Organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of organic composite efficient sulfur removal agent

A technology of oil and gas field and sulfur removal agent, which is applied in the field of oil and gas field chemistry, can solve the problems of staff poisoning, economic loss, and threat to the personal safety of on-site operators, and achieve the goals of wide application range, broad application prospects, great economic benefits and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described by examples below. It should be noted that the following examples are only examples of the present invention, and do not represent the limited scope of rights of the present invention. The scope of protection of rights of the present invention is as the criterion with the claims.

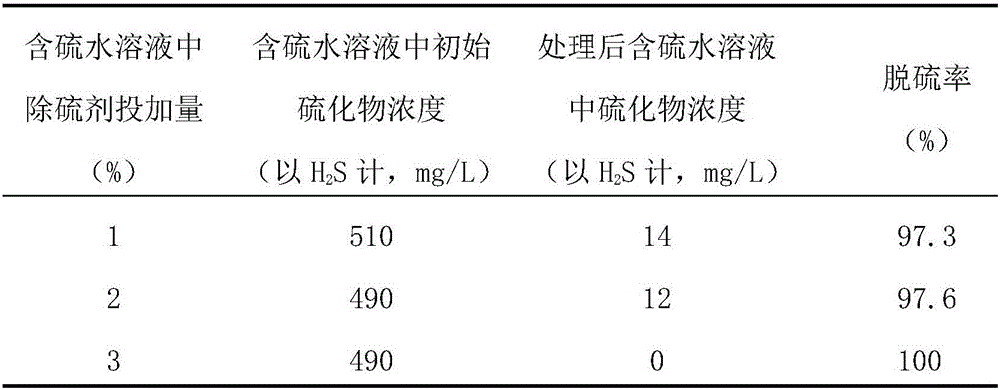

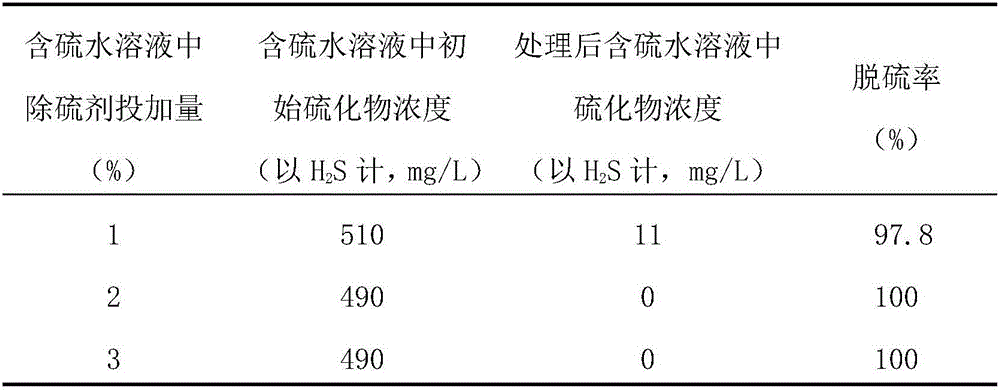

[0020] (1) Sulfur removal efficiency experiment

[0021] Simulated water configuration reference: Q / SY 126-2014 Simulated water: 50g NaCl, 2.0g MgCl 2 ·6H 2 O, 6.0gNaSO 4 , 4g anhydrous CaCl 2 , 0.4g NaHCO 3 .

[0022] Preparation of hydrogen sulfide solution: Prepared by a Kipp generator in an indoor fume hood, put the prepared hydrogen sulfide into simulated water, and determine the concentration of hydrogen sulfide to be 500mg / L±20mg / L by iodometric titration.

[0023] (1) Preparation of sulfur removal agent 1#

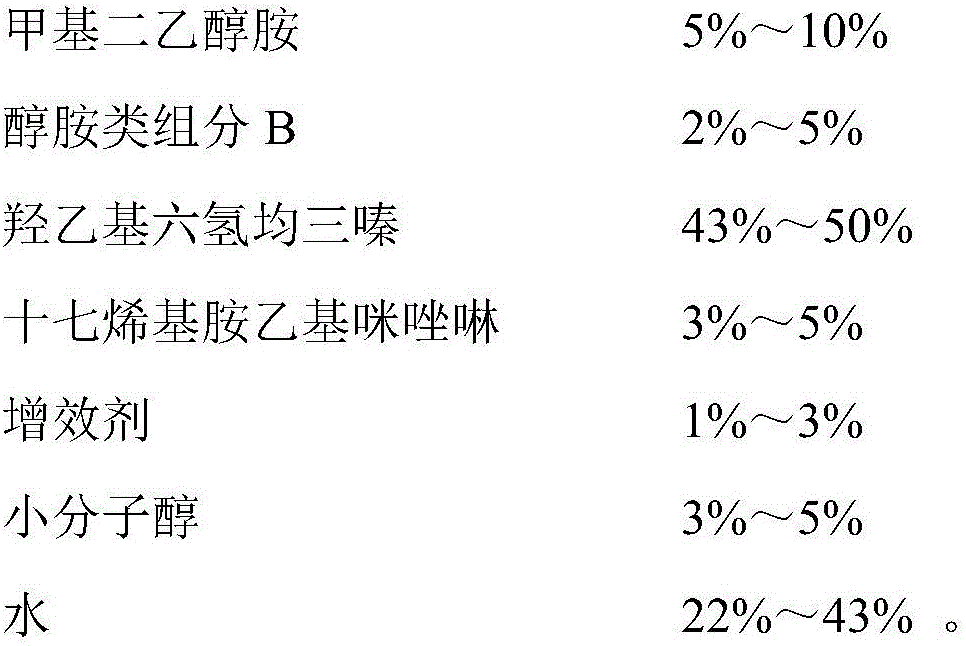

[0024] The formula composition of sulfur removal agent 1#: alcohol amine A methyldiethanolamine is 100kg, alcohol amine B tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com