Premelting compound refining slag for producing ultra-low sulfur steel

A compound refining and ultra-low sulfur technology, which is applied in the field of refining deep desulfurization, can solve the problems of high cost, large amount of binder, large amount of addition, etc., and achieve stable desulfurization effect, light lining erosion, and less usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

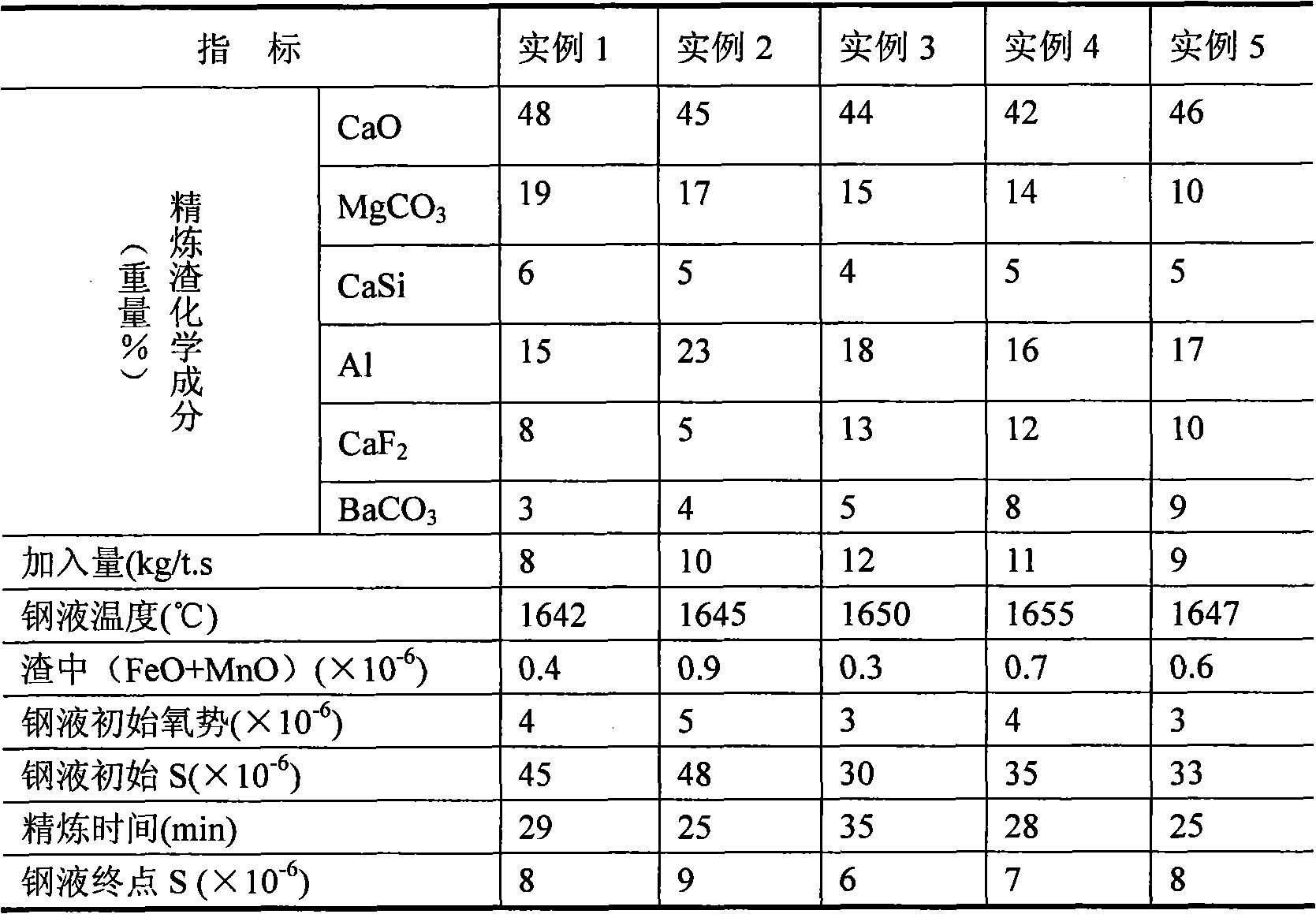

[0019] According to the proportioning of the present invention, CaO, CaF 2 After the powder is mixed, it is pre-melted by high temperature heating, cooled and crushed, and then mixed with the corresponding proportion of MgCO 3 , CaSi, BaCO 3 mixed with Al to obtain the ultra-low sulfur steel premelted composite refining slag of the present invention. After it is finished, it can be packaged with a plastic bag inside, and then packed with a nylon bag for the outer layer, and added to the surface of the molten steel when used. It can also be made into cored wire and fed into molten steel. The invention takes X65, X70 and other Al-killed steels as the carrier, and successfully carries out the production test of X65 steel and X70 steel (because the composition of X80 steel and X70 steel is similar, the slag can also be used to produce X80 and above steel types). Concrete embodiment of the present invention and test obtain effect as shown in table 1.

[0020] Table 1 Concrete e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com