Composite adsorbent for removing hydrogen sulfide at high temperature, and preparation method and application thereof

A composite adsorption and hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, alkali metal compounds, etc., can solve the problems of poor desulfurization cycle stability, low desulfurization efficiency, and difficult regeneration, and achieve good desulfurization effect and reduce water consumption. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

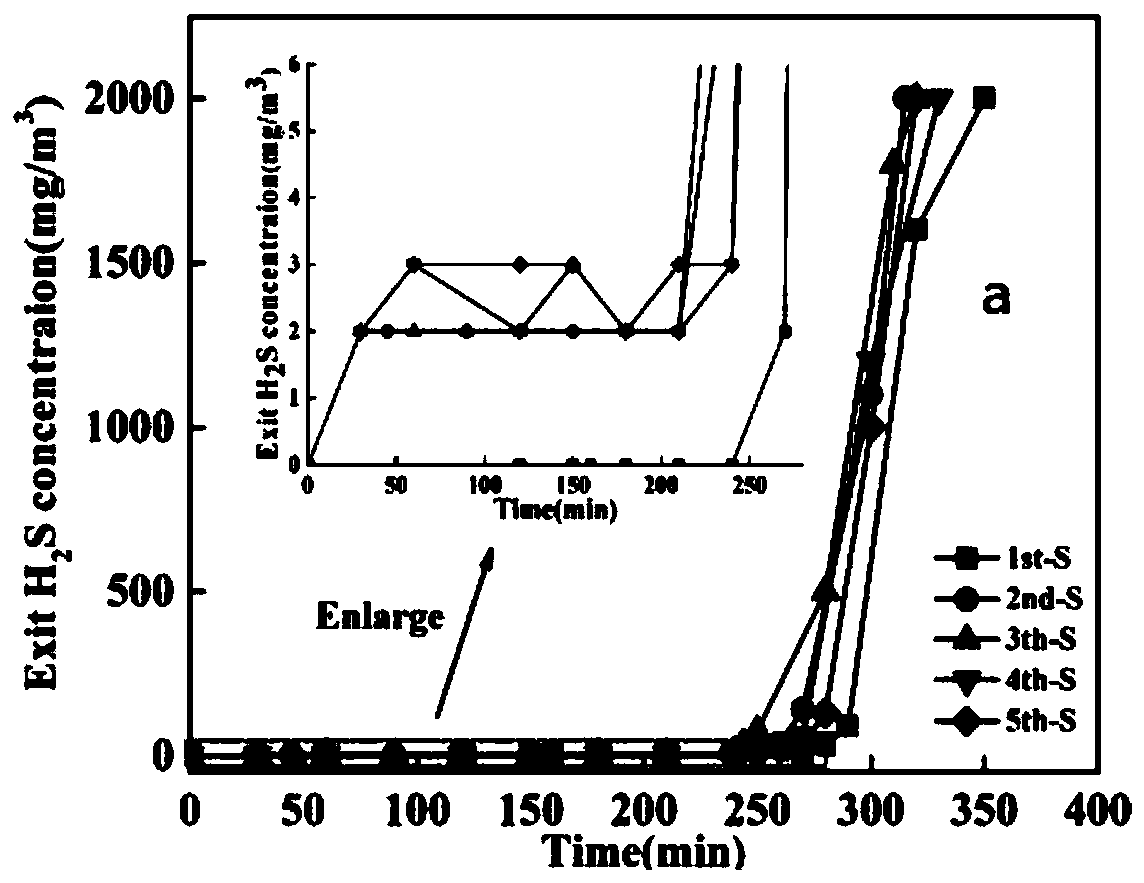

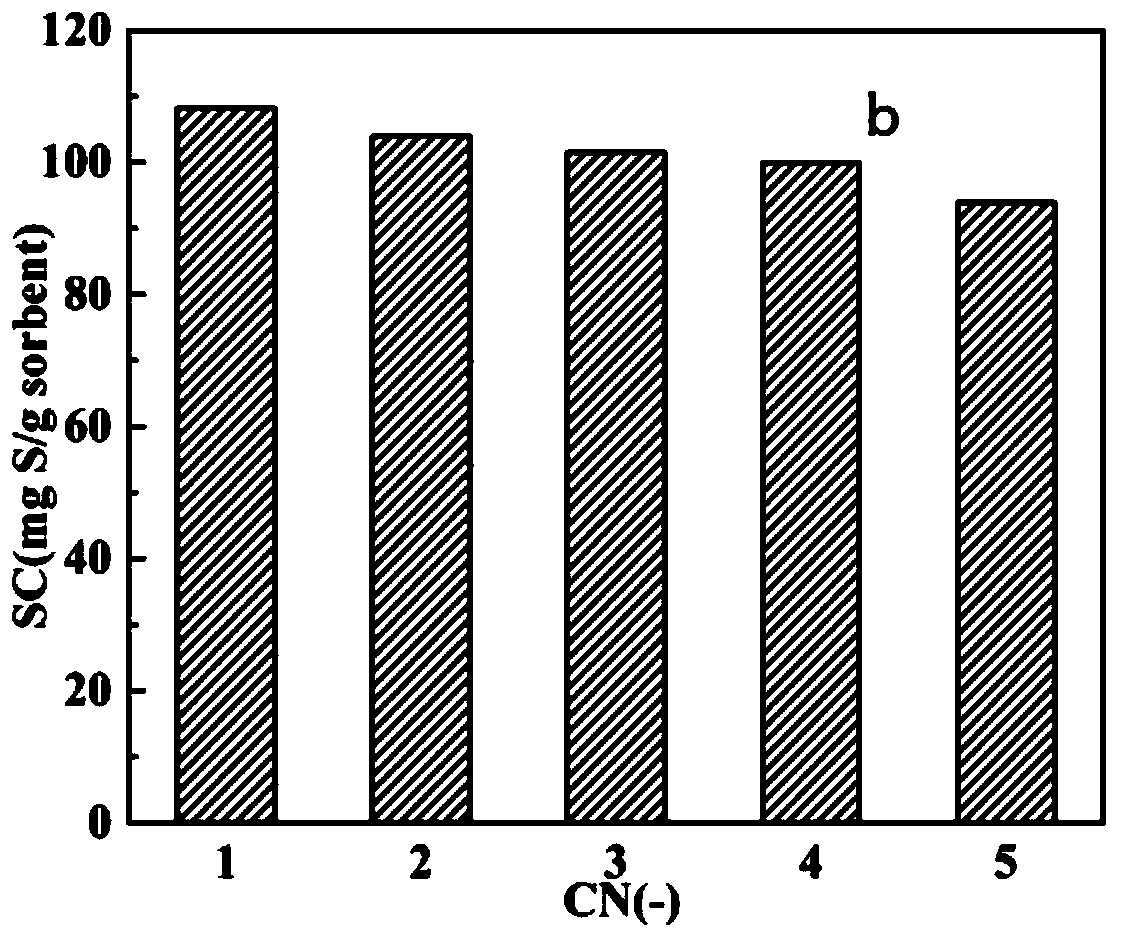

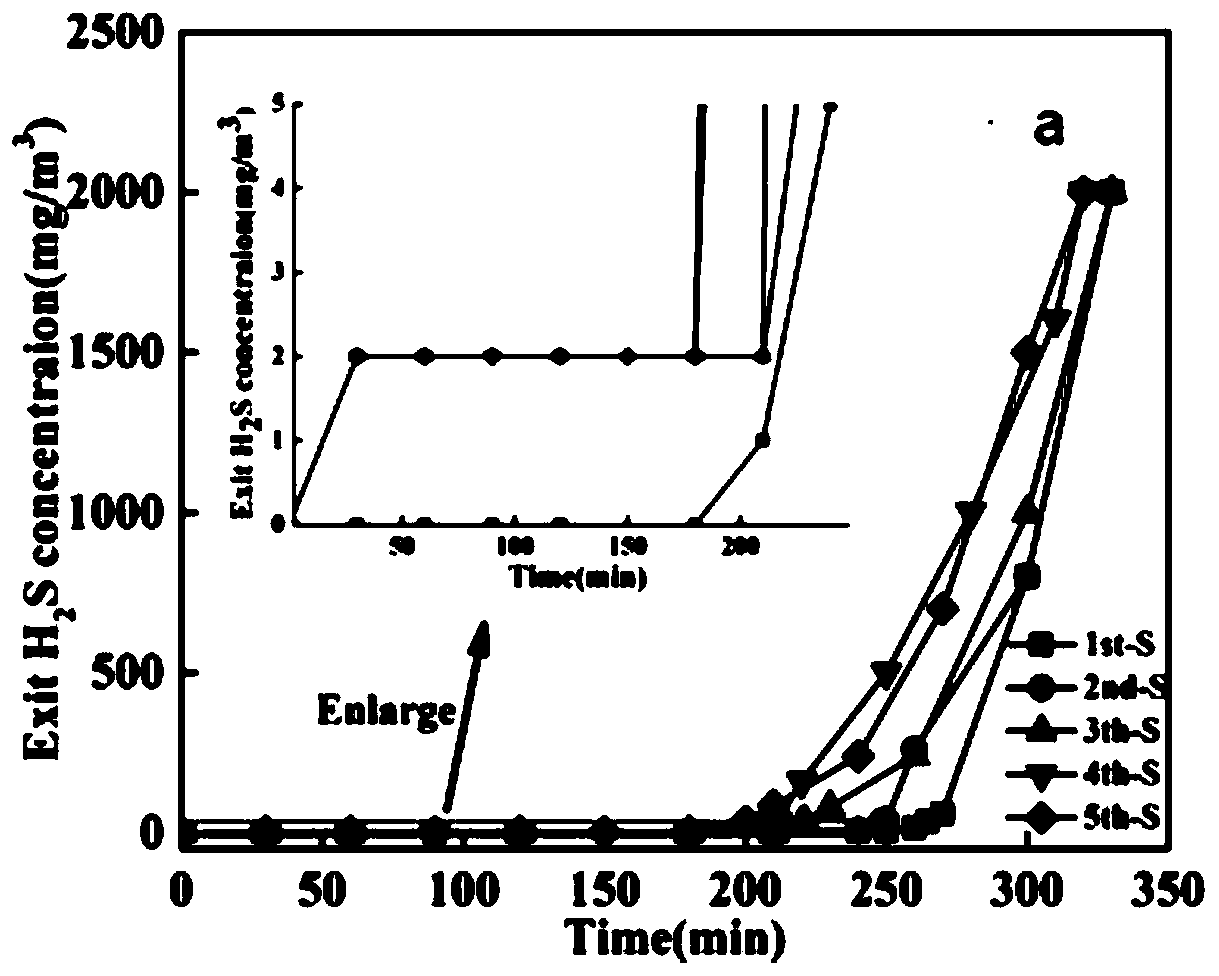

Embodiment 1

[0045] Take 30 grams of aluminum nitrate and dissolve it in distilled water, add 4.5 grams of polyvinyl alcohol, and add 1 gram of lanthanum nitrate, and ultrasonically treat it for 6 hours to completely dissolve it. Diluted aqueous ammonia was then added dropwise to the solution and stirred until pH reached 9. Alumina gel was prepared and rinsed 3 times with distilled water. The samples were dried at 110 degrees, calcined at 600 degrees for 6 hours, and cooled to room temperature to obtain modified alumina. The 20% lanthanum nitrate solution with a mass concentration of 20% was immersed in an equal volume of modified alumina, dispersed by ultrasonic to make it evenly mixed, immersed in a rotary mixer for 12 hours, and calcined at 800 degrees for 6 hours. The mixed solution of manganese nitrate (2mol / L) and nickel nitrate (12%) was immersed in the calcined sample in equal volume. During the immersion process, it was first sonicated for 10 minutes, then immersed in a rotary mi...

Embodiment 2

[0047]Take 30 grams of aluminum nitrate and dissolve it in distilled water, add 4.5 grams of polyvinyl alcohol, and add 1 gram of cerium nitrate, and ultrasonically treat it for 6 hours to completely dissolve it. Diluted aqueous ammonia was then added dropwise to the solution and stirred until pH reached 9. Alumina gel was prepared and rinsed 3 times with distilled water. The samples were dried at 110 degrees, calcined at 600 degrees for 6 hours, and cooled to room temperature to obtain modified alumina. The 20% lanthanum nitrate solution with a mass concentration of 20% was immersed in an equal volume of modified alumina, dispersed by ultrasonic to make it evenly mixed, immersed in a rotary mixer for 12 hours, and calcined at 800 degrees for 6 hours. The mixed solution of manganese nitrate (2mol / L) and cerium nitrate (20%) was immersed into the calcined sample in equal volume. During the immersion process, it was first ultrasonicated for 10 minutes, then immersed in a rotary...

Embodiment 3

[0049] Take 30 grams of aluminum nitrate and dissolve it in distilled water, add 5 grams of polyvinyl alcohol, and add 2 grams of lanthanum nitrate, and ultrasonically treat it for 6 hours to completely dissolve it. Diluted aqueous ammonia was then added dropwise to the solution and stirred until pH reached 9. Alumina gel was prepared and rinsed 3 times with distilled water. The samples were dried at 110 degrees, calcined at 600 degrees for 6 hours, and cooled to room temperature to obtain modified alumina. The 20% lanthanum nitrate solution with a mass concentration of 20% was immersed in an equal volume of modified alumina, dispersed by ultrasonic to make it evenly mixed, immersed in a rotary mixer for 12 hours, and calcined at 800 degrees for 6 hours. The mixed solution of manganese nitrate (1mol / L) and barium nitrate (20%) was immersed into the calcined sample in equal volume. During the immersion process, it was first ultrasonicated for 10 minutes, then immersed in a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com