A processing method and apparatus of coal-firing gas

A coal-fired flue gas and treatment method technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve problems such as the inability to achieve CO2 removal, achieve significant desulfurization effects, improve heat exchange efficiency, and high added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

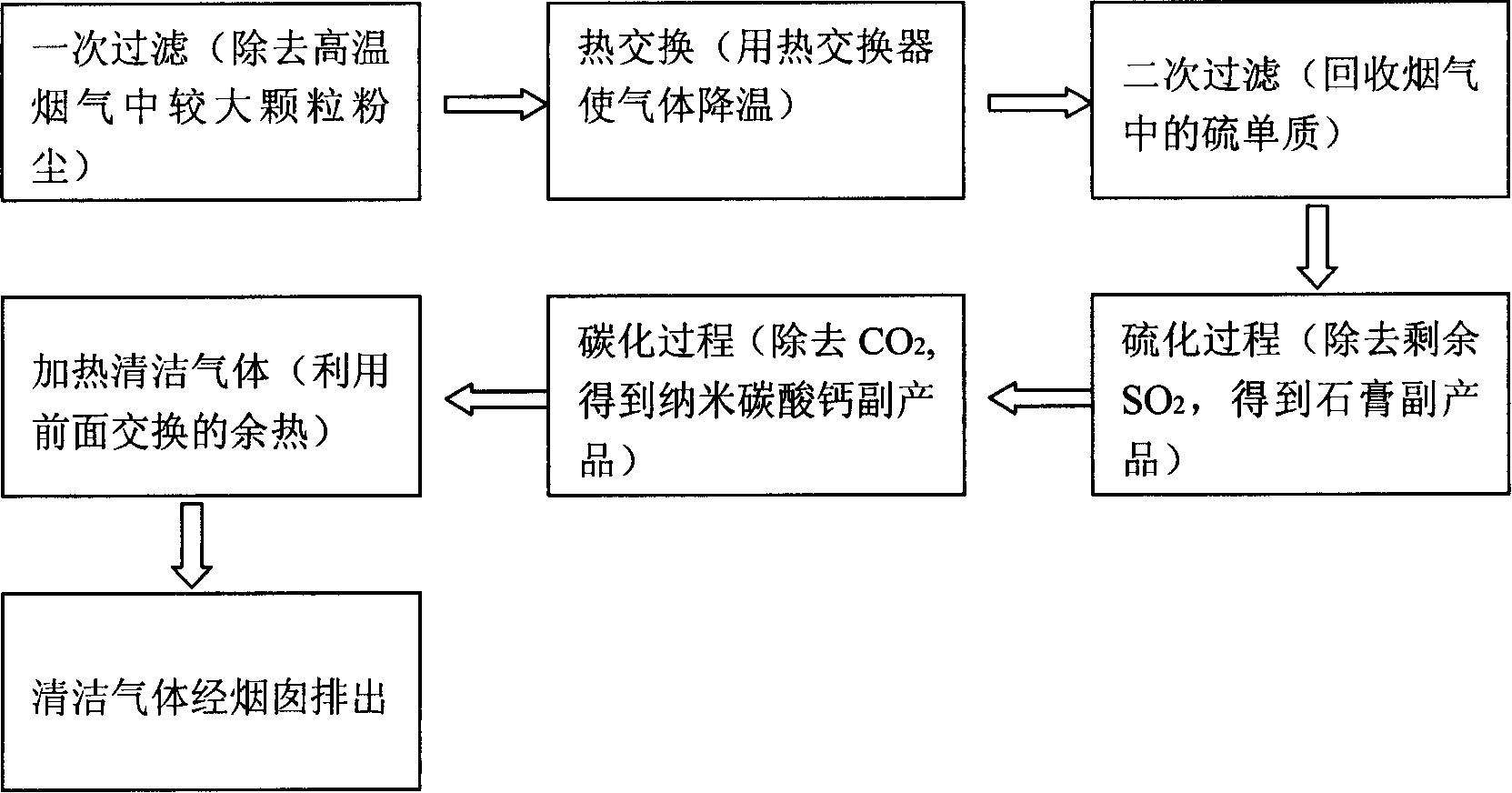

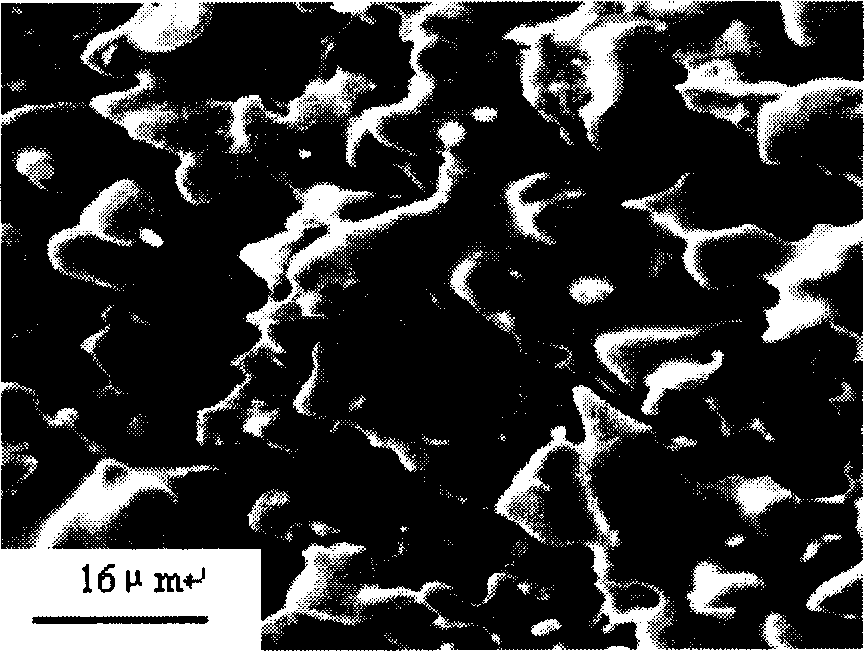

[0051] Coal-fired flue gas from thermal power plants, in which the contents of soot particles, sulfur vapor, sulfur dioxide, and carbon dioxide are 2123mg / m 3 、1859mg / m 3 , 8000mg / m 3 , 700mg / m 3 , first pass the coal-fired flue gas into the primary filter equipment. The filter element is a SiC porous ceramic filter with pores distributed in a three-dimensional network, with a pore size of 100 microns; the SiC porous ceramic filter is supported by a carrier, sealed with a graphite gasket, and connected by a flange. . The solid particles intercepted by filtration fall into the temporary ash bin; the porous ceramic filter is backflushed by pulse backflushing. The dust content of the flue gas from the primary filter device is reduced to 1%, and it enters the heat exchanger. Part of the recovered sensible heat enters the boiler steam circulation system, and part of it heats the gas after wet desulfurization; the outlet temperature of the heat exchanger is controlled at 150°C; ...

Embodiment 2

[0055] Coal-fired flue gas from thermal power plants, in which the contents of soot particles, sulfur vapor, sulfur dioxide, and carbon dioxide are 2123mg / m 3 、1859mg / m 3 、5000mg / m 3 、685mg / m 3 , The coal-fired flue gas is passed into the filter equipment. The filter element is a SiC porous ceramic filter with pores distributed in a three-dimensional network, with a pore size of 100 μm; the SiC porous ceramic filter is supported by a carrier, sealed with a graphite gasket, and connected by a flange. The solid particles intercepted by filtration fall into the temporary ash bin; the porous ceramic filter is backflushed by pulse backflushing. After filtration, the filtration efficiency of soot particles in the flue gas is as high as 90%; 60% recovery of steam sulfur element is achieved, SO 2 30% were adsorbed. The flue gas from the dry filtration device directly enters the heat exchanger, part of the recovered sensible heat enters the boiler steam circulation system, and part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com