Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243 results about "Boiling heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiling heat transfer is heat transferred by the boiling of water. In BWRs boiling of coolant occurs at normal operation and it is very desired phenomenon.

Two-phase, water-based immersion-cooling apparatus with passive deionization

InactiveUS20130021752A1Wave amplification devicesSemiconductor/solid-state device detailsWater basedComputer module

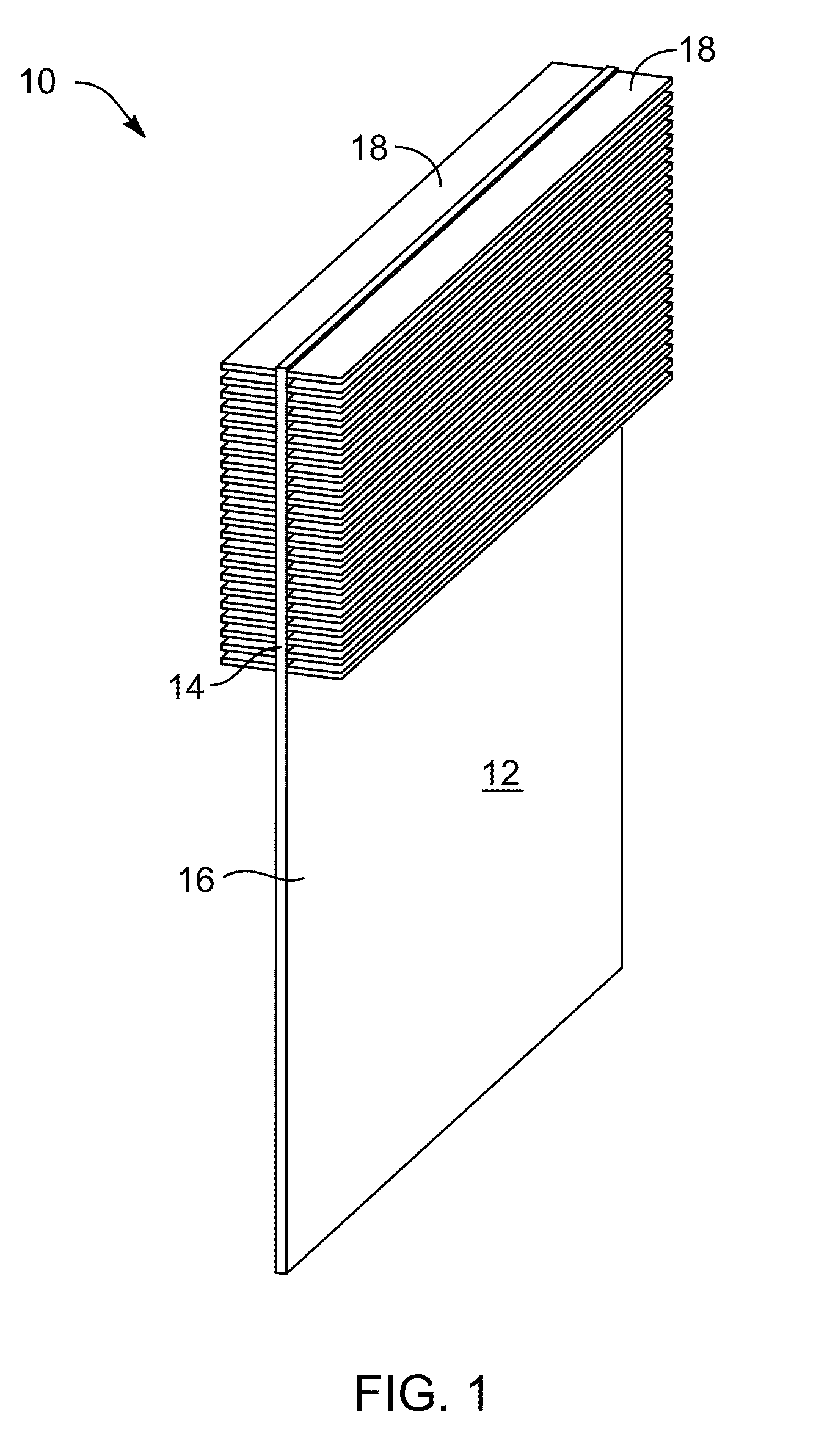

Cooling apparatuses, cooled electronic modules and methods of fabrication are provided for fluid immersion-cooling of an electronic component(s). The cooled electronic module includes a substrate supporting the electronic component(s), and the cooling apparatus couples to the substrate, and includes a housing at least partially surrounding and forming a compartment about the electronic component(s). Additionally, the cooling apparatus includes a fluid and a deionization structure disposed within the compartment. The electronic component is at least partially immersed within the fluid, and the fluid is a water-based fluid. The deionization structure includes deionizing material, which ensures deionization of the fluid within the compartment. The deionization structure facilitates boiling heat transfer from the electronic component(s) to a condenser structure disposed in the compartment. Transferred heat is subsequently conducted to, for example, a liquid-cooled cold plate or an air-cooled heat sink coupled to the housing for cooling the condenser structure.

Owner:IBM CORP

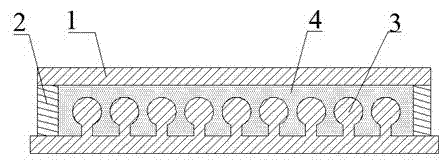

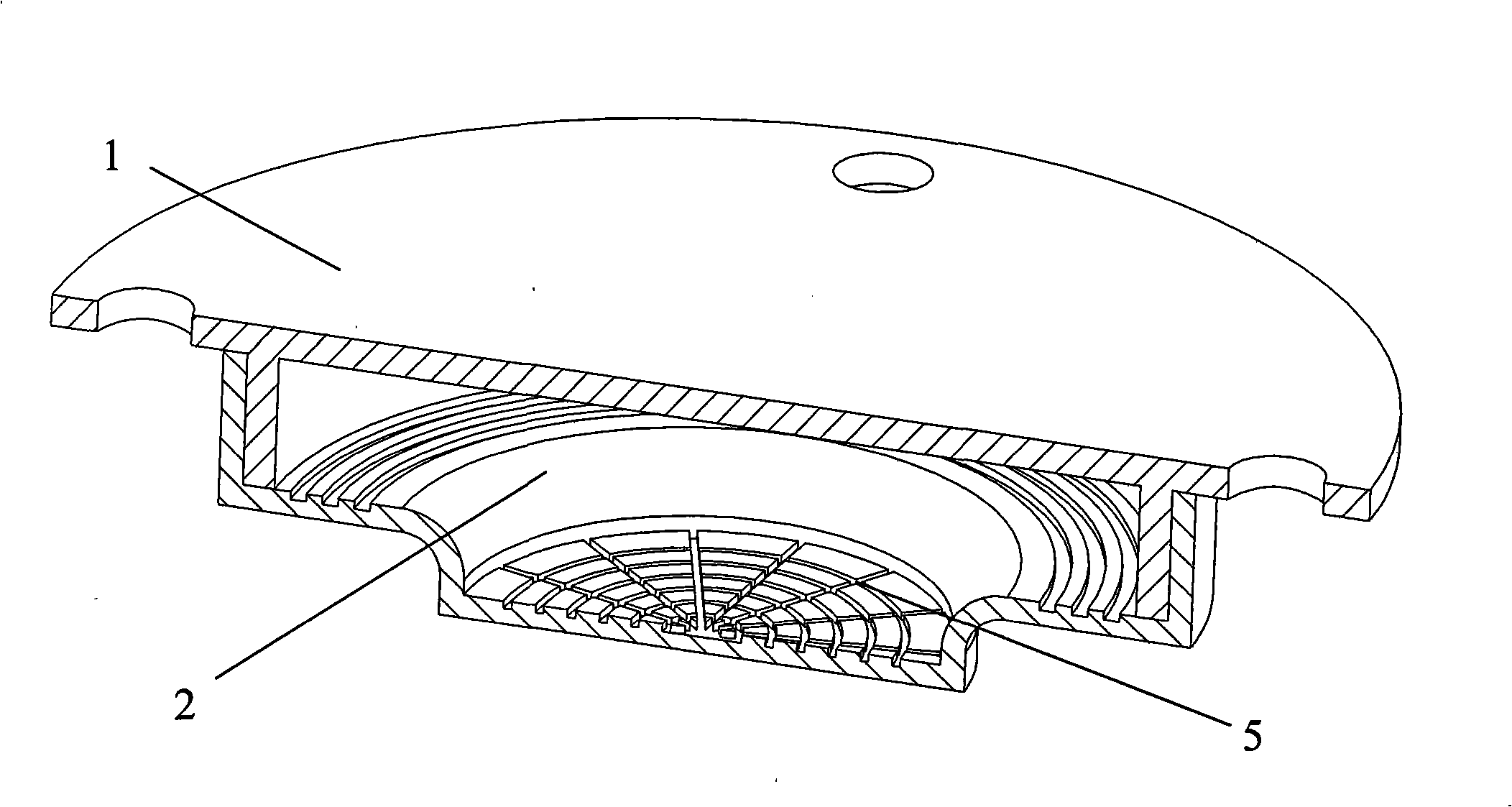

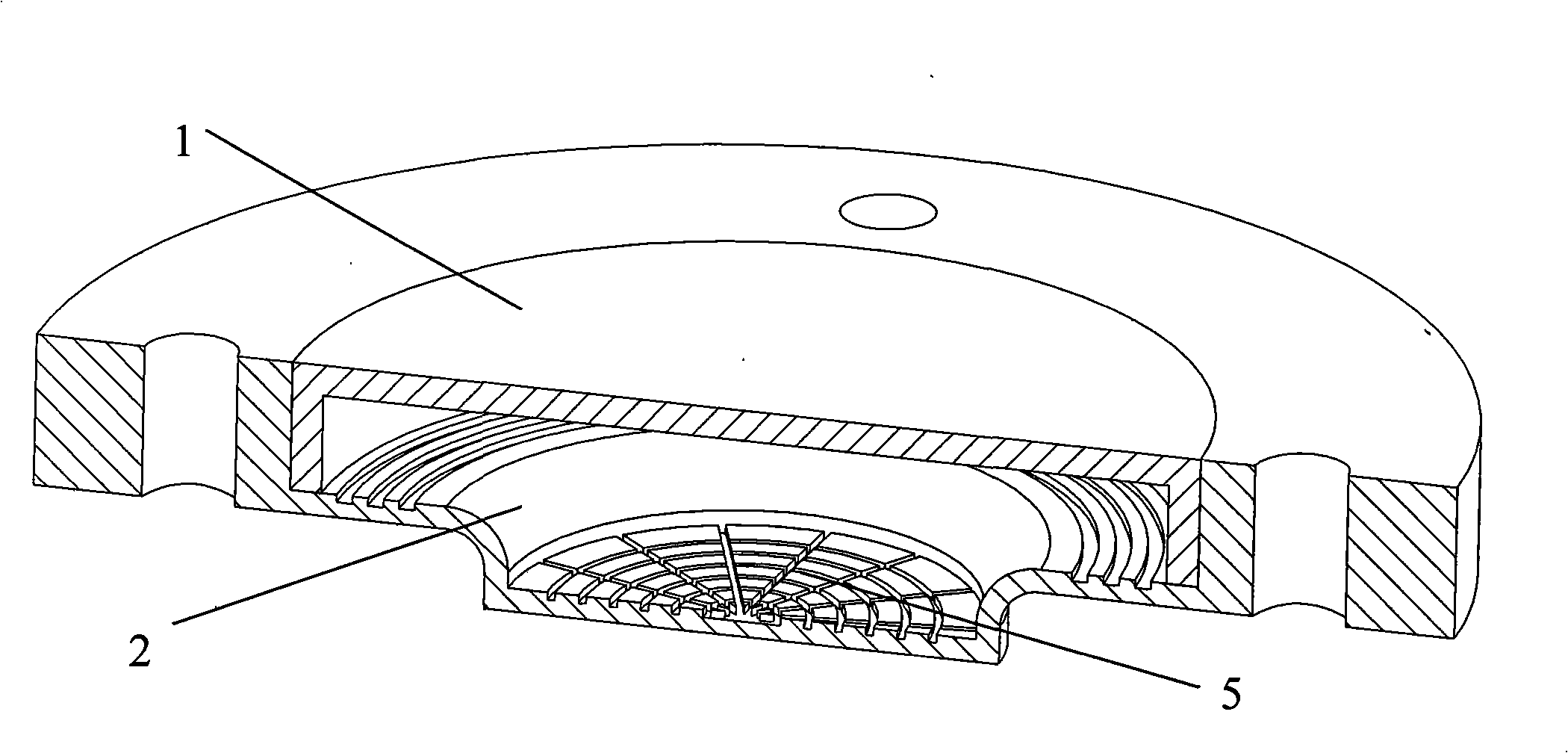

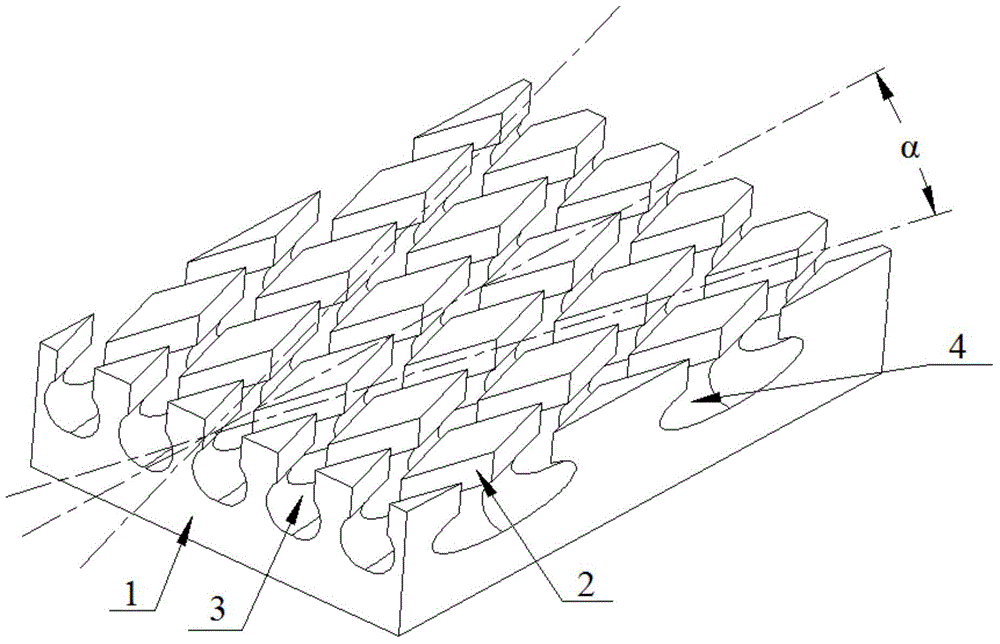

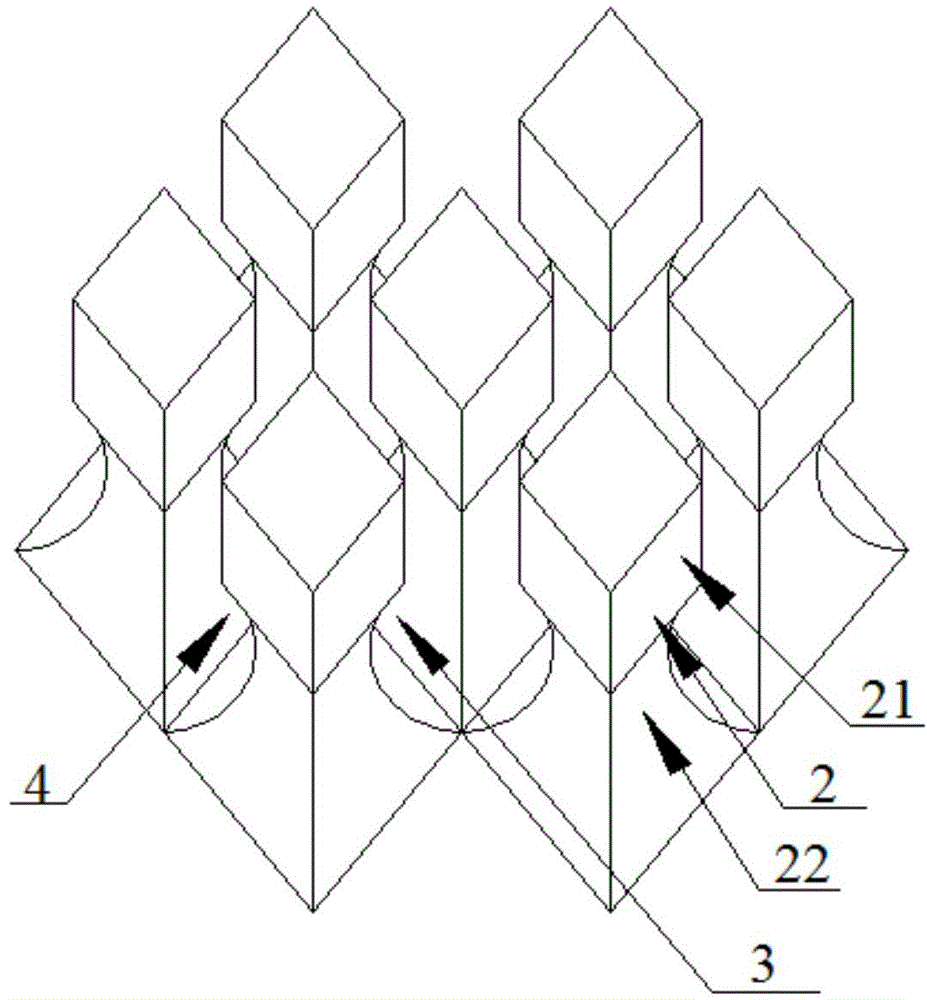

Heat transfer tubes for evaporators

ActiveUS20070034361A1Improve boiling heat transfer coefficient heat transferWeight of transfer being reducedCorrosion preventionIndirect heat exchangersEngineeringAir conditioning

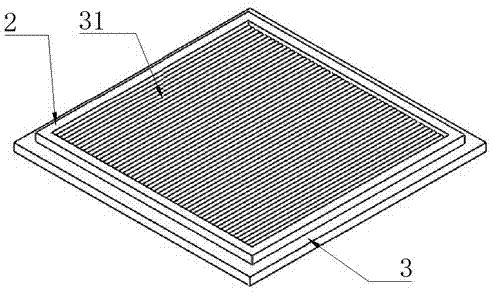

The present invention discloses heat transfer tubes for evaporators in air conditioning and refrigeration systems, comprising: a tube body (1); outer fins (2) extending on an outer wall surface of the tube body (1) and having outer fin walls opposite to the outer fin walls of the adjacent outer fins; channels (6) located between the adjacent fins (2) so as to constitute channel chambers; fin top platforms (3) on respective tops of the outer fins (2), the fin top platforms (3) including fin top edges (3a) extending from both sides of the fin top platforms (3) so that the channel chambers take a form of a cavity structure as a whole; channel chamber openings constituted by gaps between the adjacent fin top edges (3a) of the fin top platforms (3) of the outer fins; and lateral fins (4) arranged on portions or substantially middle portions of the outer fin walls of the outer fins (2) in a height direction of the outer fins (2) and at intervals in an spreading direction of the outer fins (2), so that the cavity structure is formed into a double cavity structure. The heat transfer tube of the present application can achieve the technical effect of producing an excellent boiling heat transfer coefficient and enhancing the boiling heat transfer as well as saving material and reducing the weight of the tube body.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Cooling apparatus with surface enhancement boiling heat transfer

InactiveUS20070230128A1Improve boiling heat transfer efficiencyEasy and flexible coating processSemiconductor/solid-state device detailsSolid-state devicesEngineeringBoiling heat transfer

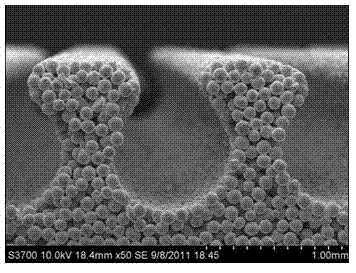

A cooling apparatus boiling and condensing liquid coolant has a vessel including a microporous surface enhancement coating applied on a thermally-conductive plate which is fully immersed under the liquid coolant in the vessel. The surface enhancement coating augments significantly a nucleate boiling heat transfer and critical heat flux when receiving heat from a heating object coupled to the thermally-conductive plate at a surface outside of the vessel. One embodiment of this invention including a vessel with a height / length dimension less than 300 mm, a microporous coating with nickel particles of 30-50 μm in size bonded by a thermally-conductive binder, and water as the liquid coolant, without complicated radiator component, is used for cooling a heating electronics element.

Owner:UNIVERSITY OF TEXAS AT ARLINGTON +1

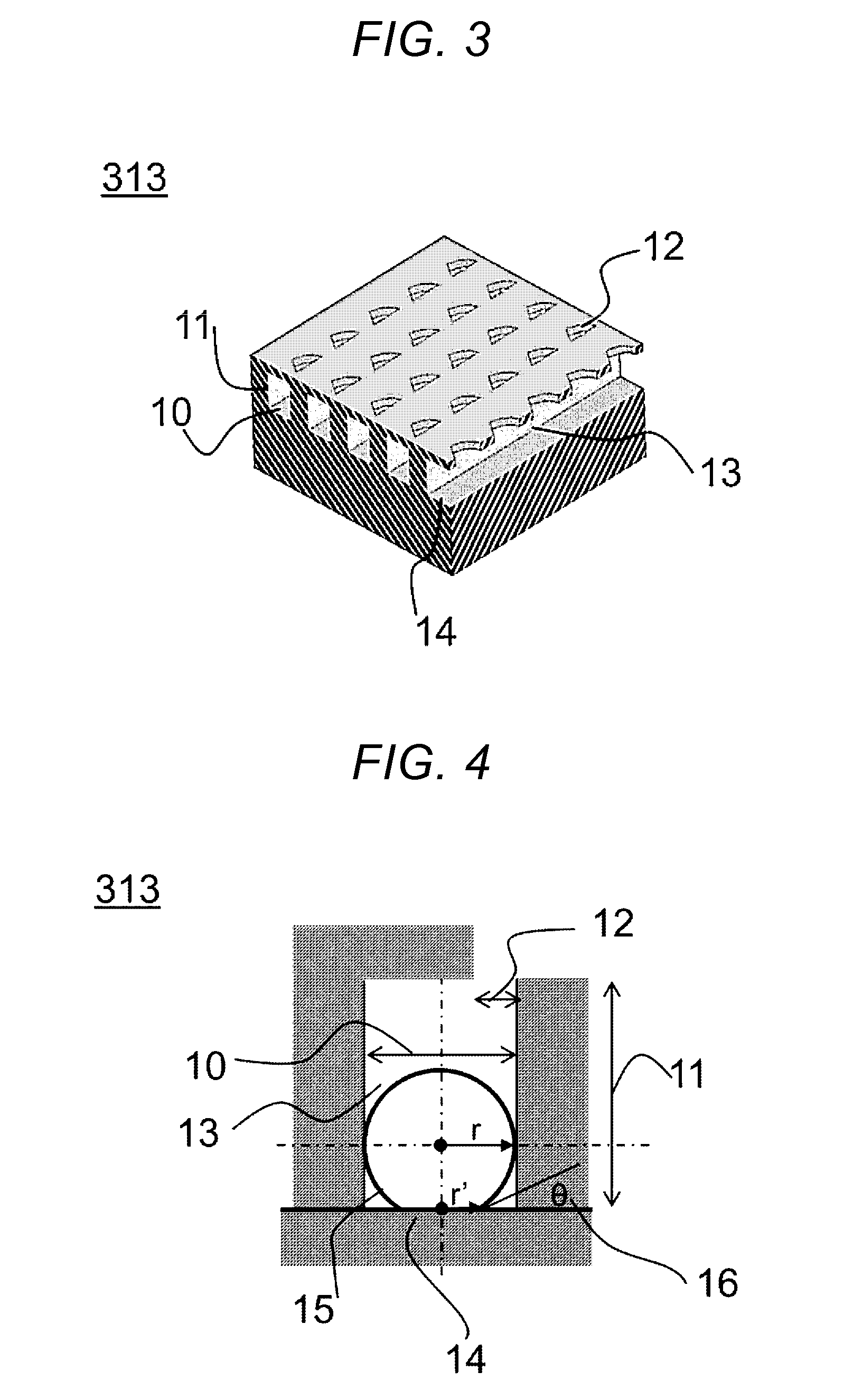

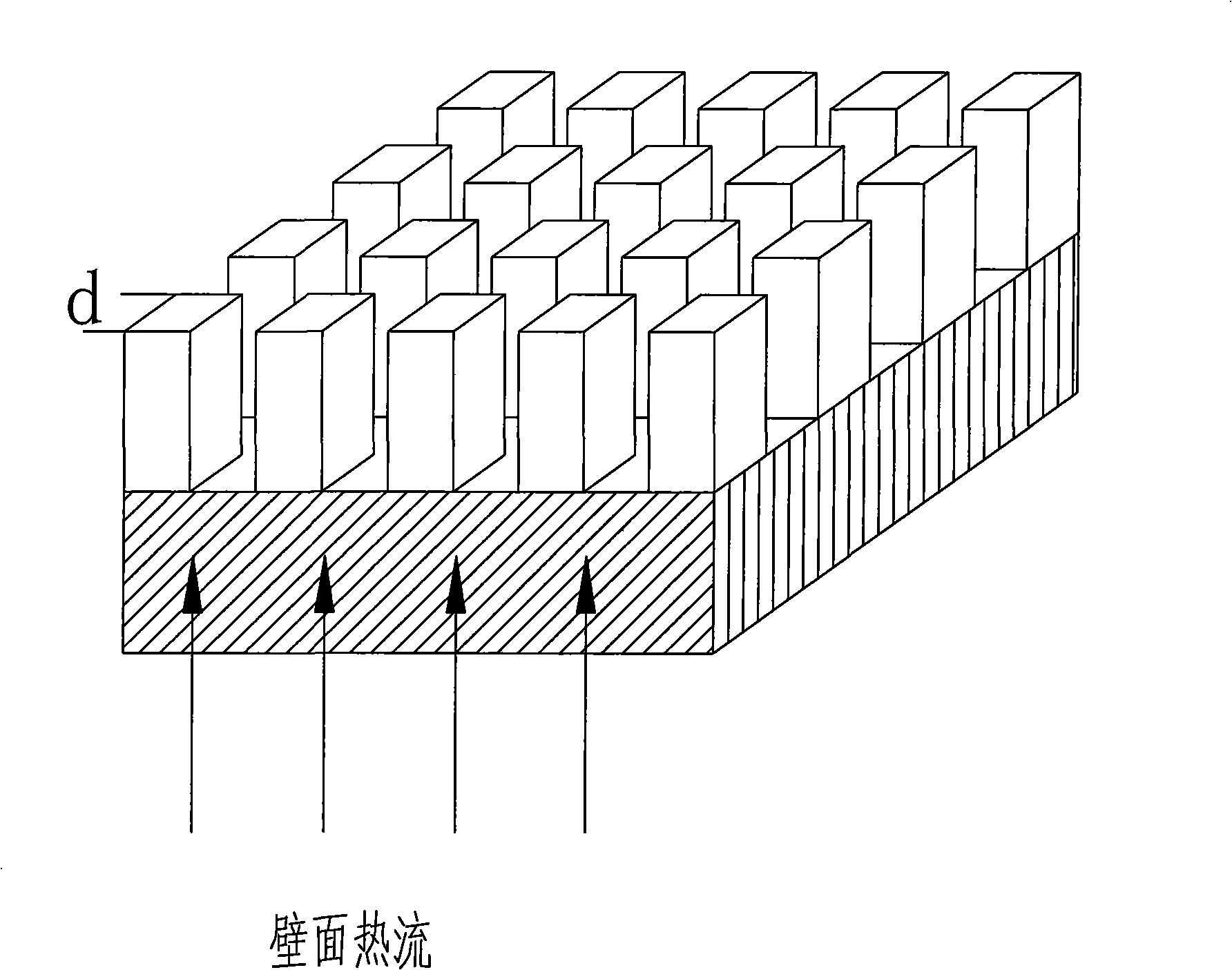

Chip reinforced boiling heat transfer structure of multi-pore microcolumn variable camber molded surfaces

InactiveCN102683305AIncrease the number ofImprove nucleate boiling heat transferSemiconductor/solid-state device detailsSolid-state devicesHeat flowThree dimensional microstructure

The invention relates to an ultra-high heat-flow density reinforced boiling heat transfer technology, in particular to a chip reinforced boiling heat transfer structure of multi-pore microcolumn variable camber molded surfaces, which is suitable for an ultra-high heat-flow density micro-electronic chip efficiently-cooling technology. The chip reinforced boiling heat transfer structure comprises a heat radiating plate on the surface of a chip, and a plurality of multi-pore variable camber molded surface three-dimensional microstructures formed on the heat radiating plate by using foam metal, wherein the multi-pore variable camber molded surface three-dimensional microstructures are arranged in an array form and are of a six-faced shape, the upper surfaces and the lower surfaces of the multi-pore variable camber molded surface three-dimensional microstructures are squares with different sizes, and four side surfaces of the multi-pore variable camber molded surface three-dimensional microstructures are arc surfaces with same shapes. According to the chip reinforced boiling heat transfer structure, enough steam bubble nucleuses of boiling and large specific surface area as well as high heat transfer efficiency are provided, the problem of interaction of a suction function of a capillary pump and synchronous increasing or synchronous reducing of a fluid flow resistance is effectively solved, therefore, ultra-high heat-flow density nucleate boiling heat transfer is remarkably improved, thus effective heat transfer of an ultra-high critical heat-flow density micro-electronic device is ensured.

Owner:XI AN JIAOTONG UNIV

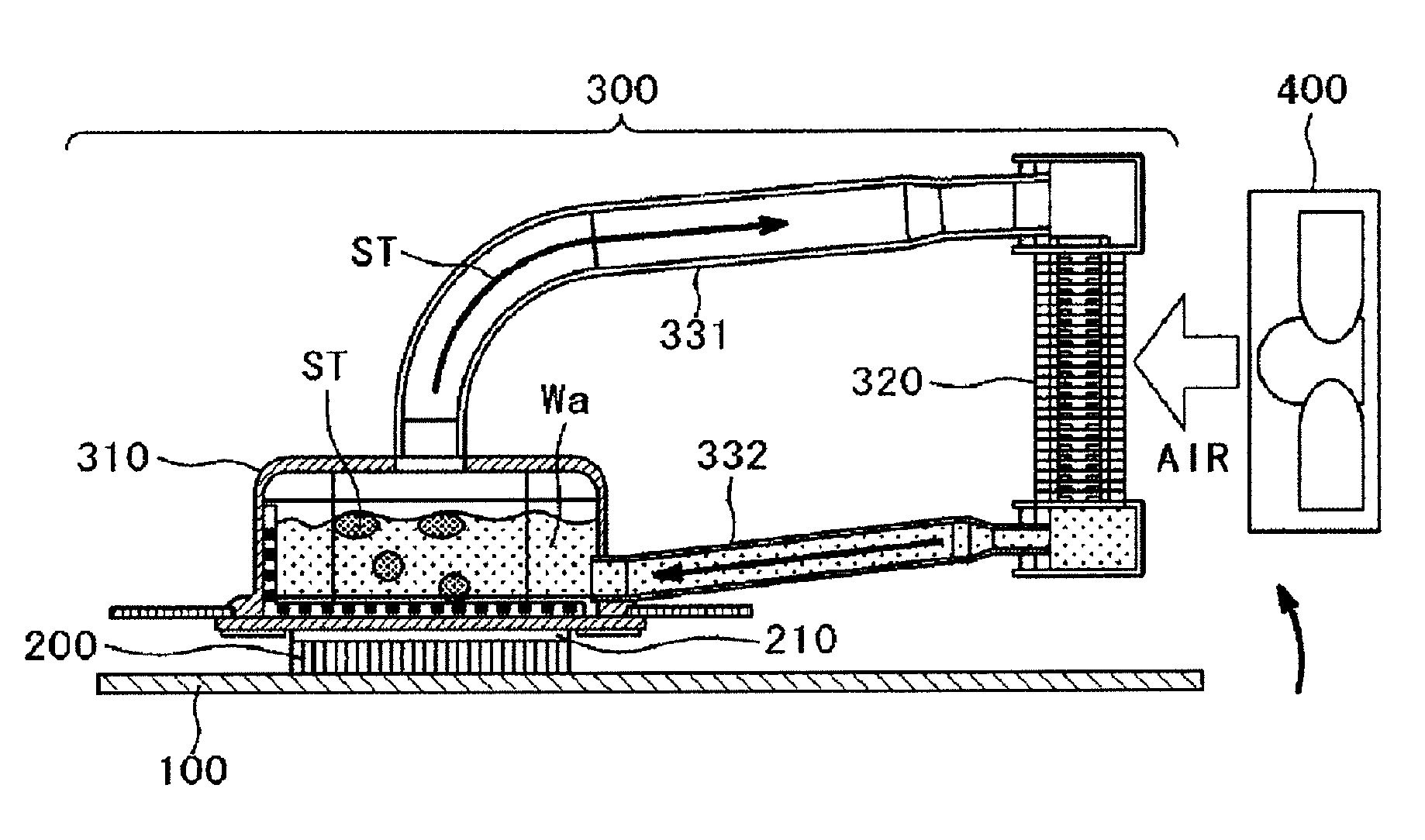

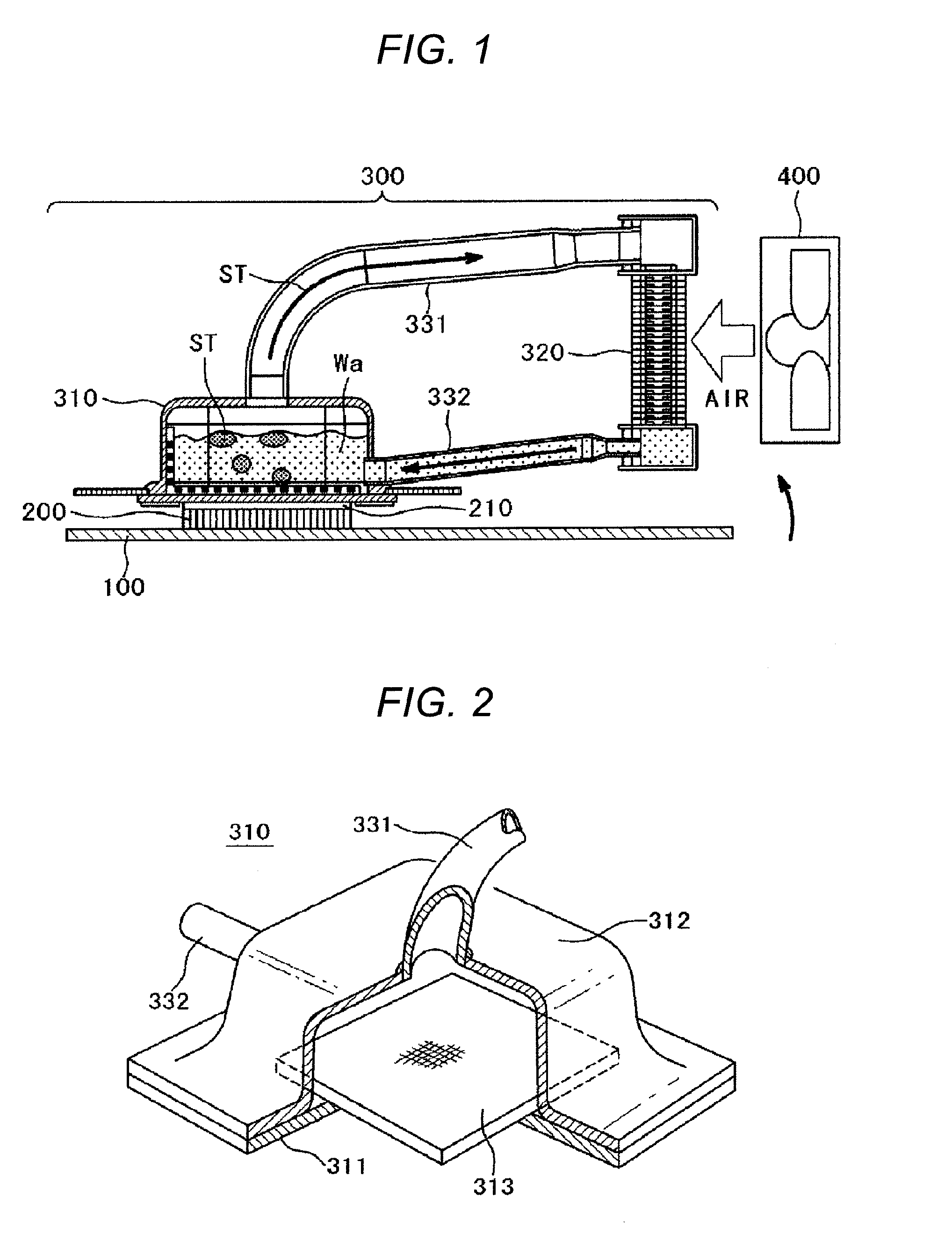

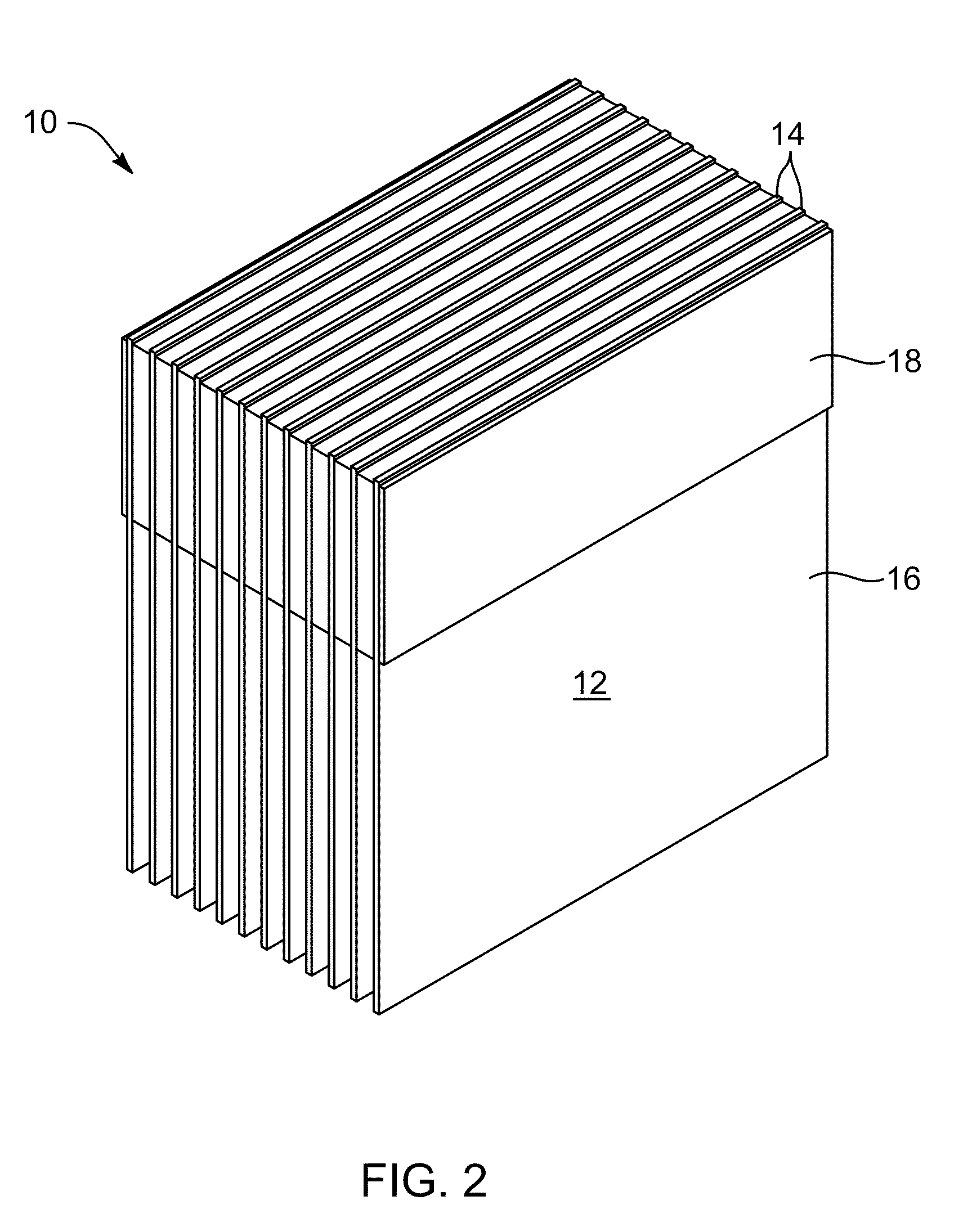

Cooling system and electronic apparatus using the same

InactiveUS20140090814A1Improve heat transfer performanceGenerated heat is relatively largeSemiconductor/solid-state device detailsSolid-state devicesEngineeringBoiling heat transfer

The invention relates to a cooling system and an electronic apparatus using the same, and particularly aims to use a thermosiphon as the cooling system and derives an optimum shape (inter-fin gap, fin height, and fin upper-end hole diameter) of a boiling heat transfer surface for different coolants. In a cooling system using a thermosiphon according to the invention, an optimum shape (inter-fin gap, fin height, and fin upper-end hole diameter) of a boiling heat transfer surface of a heat receiving jacket that forms the cooling system is identified based on a critical radius of a steam bubble produced in an overheated liquid and the diameter of an air bubble departing from the heat transfer surface for a variety of coolants.

Owner:HITACHI LTD

Two-phase-flow, panel-cooled, battery apparatus and method

InactiveUS20100252238A1Eliminate needEnhancing free convectionSemiconductor/solid-state device detailsSolid-state devicesHeat fluxWorking fluid

Two-phase, boiling heat transfer in confined channels close to a source of heat, such as an electrical component or device, carries the latent heat of vapors away to remote locations where “real estate” demands of air convection are tolerable operationally, economically, and technologically. Liquid-to-vapor, phase-change, heat transfer in a narrow channel (e.g., typically less than 0.200 inches total thickness, and often less than 0.150 in the channel itself) improves by several hundred percent the heat extraction from modest temperature (e.g., about 120 degree F.) devices, when compared to heat fluxes in pool boiling. Saturated working fluids provide nearly isothermal conditions in the working fluid. Minimal conduction paths provide minimal temperature gradients, and capillary action may maintain nearly constant temperature conditions about a surface of a heat source, while carrying heat of vaporization away to a condensation location.

Owner:BATTY J CLAIR +1

Inner groove porous strengthened boiling micro-channel structure, manufacture method and application

InactiveCN102878845AHigh transmission frequencyHigh porosityIndirect heat exchangersHeat flowEnhanced heat transfer

The invention discloses an inner groove porous strengthened boiling micro-channel structure, which includes a metal sintered felt formed by sintering metal powder and provided with uniformly-distributed particles, wherein a plurality of inner grooves are uniformly distributed in the metal sintered felt. The porous surface of the inner groove porous strengthened boiling micro-channel structure has excellent capillary characteristics, can keep the wall surface to be sufficiently damp, avoids the local scabbing and polymer deposit caused by hot spot and local drying, improves the heat transfer coefficient and critical heat flux density by adopting the porous structure for strengthened boiling heat transfer, and has excellent strengthened heat transfer effect.

Owner:SOUTH CHINA UNIV OF TECH

Boiling heat transfer device of electronic component

InactiveCN101541159AGood effectAvoid shockSemiconductor/solid-state device detailsSolid-state devicesElectronic componentBoiling heat transfer

The invention relates to the research field of boiling phase change heat transfer, in particular to a boiling heat transfer device of an electronic component. The boiling heat transfer device comprises a cooling plate fixed to the surface of the electronic component, a metal foam layer is sintered or welded on the upper surface of the cooling plate, the metal foam layer is provided with square column type microstructures with the width of 50 micron to 200 micron, and the interval between the square column type microstructures is 50 micron to 200 micron.

Owner:XI AN JIAOTONG UNIV

High power LED phase transition heat sink structure

InactiveCN101315927AEfficient transferImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringTemperature difference

The invention discloses a high-power LED phase-change heat sink structure, the heat sink body of the structure is a circular or square structure with an cavity, a boiling structure and a low temperature boiling heat transfer working medium are arranged in the cavity, a sealing end cover is arranged at the upper end of the heat sink body and tightly connected with the heat sink body, thus forming the closed cavity, the inner surface of the sealing end cover is a condensation structure, and the cavity is sealed into the vacuum state; at least one high-power LED chip is fixed at the lower end of the outside of the heat sink body, an electrode is arranged outside of the phase-change heat sink, the phase-change heat sink, the electrode and a lens are connected by packaging resin, and the high-power LED chip is directly connected with the electrode by a gold wire. The high-power LED phase-change heat sink structure utilizes the liquid-gas phase change of the working medium to realize the isothermal effect of the heat sink body to reduce the temperature difference at upper and lower ends of the heat sink, thus effectively conducting the generated heat of the high-power LED chip out, realizing the integration of the high-power LED and a high-efficiency heat radiating device and having the advantages of light weight, high power, simple structure, high heat radiation efficiency, long service life and no consumption of additional energy, etc.

Owner:SOUTH CHINA UNIV OF TECH

Coupling heat transfer method of array jet and boiling cooling under high heat flux

ActiveCN102271485AReduce temperature riseMeet cooling needsCooling/ventilation/heating modificationsWorking fluidEngineering

The invention discloses a coupling heat exchange method of array jet flow and boiling cooling under the condition of high heat flux, which combines single-phase array jet impact cooling and boiling heat exchange, and uses the latent heat of evaporation of cooling liquid to remove the heat of electronic devices, that is, selects the boiling point For the coolant at -20°C-30°C, by controlling the pressure of the working fluid at -0.5bar-10bar, the boiling point temperature in the required range is obtained, and the coolant is pumped to the array jet impact device, and the jet flow through the jet hole is in heat exchange On the surface, the temperature and pressure of the cooling liquid are controlled at the same time, so that the cooling liquid partially undergoes a phase change after the jet heat exchange, and the latent heat of vaporization of the cooling liquid is used to dissipate heat. The entire array jet flow, boiling cooling coupled heat transfer process. The invention realizes the heat dissipation of the electronic device under the condition of high heat flux density, thereby meeting the heat dissipation requirement of the electronic device under the condition of high heat flux density, effectively controlling the temperature of the electronic device, and meeting the working temperature requirement of the electronic device.

Owner:NANJING UNIV OF SCI & TECH

Composite hydrophilic/hydrophobic enhanced boiling heat transfer sheet with columnar microstructure

ActiveCN106102414AExtended service lifeHave mechanical strengthModifications using liquid coolingNucleationBoiling heat transfer

The invention discloses a composite hydrophilic / hydrophobic enhanced boiling heat transfer sheet with a columnar microstructure. The composite hydrophilic / hydrophobic enhanced boiling heat transfer sheet comprises a hydrophobic region in a columnar micro-structural array and a smooth hydrophilic channel and is used for enhancing a boiling heat transfer process. The columnar microstructure of the micro-structural array can capture incondensable gas and provide a nucleation site of nucleate boiling in the boiling heat transfer process; steam bubbles grow in the hydrophobic region, slip and retain in the hydrophilic channel, gather and combine; when diameters of the steam bubbles increase to the order of magnitude of a width of the smooth hydrophilic channel, the steam bubbles separate from a smooth surface rapidly. Thus the separation of the steam bubbles is effectively promoted while the efficient heat transfer performance on the surface of the columnar microstructure is retained on a surface of the heat transfer sheet, and the wall superheat is reduced and the phenomenon of a boiling crisis is delayed.

Owner:XI AN JIAOTONG UNIV

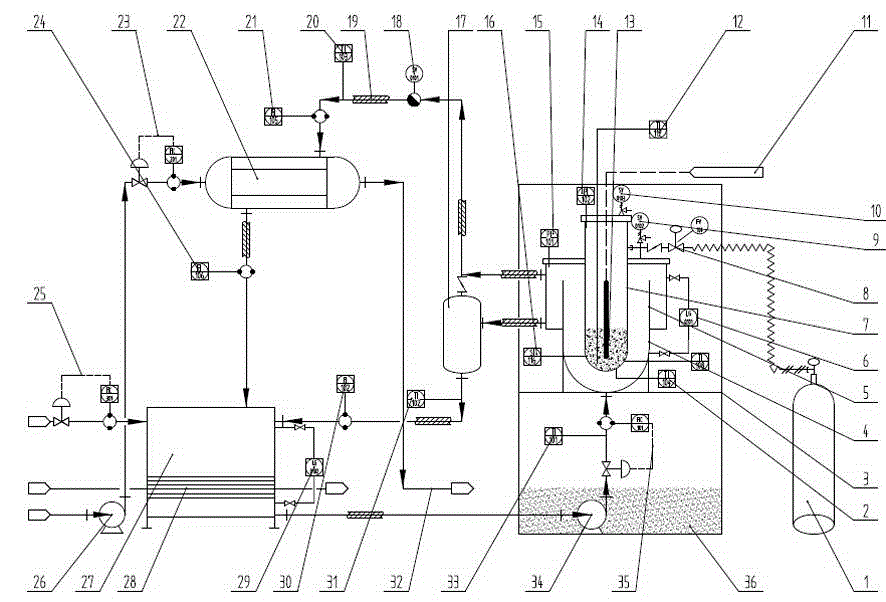

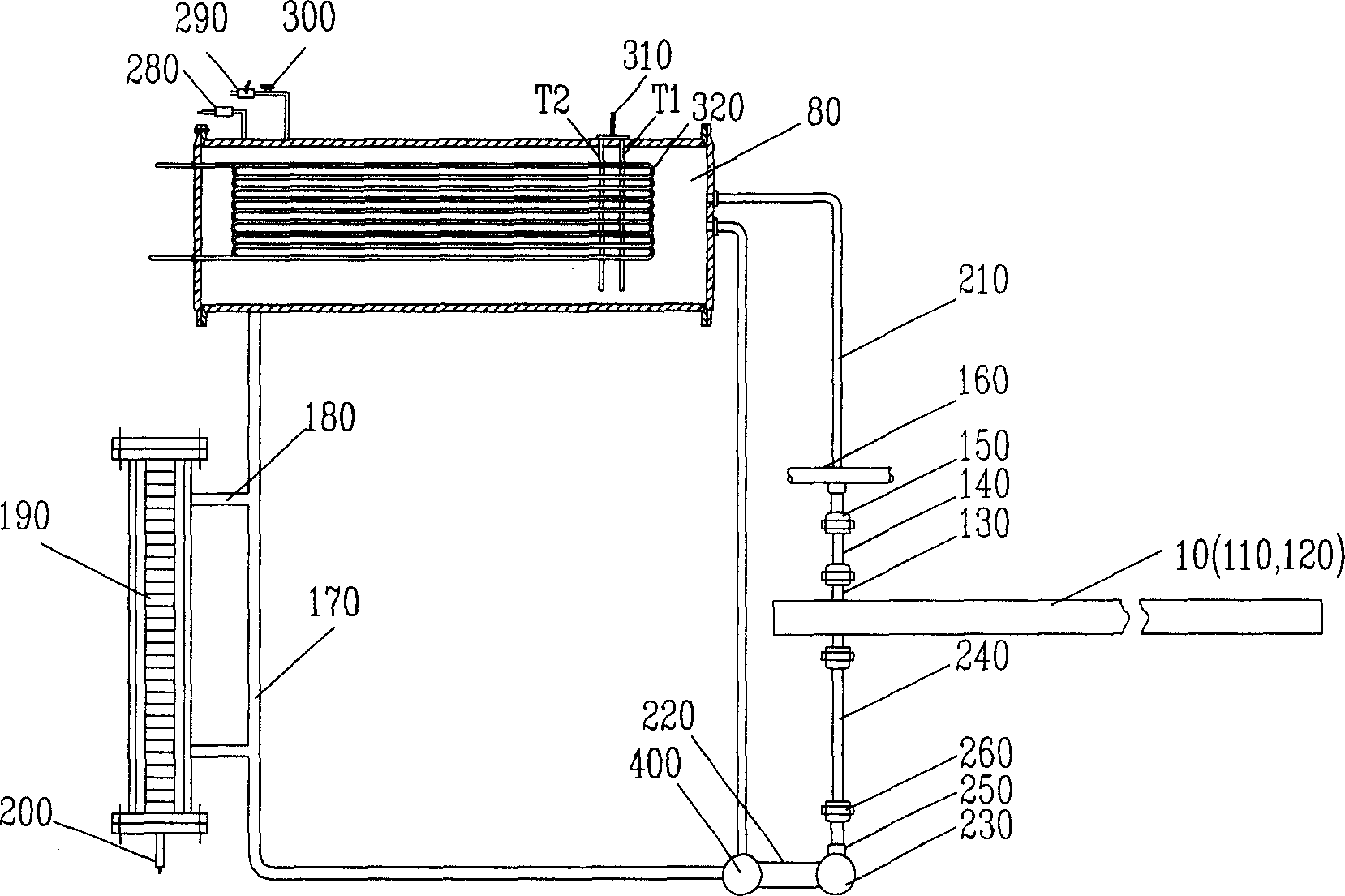

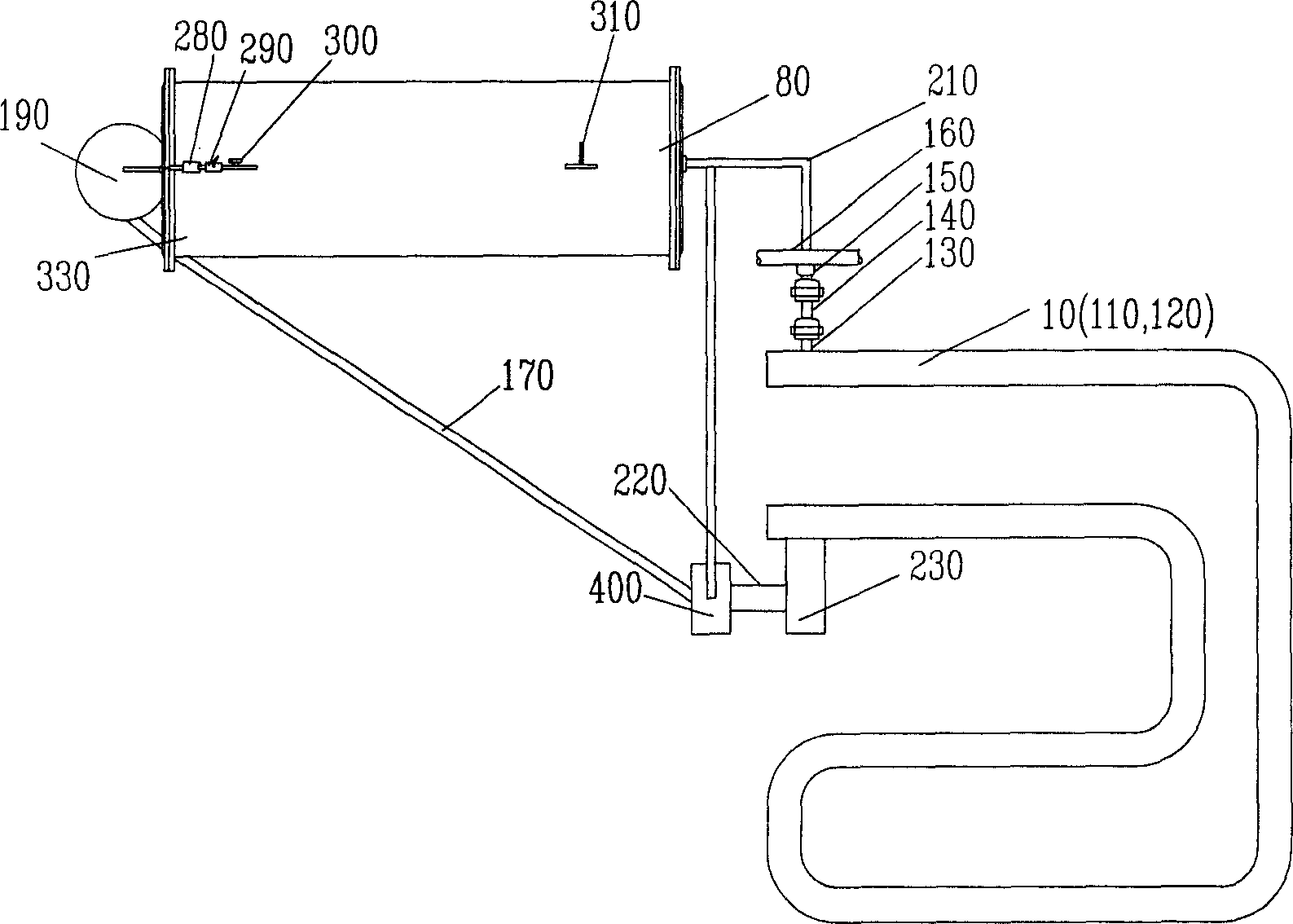

Platform for testing structural integrity of reactor pressure vessel under IVR condition

ActiveCN104979025AStructural Integrity GainedThe heat transfer properties are obtainedNuclear energy generationNuclear monitoringReactor pressure vesselData acquisition

The invention discloses a platform for testing the structural integrity of a reactor pressure vessel under an IVR condition. The platform comprises a working condition simulation system, a data acquisition and analysis system, and a safety system. The working condition simulation system is provided with a water supply unit, a steam condensing unit, and a heating unit; the data acquisition system is composed of measuring elements of each unit; and the safety system is arranged on the periphery of the working condition simulation system. The boiling heat transfer process in a reactor pressure vessel can be simulated by controlling the water flow of a cooling unit and the heating power of a hot pool simulation unit; by measuring and simulating the wall temperature, strain, and pressure, the heat transfer characteristics of a reactor pressure vessel can be simulated and analyzed; a referential model is provided for the boiling heat transfer tests on a reactor pressure vessel; and the test platform has a simple and compact structure, can carry out structural integrity analysis on a simulated reactor pressure vessel, comprises a nitrogen gas pressurizing unit, thus can also carry out analysis on the heat transfer characteristics of a pressurized reactor pressure vessel, and has a wide application range.

Owner:ZHEJIANG UNIV OF TECH

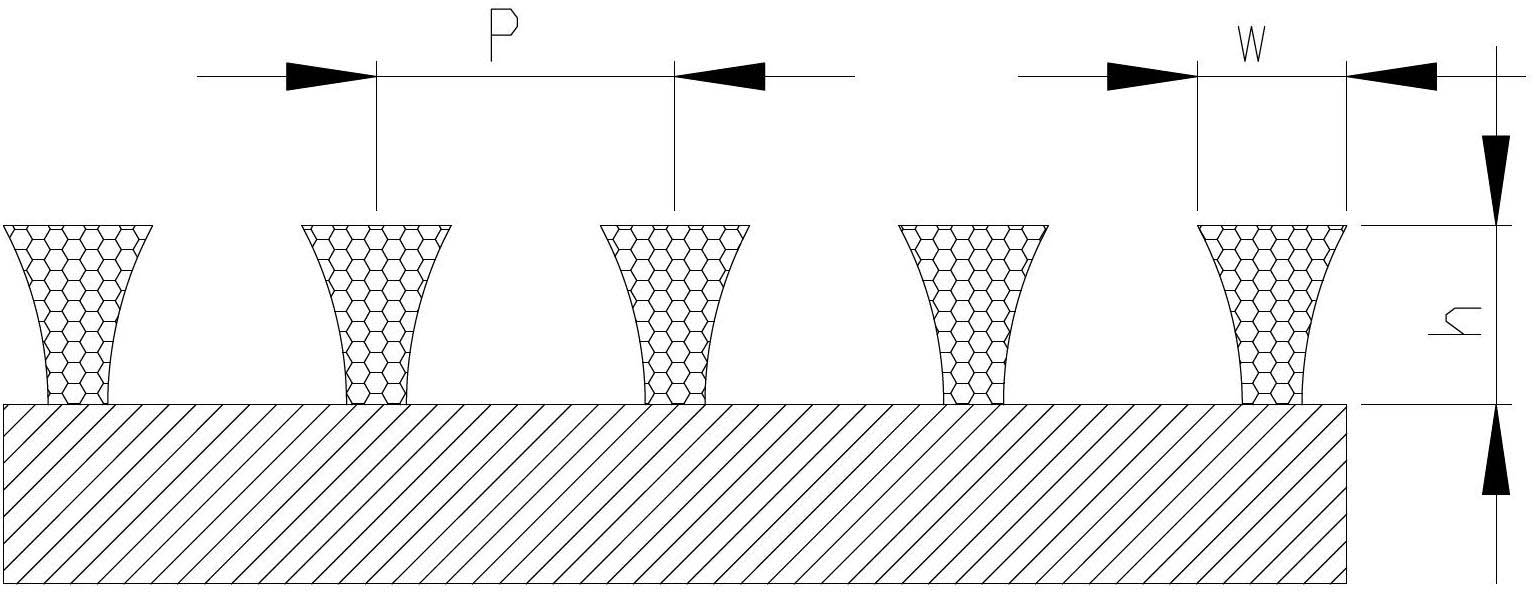

Porous coatings

ActiveUS20170108148A1Chemical industryMetallic material coating processesPorous coatingAir separation

A porous metallic coating is provided. The coating is characterized by a combination of optimized properties that improve coating performance, as measured by heat transfer efficiency. The porous coating has optimal ranges for properties such as porosity, particle size and thickness, and has particular applicability in boiling heat transfer applications as part of an air separations unit. The porous coatings are derived from slurry-based formulations that include a mixture of metallic particles, a binder and a solvent.

Owner:PRAXAIR TECH INC

High efficiency heat radiation cool plate for electronic device

InactiveCN101052290ASolve the cooling problemCompact structureSemiconductor/solid-state device detailsSolid-state devicesCondensation processEvaporation

The invention comprises: a cold plate with 3D saw tooth-like fins and a surface evaporation plate with multi holes whose bottoms are connected each other with micro channels; the cold plate with 3D saw tooth-like fins is welded with the surface evaporation plate to form a sealed room filled out with working materials. The 3D saw tooth -like fins triggers the turbulent motion of gas and enhances the condensation process; the multi holes structure improves the heat conduction efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Heat radiation packaging for high power LED

InactiveCN1828956AIncrease powerImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyBoiling point

The present invention relates to high power LED heat radiation packaging technology field. It contains LED, heat sink realized adopting phase transition boiling heat transfer mode, LED packaging body adopting epoxy and heat tube integrated packaging, heat sink also capable of container having low-boiling point liquid, heat generated in LED packaging body taken by vaporizing low-boiling point liquid, heat sink also capable of adopting liquid drop impulsion. Said invention greatly raises heat transfer rate, improving LED heat-sinking capability to external environment and raising single LED packaging unit power.

Owner:胡志国

Composite electronic chip cooling and boiling heat transfer enhancement experiment device

InactiveCN103033535AReduce superheatGuaranteed contactMaterial heat developmentSmall footprintEngineering

The invention relates to a composite electronic chip cooling and boiling heat transfer enhancement experiment device, which comprises a peripheral pump, wherein the outlet of the peripheral pump is connected with a total flow meter inlet; a total flow meter outlet is divided into two paths, one path passes through a jet branch to enter the flow jet segment of a composite boiling experiment box, and the other path is further divided into two paths; one path passes through a transverse flow branch to enter the flow jet segment of the composite boiling experiment box, and the outlet of the flow jet segment of the composite boiling experiment box is connected with the boiling segment of the composite boiling experiment box; the other path directly enters the boiling segment of the composite boiling experiment box, and the outlet of the boiling segment of the composite boiling experiment box is connected with the inlet of a heat transfer device; the outlet of the heat transfer device is connected with the peripheral pump; and a circle is completed. The device combines the advantages of pool boiling, pure flow boiling, pure jet impact boiling and flow jet composite boiling heat transfer, and has the advantages of flexibility in operation, simplicity in control, small occupied area and short experimental period.

Owner:XI AN JIAOTONG UNIV

Micro-channel boiling heat transfer system and method based on vapor-liquid multiphase fluid staggered division

PendingCN110282596AIncrease the number ofIncrease contact areaDecorative surface effectsSemiconductor/solid-state device detailsVapor liquidThermal instability

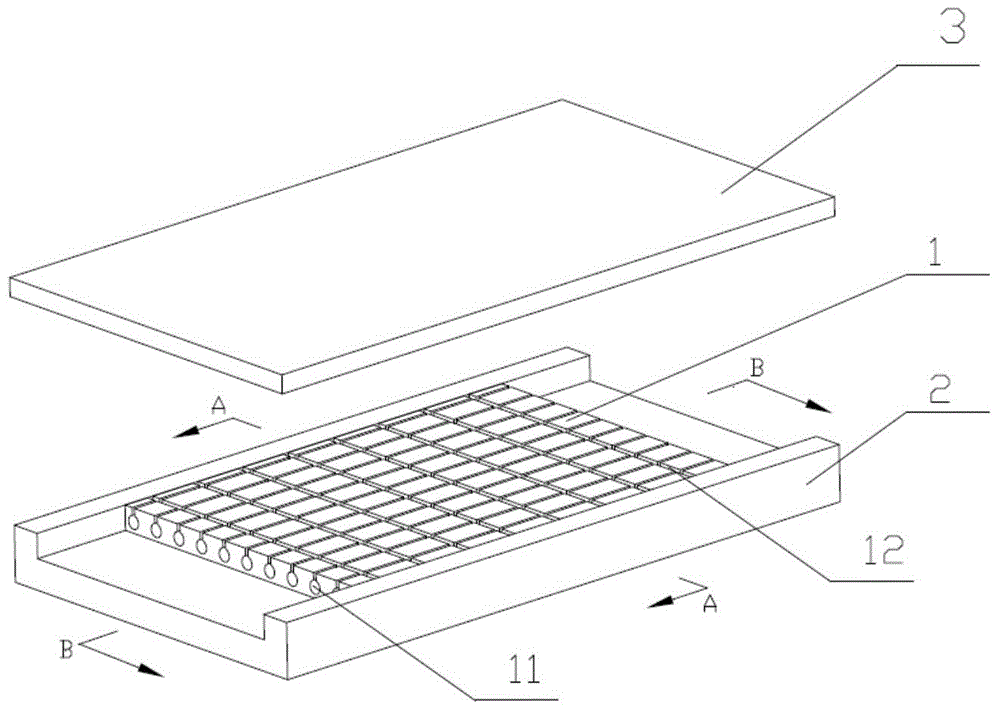

The invention discloses an enhanced heat transfer system and method, and belongs to the field of micro evaporators. The enhanced heat transfer system is composed of an upper cover plate, a periodic staggered micro-channel array plate and a simulation heat source. A liquid working medium enters the staggered micro-channel array and is heated to generate gas-liquid phase change, the gas-liquid two-phase working medium is periodically divided in the staggered micro-channel array, and meanwhile, five types of enhanced heat transfer modes are realized: (1) the gas-liquid contact area is increased through gas-phase division, so that latent heat exchange is increased; (2) superheated liquid energy is released from more gas-liquid interfaces, so that the interface expansion rate is reduced, and flow and thermal instability caused by rapid expansion of the interface are fundamentally inhibited; (3) bubble segmentation delays heat transfer deterioration caused by the fact that a large-area steam film covers a heating surface; (4) a bubble tail turbulent flow area is increased, and convection heat exchange is enhanced; and (5) periodical separation and re-development of the heat boundary layer of the near-wall area occur through periodical division of the liquid phase, the heat exchange resistance of the near-wall area is remarkable, and convection heat exchange is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

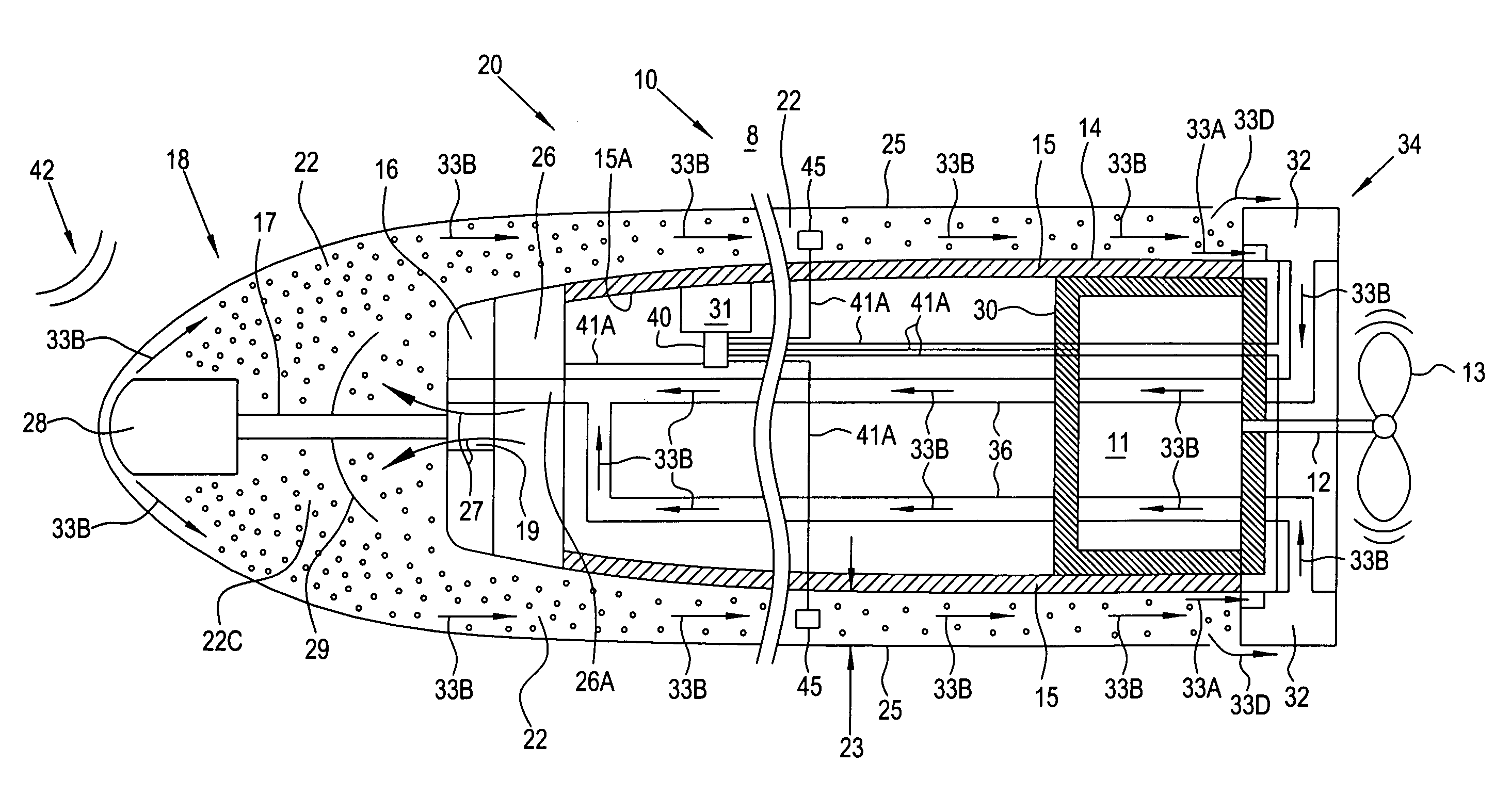

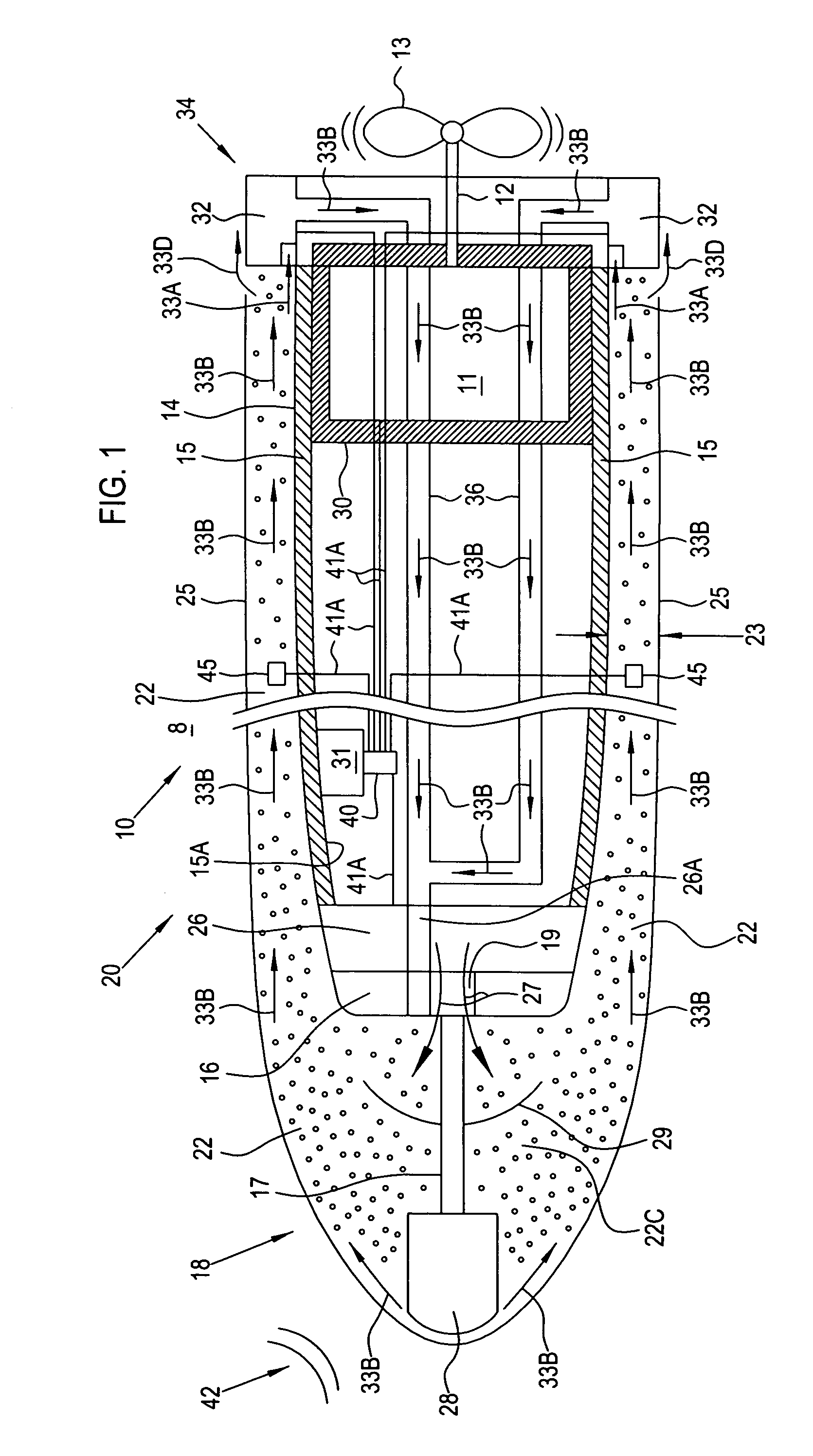

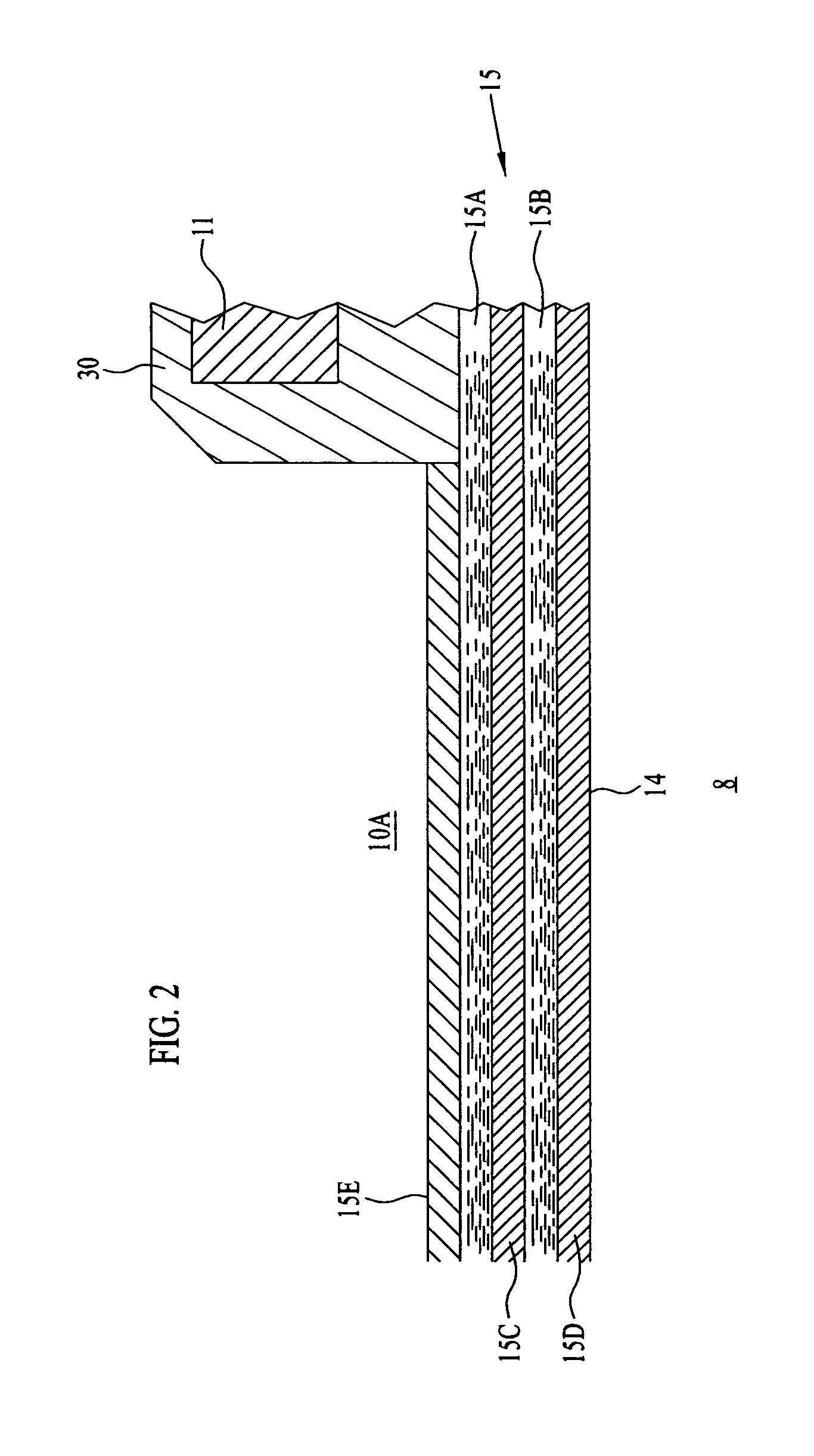

Boiling heat transfer torpedo

InactiveUS6962121B1Improve efficiencyReduce resistanceMarine torpedoesSelf-propelled projectilesAmbient waterEngineering

A system has a source of gas venting gas at a nose portion of the vehicle to create a gas / vapor cavity on the nose portion and an adjacent hull of the vehicle. A thermal engine propelling the vehicle through ambient water creates waste heat for heating the hull to raise the temperature of the gas / vapor cavity extending over it. A pump aft on the vehicle recirculates a portion of the gas / vapor cavity as recirculated gas to the nose portion. The velocity of the recirculated gas of the gas / vapor cavity is controlled by the pump to be virtually the same as the relative flow rate of the ambient water along an interface boundary between the gas / vapor cavity and the ambient water.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Micro-channel heat exchanger with staggered inner groove structure and manufacturing method of micro-channel heat exchanger

ActiveCN104154777AImprove distributionIncrease heat transfer areaStationary conduit assembliesHeat transfer modificationPlate heat exchangerEngineering

The invention discloses a micro-channel heat exchanger with a staggered inner groove structure and a manufacturing method of the micro-channel heat exchanger. The micro-channel heat exchanger with the staggered inner groove structure comprises a metal micro-channel substrate, wherein the metal micro-channel substrate comprises a plurality of longitudinal micro-channels and a plurality of transverse micro-channels; the longitudinal micro-channels are arrayed in parallel along a cooling liquid flowing direction; the transverse micro-channels are perpendicular to the longitudinal micro-channels; the longitudinal micro-channels and the transverse micro-channels are arranged at intervals; the micro-channels are in the shape of an inner groove; each micro-channel comprises an inlaid groove body and a slit; the inlaid groove bodies are positioned in the substrate; an opening position of the substrate is formed by the slits; and each inlaid groove body is connected with the corresponding slit. When the micro-channel heat exchanger is manufactured, the longitudinal inner groove micro-channels are machined along the liquid flowing direction in a linear cutting manner; after a workpiece rotates at an angle of 90 degrees, the transverse inner grooves are machined in a linear cutting manner, so that a crisscross micro-channel array is obtained; and the micro-channels are packaged by heat-resistant glass, and the staggered inner groove micro-channel heat exchanger is formed. The manufacturing process is simple and is low in cost; a thermal boundary layer is developed intermittently, and the heat transfer area is increased; and moreover, by the inner groove structure, boiling nucleation can be remarkably facilitated, and boiling heat transfer is strengthened, so that heat transfer is strengthened integrally.

Owner:XIAMEN UNIV

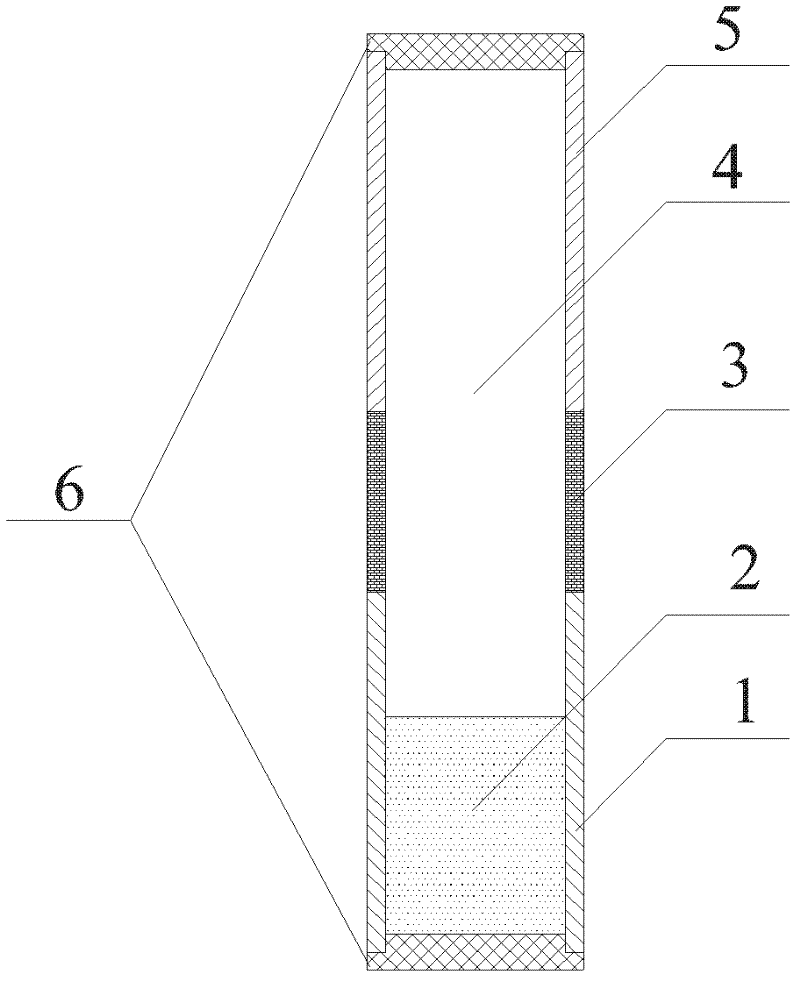

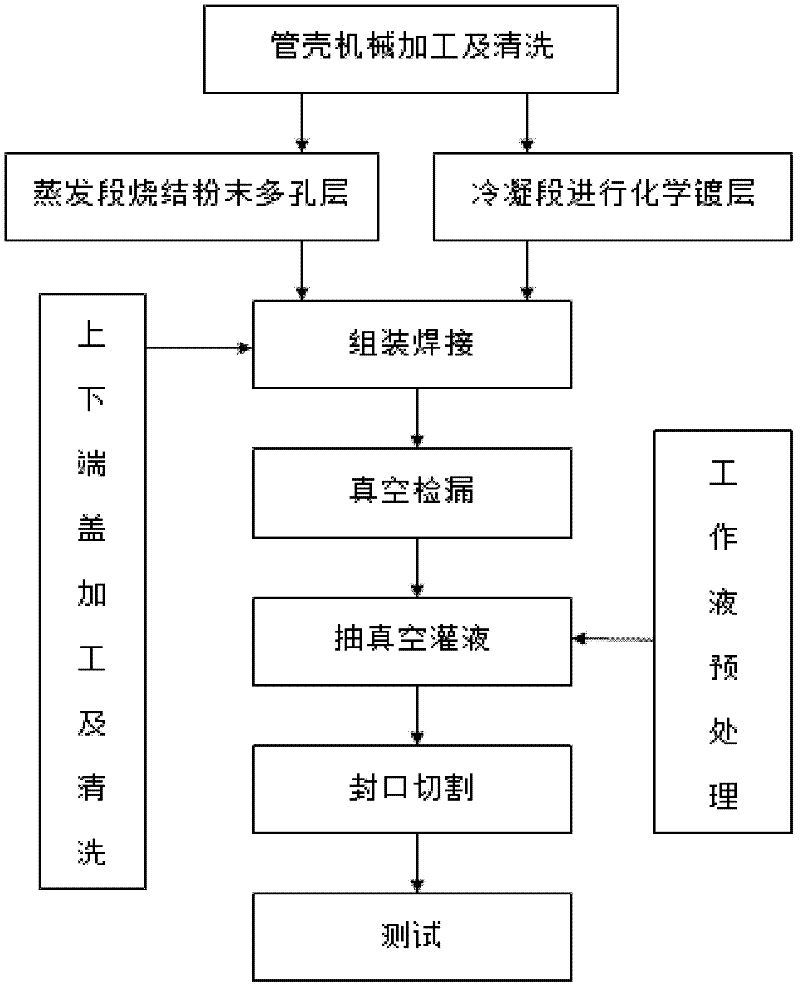

High-efficiency gravity heat pipe and manufacturing method thereof

ActiveCN102445097AContinuous boiling phenomenonEnhanced boiling heat transferIndirect heat exchangersLiquid/solution decomposition chemical coatingFree energiesPorous layer

The invention relates to a high-efficiency gravity heat pipe and a manufacturing method thereof. The high-efficiency gravity heat pipe comprises an evaporating section, a heat insulating section and a condensing section, and is characterized in that a metal powder porous layer is sintered on the inner surface of the heat tube evaporating section, and the condensing section is chemically coated. The heat tube manufactured by the process method in the invention can simultaneously reinforce boiling heat transfer and condensing heat transfer, so that a plurality of ideal vaporization cores are artificially increased, thus the boiling phenomenon of the liquid is continuously carried out to achieve a purpose of reinforcing the boiling heat transfer; on the other hand, the surface of a chemical coating of the heat tube condensing section is modified to acquire a low surface free energy value; simultaneously, the coating layer is a metal-based coating layer with good thermal conductivity, thus the condensing heat transfer can be reinforced; from the above, the high-efficiency gravity heat tube reinforce the boiling and condensing effects very remarkably, has the characteristics of good heat transfer reinforcing effect, high production efficiency, low cost and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

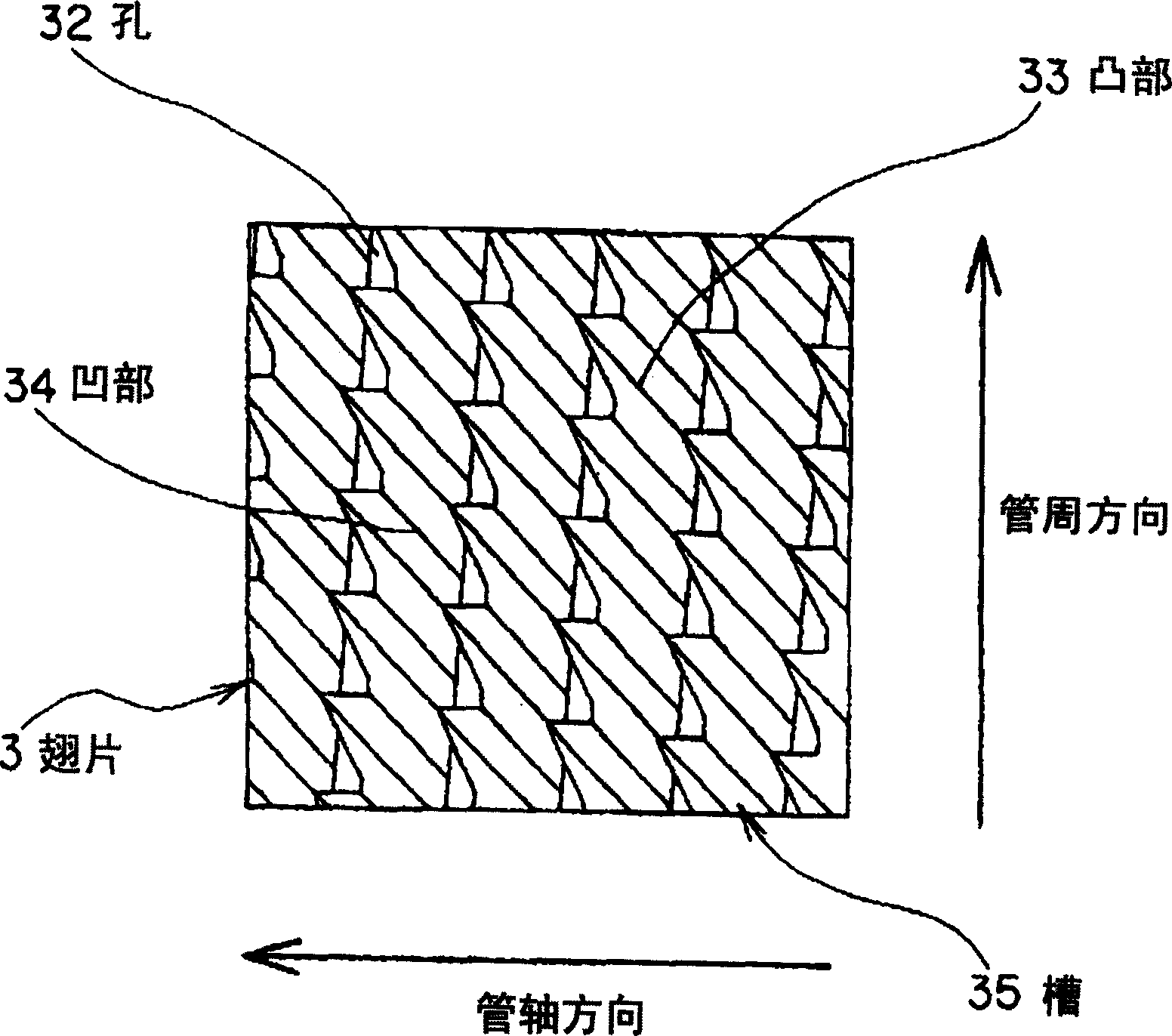

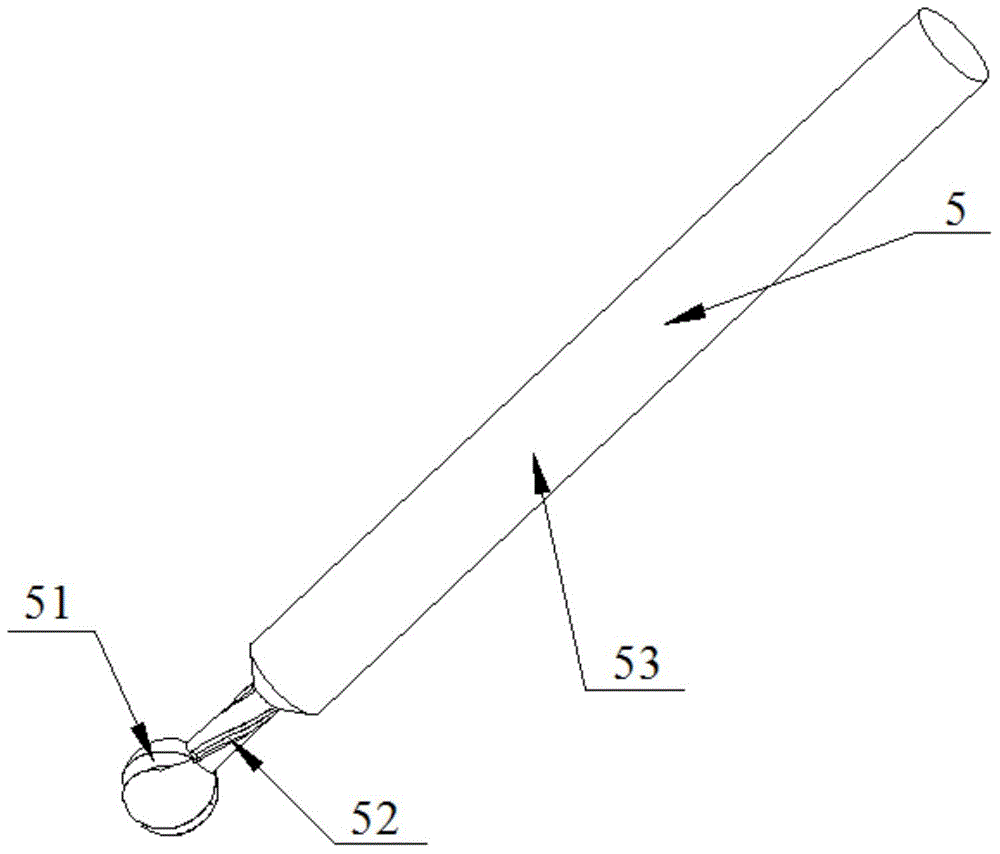

Boiling heat-transfer tube and making method thereof

InactiveCN1624412ASmooth disengagementAchieve high performanceEvaporators/condensersMetal-working apparatusRefrigerantBoiling heat transfer

PROBLEM TO BE SOLVED: To provide a boiling heat transfer tube having improved heat transfer performance by improving the wettability of refrigerant liquid to accelerate nuclear boiling, and to provide its manufacturing method. SOLUTION: On the outer peripheral face of a tube 2, fins 3 are formed by continuing spading and bending in such a manner that a spiral or annular cavity portion 31 is formed in the circumferential direction thereof. At the front ends of the fins 3, grooves 35 are formed with protruded portions 33 and recessed portions 34 by using a grooved roll for applying suppressing pressure. The grooves 35 have holes 32 at preset spaces in communication with the outside (refrigerant liquid). COPYRIGHT: (C)2005,JPO&NCIPI

Owner:HITACHI CABLE

Boiling refrigerant type cooling system

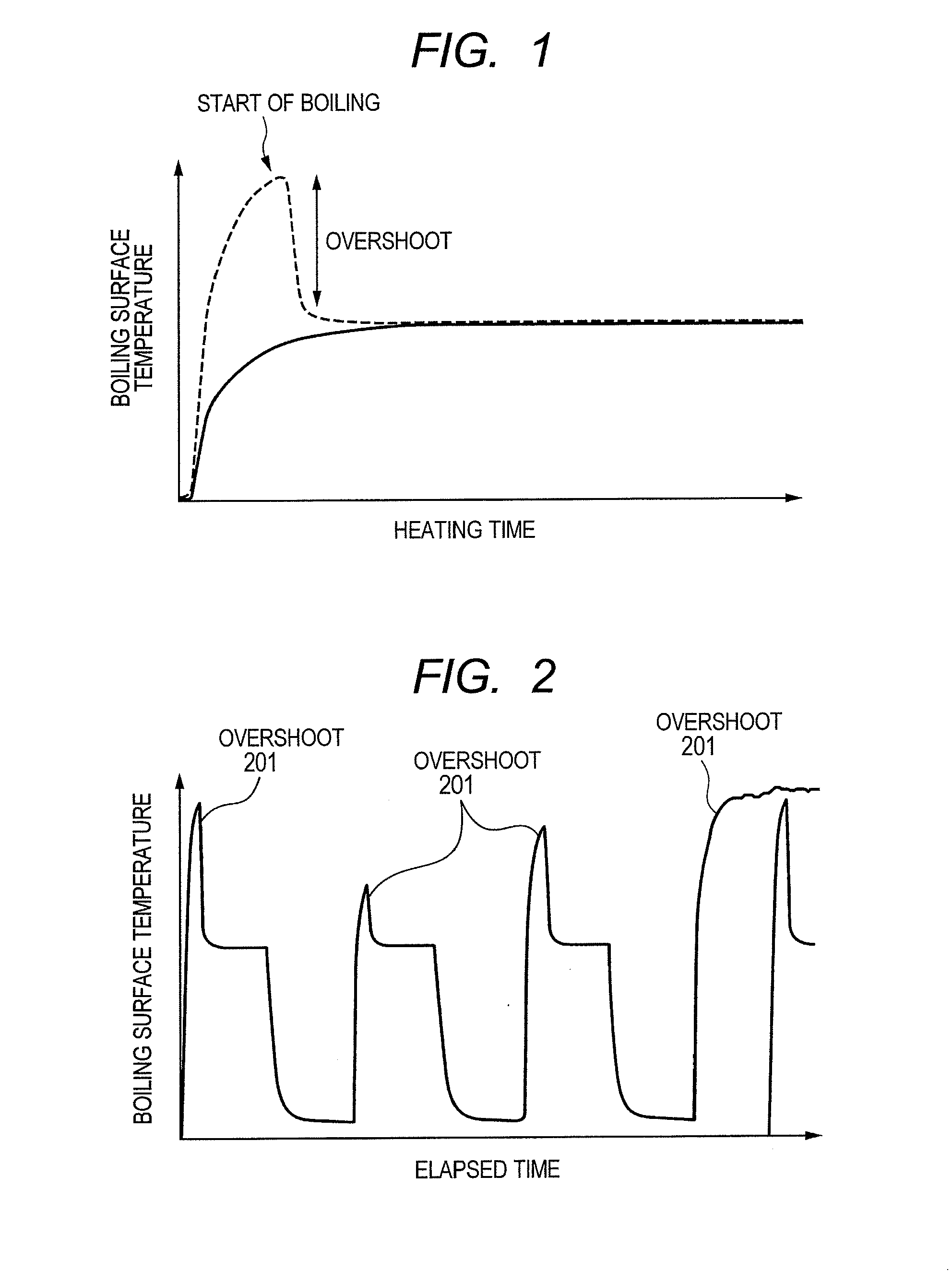

InactiveUS8929073B2Smooth startSuppress overshootSemiconductor/solid-state device detailsEvaporators/condensersEngineeringThermal contact

Owner:HITACHI LTD

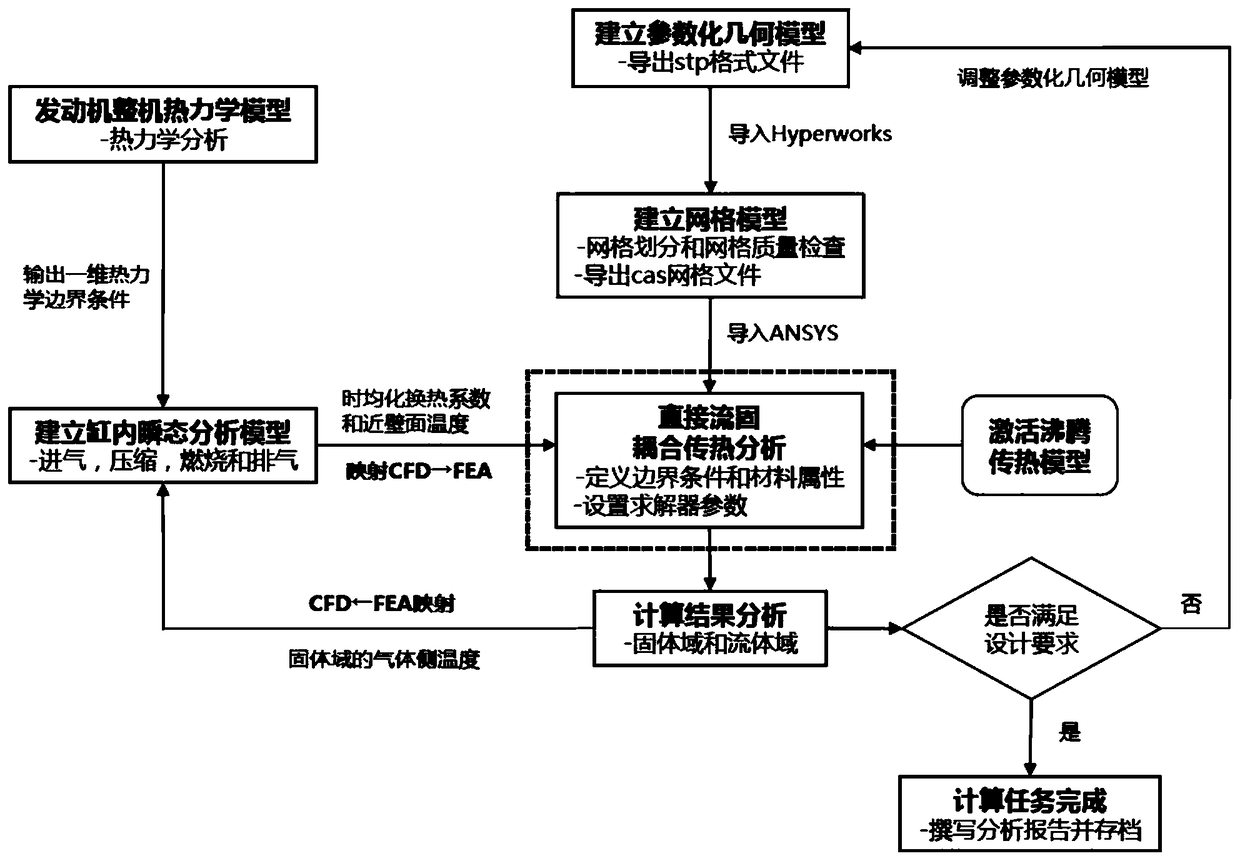

A direct fluid-solid coupling heat transfer analysis method for engine cooling water jacket

ActiveCN108984920ASolve crackingExtended service lifeGeometric CADSustainable transportationSolid regionCoolant flow

The invention discloses a direct fluid-solid coupling heat transfer analysis method for an engine cooling water jacket. The method comprises the following steps: 1, establishing a solid domain and a fluid domain parametric geometric model; 2, carrying out grid partition and grid quality inspection; 3, defining material attributes; 4, defining boundary conditions; 5, defining a coupling heat transfer interface; 6, setting solver parameters; 7, carrying out direct fluid-solid coupling heat transfer analysis considering boiling heat transfer and obtaining calculation results. The method can compensate for the inability to effectively evaluate the heat transfer process and the coolant flow condition between the solid region and the fluid region in a conventional engine cooling water jacket design process, and the method avoids the risk of cracking failure caused by the high temperature of the bridge area of the cylinder head fire surface.

Owner:ANHUI JIANGHUAI NAVISTAR DIESEL ENGINE CO LTD

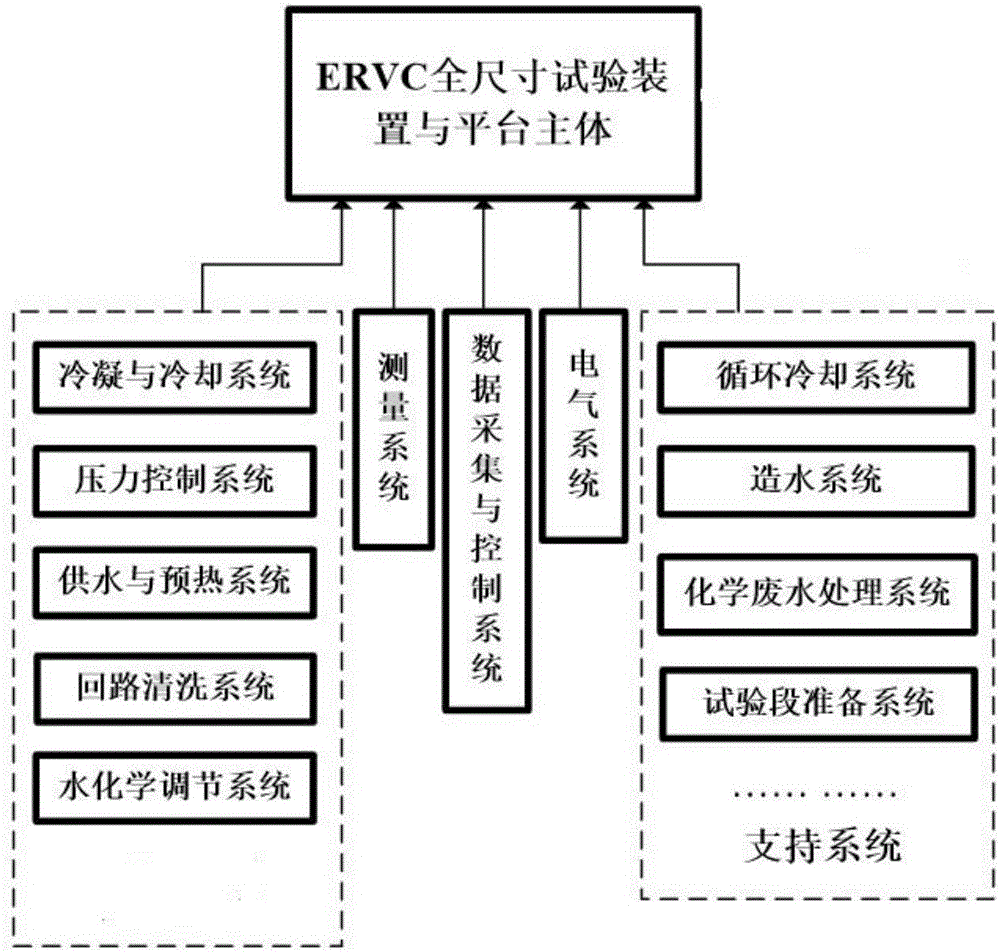

External-cooling full-height comprehensive test platform for large-scale advanced reactor pressure vessel

InactiveCN106653110AImprove flow characteristicsImprove heat transfer characteristicsNuclear energy generationNuclear monitoringTemperature controlReactor pressure vessel

The invention provides an external-cooling full-height comprehensive test platform for a large-scale advanced reactor pressure vessel. The test platform comprises a main device loop system, a condensing and cooling system, a water supply and preheating system, a water chemistry adjusting system and a pressure control system, the condensing and cooling system is used for controlling and adjusting temperature of primary fluid in an upper water tank of the main device loop system and providing circularly cooling for test water in the upper water tank, the water supply and preheating system is used for providing the test water to the main device loop system, initially preheating the test water and keeping temperature, the water chemistry adjusting system is communicated with a lower water tank of the main device loop system and used for controlling solute and concentration of water chemistry solution in different tests, and the pressure control system is used for controlling pressure of the upper water tank. According to the test platform, engineering verification test of value and distribution of boiling heat transfer limit CHF (critical heat flux) of the outer wall of a lower sealing head of the pressure vessel can be determined when IVR-ERVC (in-vessel retention-external reactor vessel cooling) is implemented under severe accident conditions.

Owner:SHANGHAI JIAO TONG UNIV

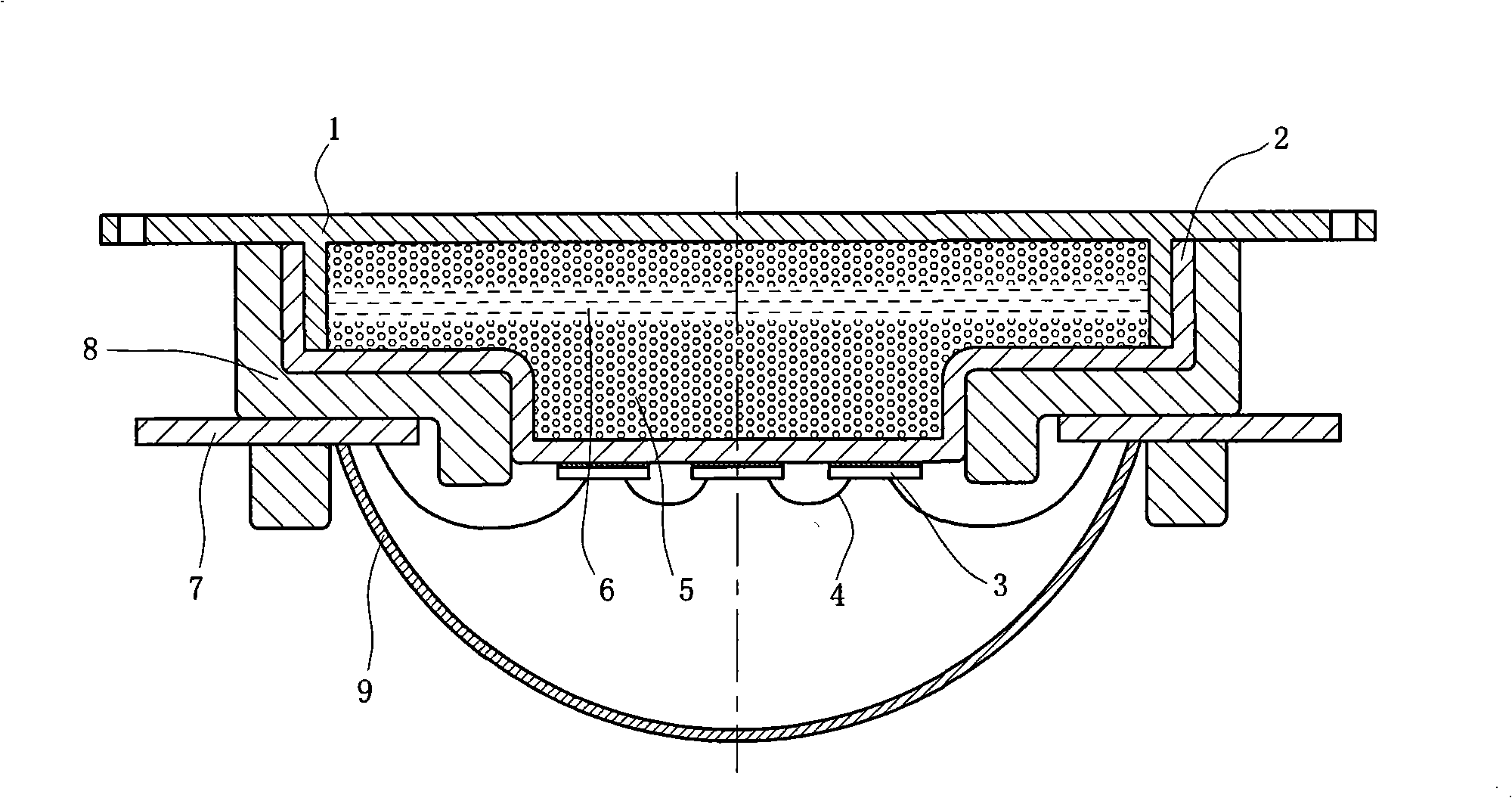

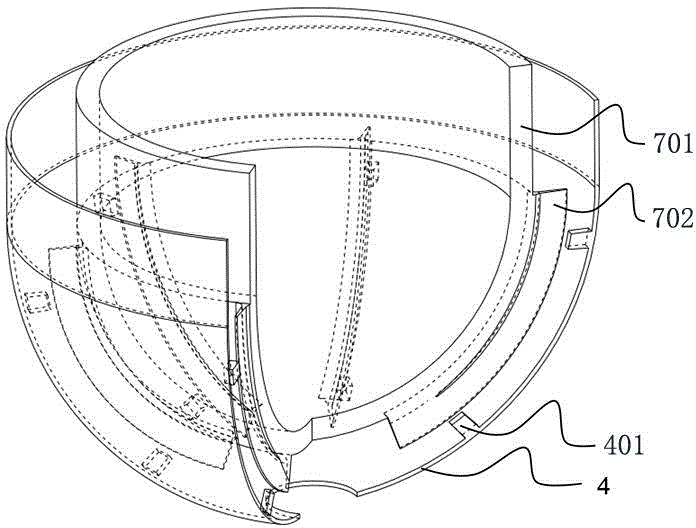

Boiling refrigerant type cooling system

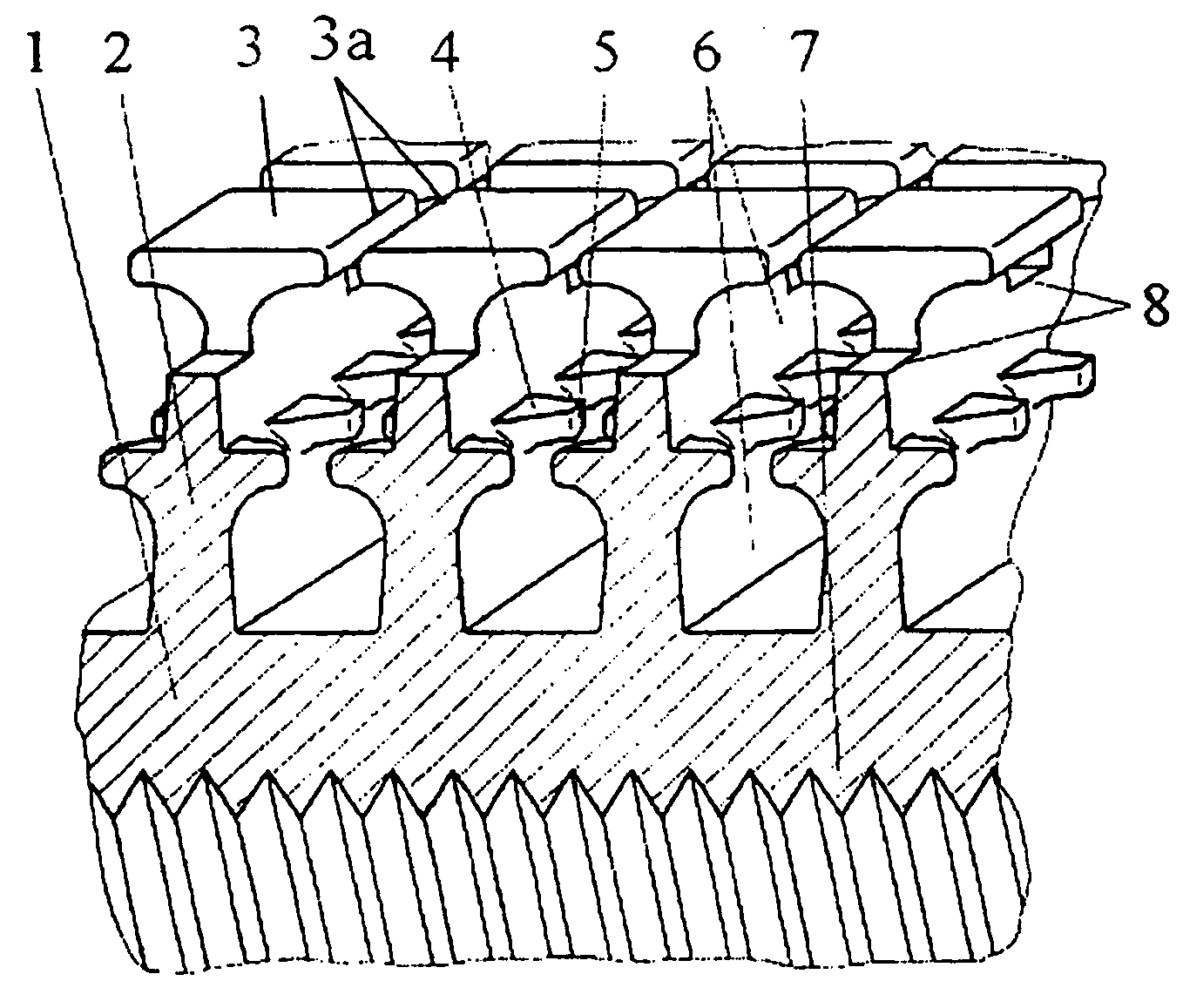

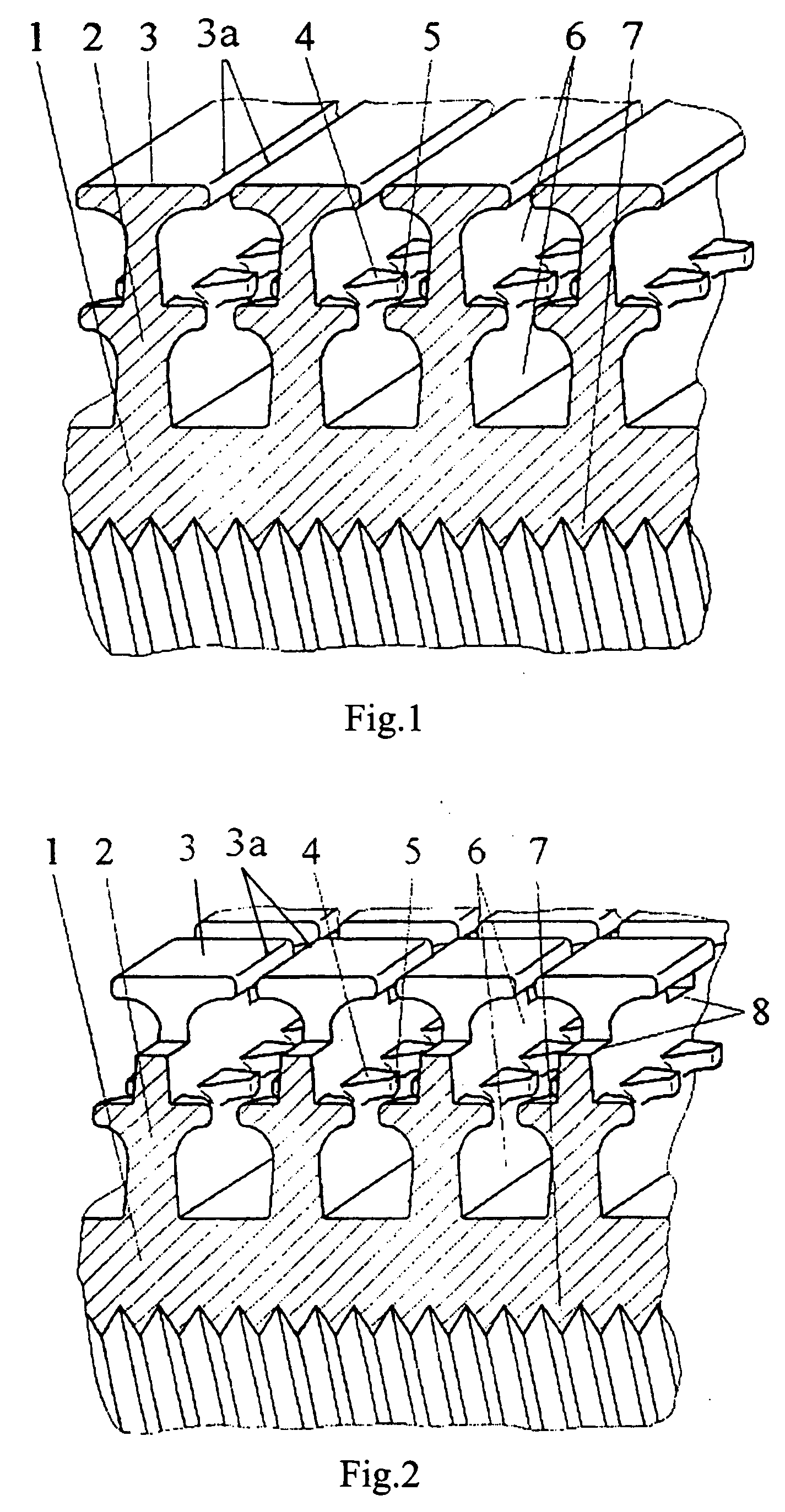

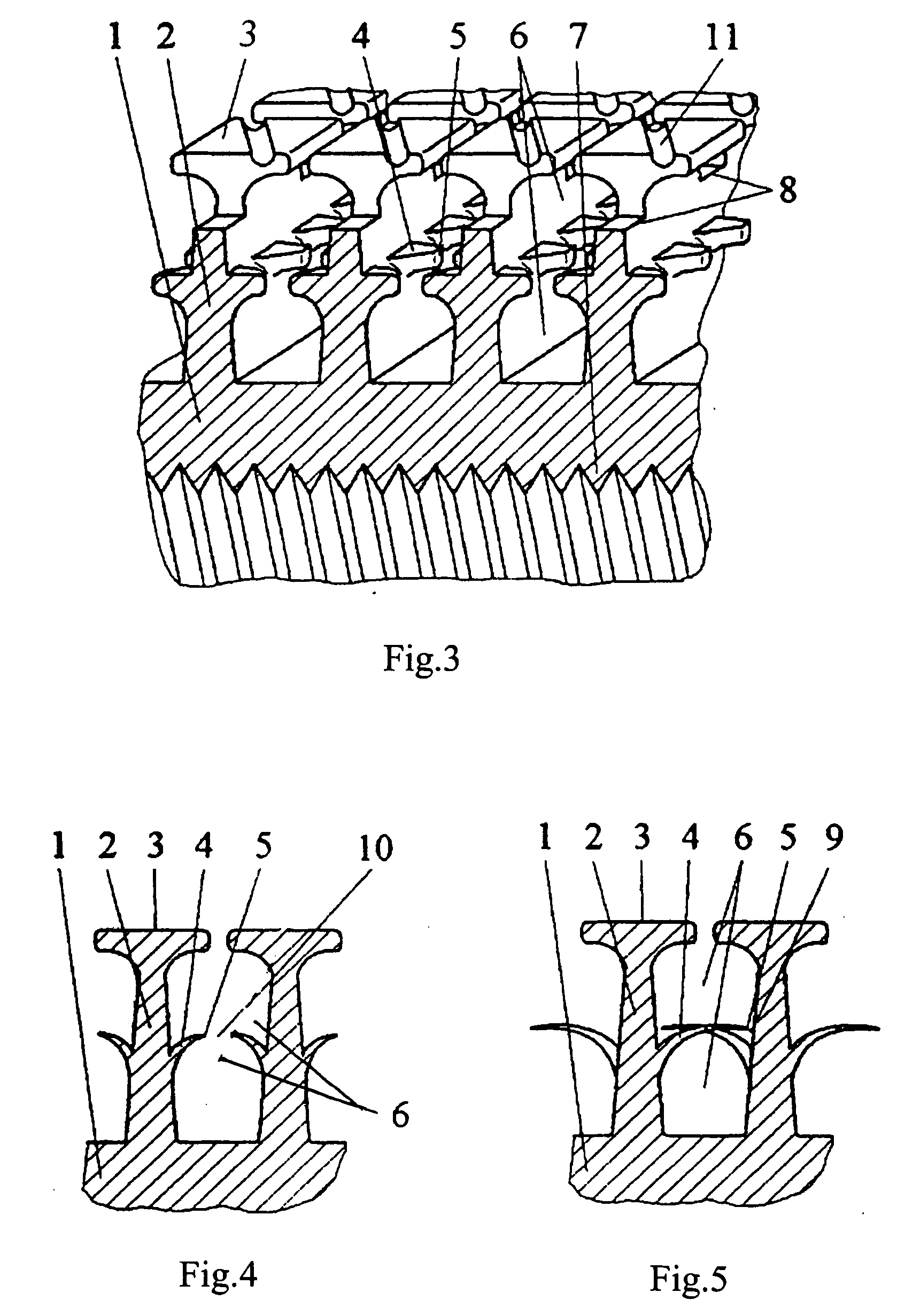

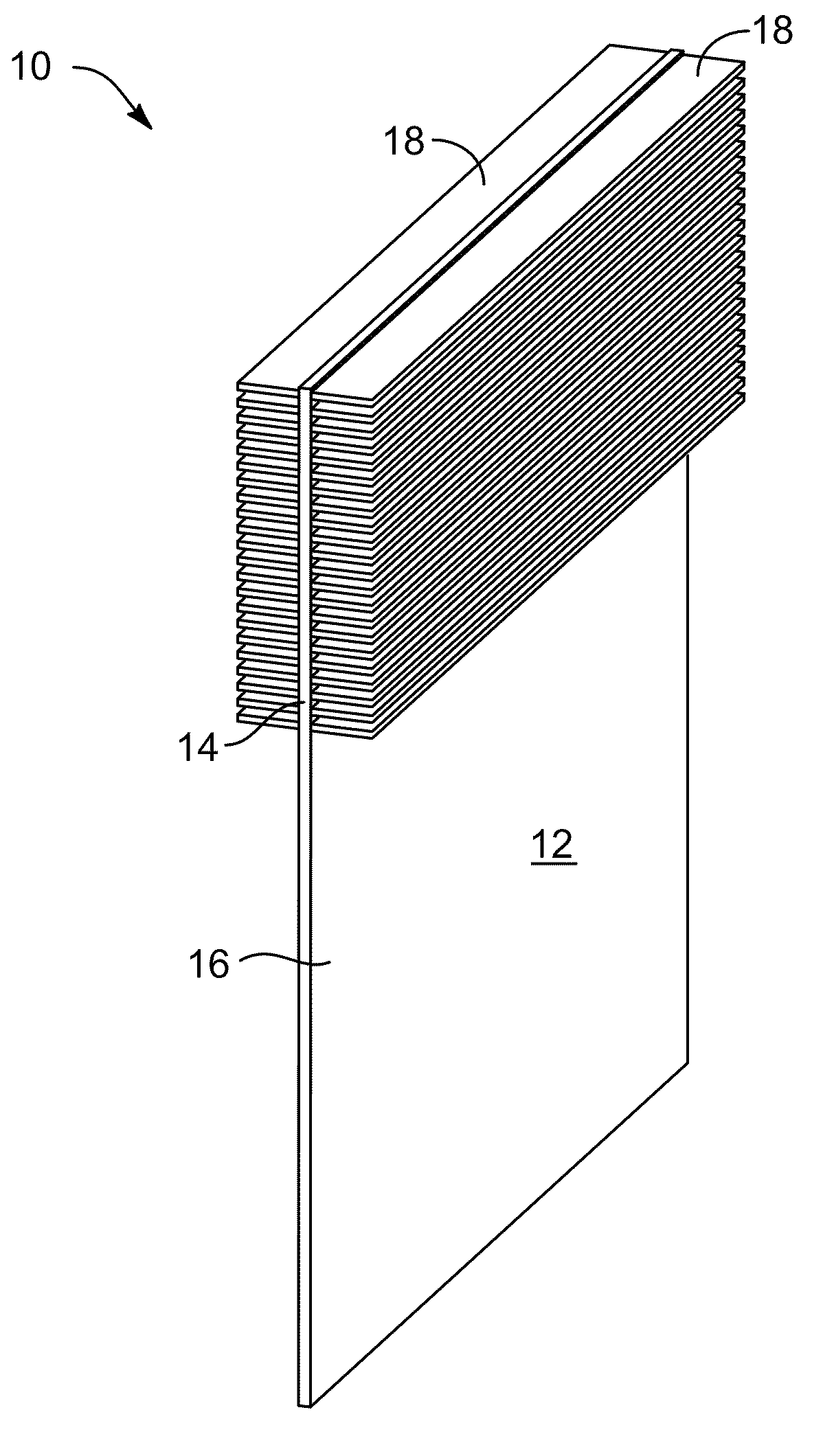

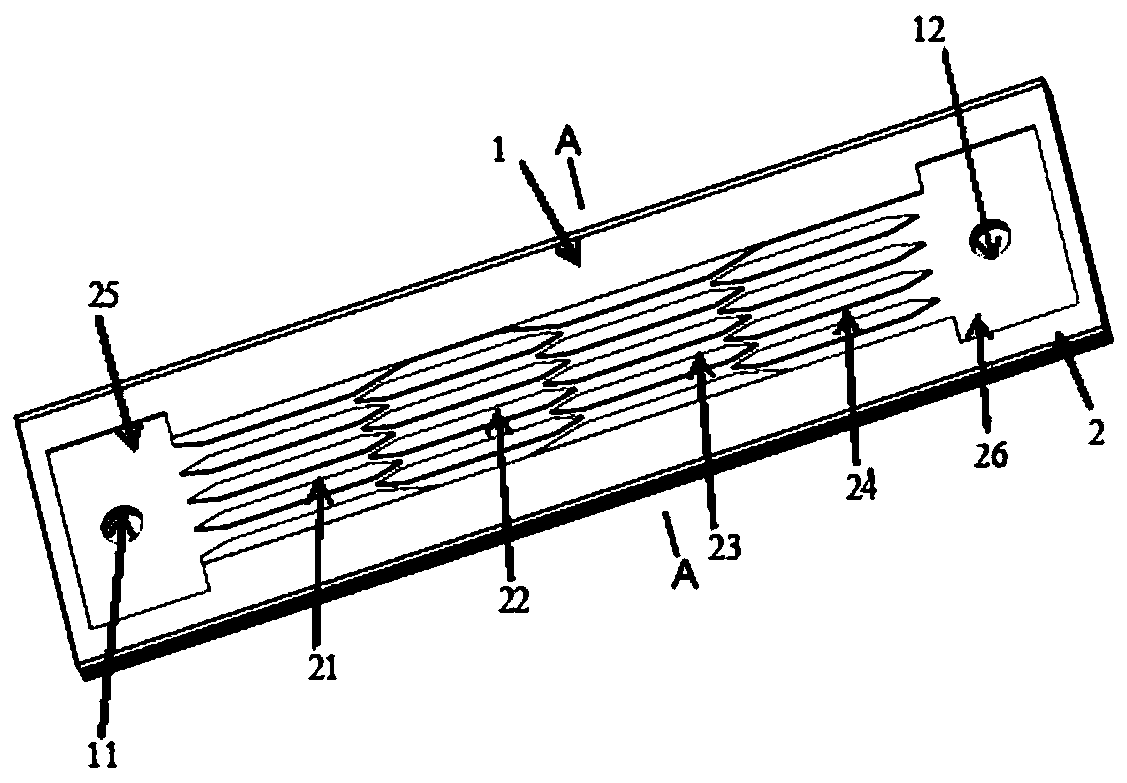

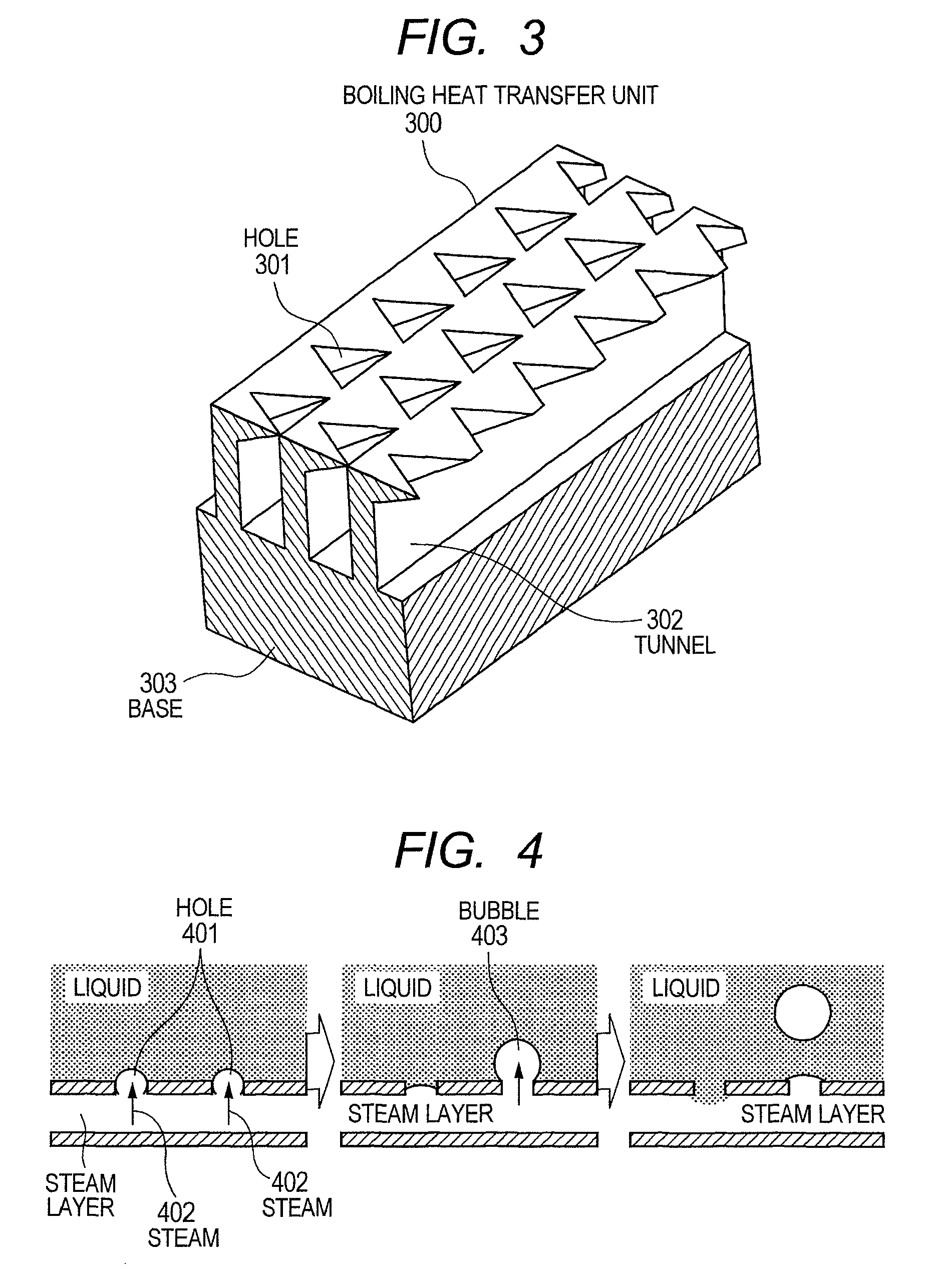

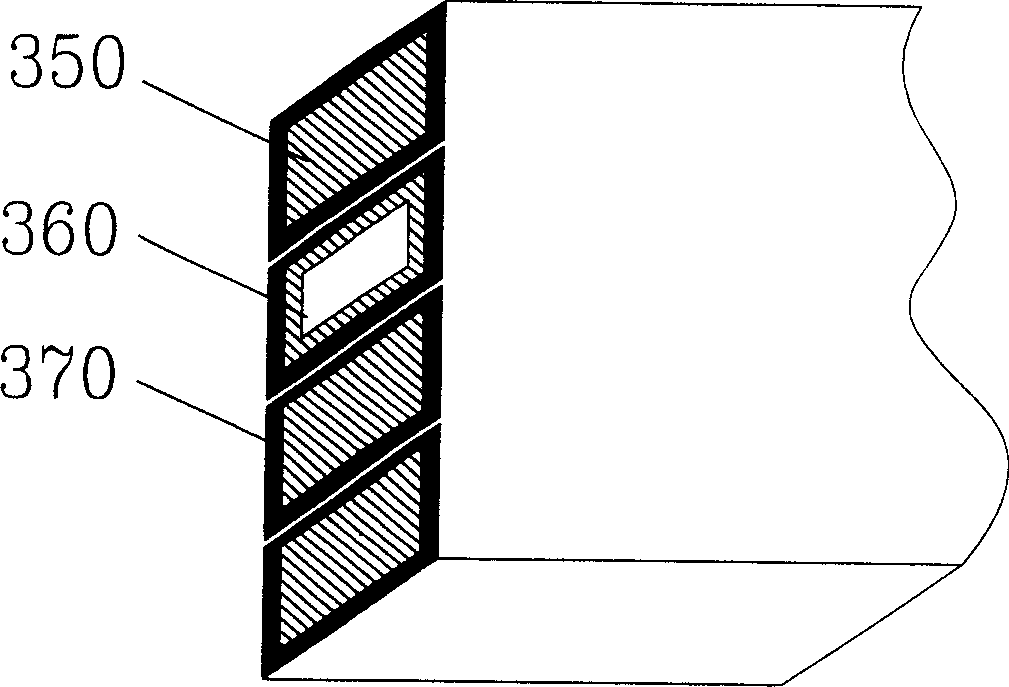

InactiveUS20120312504A1Stable start of boilingBubble generation is promotedSemiconductor/solid-state device detailsEvaporators/condensersEngineeringThermal contact

A boiling refrigerant type cooling system to suppress overshoot upon start of heat generation and realize stable start of boiling. In the boiling refrigerant type cooling system, a metal boiling heat transfer unit has a base in thermal contact with a heat generating body. The boiling heat transfer unit is in contact with a liquid refrigerant. The boiling heat transfer unit has plural parallel tunnels communicating with the outside via holes or gaps under its surface, a groove deeper than a tunnel diameter formed through all the tunnels in an orthogonal direction to the tunnels, and a cover plate on the groove.

Owner:HITACHI LTD

Flat heat pipe liquid suction core provided with fins and embedded grooves and manufacturing method thereof

InactiveCN104864755AIncrease disturbanceIncrease the heat exchange areaIndirect heat exchangersCapillary pressureMarine engineering

The invention discloses a flat heat pipe liquid suction core provided with fins and embedded grooves and a manufacturing method thereof. The flat heat pipe liquid suction core comprises a metal evaporation plate, wherein multiple first embedded grooves and multiple second embedded grooves which are arranged at intervals and distributed in a staggered mode in the first direction and the second direction and multiple fins distributed in an array mode are arranged on the evaporation face of the metal evaporation plate, and each first embedded groove and each second embedded groove respectively comprises a groove body forming a groove cavity and a vertical gap forming a groove opening. Each fin comprises a fin body and a supporting boss and is formed by the gaps and internal groove bodies of the corresponding first embedded groove and the corresponding second embedded groove in a staggered mode. The liquid suction core can increase heat exchange area, promote boiling for nucleus formation, enhance boiling heat transfer, improve capillary pressure and reduce backflow resistance. During manufacture, a ball-end milling cutter is utilized to mill the embedded grooves in the first direction, and a base plate is turned to mill the embedded grooves in the second direction and meanwhile form a fin structure. The flat heat pipe liquid suction core is simple in manufacturing process and low in machining cost and can remarkably strengthen heat transfer.

Owner:XIAMEN UNIV

Heat-transfer pipe of evaporator

ActiveCN101556125AEfficient heat transferImprove evaporation effectEvaporators/condensersHeat transfer modificationEvaporationEngineering

The invention discloses a heat-transfer pipe of an evaporator, which comprises a fin part arranged on the external surface and an internal tooth part arranged on the internal surface. The internal tooth part comprises a primary internal tooth and a secondary internal tooth which are arranged crossways high and low in double-layer. The fin part is provided with a secondary fin groove, a third fin groove and a primary evaporation cavity, and the bottom of the evaporation cavity extends upwards and is provided with a quarternary fin, which is divided into two small hollow cavities in the primary evaporation cavity. Each primary evaporation cavity is internally provided with 1-4 quarternary fins. The fin groove and the evaporation cavity arranged on the fin part of the heat-transfer pipe of the evaporator increase the heat exchange area of the heat-transfer pipe and the number of vaporized core; and the internal tooth of the internal tooth part decreases the laminar flow effect of cooling mediums, strengths the turbulence and greatly reinforces the boiling heat transfer property.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

Single-layer micro-nano double-scale enhanced boiling heat transfer copper surface structure and preparing method thereof

The invention discloses a single-layer micro-nano double-scale enhanced boiling heat transfer copper surface structure and a preparing method thereof. A copper surface of the enhanced boiling heat transfer copper surface structure is of a single-layer surface structure composed of micron large holes and hole walls with nano hole gaps. The single-layer multi-scale micro-nano enhanced boiling heat transfer surface has the lower wall face overheat degree when boiling begins and in the boiling process. In addition, the simple low-cost large-scale preparing method for preparing the single-layer micro-nano double-scale enhanced boiling heat transfer copper surface is suitable for modifying shapes of various boiling substrate surfaces, expensive mechanical devices are not needed, and the surface saves energy, is environment-friendly, is short in generation period and has the good industrial application prospect.

Owner:SUN YAT SEN UNIV

System and method for internal passive cooling of composite structures

ActiveUS7686248B2Reduce heat loadCost-effectiveCosmonautic vehiclesCosmonautic thermal protectionThermal energyEngineering

According to one embodiment of the invention, an apparatus comprises a passive cooling system and a portion of an air vehicle which receives thermal energy. The passive cooling system is disposed adjacent the portion of the air vehicle and comprises a fluid transfer chamber. A fluid transfer element and a coolant are disposed within the fluid transfer chamber. The fluid transfer element wicks a portion of the coolant towards the portion of the air vehicle. The portion of the coolant wicked towards the portion of the air vehicle absorb at least a portion of the thermal energy in a boiling heat transfer.

Owner:RAYTHEON CO

Self-circulation cooling loop of heavy current fixture wire

InactiveCN1841885AEliminate uneven temperature distributionRealize the purpose of self-circulation coolingTransformers/inductances coolingEnergy efficient heating/coolingInternal pressurePower flow

The invention relates to a large current equipment pin equipment cooler circuit. It is characterized in that it comprises a large current device pin (10) and an evaporative cooling circulation system; the large current device pin (10) is formed by a solid conductor and circular or polygonal hollow conductor or hollow pipe conductor; it injects the evaporative cooling media in the hollow conductor. The current can lead the loss and the winding heats whose heat transmits to the cooling media of the hollow conductor, when the temperature lifts to the corresponding saturation temperature; the winding inner hollow conductor evaporative cooling media evaporates to form boiling heat transfer and then uses cooler to be liquefied, and then cycles.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com