Technique for heating and cooling material in reactor by heat carrier through jacket

A technology of heat transfer medium and reaction kettle, which is used in cooling, the heat transfer medium heats the materials in the reactor through the jacket, and the material in the reactor is heated. Use and other issues to achieve the effect of high heat exchange efficiency, small footprint and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

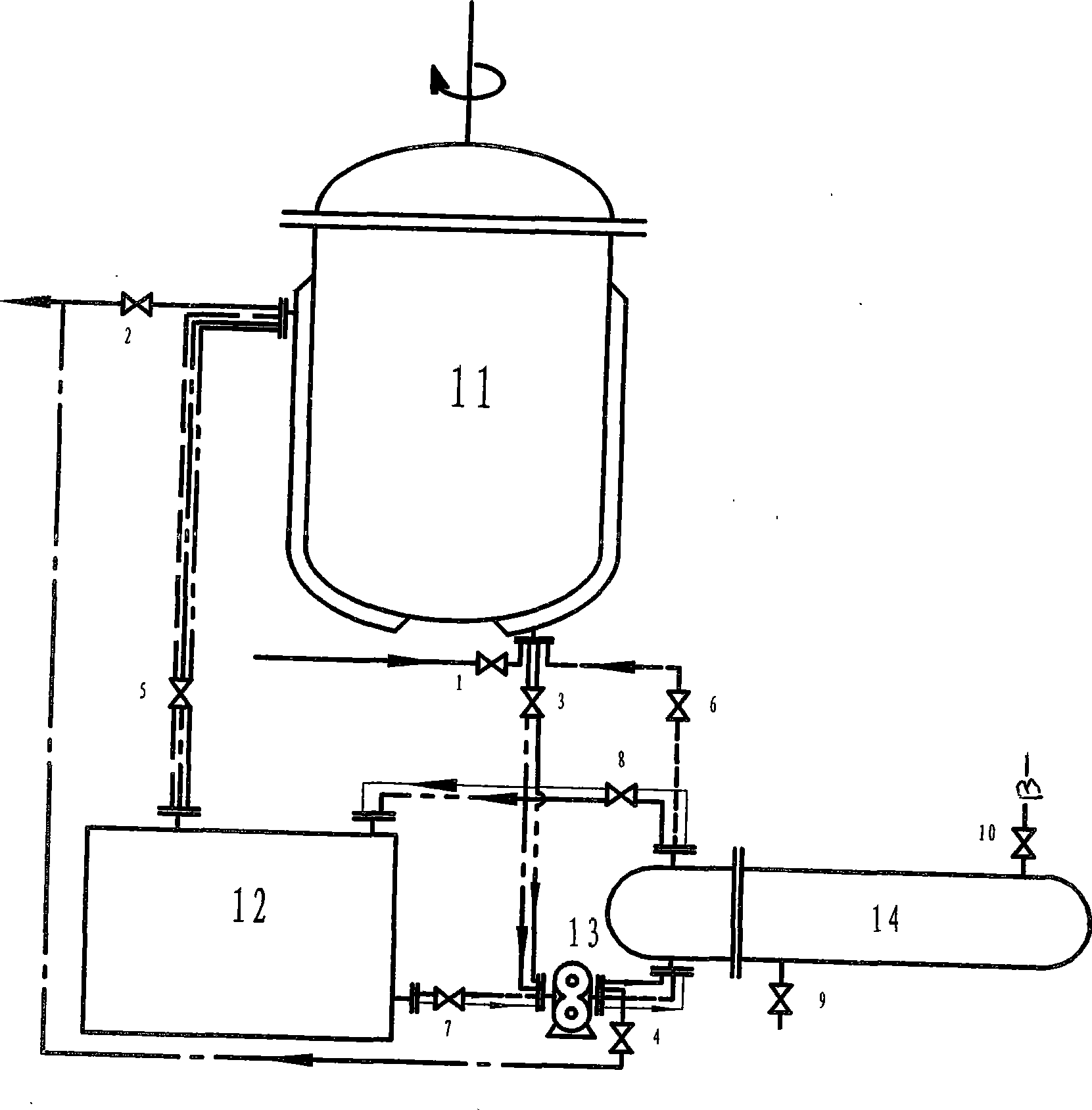

[0028] It can be seen from the drawings that the device used in the present invention consists of 6 circuits. Now the 6 circuits are described as follows:

[0029] The heat transfer oil heating circuit is composed of boiler, reaction kettle 11, connecting pipelines and valves 1 and 2. The oil inlet and outlet interface pipes of the boiler are connected to the lower and upper jackets of reaction kettle 11 through connecting pipelines and valves 1 and 2 Interface tube connection.

[0030] The heating-to-cooling circuit consists of a boiler, a reactor 11, connecting pipes and its valves 3, 4, 5, and an oil pump 13. The nozzle under the jacket of the reactor 11 is connected to the inlet of the oil pump 13 through the pipeline with valve 3, and the oil pump The outlet of 13 is connected to the boiler oil inlet through a pipeline with valve 4, and valve 5 is a balance valve.

[0031] The cold heat transfer oil cooling circuit is composed of cold oil tank 12, reaction kettle 11, cooler 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com