Recyclable sulfur dioxide gas absorbent and preparation method thereof

A gas absorbent, sulfur dioxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation and other directions, can solve the problems of unfavorable industrialization and high cost of amino acid ionic liquids, achieve low operating costs, improve desulfurization effect, synthesis conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

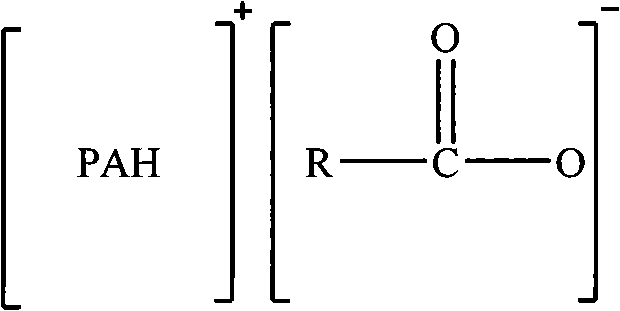

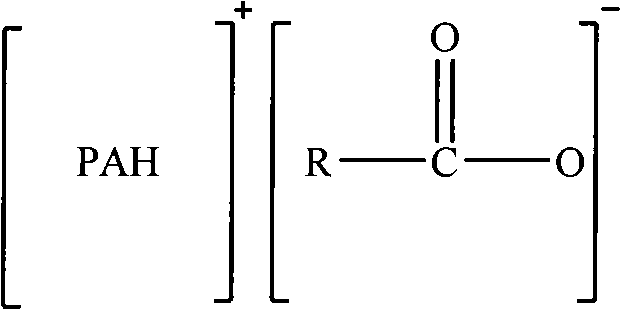

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Assemble the three-neck flask, condensing reflux tube, sealing dropping funnel and stirring device together. The molar ratio of diethylenetriamine to formic acid is 1:3, and water is used as a solvent. The temperature was controlled at 60° C., formic acid solution was added dropwise, and the reaction was carried out for 12 hours. The mixed liquid was decompressed and rotated at 80°C to remove the solvent and excess raw materials, and the obtained liquid was placed in a vacuum oven at 50°C for 24 hours to finally obtain a yellow ionic liquid of diethylenetriamine formic acid. The absorbent was placed in a vacuum oven at 50°C for use.

[0028] Accurately weigh the ionic liquid of diethylenetriamine formate and place it in the absorber, place the absorber in a constant temperature system at 30°C, and feed SO into the absorber 2 gas, the absorbent turns yellow and transparent, and can reach 98.35% of the equilibrium absorption in 1 hour, diethylenetriamine formic acid abs...

Embodiment 2

[0032] Assemble the three-neck flask, condensing reflux tube, sealing dropping funnel and stirring device together. The molar ratio of triethylenetetramine to formic acid is 1:4, and ethanol is used as a solvent. The temperature was controlled at 90° C., formic acid solution was added dropwise, and the reaction was carried out for 6 hours. The mixed liquid was decompressed and rotated at 50°C to remove the solvent and excess raw materials, and the obtained liquid was placed in a vacuum oven at 50°C for 36 hours to finally obtain a yellow ionic liquid of triethylenetetramine formic acid. The absorbent was placed in a vacuum oven at 50°C for use.

[0033] Accurately weigh the triethylenetetramineformic acid ionic liquid and place it in the absorber, place the absorber in a constant temperature system at 30°C, and feed SO into the absorber 2 gas, the absorbent turns yellow and transparent, and can reach 99.54% of the equilibrium absorption in 1 hour, triethylenetetramine formic...

Embodiment 3

[0036]Assemble the three-neck flask, condensing reflux tube, sealing dropping funnel and stirring device together. The molar ratio of tetraethylenepentamine to formic acid is 1:5, and ethanol is used as a solvent. The temperature was controlled at 60°C, and formic acid solution was added dropwise, and reacted for 10 hours. The mixed liquid was decompressed and rotated at 50°C to remove the solvent and excess raw materials, and the obtained liquid was put into a vacuum oven at 50°C for 36 hours to finally obtain a brown-yellow ionic liquid of tetraethylenepentaamine formate. The absorbent was placed in a vacuum oven at 50°C for use.

[0037] Accurately weigh the ionic liquid of tetraethylenepentamine formate and place it in the absorber, place the absorber in a constant temperature system at 30°C, and feed SO into the absorber 2 gas, the absorbent turns yellow and transparent, and can reach 98.27% of the equilibrium absorption in 1 hour, tetraethylenepentamine formic acid abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com