Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157results about "Ion exchange regulation/control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

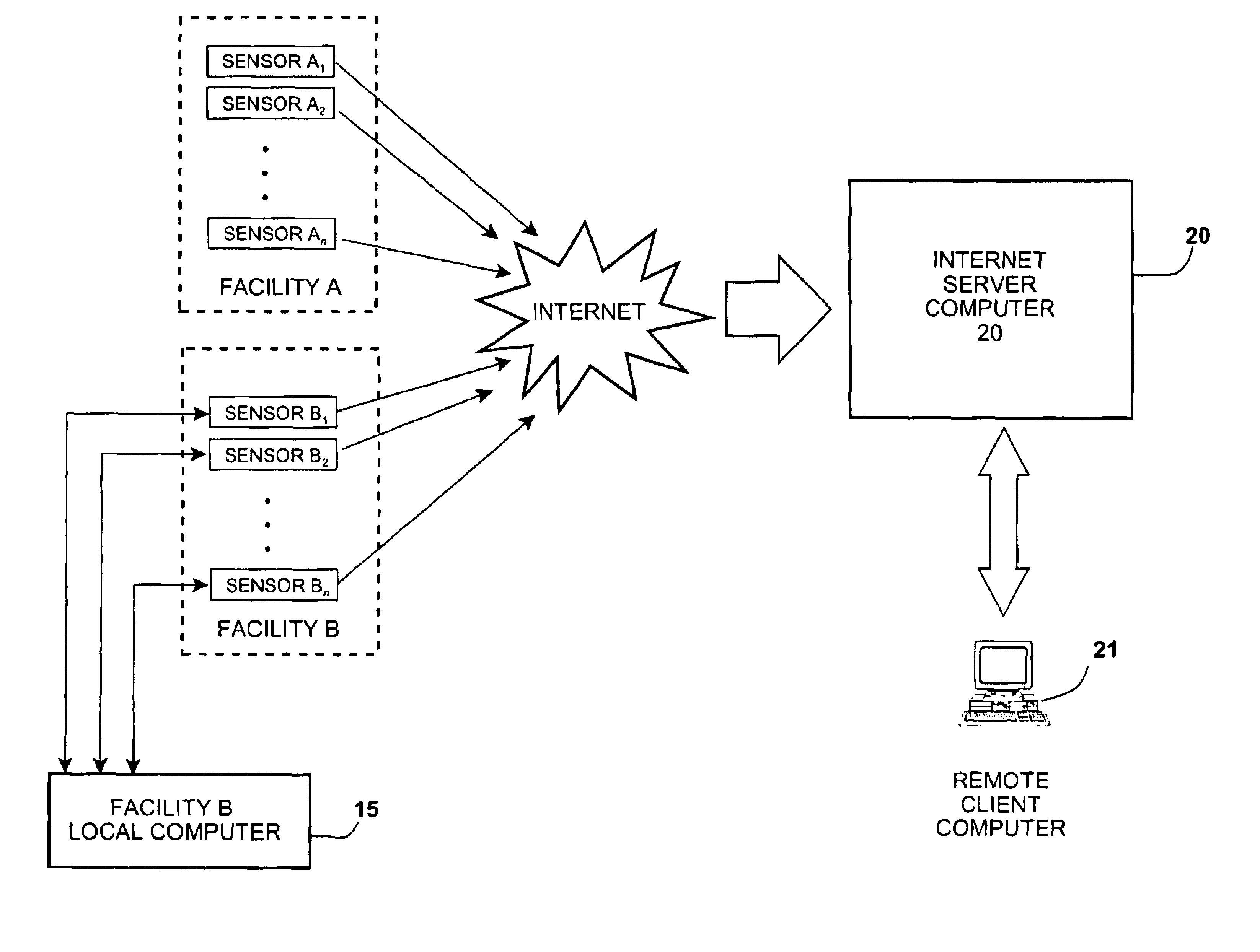

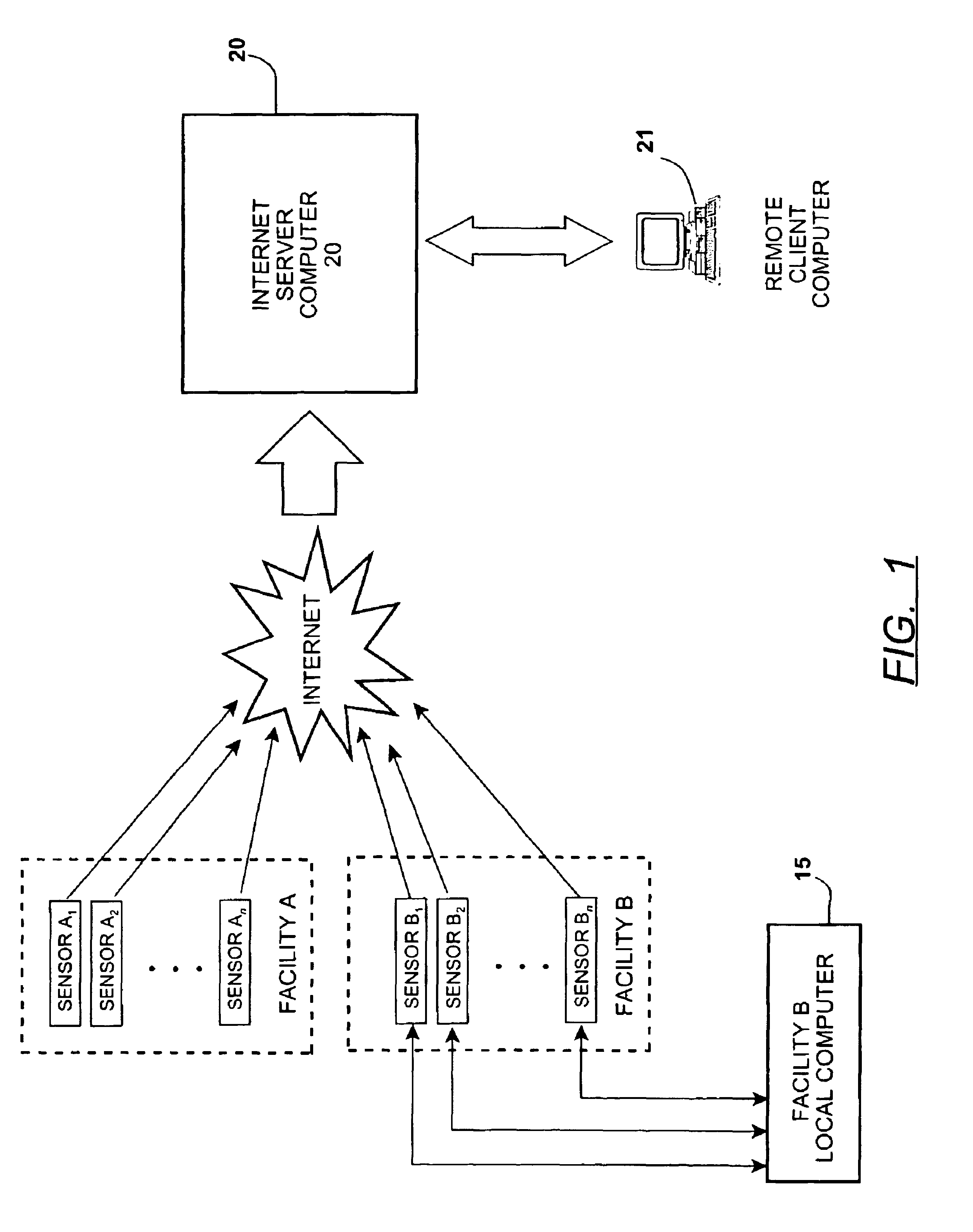

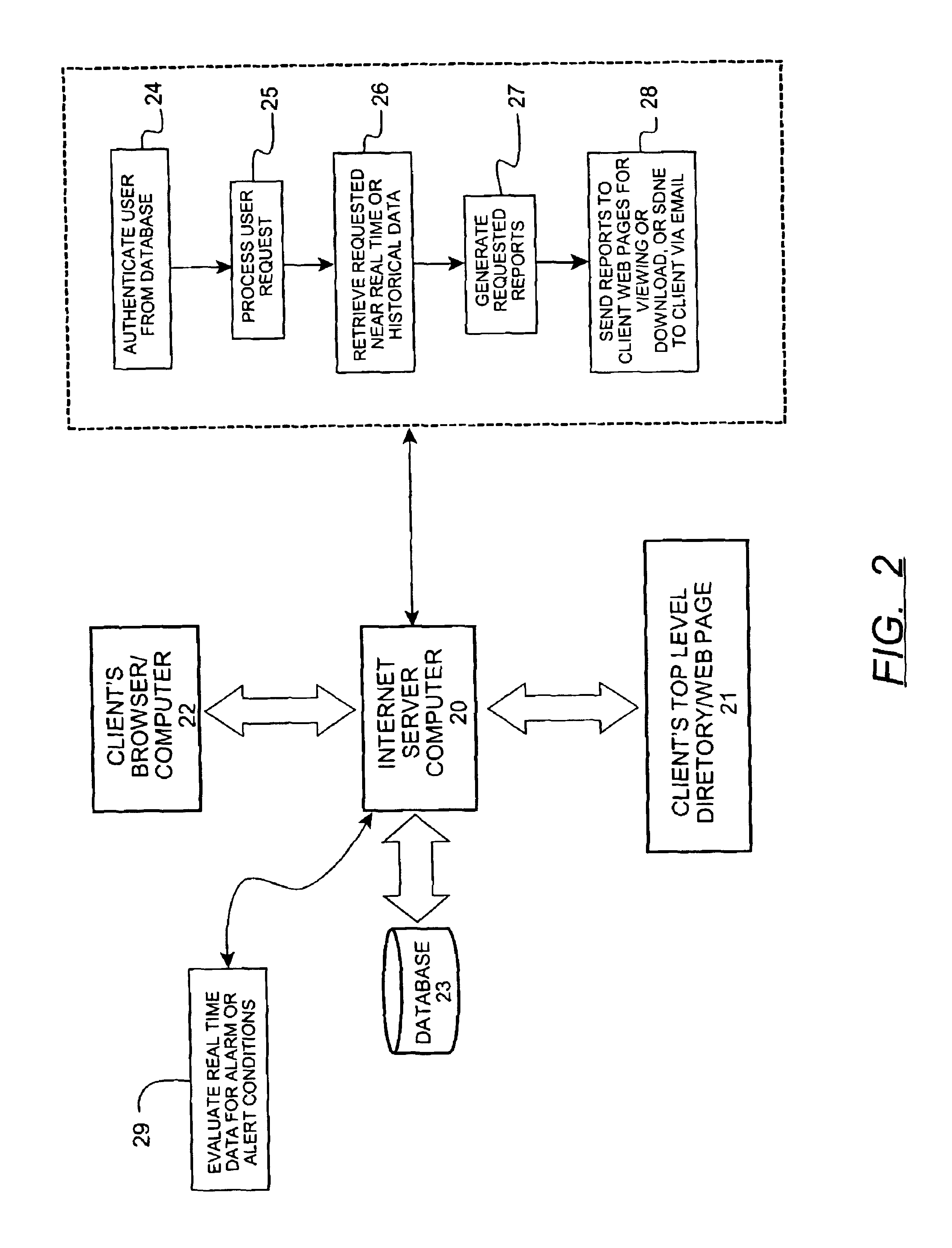

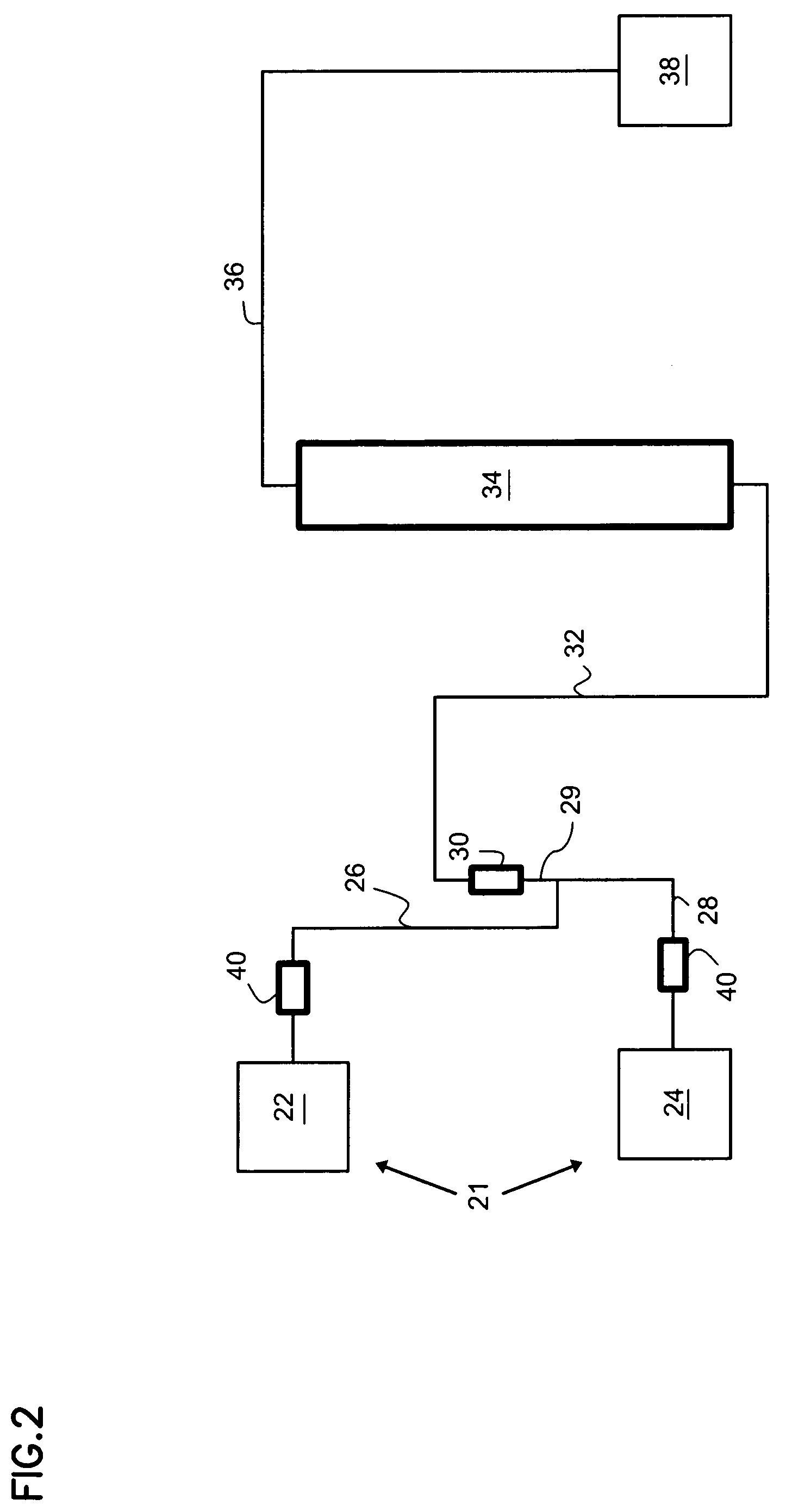

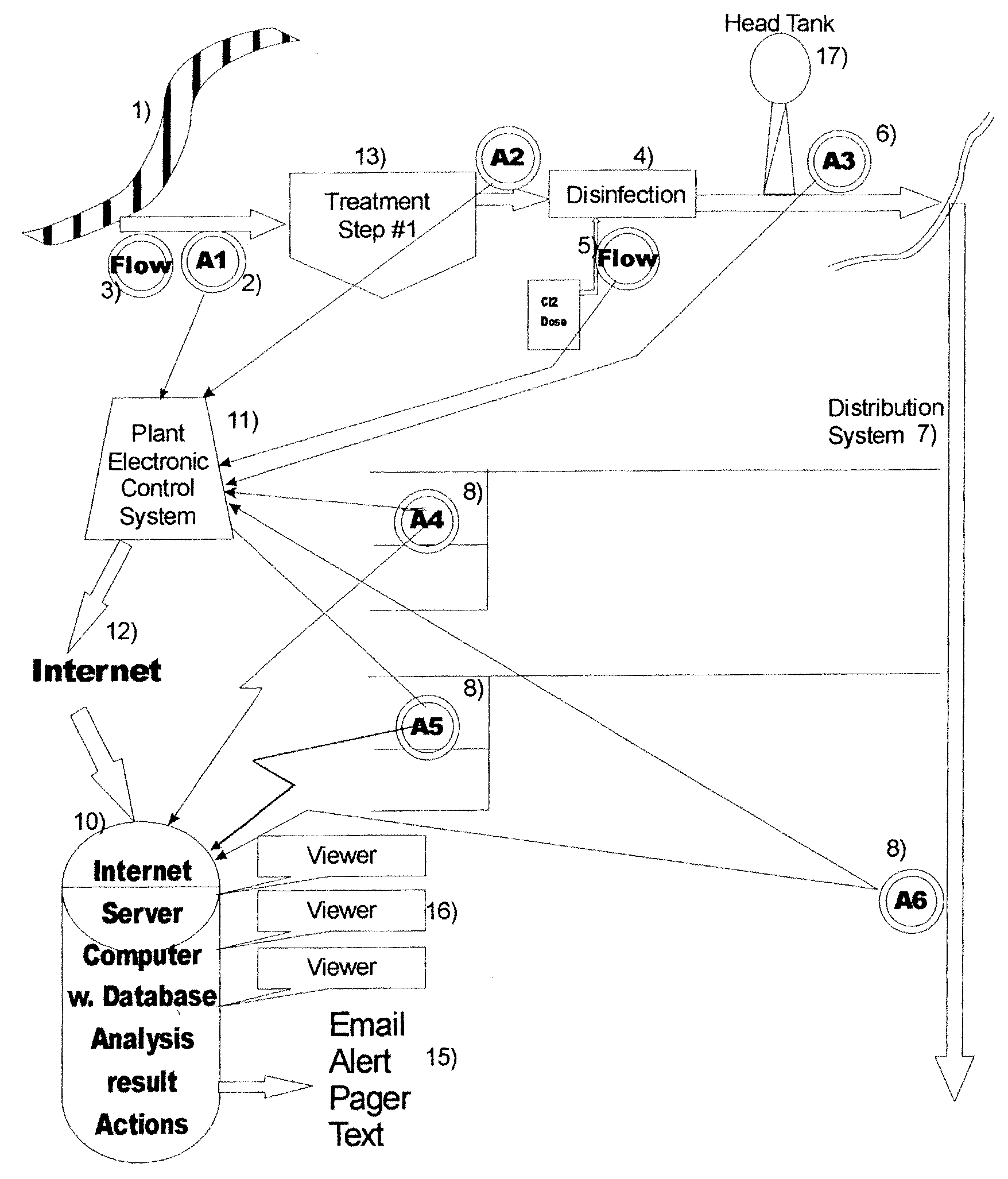

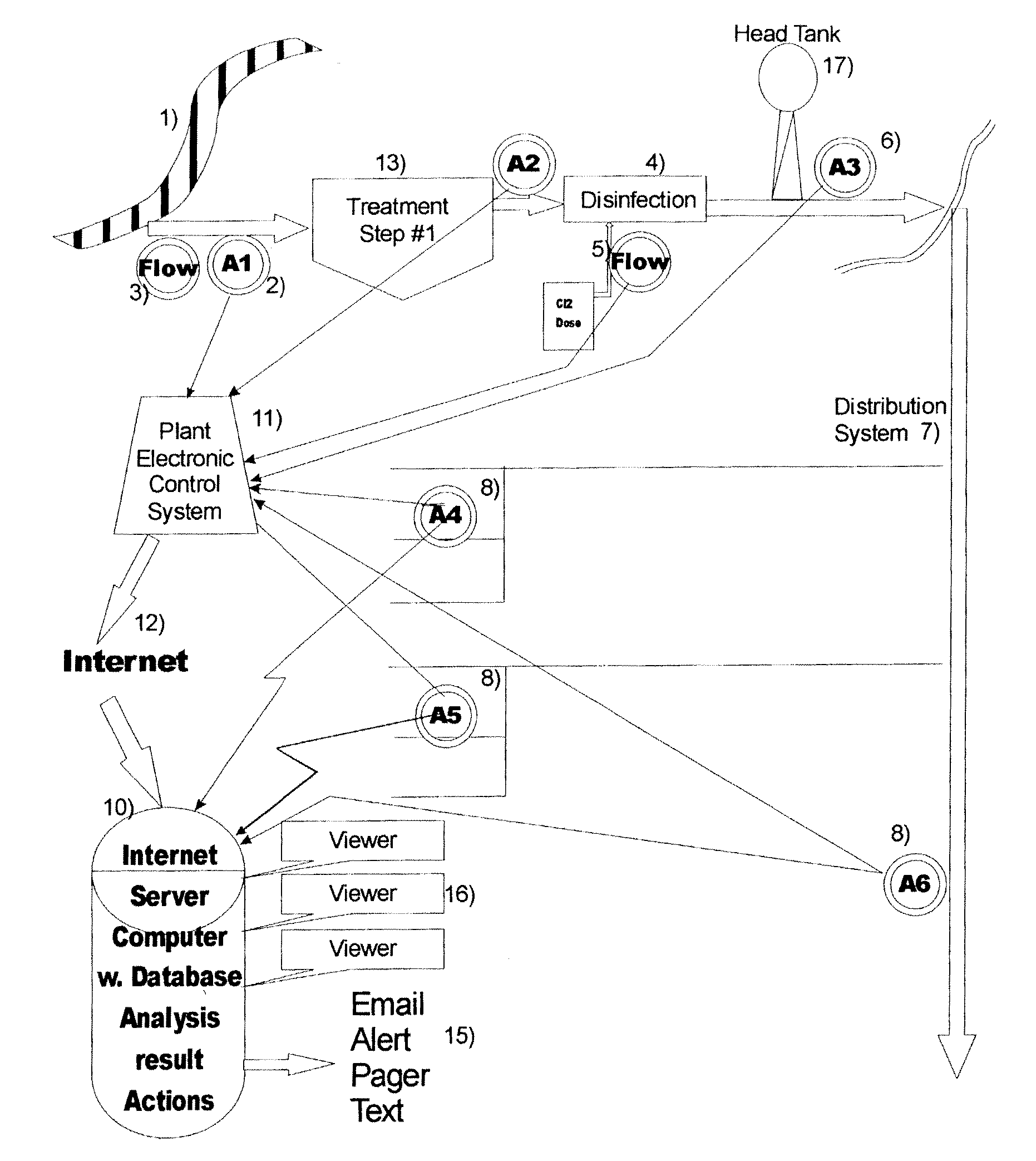

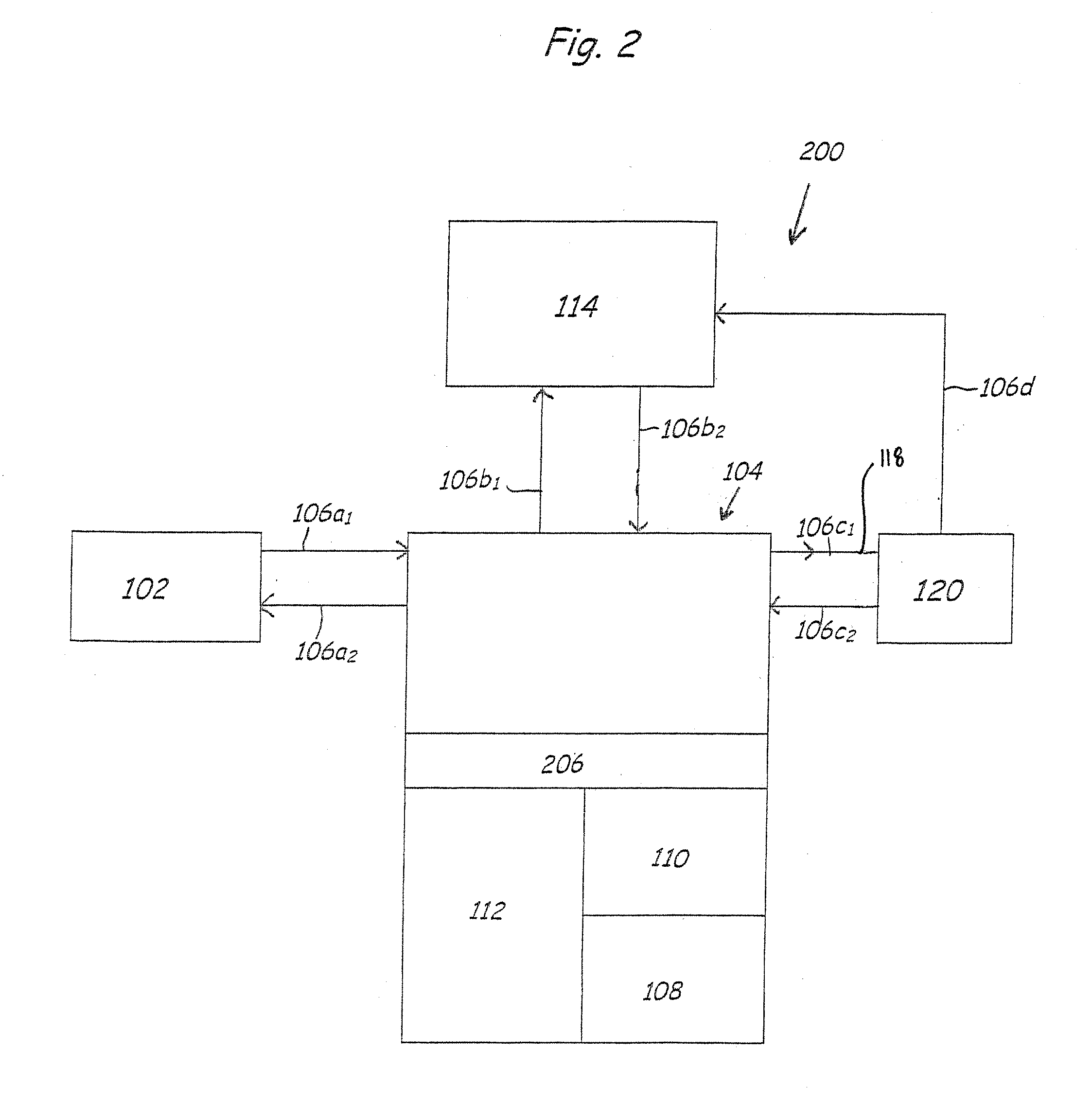

Method for remote monitoring of water treatment systems

InactiveUS6954701B2Rule out the possibilityNegating human error or tamperingUltrafiltrationSolid sorbent liquid separationWater treatment systemQuality assurance

A method of monitoring the daily operating performance parameters for water treatment processes through the collection of localized data. The data is manipulated to generate preconfigured performance, maintenance, and quality assurance reports and further provide automatic submission of data as required for regulatory review of certain water treatment systems such as potable water treatment. The data is collected from sensors located at an equipment site and transferred to a remote computer located by use of the Internet, further all data received and used for generation of reports is also accessible by Internet connection and be delivered directly to the regulatory agency without additional process.

Owner:WATEREYE +1

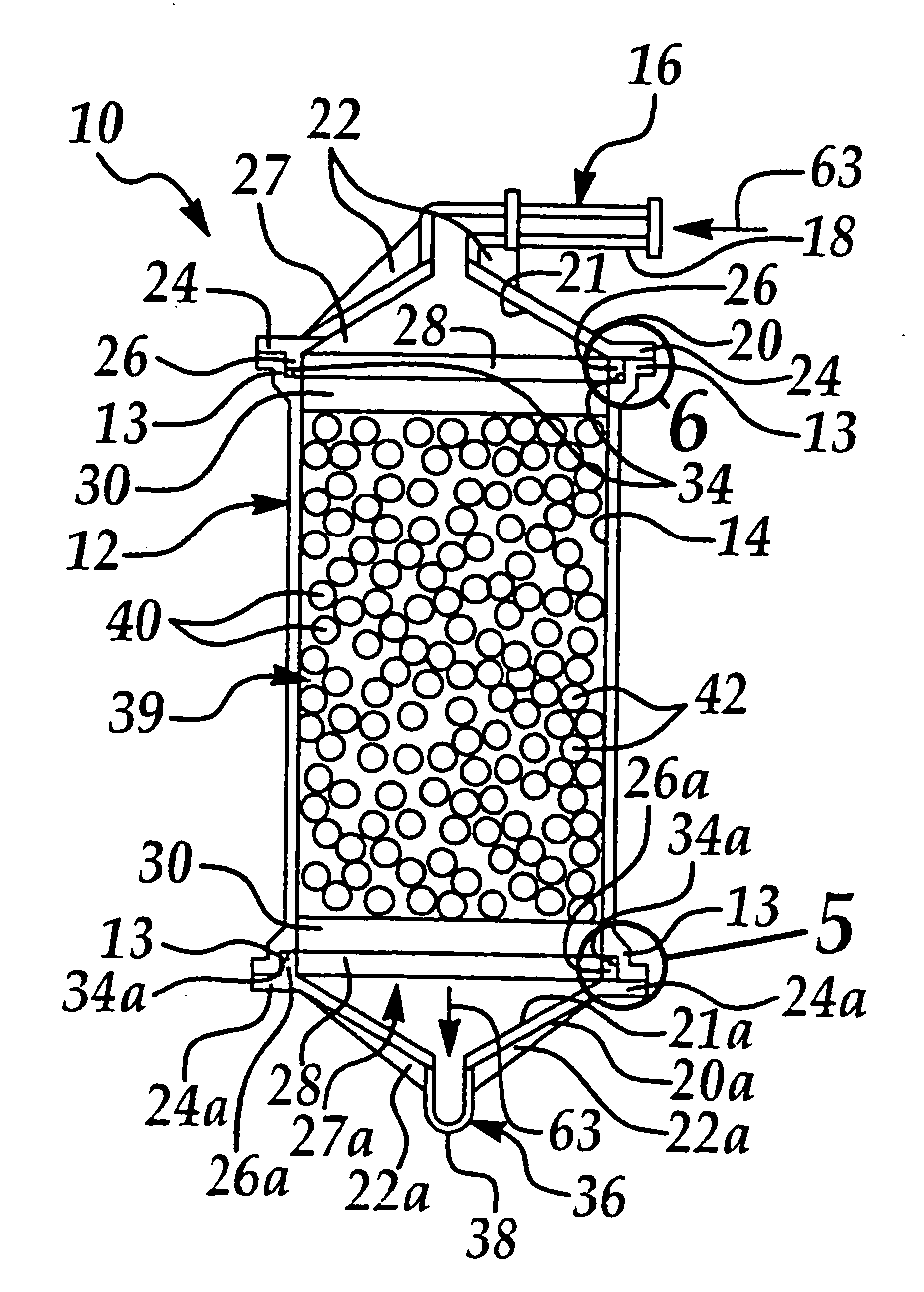

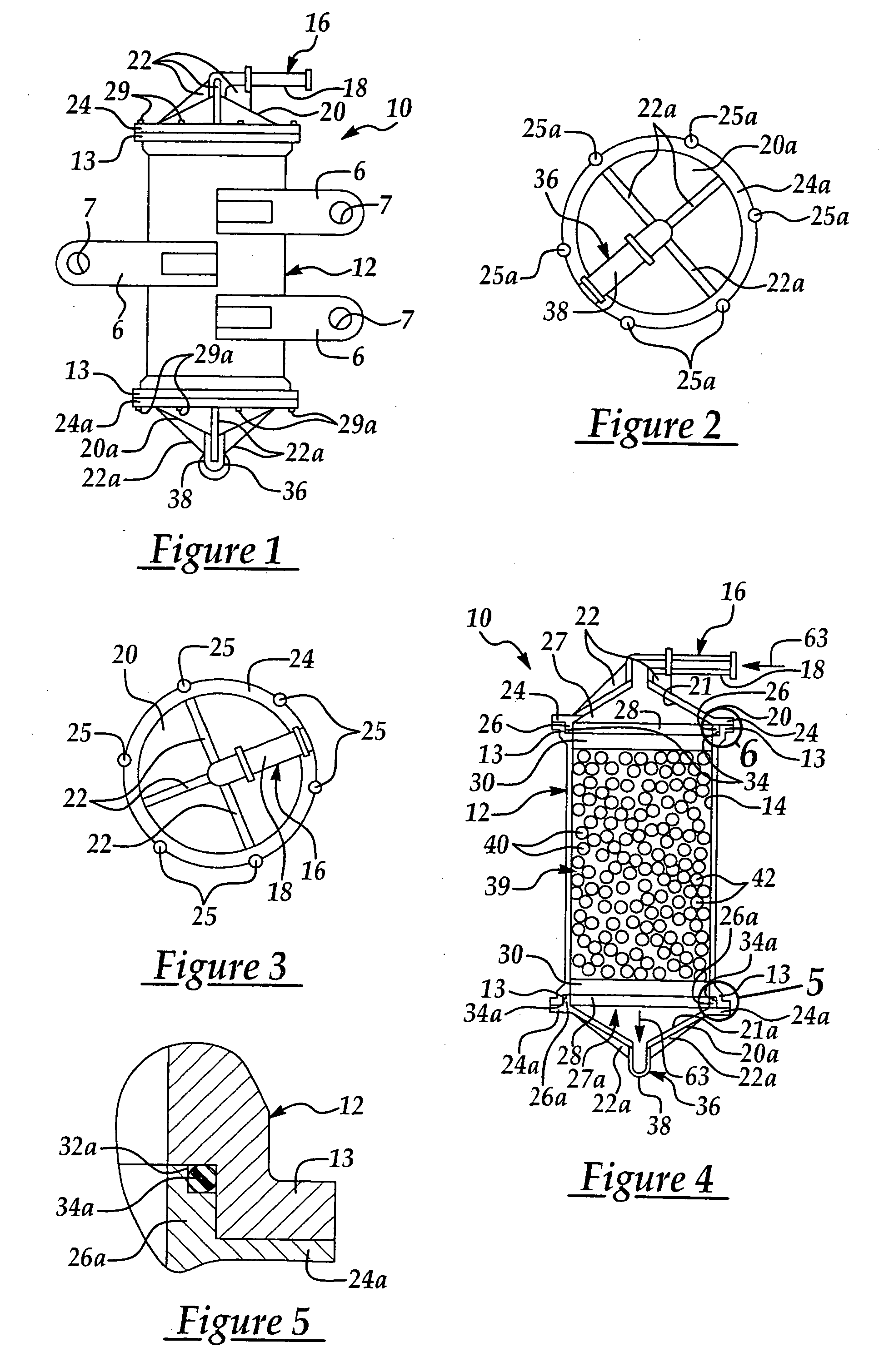

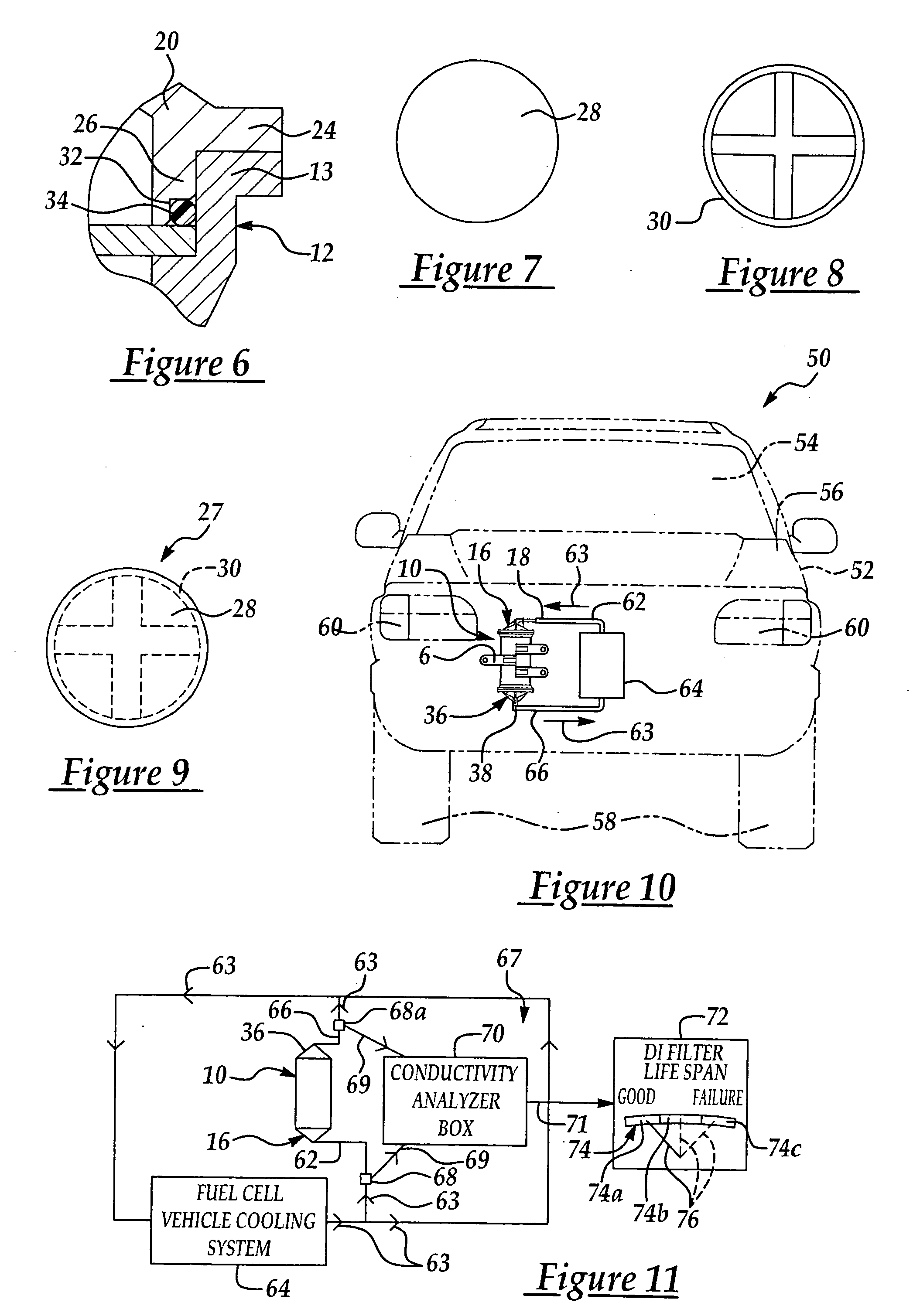

Deionization filter for fuel cell vehicle coolant

A novel deionization filter for removing ions from a coolant in an electric fuel cell vehicle cooling system is disclosed. The deionization filter includes a filter housing having a coolant inlet port, through which the coolant enters the filter housing; and a coolant outlet port, through which the coolant exits the filter housing. An ion exchange bed having positively-charged and negatively-charged ion exchange resin beads is provided in the filter housing for removing negative and positive ions, respectively, from the coolant. At least one filter assembly is typically provided in the filter housing for filtering particles from the coolant.

Owner:FORD MOTOR CO

Apparatus and method for making a peroxycarboxylic acid

ActiveUS7547421B2Increase life and activity and safetyProcess control/regulationExhaust apparatusCarboxylic acidReagent

Owner:ECOLAB USA INC

Purification of organic solvent fluids

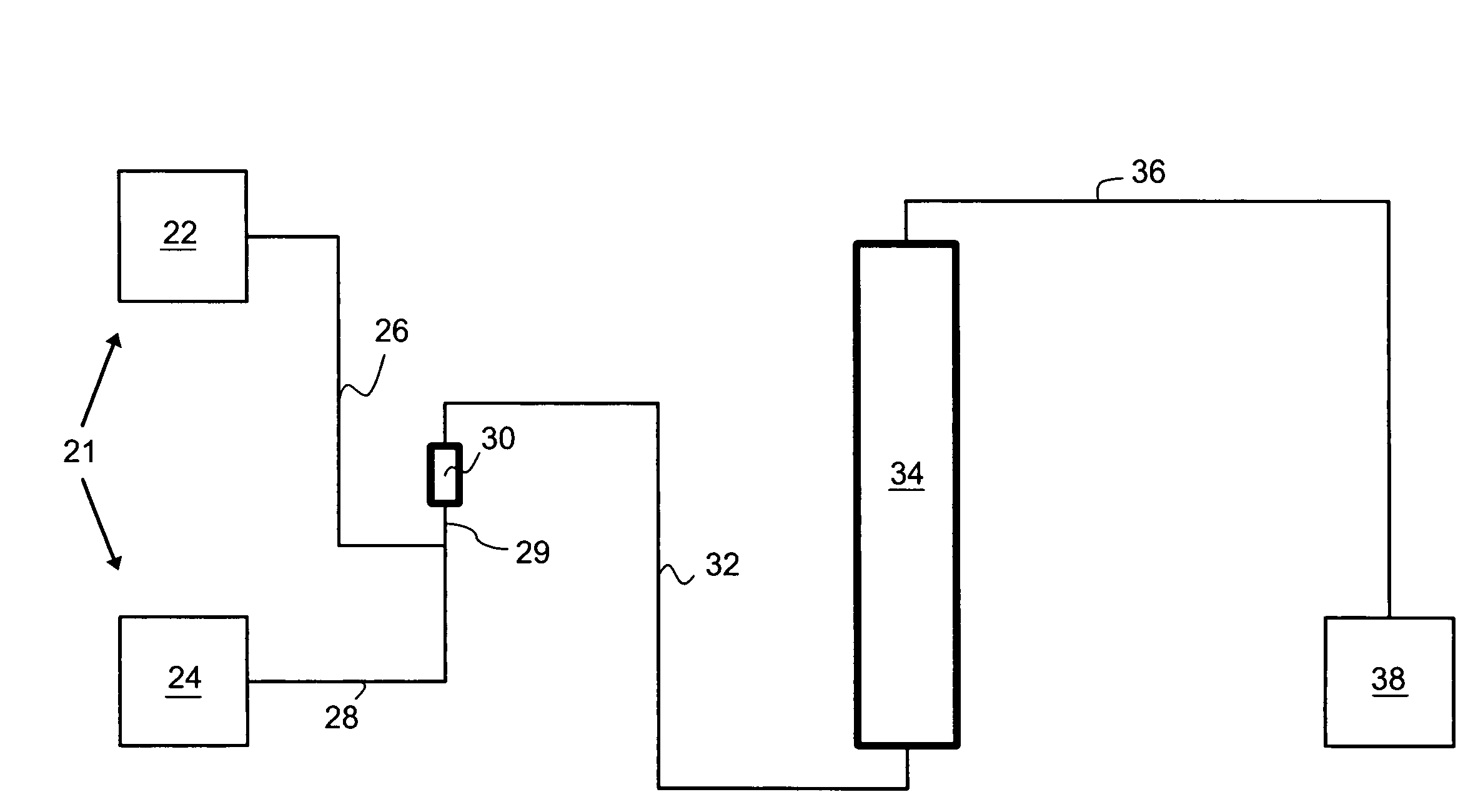

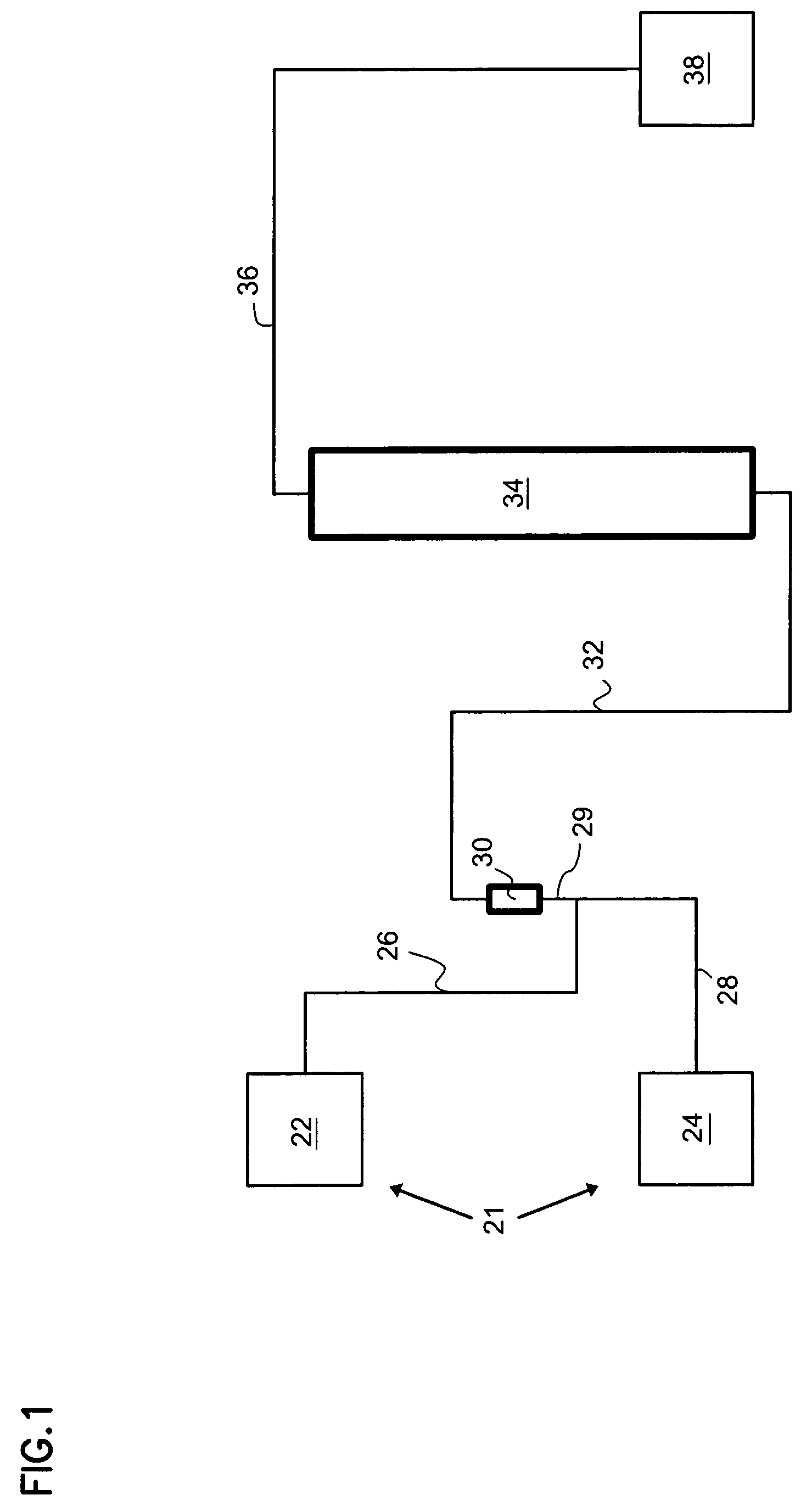

InactiveUS7329354B2Precision productionSmooth connectionIon exchange regulation/controlIon-exchange column/bed processesOrganic solventIon exchange

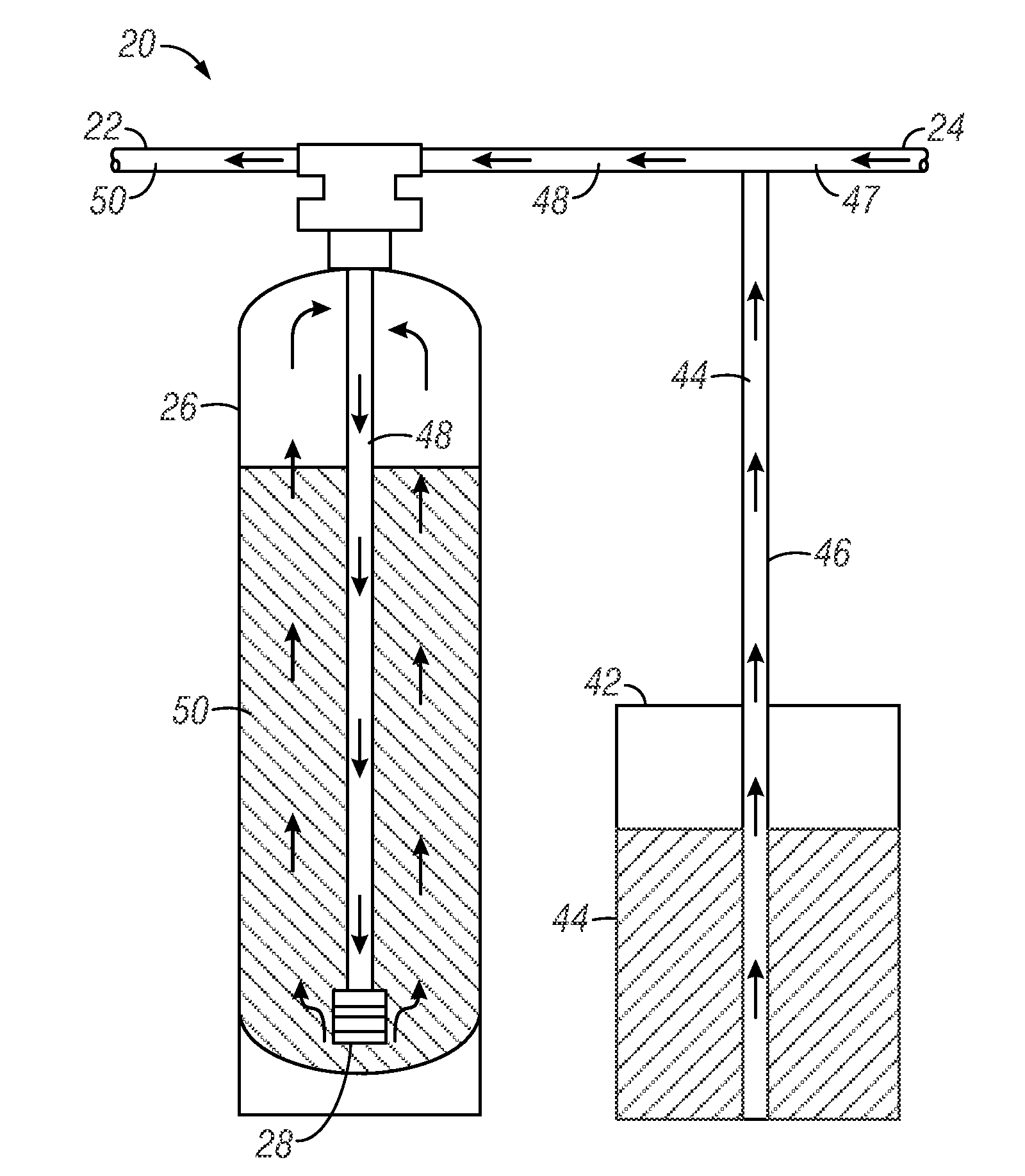

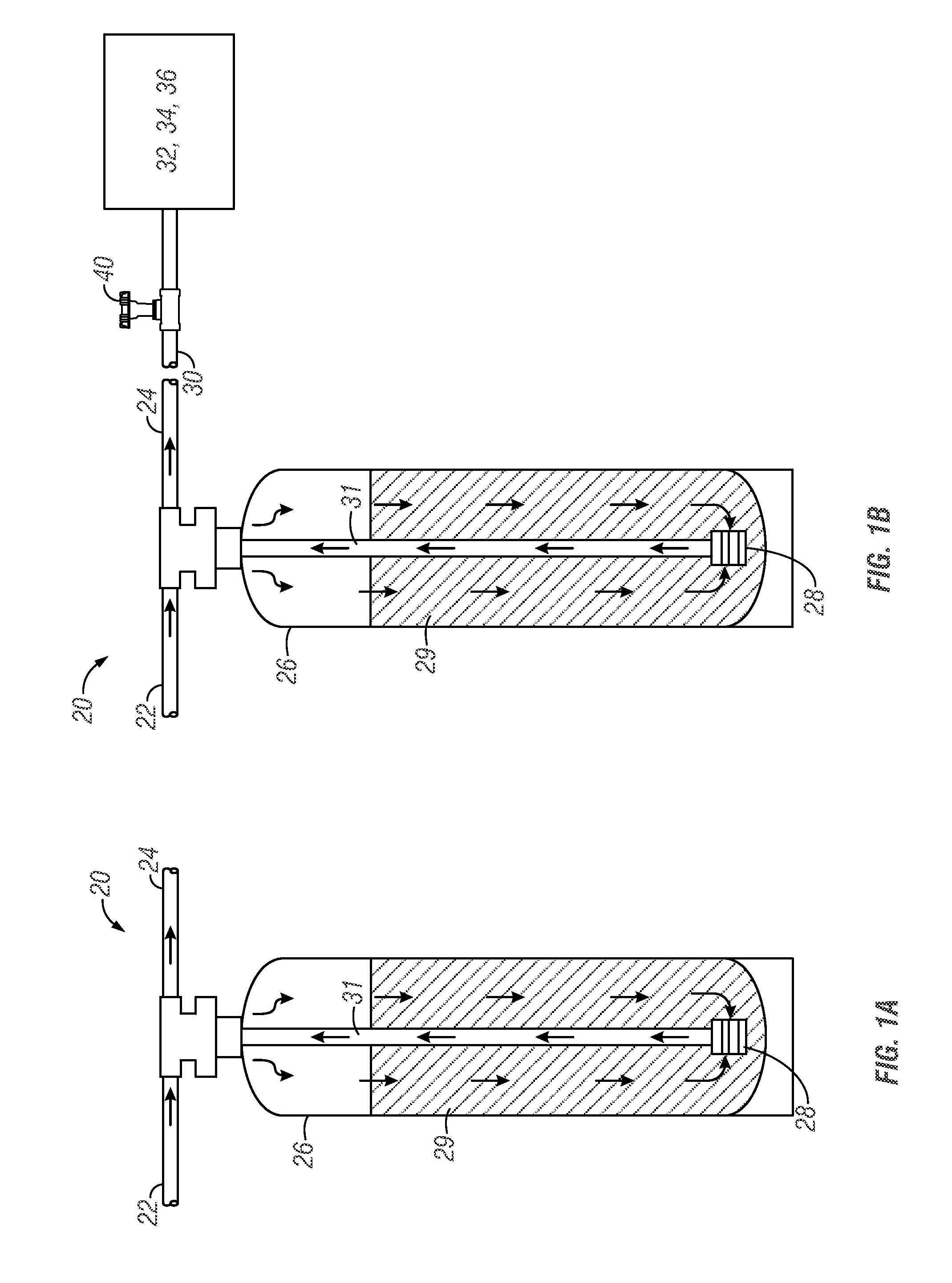

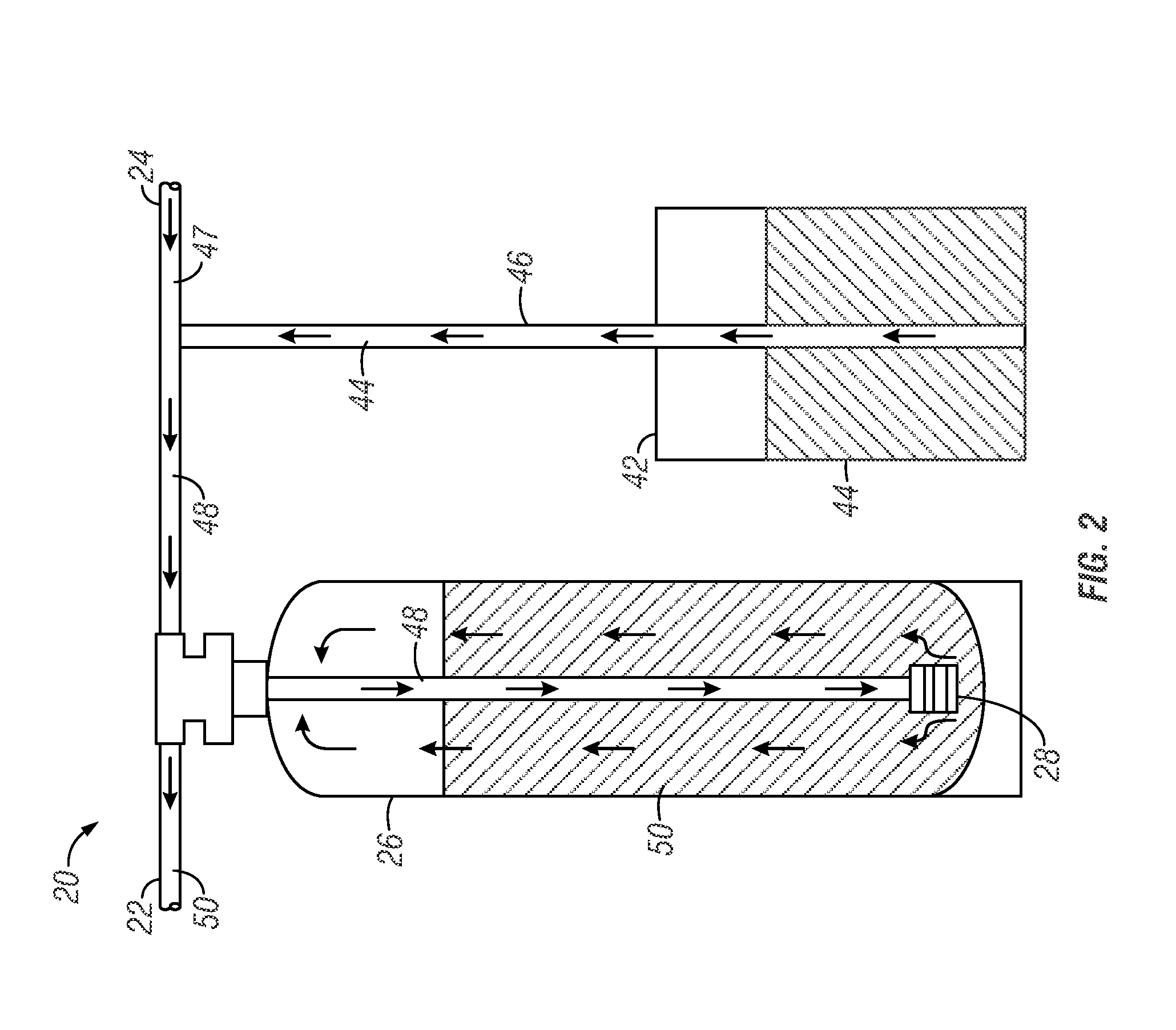

A chemical distribution system having improved organic solvent fluid purity and consistency includes a vessel containing ion-exchange media positioned within a fluid flow pathway such that the organic solvent fluid passes through the ion-exchange media, thereby effecting removal of undesired impurities. Different embodiments of the invention position the vessel at varying locations within the fluid flow pathway. The chemical distribution system also preferably includes a return chemical flow pathway that recirculates purified organic solvent fluid through the ion-exchange media-containing vessel and thereby enables the system operator to conduct incremental adjustment of the solvent purity until a desired overall purity is attained.

Owner:PPT TECH

Apparatus and method for making a peroxycarboxylic acid

ActiveUS8075857B2Increase life and activity and safetyBiocideExhaust apparatusCarboxylic acidPre treatment

Owner:ECOLAB USA INC

Particle separation system

Owner:DRAKE WATER TECH

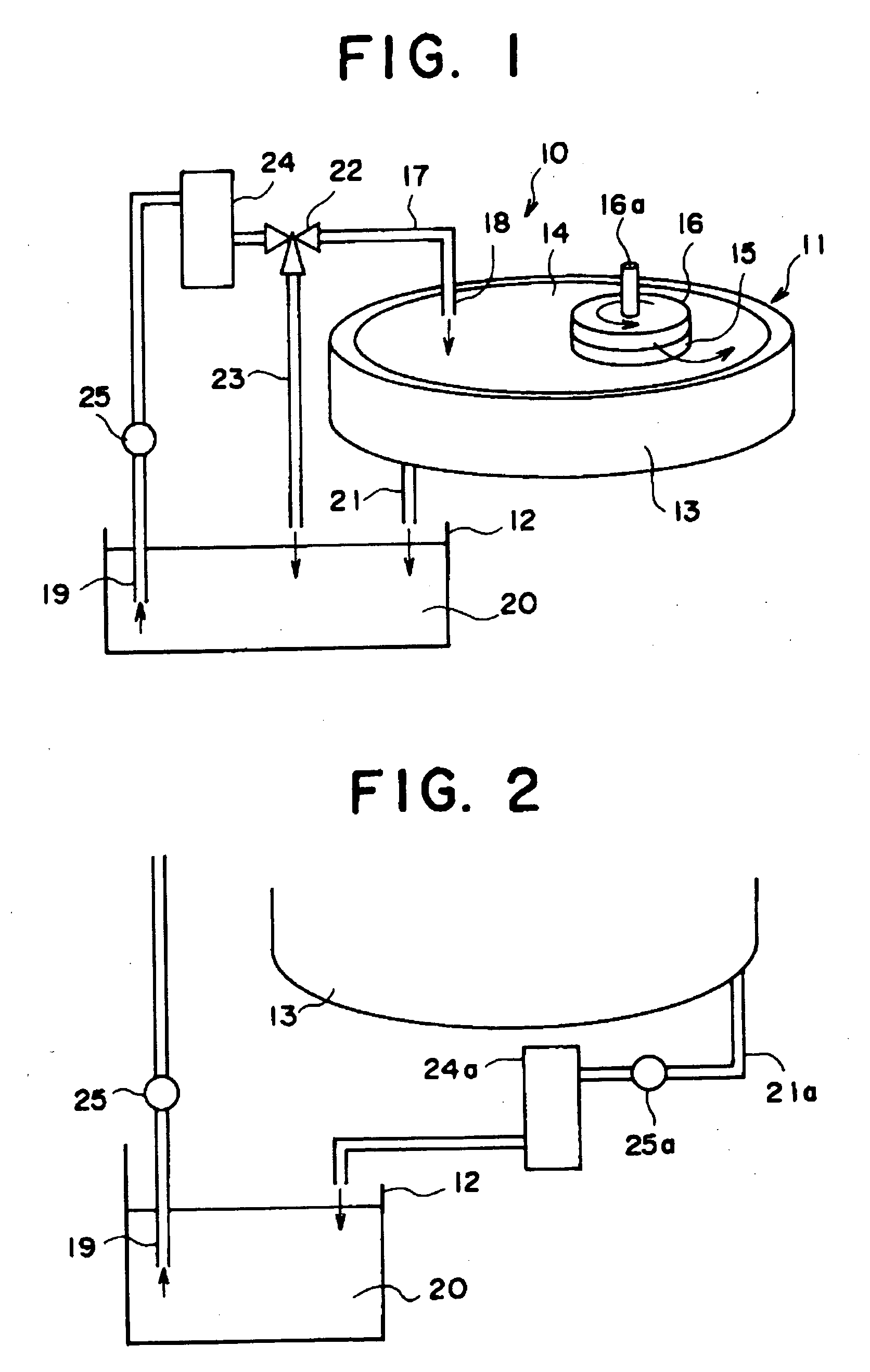

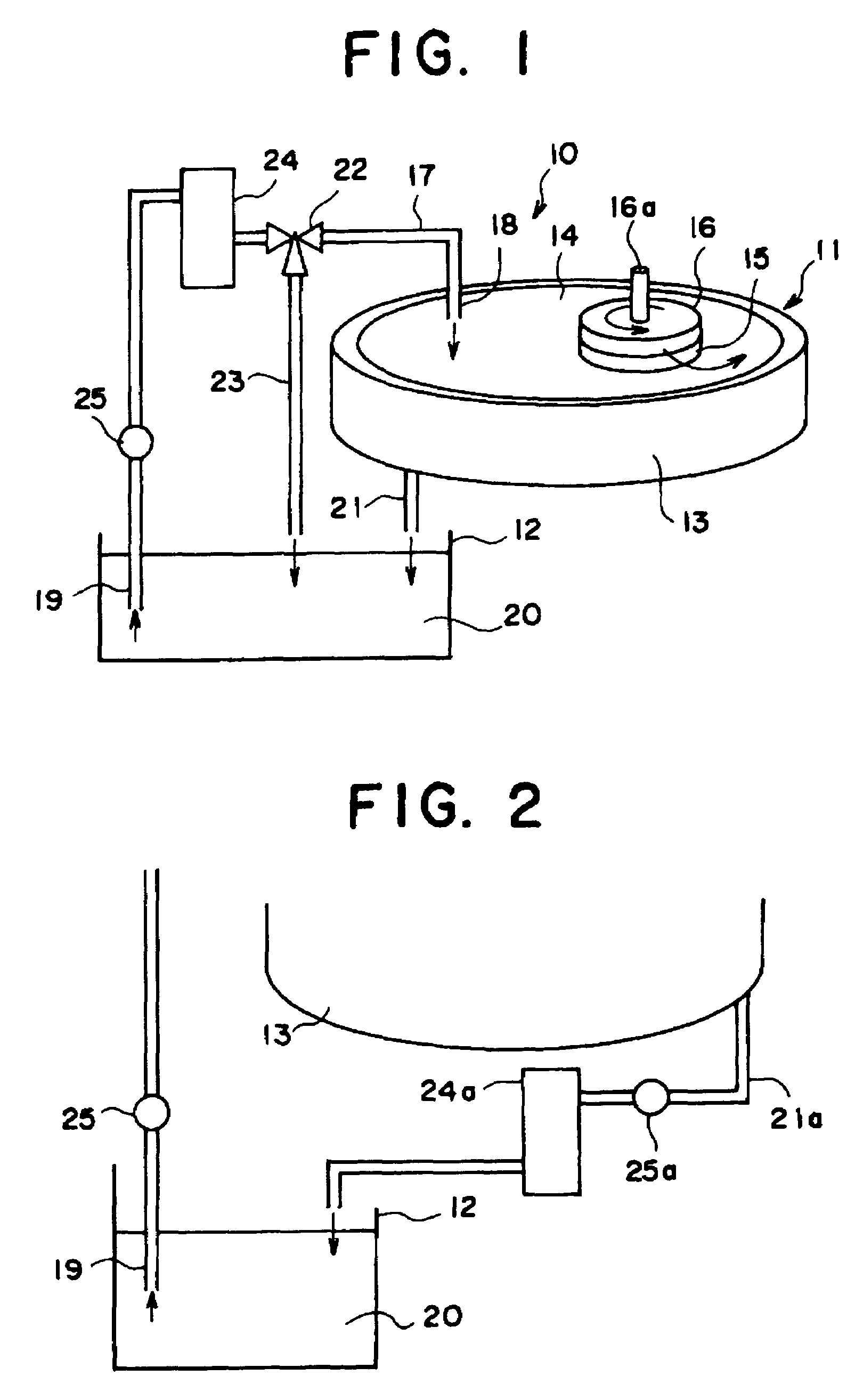

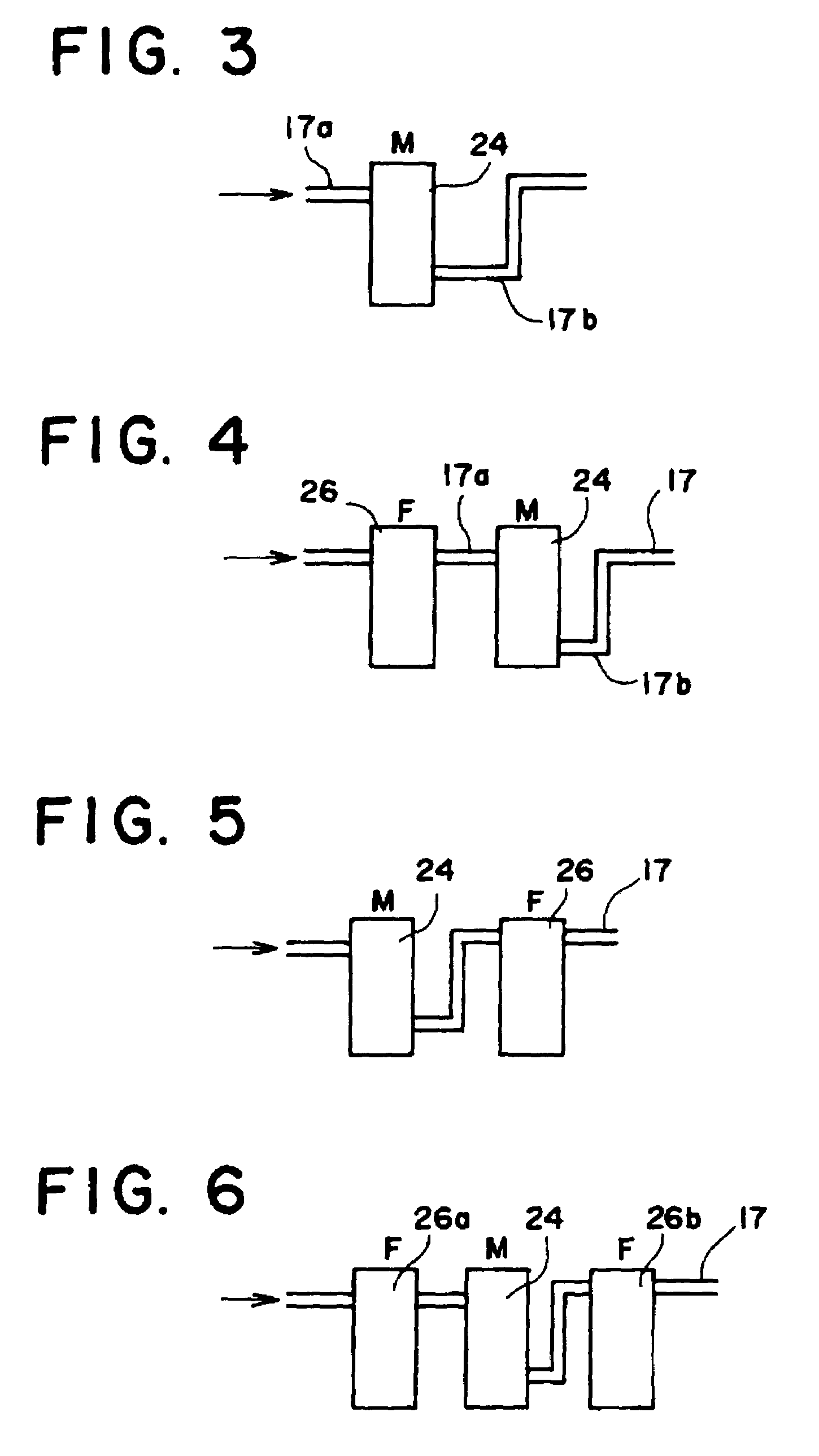

Dielectric-Fluid Quality Control Apparatus and Electrical-Discharge Machining Apparatus

ActiveUS20070289925A1Avoid corrosionIon exchange regulation/controlWater treatment parameter controlDielectricEngineering

A water purifying unit generates pure water by eliminating impurity ions from dielectric fluid. A corrosion-protection-ion generating unit generates corrosion protection ions, substitutes predetermined cations for impurity cations contained in the dielectric fluid, and substitutes the corrosion protection ions for impurity anions contained in the dielectric fluid. A switching unit switches a supply of the dielectric fluid between the water purifying unit and the corrosion-protection-ion generating unit. A switching control unit controls the switching unit based on a conductivity of the dielectric fluid measured by a conductivity measuring unit.

Owner:MITSUBISHI ELECTRIC CORP

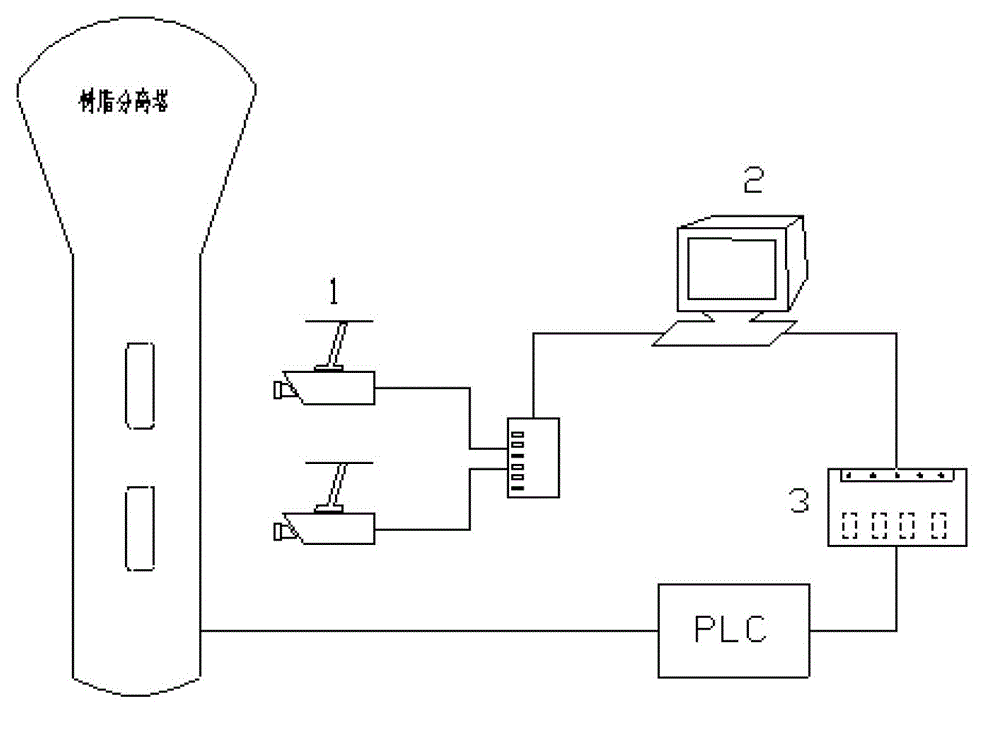

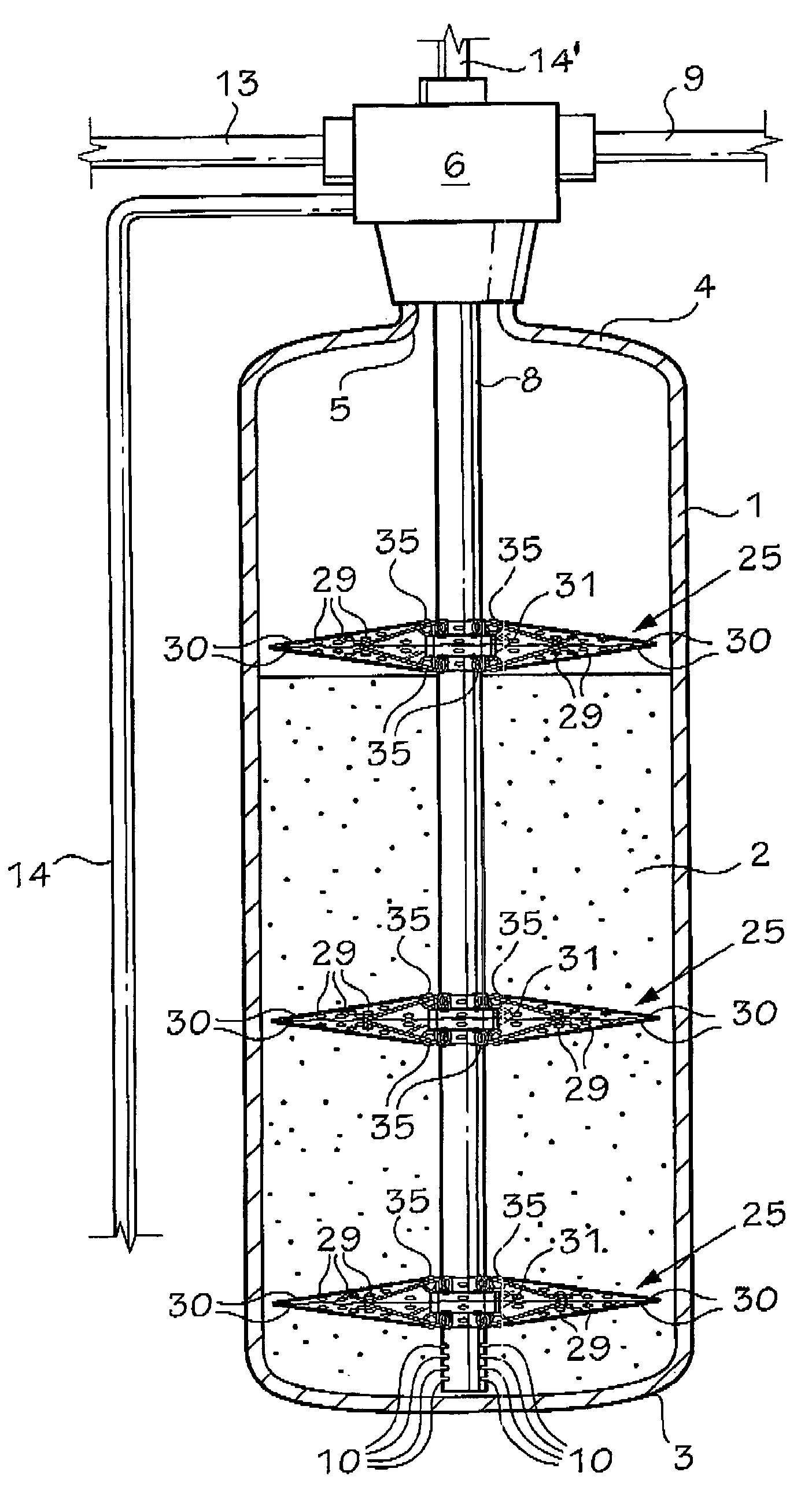

Mixed-bed resin in-vitro separating and conveying process intelligent monitoring control device and mixed-bed resin in-vitro separating and conveying process intelligent monitoring control method

ActiveCN102874898AHigh degree of automationReasonable separation and conveying processIon exchange regulation/controlWater treatment parameter controlImaging analysisProcess engineering

The invention discloses a mixed-bed resin in-vitro separating and conveying process intelligent monitoring control device and a mixed-bed resin in-vitro separating and conveying process intelligent monitoring control method. A computer intelligent image analysis technology is applied to mixed-bed resin in-vitro separating monitoring, so that a separated resin conveying end point is reliably judged, and a resin separating and conveying process is relatively rational. On the one hand, the volume and proportion of the mixed-bed resin can be prevented from being mixed; on the other hand, the volume and proportion of the stirred mixed-bed resin can be gradually and automatically adjusted in the resin separating and conveying process until the volume and the proportion are recovered; therefore, the operating effect of a mixing bed can be well maintained, and the automation degree of mixed-bed resin in-vitro separating can be improved; and the working intensity of a worker is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

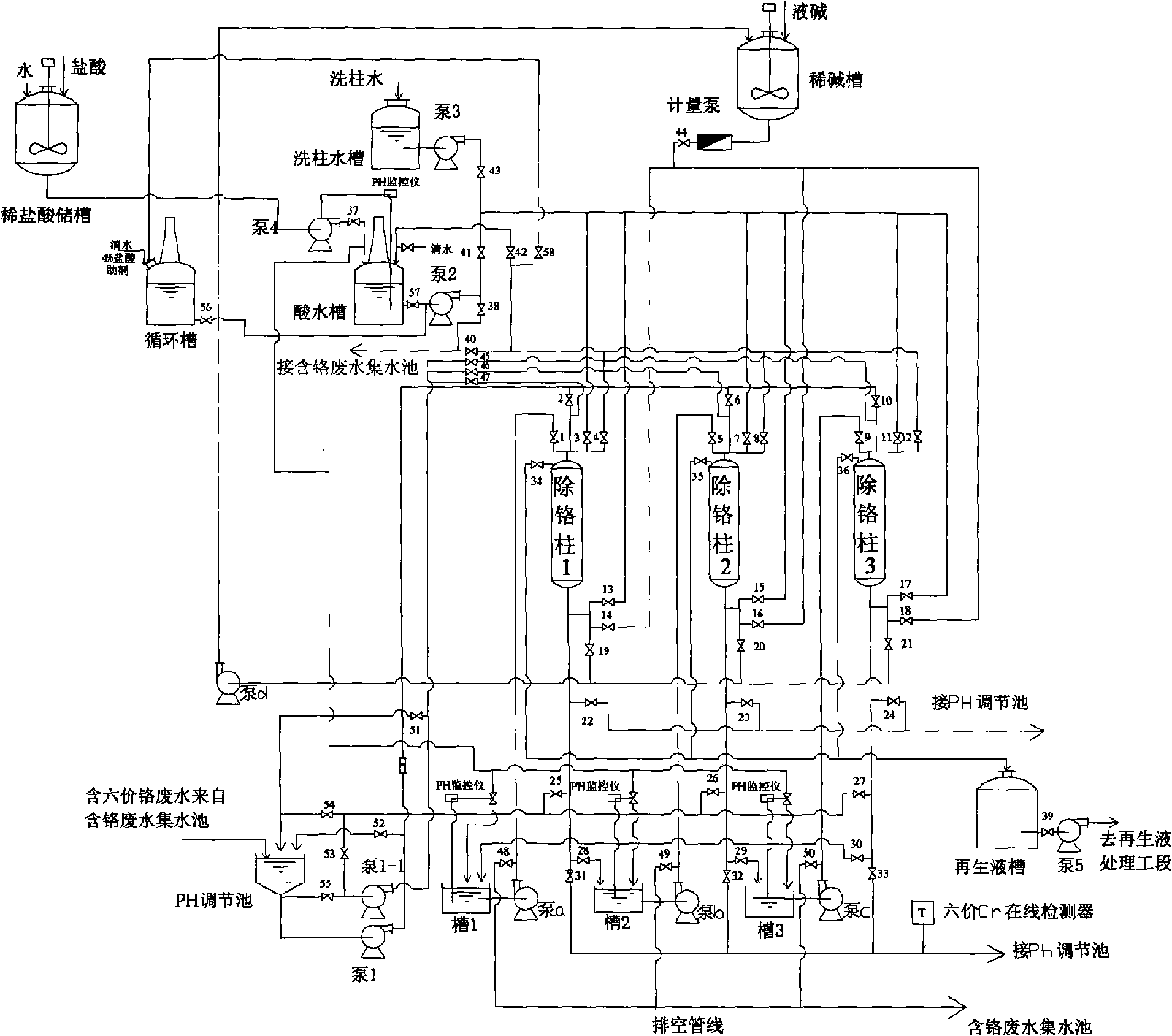

Ion-exchange process technique of hexavalent chrome-containing waste water

InactiveCN101357794AEasy to handleOvercoming the problem of decreased adsorption capacityIon exchange regulation/controlIon-exchange column/bed processesWater qualityIon exchange

The invention discloses an ion exchange treatment technology of wastewater containing hexavalent chromium, the ion exchange treatment technology combines the regulation of pH value of the wastewater, the absorption, the regeneration, the maintenance and the recovery of Cr<6+> ions, thereby realizing the automatic treatment of the Cr<6+> ions in the wastewater containing the chromium; the technology of the invention has high degree of automation and good treatment effect and can be applied in the large-scale water treatment; chromium removing columns are designed to three columns or multiple columns, intermediate tanks which can regulate the pH value are arranged among various ion exchange columns, when two columns or multiple columns are connected in series for working, the pH value can be regulated during the intermediate process, thereby ensuring the wastewater treatment effect to be better and being capable of overcoming the problem that the pH is changed due to the change of the concentration of the ions during the conventional ion exchange process, thereby causing the decrease of the absorption ability of the ions by the resin; the outlet water quality can stably maintain the Cr<6+> to be less than 0.5mg / L; ion exchange resin can be effectively maintained and be stably worked for a long time; regenerated liquid can be recovered, thereby saving resources.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV

Material for purification of semiconductor polishing slurry, module for purification of semiconductor polishing slurry and process for producing semiconductor polishing slurry

InactiveUS20060205325A1Improve the level ofControl changesIon exchange regulation/controlSludge treatmentMetal chelateMetal contamination

A material for purification of a semiconductor polishing slurry that without changing of pH value, is capable of efficiently purifying a polishing slurry to thereby not only prevent metal contamination of a polished object as effectively as possible but also achieve recycling of a polishing slurry without any problem; a relevant module for purification of a semiconductor polishing slurry; and a process for purifying a semiconductor polishing slurry with the use thereof. In particular, a material for purification of a semiconductor polishing slurry characterized in that it comprises a fibrous substrate having a functional group capable of forming a metal chelate or such a functional group together with hydroxyl fixed onto at least the surface thereof. This material for purification of a semiconductor polishing slurry is, for example, used in such a manner that it is inserted in a container fitted with polishing slurry inflow port and outflow port while ensuring passage of polishing slurry flow.

Owner:NOMURA MICRO SCI CO LTD

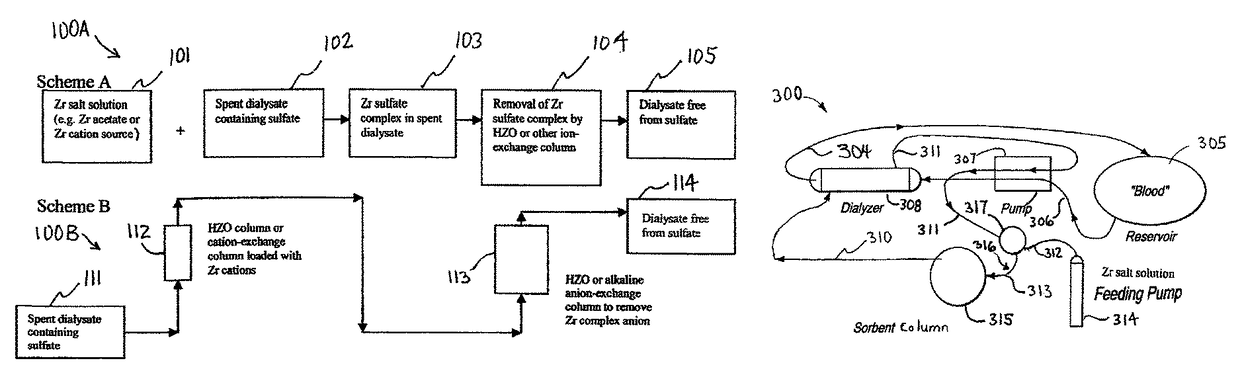

Method and system of enhancing removal of toxic anions and organic solutes in sorbent dialysis

ActiveUS9616163B2Ion exchange regulation/controlIon-exchange column/bed processesSorbentDialysis fluid

A method of sorbent dialysis is provided for enhanced removal of uremic toxins, such as toxic anions and / or organic solutes, from spent dialysate. More highly adsorbable zirconium polymeric complexes of these anions and / or organic solutes can be initially formed in spent dialysate by treatment with zirconium salt solution or other zirconium cation source, and then removed with adsorbent to provide purified or regenerated dialysate. Sorbent dialysis systems for detoxifying spent dialysate containing toxic anions and organic solutes are also provided.

Owner:FRESENIUS MEDICAL CARE HLDG INC

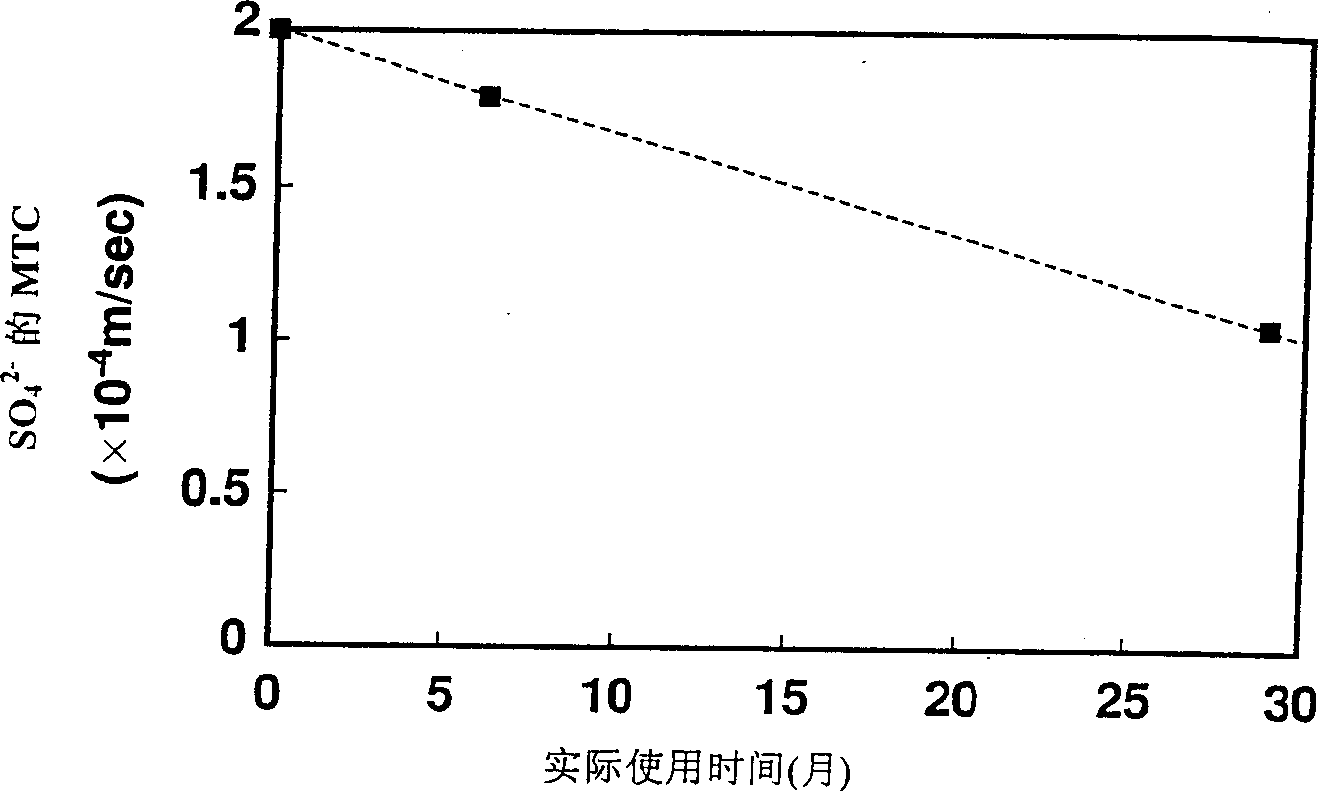

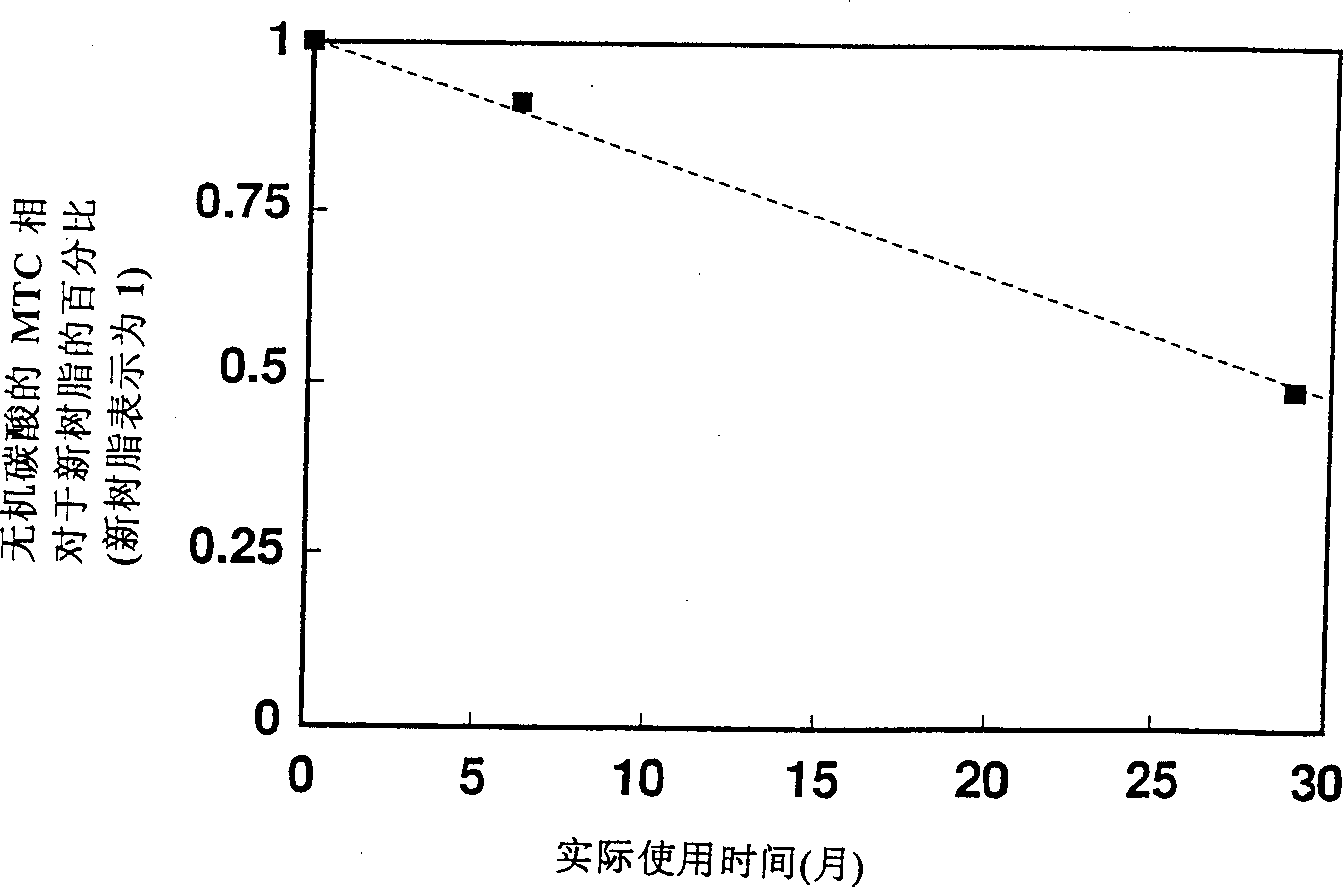

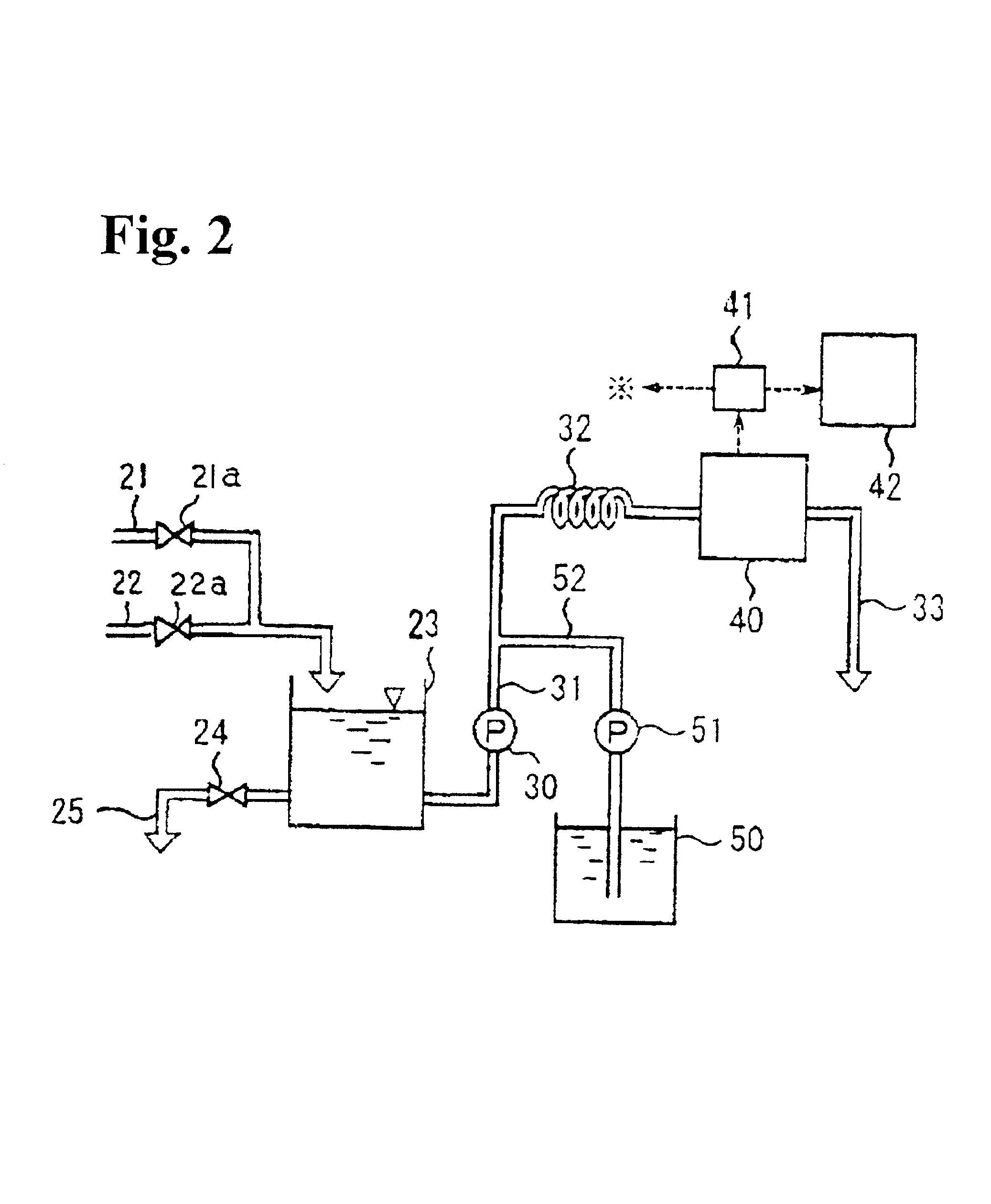

Method and apparatus for estimating performance of anion-exchange resin and condensed-water desalting device

The performance of an anion exchange resin is evaluated on-line by measuring inorganic carbonic acid concentrations at the inlet and at the outlet of an ion exchange resin vessel (such as a demineralizer vessel) of an ion exchange apparatus such as a condensate water demineralization system. Moreover, an MTC (Mass Transfer Coefficient) with respect to the inorganic carbonic acid is calculated and the dynamic performance and / or degree of degradation of the anion exchange resin are evaluated. The degree of degradation of the anion exchange resin is evaluated from the MTC and the replacement timing, lifetime, and throughput capacity for the anion exchange resin are judged.

Owner:ORGANO CORP

Anti-terrorism water quality monitoring system

InactiveUS20090138240A1Rule out the possibilityGeneral water supply conservation2D-image generationChloramine BChlorine dioxide

Owner:HACH CO

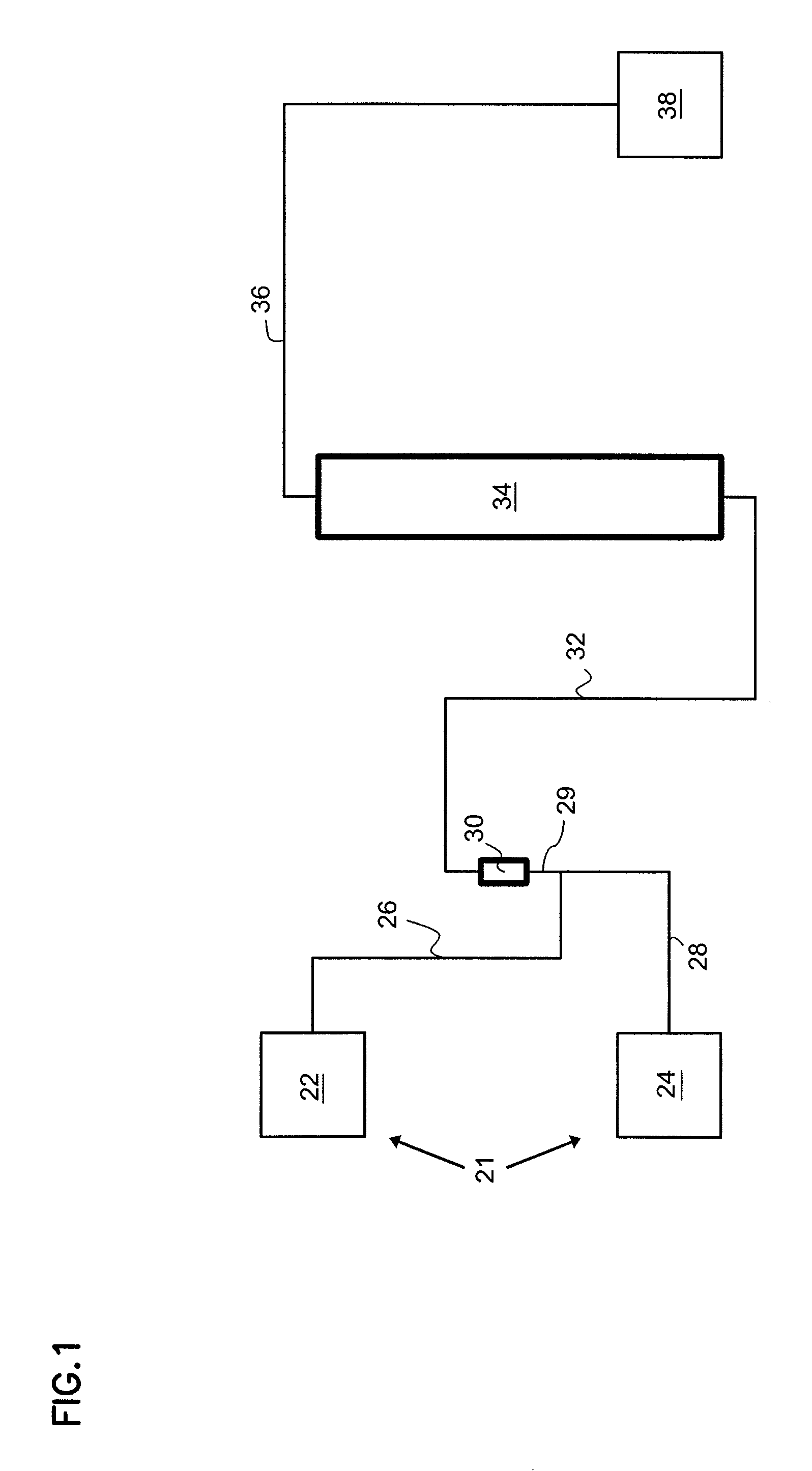

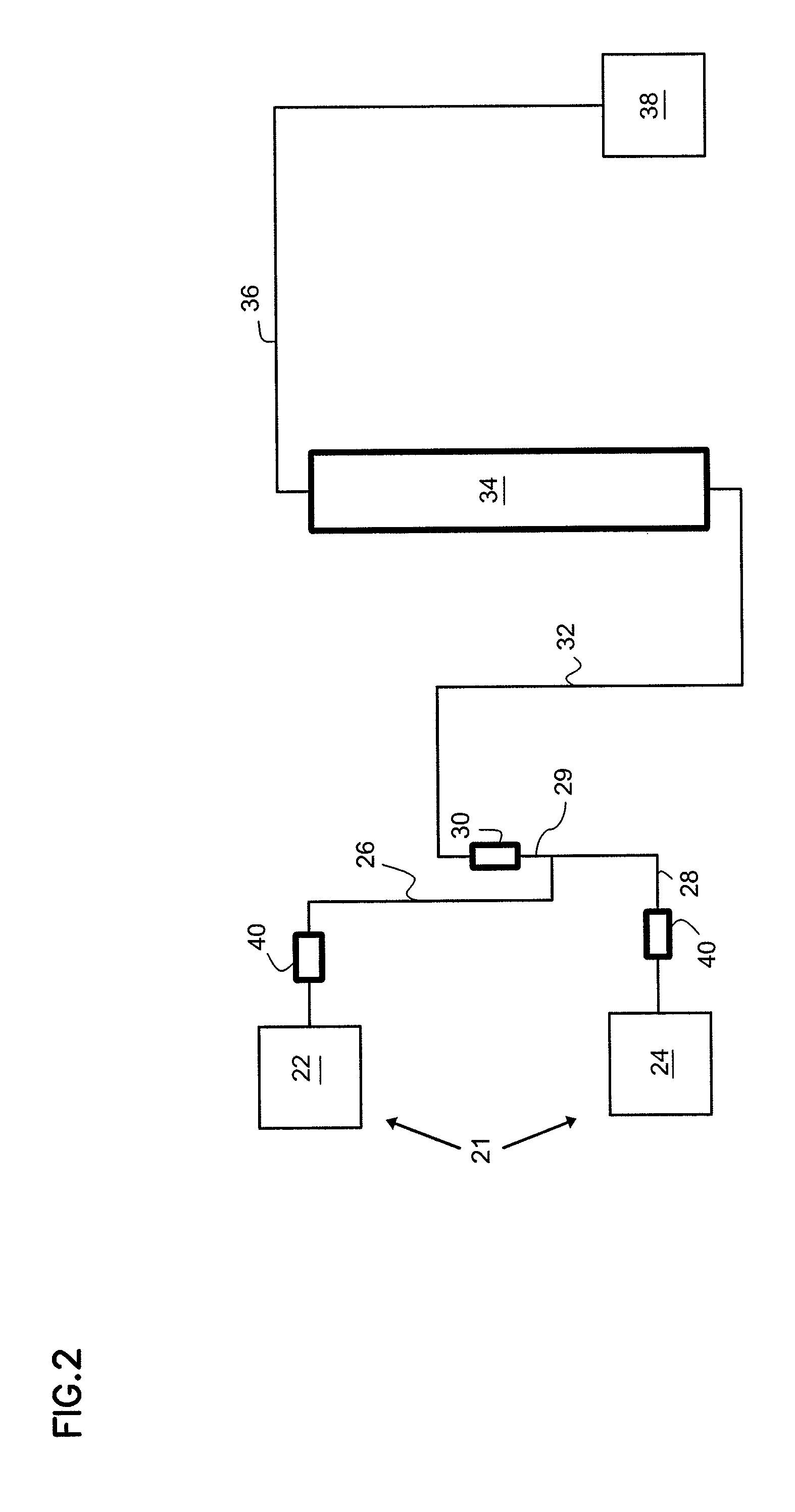

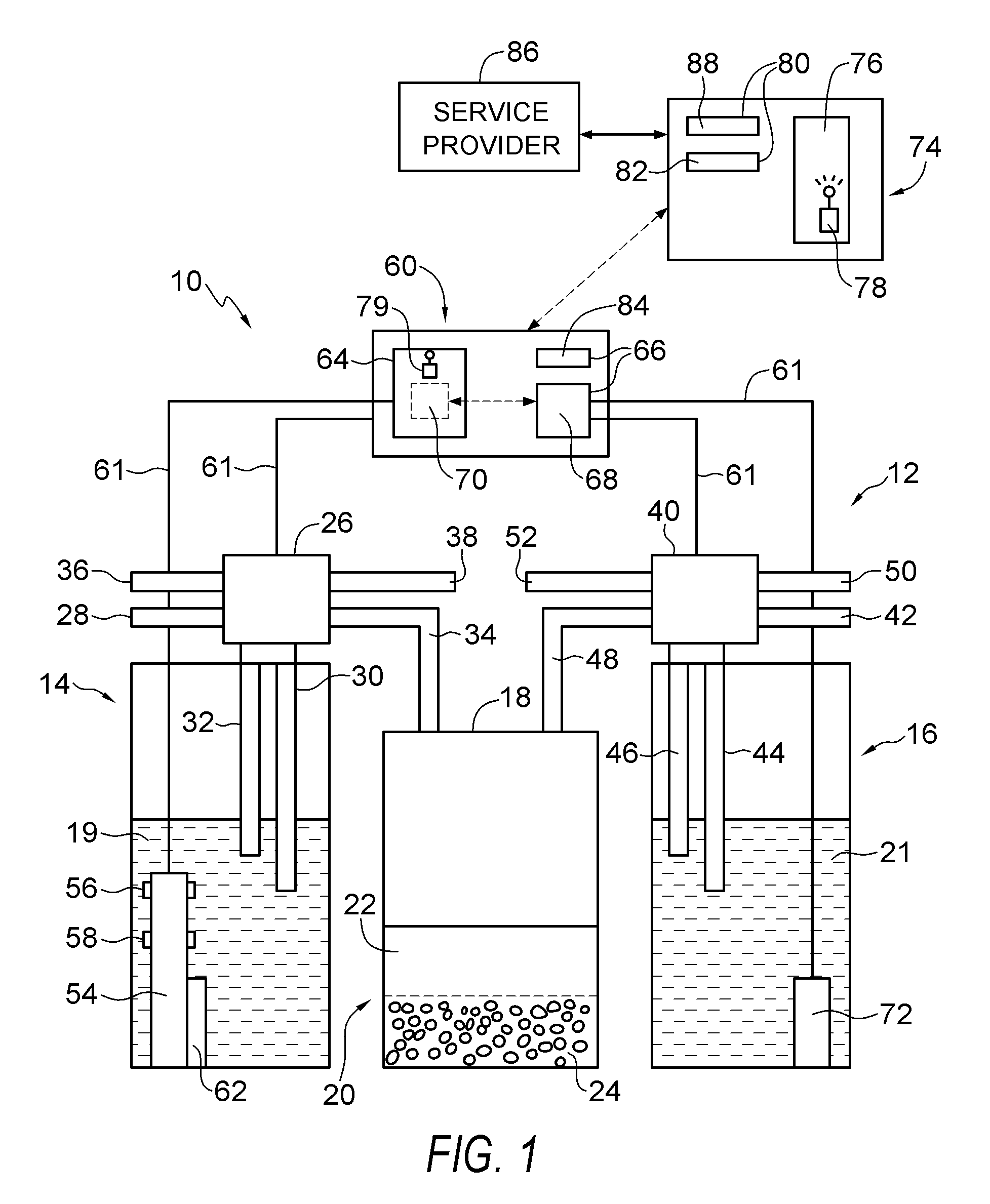

Sensor assembly for controlling water softener tanks

ActiveUS8758628B2Low costLower manufacturing requirementsCation exchanger materialsOrganic anion exchangersWater softeningWaste management

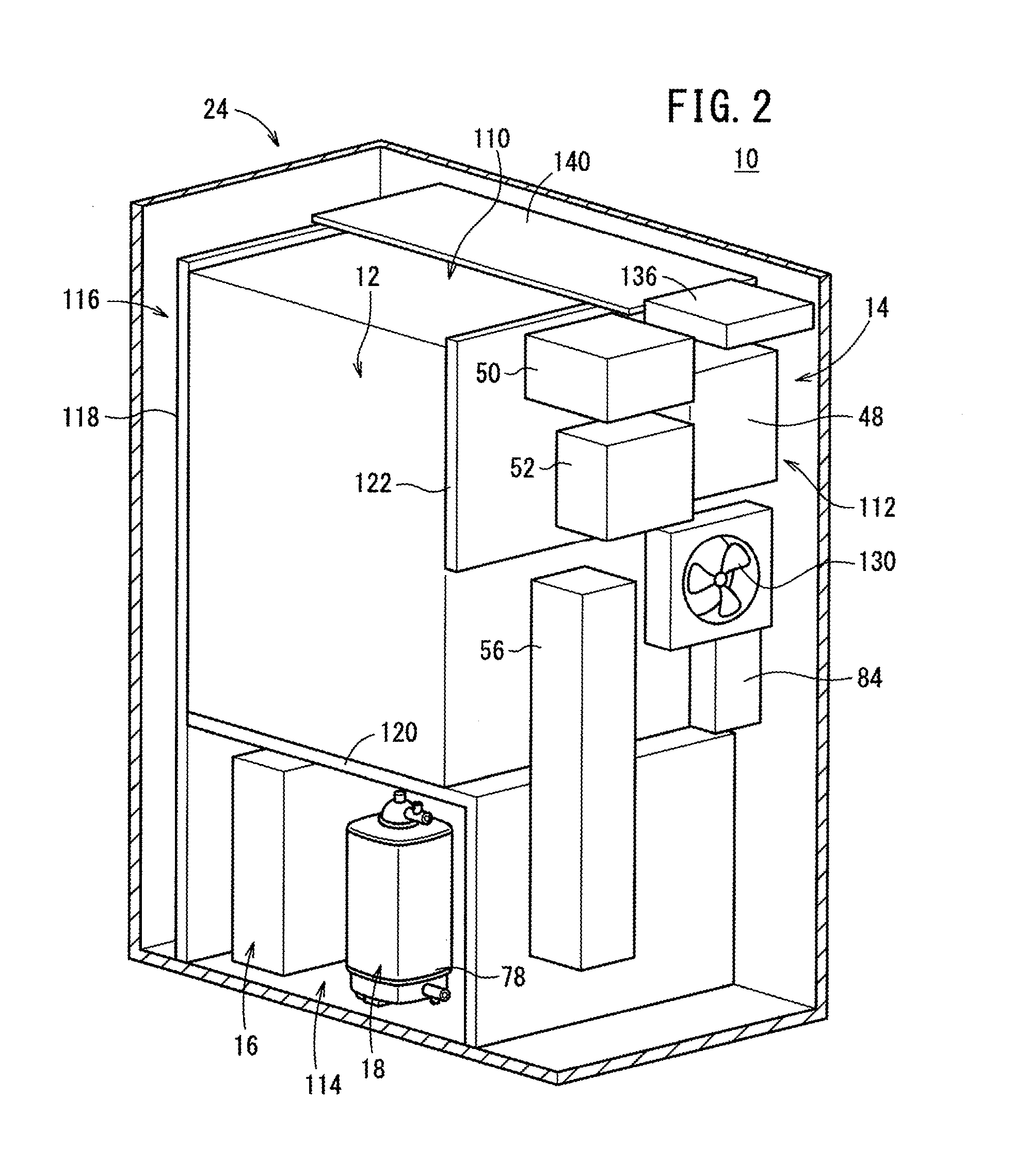

A sensor assembly for a water softening system and includes a first treatment tank having a first valve assembly, a first flow meter and a sensor probe, a second treatment tank having a second valve assembly and a second flow meter and a brine tank independently connected to each of the first treatment tank and the second treatment tank. A controller is configured for communicating with the sensor probe and the first flow meter in the first treatment tank, and the second flow meter in the second treatment tank.

Owner:CULLIGAN INTERNATINOAL COMPANY

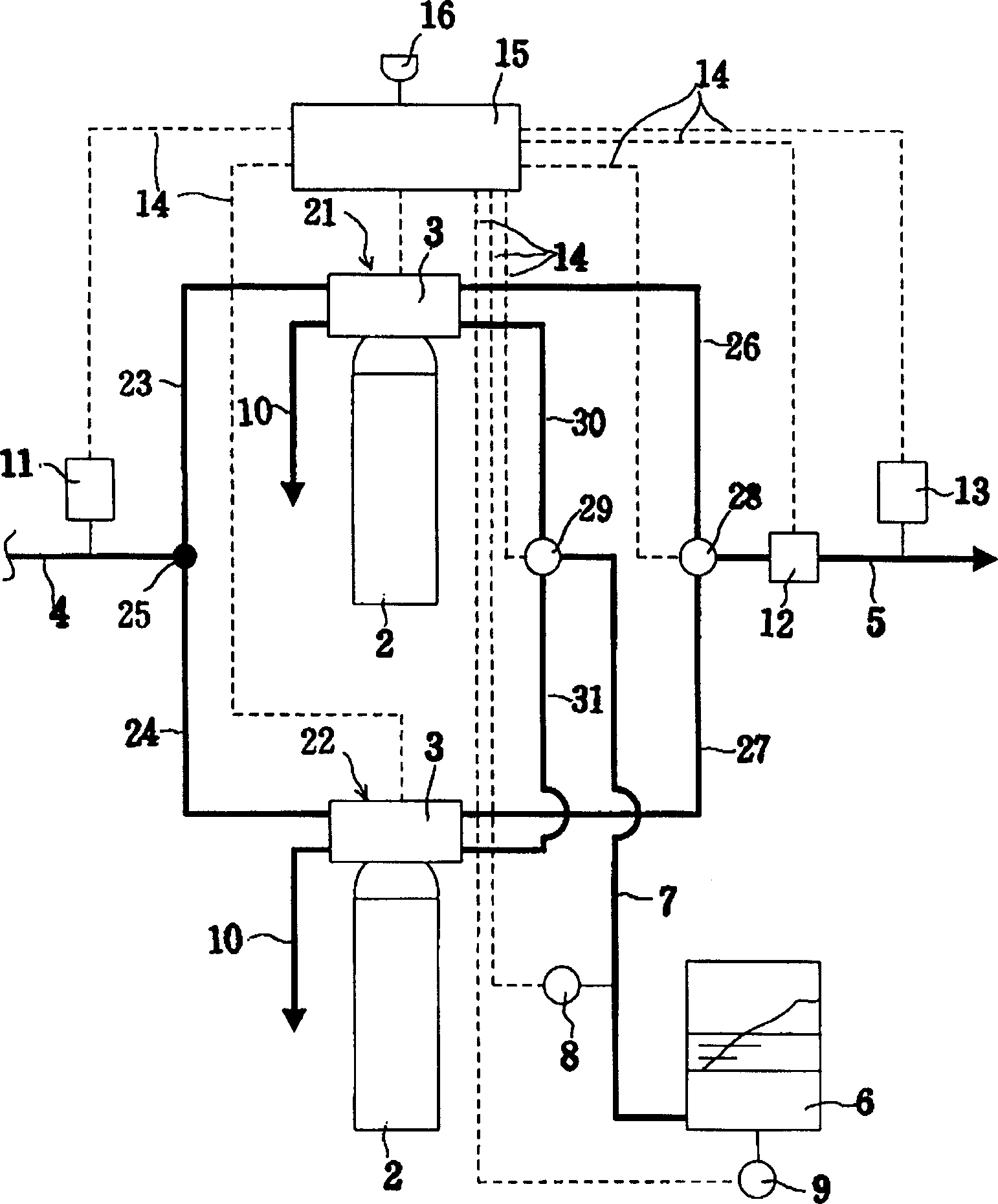

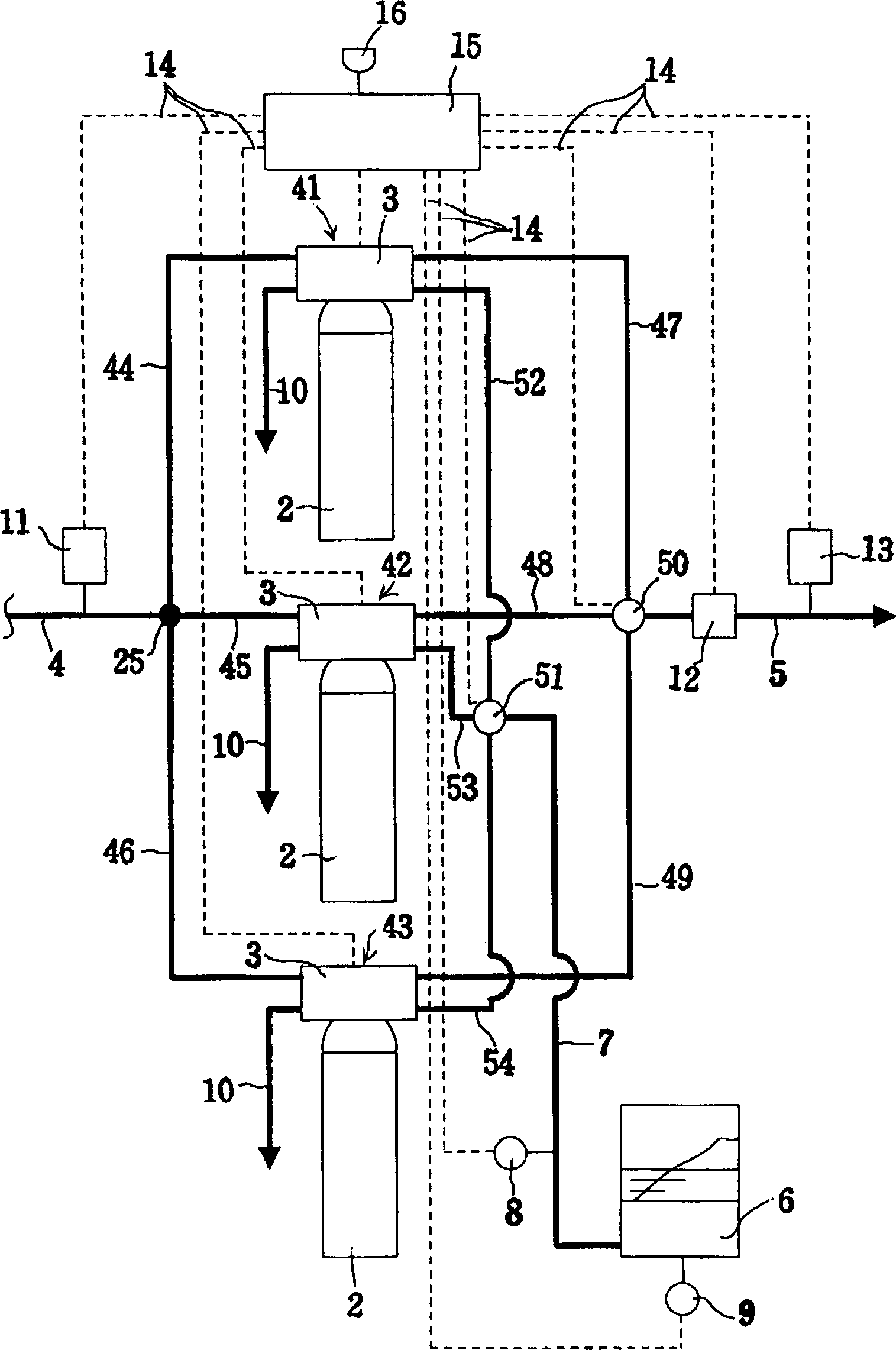

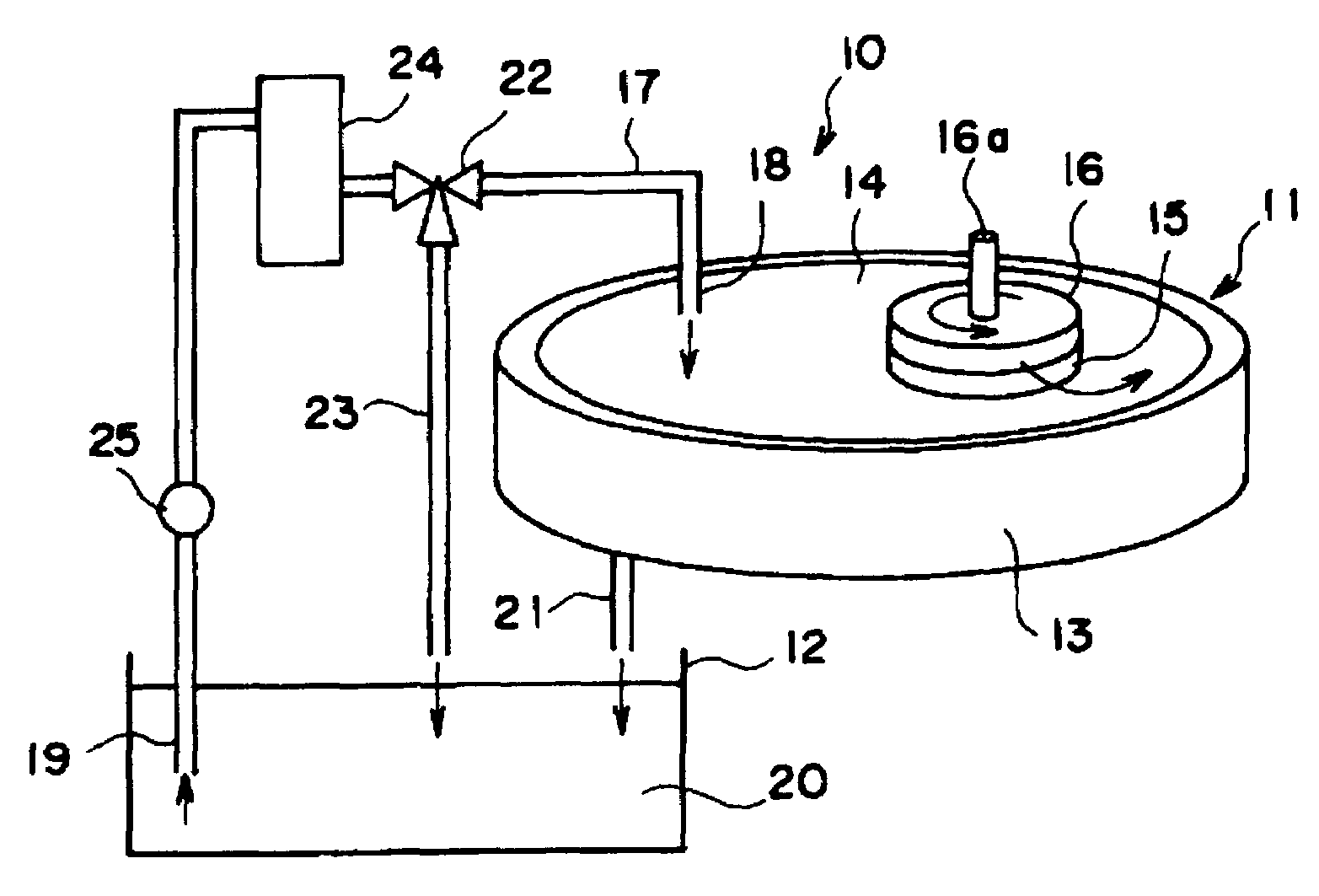

Water-softening apparatus and regeneration control method

InactiveCN1405095AEfficient regenerationSave salt waterIon exchange regulation/controlWater treatment parameter controlWater softeningSaline water

The invention provides a water softening device and its regeneration controlling method capable of detecting the hardness of the supply water to be softened with the large of time and controlling regeneration timing based on the detected value. The water softening device is provided with an inlet water hardness measuring means 10 for measuring the hardness of supply water to the water softener 1, a treated water quantity measuring means 11 for measuring the flow rate of treated water after passing through the water softener 1, a salt water concentration detecting means 8 for detecting the salt water concentration at regeneration and a salt water consumption detecting means 9 for detecting the salt water consumption at regeneration. Further, a hardness overlooking detecting means 12 which measures the hardness of water which passed through the water softener 1 and detects the overlooking of hardness is provided.

Owner:MIURA COMPANY LIMITED +1

High efficiency ion exchange system for removing arsenic from water

InactiveUS20020125195A1Reduce amountEasy maintenanceIon-exchanger regenerationScale removal and water softeningIon exchangeFixed bed

Owner:HSBC BANK

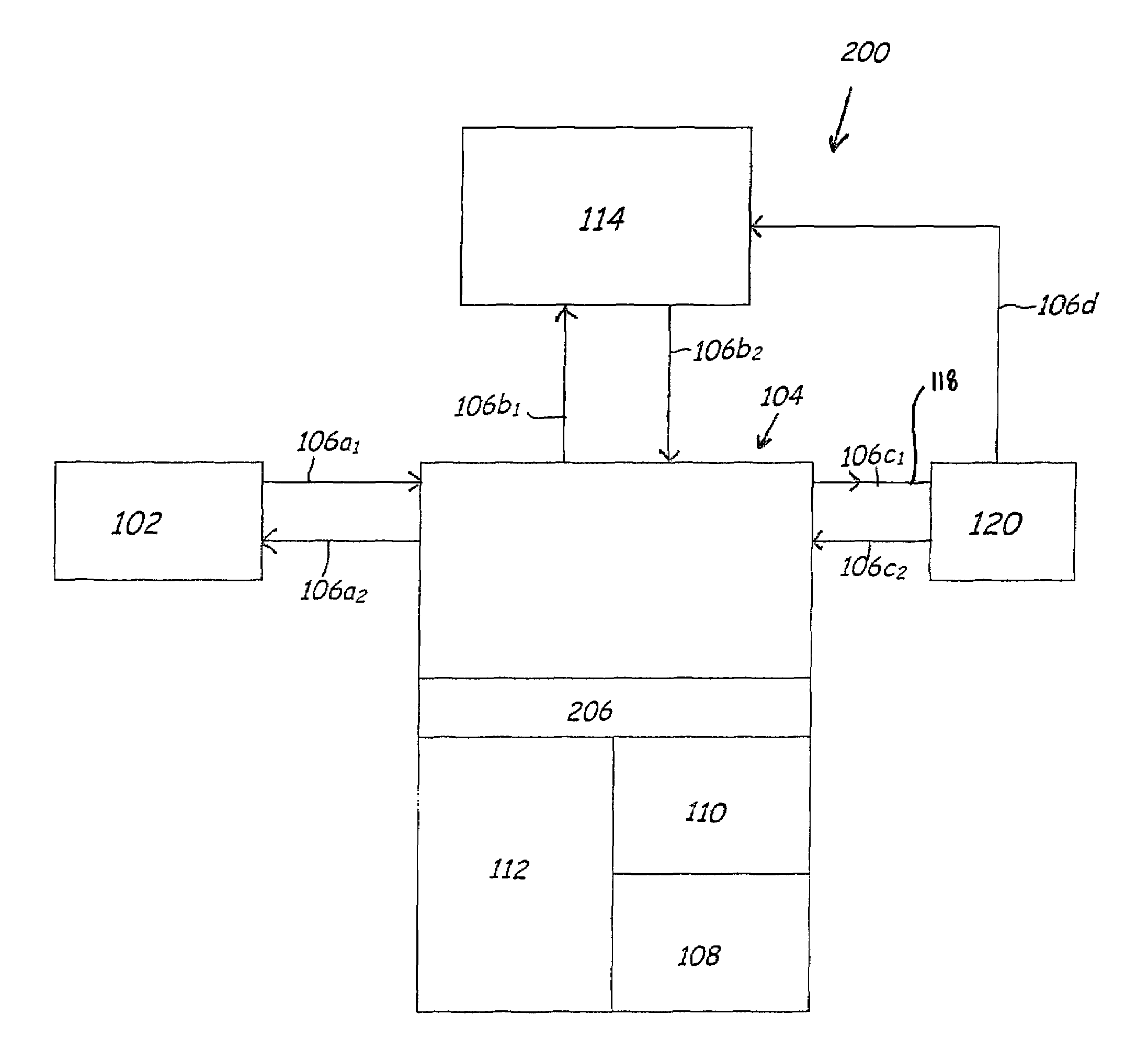

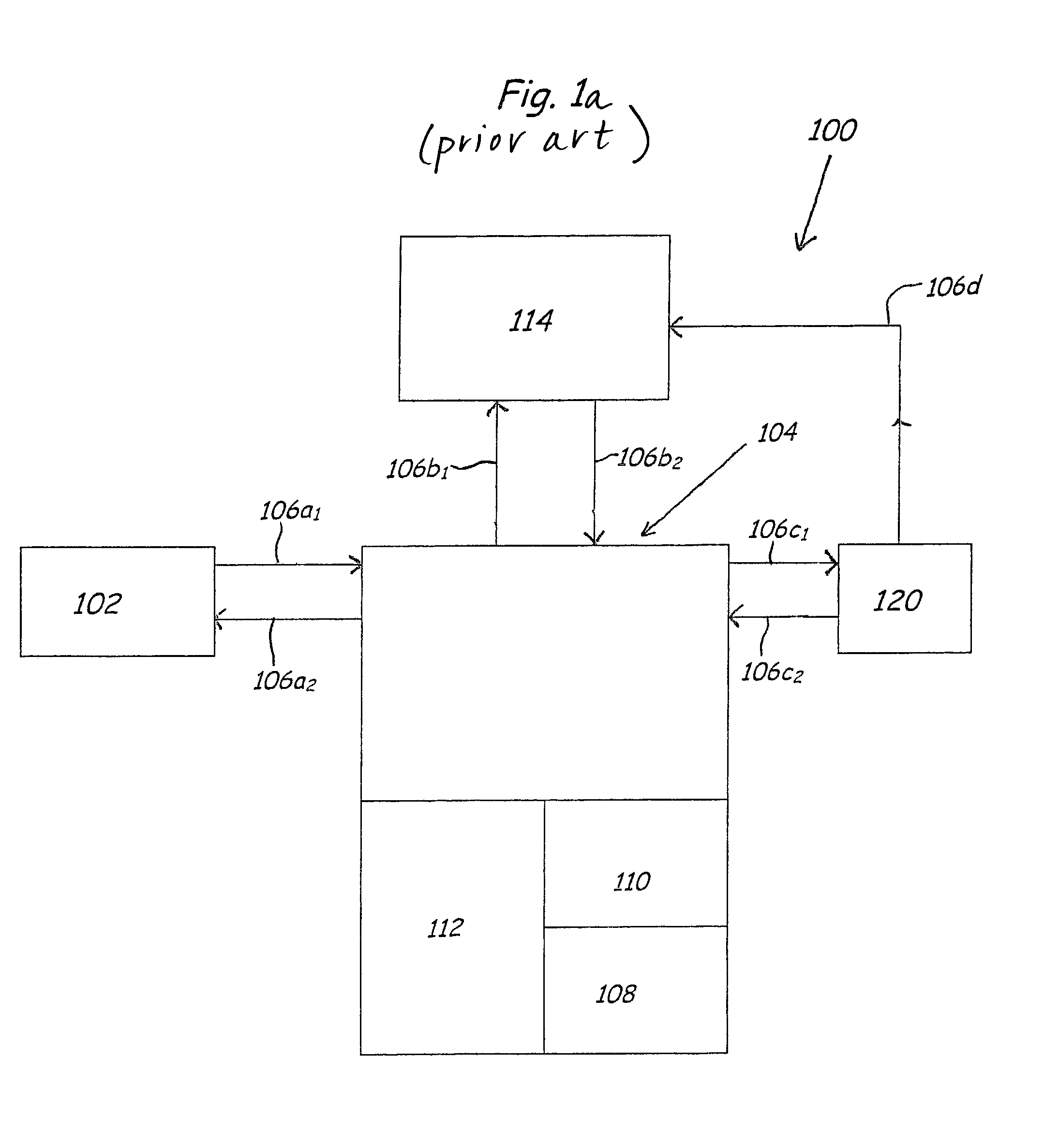

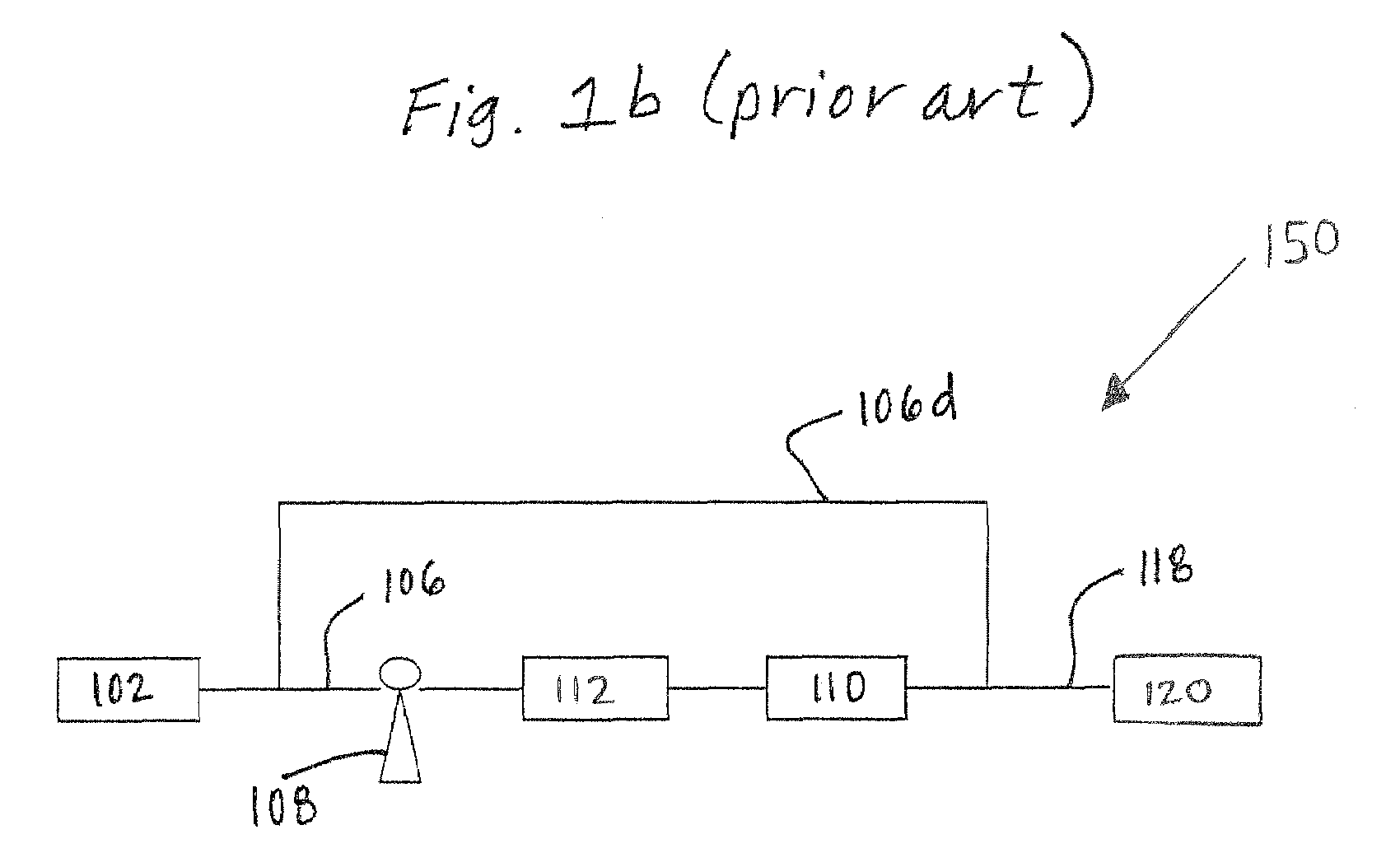

Purification of organic solvent fluids

InactiveUS20070084792A1Cost efficientPrecision productionIon exchange regulation/controlGroup 4/14 element organic compoundsOrganic solventIon exchange

A chemical distribution system having improved organic solvent fluid purity and consistency includes a vessel containing ion-exchange media positioned within a fluid flow pathway such that the organic solvent fluid passes through the ion-exchange media, thereby effecting removal of undesired impurities. Different embodiments of the invention position the vessel at varying locations within the fluid flow pathway. The chemical distribution system also preferably includes a return chemical flow pathway that recirculates purified organic solvent fluid through the ion-exchange media-containing vessel and thereby enables the system operator to conduct incremental adjustment of the solvent purity until a desired overall purity is attained.

Owner:MULLEE WILLIAM H

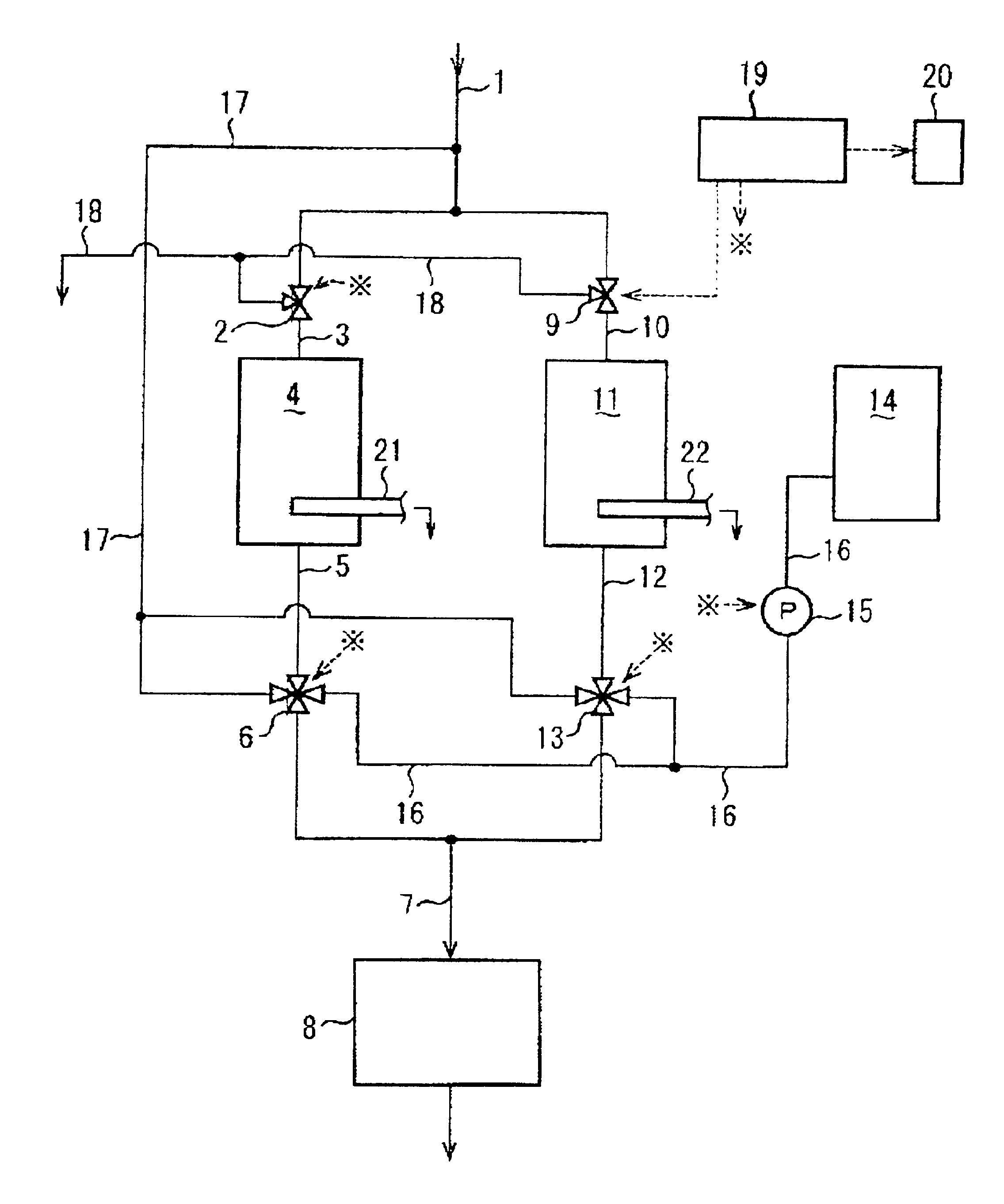

Water softening device

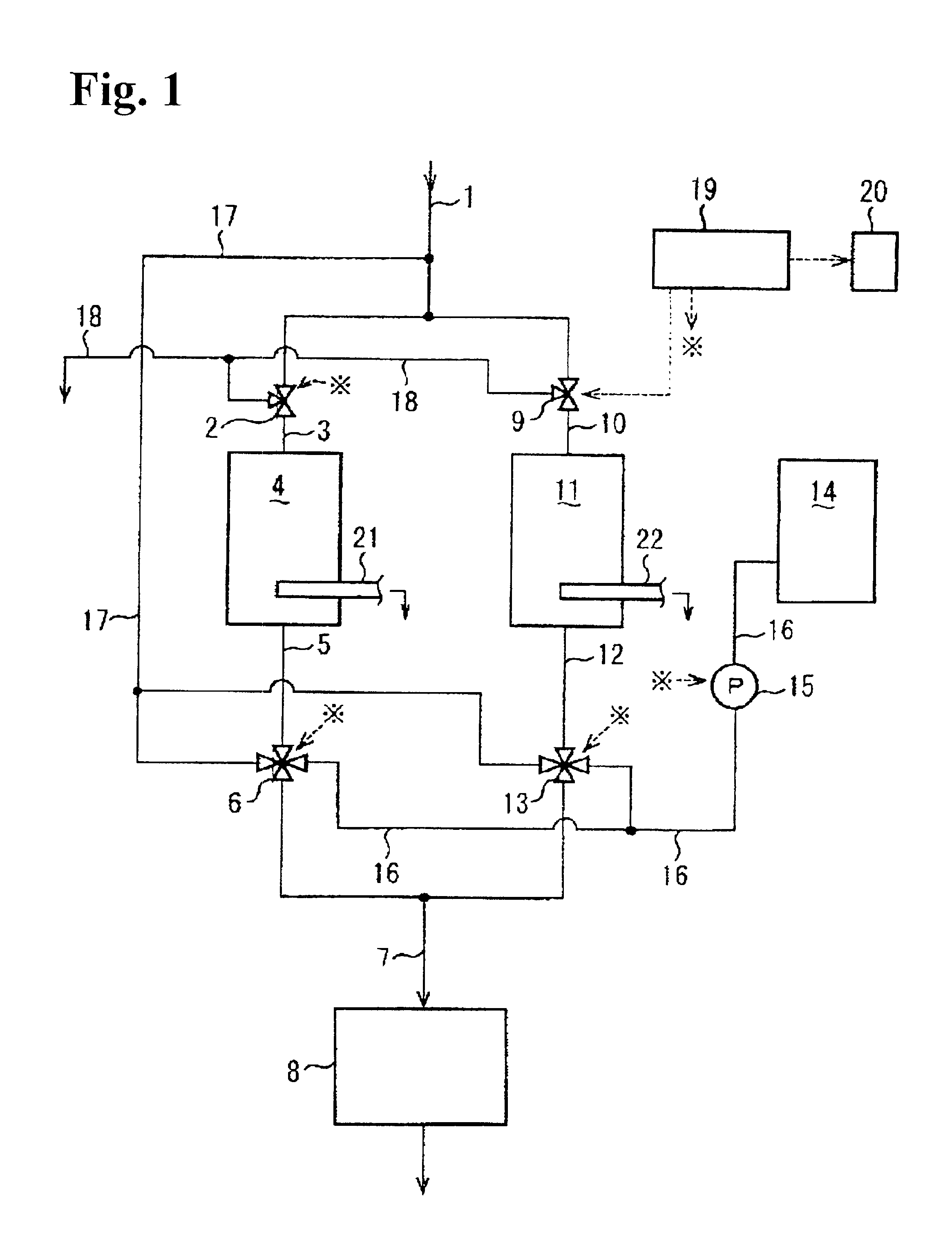

InactiveUS6926835B2Reliably prevents leakageAvoid hardnessIon exchange regulation/controlIon-exchanger regenerationWater softeningSalt water

Sampling pipes 21 and 22 are inserted, separated from outlet openings, into first and second water softeners 4 and 11. Raw water flows through first water softener 4, and raw water does not flow through second water softener 11. Once the hardness component concentration of the treatment water sampled by sampling pipe 21 reaches a specified concentration, the watercourse selection of valves 2 and 6 and valves 9 and 13 are switched, causing raw water to flow through second water softener 11. First water softener 4 is regenerated by salt water from a salt water chamber 14. The resulting water softening device prevents the leaking of hardness components, even with there is a fluctuation in the water quality of the raw water or when there is performance deterioration in the ion exchange resin.

Owner:KURITA WATER INDUSTRIES LTD

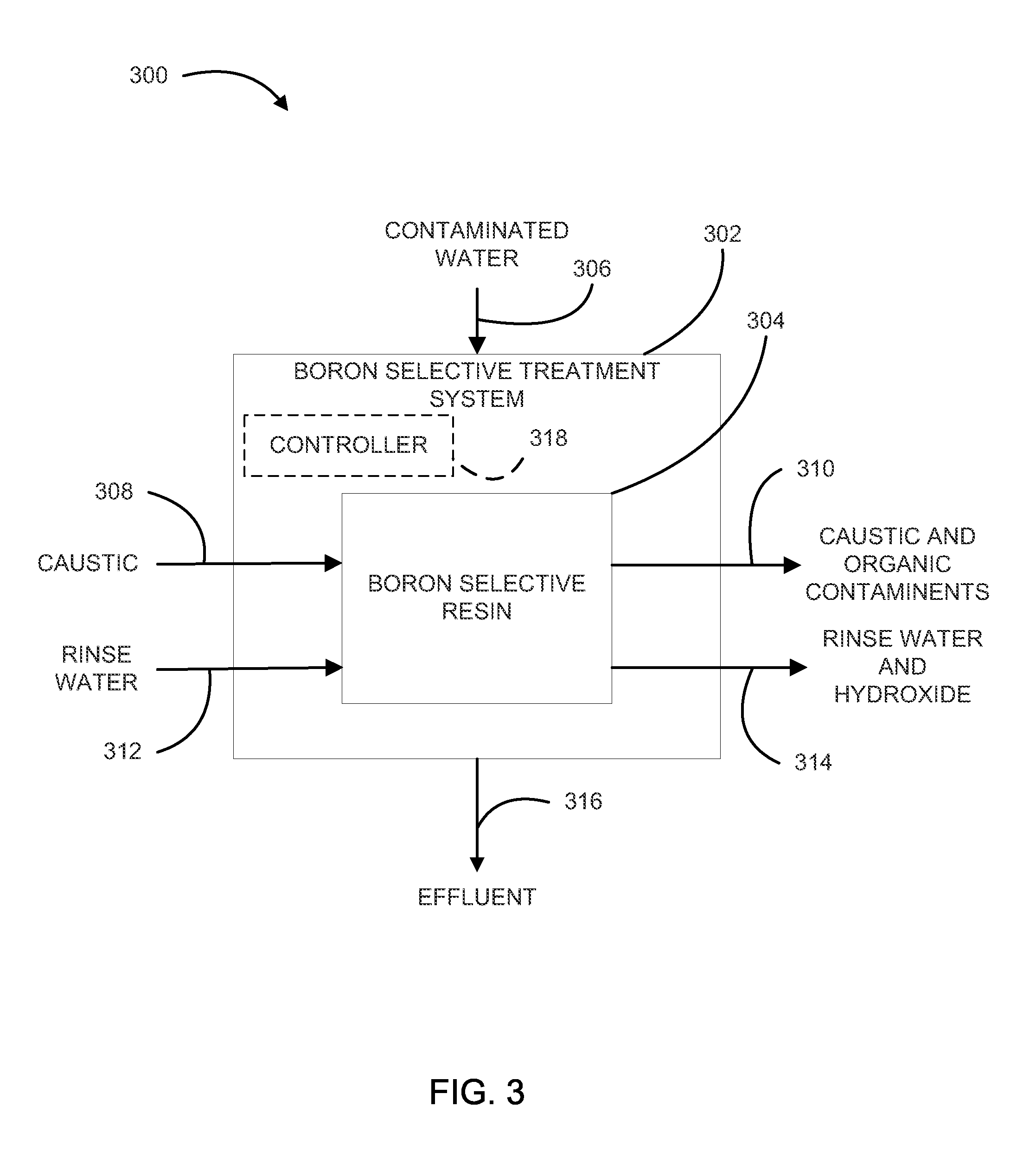

Method for removing organic contaminants from resins

InactiveUS20100224564A1Good removal effectIon exchange regulation/controlWater treatment parameter controlTreatment systemChemistry

The disclosure describes a novel method for operating a resin treatment system and a novel organic polisher. The method for operating the resin treatment system is efficient and cost effective.

Owner:ANTICLINE DISPOSAL

Sensor assembly for controlling water softener tanks

ActiveUS20090090662A1Lower manufacturing requirementsReducing consumer costIon exchange regulation/controlWater treatment parameter controlWater softeningSalt water

A sensor assembly for a water softening system and includes a first treatment tank having a first valve assembly, a first flow meter and a sensor probe, a second treatment tank having a second valve assembly and a second flow meter and a brine tank independently connected to each of the first treatment tank and the second treatment tank. A controller is configured for communicating with the sensor probe and the first flow meter in the first treatment tank, and the second flow meter in the second treatment tank.

Owner:CULLIGAN INTERNATINOAL COMPANY

Acid regeneration of ion exchange resins for industrial applications

ActiveUS20130146086A1Improve ware washCation exchanger materialsIon-exchanger regenerationWater sourceIon exchange

Methods and systems for acid regeneration of ion exchange resins are disclosed. Acid resins designed for use in a variety of cleaning application using a water source use a treated, softened, acidic water source according to the invention. Various methods of using the softened acidic water generated by acid regenerate-able ion exchange resins are disclosed to beneficially reduce spotting, filming and scale buildup on treated surfaces, reduce and / or eliminate the need for polymers, threshold reagents and / or rinse aids, and using protons generated in the acidic water effluent for triggering events useful in various cleaning applications.

Owner:ECOLAB USA INC

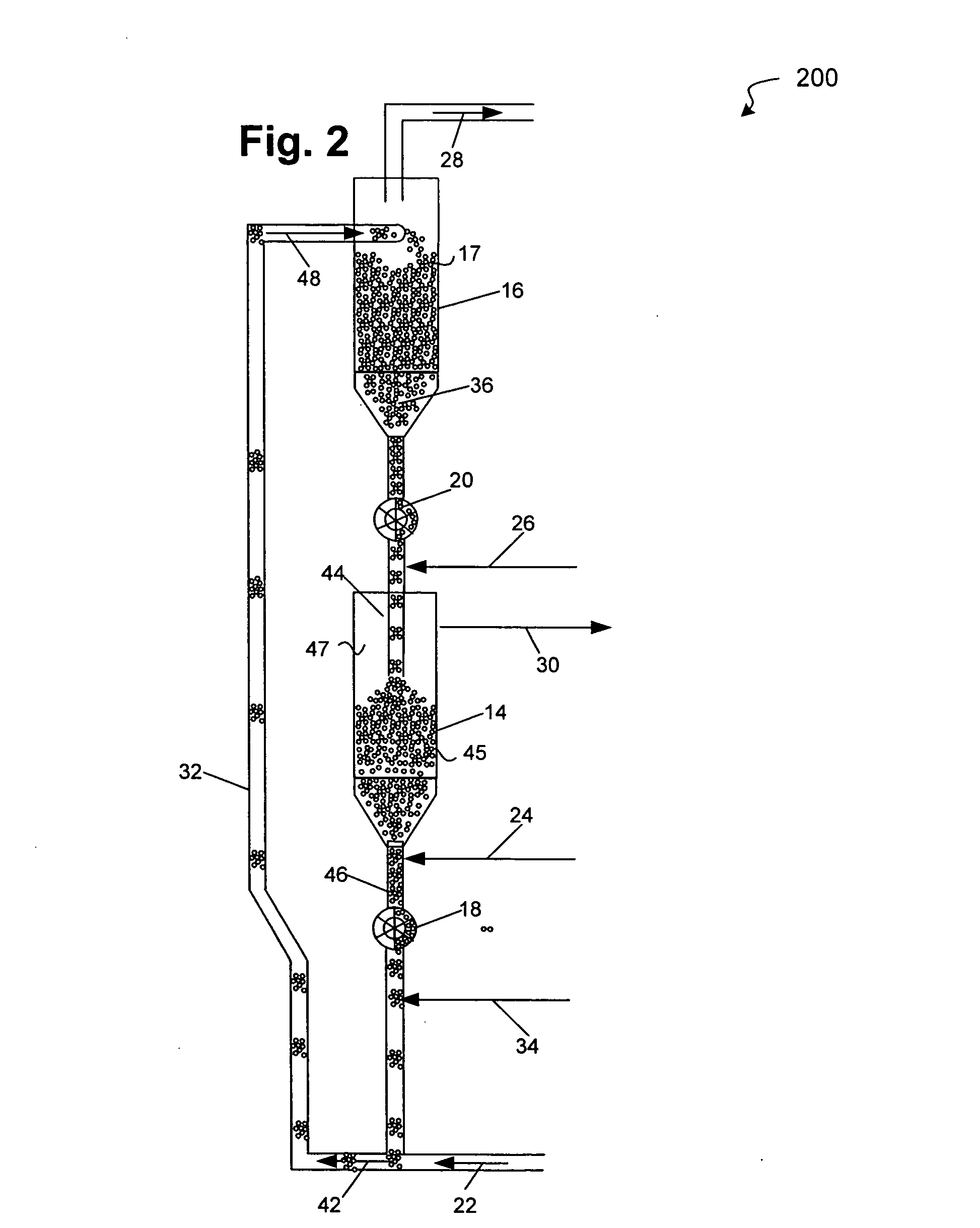

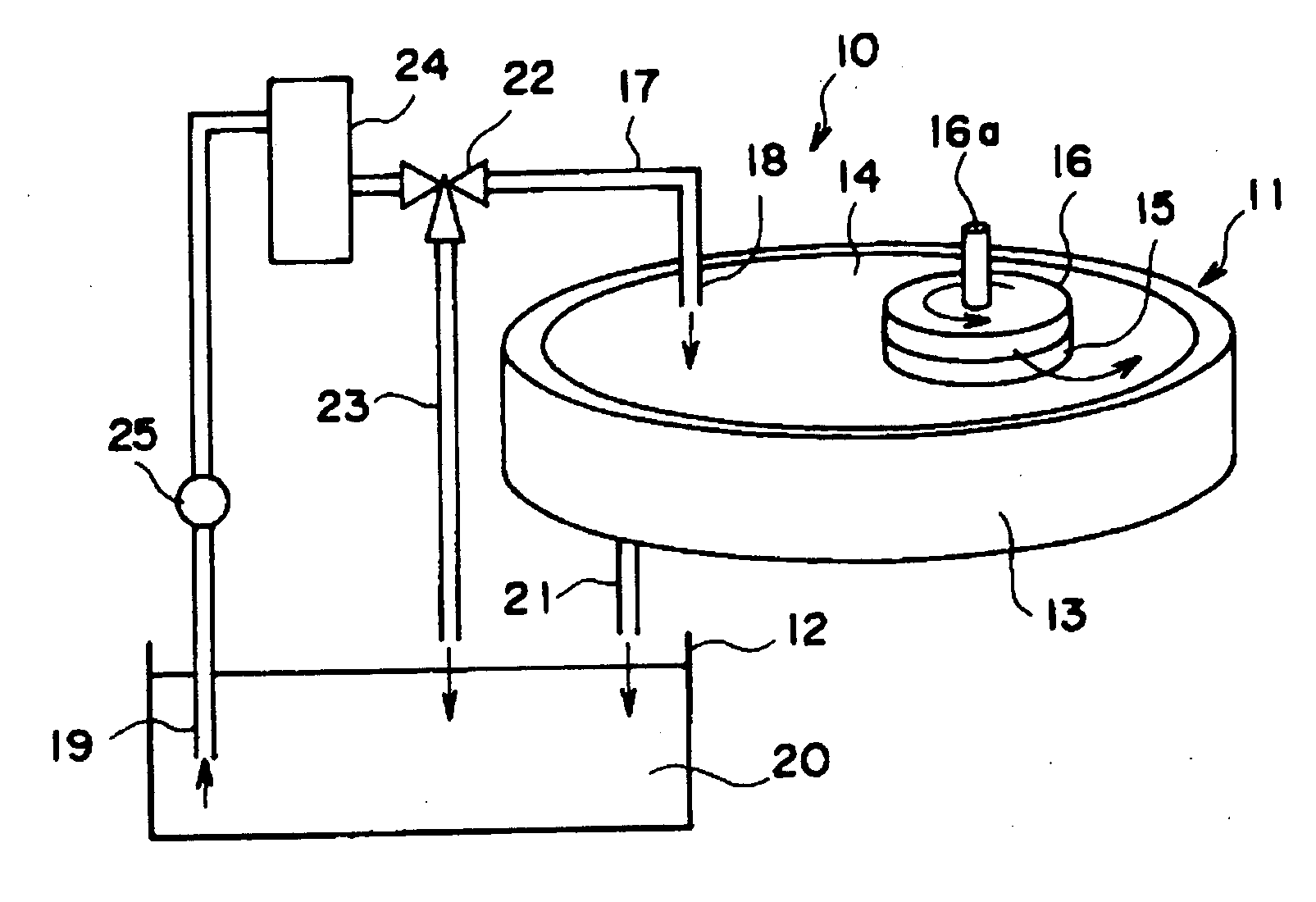

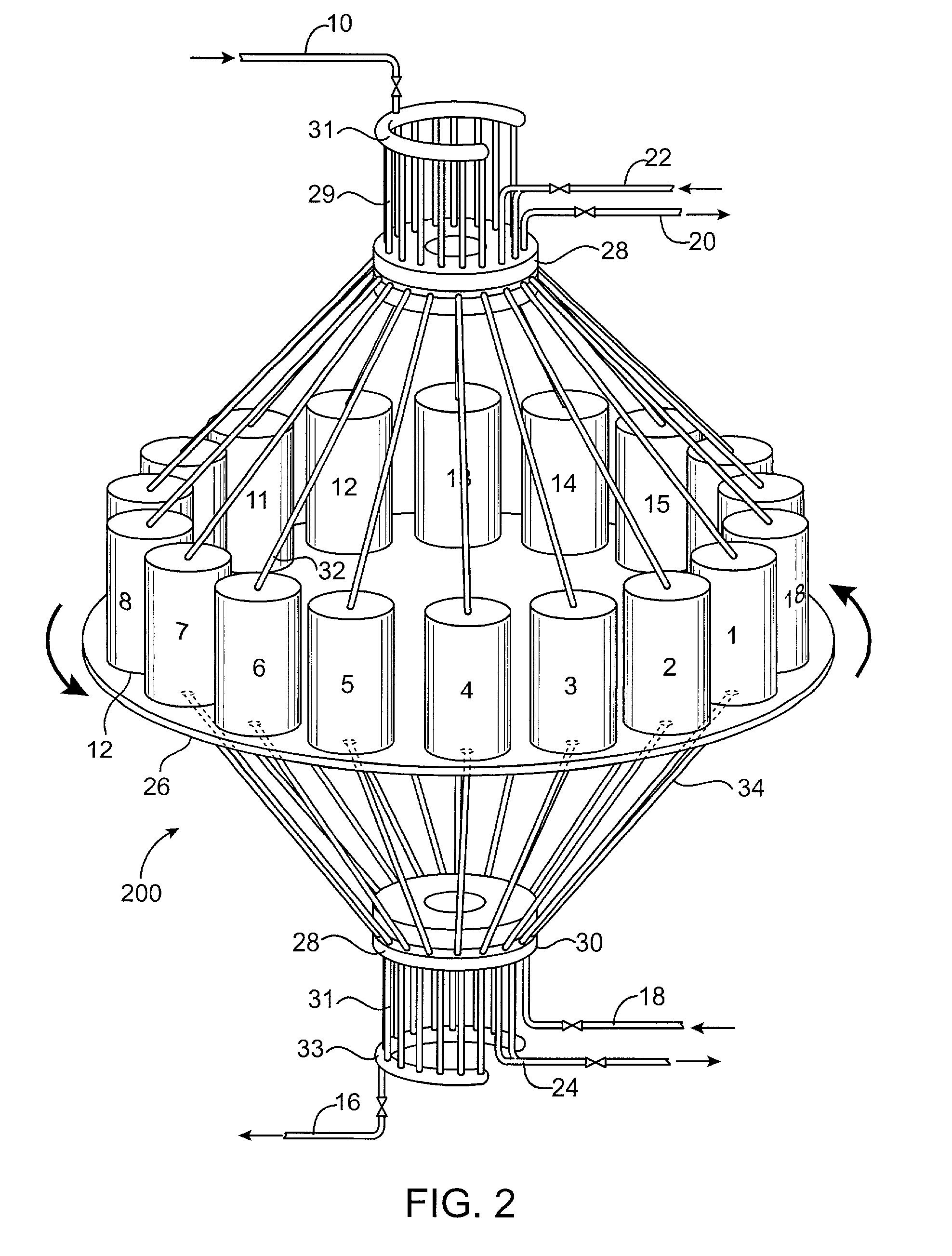

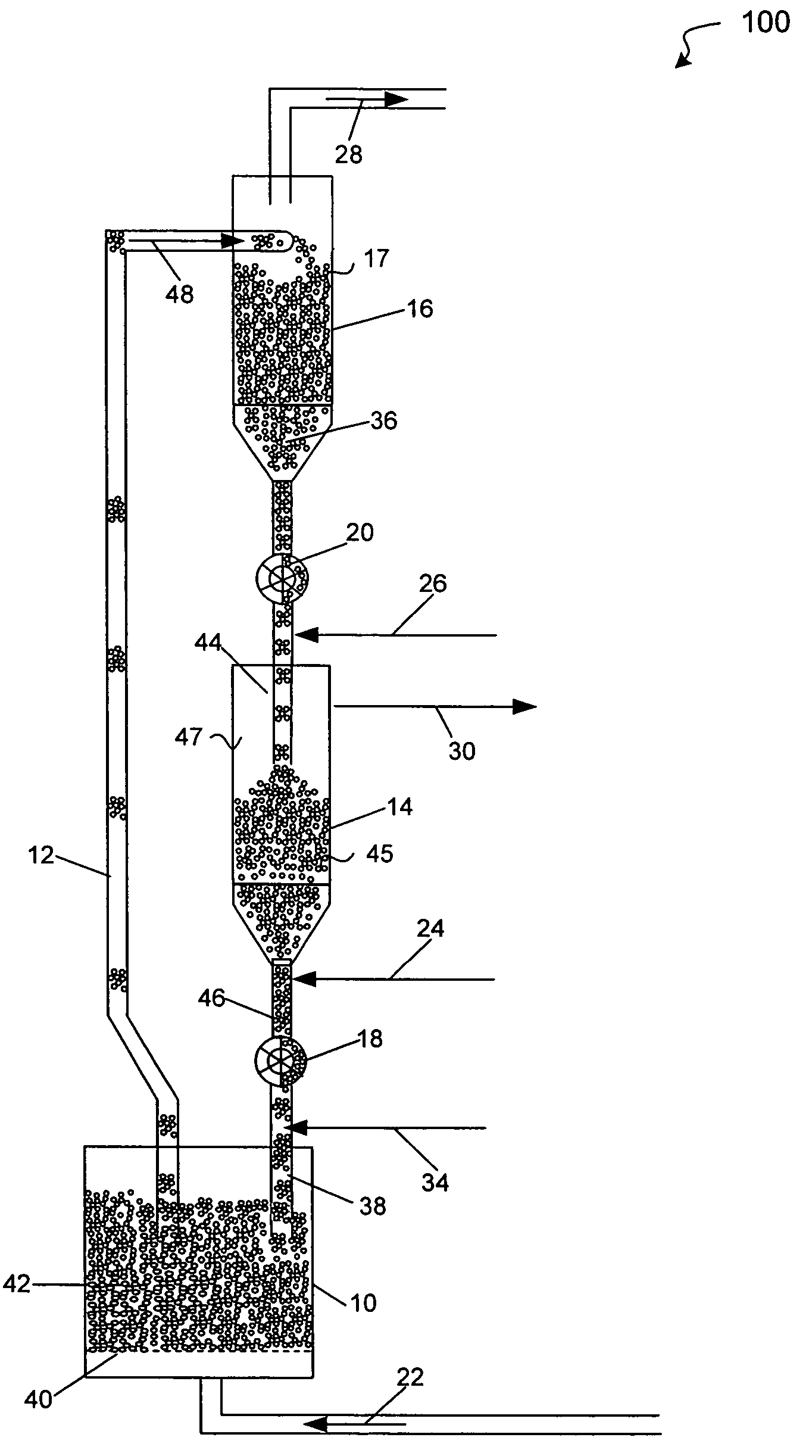

Method for preferentially removing monovalent cations from contaminated water

ActiveUS7368059B2Simple and economical treatmentSuitable assemblyIon exchange regulation/controlWater treatment parameter controlPhysical chemistryIon exchange

A process and apparatus for continuously removing ions from solution in proportion to their prevalence in solution using an ion exchange media. The process comprises: (a) mixing fresh or regenerated ion exchange media and a feed solution containing diverse ions; (b) reacting the resulting slurry to produce a product slurry comprised of loaded ion exchange media and stripped product solution; (c) separating the loaded ion exchange media from the product slurry; (d) regenerating the loaded ion exchange media by counter current contact with a regenerant; and (e) conducting the process steps continuously and concurrently, whereby a continuous circuit is produced for dosing, loading, separating, and regenerating the ion exchange media, and whereby more concentrated ions are preferentially depleted in the product solution. An apparatus particularly adapted to practice the process and to treat sodic water is also provided.

Owner:DRAKE ENG

Fuel cell system and method of controlling the fuel cell system

ActiveUS20160064756A1Reduce component countSuppression mixingIon exchange regulation/controlFuel cells groupingFuel cellsIon exchange

A control device of a fuel cell system includes an electric conductivity comparing unit for comparing the electric conductivity of the water inside the ion exchanger which is measured by the electric conductivity measuring unit with a predetermined electric conductivity range, and an ion exchange environment determining unit for arbitrarily determining whether or not air has been mixed into an ion exchanger and whether or not the ion exchange efficiency of the ion exchanger has been degraded, based on a comparison result by the electric conductivity comparing unit.

Owner:HONDA MOTOR CO LTD

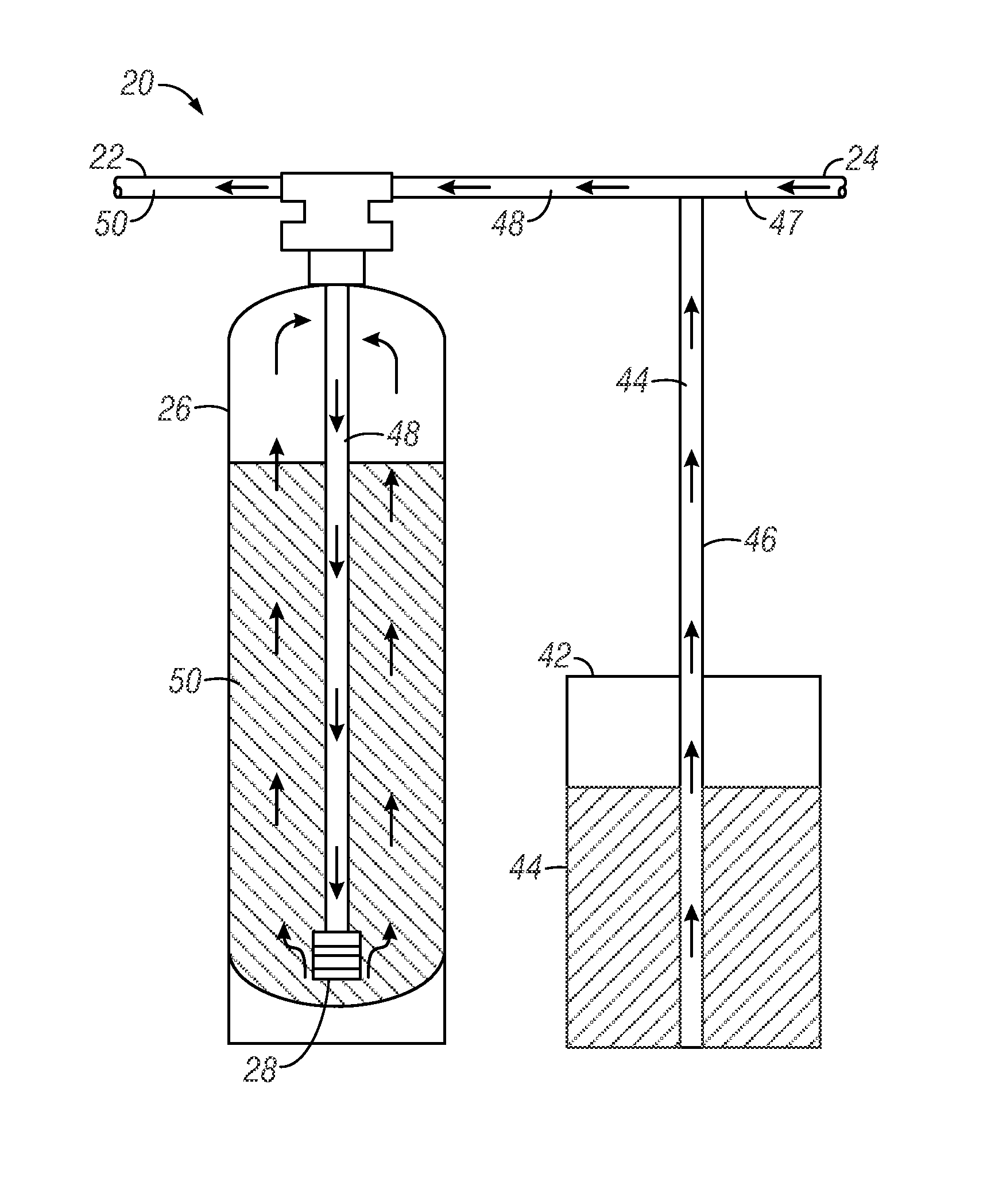

Water conditioner assembly

InactiveUS8349183B2Improve distributionEnsure even distributionIon exchange regulation/controlIon-exchanger regenerationParticulatesWater flow

A distributor for use on a dip tube in the particulate bed of a water conditioner includes a sleeve mounted on the dip tube, a plurality of resilient vanes extending radially outwardly from the sleeve, thin membranes on the vanes, and holes in the membranes, whereby water flowing through the bed is evenly distributed throughout the bed and the bed is agitated by up and down flexing of the distributor in the bed.

Owner:FIELD GEORGE RAYMOND

Apparatus for removing undesirable components from a contaminated solution containing both desirable and undesirable components

Owner:DRAKE WATER TECH

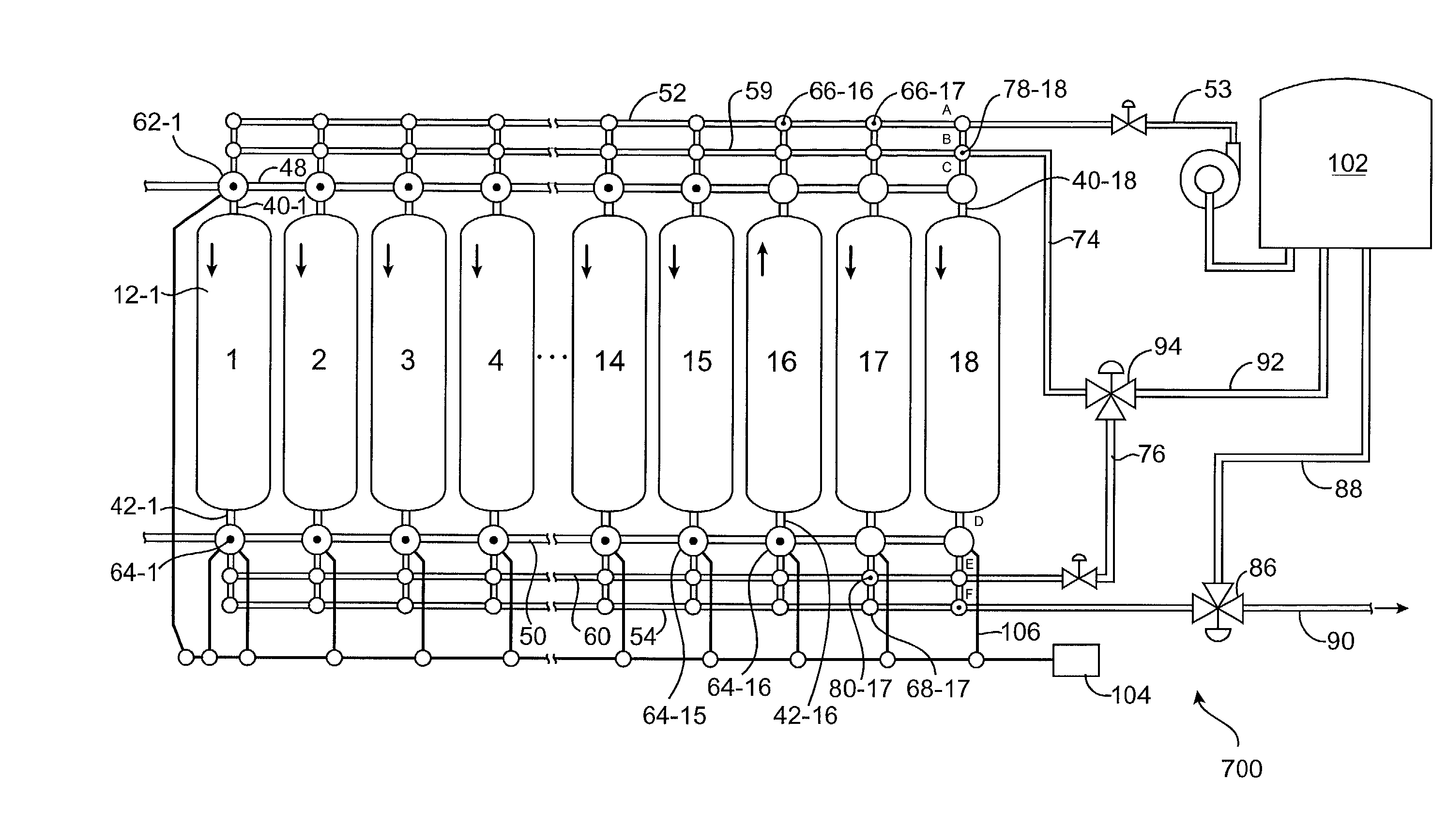

Continuous ion exchange unit for organic acid production

ActiveCN102029202ANo chaosIon exchange regulation/controlIon-exchange column/bed processesOrganic acidIon exchange

The invention relates to a continuous ion exchange unit for organic acid production, comprising resin, at least three resin columns, feeding main pipes communicated with the upper ends of the resin columns and discharging main pipes communicated with the lower ends of the resin columns, wherein the feeding main pipes include a liquid feeding main pipe, an elution feeding main pipe and a regeneration feeding main pipe; the discharging main pipes include a liquid discharging main pipe, an elution discharging main pipe and a regeneration discharging main pipe; each resin column is respectively provided with a feeding branch pipe in one-to-one corresponding communication with the feeding main pipes and a discharging branch pipe in one-to-one corresponding communication with the discharging main pipes; and each feeding branch pipe and each discharging branch pipe are respectively provided with a control valve for cooperatively controlling all the resin columns to realize ion exchange, elution and resin regeneration in turn. The invention can reduce the usage amount of chemical agents, reduce the production cost, improve the yield of products, stabilize the quality of products, reduce the discharge of waste liquid and lighten the pressure for environment protection.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Parallel separation system

PendingUS20130026100A1Separation efficiency can be improvedSpeed up the flowIon exchange regulation/controlComponent separationSeparation systemEnvironmental geology

A method in a separation system comprising parallel fluid paths each comprising a separation module.According to the invention said method comprises the steps of:providing an adjustable flow restrictor in each fluid path;identifying the fluid path with highest hydraulic resistance by measuring the hydraulic resistance of each fluid path sequentially and separately while stopping the fluid flow through all other fluid paths;adjusting the hydraulic resistance of each of the parallel fluid paths to be substantially the same by adjusting the adjustable flow restrictor in each fluid path sequentially and separately while stopping the fluid flow through all other fluid paths, such that the hydraulic resistance of said fluid path is equal or higher than the resistance of the fluid path identified to have the highest hydraulic resistance.

Owner:CYTIVA BIOPROCESS R&D AB

Urea sulfate and sodium chloride blend for regeneration of cation exchange resins

Methods and systems for acid regeneration of ion exchange resins are disclosed. Acid resins designed for use in a variety of cleaning application using a water source use a treated, softened, acidic water source according to the invention. Various methods of using the softened acidic water generated by acid regenerate-able ion exchange resins are disclosed to beneficially reduce spotting, filming and scale buildup on treated surfaces, reduce and / or eliminate the need for polymers, threshold reagents and / or rinse aids, and using protons generated in the acidic water effluent for triggering events useful in various cleaning applications.

Owner:ECOLAB USA INC

Retrofittable control unit for a softening apparatus

ActiveUS20110132818A1Reduce effortLow costIon exchange regulation/controlWater treatment parameter controlWater flowHardness

A control unit (1, 1a) for a softening device (2), comprising a primary inlet (4) for untreated water, a primary outlet (7) for blended water, a sensor for determining the water hardness of the untreated water WHraw or the blended water WHblend, a secondary outlet (5), a secondary inlet (6), a bypass line (9), a blending means which can be automatically adjusted for mixing a blended water flow Vblend(t) from a first partial flow (V(t)part1soft of the secondary inlet (6) and a second partial flow V(t)part2raw of the bypass line (9), and an electronic control means (11, 11a), wherein the control means (11, 11a) is designed to readjust the adjustment position of the blending means by means of the determined water hardness in such a fashion that the water hardness in the blended water flow Vblend(t) is adjusted to a predetermined desired value, is characterized in that the control unit (1, 1a) is designed in the form of an external control unit (1, 1a) for the softening device (2), wherein the control unit (1, 1a) has a control unit housing (3), the outer side of which is provided with the primary inlet (4), the primary outlet (7), the secondary outlet (5), and the secondary inlet (6), and wherein the control unit housing (3) contains the sensor, the bypass line (9), the blending means and the electronic control means (11, 11a). The inventive control unit enables partial softening of water on the basis of fully automatic blending, thereby utilizing already existing softening devices.

Owner:JUDO WASSERAUFBEREITUNG

Material for purification of semiconductor polishing slurry, module for purification of semiconductor polishing slurry and process for producing semiconductor polishing slurry

InactiveUS7625262B2Control changesIon exchange regulation/controlIon-exchange column/bed processesMetal chelateMetal contamination

A material for purification of a semiconductor polishing slurry that without changing of pH value, is capable of efficiently purifying a polishing slurry to thereby not only prevent metal contamination of a polished object as effectively as possible but also achieve recycling of a polishing slurry without any problem; a relevant module for purification of a semiconductor polishing slurry; and a process for purifying a semiconductor polishing slurry with the use thereof. In particular, a material for purification of a semiconductor polishing slurry characterized in that it comprises a fibrous substrate having a functional group capable of forming a metal chelate or such a functional group together with hydroxyl fixed onto at least the surface thereof. This material for purification of a semiconductor polishing slurry is, for example, used in such a manner that it is inserted in a container fitted with polishing slurry inflow port and outflow port while ensuring passage of polishing slurry flow.

Owner:NOMURA MICRO SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com