External cooling test system and method for pressure vessel

A pressure vessel and external cooling technology, applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve problems such as difficult to achieve one-dimensional slice heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

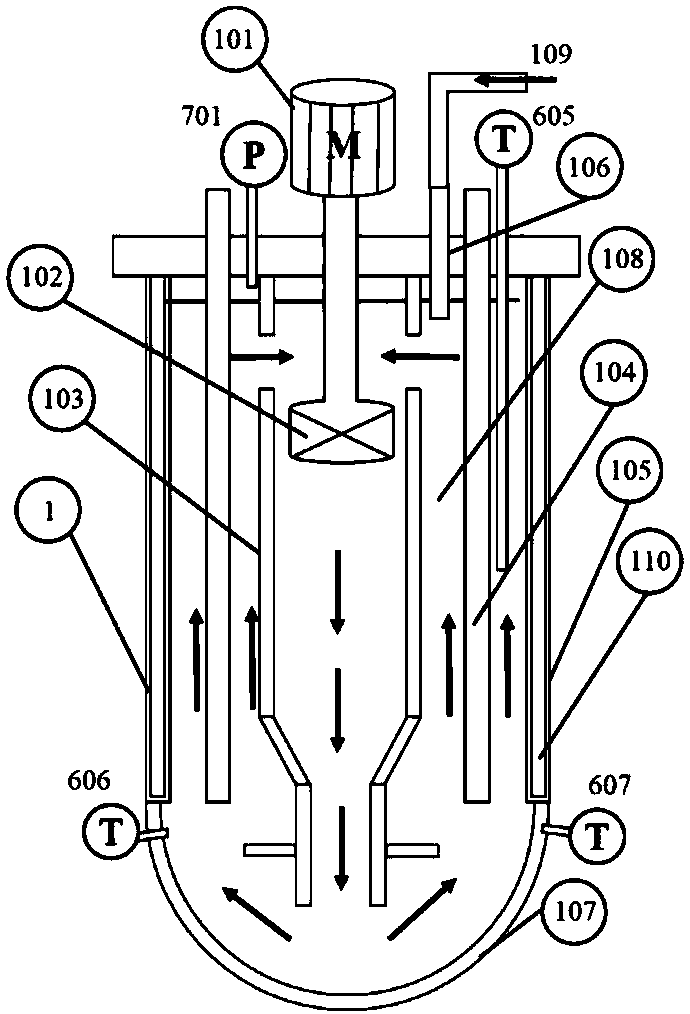

[0039] Such as figure 1 As shown, the test piece 1 is provided with a flow channel structure 3 outside and placed in the test water tank 2. A second electric heater 502 is arranged in the test water tank 2, and a bypass pipe between the upper part of the test water tank 2 and the upper part of the spare water tank 6 A 404 valve and a third flow meter 203 are installed on it, and the test water tank 2 is connected to a nitrogen source 5. The connecting pipe is equipped with a 407 valve, a 410 valve and a second pressure sensor 702; the lower part of the test water tank 2 passes through the water pump 301, A flow meter 201 and 403 valves are connected to the lower part of the standby water tank 6; the upper part of the standby water tank 6 is connected to the lower part of the deionized water equipment 7 through the 401 valve; the top of the standby water tank 6 is connected to the air cooler 8 through the 402 valve and the first temperature sensor 601; The device 8 is then connec...

no. 2 example

[0052] Image 6 It is a schematic diagram of a pressure vessel external cooling test system provided by the second embodiment of the present invention. The structure of this embodiment is basically the same as that of the first embodiment. The main difference is that the length of the liquid metal nozzle 106 is different. In the first embodiment, the outlet of the liquid metal nozzle 106 is arranged on the top of the test piece 1; In the example, the outlet of the liquid metal nozzle 106 is at the bottom of the test piece 1. In this embodiment, the liquid metal 108 can be transported into the high temperature molten pool 4 by injecting nitrogen into the test piece 1, so that the lower head 107 of the pressure vessel can be replaced. Therefore, the lower head of pressure vessel with different variable thickness designs can be studied, and the boiling heat transfer performance of the outer structure surface of the lower head of different pressure vessels can be studied, so as to ...

no. 3 example

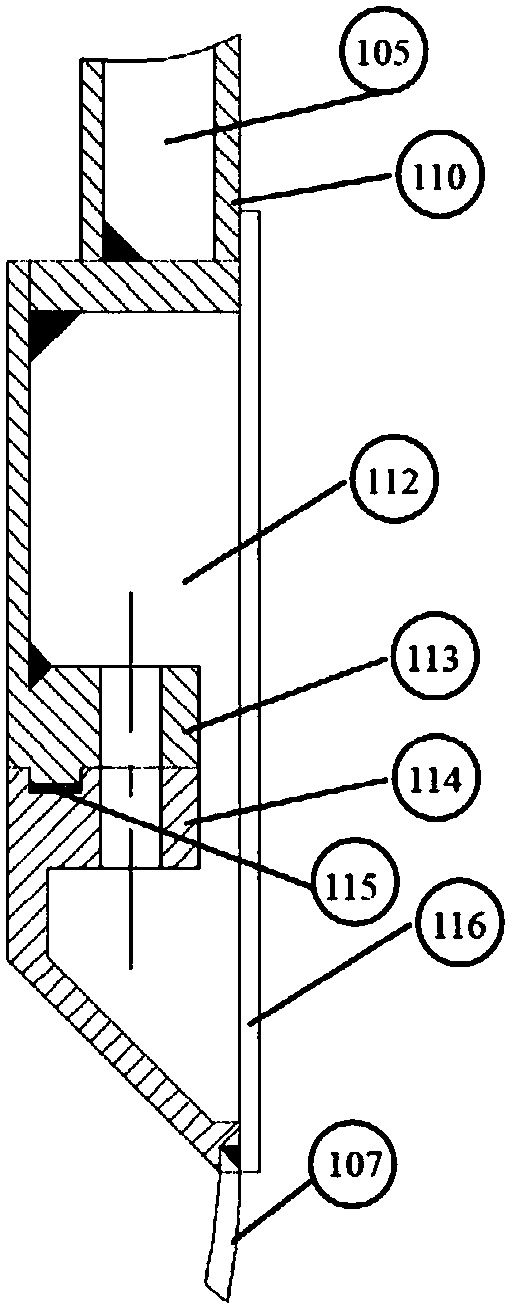

[0054] Figure 7-Figure 11 It is a schematic diagram of another pressure vessel external cooling test system provided by the third embodiment of the present invention. The structure of this embodiment is basically the same as that of the first embodiment. The main difference is that this embodiment adds a baffle 111 inside the lower head of the pressure vessel, and the shape of the baffle in each figure is different; A high-temperature heat insulation layer is arranged between the inner surface of the lower head 107 of the pressure vessel, so that most of the heat is transferred to the local area of the lower head of the pressure vessel, and the relationship between the average heat flux and the wall temperature in different zones can be studied. The relationship between the average heat flux density of the outer surface of the lower head 107 of the pressure vessel and the inclination angle is obtained. Therefore, it is possible to accurately evaluate whether the critical he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com