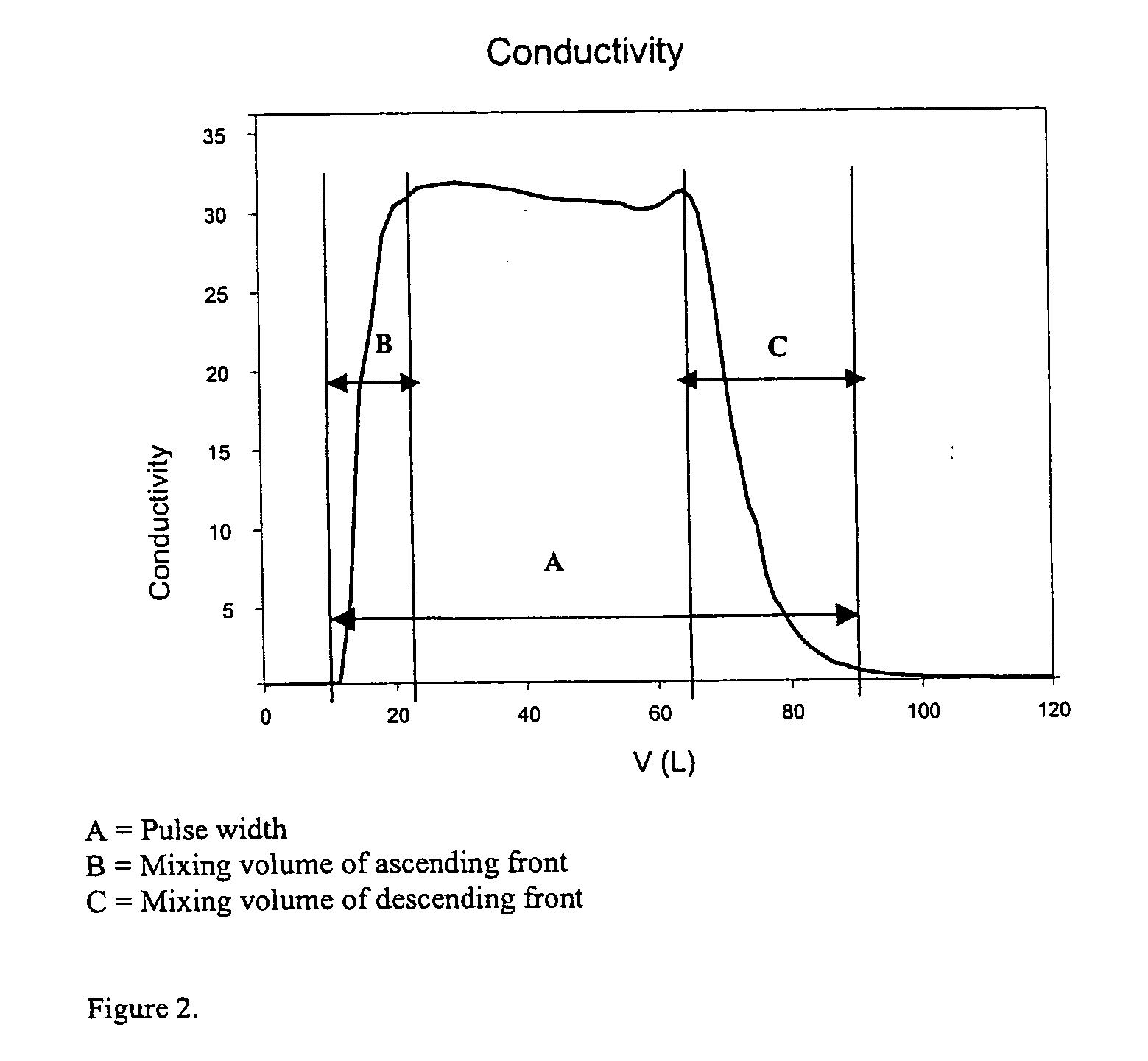

InactiveUS20040251204A1Cation exchanger materialsIon-exchanger regenerationIon-exchange resinSeparation system

The invention relates to a system and a process for fractionating a solution into two or more fractions. The system of the invention comprises at least two compartments having a diameter of at least about one meter and including a uniform packing of a polymer-based ion exchange resin with a bead size in the range of about 50 to about 250 mum. The mixing volume of the fluid fronts in the system of the invention is not more than 5% of the volume of the compartment.

Owner:FINPHIDE

Purification of organic solvent fluids

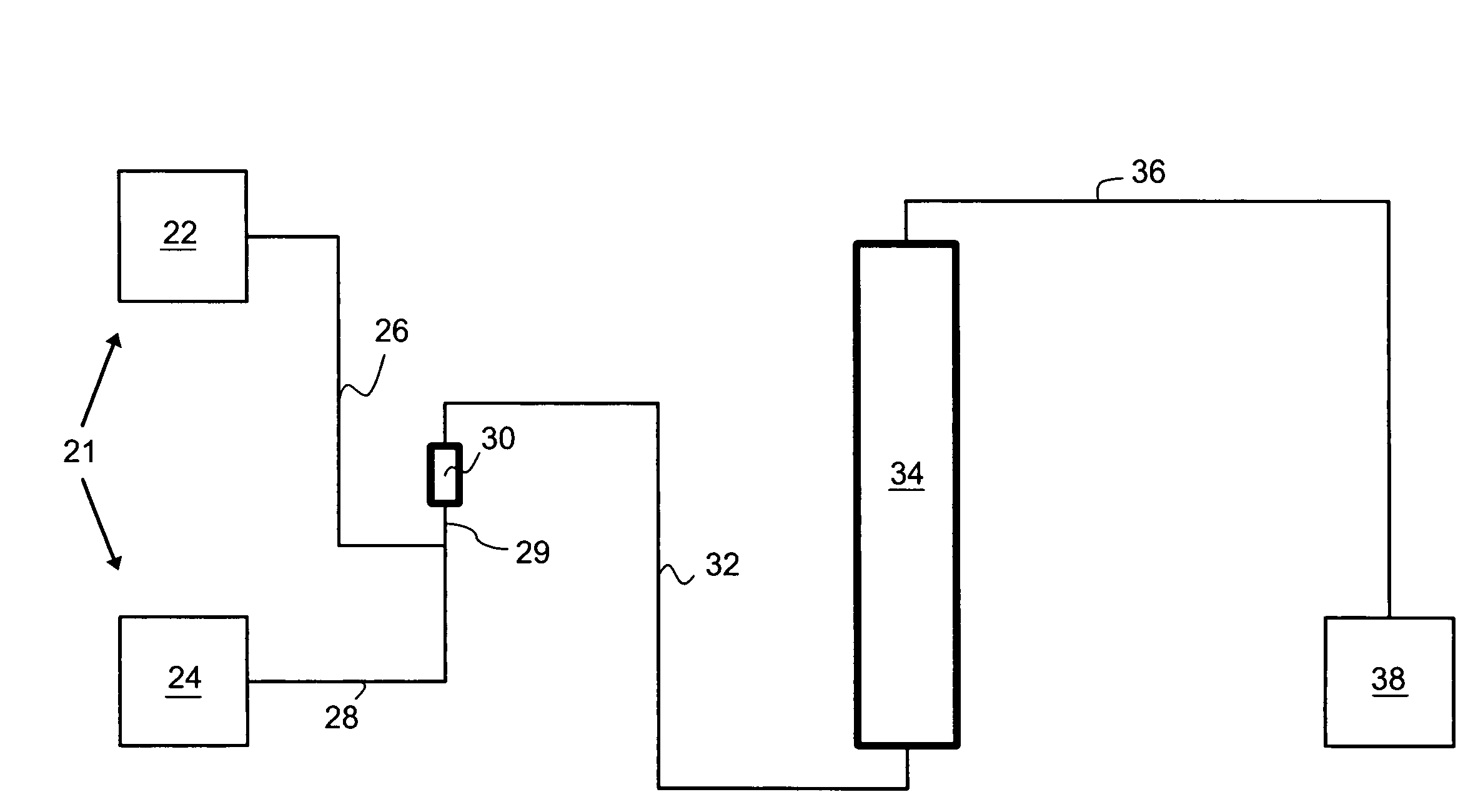

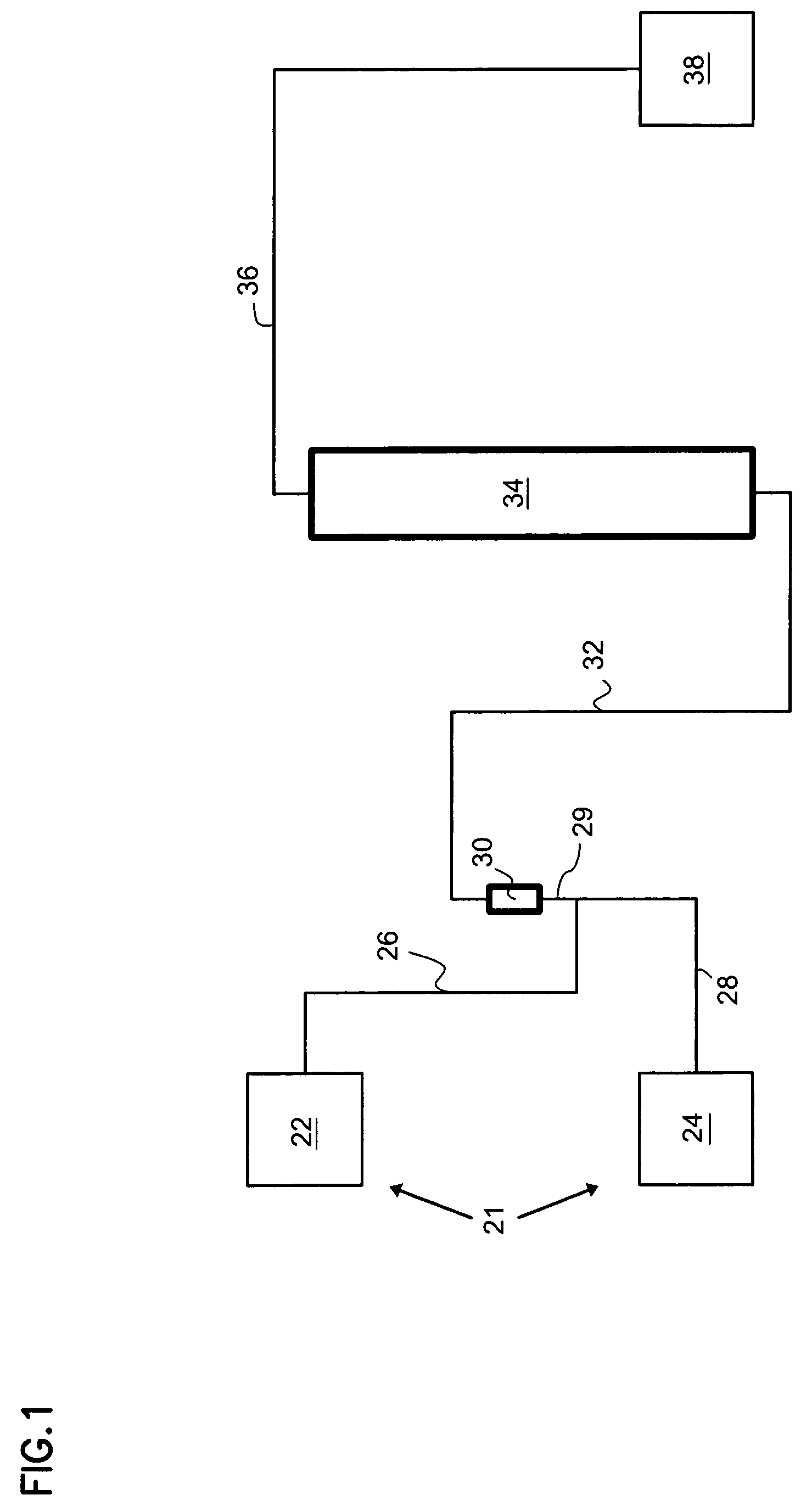

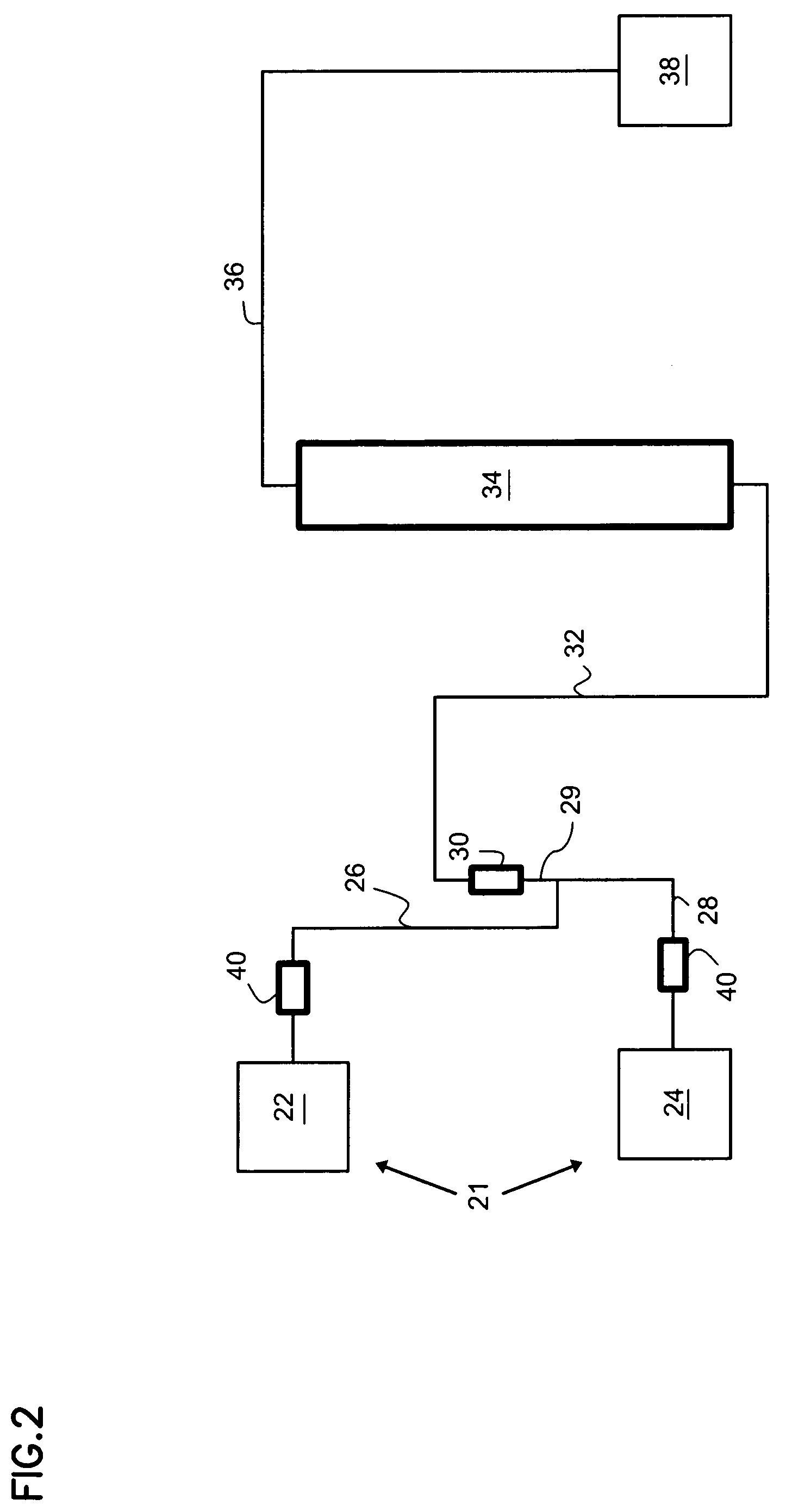

InactiveUS7329354B2Precision productionSmooth connectionIon exchange regulation/controlIon-exchange column/bed processesOrganic solventIon exchange

A chemical distribution system having improved organic solvent fluid purity and consistency includes a vessel containing ion-exchange media positioned within a fluid flow pathway such that the organic solvent fluid passes through the ion-exchange media, thereby effecting removal of undesired impurities. Different embodiments of the invention position the vessel at varying locations within the fluid flow pathway. The chemical distribution system also preferably includes a return chemical flow pathway that recirculates purified organic solvent fluid through the ion-exchange media-containing vessel and thereby enables the system operator to conduct incremental adjustment of the solvent purity until a desired overall purity is attained.

Owner:PPT TECH

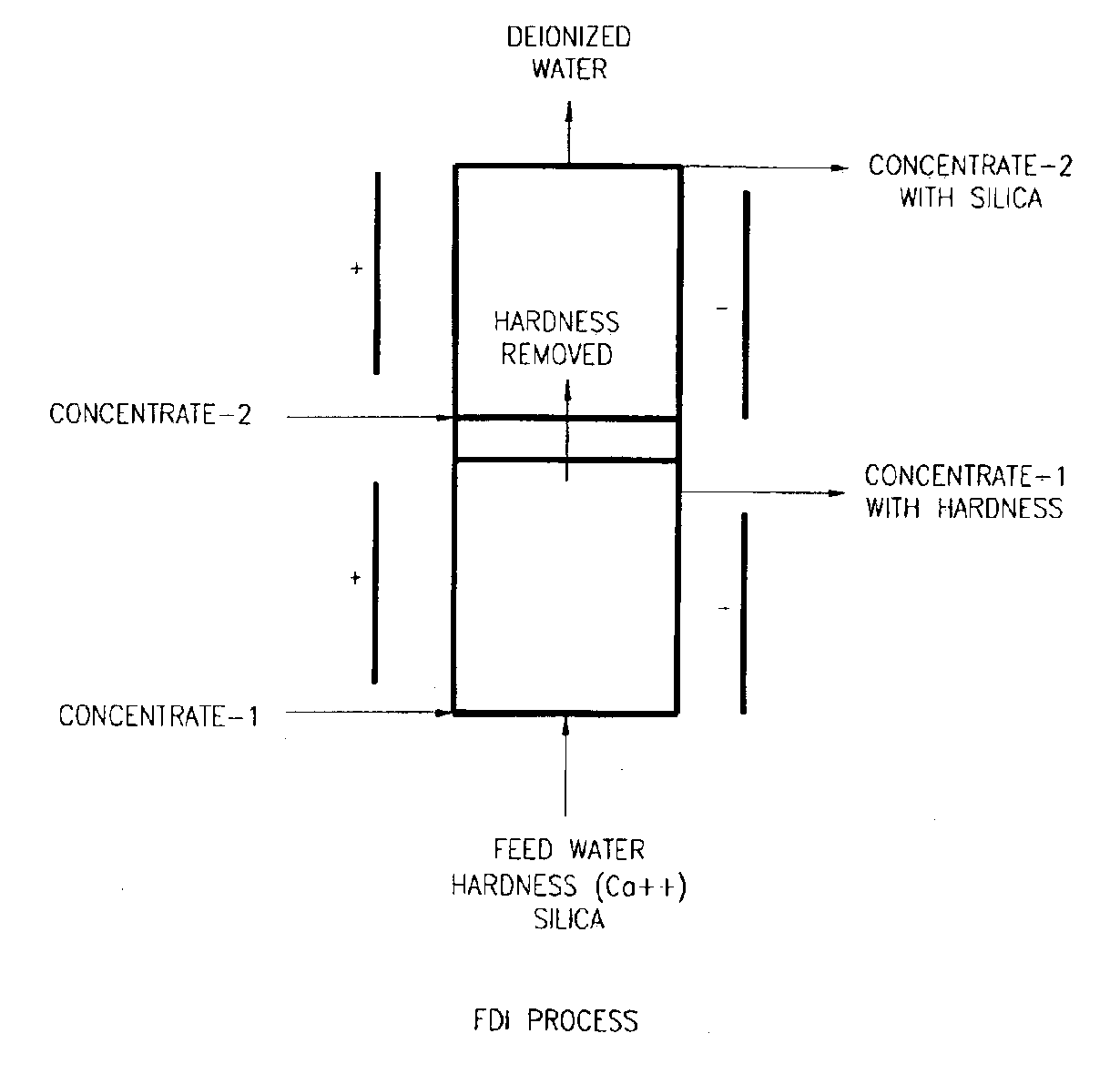

Fractional deionization process

InactiveUS6896814B2Easy to disassembleEfficient removalElectrolysis componentsIon-exchanger regenerationElectricityIonic strength

A liquid treatment process is described for sequential removal of ionic species of progressively decreasing ionic strength without precipitation or “scaling.” An aspect of the invention includes dual electrodeionization operations. The first electrodeionization operation is performed at a voltage calculated to remove strongly ionized species such as calcium and magnesium from the feed water without scaling. The product of the first electrodeionization operation is then subjected to a second electrodeionization operation. The second electrodeionization operation is performed at a voltage greater than the first electrodeionization operation, and is designed to remove more weakly ionized species such as silica and carbon dioxide, preventing scaling. More than two successive electrodeionization operations may be performed if desired. Multiple electrodeionization operations may occur in a single electrodeionization stack or in multiple electrodeionization stacks.

Owner:AQUATECH INT LLC

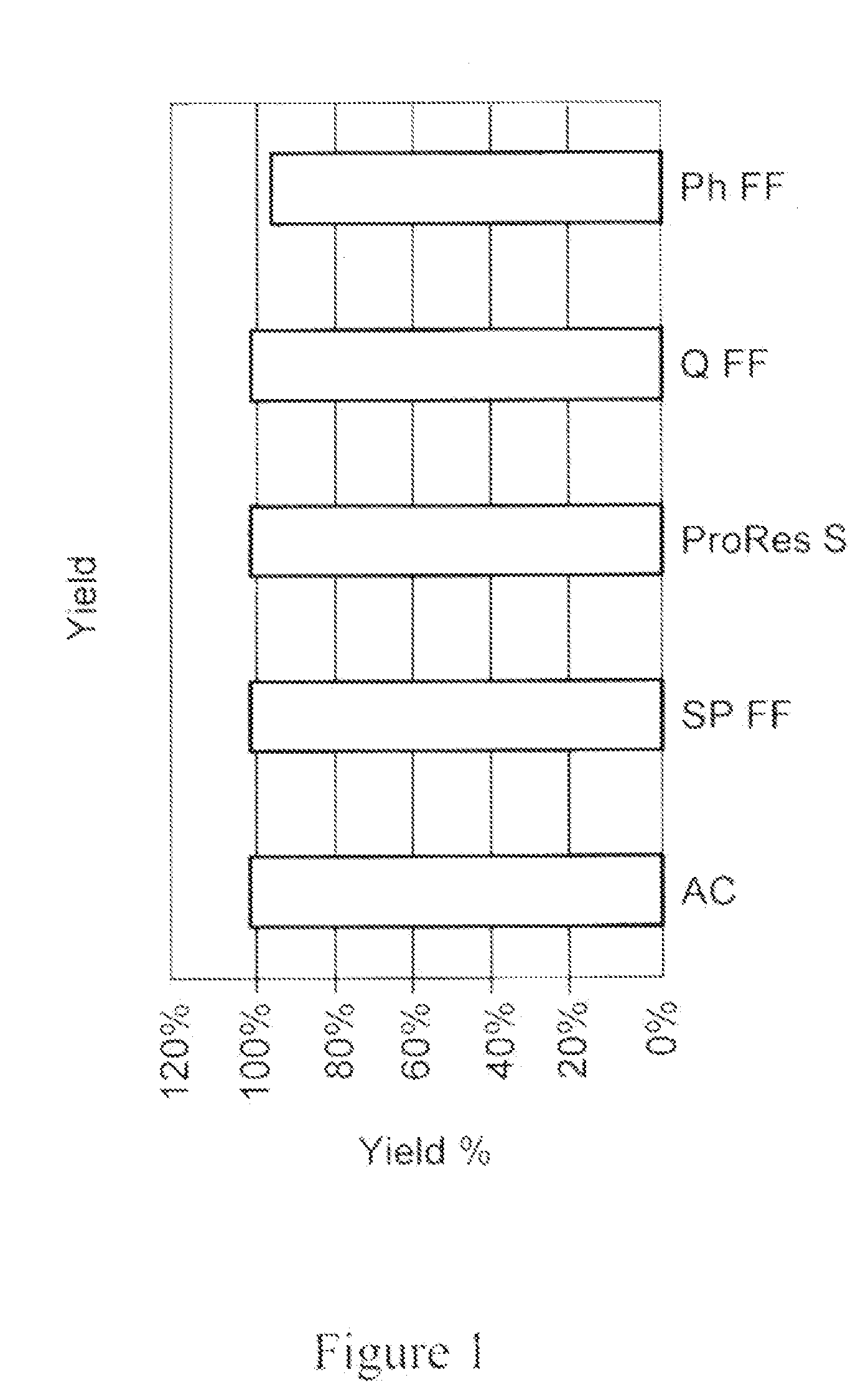

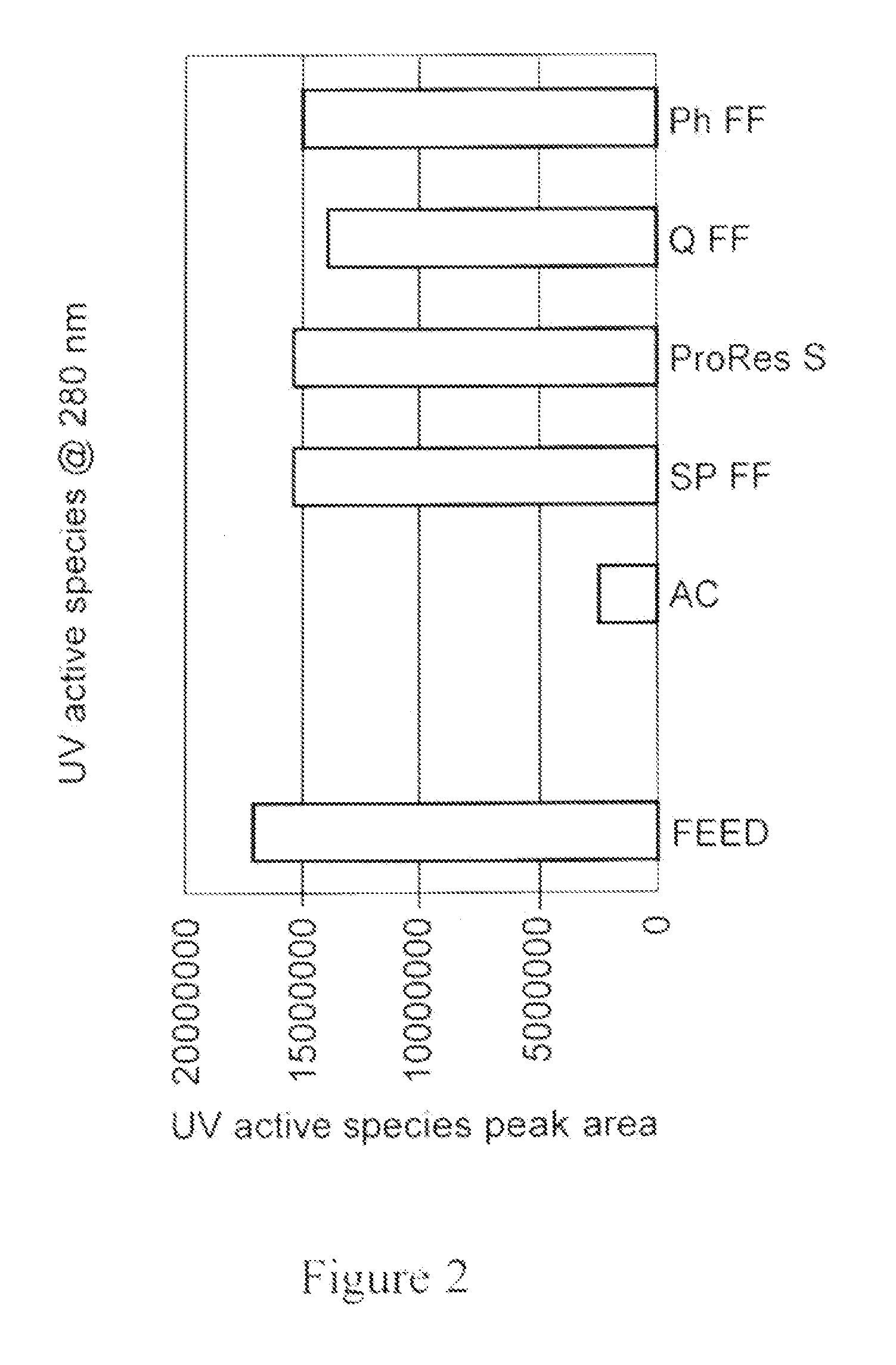

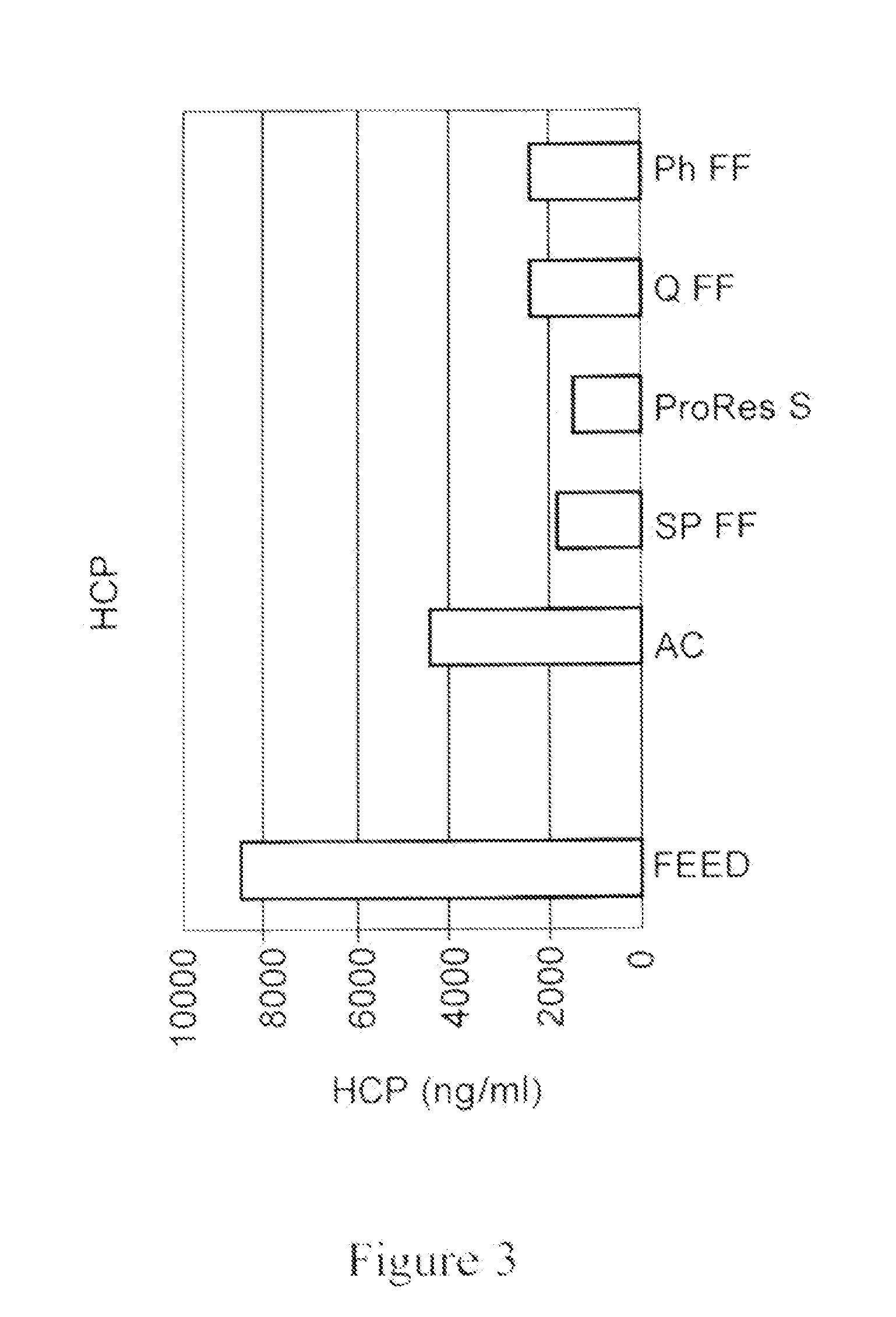

Methods of reducing level of one of more impurities in a sample during protein purification

ActiveUS20130197200A1Reduce the burden onExtend your lifeChromatographic cation exchangersIon-exchange column/bed processesProtein purificationImpurity

Owner:MILLIPORE CORP

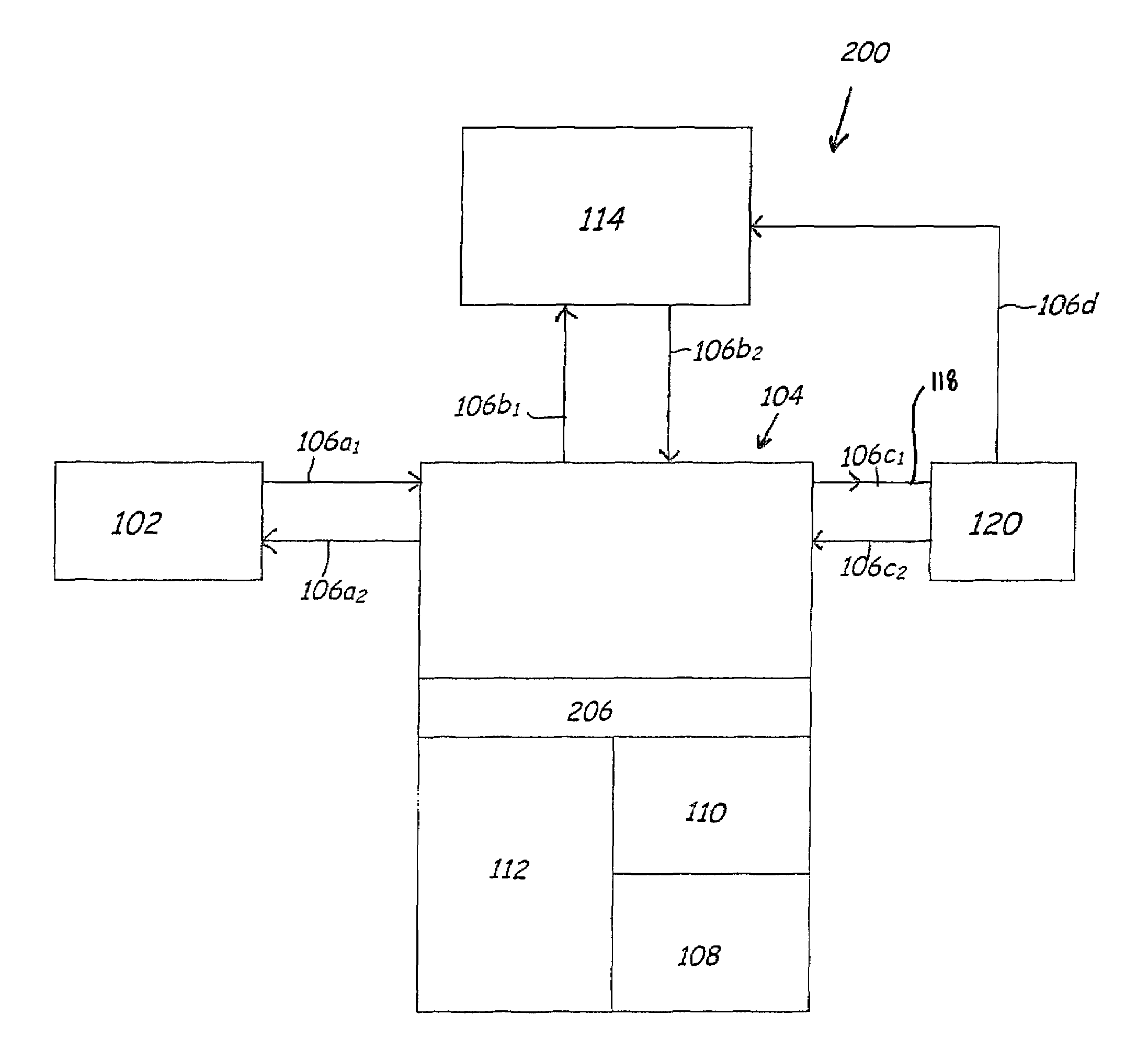

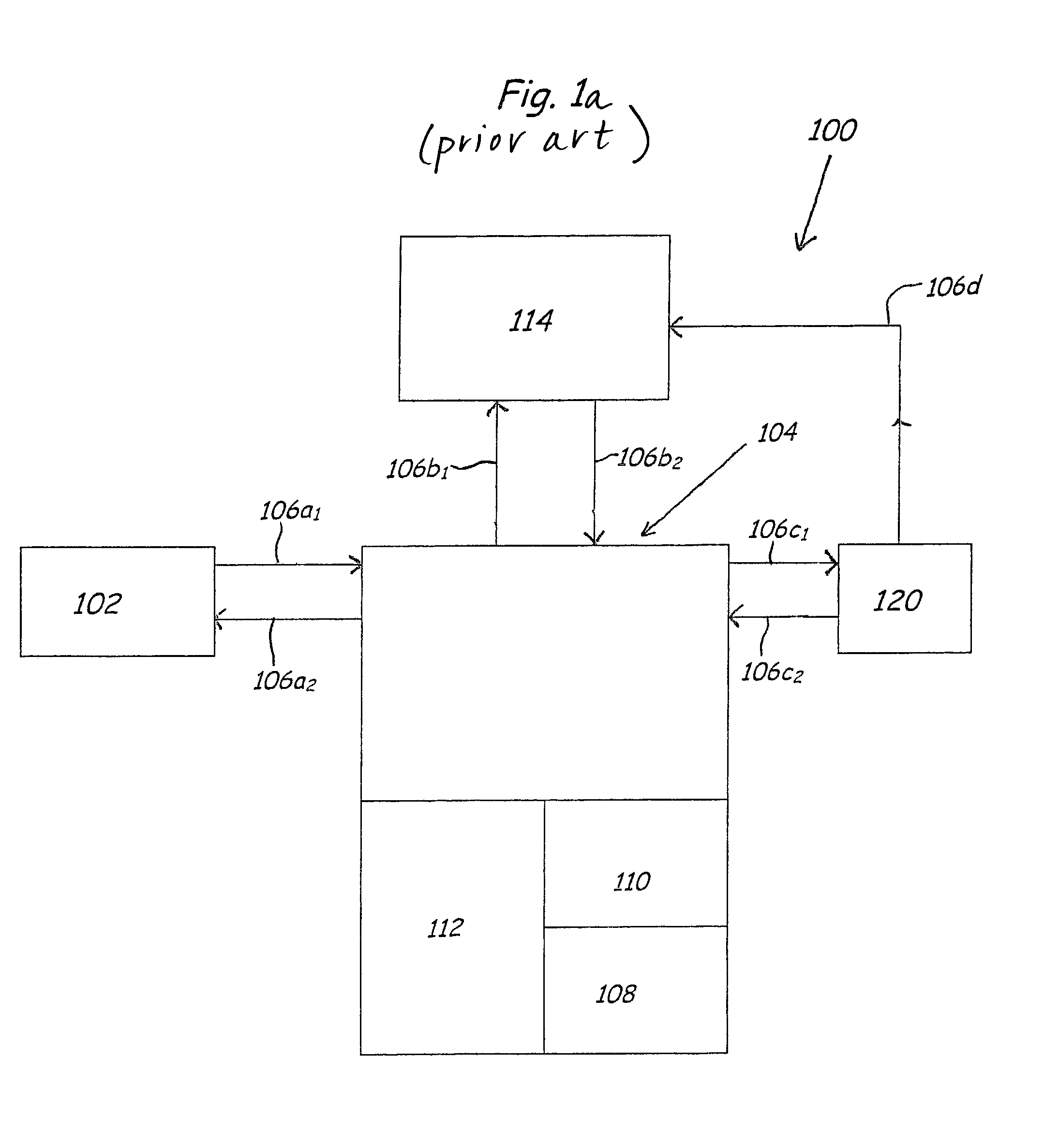

Water treatment system and method

InactiveUS20060157422A1Sludge treatmentLiquid separation by electricityWater treatment systemWater source

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

Water treatment system and method

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point-of-entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system. A flow regulator regulates a waste stream flow to drain and can be operated to recirculate fluid through electrode or concentrating compartments of an electrochemical device and can opened and closed intermittently according to a predetermined schedule or based on an operating parameter of the water treatment system. The flow regulator can also be charged so that ionic species can be generated in the surrounding fluid, which, in turn, can lower the pH of the surrounding fluid.

Owner:EVOQUA WATER TECH LLC

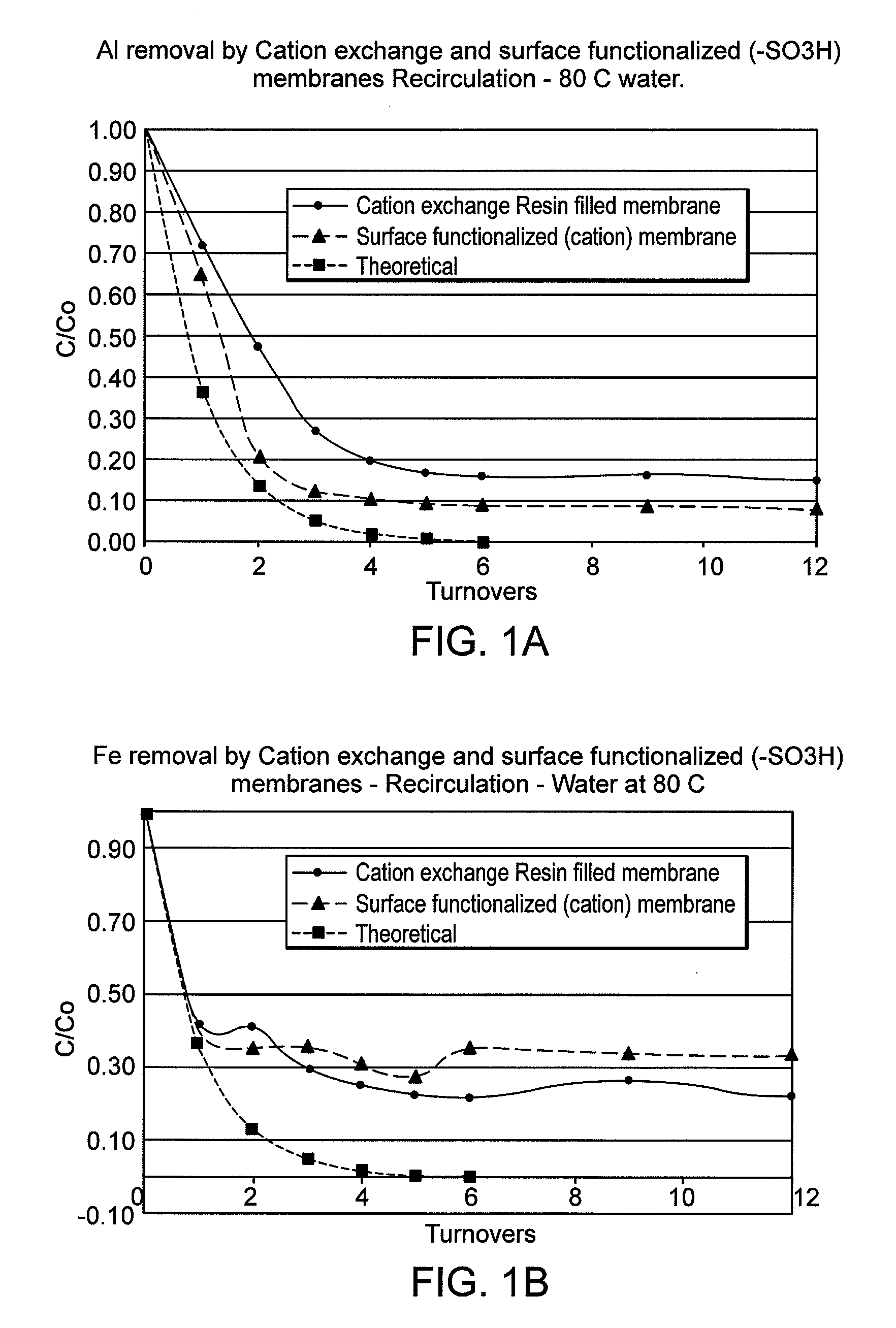

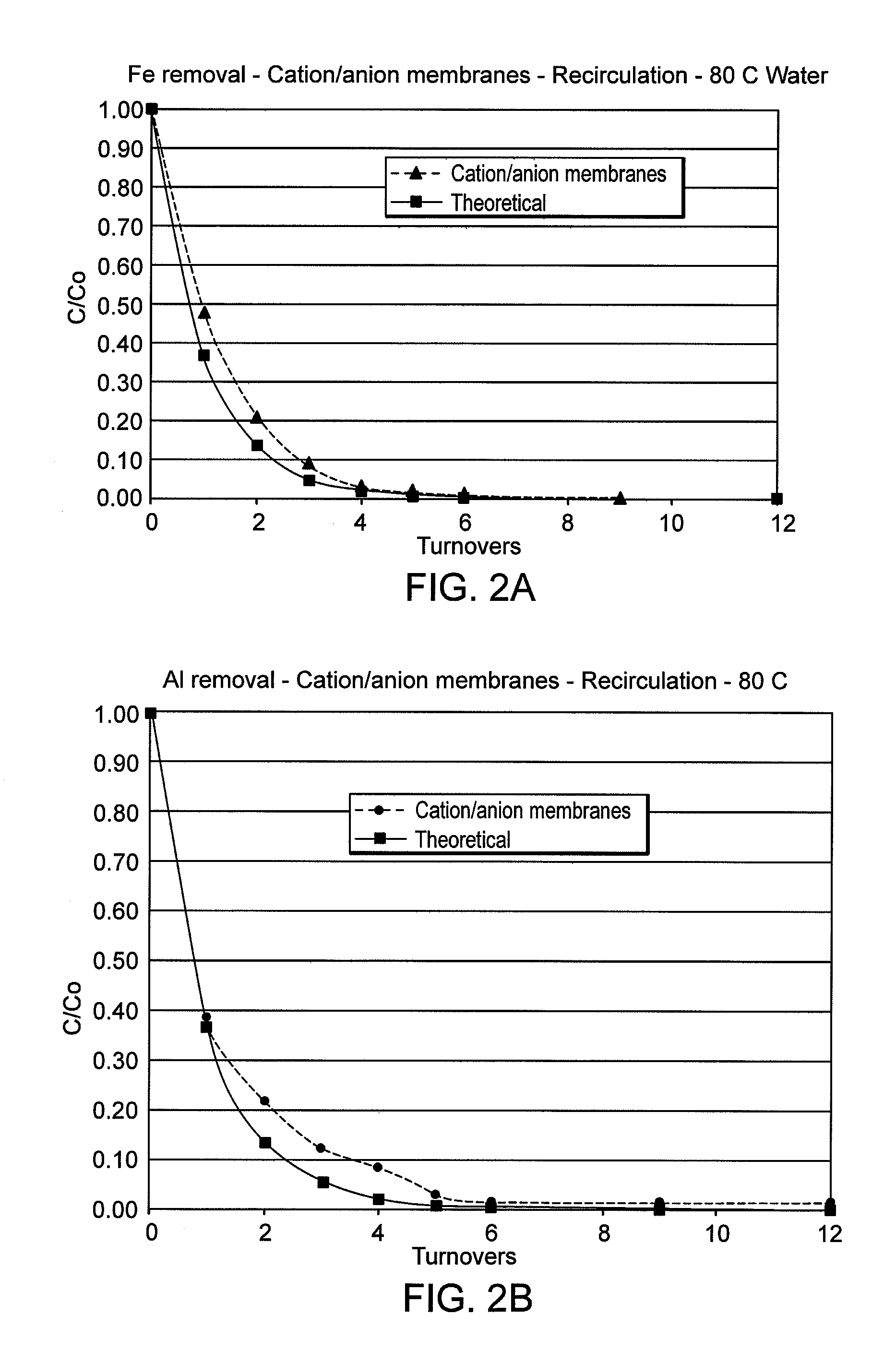

Porous membranes containing exchange resins

InactiveUS20090039019A1Fast dynamicsLower overall pressure dropMembranesSemi-permeable membranesPorous membraneCharged impurity

Articles that include two or more exchange resins in one or more microporous membranes, where the membranes remove oppositely charged impurities from a fluid in contact with the membranes, are disclosed. Methods for using such devices to remove charged impurities from fluid in contact with the membrane are provided.

Owner:ENTEGRIS INC

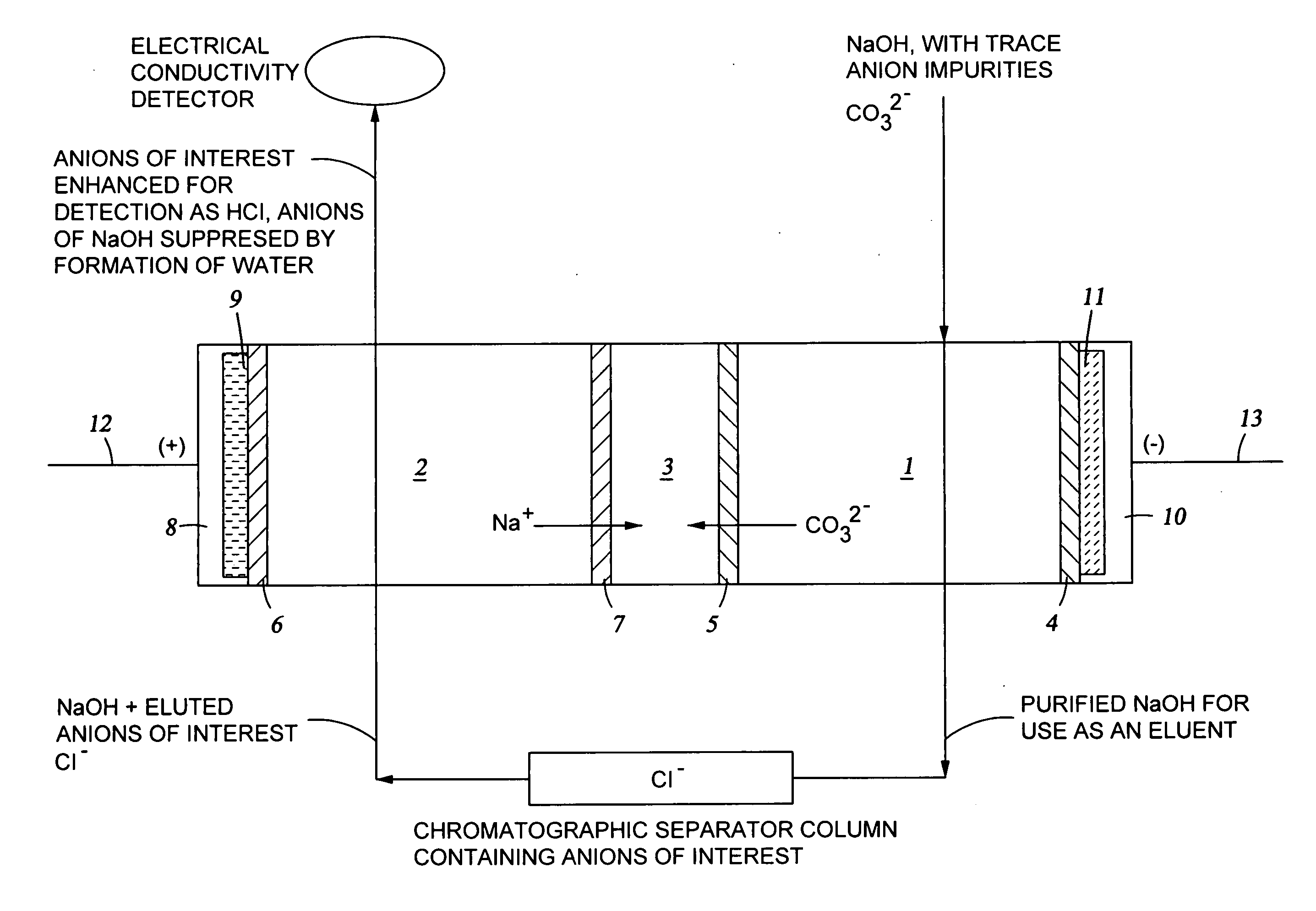

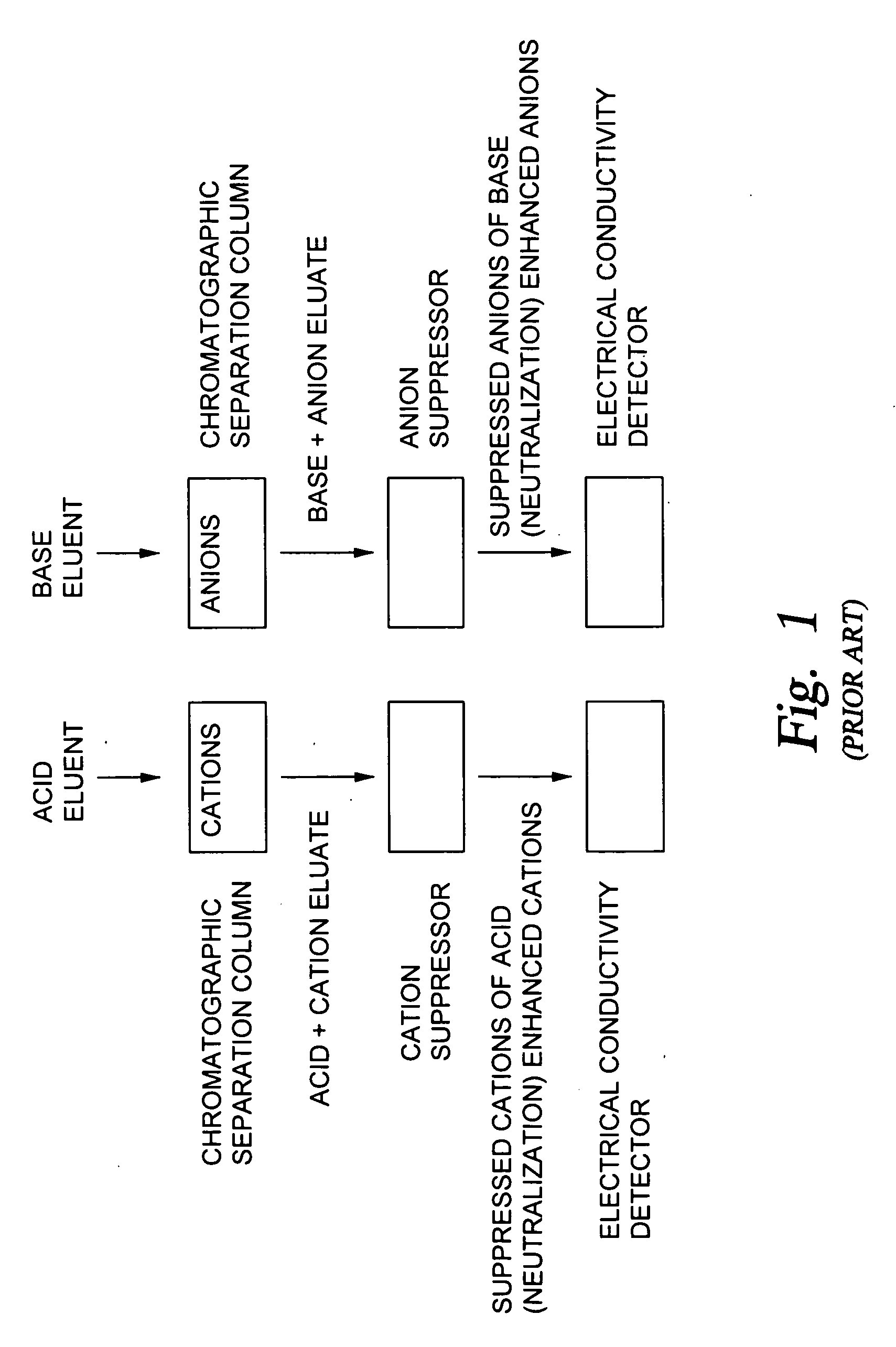

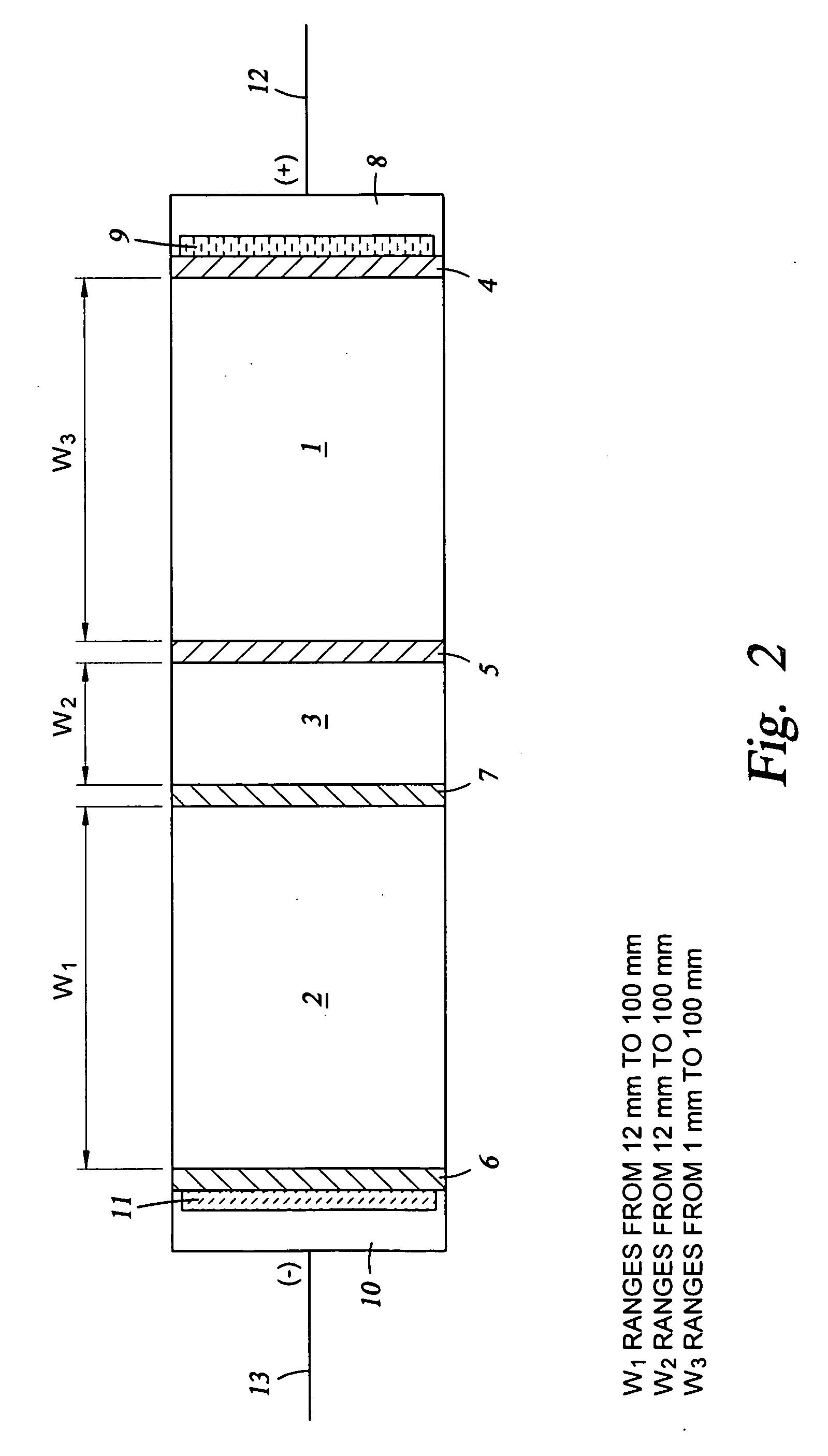

Method of ion chromatography wherein a specialized electrodeionization apparatus is used

The present invention pertains to a method of ion chromatography wherein a specialized electrodeionization (EDI) apparatus is used for (1) the preparation of a pure acid or pure base for use as an eluent in a chromatographic separation column and / or (2) for ion suppression (or neutralization) of the acid or base after it has been used to elute ions from a chromatographic separation column. Methods for trace ion removal, acid and base neutralization, and ion suppression using a specialized EDI apparatus are also described. The methods described herein allow for the ion suppression of samples containing chloride, nitrate, and other electrochemically active anions, without causing damage to the suppressor.

Owner:TROVION PTE

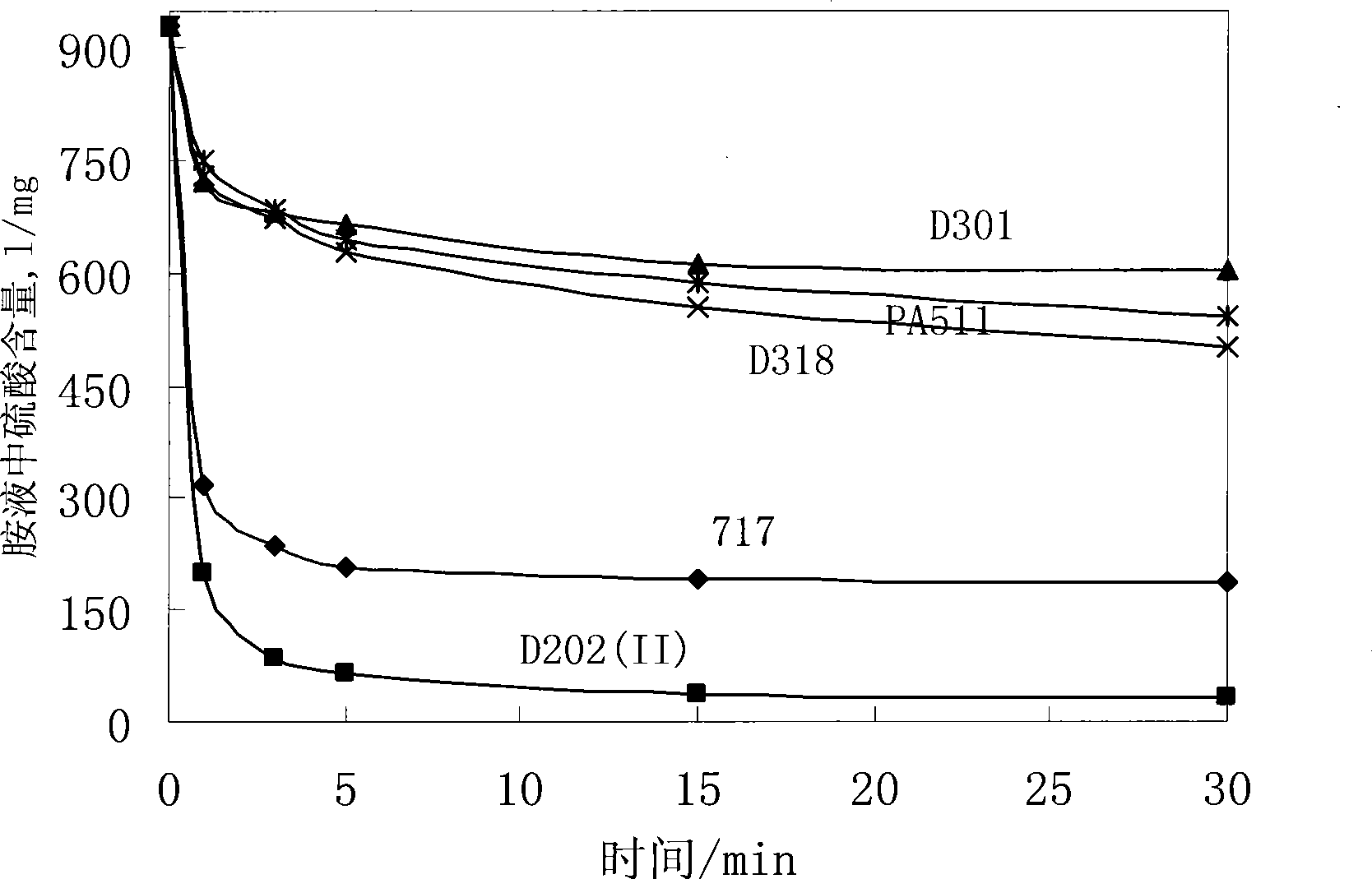

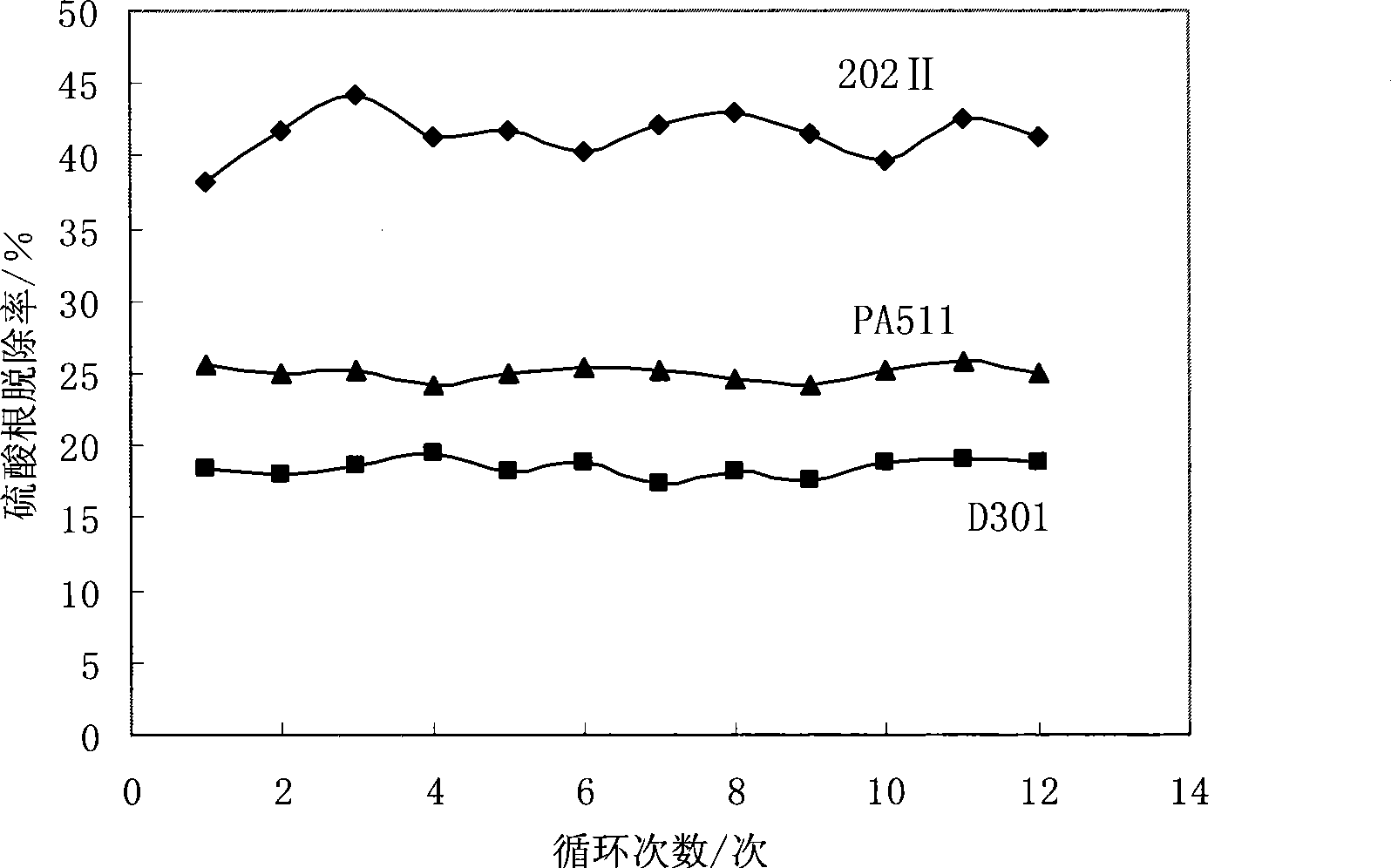

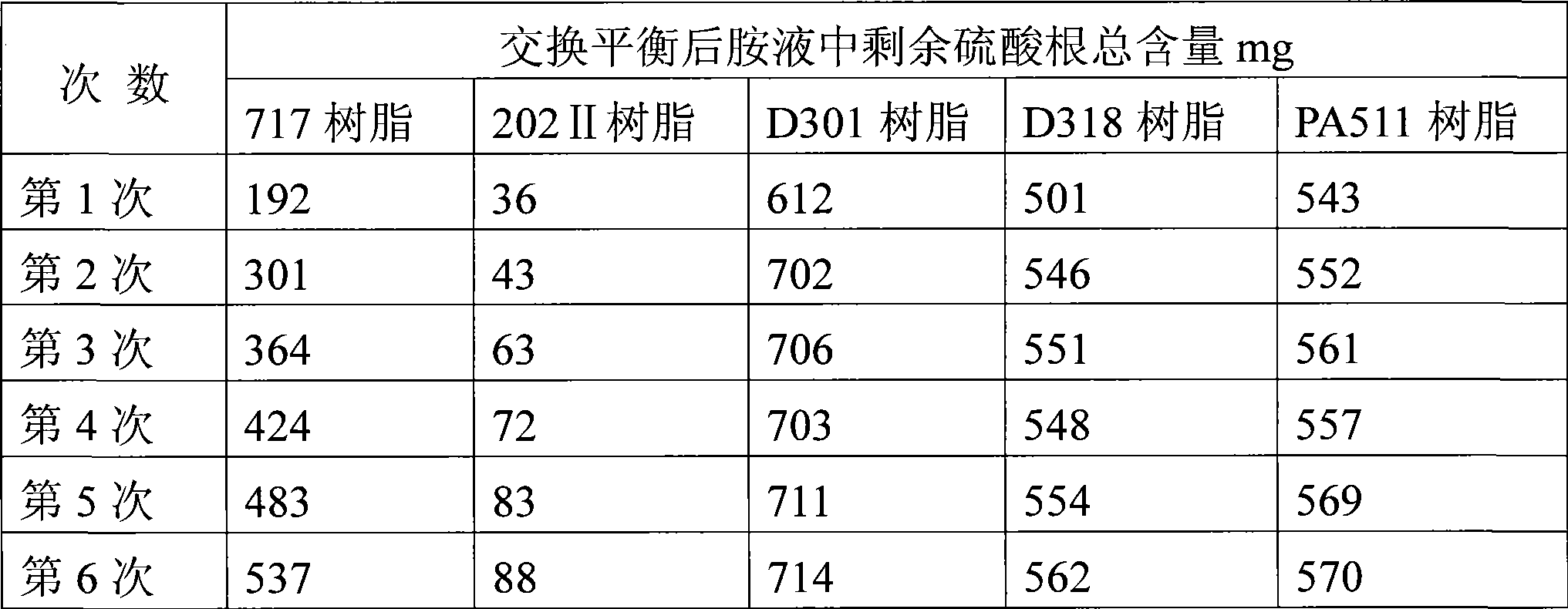

Method for removing thermostable salt in amine liquid for desulphurization

ActiveCN101502742AQuick releaseSolve the speed problemIon-exchange column/bed processesOrganic compound preparationSulfate radicalsFlue gas

The invention discloses a method for removing heat-stable salts in amine desulphurization, aiming at solving the problem that the prior art has difficulty in treating desulphurizer with high content of sulfate radical. The method is as follows: strong base type II anion exchange resin with particle size of 0.5-1.5mm is filled in an ion exchange resin tower with height-diameter ratio of 1:1-3:1, the desulphurized amine solution with PH value less than 5.4 passes through the ion exchange resin tower at the airspeed of 30h-50h to experience purifying treatment, when the PH value of the desulphurized amine solution at the exit of the resin tower is equal to that at the entrance of the resin tower, sodium hydroxide solution is used to carry out upflow regeneration on the ion exchange resin, and the regenerated ion exchange resin is recycled. The method can solve the problems of rapid cumulative rate and large total content of the sulfate radical in reproducible wet method flue gas desulphurization system.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

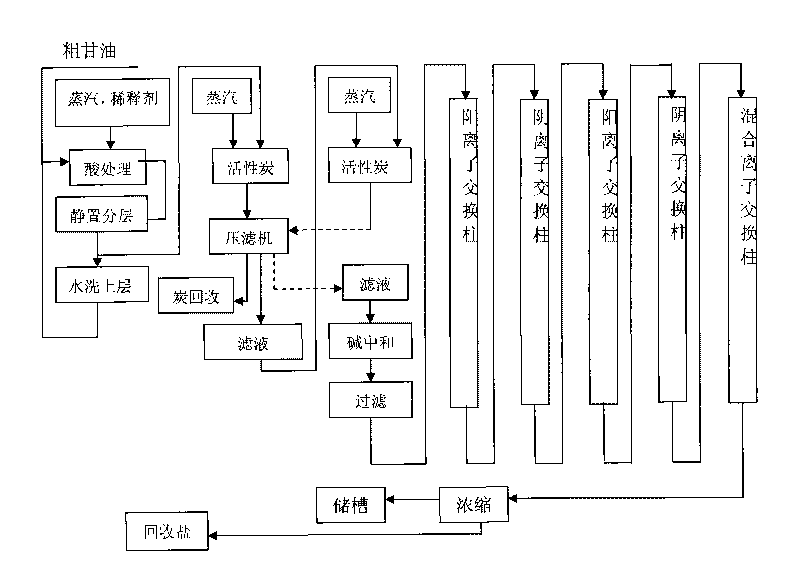

Refining production method of glycerin

InactiveCN101759526ALess investmentSave energyIon-exchange column/bed processesHydroxy compound separation/purificationTrans esterificationBiodiesel

The invention provides a refining production method of crude glycerin. Byproducts of grease ester exchange or hydrolyzation are used as ingredients, and byproducts of biodiesel can also be used as ingredients. The method comprises the following steps: acidizing treatment, decolourization, alkali return for neutralization, concentration for salt removal, ion exchange and concentration treatment, wherein the ion exchange step comprises the substep of sequentially using cations, anions, cations, anions and zwitterions to exchange resin posts in a mixed way, the operation temperature of the resin posts is controlled between 40 and 60 DEG C, the flow rate is 15 mL / min, and finally, the pure glycerin solution is collected. The process of the invention has the advantages of simple operation condition, low temperature, little pollution and high yield, and can avoid the deterioration of the glycerin at the high temperature, the yield is higher than 97 percent, and the product purity is higher than 99.2 percent. The invention also provides a multiplex mixed type anion-cation exchange resin post combination device applicable to the method.

Owner:HUNAN ACAD OF FORESTRY

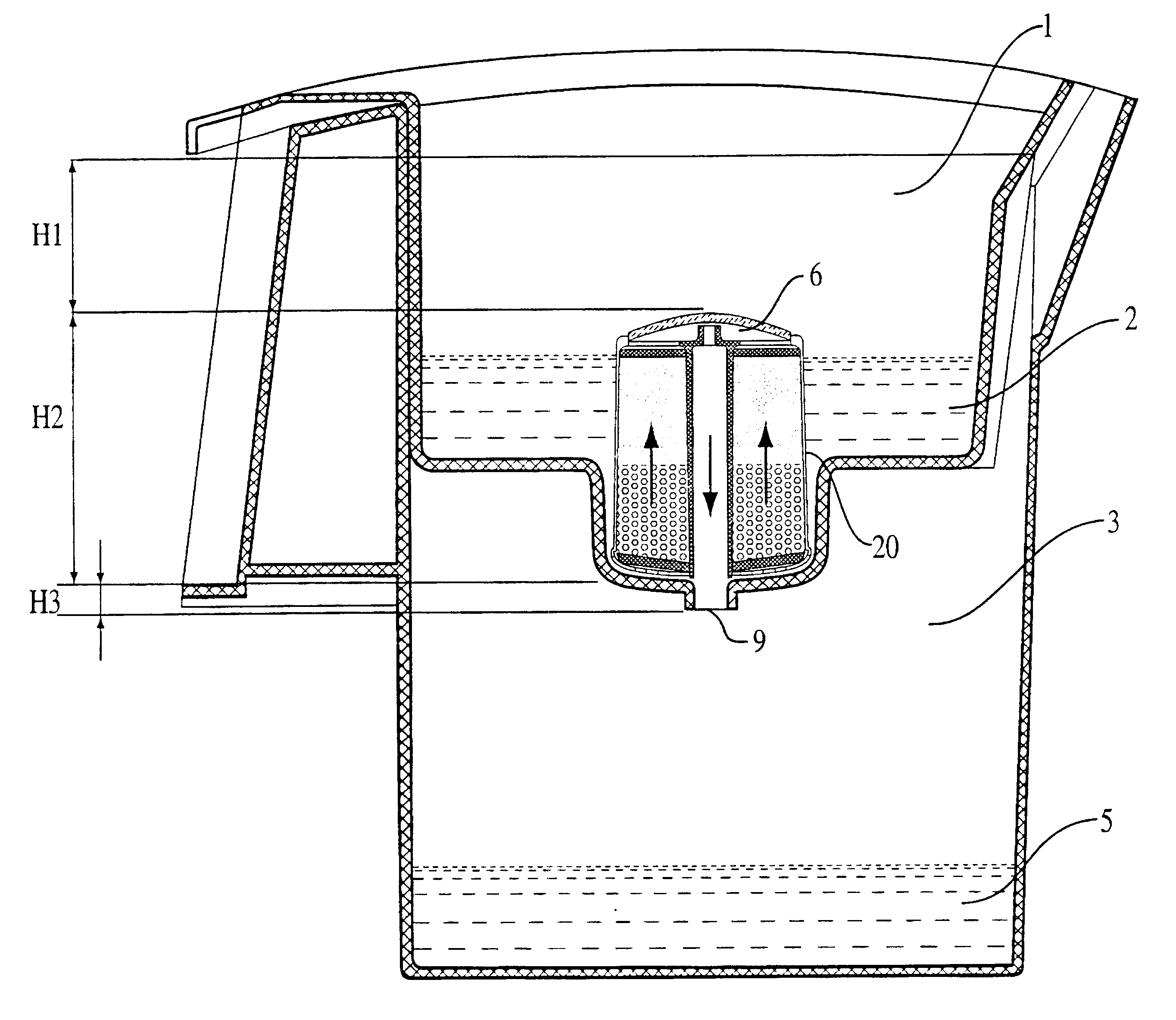

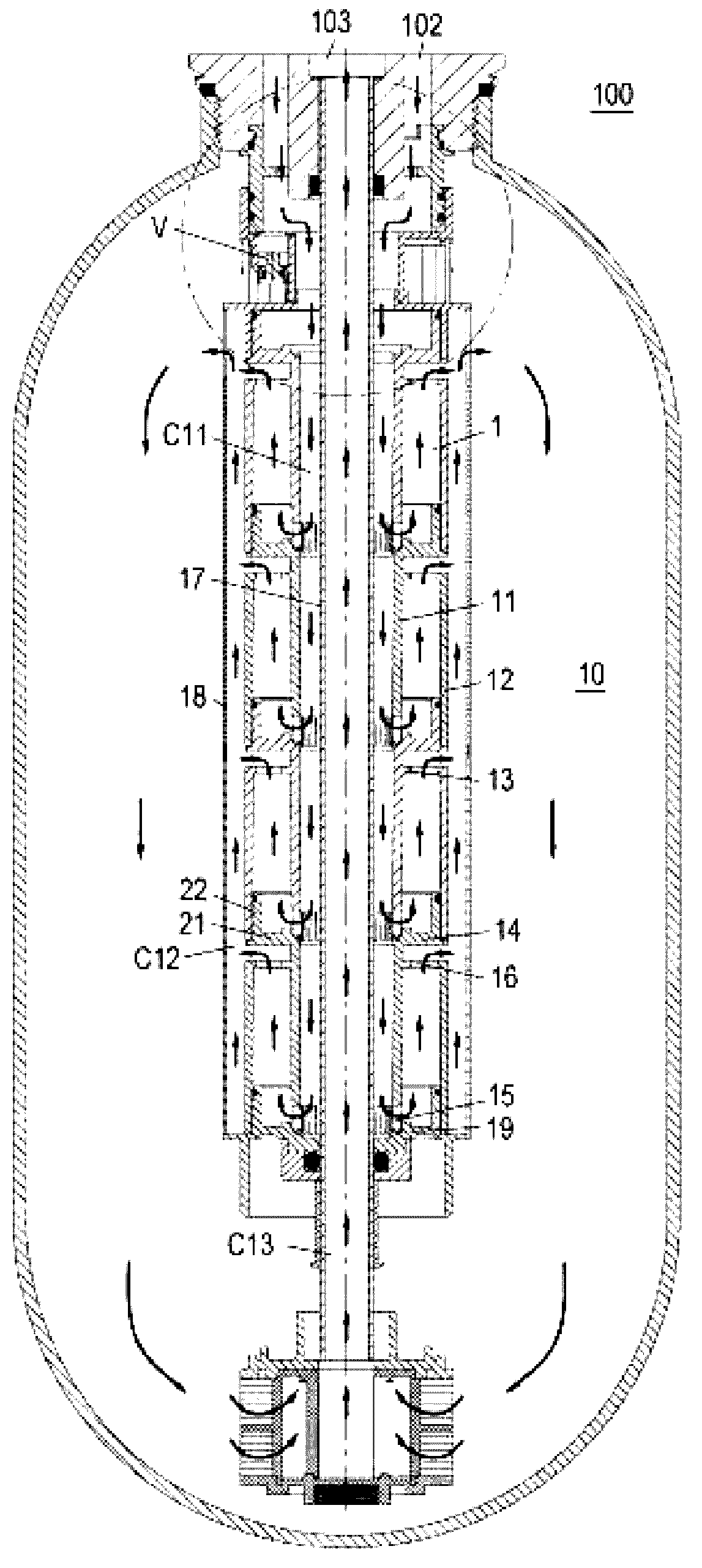

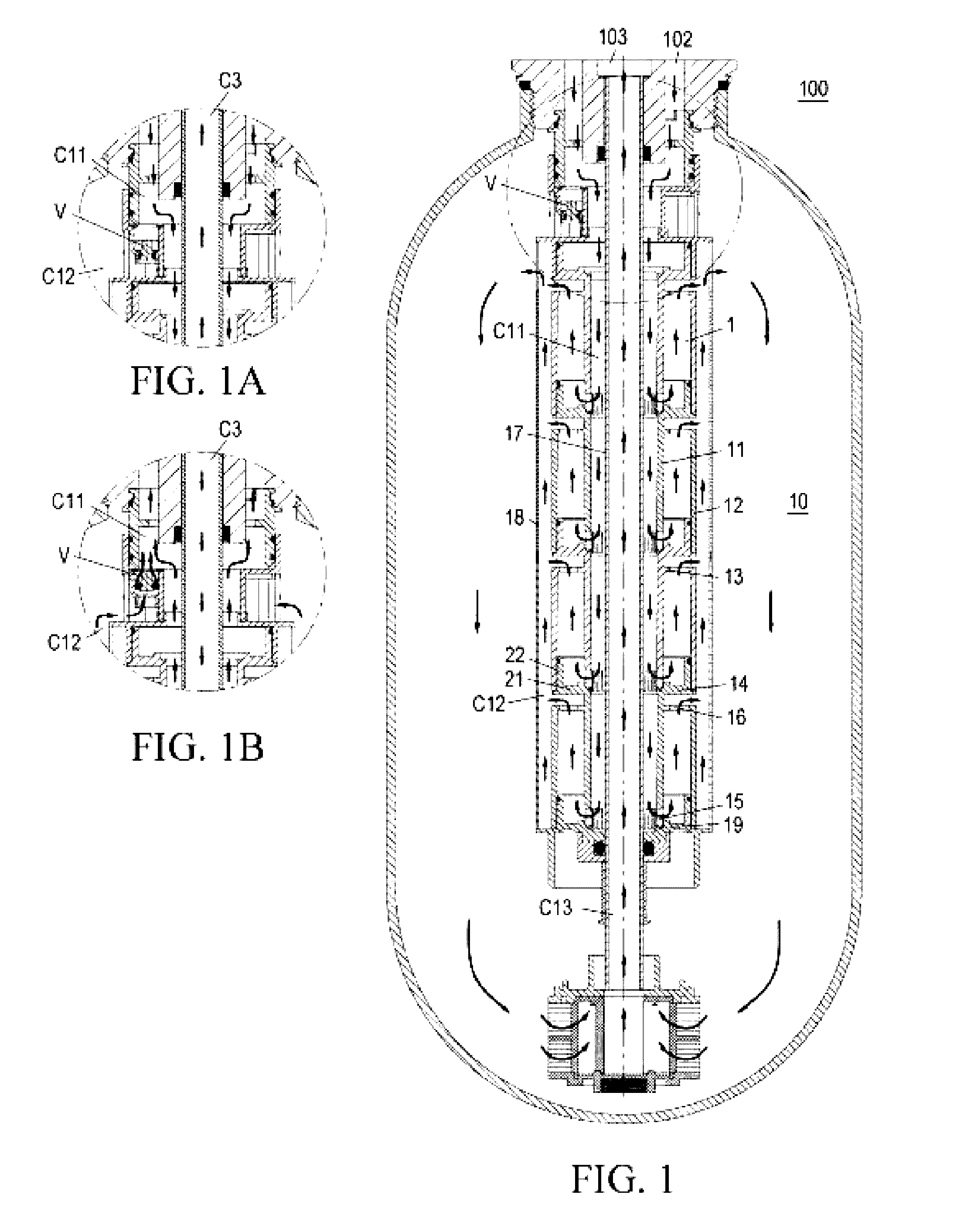

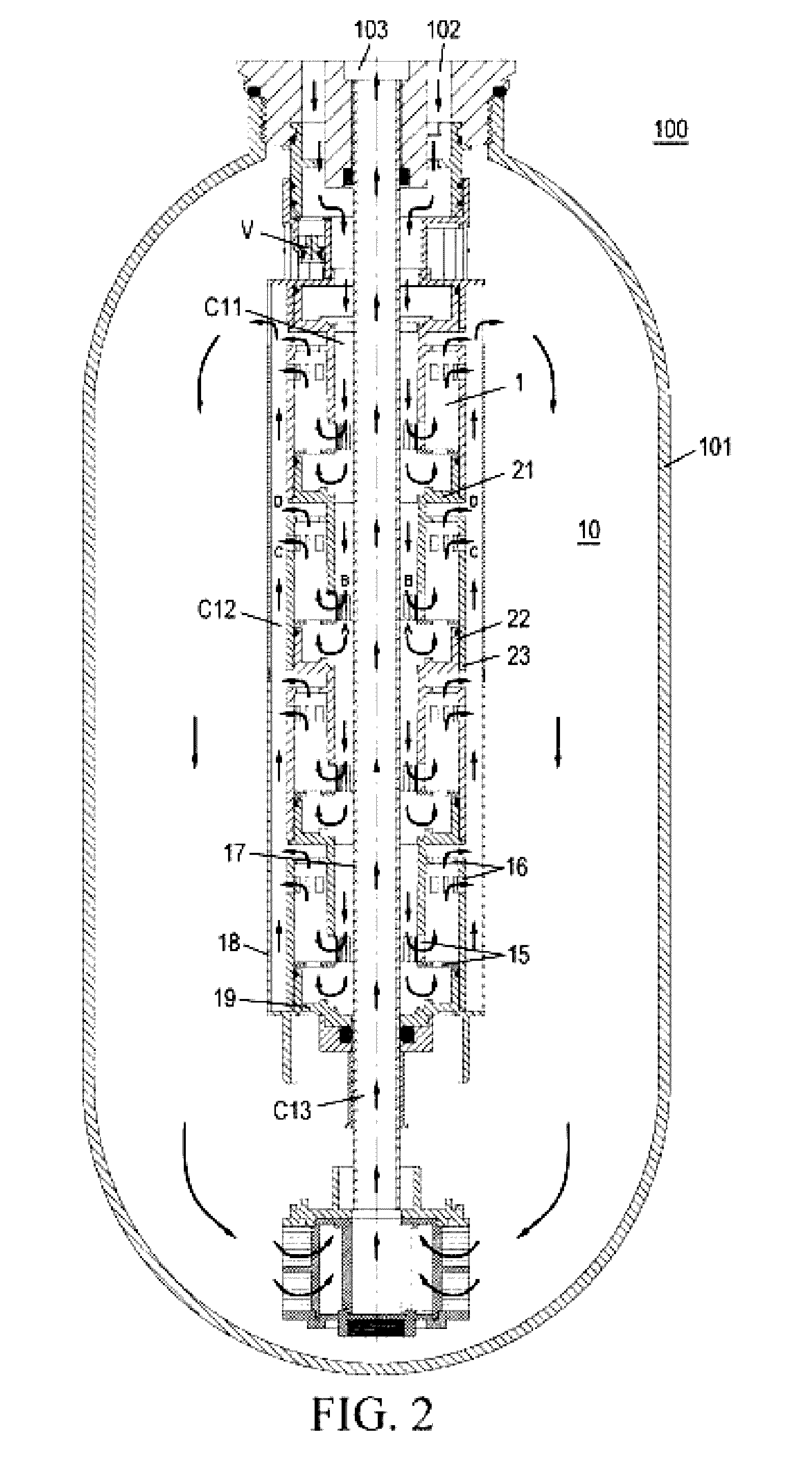

Unit, assembly and apparatus for treating fluid

ActiveUS9527015B2Easy to cleanSpeed up the flowIon-exchange column/bed processesTreatment involving filtrationEngineeringMechanics

A fluid treatment unit (1) is provided. The fluid treatment unit (1) comprises a chamber, in which at least one fine grinding fluid treatment medium is accommodated. The chamber has an inlet (15) for introduction of a fluid to be treated and an outlet (16) for discharge of a treated fluid. The inlet (15) is provided at a lower portion of the chamber and the outlet (16) is provided at an upper portion of the chamber. A fluid treatment device (100) adopting the above fluid treatment unit (1) is also provided. The fluid treatment unit (1) and the fluid treatment device (100) enable the fluid treatment medium to be self-cleaned and the fluid to be treated uniformly.

Owner:CHAU YIU CHAU

Apparatus and method for making a peroxycarboxylic acid

ActiveUS8075857B2Increase life and activity and safetyBiocideExhaust apparatusCarboxylic acidPre treatment

Owner:ECOLAB USA INC

Mixed bed ion exchange resin system and method of preparation

InactiveUS6060526AEasy to measureSatisfied levelIon-exchange column/bed processesCation exchanger materialsPolyelectrolyteIon exchange

A method for preparing non-agglomerating mixed bed ion exchange resin systems without affecting the ion exchange kinetics of the anion exchange resin component of the mixed bed system is disclosed. Pretreatment of the anion exchange resin component with a sulfonated poly(vinylaromatic) polyelectrolyte is particularly effective in providing non-agglomerated mixed bed systems without affecting ion exchange kinetics. Treatment levels of 10 to 800 milligrams per liter of anion exchange resin with sulfonated poly(vinylaromatic) polyelectrolyte having number average molecular weight from 5,000 to 1,000,000 are particularly preferred.

Owner:ROHM & HAAS CO

Air filter sheet, process for manufacturing same, and air filter

InactiveUS20060185336A1Improve adsorption capacityGood formabilityGas treatmentIon-exchange column/bed processesFiberAir filter

An air filter sheet comprising particles of a functional agent with an average particle diameter of 0.1 to 30 μm and fibrils of a polytetrafluoroethylene resin with a number average molecular weight of 3,000,000 to 50,000,000, the ratio by weight of the functional agent to the fibrils of the polytetrafluoroethylene resin being from 1 to 99. According to the present invention, an air filter sheet comprising fibrils of polytetrafluoroethylene resin with a functional agent carried thereon, possessing excellent formability, and being free from a lubricant, a process for manufacturing the air filter sheet, and an air filter free from contamination of outgas with a lubricant are provided.

Owner:NICHIAS CORP

Water purification cartridge using zirconium ion-exchange sorbents

ActiveUS8758626B2Avoid disadvantagesCompact and economicalCation exchanger materialsOrganic anion exchangersSorbentIon exchange

Owner:FRESENIUS MEDICAL CARE HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com