Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Short generation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

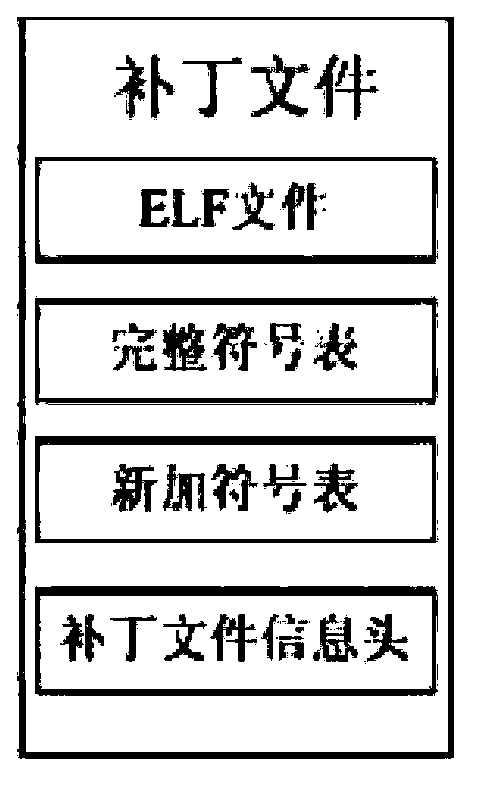

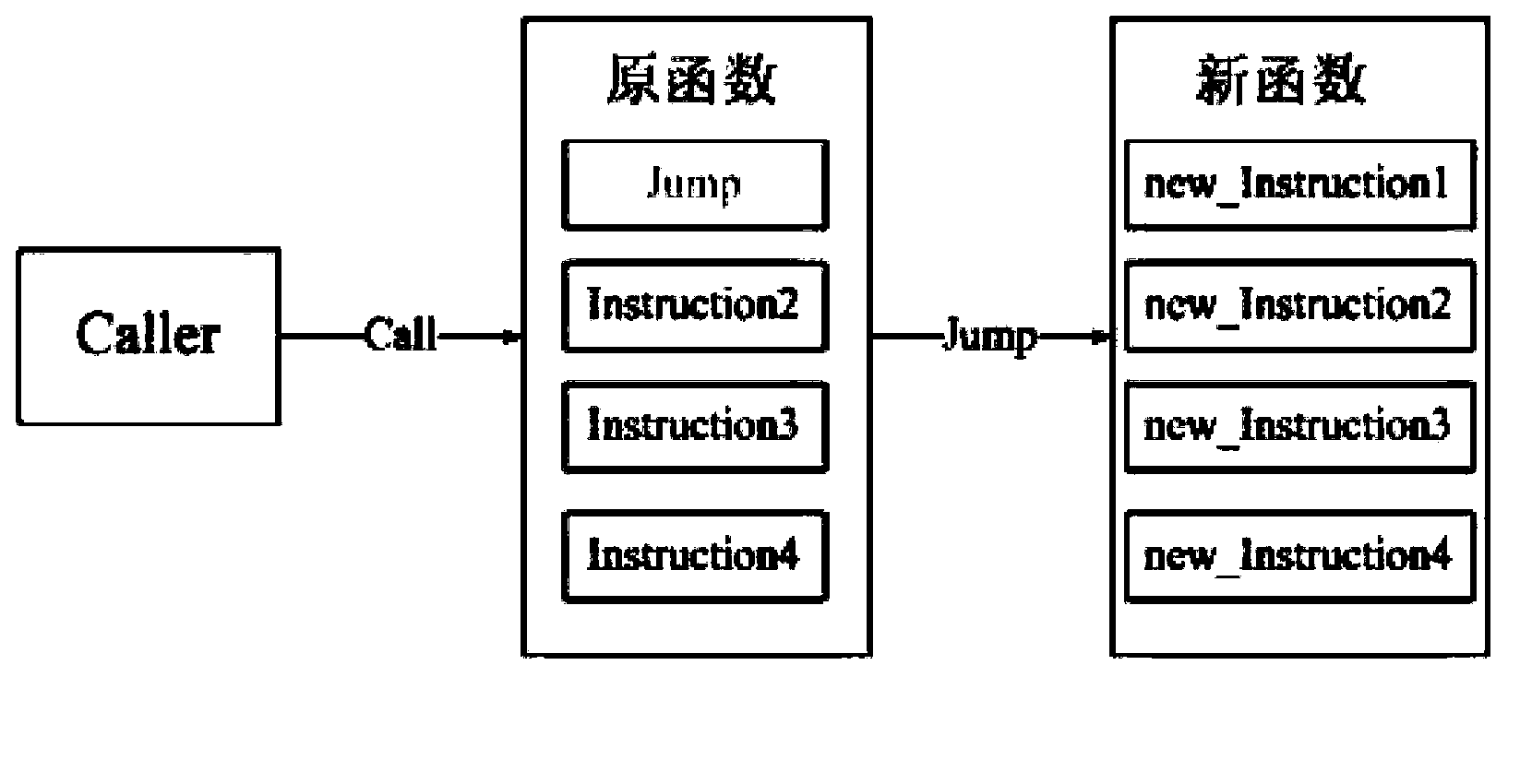

Hot patching implementation method of embedded system

ActiveCN104239082ALow costSimple and reliable implementationProgram loading/initiatingRedundant operation error correctionSoftware systemEmbedded system

The invention discloses a hot patching implementation method of an embedded system. The method includes: finding the old function in an existing system, changing the first instruction of the function into a skip instruction with the skip address pointing to a new function so as to allow the new function to replace the old function. By the method, system software function updating and defect fixing can be completed while a software system cannot be replaced and equipment restarting is unavailable.

Owner:SHANGHAI BAUD DATA COMM

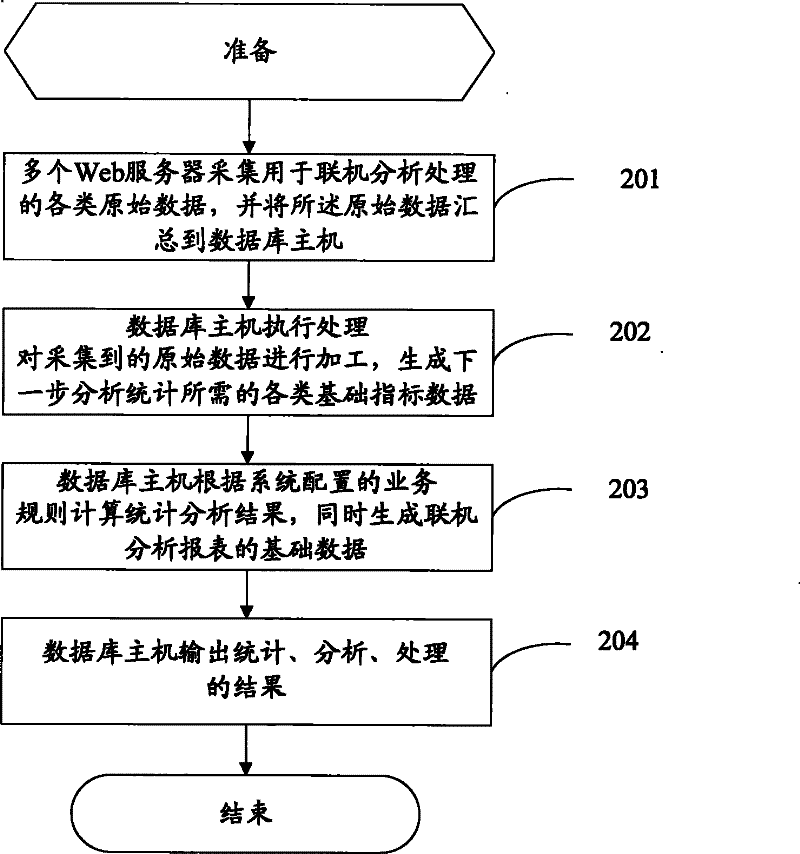

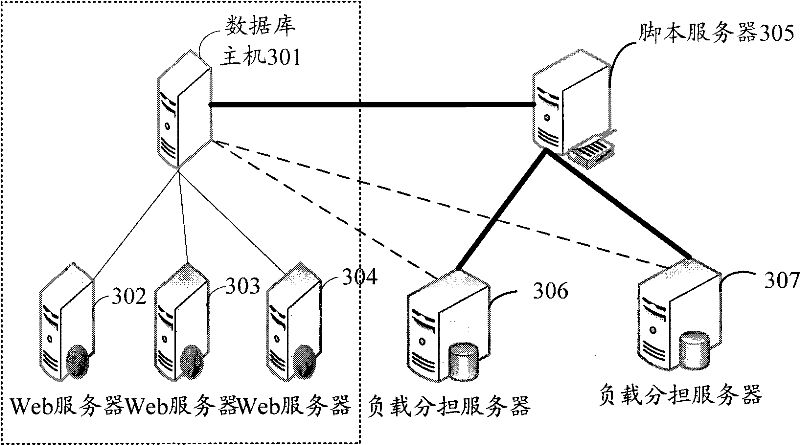

Distributed data analyzing and processing method and system

ActiveCN102479225AExtended processing timeReduce processing timeResource allocationSpecial data processing applicationsDistributed computing

The invention provides a distributed data analyzing and processing method, comprising the following steps that: A, a load-sharing server transmits a request for obtaining an executable object script to a script server, and the script server judges whether the executable object scrip is found, if so, a step C is executed, otherwise, a step B is executed; B, the script server reads script source codes from a database host, and edits the script source codes to obtain the executable object script; C, the script server obtains the executable object script from the script server, calls an entrance method of a script object, and executes data acquisition, clearing, counting, analysis and processing types of function codes defined by the executable object script; and D, the load-sharing server transmits the processing result of executing the executable object script back to the database host through a remote database connection. The invention further provides a distributed data analyzing and processing system.

Owner:CHINA MOBILE GROUP SICHUAN

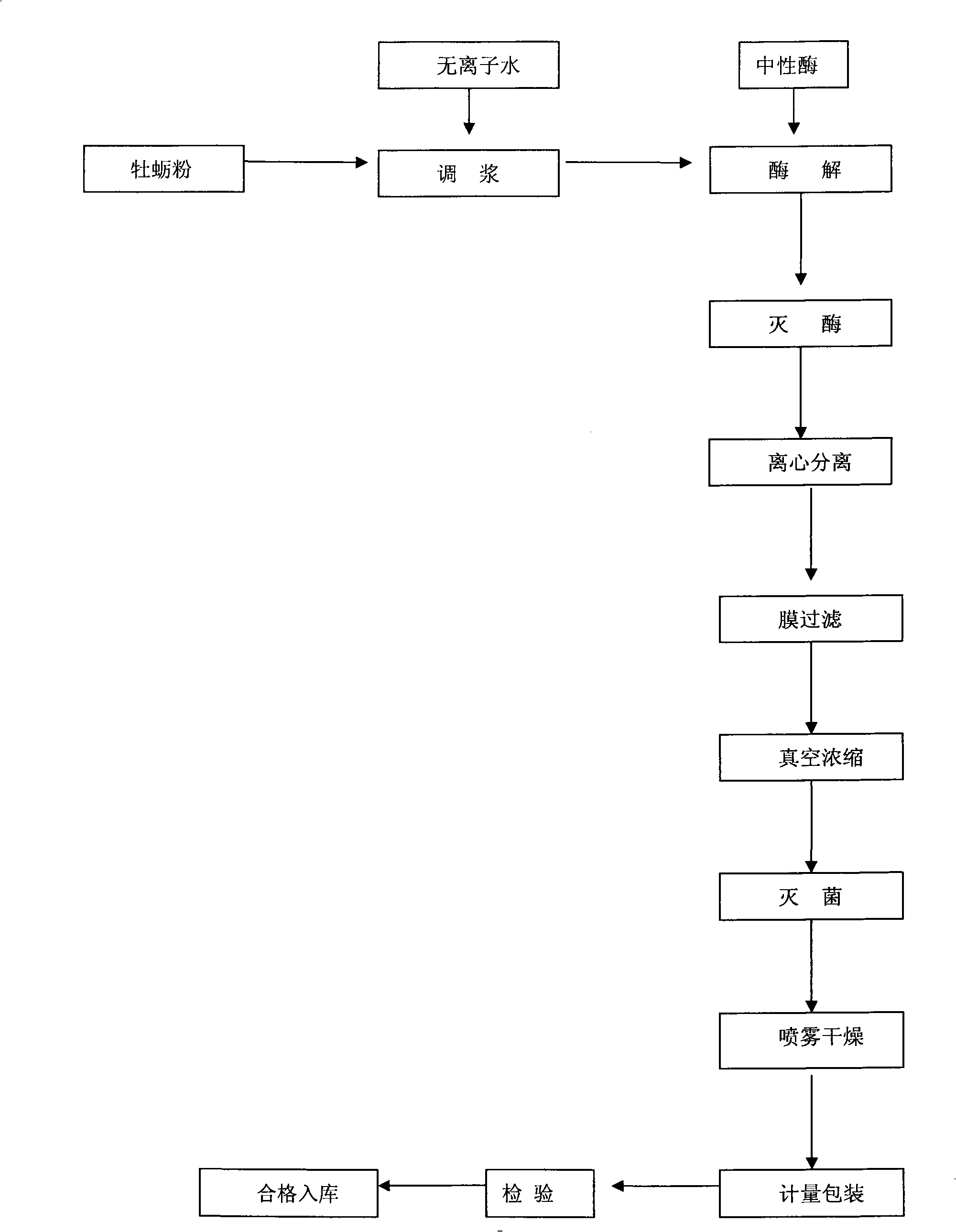

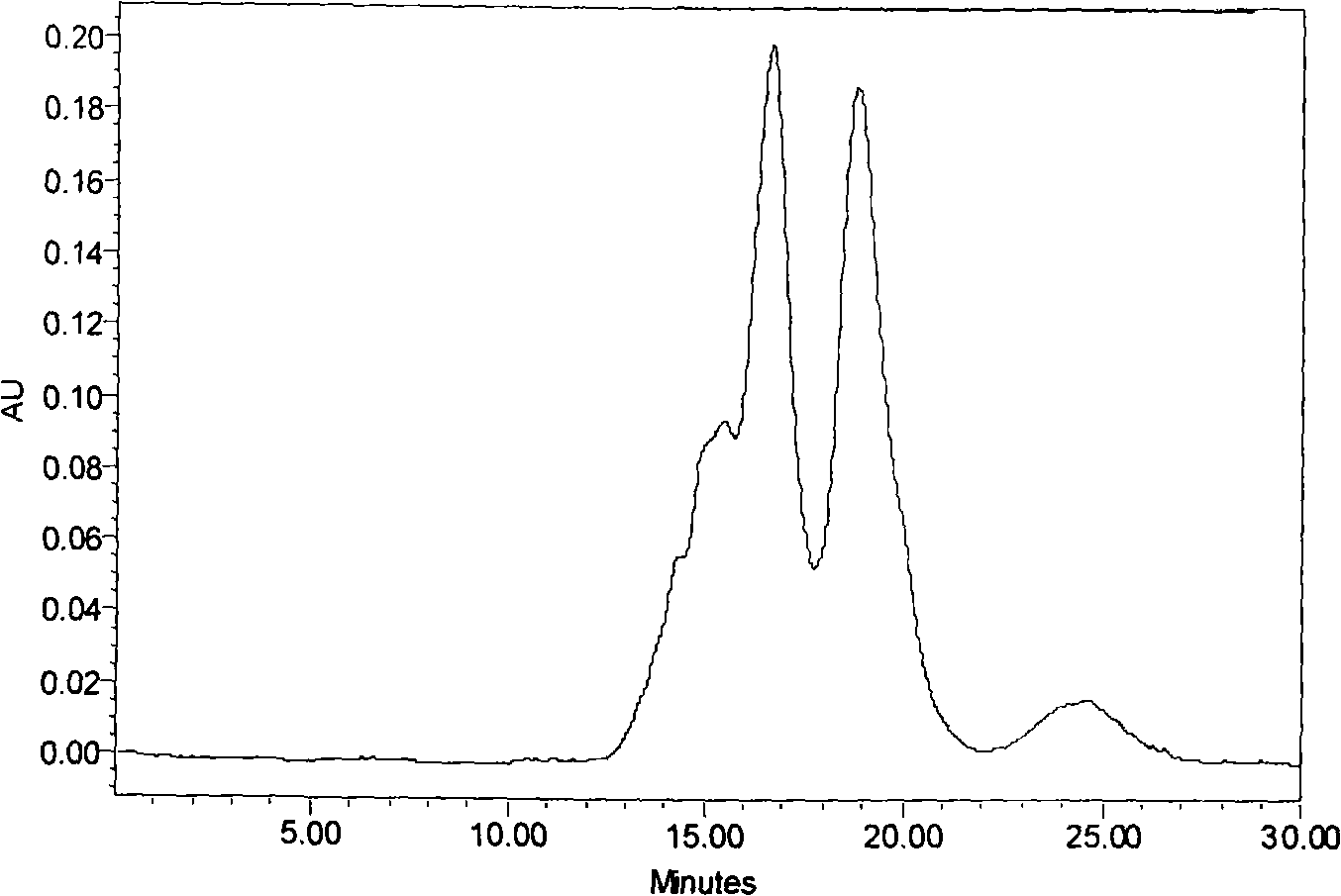

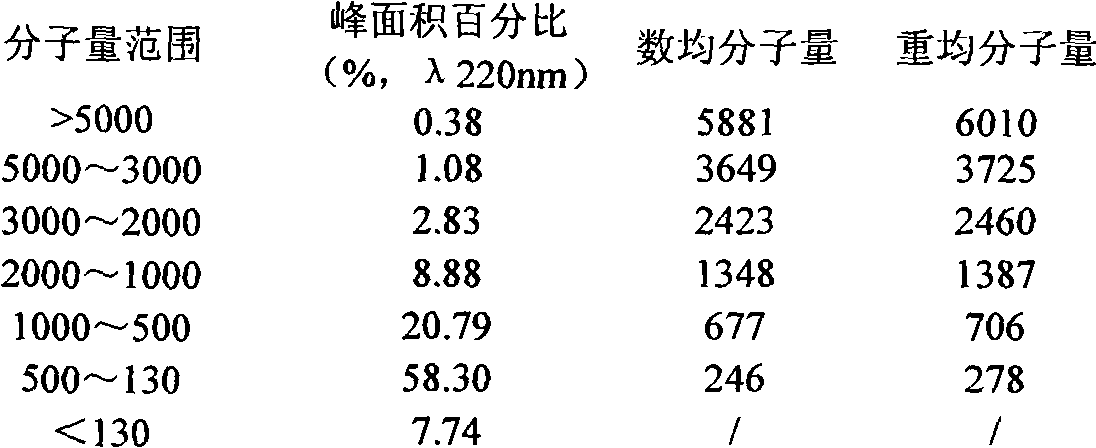

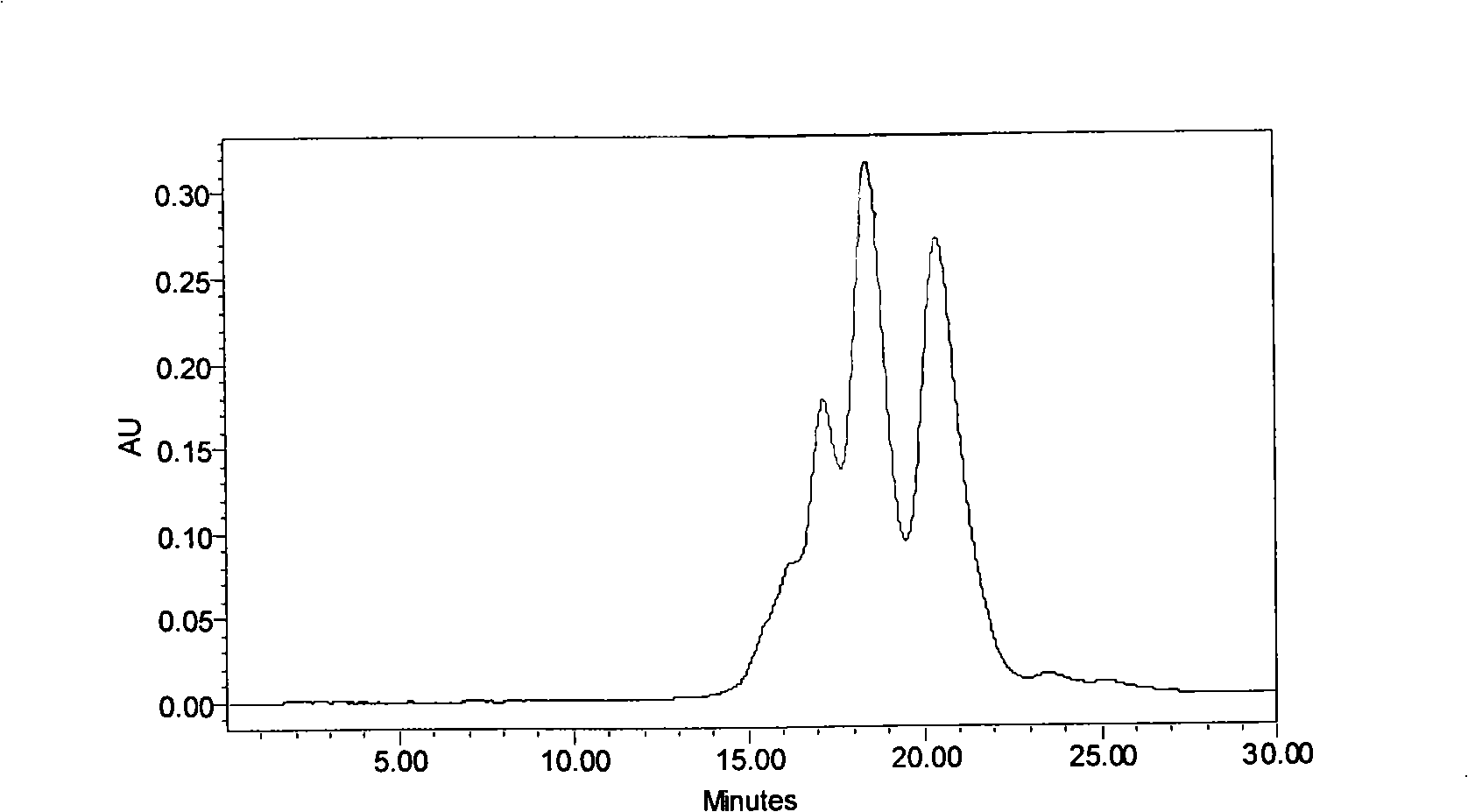

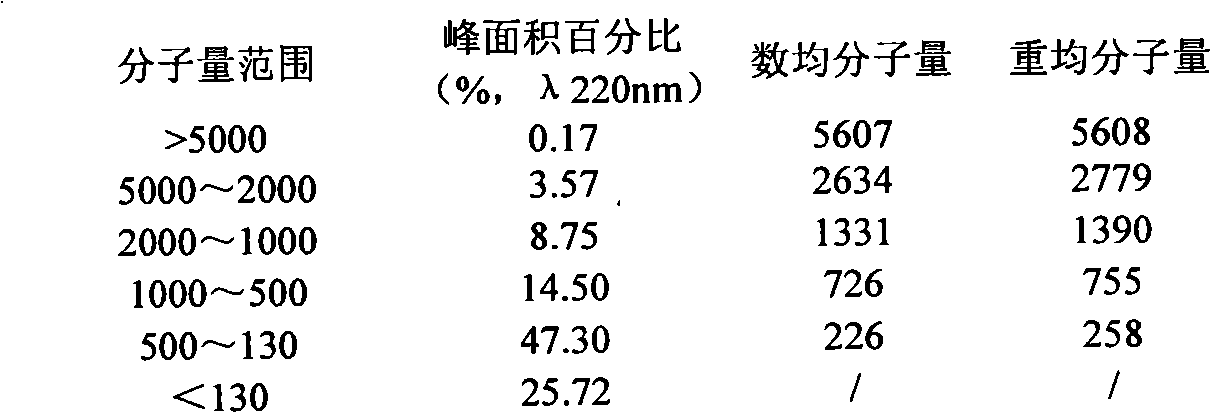

Industrial production method for making peptide of oyster from oyster powder by enzyme method

ActiveCN101263860AHigh peptide yieldHigh technology contentAnimal proteins working-upFood preparationNeutral proteaseEmulsion

The invention discloses an industrial production method for preparing oyster bioactive peptides from oyster powder through enzymatic method, which is characterized in that: the special of the production method lies in comprising the following steps: (1) inputting the oyster powder of 1kg, adding deionized water, carrying out shear through the emulsion shearing machine on the bottom of a tank after finishing feeding and reflowing into the tank; (2) regulating the PH of the feed liquid to 7.0 to 7.5, warming up to 48 to 52 DEG C, adding neutral protease of 10 to 20g and beginning enzymolysis for 6 hours; (3) warming up to 80 DEG C and carrying out killing enzyme for 10 minutes; (4) filtering with ceramic membrane, carrying out spray drying and passing through 60 mesh sieve for the feed liquid when the concentration of vacuum concentration is 20% and packaging with compound bag. The industrial production method has the advantages that: the technology is simple; the generating period is short; the produced oyster bioactive peptides are white, not fishy smell and good taste; and the molecular weight of the contained mixing peptide is small.

Owner:中食都庆(山东)生物技术有限公司

Industrial process for producing wheat peptide from glutelin powder by enzymic method

ActiveCN101297675AHigh peptide yieldHigh technology contentVegetable proteins working-upFood preparationChemistryProtein formation

The invention discloses an industrial production method for enzymatic preparing wheat peptide from wheat gluten. The production method is characterized by comprising the following steps: (1) putting wheat gluten of 1kg, adding deionized water, and reflowing to a pot; (2) heating up to 50 to 55 DEG C, pH of feed fluid is 7.5 to 8.0, then adding protamex of 1 to 2g, and carrying out enzymolysis for 8 hours; (3) heating up to 80 DEG C, and extinguishing enzyme for 10min; and (4) carrying out filtration by a ceramic membrane and vacuum concentration, treating the feed fluid with spray drying, sieving by a sieve with 60 meshes, and packing by compound bags. The wheat peptide prepared by the method of the invention has the protein content of above 50 percent, molecular weight of wheat peptide of 90 percent is below 1000Dalton. The method of the invention has simple technique and short production cycle, the wheat peptide product produced by the method is white and has good mouthfeel.

Owner:中食都庆(山东)生物技术有限公司

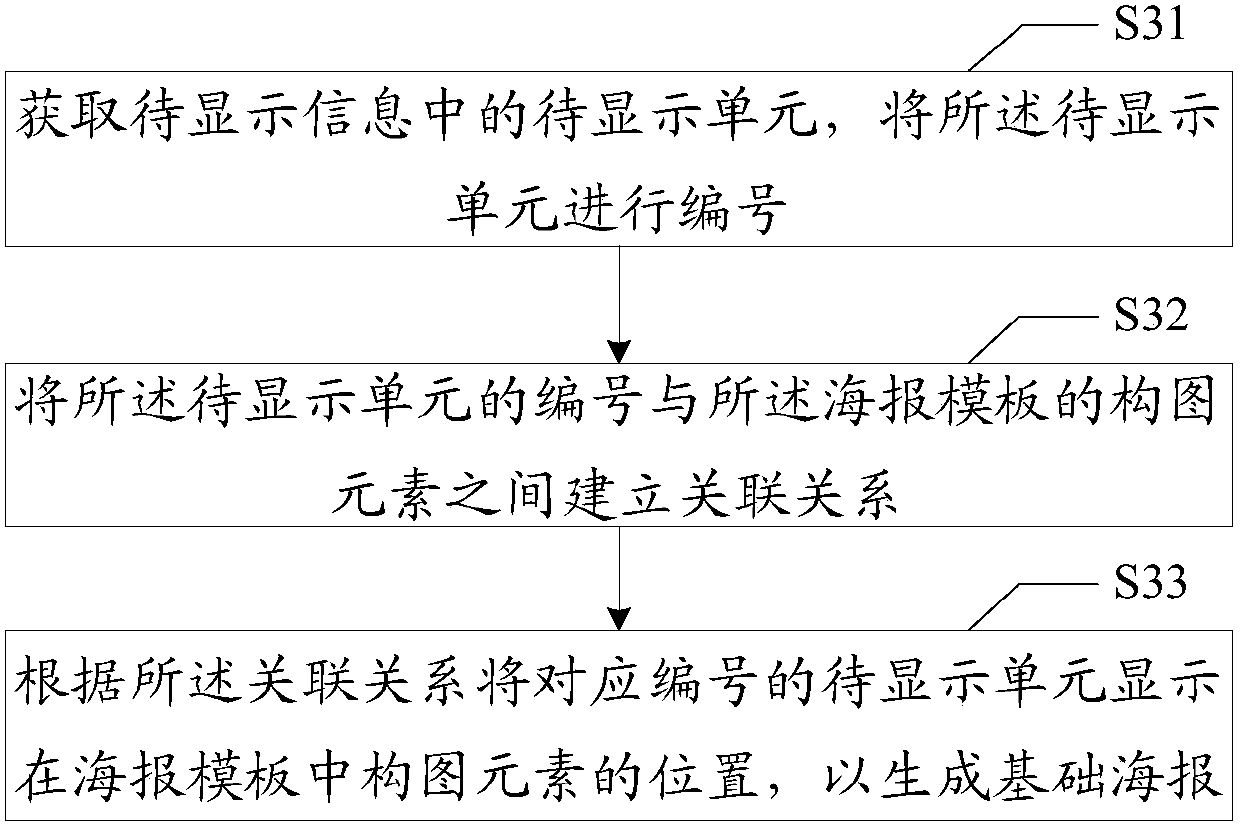

Poster generation method, device and equipment and computer storage medium

PendingCN109727298AShort generation cycleFlexible changeEditing/combining figures or textComputer engineeringInstruction selection

The invention discloses a poster generation method, which comprises the following steps that: enabling a front-end server to receive a poster generation instruction, obtaining to-be-displayed information contained in the poster generation instruction, and displaying a preset poster template set on a display interface of the front-end server; Receiving a template selection instruction triggered based on a pre-stored poster template set so as to select a poster template according to the template selection instruction; Displaying the to-be-displayed information on the poster template to generatea basic poster; When it is detected that the user triggers an editing instruction based on the basic poster, editing the basic poster according to the editing instruction, and generating a standby poster meeting the user requirement. The invention further discloses a poster generation device and equipment and a computer storage medium. According to the pure front-end poster generation method driven by the configuration data, the lightweight server is established through the front end, frequent interaction between the front end and the rear end is not needed, and the poster generation flexibility is improved.

Owner:平安好房(上海)电子商务有限公司

Method for screening allotrophic nitrobacteria

InactiveCN1884480AShort generation cycleFast growth rateBacteriaBiological water/sewage treatmentSewage treatmentScreening method

A sieve method of heterotrophic nitrifying bacteria belongs to sewage treatment technical sphere. The invention is to carry out heterotrophic nitrifying phenomenon from the biology angle by screening heterotrophic nitrifying bacteria and the technology is the condition precedent to carry out short-range self-synchronous nitration and denitrification. The invention is proceeded by the following steps: 1. enriched culturing of microorganism; 2. picking out single colony from beef cream protease leather solid medium and seeding them in ammonifying culture medium to culture and purify; 3. picking out single colony from ammonifying culture medium solid medium and seeding them in nitrosation culture medium to culture and purify to obtain heterotrophic nitrifying bacteria. The heterotrophic nitrifying bacteria of this invention not only can grow and breed in culture medium using ammonia nitrogen as unique nitrogen source but also can normally grow and breed in culture medium using nitrite as unique nitrogen source, which has stronger adaptive capacity for environment and has bigger development potential in actual engineering application.

Owner:HARBIN INST OF TECH

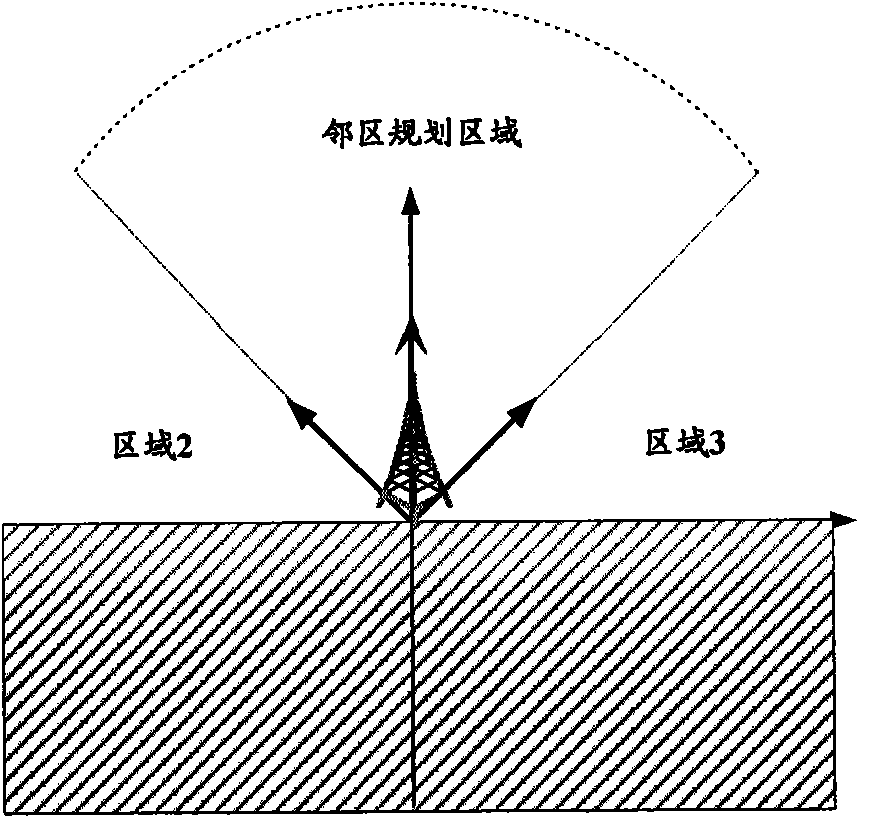

Method and device for generating neighboring cells among different systems

ActiveCN101959227AImprove accuracyImprove performanceWireless communicationDirection angleBase station

The invention discloses a method and a device for generating neighboring cells among different systems, which aim to automatically generate the neighboring cells among different systems, shorten generating periods and improve the accuracy of generated results. The method comprises the following steps of: selecting alternative different-system neighboring cells according to a station distance between a base station cell and each adjacent different-system cell and a relative position between each adjacent different-system cell and the base station cell; respectively determining the weight of each alternative different-system neighboring cell according to a station distance between each alternative different-system neighboring cell and the base station cell and a direction angle formed between each alternative different-system neighboring cell and the base station cell; and selecting the different-system neighboring cells according to the weight of each alternative different-system neighboring cell so as to generate a list of the different-system neighboring cells of the base station cell.

Owner:CHINA MOBILE GROUP DESIGN INST

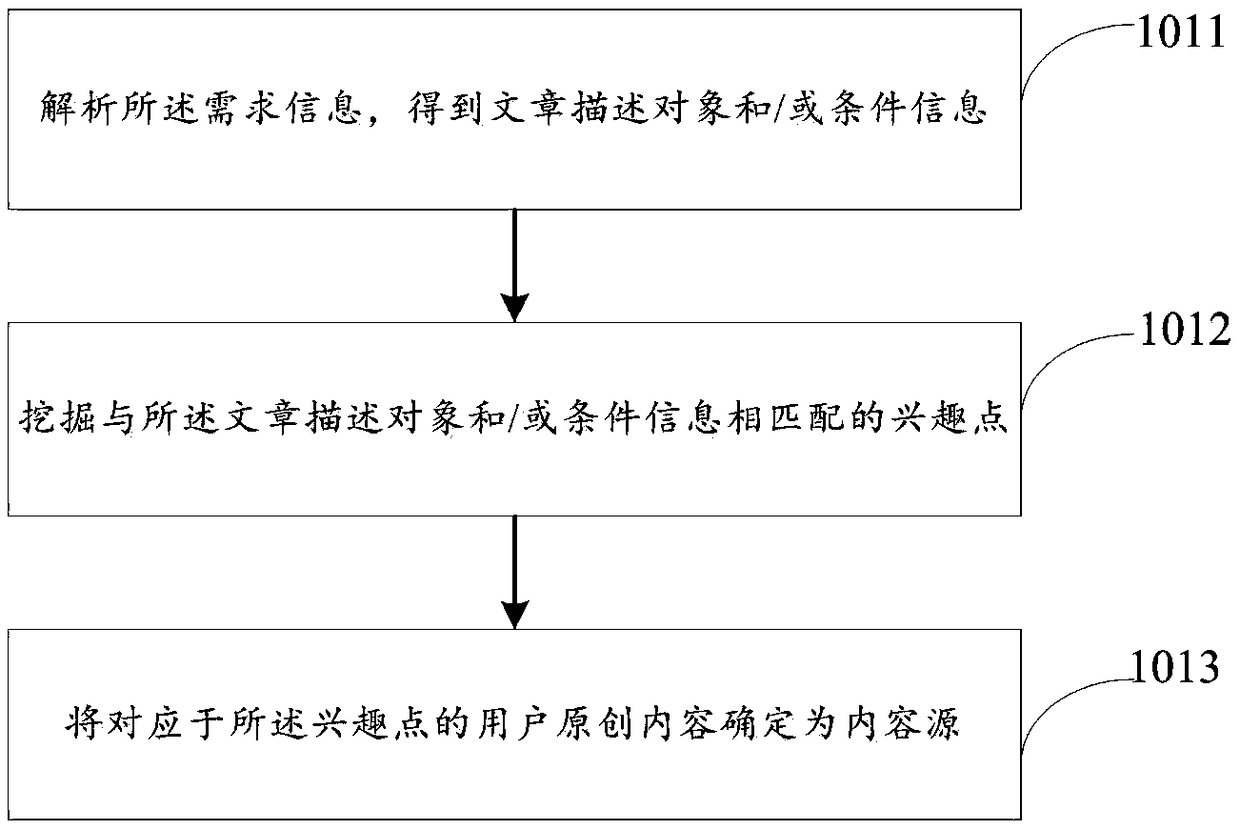

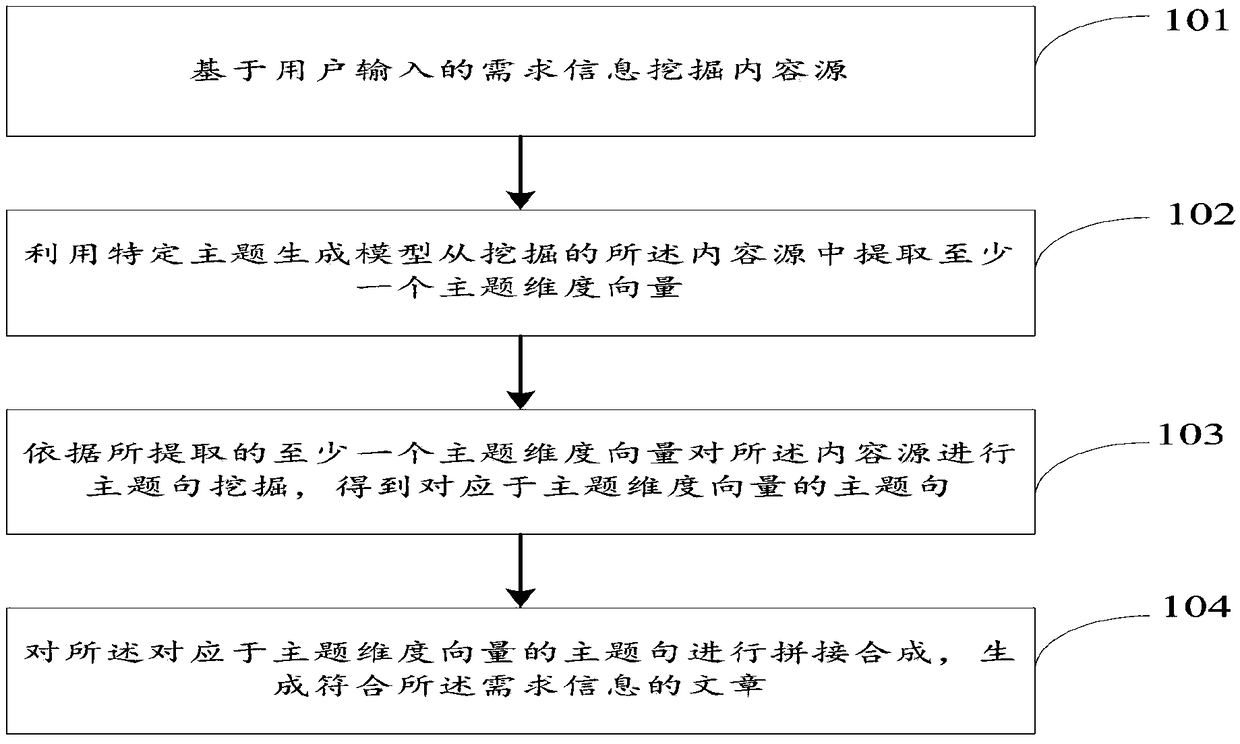

Article generation method and device, and storage medium

ActiveCN108694160AAutomatically composeShort generation cycleSemantic analysisSpecial data processing applicationsUser inputSubject matter

The present invention provides an article generation method and device, and a computer storage medium. The method comprises: mining a content source based on user input demand information; extractingat least one topic dimension vector from the mined content source by using a specific topic generation model; performing topic sentence mining on the content source according to the at least one topicdimension vector extracted to obtain a topic sentence corresponding to the topic dimension vector; and splicing and synthesizing the topic sentence corresponding to the topic dimension vector to generate an article conforming to the matching requirement information.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

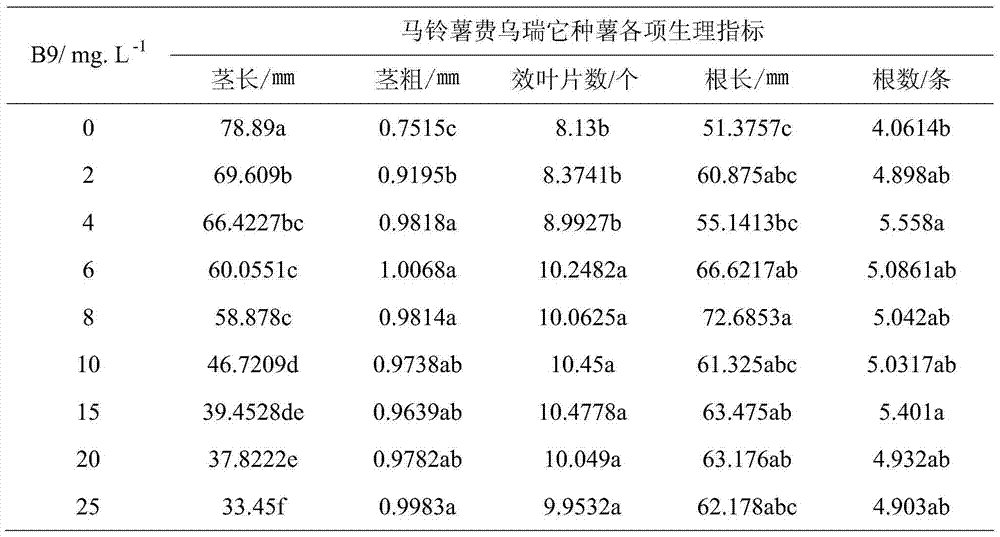

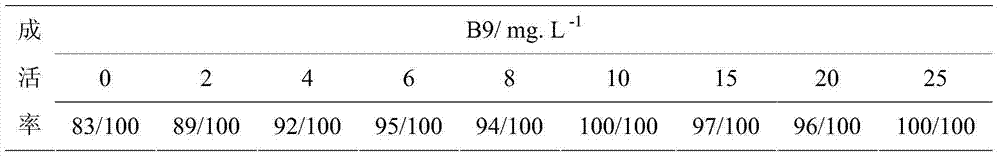

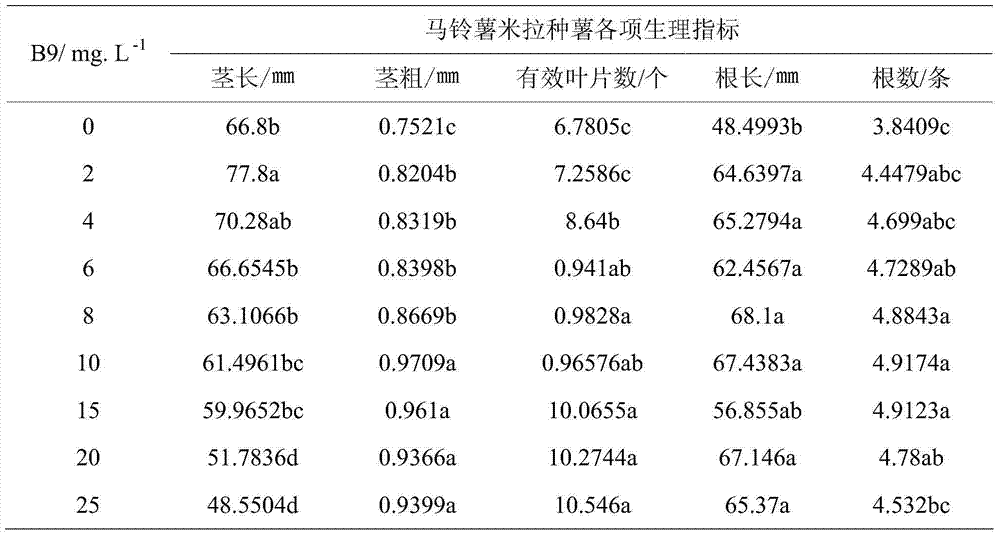

Method for culturing strong seedling of potato virus-free tube seedling

InactiveCN103563748AEffective cultivationShort training periodCultivating equipmentsHorticulture methodsSugarSolanum tuberosum

The invention relates to the technology of strengthening seedlings of potato virus-free tube seedlings, and particularly relates to a method for culturing a strong seedling of a potato virus-free tube seedling. The method mainly comprises the following steps: preparation of a culture medium; rapid propagation of a virus-free seedling; transplanting of the virus-free seedling. According to the method, B9 with different concentrations are added in different stages of tissue culture and rapid propagation of potato by taking an improved 1 / 2 MS as a culture medium and tap water and edible white sugar as raw materials, so that the subculture period is shortened and the test-tube seedling is more robust. The concentration of the B9 added in the rapid propagation stage of the virus-free tube seedling is 4-8mg / L, so that stem diameter, number of effective stems and number of roots of the virus-free tube seedling are effectively promoted. The blade is thickened and deeply green. The subculture period is shortened from conventional 3-4 weeks to just 14-18 days, so that the propagation efficiency of the potato virus-free tube seedling is extremely improved. B9 with concentration of 10-15mg / L is added into the culture medium before the virus-free seedling is transplanted, so that the steam of the virus-free tube seedling is thicker and stronger, shorter in internode and higher in degree of lignification of the stem, and the transplanting survival rate of the seedling can be improved.

Owner:四川省植物工程研究院

Method for preparing sheath for cold isostatic pressing

The invention discloses a method for preparing a sheath for cold isostatic pressing. The method includes the steps: combining cut paperboards into a shape required by the size of a product, manufacturing an upper sheath cover and a lower sheath cover, and coating thin films inside and outside the upper sheath cover and the lower sheath cover; filling powder on one sheath cover after the upper sheath cover and the lower sheath cover coated with the thin films are completely dried, and closing the other sheath cover after the powder is compacted; integrally packaging the upper sheath cover and the lower sheath cover filled with the powder by a vacuum bag, drawing out air from the vacuum bag and sealing the vacuum bag; and stripping the upper sheath cover and the lower sheath cover after forming by cold isostatic pressing. The sheath prepared by the method is low in cost, a current frequently-used rubber and plastic sheath needs to be formed by a metal mould, the sheath is prepared by the aid of the paperboards without a special mould, investment cost is reduced, generating period is shortened, and the sheath is easy to control and has a high promotional value.

Owner:DAYA PRECISION MACHINERY

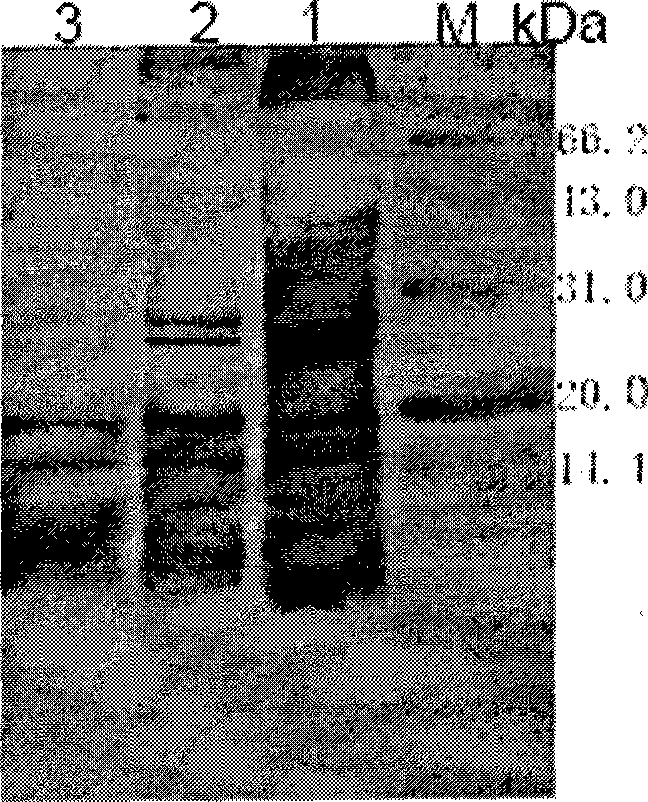

Musca domestic pupae natural antimicrobial peptide products and preparation method and use thereof

InactiveCN101392020AMeet production needsLess likely to develop drug resistanceCosmetic preparationsPeptide/protein ingredientsFiltrationUltrafiltration

The invention relates to a house-fly pupa natural antibiotic peptide product as well as a preparation method and application thereof; house-fly pupas, the raw material of the antibiotic peptide product, are extracted overnight by acid and hot-processed to collect supernatant; and after going through siever filtration and ultrafiltration precessing, the supernatant is treated with spray dring to obtain the antibiotic peptide product. The preparation technique of the antibiotic peptide product is simple and quick, the yield of the antibiotic peptide reaches 1.2 percent and the recovery rate of the antibacterial activity is over 80 percent. The prepared house-fly antibiotic product consists of peptides which have the molecular weight less than 20kDa and are mainly micromolecular peptides with the molecular weight less than 14.4 kDa. The antibiotic peptide product has broad-spectrum antibiotic activity and no hemolytic activity to blood erythrocytes of mice and is characterized by high temperature resistance, acid and alkali resistance and good stability. The byproducts of the technique can serve as feeding insect protein powder. The prepared antibiotic peptide product can be widely applied to the fields such as the antisepsis and storage of foods, fruits and vegetables, feed additives, cosmetic and the like.

Owner:SUN YAT SEN UNIV

Method for preparing cathode material for LiVPO4F lithium-ion batteries by means of double-layer carbon coating

InactiveCN108666558AImprove electronic conductivityReduce sizeSecondary cellsPositive electrodesCarbon coatingPhosphoric acid

The invention relates to a method for preparing a cathode material for LiVPO4F lithium-ion batteries by means of double-layer carbon coating. The method comprises the following steps: uniformly mixingvanadium salt, a carbon source and a phosphate source according to a molar ratio of V to P being equal to 1 to 1 and a molar ratio of C to P being equal to 1.5 to 1, carrying out heat treatment in aprotective atmosphere, and then pulverizing and grinding to obtain a mesophase product; evenly mixing the mesophase product, lithium fluoride and the carbon source according to a molar ratio of Li toV to P to F being equal to 1 to 1 to 1 to 1 and a molar ratio of C to P being equal to (0.02-0.2) to 1, and then carrying out heat treatment at 500-800 DEG C for 1-12h. By means of control of phase composition and ratio in the two steps of synthesis, the method can control the carbon content, coating layers and layer thickness of the final product. Good carbon coating situation can improve the electronic conductivity of the material and control the sizes of particles, so that the modified LiVPO4F material can achieve ultra-stable cycle performance and excellent rate capability.

Owner:XI AN JIAOTONG UNIV

Ganoderma lucidum antler culture medium utilizing domestic garbage and method for cultivating ganoderma lucidum antler

InactiveCN104987157AIncrease the number ofIncrease the content of trace elementsHorticultureFertilizer mixturesSucroseSaccharum

The invention relates to a ganoderma lucidum antler culture medium utilizing domestic garbage and a method for cultivating the ganoderma lucidum antler. The culture medium is prepared from the following ingredients in parts by weight: 50 to 60 parts of domestic garbage powder, 50 to 70 parts of wood chips, corn cores and / or cotton seed hulls, 15 to 20 parts of wheat bran, 2 to 3 parts of saccharose, 0.2 to 0.4 part of urea, 2 to 4 parts of gypsum and 2 to 3 parts of lime. The useless domestic garbage is applied to the field of medicinal fungus production, meanwhile, the substitute material cultivation mode of the ganoderma lucidum antler being the highest-grade lucid ganoderma is realized, and the industrial cultivation of the ganoderma lucidum antler is favorably realized. The domestic garbage is used in the ganoderma lucidum antler production; the problems of environment pollution and the like due to improper disposal modes and low utilization rate of the traditional domestic garbage treatment are solved; the extremely high practical value is realized.

Owner:辽宁省农业科学院蔬菜研究所

Method for preparing manganese-cobalt-nickel ternary oxide nano powder material

ActiveCN103435109ASimple and fast operationLow costManganese oxides/hydroxidesNickel oxides/hydroxidesManganeseCobalt

The invention relates to a method for preparing a manganese-cobalt-nickel ternary oxide nano powder material, which is an improved method for synthesizing the Mn-Co-Ni ternary oxide nano powder by a room temperature solid phase method. The method comprises the following steps: firstly, using sulfate of manganese, cobalt, nickel and sodium and sodium hydroxide as the raw materials; carrying out ball milling, washing, drying and calcination on the raw material powder to obtain the nano powder. The method has the advantages of simplicity and convenience for operation, low cost, short period, high yield and no pollution to the environment; the obtained Mn-Co-Ni ternary oxide nano powder is of a spinel structure and has a small grain size, a good shape, good dispersibility and high quality.

Owner:中科传感(佛山)科技有限公司

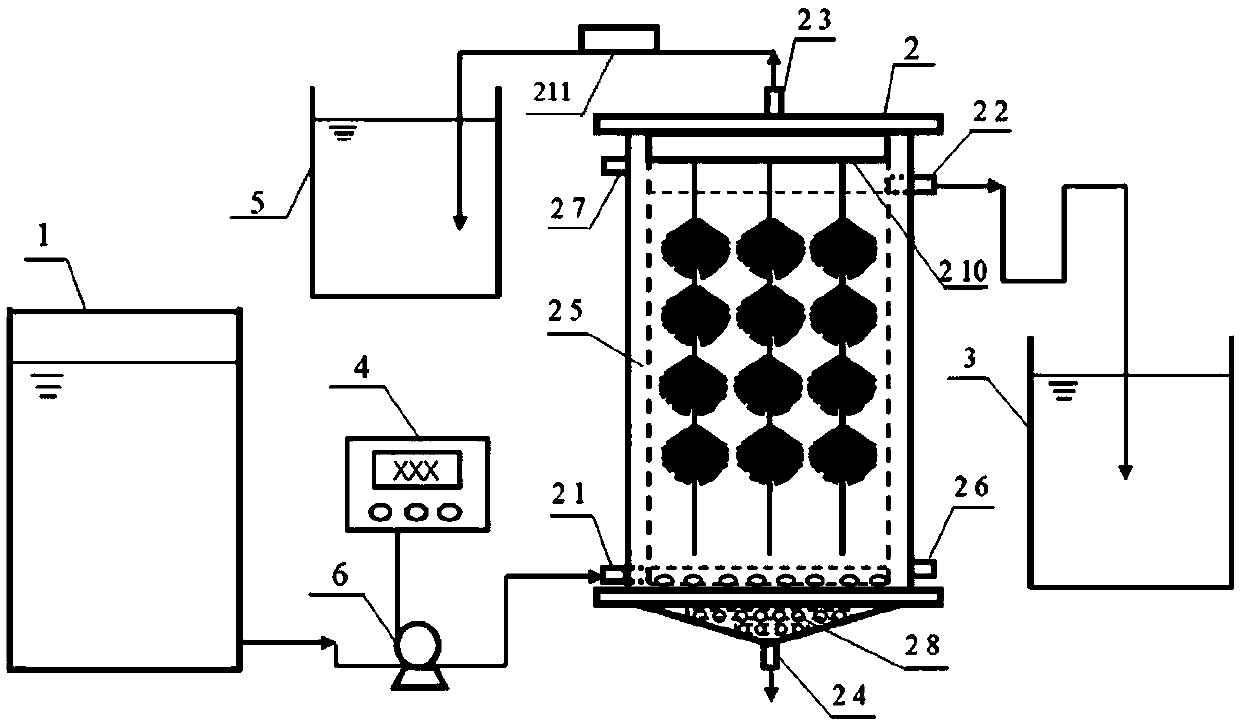

Method and device for enriching anaerobic ammonium oxidizing bacteria based on modified basalt fiber filler

ActiveCN109593685AShort generation cycleSave matrix feedBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeSewage

The invention discloses a method and a device for enriching anaerobic ammonium oxidizing bacteria based on modified basalt fiber filler, and belongs to the technical field of sewage biological treatment. The method is characterized by comprising the following steps: S1, starting a system, mixing nitrified sludge with anaerobic ammonium oxidized sludge, then adding the mixed sludge into a reactor filled with modified basalt fibers, and mixing the sludge thoroughly; S2, in an initial stage of culturing, sending matrix raw water into the reactor; at the same time, turning on circulating water forcircular flow; and S3, in a logarithmic growth phase, controlling the water inlet speed of the raw water matrix for continuous rapid enrichment culturing of the anaerobic ammonium oxidizing bacteria.By adopting the method for enriching the anaerobic ammonium oxidizing bacteria provided by the invention, the generation cycle of the anaerobic ammonium oxidizing bacteria can be effectively shortened, high-activity proliferation in a short time can be realized, effective enrichment culturing of the anaerobic ammonium oxidizing bacteria can be implemented, and a foundation is laid for the engineering application of the novel biological denitrification technology.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

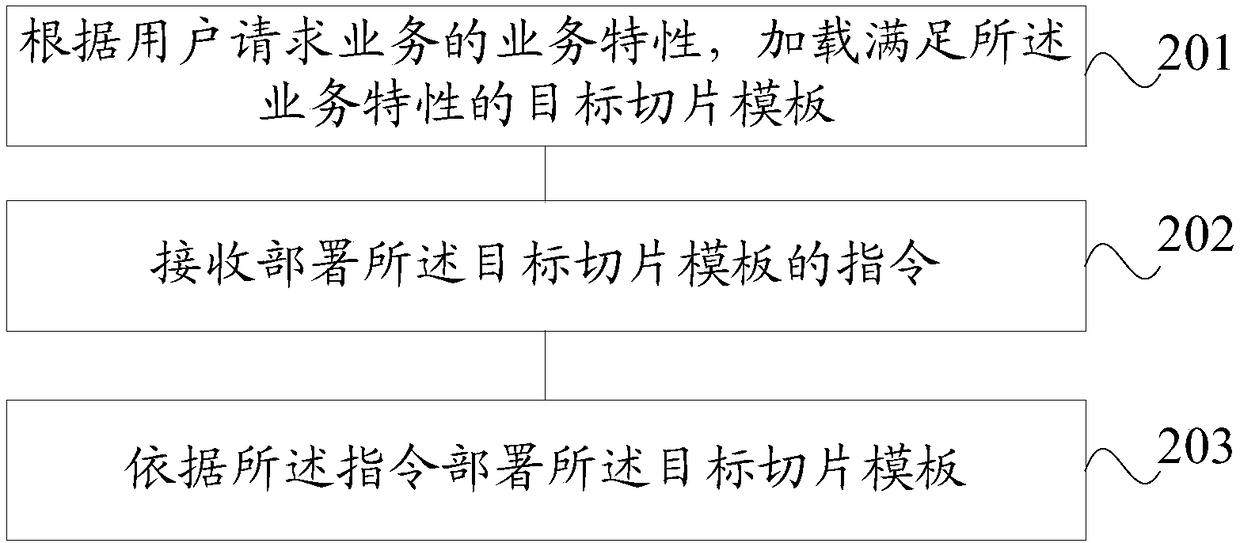

Network slice template generation and network slice template application method and device

ActiveCN108632068AShort generation cycleImprove production efficiencyData switching networksVirtualizationSkill sets

The embodiment of the invention provides a network slice template generation and network slice template application method and device. The method comprises the following steps of according to the service characteristic of a user request service, matching whether there is a slice template satisfying the service characteristic in a preset slice template database; if there is the slice template, determining the slice template satisfying the service characteristic as a target slice template; and if there is not the slice template, based on the service characteristic, a preset slice template, a virtual network function and a network function virtualization infrastructure database, generating the target slice template. In the embodiment of the invention, the slice template which satisfies the service characteristic is matched in the preset slice template database, or based on the preset slice template, the virtual network function and the network function virtualization infrastructure database, the target slice template is generated and a user does not need a plurality of service field skills so that an operation is simplified, large work strength is reduced, the generation period of a network slice template is shortened and the generation efficiency of the network slice template is increased.

Owner:DATANG MOBILE COMM EQUIP CO LTD

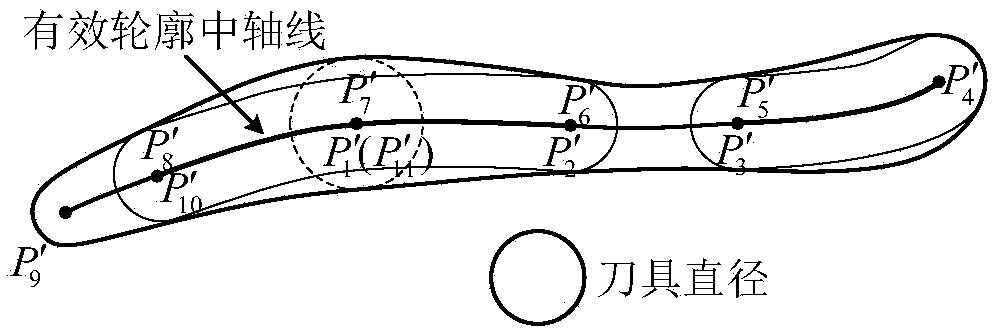

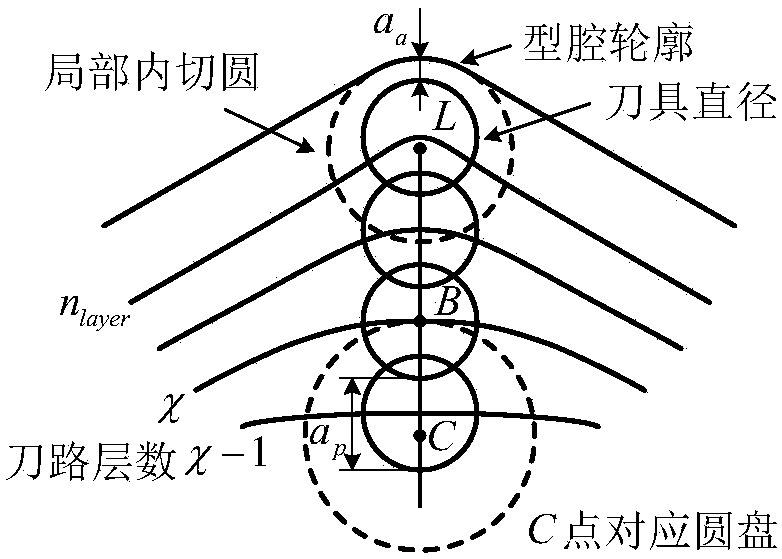

Method for planning path of helical milling tool efficiently for mold cavity based on contour central axis

ActiveCN108415365AImprove smoothnessIncrease the average cutting widthNumerical controlCircular discEngineering

The invention provides a method for planning the path of a helical milling tool efficiently for a mold cavity based on a contour central axis, and the method comprises the steps: calculating a tool path at each layer, carrying out the cutting of a central axis loop, cutting and calculating discs in the actual radial directions of all points, and taking the envelope curves of the discs are the toolpaths of all layers; calculating the path of the helical milling tool, solving the linear difference of two adjacent tool paths, enabling the two adjacent tool paths to be smoothly connected, and obtaining the path of the helical milling tool. The method integrates the advantages of the path of the helical milling tool and a conventional tool path, and the calculated and obtained tool path is smooth. Moreover, the total length of the tool is short, and the method is suitable for the processing of mold cavities in various shapes.

Owner:WUHAN UNIV

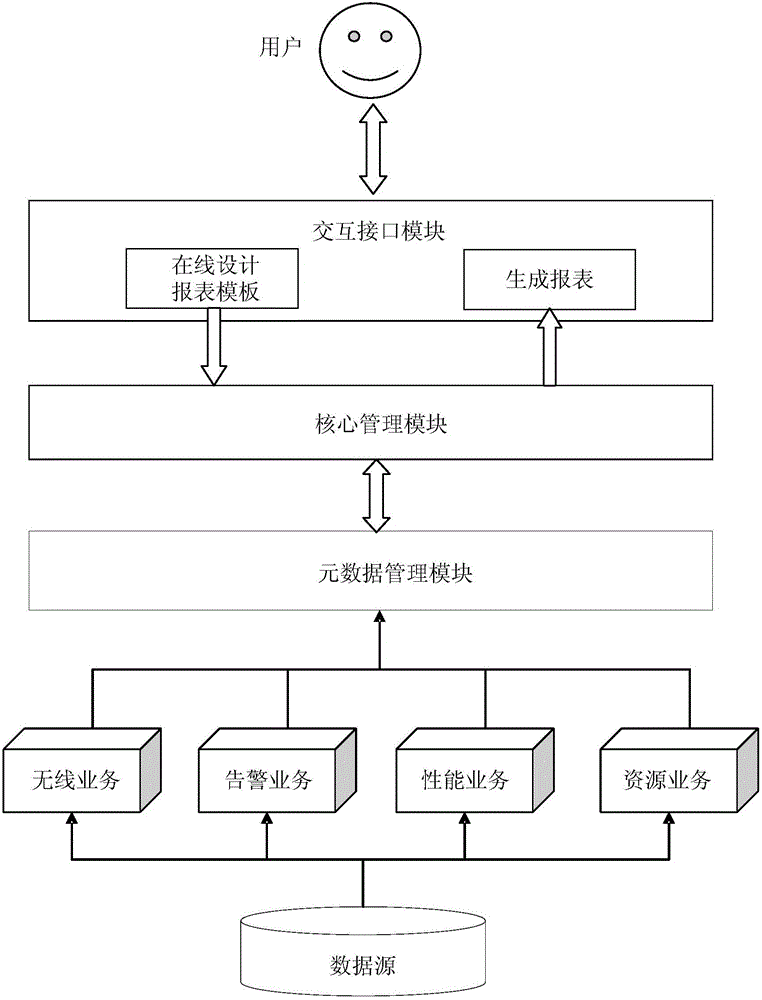

Statement generation method and device

InactiveCN106294299ALong lead timeShort generation cycleNatural language data processingSpecial data processing applicationsData sourceBusiness data

The embodiment of the invention provides a statement generation method and device. The method comprises the following steps of: determining a first statement template corresponding to first business, wherein the first statement template is generated in advance according to a first metadata interface corresponding to the first business and the selection operation of a user, and the first metadata interface comprises at least one optional class; analyzing the first statement template to obtain a target optional class which is contained in the first statement template; obtaining business data corresponding to the target optional class from a data source; and according to the business data and the first statement template, generating a business statement corresponding to the first business. By use of the embodiment, the generation period of the statement can be shortened.

Owner:NEW H3C TECH CO LTD

Software test case generation method with every two cases forming one combination

InactiveCN107704381AShort generation cycleSave test resourcesSoftware testing/debuggingConstraint relationMethod of undetermined coefficients

The invention provides a software test case generation method with every two cases forming one combination. According to the method, a boundary value algorithm, an equivalent partitioning algorithm, arandom algorithm and other algorithms are applied to extraction of software input factors, and the generation cycle of a value set is lowered; a combination coverage method is adopted to combine theinput factors in sequence according to the order of products of every two weights to generate a test case set with a priority order; in the testing process, if the test cases with high priorities areused first, a problem can be discovered earlier, and test resources can be saved; and by performing position improvement on limited combinations in the test cases, the problem that a constraint relation exists in the test case set is solved. Through the method, redundancy of the test cases is remarkably reduced, influences of all the factors on a software system are better checked with less test cases, and system efficiency is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

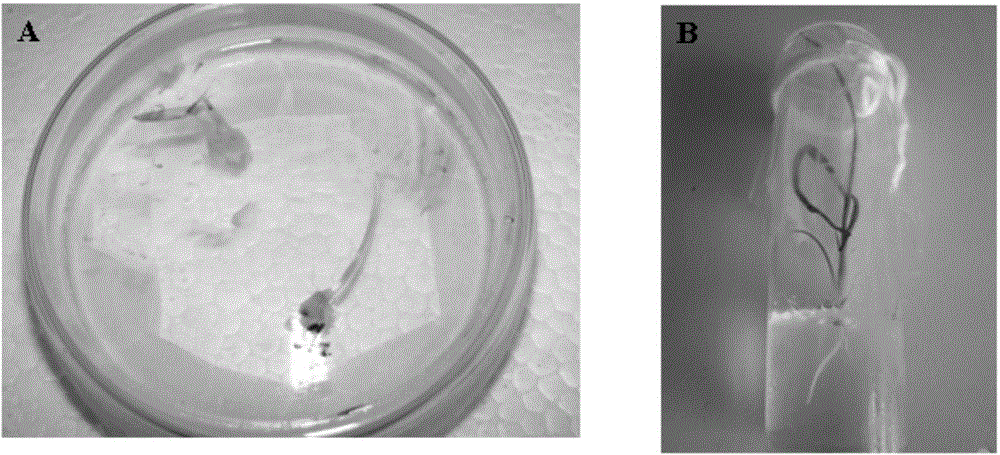

Method for rapid propagation of zephyr lily

Owner:ZHENGZHOU NORMAL UNIV BIOLOGY ENG RES

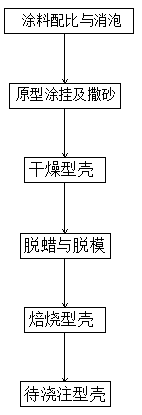

Novel manufacturing process of impeller

InactiveCN111558689AReduce lossImprove shock absorptionAdditive manufacturing apparatusFoundry moulds3d printManufacturing technology

The invention relates to a novel manufacturing process of an impeller. The novel manufacturing process is characterized by comprising the following specific process steps of S1, carrying out 3D printing on an impeller prototype; S2, manufacturing a casting system with a riser to form a module; S3, manufacturing a shell; S4, dewaxing and demolding treatment; and S5, carrying out casting molding. According to the novel manufacturing process of the impeller, compared with a traditional casting or forging method, the method has great advantages that a corresponding mold is needed when the castingor forging method is used, raw materials and time are wasted, the tedious procedures are omitted through the 3D printing technology, computer related software can be helped to directly generate the impeller, and any complex impeller can be quickly printed, so that the generation period is shortened, the cost is reduced, the advantage of greatly reducing the raw material loss in the research and development process is achieved, meanwhile, the impeller produced by using the process can greatly improve the overall shock absorption and noise reduction capabilities of a pumping set, actual production reference is provided for the rapid low-pressure investment casting production process of castings, and the feasibility of the process is verified.

Owner:JIANGSU UNIV OF SCI & TECH +1

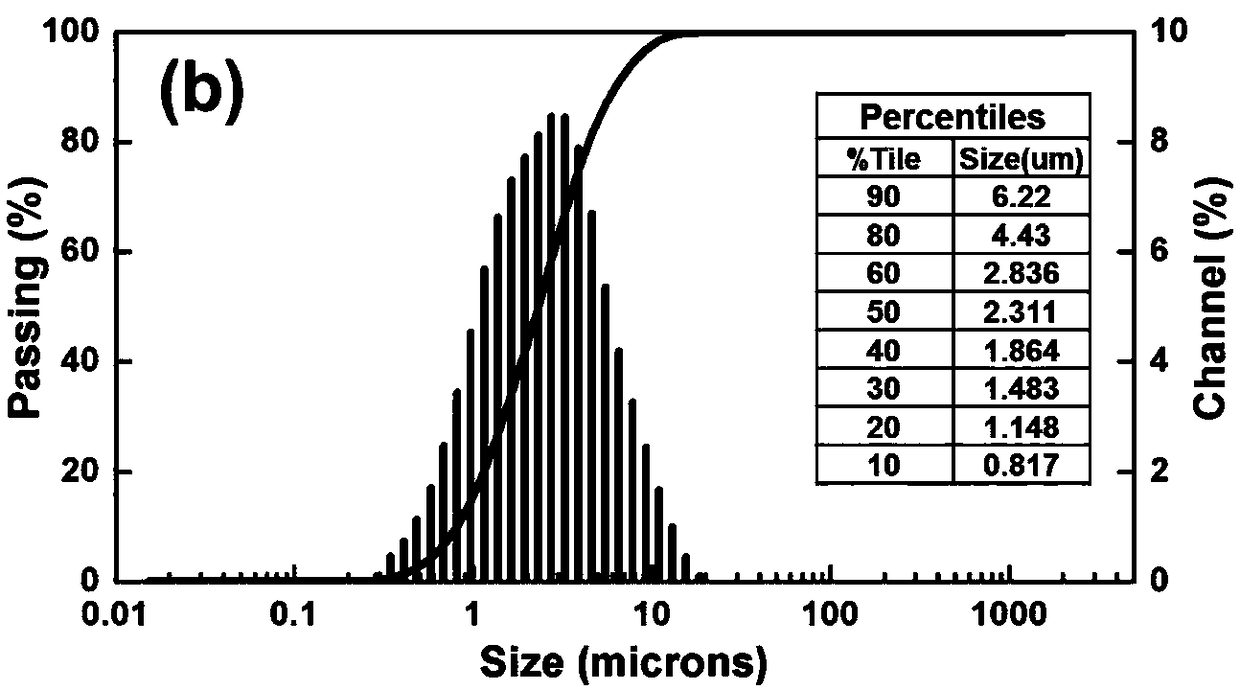

Preparation method of MgZn ferrite products

The invention discloses a preparation method of MgZn ferrite products, which comprises the following steps: crushing recycled MgZn ferrite into magnetic powders and then mixing with ferric oxide, zinc oxide, magnesium oxide and additives to prepare raw materials; grinding the raw materials into powders; performing spray granulation process: adding water into a sand mill and then adding the grinded powders, controlling the solid content to be 55-65wt%, sanding for 3 hours, adding 17-20wt % of PVA (polyvinyl alcohol) glue in the sanding process, performing the spray granulation when the granularity of the sanded powder is smaller than 1.0 mum; adding zinc stearate into the granulated powder, pressing and molding to prepare semi-finished products, and then sintering the semi-finished products for 3-4 hours in a high-temperature furnace at 1260-1310 DEG C to obtain the products. The method is low in cost, suitable for recycling and short in production period; the prepared MgZn ferrite products are characterized by high magnetic conductivity and frequency impedance selectivity; and the method is widely applied to manufacturing the MgZn ferrite products.

Owner:CHENGDU GUOGUANG ELECTRIC

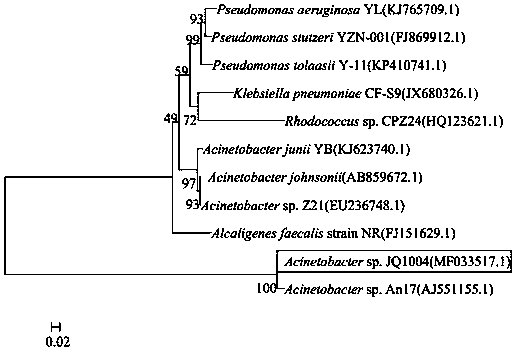

Acinetobacter and application thereof

InactiveCN109913382ARealize synchronous removalAchieve removalBacteriaWater contaminantsMicroorganismHigh concentration

The invention discloses acinetobacter and application thereof. The acinetobacter is named as Acinetobacter JQ1004, and the Acinetobacter strain JQ1004 was deposited in China Microbiological Culture Collection Management Committee (CGMCC) on March 06, 2018 under the accession number of CGMCC No. 15414. The acinetobacter is a heterotrophic nitrifying aerobic denitrifying bacterium, can carry out nitrifying and denitrifying by taking organic carbon as a carbon source under the same aerobic condition, and can respectively grow by taking ammonia nitrogen and nitrate nitrogen as nitrogen sources. The acinetobacter disclosed by the invention has the characteristic of high-concentration ammonia nitrogen load resistance, and can be propagated and metabolized under the condition that the ammonia nitrogen concentration is 0-2000 mg / L.

Owner:BEIJING UNIV OF TECH

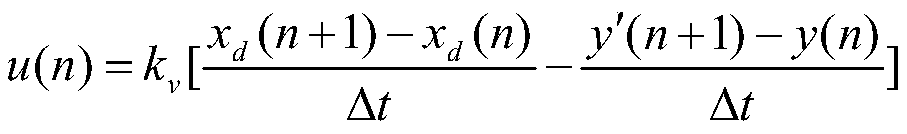

RT operation system and FPGA-based rotary table state space control system and method

ActiveCN110045654AReduce overheadImprove computing efficiencyProgramme controlComputer controlOperational systemControl system

The invention discloses an RT operation system and FPGA-based rotary table state space control system and method. The system which comprises an RT operation module, an FIFO data flow, an FPGA servo operation module and an encoder module is adopted, a simulation rotary table control scheme which adopts RT and FPGA is provided, target position instruction obtaining is carried out through an RT module, and control output calculation is carried out by utilizing the FPGA servo operation module at the same time, so that the requirements, for instantaneity and servo bandwidth in simulation rotary table dynamic control process, of semi-physical simulation tests are satisfied, the calculation precision is high and the operation time is short.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Stage purification method for black and odorous river water

InactiveCN102206016AEfficient removalGuaranteed uptimeWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesAmmoniacal nitrogenPurification methods

The invention provides a stage purification method for black and odorous river water. The method comprises the following steps: (1) carrying out first-stage preprocessing: adding photosynthetic bacteria and anaerobic ammonia oxidation bacteria in the black and odorous river water and enriching on surfaces of an Aquamats material to form biomembranes in natural light; (2) carrying out second-stageprocessing: adding sulfur-oxidizing bacteria in the black and odorous river water and enriching on the surfaces of the Aquamats material to carry out oxidation on sulphions and ferrousions under an aerobic condition; and (3) carrying out third-stage processing: adding nitrobacteria in the black and odorous river water and enriching on the surfaces of the Aquamats material to carry out nitration on ammonia nitrogen under the aerobic condition. The method has the advantages of high efficiency and stability of black and odorous river water purification, energy saving and low carbon.

Owner:EAST CHINA NORMAL UNIV

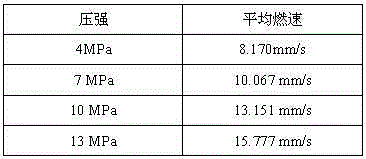

Combustion speed testing method for gel propellant

InactiveCN103604905AEasy to prepareEasy to promoteChemical analysis using combustionAutomotive engineeringThin walled

The invention discloses a combustion performance testing method for a gel propellant. The method comprises the following steps: directly taking a prepared gel propellant as a sample to be tested and injecting the sample into a thin-wall straight plastic pipe of which the inner diameter is 8mm-10mm and one end is closed to prepare a powder pipe to be detected; fixing the powder pipe to be detected on a powder rack of a combustion room; placing ignition powder on one unclosed end and fixing by using a nickel-chrome wire; coating an end face by using a coating agent; and putting the powder rack of the combustion room, which carries the fixed powder pipe to be detected, into an underwater acoustic emission combustion speed meter to test a combustion speed and finally calculating an average combustion speed, a combustion speed pressure index and a combustion speed temperature sensitivity coefficient. The method is simple and easy to operate and short in testing period, and can rapidly and accurately test the combustion performance of the gel propellant.

Owner:XIAN MODERN CHEM RES INST

Chinese medicine capable of making cultured prawn quickly shelling and disinfecting water thereof

InactiveCN1422657AShort generation cycleImprove living qualityBiocideUnknown materialsEscherichia coliSophora Root

The present invention discloses a Chinese medicine capable of accelerating cultivation of penaeus, making it quickly shell and disinfecting water body for killing red achoricine, dermal fungi, anthrax bacteria, xanthous staphylococcus, colibacillus and parotid virus, etc. being in the water pool for cultivating penaeus. Said Chinese medicine is made from 19 Chinese medicinal materials of corter pseudolaricis, flavescent sophora root, polygonatum root and others. After said medicine is applied into the cultivation pool for 0.5-1 hr., it can produce medicine effect.

Owner:文仁肇

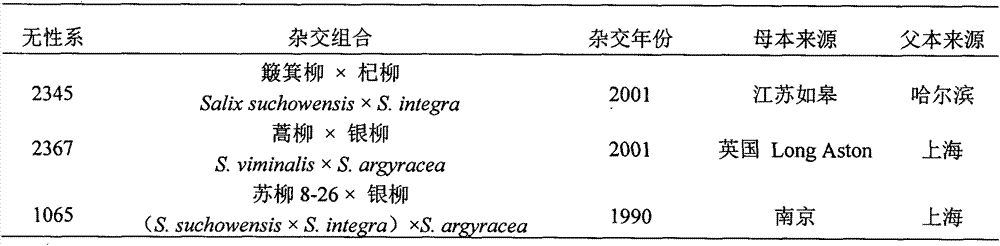

Salix saposhnikovii tissue culture method

ActiveCN103168692AImprove reproductive efficiencyShortened growth timePlant tissue cultureHorticulture methodsBiological studiesMolecular breeding

The invention discloses a salix saposhnikovii tissue culture method. The salix saposhnikovii tissue culture method comprises the following steps of: (1) material selection and disinfection treatment; (2) cultivation of tube seedlings; (3) proliferation and rooting cultivation; and (4) acclimatization of seedlings and transplanting. The salix saposhnikovii tissue culture method provided by the invention is high in propagation efficiency and small in occupied space without being limited by seasons or outside environments, needs few parent materials, and can provide a large number of high-quality nursery stocks in a short term. In addition, the successful establishment of an efficient salix saposhnikovii tissue regeneration system has great significance for the development of work such as biological research, genetic improvement and multi-target molecular breeding of salix saposhnikovii.

Owner:JIANGSU ACAD OF FORESTRY

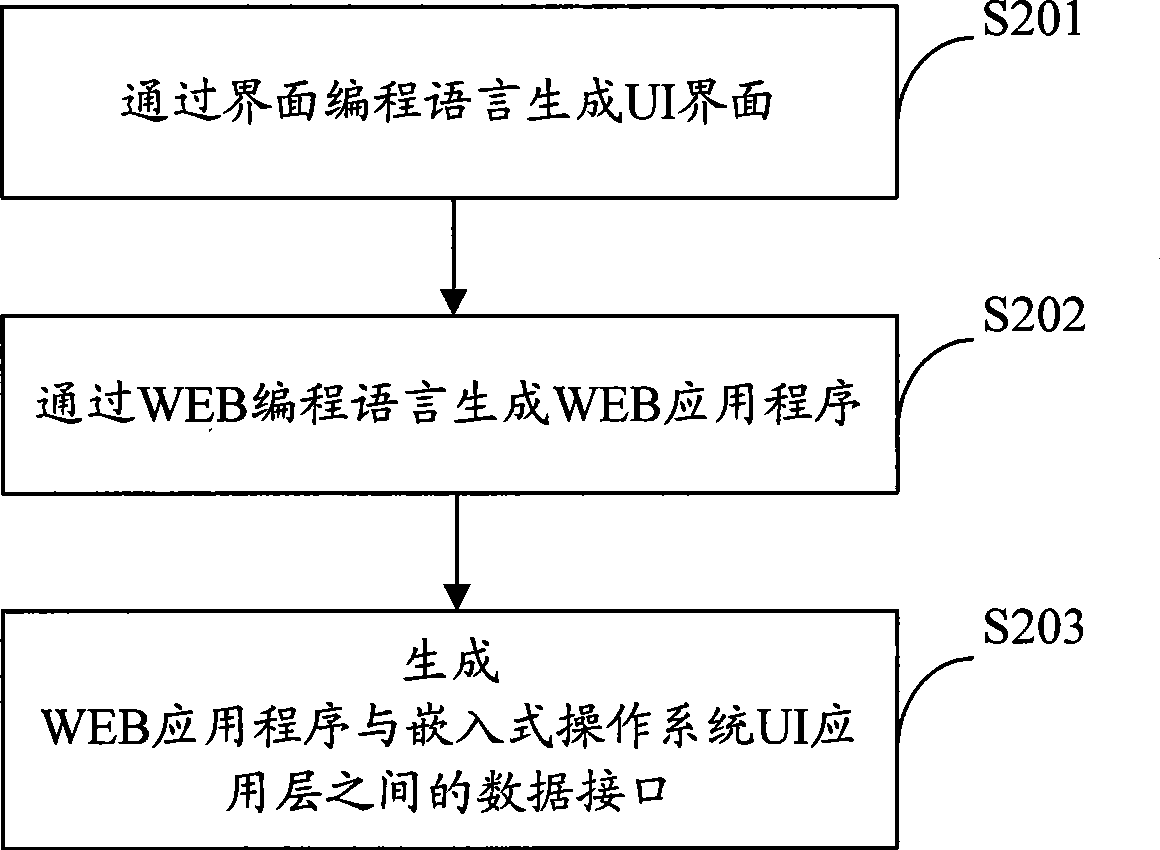

Generation system, method for television user interface

InactiveCN101483737AImprove portabilityShort generation cycleTelevision system detailsColor television detailsOperational systemEmbedded operating system

The invention is suitable for the technical field of TV, providing a system and method for generating TV user interface. The system comprises an embedded operation system UI application layer. The system also comprises an UI interface used for generating the resource related to the interface; WEB application program used for receiving the operating directive of the user for updating the UI interface resource according to the operating directive; the embedded operation system UI application layer used for generating the application UI with embedded operating system referred to in the application layer data transmission between the interface; data transmission through the embedded operating system interface will be described in UI application layer data transmission to the applications described in WEB or WEB application will be described in data transfer to the WEB application described; WEB application layer, used to run WEB application described shows that the interface described in UI to generate resources. The UI interface of the invention has a great portability.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

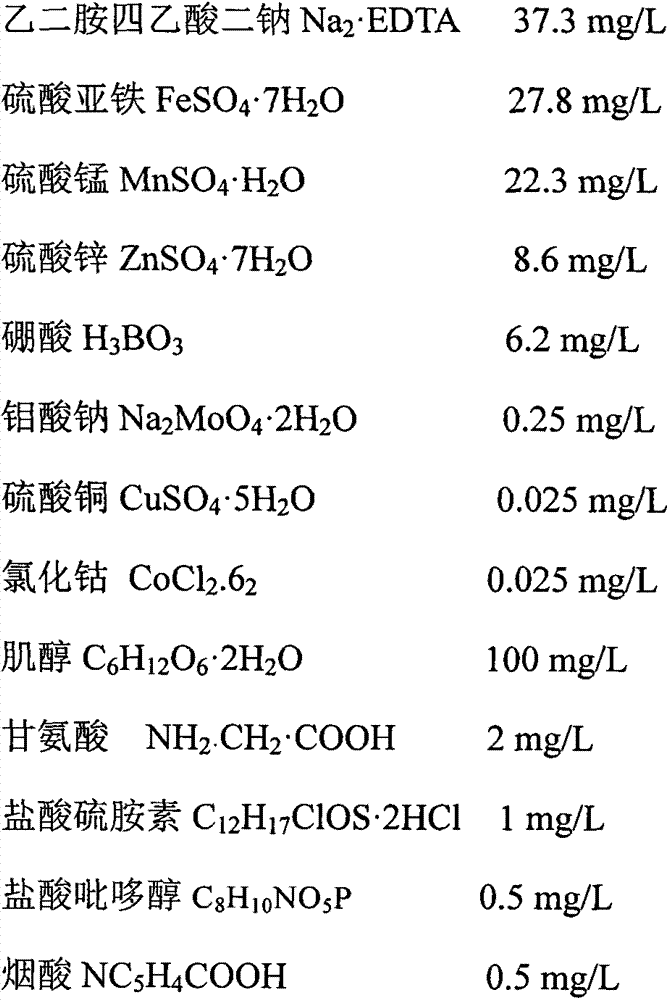

Tissue culture method for directly growing seedling from barley embryo and culture medium used in method

ActiveCN103947550AShortened maturation timeEasy to operateHorticulture methodsPlant tissue cultureHordeum vulgareEmbryo

The invention discloses a tissue culture medium for directly growing a seedling from a barley embryo. The tissue culture medium comprises a seedling growing culture medium and a root growing and seedling strengthening culture medium. A preparation method of the seedling growing culture medium comprises the following steps: firstly, regulating the pH value of every 1L of mother solution of the seedling growing culture medium to be 5.7-5.9; secondly, adding plant gel; thirdly, performing sterilization; and finally, adding filtered and sterilized vitamin B1, vitamin B6, nicotinic acid, 6-benzylaminopurine and 2,4-dichlorphenoxyacetic acid. A preparation method of the root growing and seedling strengthening culture medium comprises the following steps: firstly, adding inositol, casein hydrolysate, proline and malt sugar into every 1L of MS basic culture solution; secondly, regulating the pH value to be 5.8-6.0, then adding the plant gel and then performing the sterilization; and finally, adding the filtered and sterilized vitamin B1. The invention also provides a tissue culture method for directly growing the seedling from the barley embryo, and in the method, tissue culture medium is used.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com