Ag2O@Ti-Ce-O difunctional catalytic adsorption desulfurizer, and preparation method and application thereof

A dual-function catalysis and adsorption desulfurization technology, applied in the field of desulfurizers, can solve the problems of further improvement of desulfurization efficiency, low efficiency of adsorbent recycling, hindering technical industrial application, etc., and achieves excellent fuel oil deep desulfurization effect and good industrial application. The effect of foreground, high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

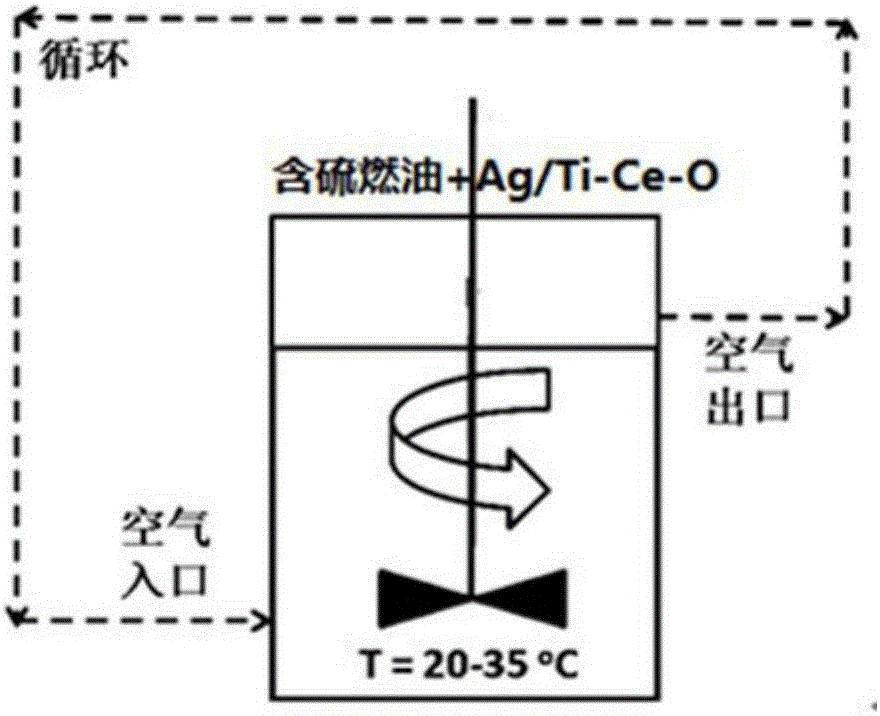

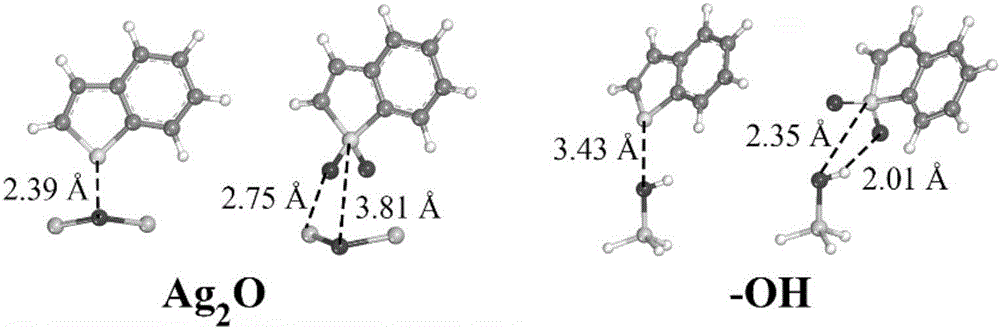

Method used

Image

Examples

Embodiment 1

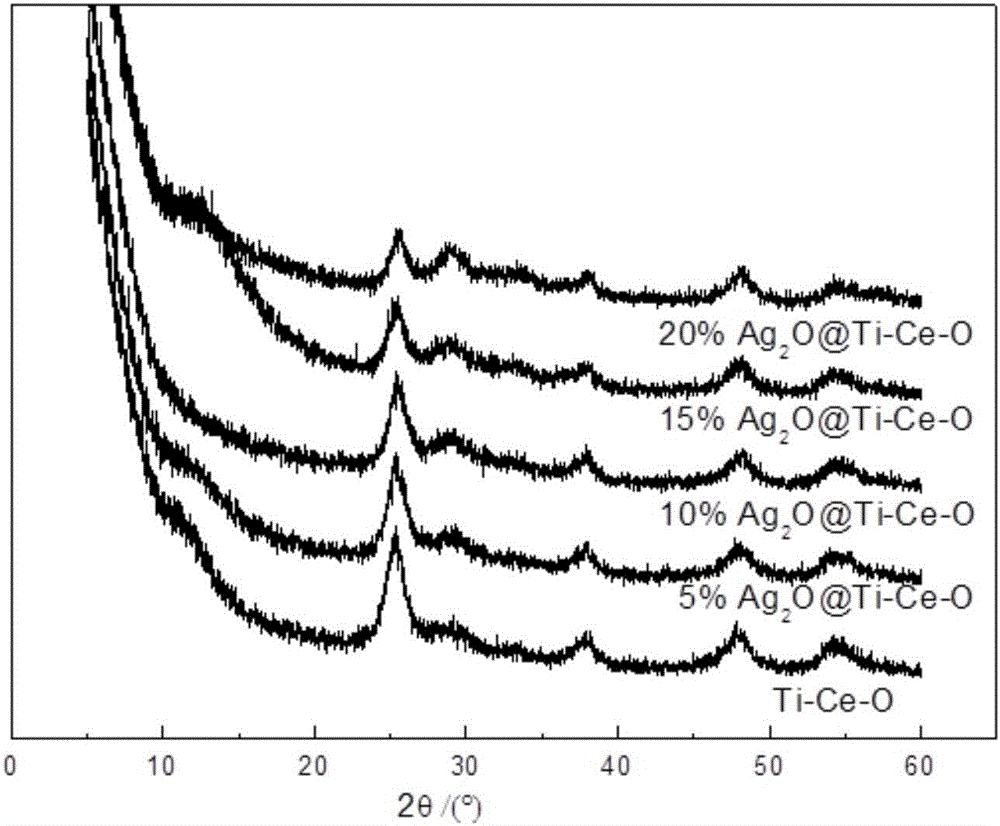

[0032] This embodiment provides an Ag 2 O@Ti-Ce-O bifunctional catalytic adsorption desulfurizer, which is prepared by the following steps:

[0033] (1) The precursors of Ti and Ce, titanium oxysulfate and ammonium cerium nitrate, are divided into TiO 2 / CeO 2The molar ratio is 1:9, mixed in the urea solution with a concentration of 40g / L, and magnetically stirred until completely dissolved to obtain a mixed solution of titanium cerium precursor;

[0034] (2) Heat the titanium-cerium precursor mixed solution to 90-95°C in a water bath, then stir and react at a constant temperature for 6 hours, filter the obtained gel, wash with water, dry, and calcinate at 400°C for 4 hours in an air atmosphere to obtain Ti-Ce -O base material;

[0035] (3) Uniformly load the silver nitrate solution on the Ti-Ce-O base material according to the silver loading amount of 5wt.%, dry, grind, and calcinate at 400 ° C in the air atmosphere to obtain Ag 2 O@Ti-Ce-O bifunctional catalytic adsorpti...

Embodiment 2

[0038] This embodiment provides an Ag 2 O@Ti-Ce-O bifunctional catalytic adsorption desulfurizer, which is prepared by the following steps:

[0039] (1) The precursors of Ti and Ce, titanium oxysulfate and ammonium cerium nitrate, are divided into TiO 2 / CeO 2 The molar ratio is 1:1, mixed in the urea solution with a concentration of 60g / L, and magnetically stirred until completely dissolved to obtain a mixed solution of titanium cerium precursor;

[0040] (2) Heat the titanium-cerium precursor mixed solution to 90-95°C in a water bath, then stir and react at a constant temperature for 6 hours, filter the obtained gel, wash with water, dry, and calcinate at 400°C for 4 hours in an air atmosphere to obtain Ti-Ce -O base material;

[0041] (3) Uniformly load the silver nitrate solution on the Ti-Ce-O base material according to the silver loading amount of 10wt.%, dry, grind, and calcinate at 400 ° C in the air atmosphere to obtain Ag 2 O@Ti-Ce-O bifunctional catalytic adsorp...

Embodiment 3

[0044] This embodiment provides an Ag 2 O@Ti-Ce-O bifunctional catalytic adsorption desulfurizer, which is prepared by the following steps:

[0045] (1) The precursors of Ti and Ce, titanium oxysulfate and ammonium cerium nitrate, are divided into TiO 2 / CeO 2 The molar ratio is 5:1, mixed in the urea solution with a concentration of 80g / L, and magnetically stirred until completely dissolved to obtain a mixed solution of titanium cerium precursor;

[0046] (2) Heat the titanium-cerium precursor mixed solution to 90-95°C in a water bath, then stir and react at a constant temperature for 6 hours, filter the obtained gel, wash with water, dry, and calcinate at 400°C for 4 hours in an air atmosphere to obtain Ti-Ce -O base material;

[0047] (3) Uniformly load the silver nitrate solution on the Ti-Ce-O base material according to the silver loading amount of 15wt.%, dry, grind, and calcinate at 400 ° C in the air atmosphere to obtain Ag 2 O@Ti-Ce-O bifunctional catalytic adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com