Mixed-bed resin in-vitro separating and conveying process intelligent monitoring control device and mixed-bed resin in-vitro separating and conveying process intelligent monitoring control method

A resin separation and transportation process technology, applied in the direction of ion exchange column/bed method, ion exchange mediation/control, water treatment parameter control, etc., can solve the problem that the amount of cation/anion resin is difficult to accurately control, the accuracy is poor, and the mixed bed cannot Normal operation and other problems, to achieve the effect of reasonable resin separation and transportation process, reliable judgment and favorable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

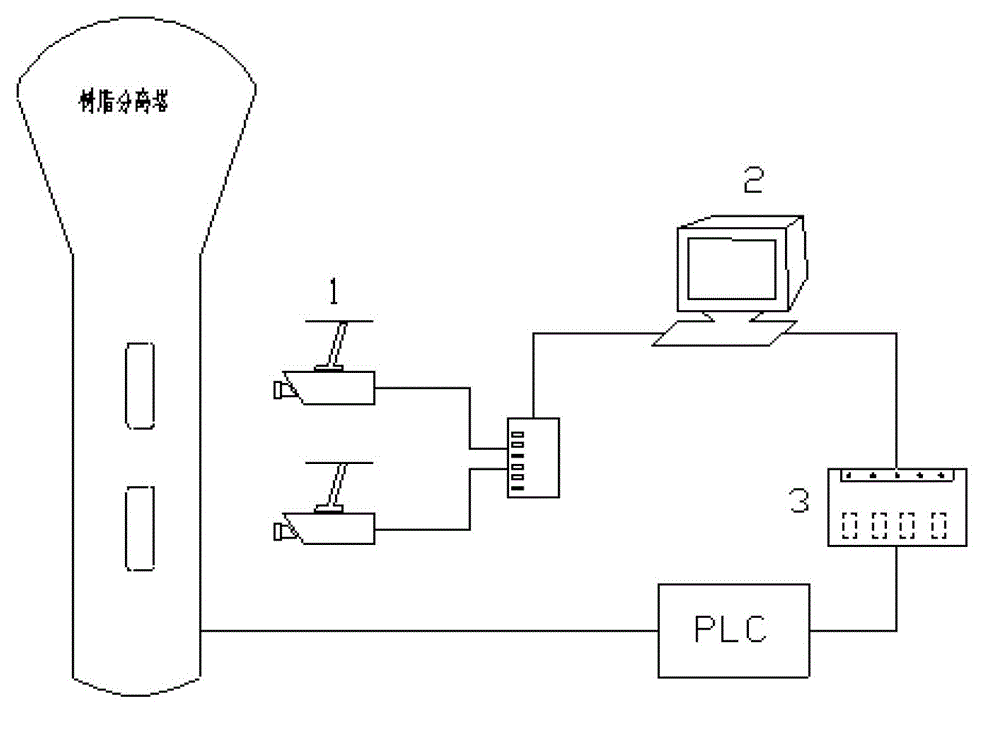

[0019] Embodiment 1, the implementation process of cone bottom separation monitoring

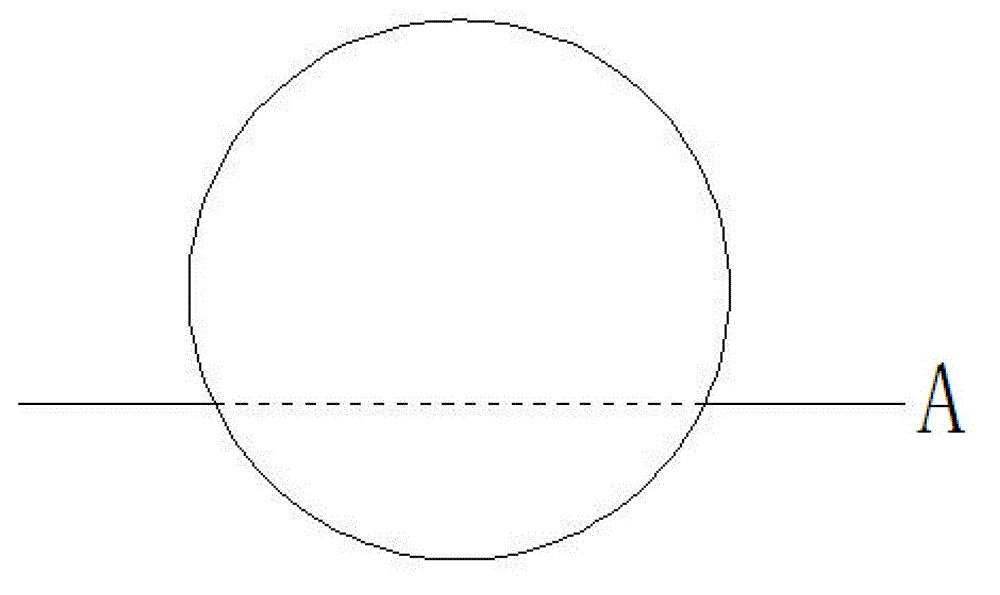

[0020] (1) The cation / anion resin backwashing layering in the cone-bottom separation tower is completed. Before starting the cation resin output operation, start the intelligent monitoring and control device, and the image acquisition unit 1 will wirelessly transmit the picture to the computer intelligent analysis unit 2. The picture Should be as figure 2 shown.

[0021] (2) Set the "reference line" on the computer intelligent analysis unit 2 according to the required ratio of yin and yang resins, such as figure 2 As shown in the "line A" in the figure; at the same time as the delivery of the positive resin, click the start analysis image function key, and the computer intelligent analysis unit 2 starts to dynamically analyze the "line A" and the position of the positive / yin interface in the resin image. During the conveying process of cation resin, the interface continues to decline. Wh...

Embodiment 2

[0022] Embodiment 2, the implementation process of high tower separation monitoring

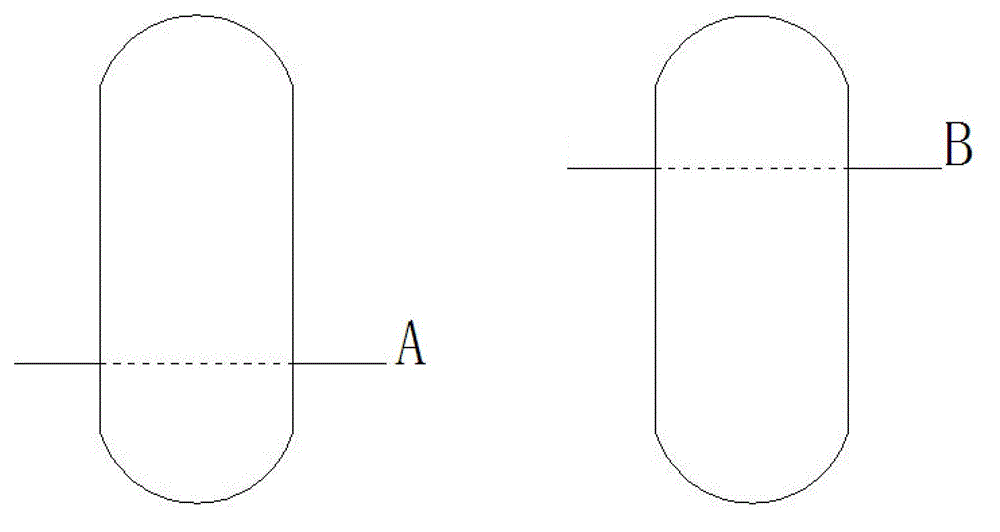

[0023] (1) The monitoring of the separation process of the high tower requires two image acquisition units 1, the upper-view mirror image acquisition unit 1A, and the lower-view mirror image acquisition unit 1B. After the positive / negative resin backwashing in the high tower is successfully stratified, the intelligent monitoring and control device is turned on, and the image acquisition units 1A and 1B respectively transmit the current mirror image information to the computer intelligent analysis unit 2 interface, and the image is as follows: image 3 shown.

[0024] (2) According to the amount of resin in the high tower and the required ratio of anion and yang resins, set two resin-separated "reference lines A and reference line B" in the upper and lower mirror screens of the computer intelligent analysis unit 2: image 3 Shown in "Line A" and "Line B".

[0025] (3) Click the start image a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com