Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Realize synchronous removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

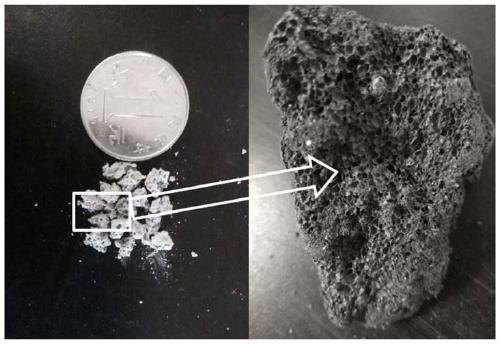

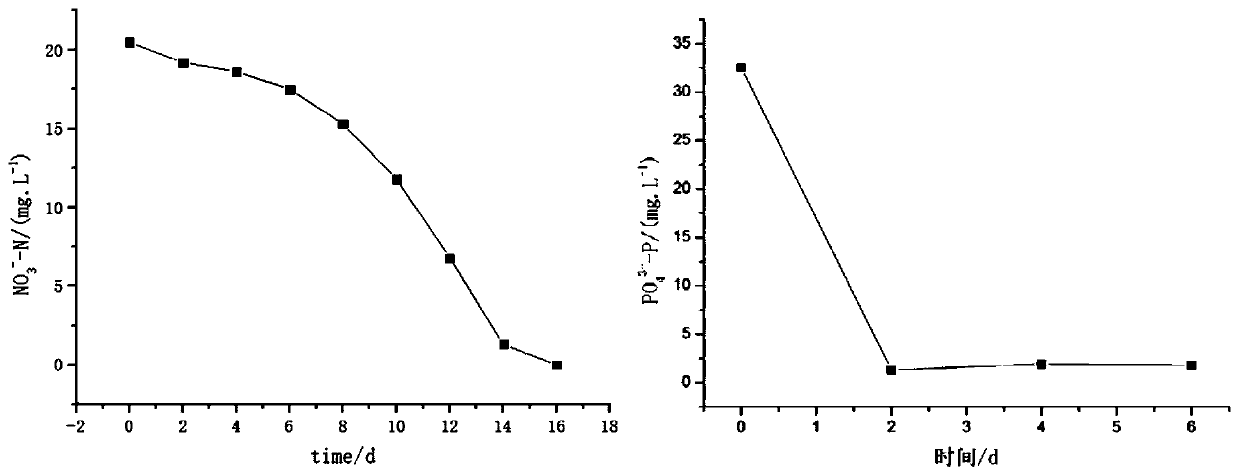

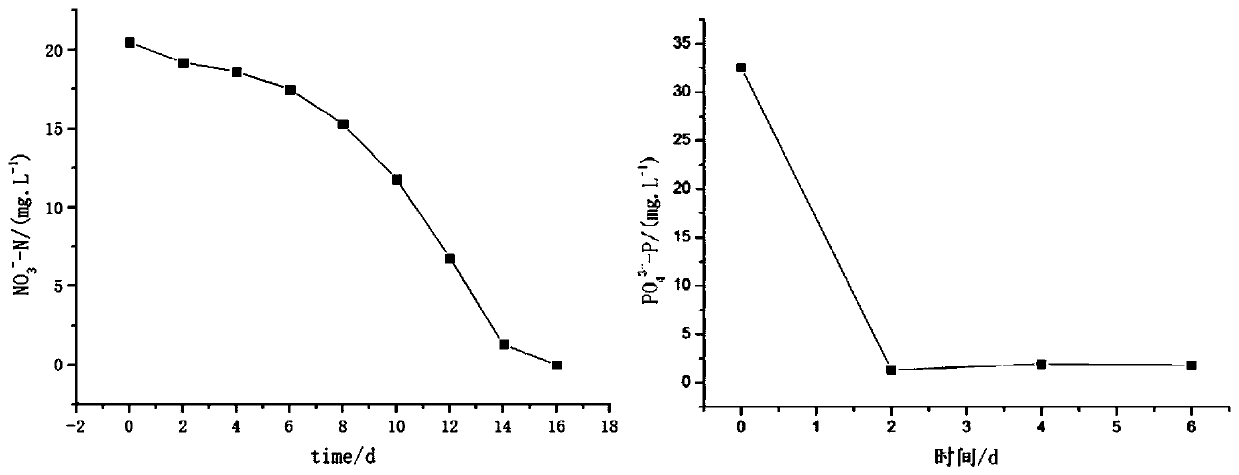

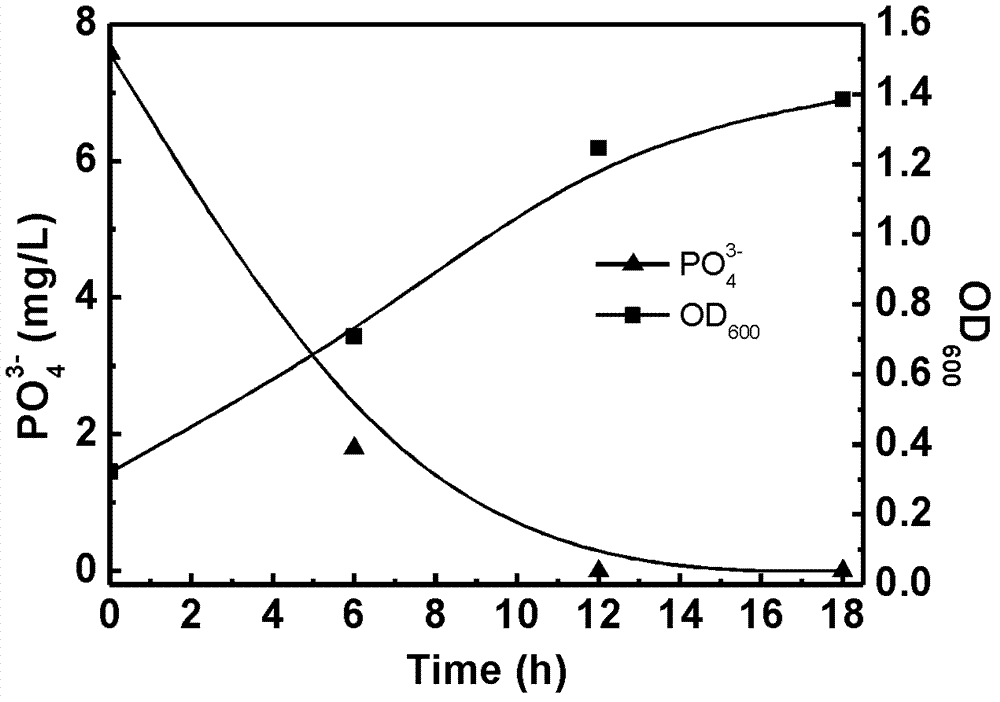

Lightweight slow-release nitrogen and phosphorus removal material and preparation method and application thereof

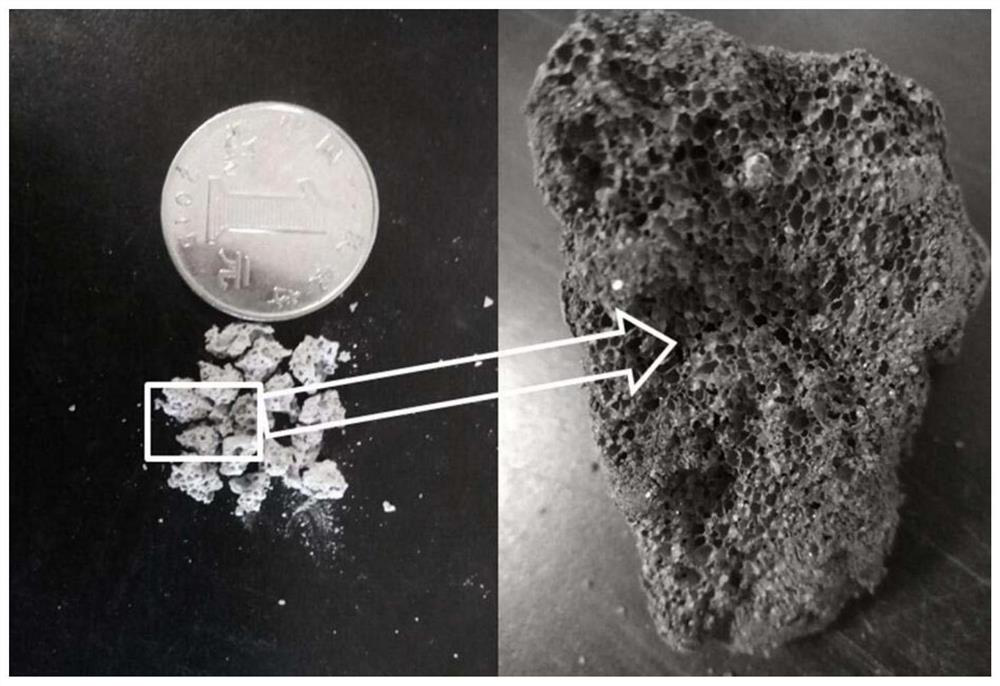

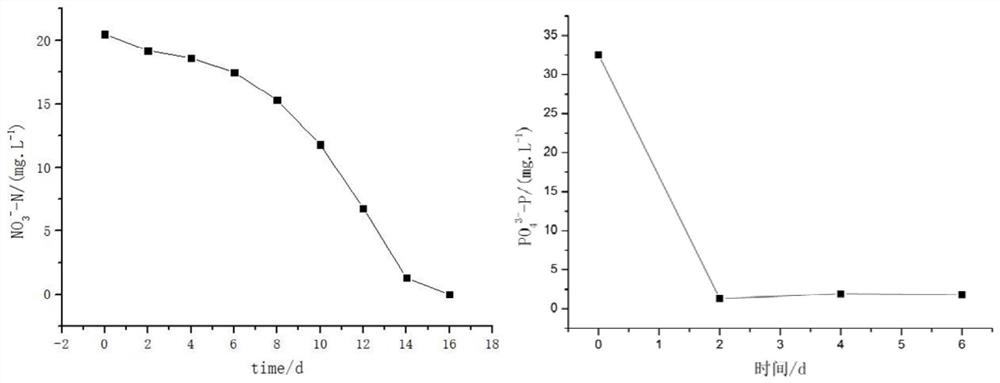

ActiveCN110002806AHigh specific surface areaDensity controllableWater treatment parameter controlTreatment with aerobic and anaerobic processesIonChemistry

The invention discloses a lightweight slow-release nitrogen and phosphorus removal material and a preparation method and application thereof, and belongs to the field of environment function materialsand sewage treatment. The preparation method comprises the following steps: uniformly mixing cement, pyrite, a foaming agent and a foam stabilizer to obtain dry-mixed mortar; adding water into the dry-mixed mortar, and stirring to prepare the lightweight slow-release nitrogen and phosphorus removal material. The lightweight slow-release nitrogen and phosphorus removal material of the invention has characteristics of high specific surface area, controllable density, high reactivity, easy microbial biofilm formation, slow-release electron donor nitrogen-removal and iron ion phosphorus-removal,etc., can be used as a filling material for sewage treatment fluidized beds and fixed beds, a filling materials for constructed wetlands and in-situ and ex-situ purifying material for polluted water bodies, and has a good purifying effect on pollutants in water, especially on total nitrogen and total phosphorus.

Owner:NANJING UNIV

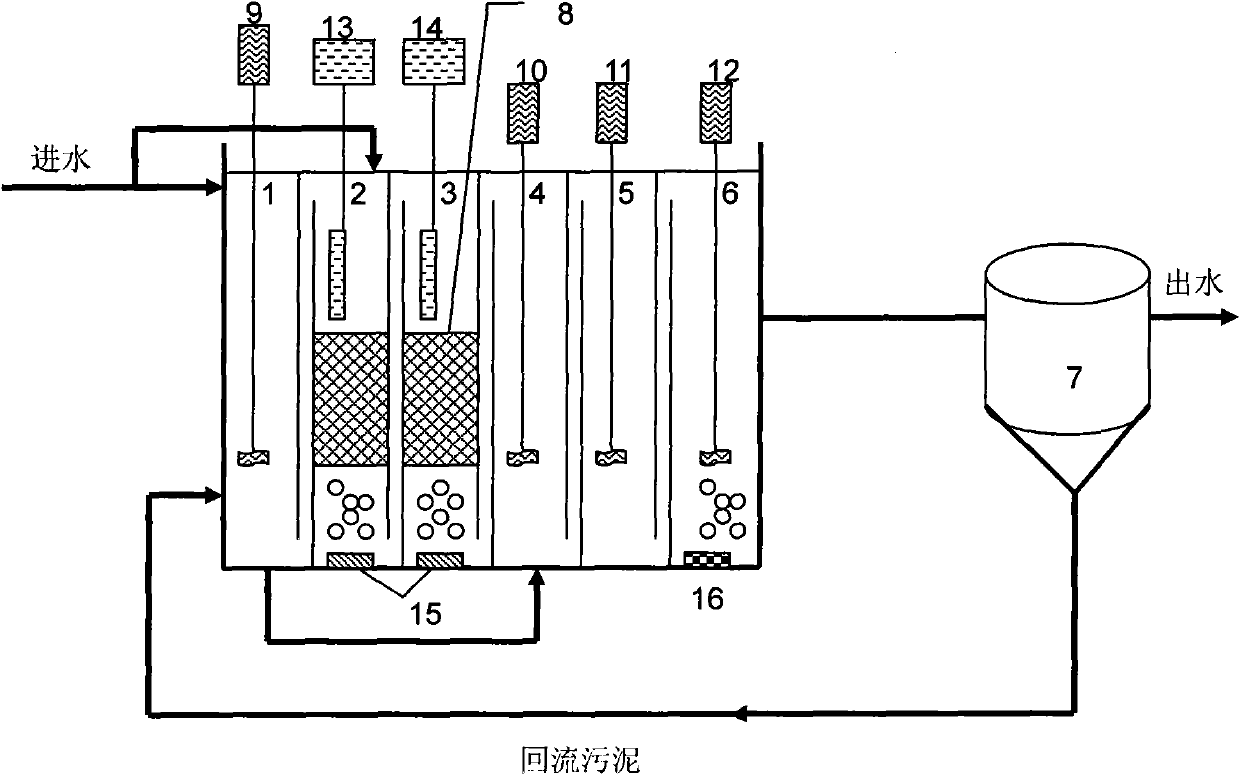

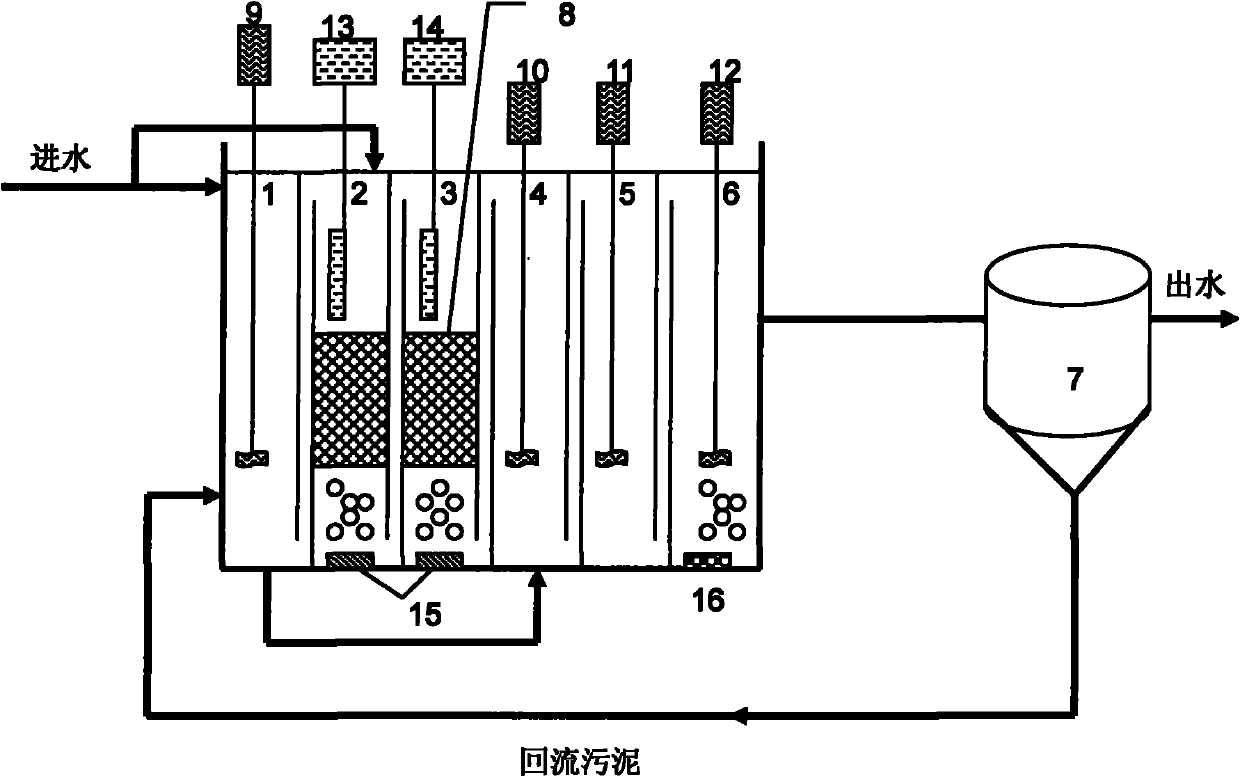

Energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and device thereof

ActiveCN101792233AAccumulation and stabilityRealize energy saving and consumption reductionWater contaminantsMultistage water/sewage treatmentElectron donorNitration

The invention discloses an energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and a device thereof, belonging to technical field of domestic and industrial sewage treatment. A metal carrier bed is installed in an aerobic section with integrated reaction, and is made of iron wood shaving washed through acid cleaning; and the outer part of the iron wood shaving is covered by wire netting. Under conditions of normal temperature and low dissolved oxygen, the aims of short-range nitration and synchronous denitrification can be realized; an anaerobic section is used for finishing phosphorous releasing; the aerobic section is used for finishing short-range nitration, an anoxic section is used for finishing denitrification for removing phosphorous, a fast aerobic section is used for removing remaining ammonia and nitrogen and phosphorous. The invention uses iron wood shaving with low cost to realize stable accumulation of nitrite; the aerating amount is small, the carbon source is saved, and denitrification for phosphorous removing is carried out by taking the nitrite produced via short-range nitration as electron donor, thus the nitrogen and phosphorous can be removed synchronously; and the problem that the nitrite in water could damage the environment and has toxicity is solved. The invention can realize the aims of saving energy and reducing consumption to the largest extent, and is suitable for purifying and treating domestic sewage continuously for a long time.

Owner:TSINGHUA UNIV

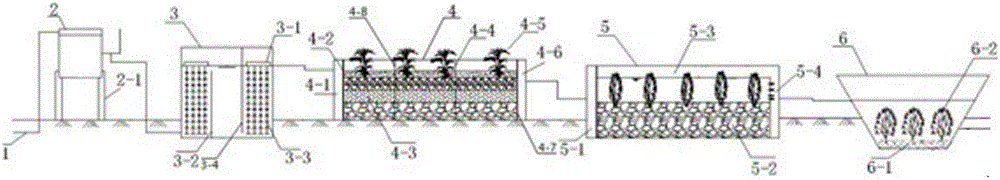

Combined multi-level ecological unit system for deeply treating secondary effluent of sewage plant

InactiveCN105859041AGravity self-flowImprove purification efficiencyWater contaminantsBiological treatment apparatusConstructed wetlandUnit system

The invention discloses a combined multi-level ecological unit system for deeply treating secondary effluent of a sewage plant. The system sequentially consists of a water distribution tank, an ecological pond, a secondary constructed wetland and a submerged plant pond. When the system runs, tail water of a sewage treatment plant sequentially passes through the ecological pond, a subsurface flow wetland, a surface flow wetland and the submerged plant pond, and is purified under the joint action of a filler-microorganism-plant system, and effluent is high in water quality and stable. The system has the advantages of capability of efficiently removing nitrogen and phosphorus, low capital construction cost, no power consumption, convenience for subsequent maintenance and operation and the like, and has a landscaping value, and the aim of deeply treating the effluent can be fulfilled.

Owner:无锡城建发展集团有限公司 +3

Device and method for processing coking wastewater by adopting suspended filler-anaerobic membrane bioreactor

InactiveCN104085988ARealize synchronous removalSimple processTreatment with aerobic and anaerobic processesActivated sludgeChemical oxygen demand

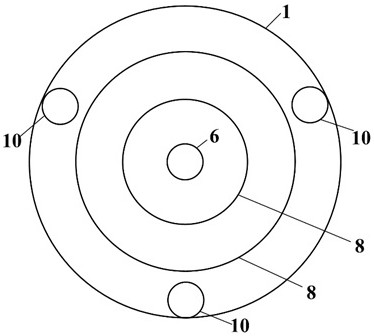

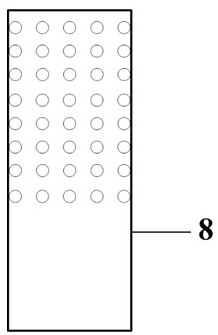

The invention discloses a device and a method for processing a coking wastewater by adopting a suspended filler-anaerobic membrane bioreactor, belonging to the field of coking wastewater treatment. The device comprises an anaerobic reaction pool and a sludge sedimentation pool, wherein a micropore aeration system, a suspended particle packing, a membrane module and a stirring system are arranged inside the anaerobic reaction pool; the activated sludge in the anaerobic reaction pool takes a biological membrane attached to the suspended particle packing as a main component; the suspended activated sludge is collected, separated and discharged out of the system through the sludge sedimentation pool; and synchronous nitrification and denitrification functions of the biological membrane on the suspended packing are enhanced by stirring for fluidization of the stirring system under an anaerobic condition, thereby achieving the treatment effect of synchronously removing chemical oxygen demand (COD) and total nitrogen in the coking wastewater. By adopting the device, the aeration rate is significantly reduced, and the operating cost is reduced. The activated sludge takes the biological membrane in the attached state as the primary component, so that the contact frequency of the activated sludge and the membrane module filtering surface is reduced, and the membrane pollution process is effectively retarded by the scraping effect of the suspended particle packing.

Owner:UNIV OF SCI & TECH BEIJING

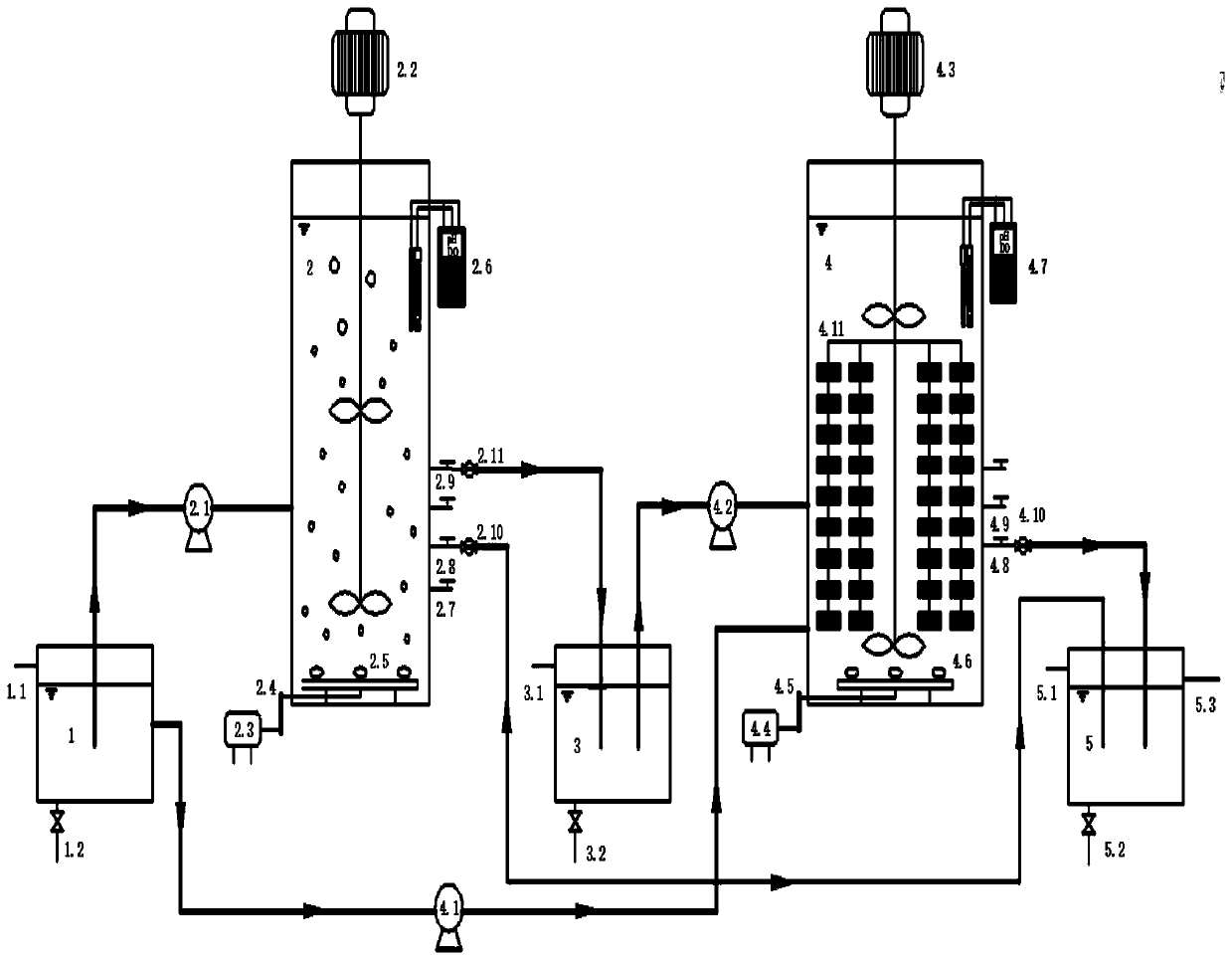

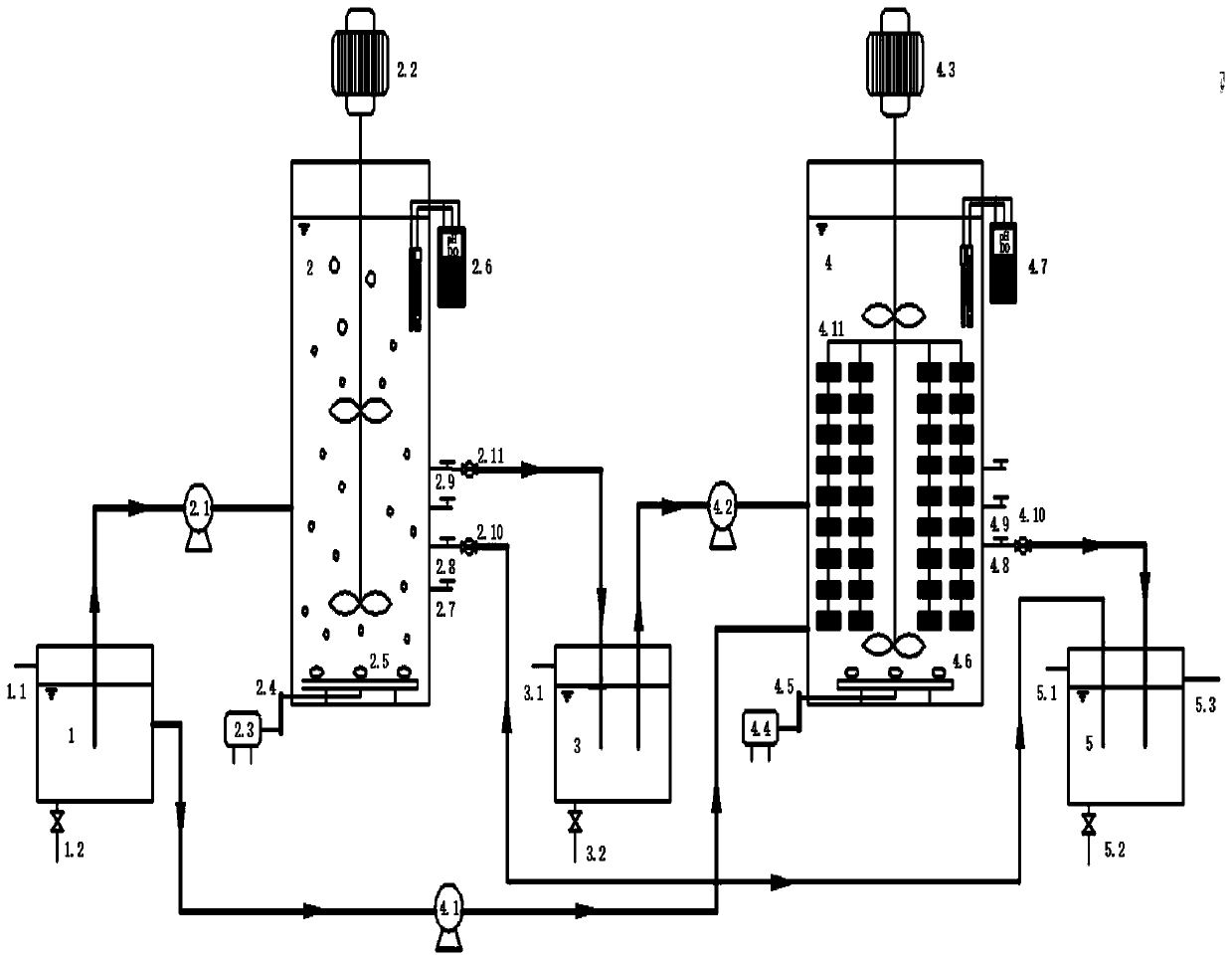

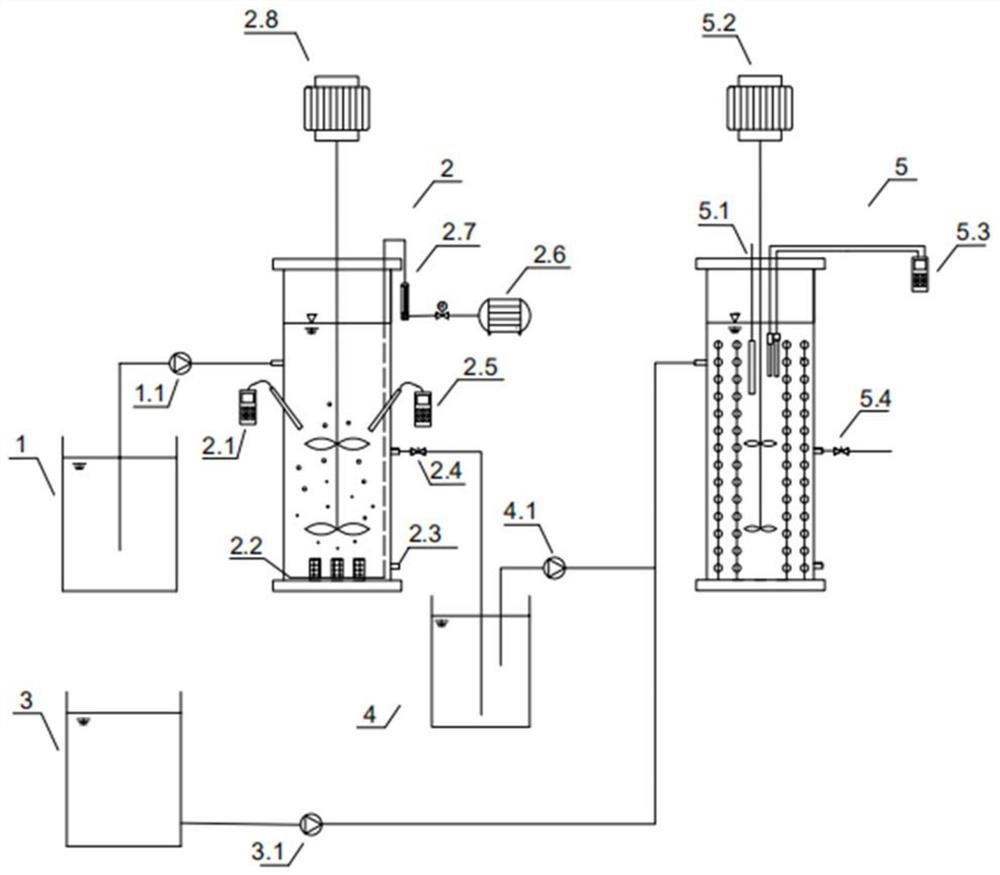

Device and method for synchronous SBR denitrifying phosphorus removal and internal source short-range denitrifying anaerobic ammonia oxidation

ActiveCN106006963ARealize synchronous removalEfficient use ofTreatment with aerobic and anaerobic processesSustainable biological treatmentDenitrifying bacteriaWastewater

The invention provides a device and method for synchronous SBR denitrifying phosphorus removal and internal source short-range denitrifying anaerobic ammonia oxidation, and belongs to the field of biological treatment of sewage. The device mainly comprises an urban sewage raw water tank, an anaerobic / anoxic SBR, an intermediate water tank, an all-way nitrifying SBR, a blast aerator and a water drainage tank. Urban sewage with low C / N enters the anaerobic / anoxic SBR at first, PAOs carries out anaerobic phosphorus release, and meanwhile, the urban sewage is stored as an internal carbon source PHA by COD in raw water. Anaerobic / anoxic SBR denitrifying phosphorus-accumulating bacteria exist as bio-flocculate, short-range denitrifying bacteria and anaerobic ammonium oxidation bacteria which have long sludge age exist as biological membranes and grow in packing of a reactor, and the SBR discharges flocculate sludge at regular intervals to remove phosphorous, so that competition of different bacteria to the sludge age is avoided. By the device and method, N, P and COD of the urban sewage with low C / N can be removed effectively, and an external carbon source is not required; the problem that NO2<-> is difficult to obtain stably by short-range nitrifying is solved; a new treatment mode is provided for wastewater containing NO3<-> and P.

Owner:BEIJING UNIV OF TECH +1

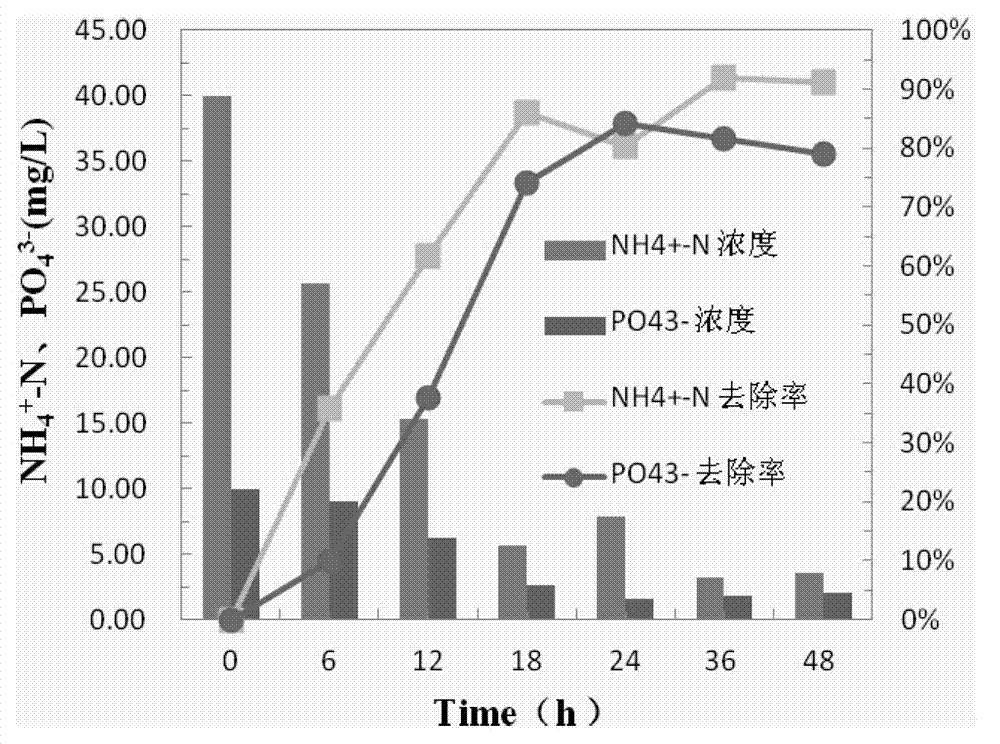

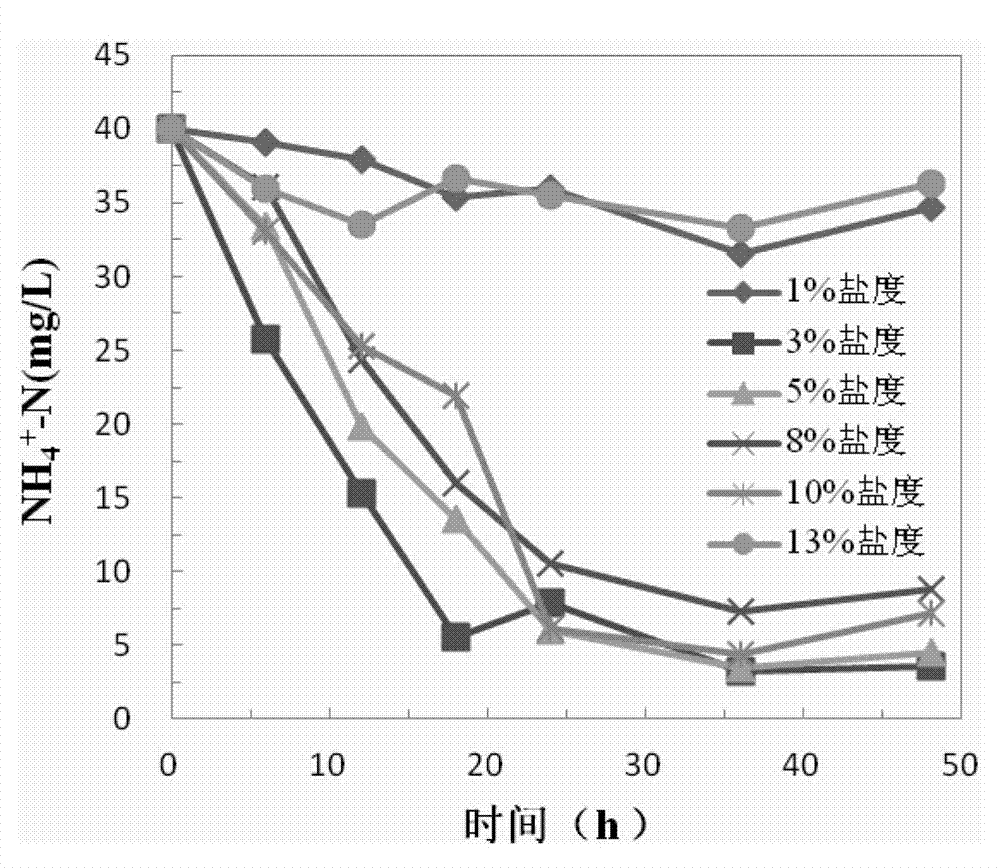

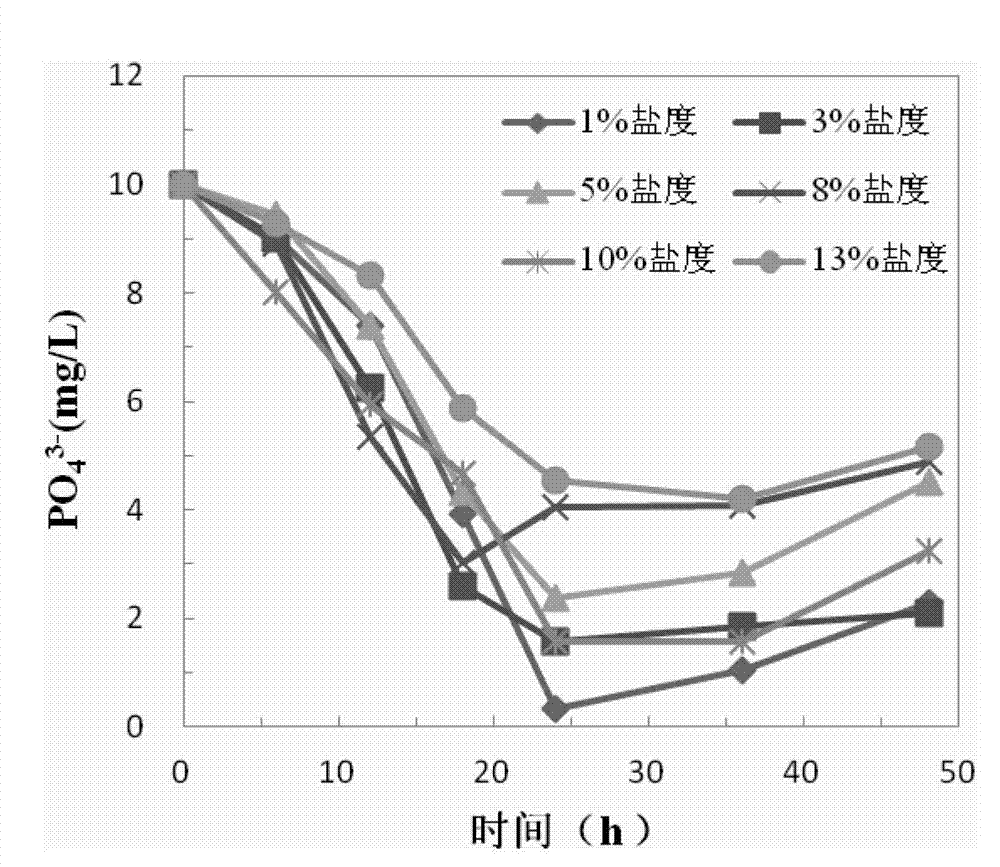

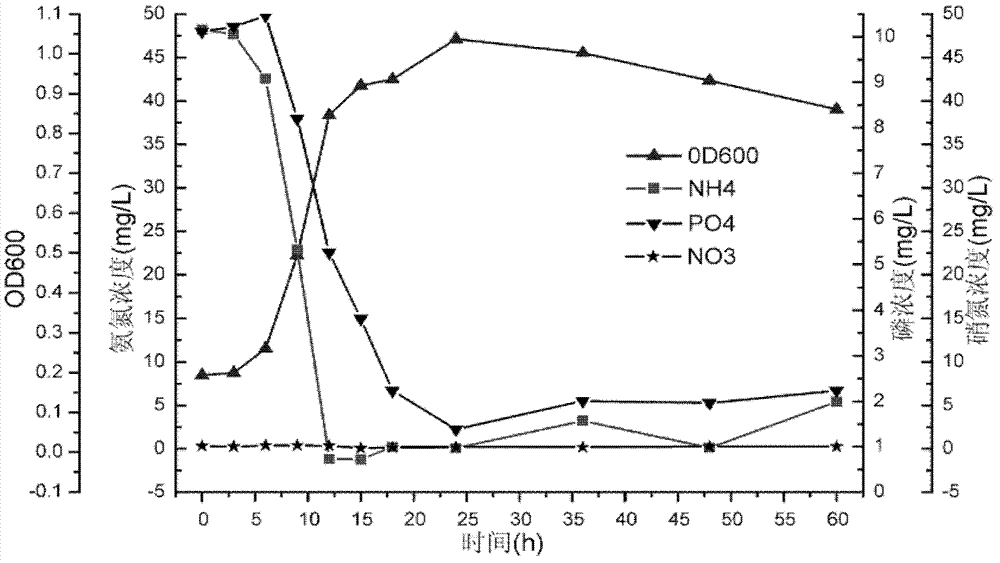

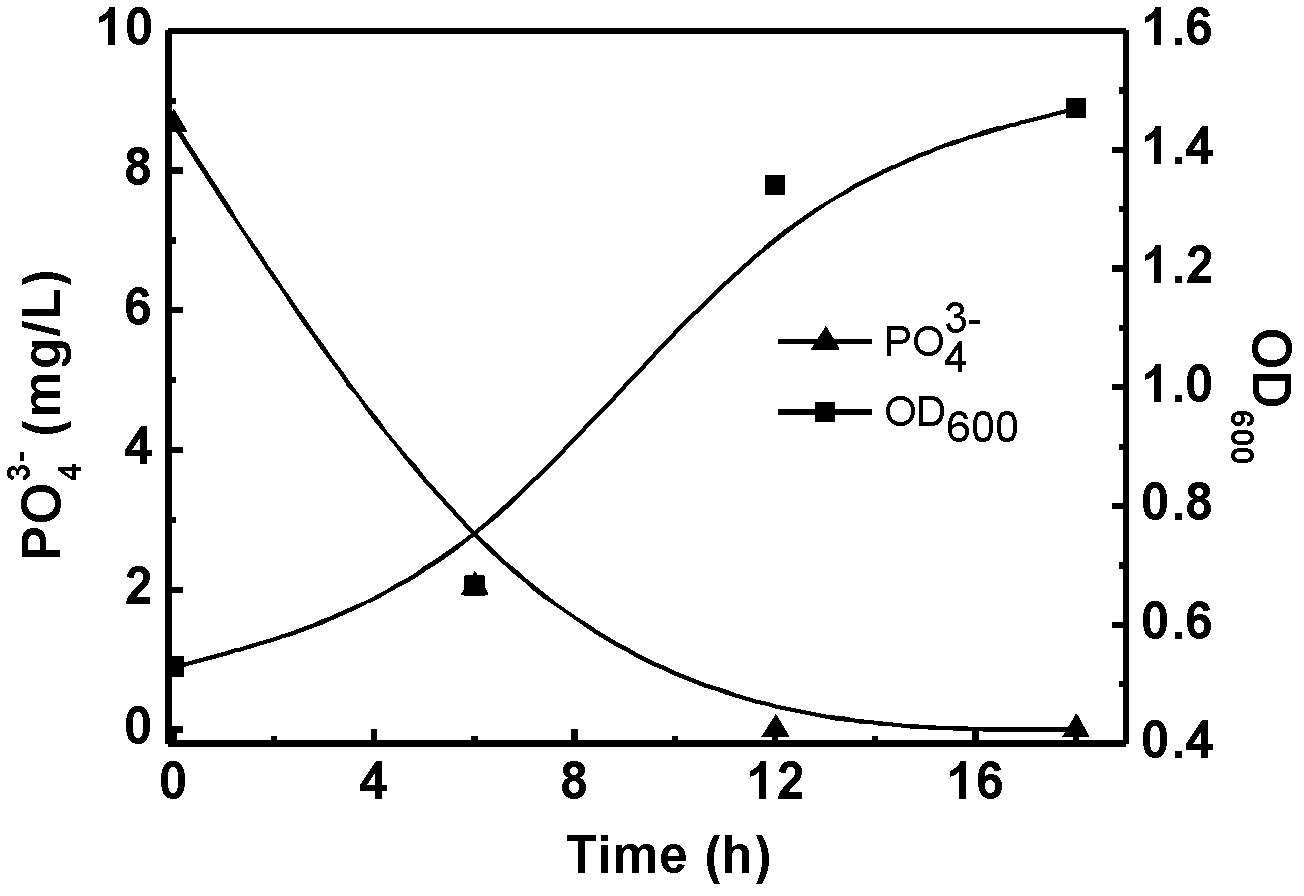

Application of salt-tolerant nitrogen and phosphorus removing bacillus altitudinis to wastewater treatment

ActiveCN102703350BStrong toleranceRealize synchronous removalBacteriaWater contaminantsNitrate nitrogenSewage

The invention relates to a high salt-tolerant bacillus alitudinis with functions of heterotrophic nitrification-aerobic denitrification and phosphorous removal and application thereof to wastewater treatment. The bacillus alitudinis has strong high salt environment tolerance, grows well under a high-salt condition, and can metabolize by taking organic carbon as one and only carbon source and ammonia nitrogen as one and only nitrogen source; through the heterotrophic nitrification-aerobic denitrification, the ammonia nitrogen is directly converted into a gaseous product so as to achieve a denitrifying purpose; the bacillus alitudinis can also take nitrate nitrogen as one and only nitrogen source, the nitrate nitrogen is converted into a gaseous product through the aerobic denitrification; and under aerobic conditions inorganic phosphorus can be taken into a body and converted into a component of the body so as to realize a purpose of removing phosphorus in sewage. The bacillus alitudinis is applied to high-salt wastewater treatment, can achieve synchronization removal of nitrogen and phosphorus under a single aerobic condition, and provides a new way for solving a problem of biological removal of the nitrogen and phosphorus under the high-salt condition.

Owner:北京大学科技开发有限公司

Wastewater nitrogen removal treatment method based on photoelectrocatalysis-autotrophic biofilm

InactiveCN104671589ARealize synchronous removalStrong complementarityWater contaminantsMultistage water/sewage treatmentNitrogen removalBiofilm

The invention discloses a wastewater nitrogen removal treatment method based on a photoelectrocatalysis-autotrophic biofilm. The method is that wastewater to be treated is fed into a reaction chamber to be subjected to nitrogen removal treatment; at least part of the reaction chamber is manufactured from a light transmission material; a visible-light response photoanode is arranged in the reaction chamber, and a cathode of an autotrophic denitrifying biofilm develops in the reaction chamber; the pH of the wastewater is regulated to be 7 to 8 during the nitrogen removal treatment, then the wastewater is fed into the reaction chamber, 1 to 3V working voltage is applied across the photoanode and the cathode, the visible light irradiates through the light transmission part of the reaction chamber until the concentration of ammonia nitrogen and the concentration of nitrate nitrogen decrease to reach the set target value, and then the reacted wastewater is drained from the reaction chamber. According to the wastewater nitrogen removal treatment method, the autotrophic biofilm denitrifying and photoelectric catalyzing technologies are carried out, so that the shortage that the ammonia-nitrogen wastewater cannot be treated by the autotrophic biofilm denitrifying technology, and the nitrate-nitrogen wastewater cannot be treated by the photoelectric catalyzing technology can be overcome, and various nitrogen elements can be synchronously removed.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

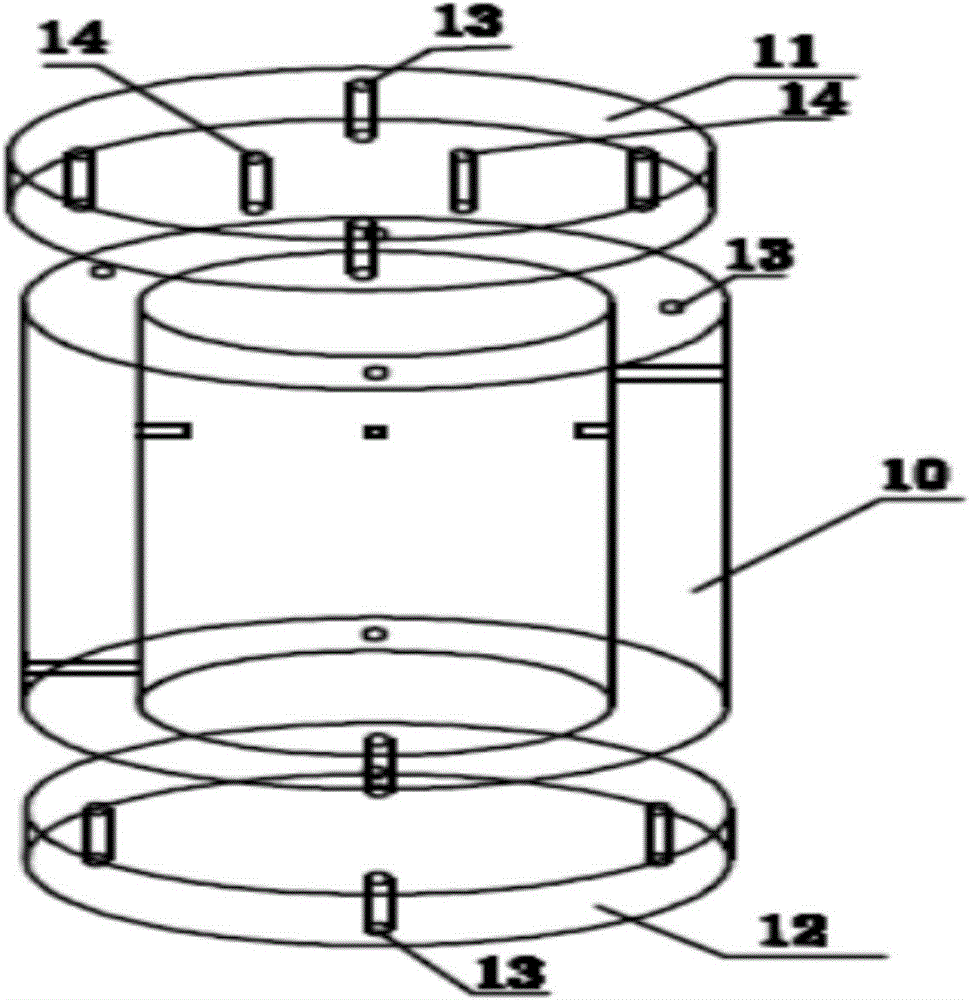

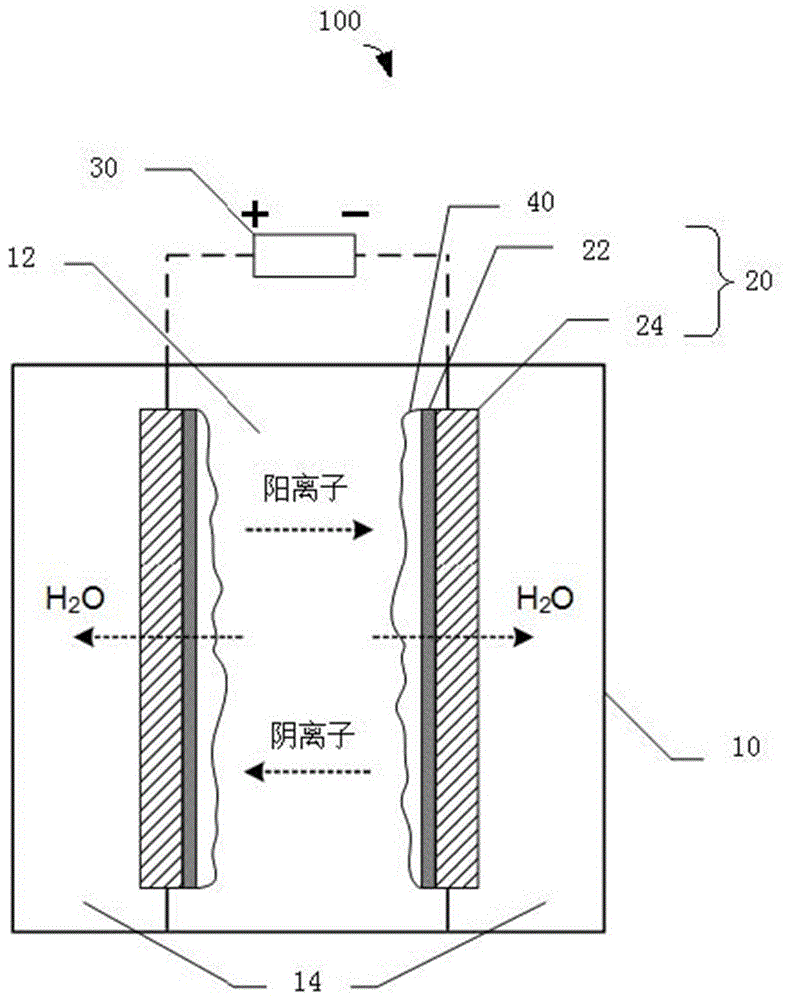

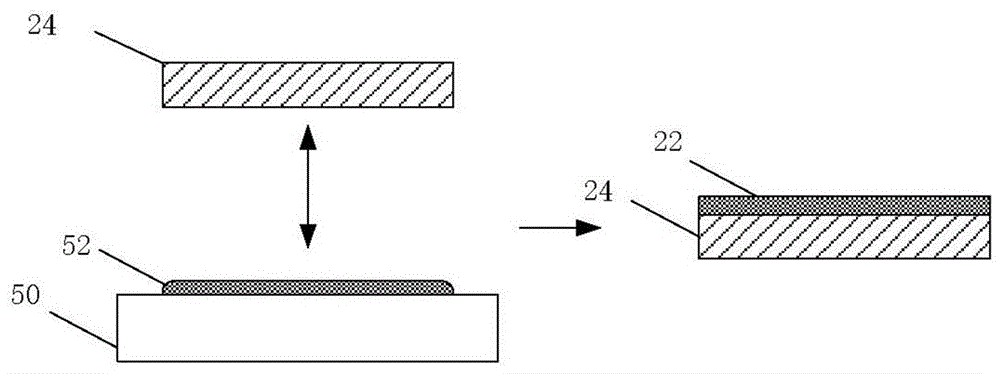

Sewage treatment method and device with function of removing salt and organic substances synchronously

InactiveCN106044967ARealize synchronous removalSimple processDispersed particle separationWater/sewage treatmentComposite electrodeMicrofiltration

The invention discloses a sewage treatment device with a function of removing salt and organic substances synchronously. The sewage treatment device comprises a sewage treatment tank and two composite electrodes, wherein the two composite electrodes are arranged oppositely at an interval and used for being connected with an anode and a cathode of an external power supply respectively; the sewage treatment tank is divided into a salt removing and pollution cleaning chamber and clear water chambers by the two composite electrodes; the salt removing and pollution cleaning chamber is located between the composite electrodes; the clear water chambers are located on outer sides of the two composite electrodes; each composite electrode comprises an ultrafiltration (or microfiltration) membrane layer and a conductive material layer which are arranged in a laminated manner, and the ultrafiltration (or microfiltration) membrane layers of the two composite electrodes are arranged oppositely. The invention further discloses a sewage treatment method with the function of removing salt and organic substances synchronously.

Owner:BEIJING FORESTRY UNIVERSITY +1

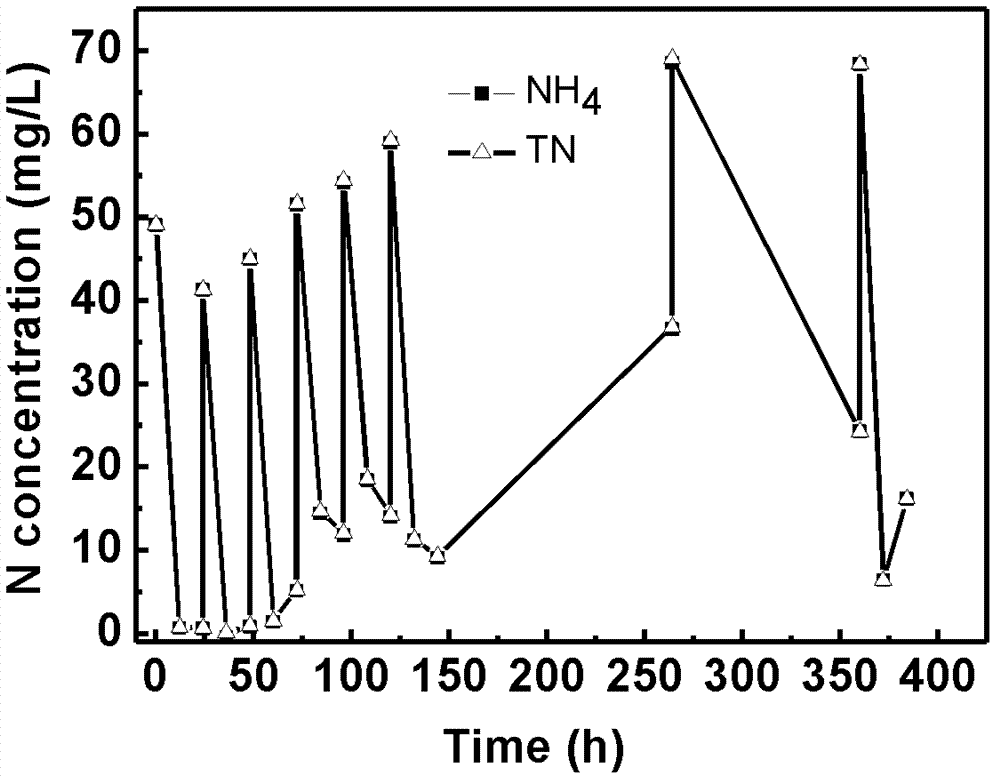

Achromobacter xylosoxidans with denitrification and dephosphorization function and application of Achromobacter xylosoxidans

ActiveCN102533623ARealize synchronous removalSolve bottlenecksBacteriaTreatment using aerobic processesPhosphateInorganic phosphorus

The invention relates to application of Achromobacter xylosoxidans with a heterotrophic nitrification-aerobic denitrification and dephosphorization function in wastewater treatment. The Achromobacter xylosoxidans can metabolize by using organic carbon as a unique carbon source and using ammonia nitrogen as a unique nitrogen source and can directly convert the ammonia nitrogen into gas products through the action of heterotrophic nitrification-aerobic denitrification so as to achieve the aim of denitrification, can also take nitrate nitrogen as a unique nitrogen source and convert the nitrate nitrogen into gas products through the action of aerobic denitrification, and can further ingest inorganic phosphorus and convert the inorganic phosphorus into a tissue of the Achromobacter xylosoxidans under an aerobic condition so as to achieve the aim of removing phosphorus from wastewater. The Achromobacter xylosoxidans are applied to the wastewater treatment, the simultaneous removal of nitrogen and phosphorus can be achieved under the single aerobic condition, and the difficult problem that the biological denitrification and dephosphorization in the traditional wastewater treatment need to adopt the segmented treatments of anaerobic phosphate release, anoxic denitrification and aerobic nitrification and phosphorus absorption, is better solved, so that the Achromobacter xylosoxidans have broad application prospects.

Owner:PEKING UNIV

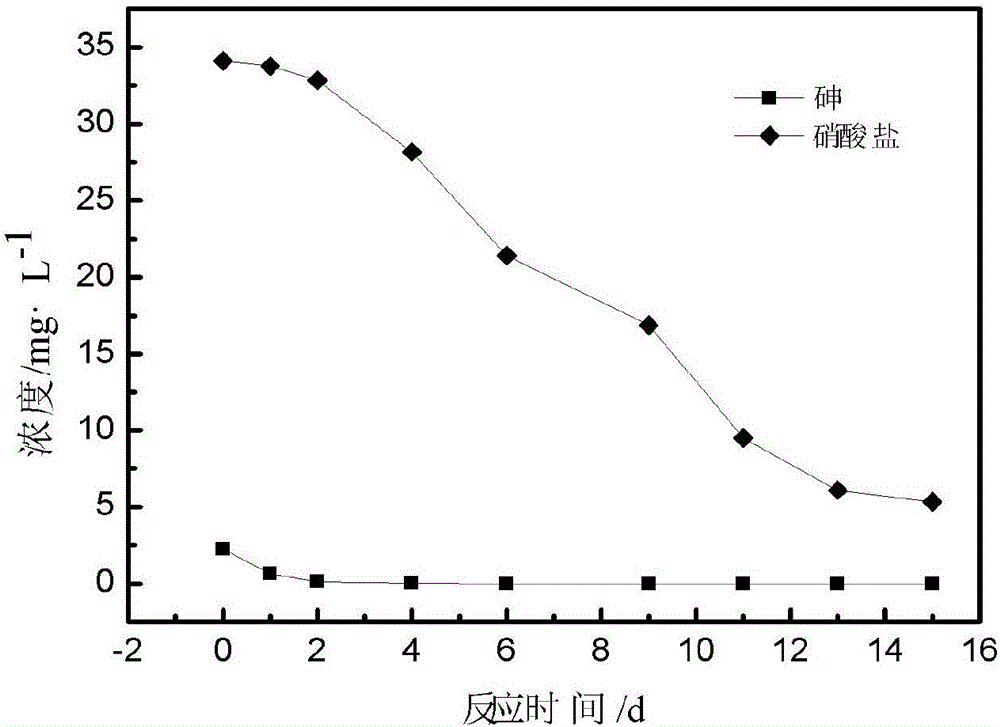

Method for synchronously removing nitrate and arsenic in underground water by natural pyrrhotite and application of method

ActiveCN106315848AStrong adsorption removal effectGood removal effectTreatment with anaerobic digestion processesTreatment involving sedimentationSoil scienceNitrate salts

The invention discloses a method for synchronously removing nitrate and arsenic in underground water by natural pyrrhotite and an application of the method, and belongs to the technical field of water resource purification. The method includes the steps: (a) material preparation: crushing the natural pyrrhotite into particles and washing the particles into neutral with water after acid pickling; (b) strain screening: screening sulfur-based autotrophic denitrification bacteria taking the natural pyrrhotite as a sulfur source from anaerobic sludge by a specific screening medium to serve as a target strain; (c) sewage treatment: taking the underground water containing the nitrate and the arsenic, inoculating the target strain and then placing the underground water in a reactor containing the natural pyrrhotite for reaction; (d) solid-liquid separation. The natural pyrrhotite is used as the sulfur source of the sulfur-based autotrophic denitrification bacteria for denitrification, the nitrate in the water is transformed into nitrogen in a reductive manner, the pyrrhotite and oxidation product thereof can remove the arsenic in the water by the aid of functions such as chemical precipitation and adsorption, so that the nitrate and the arsenic in the underground water are synchronously and efficiently removed. The method is convenient in operation and low in cost.

Owner:NANJING UNIV +1

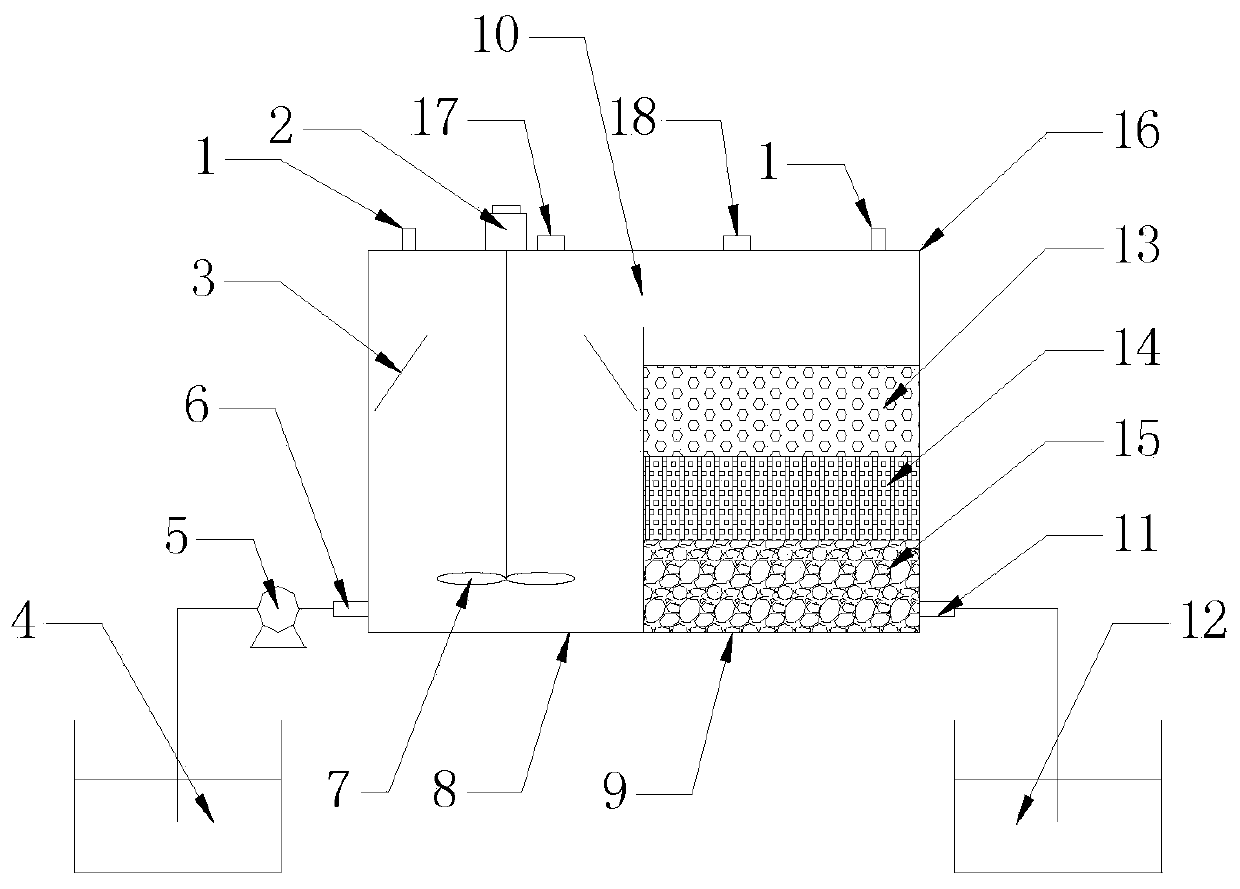

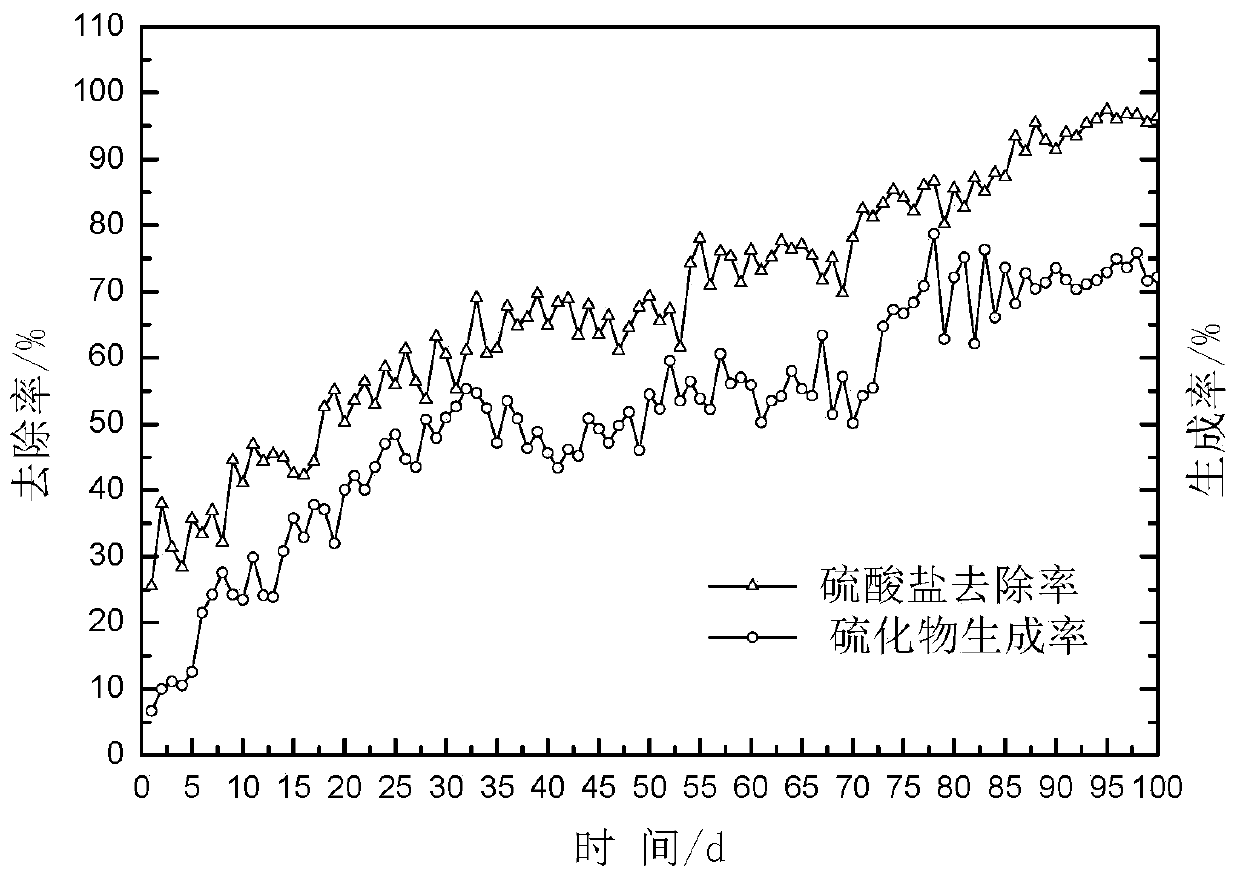

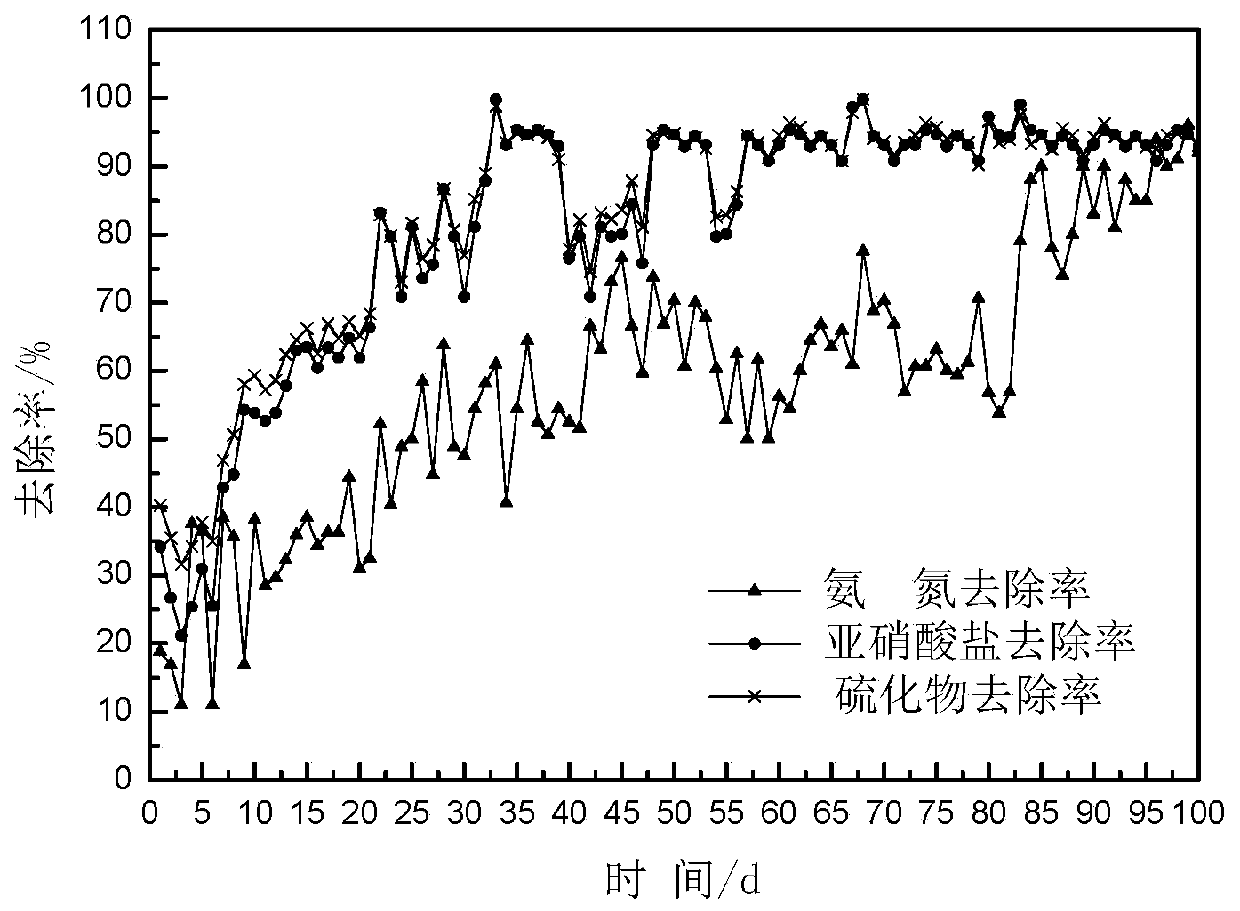

Synchronous processing device and method of ship waste gas desulfuration and denitration waste liquid and ship sanitary sewage

ActiveCN110316823ASave free spaceSave running costsWater treatment compoundsWater contaminantsLiquid wasteActivated sludge

The invention provides a synchronous processing device and method of ship waste gas desulfuration and denitration waste liquid and ship sanitary sewage. The device comprises a suspending area and a filler area. The upper portion of the suspending area is provided with an overflow area communicated with the filler area. A liquid inlet is communicated with the suspending area. A liquid outlet is communicated with the filler area. A stirrer is arranged in the suspending area. Inclined baffles are fixed to the two sides of the inner wall of the suspending area respectively. The filler area is sequentially provided with a ceramic ring layer, an activated carbon layer and a polyethylene multi-surface hollow spherical layer from top to bottom. Mixed liquid of the waste gas washing waste liquid and ship sanitary sewage is pumped in and makes sufficient contact with heterotroph activated sludge with sulfate reducing bacteria as the main part in the suspending area through stirring of the stirrer, and then the mixed liquid enters the filler area from an overflow opening in the upper portion of the suspending area, sequentially passes through all filler layers, makes sufficient contact with abiological membrane and is then discharged out of a water outlet in the bottom of the filler area. By means of the method, no carbon source is added, and the synchronous processing of sulfate and nitrite in the ship waste gas desulfuration and denitration waste liquid and organic matter in the ship sanitary sewage is realized.

Owner:DALIAN MARITIME UNIVERSITY

Method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater

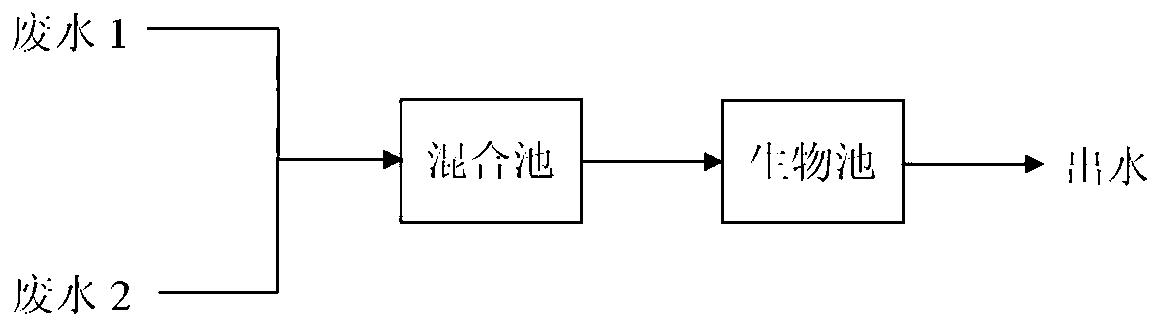

ActiveCN108191050ARealize synchronous removalSync removalWater contaminantsWaste water treatment from gaseous effluentsActivated sludgeElectron donor

A method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater comprises steps as follows: (1) flue gas desulfurization wastewater containing sulfateand ammonia-nitrogen wastewater are guided into a mixing tank to be mixed; (2) the pH and the temperature of mixed wastewater are adjusted in the mixing tank; (3) firstly, a biological reaction tank is inoculated with cultured activated sludge, the mixed wastewater is introduced from the mixing tank, microorganisms in the activated sludge take ammonia nitrogen as an electron donor in the biological reaction tank, sulfate is reduced to elemental sulfur, besides, ammonia nitrogen is oxidized into nitrogen, and synchronous removal of sulfur and nitrogen is realized. The problems that the water quality of the flue gas desulfurization wastewater hardly reaches the standard after treatment with conventional physical and chemical methods, the biodegradability is poor and biological treatment is difficult are solved, and co-treatment of two kinds of wastewater is realized.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

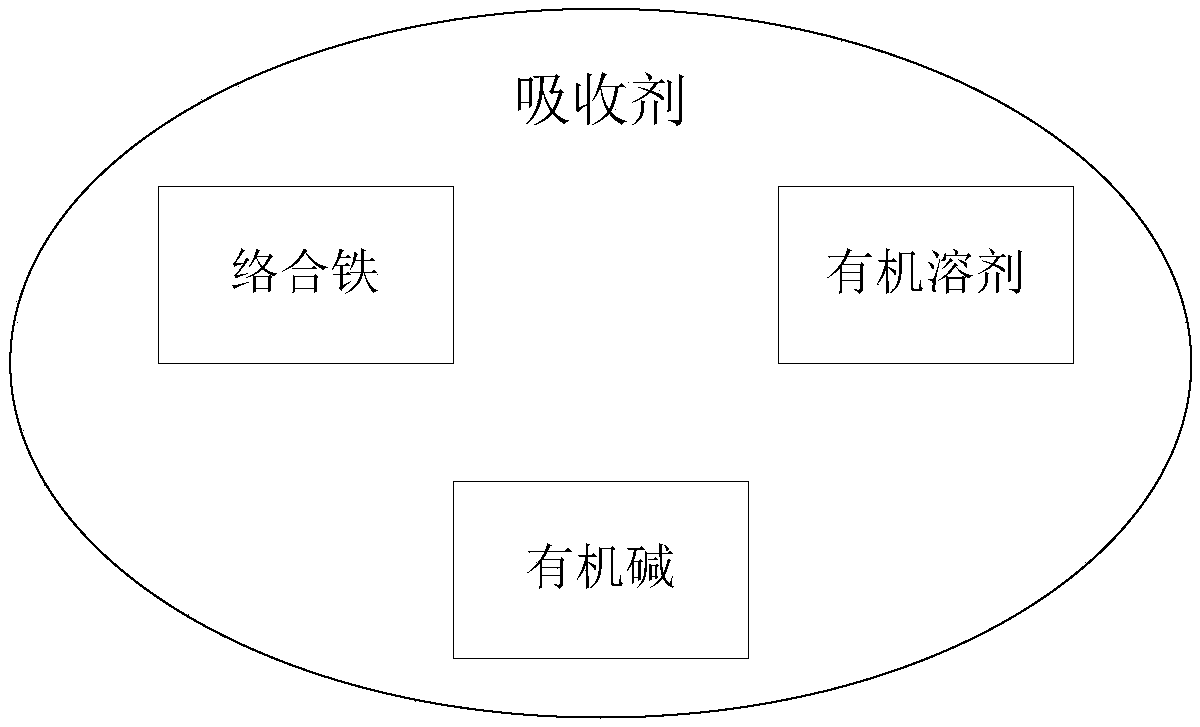

Desulfurizing and decarbonizing absorbent

InactiveCN109432990AAvoid degradationLow costProductsGas treatmentEthylenediaminePoly(ethylene glycol) dimethyl ether

The invention discloses a desulfurizing and decarbonizing absorbent which comprises complex iron, an organic solvent and organic alkali, wherein the mass content of the iron is 0.3-10 g / L, and the mass content of the organic alkali is 0-100 g / L; the complex ion comprises 1-butyl-3-methylimidazole EDTA-Fe, EDTA-Fe and EDTA ferric sodium salt, the organic solvent comprises dimethyl sulfoxide, polyethylene glycol dimethyl ether, or a mixture of dimethyl sulfoxide and polyethylene glycol dimethyl ether; the organic alkali can be dissolved into the organic solvent and specifically comprises 1-butyl-3-methylimidazole. According to the absorbent, the degradation of a complexing agent is avoided by adopting nonaqueous solution of the complex ion, and the cost of liquid phase catalytic oxidation islowered. Additionally, absorption liquid can be used for physically absorbing carbon dioxide while oxidation absorption of hydrogen sulfide, so that the cost of equipment for absorption is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

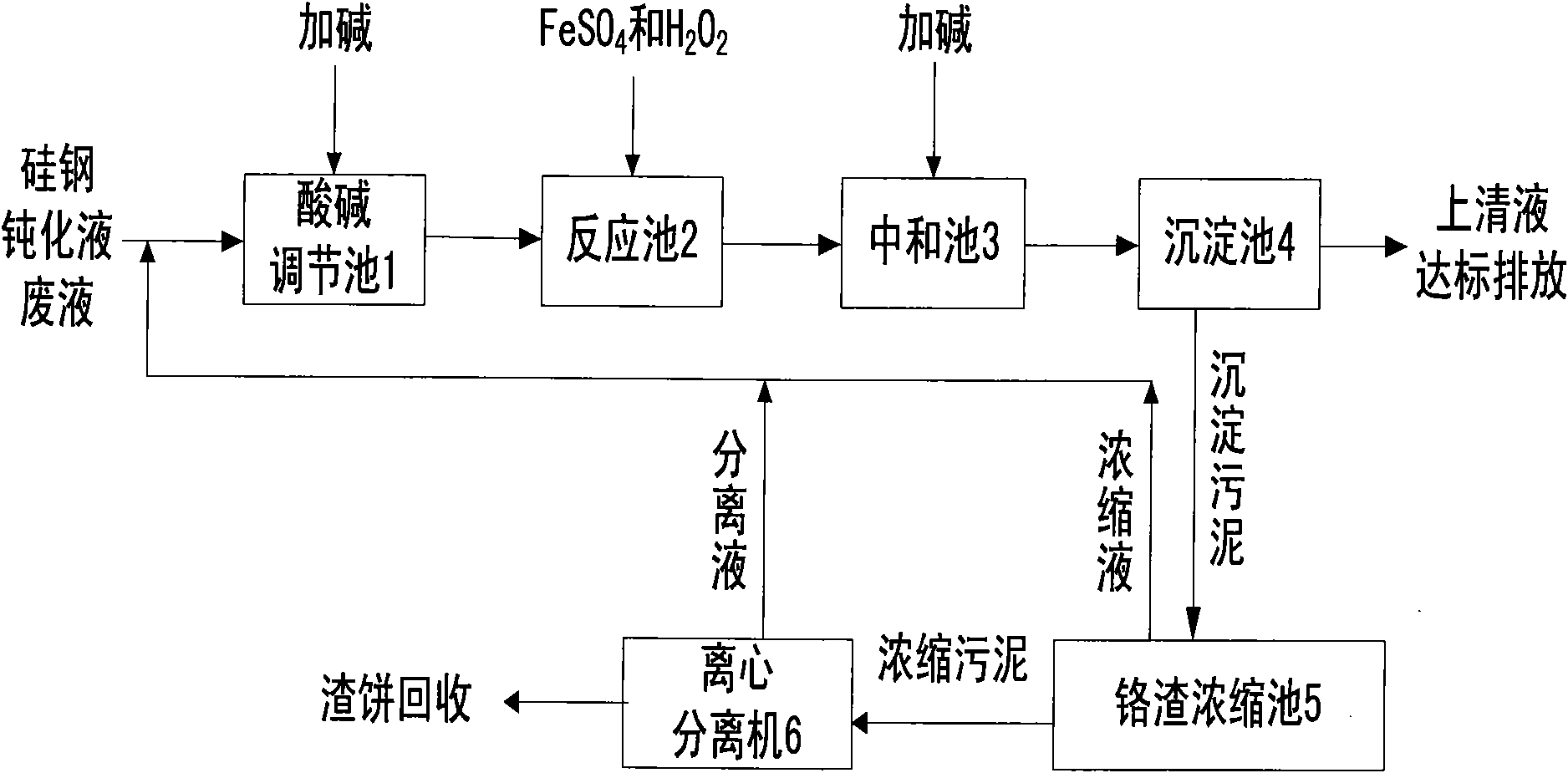

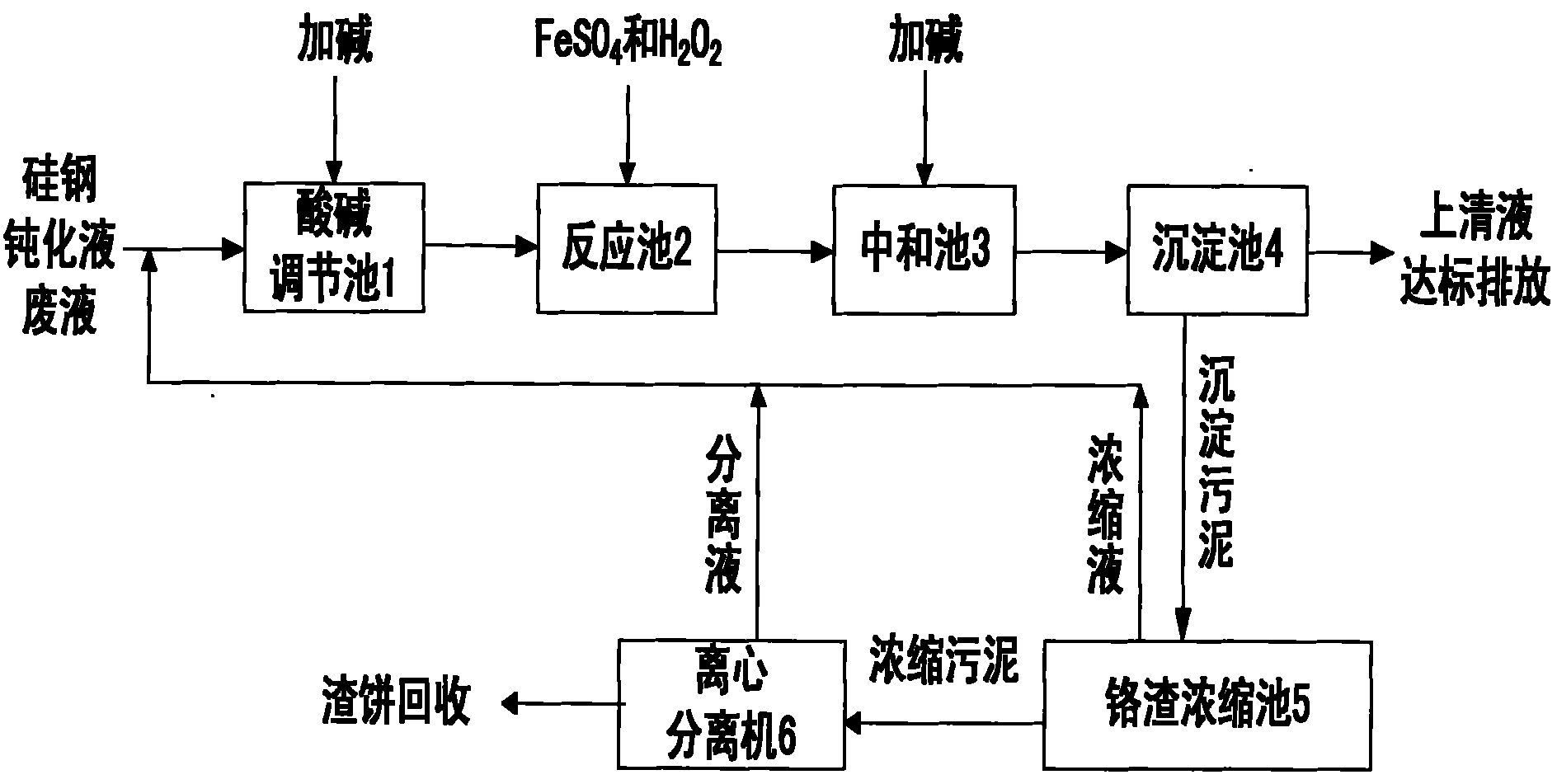

Method for treating liquid waste of silicon steel passivation solution

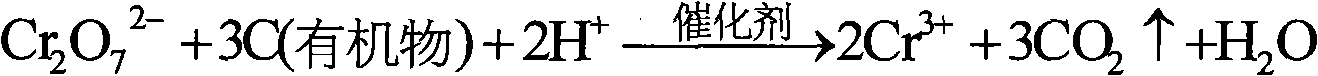

InactiveCN101921028AReduce concentrationRealize synchronous removalMultistage water/sewage treatmentWater/sewage treatment by reductionLiquid wasteChemical oxygen demand

The invention discloses a method for treating liquid waste of silicon steel passivation solution, which belongs to the technical field of the 'three wastes' (waste gas, waste water and industrial residue) treatment in the iron and steel industry. The method comprises the following steps of: firstly, collecting, mixing and homogenizing the liquid waste of the silicon steel passivation solution by using an acid-base adjusting tank, wherein the pH value is adjusted to be 3 to 4; secondly, injecting the liquid waste into a reaction tank by using a sewage pump; thirdly, adding FeSO4.7H2O and 30 percent hydrogen peroxide (H2O2) into the reaction tank so that the molar ratio of iron ion to H2O2 to chromium ion is 5.2:10.4:1, wherein the temperature is maintained to be between 15 and 35 DEG C and the residence time is 60 minutes; fourthly, after the reaction treatment, allowing the mixed solution to automatically flow into a neutralizing tank, adding alkali to adjust the pH value to be 7 to 8, and allowing the mixed solution to automatically flow into a sedimentation tank; and finally, discharging supernatant in the sedimentation tank, allowing settled sludge to enter a chromium residue concentration tank to concentrate and then automatically flow back to the acid-base adjusting tank, allowing the remained chromium residues to enter a centrifugal machine to dehydrate, recovering the dehydrated residue cakes and allowing residue liquid to flow back to the acid-base adjusting tank. By the method, the chromium and chemical oxygen demand (COD) can be removed synchronously, the chromium in the liquid waste can be recovered, and the reclamation of the liquid waste of the silicon steel passivation solution can be realized.

Owner:CHANGZHOU UNIV

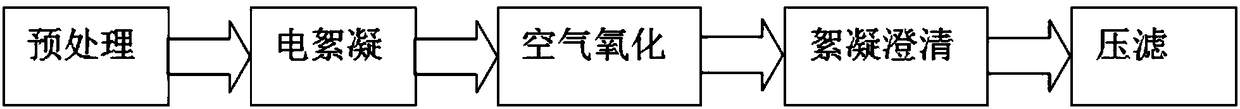

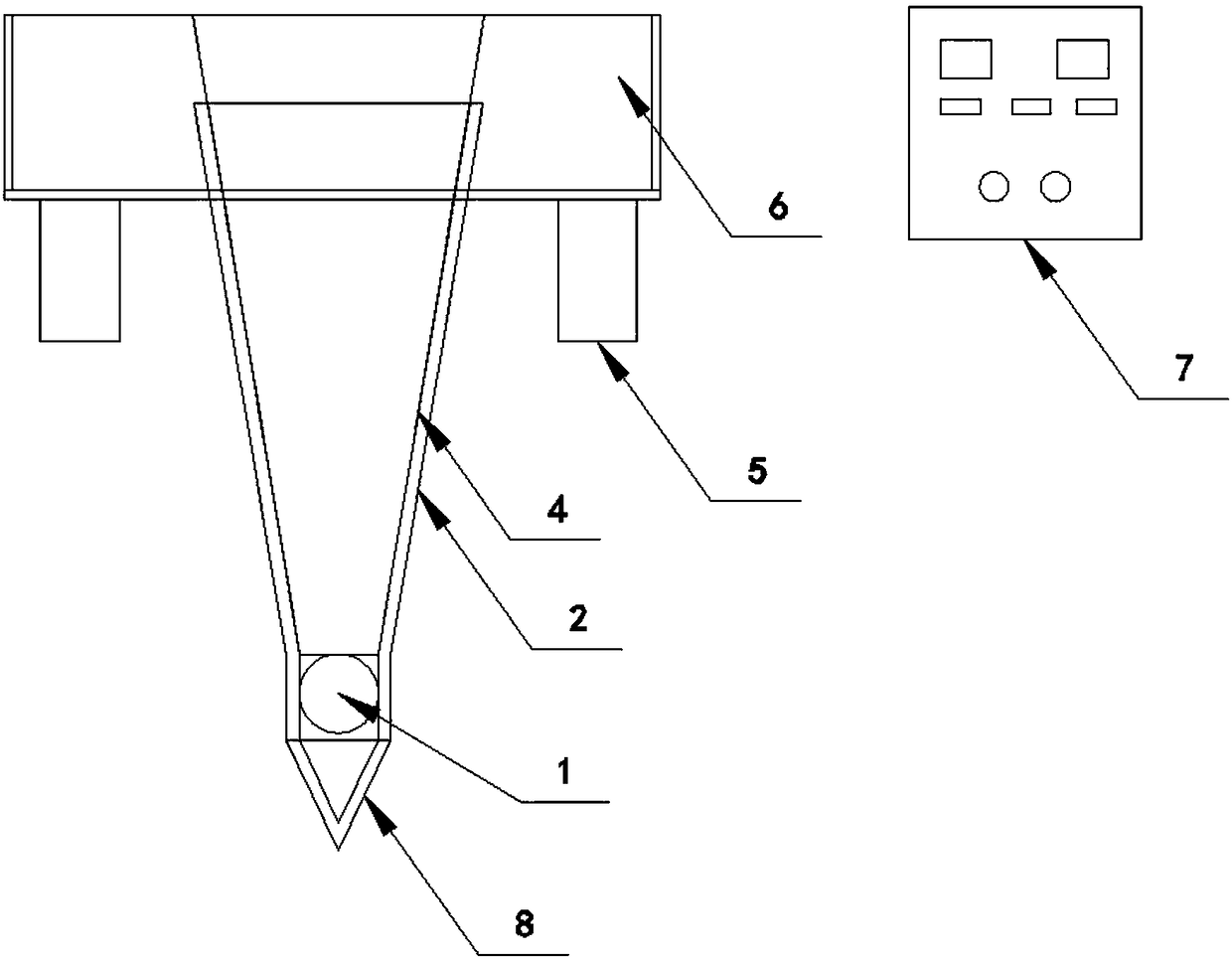

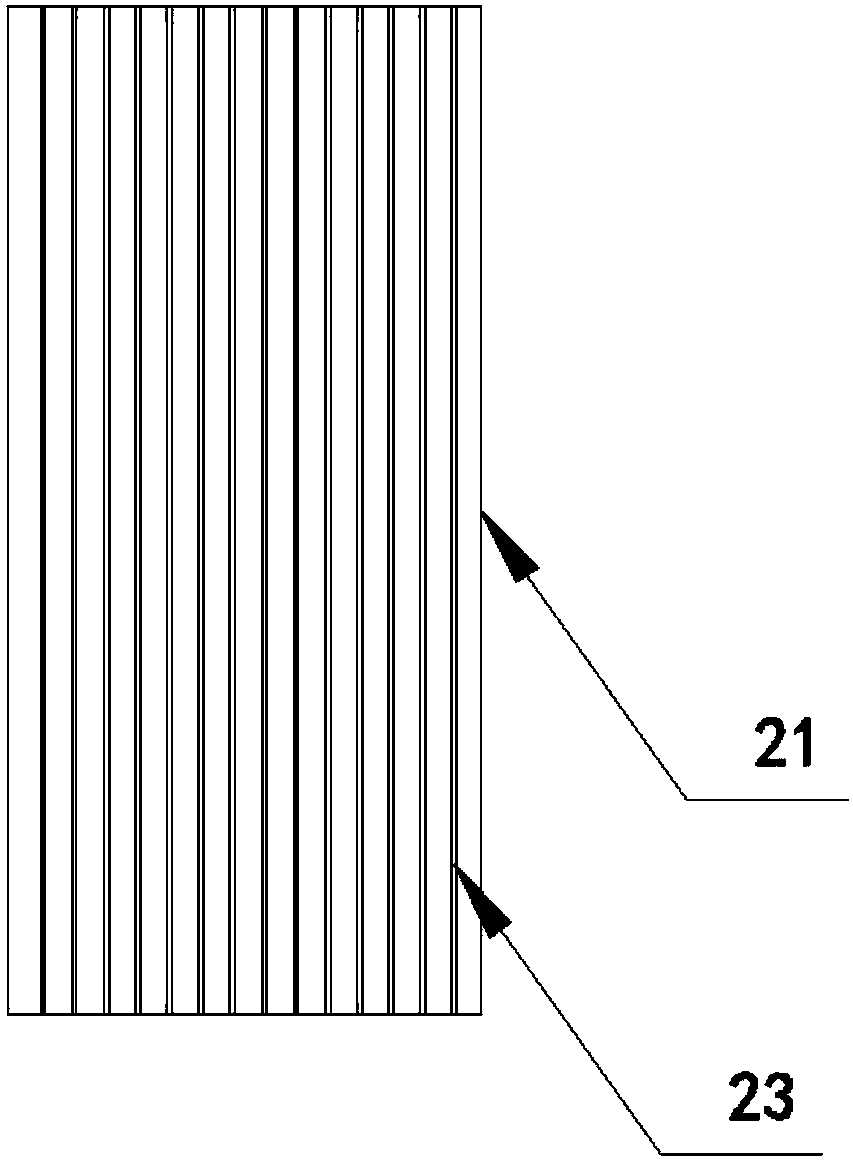

Electric flocculation deep treatment method for thallium-containing wastewater and electric flocculation device

PendingCN108395025ASimple processEasy to operateWater contaminantsTreatment involving filtrationElectricityFlocculation

The invention discloses an electric flocculation deep treatment method for thallium-containing wastewater. The electric flocculation deep treatment method comprises the following steps: (1) adding a precipitating agent into the thallium-containing wastewater and pre-treating to obtain pre-treated wastewater; (2) treating the pre-treated wastewater in step (1) by utilizing an electric flocculationtreatment device to obtain electric flocculation treated wastewater; (3) adding a flocculating agent into the electric flocculation treated wastewater obtained by step (2); after flocculating and precipitating, filtering and directly discharging filtrate. The invention further provides the electric flocculation treatment device used for the treatment method. The treatment method disclosed by the invention has a simple technological flow, is easy to operate and manage and has high automation degree and very low cost. According to the electric flocculation treatment device disclosed by the invention, an inner cavity of a reactor adopts a large-top and small-top form; the flow speed of the wastewater flowing through the reactor has gradient changes from bottom to top, and the problems that floc sinks down, caused by a repose angle of the straight-plate reactor and insufficient propelling force in the reactor, can be reduced or eliminated.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

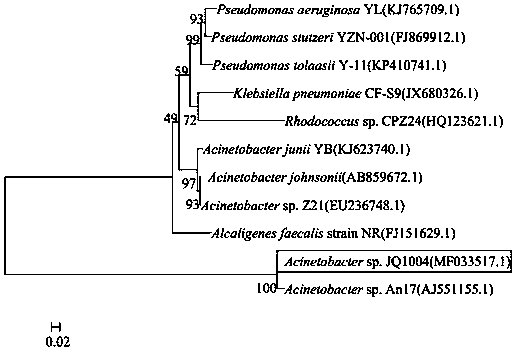

Acinetobacter and application thereof

InactiveCN109913382ARealize synchronous removalAchieve removalBacteriaWater contaminantsMicroorganismHigh concentration

The invention discloses acinetobacter and application thereof. The acinetobacter is named as Acinetobacter JQ1004, and the Acinetobacter strain JQ1004 was deposited in China Microbiological Culture Collection Management Committee (CGMCC) on March 06, 2018 under the accession number of CGMCC No. 15414. The acinetobacter is a heterotrophic nitrifying aerobic denitrifying bacterium, can carry out nitrifying and denitrifying by taking organic carbon as a carbon source under the same aerobic condition, and can respectively grow by taking ammonia nitrogen and nitrate nitrogen as nitrogen sources. The acinetobacter disclosed by the invention has the characteristic of high-concentration ammonia nitrogen load resistance, and can be propagated and metabolized under the condition that the ammonia nitrogen concentration is 0-2000 mg / L.

Owner:BEIJING UNIV OF TECH

Segmented drainage type short-cut nitrification parallelly-connected anaerobic ammonia oxidation denitrifying phosphorous removal coupled endogenous denitrification device and method thereof

ActiveCN110002587AHas the function of nitrogen and phosphorus removalHigh processing loadTreatment with aerobic and anaerobic processesMunicipal sewageOrganic matter

The invention discloses a segmented drainage type short-cut nitrification parallelly-connected anaerobic ammonia oxidation denitrifying phosphorous removal coupled endogenous denitrification device and a method thereof. Municipal sewage firstly enters a short-cut nitrification phosphorous removal reactor, denitrifying glycogen accumulating bacteria ingest the organic matter and store it as PHAs, and phosphorus-accumulating bacteria store internal carbon source and simultaneously release phosphorous; then, phosphorus is absorbed and ammonia nitrogen is converted to nitrite nitrogen under the hypoxia aeration mode, and nitrosated sewage undergoes first water draining and enters an intermediate water tank; and after anaerobic stirring and denitrification, secondary water draining is carried out. A part of raw water enters an anaerobic ammonia oxidation denitrifying phosphorus removal coupled endogenous denitrification reactor, denitrifying glycogen accumulating bacteria store PHAs, and denitrifying phosphorus accumulating bacteria store an internal carbon source and release phosphorous. After the stage, nitrite nitrogen-containing sewage in the intermediate water tank enters the anaerobic ammonia oxidation denitrifying phosphorus removal coupled endogenous denitrification reactor to realize deep nitrogen and phosphorus removal. By the method, municipal sewage deep nitrogen and phosphorus removal with low C / N ratio can be stably realized.

Owner:BEIJING UNIV OF TECH

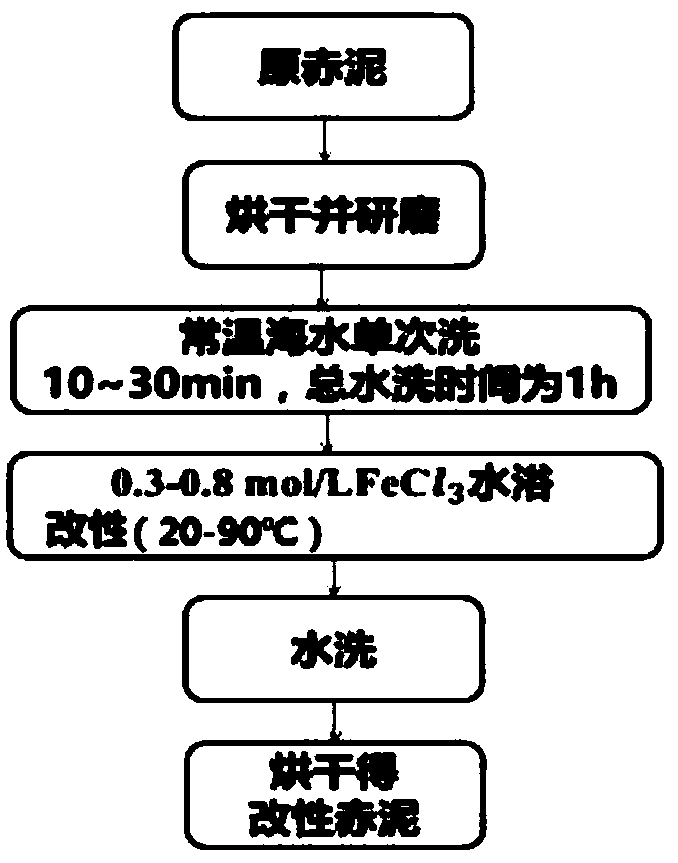

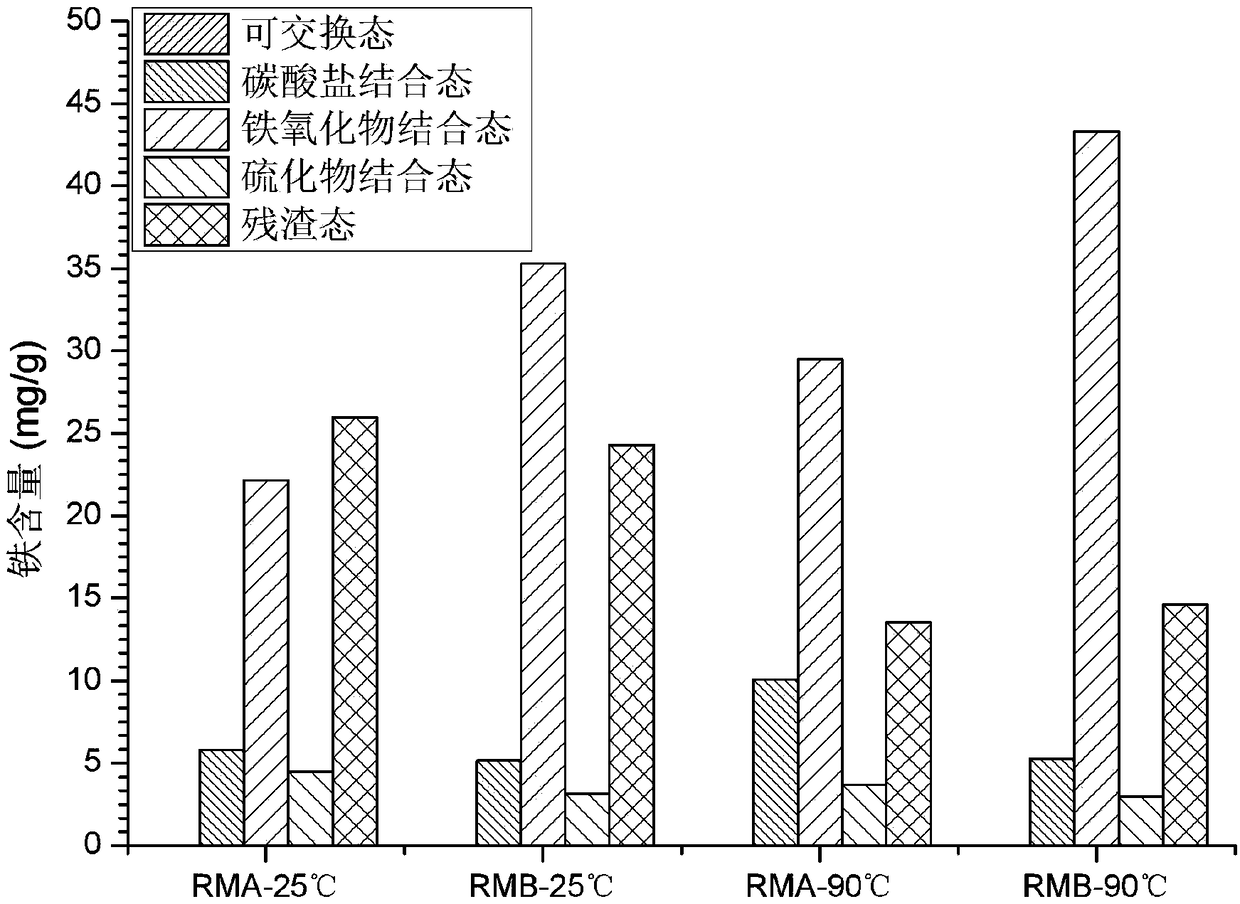

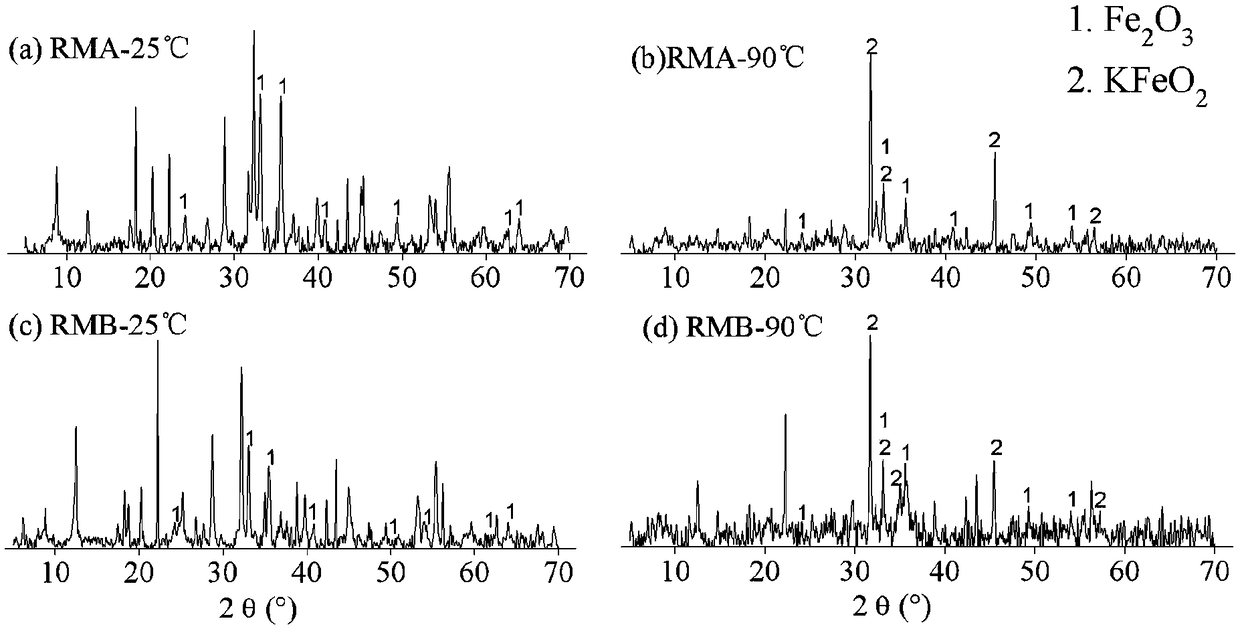

Red mud adsorbent and preparation method and application thereof

ActiveCN109107524AIncrease contentAchieve removalOther chemical processesWater contaminantsDesorptionRed mud

The invention belongs to the technical field of water treatment, and particularly provides a red mud adsorbent and a preparation method and application thereof. According to the red mud absorbent, with alkaline red mud as a material, part of free alkali in the red mud is removed by the effect of washing and precipitation in the process of seawater washing modification, the red mud is then modifiedby a ferric chloride solution, so that the content of iron oxide with an adsorbing effect in the red mud is increased, and thereby the adsorbing capability is increased. According to the red mud absorbent, the preparation cost is low, and the obtained red mud adsorbent has good adsorbing capability on arsenic and fluorine; moreover, after adsorption is completed, the red mud adsorbent can be directly piled up, and subsequent desorption is not needed.

Owner:TONGJI UNIV

Device and method for treating high-ammonia-nitrogen organic matter wastewater through series connection of half short-cut nitrification anaerobic ammonia oxidation and short-cut denitrification anaerobic ammonia oxidation

ActiveCN113200600AReduce aeration energy consumptionImprove retentionWater contaminantsTreatment with anaerobic digestion processesAmmoniacal nitrogenSludge

A device and a method for treating high-ammonia-nitrogen organic matter wastewater through series connection of half short-cut nitrification anaerobic ammonia oxidation and short-cut denitrification anaerobic ammonia oxidation belong to the field of sewage treatment. Part of ammonia nitrogen in the high-ammonia-nitrogen organic matter wastewater is converted into nitrite nitrogen through half short-cut nitrification, then effluent of a half short-cut nitrification reactor is subjected to anaerobic ammonia oxidation reaction in a UASB granular sludge system, and ammonia nitrogen and nitrite nitrogen are synchronously removed. Anaerobic ammonia oxidation effluent containing nitrate nitrogen and high-ammonia-nitrogen organic matter wastewater entering in parallel react in a short-cut denitrification and anaerobic ammonia oxidation integrated UASB reactor, nitrate nitrogen is converted into nitrite nitrogen under the action of short-cut denitrification bacteria, then the nitrite nitrogen and the high-ammonia-nitrogen organic matter wastewater entering in parallel are subjected to anaerobic ammonia oxidation reaction, and the denitrification rate of the system is further improved. The method provides a new thought for treatment of high-ammonia-nitrogen organic matter wastewater, solves the problems of high energy consumption, low denitrification efficiency and the like, and improves the effluent quality.

Owner:BEIJING UNIV OF TECH

Treatment technology of phosphorus fire retardant wastewater

InactiveCN108609788ASmall footprintReduce consumptionWater contaminantsTreatment involving filtrationFiltrationEvaporation

The invention discloses a treatment technology of phosphorus fire retardant wastewater, which comprises the following steps of: (1) regulating a pH (potential of hydrogen) of the phosphorus fire retardant wastewater to 2-9, adding soluble ferric iron salt for stirring and filtration to form filtrate I, (2) neutralizing and flocculating the filtrate I to separate and remove a sediment to form filtrate II, and (3) performing evaporation, concentration, crystallization and desalination on the filtrate II, directly discharging or recycling an evaporative condensate, and allowing concentrated liquid to directly return to step (1) for re-treatment. The treatment technology is applicable to continuous treatment of the phosphorus fire retardant wastewater, adopts dosing pretreatment-neutralizationand flocculation-evaporative condensation as a main line, is simple to operate and low in cost and can achieve zero discharge of the phosphorus fire retardant wastewater.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

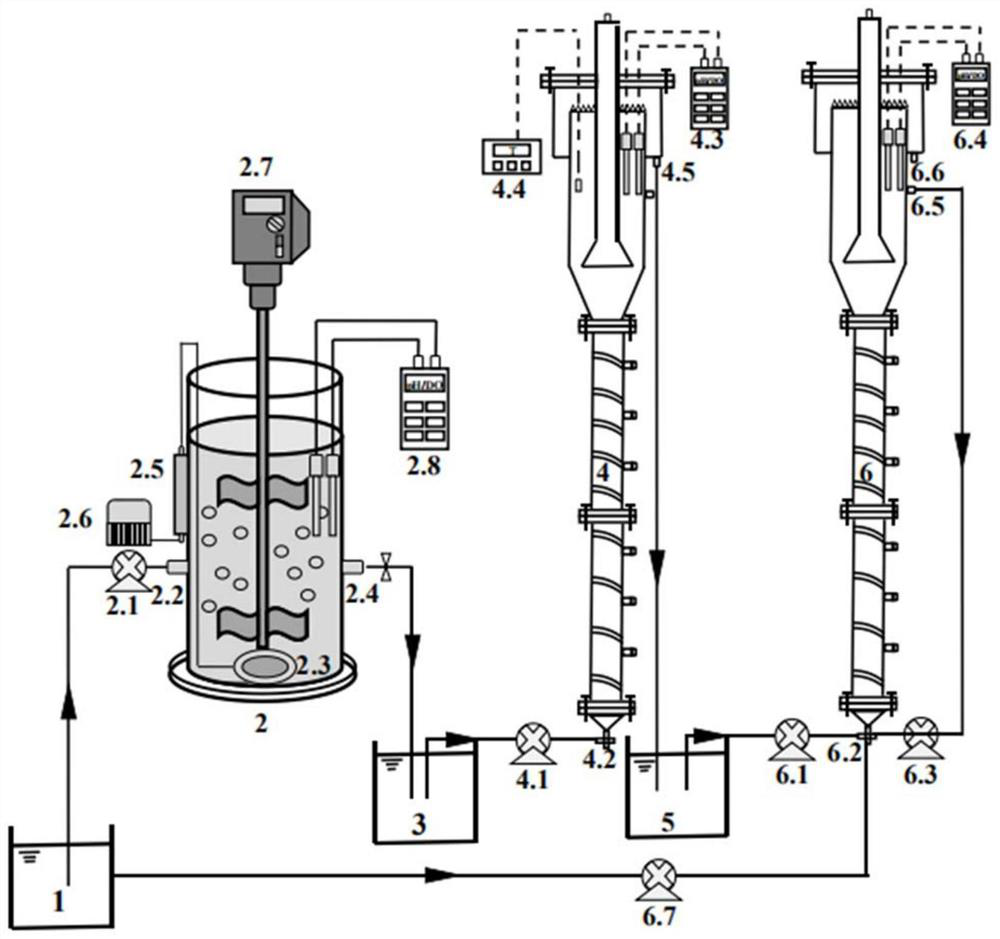

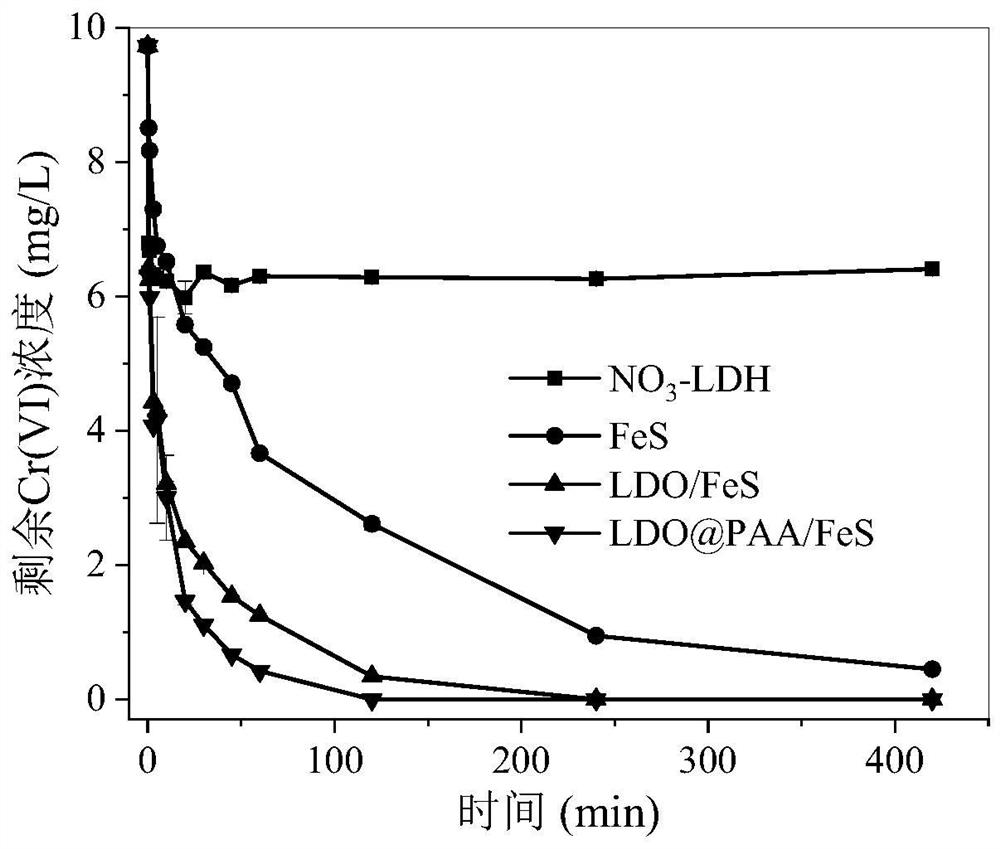

Preparation method of sodium polyacrylate dispersed ferrous sulfide intercalation layered double hydroxide

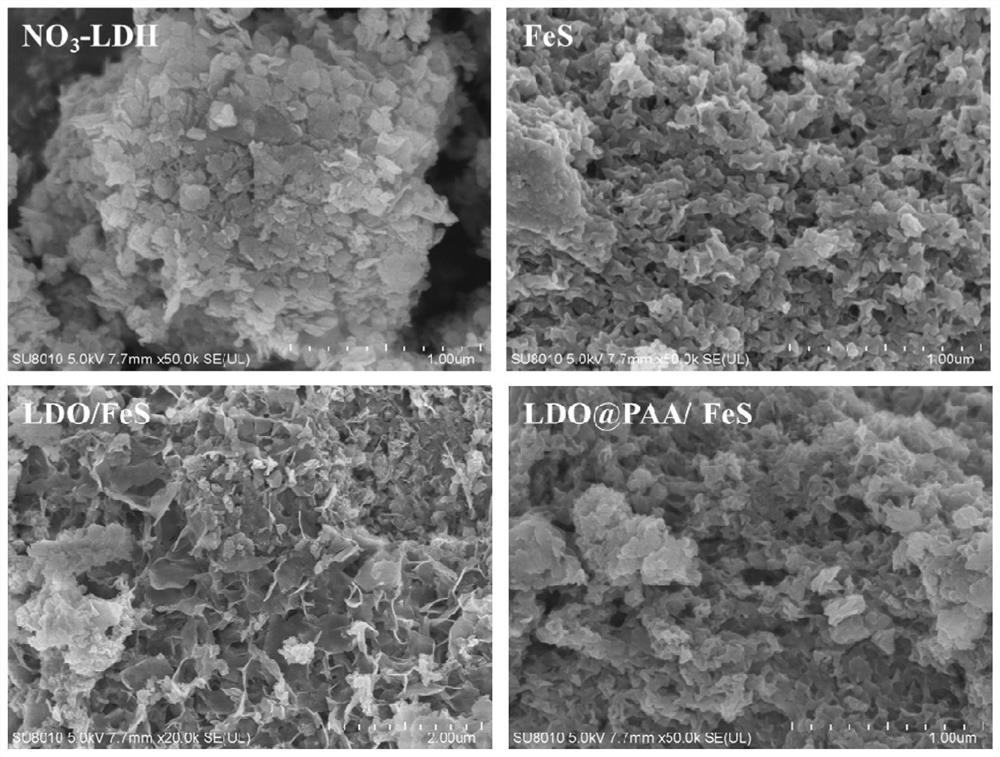

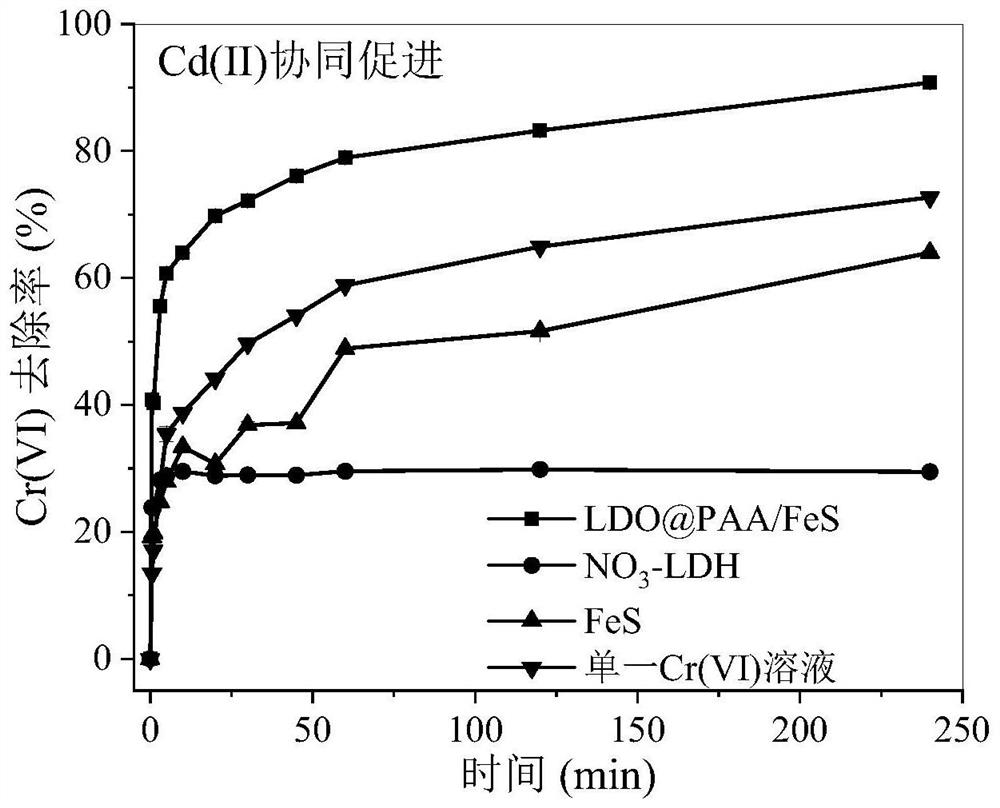

ActiveCN113398896AAvoid reunionSynergistic and efficient adsorptionPhysical/chemical process catalystsWater/sewage treatment by irradiationAqueous solutionLayered double hydroxides

The invention discloses a preparation method of a sodium polyacrylate dispersed ferrous sulfide intercalation layered double hydroxide. The preparation method comprises the following steps: s1, preparing a sodium polyacrylate aqueous solution to obtain a solution A; s2, preparing a layered double hydroxide aqueous solution to obtain a solution B; s3, adding the solution B into the solution A to obtain a mixed solution C; s4, preparing a degassed aqueous solution of FeSO4. 7H2O or FeCl3, so as to obtain a solution D; s5, preparing a Na2S and / or NaBH4 degassed aqueous solution to obtain a solution E; s6, dropwise adding the solution D into the solution C, and stirring to obtain a mixed solution F; and s7, dropwise adding the solution E into the solution F to finally generate a black precipitate, and washing and drying to obtain the sodium polyacrylate dispersed nano ferrous sulfide intercalated layered double hydroxide. Ferrous sulfide dispersed in a sodium polyacrylate solution is intercalated into layered amphiphilic hydroxide, so that ferrous sulfide agglomeration is prevented, metal anions and cations can be synergistically and efficiently adsorbed, heavy metal adsorbing and reduction effects are promoted, and heavy metal toxicity is reduced.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

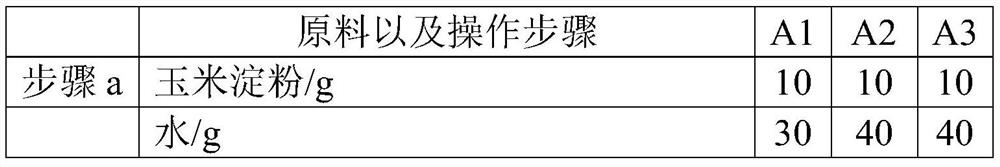

Method for treating sewage containing heavy metals

ActiveCN112759107ARealize synchronous removalReduce contentSludge treatmentWater contaminantsCatalytic oxidationSewage

The invention relates to the field of sewage treatment, and discloses a method for treating sewage containing heavy metals. The method comprises the following steps of: step 1, adjusting the pH value of the sewage to 5.8-8.0; 2, adding L-cysteine, a starch modified high-molecular polymer, ferric salt and cationic polyacrylamide into a product obtained in the step 1, and carrying out a mixed reaction; 3, carrying out solid-liquid separation on the product obtained in the step 2 to obtain solid-phase floc and separated water, concentrating and filter-pressing the solid-phase floc, and returning the obtained concentrated supernatant liquid filter pressing effluent to the step 2; and 4, performing electrocatalytic oxidation treatment on the separated water to obtain discharged water. According to the method, the heavy metal elements in the sewage can be synchronously removed, and the COD value of the sewage is reduced, so that the content of the heavy metal elements in the discharged water reaches the standard, the COD value of the discharged water is reduced to 400 mg / L or below, and the water quality requirement of subsequent biochemical treatment of an enterprise is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Achromobacter xylosoxidans with denitrification and dephosphorization function and application of Achromobacter xylosoxidans

ActiveCN102533623BRealize synchronous removalSolve bottlenecksTreatment using aerobic processesBacteriaPhosphateInorganic phosphorus

The invention relates to application of Achromobacter xylosoxidans with a heterotrophic nitrification-aerobic denitrification and dephosphorization function in wastewater treatment. The Achromobacter xylosoxidans can metabolize by using organic carbon as a unique carbon source and using ammonia nitrogen as a unique nitrogen source and can directly convert the ammonia nitrogen into gas products through the action of heterotrophic nitrification-aerobic denitrification so as to achieve the aim of denitrification, can also take nitrate nitrogen as a unique nitrogen source and convert the nitrate nitrogen into gas products through the action of aerobic denitrification, and can further ingest inorganic phosphorus and convert the inorganic phosphorus into a tissue of the Achromobacter xylosoxidans under an aerobic condition so as to achieve the aim of removing phosphorus from wastewater. The Achromobacter xylosoxidans are applied to the wastewater treatment, the simultaneous removal of nitrogen and phosphorus can be achieved under the single aerobic condition, and the difficult problem that the biological denitrification and dephosphorization in the traditional wastewater treatment need to adopt the segmented treatments of anaerobic phosphate release, anoxic denitrification and aerobic nitrification and phosphorus absorption, is better solved, so that the Achromobacter xylosoxidans have broad application prospects.

Owner:PEKING UNIV

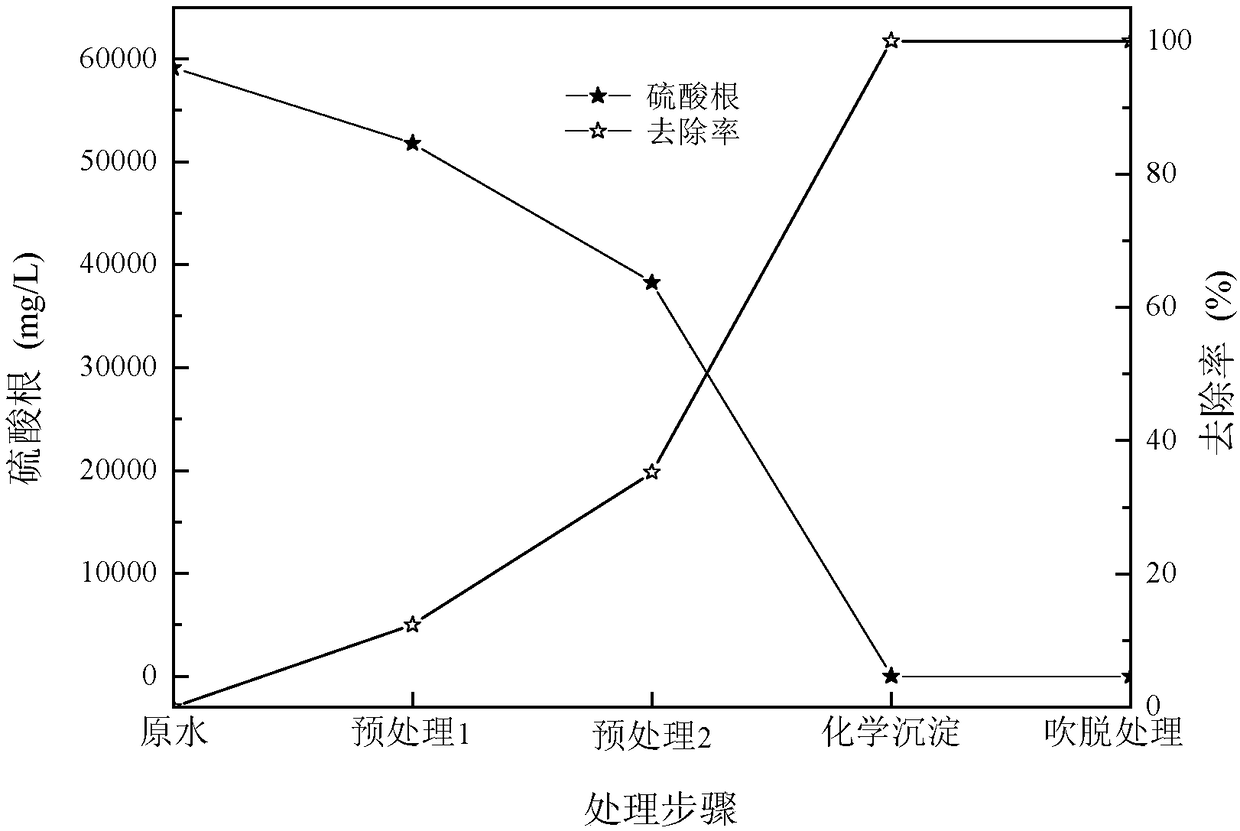

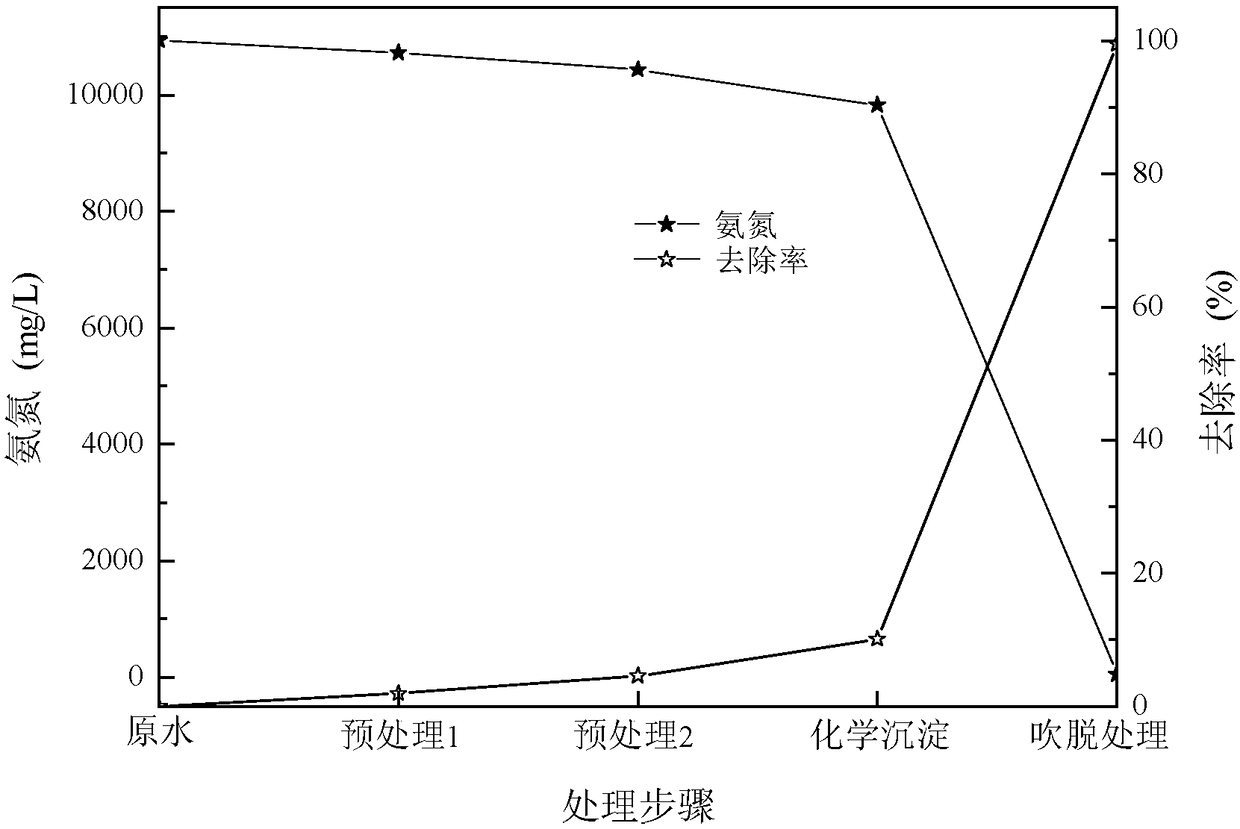

Method for simultaneously removing sulfate and ammonia nitrogen in smelting wastewater

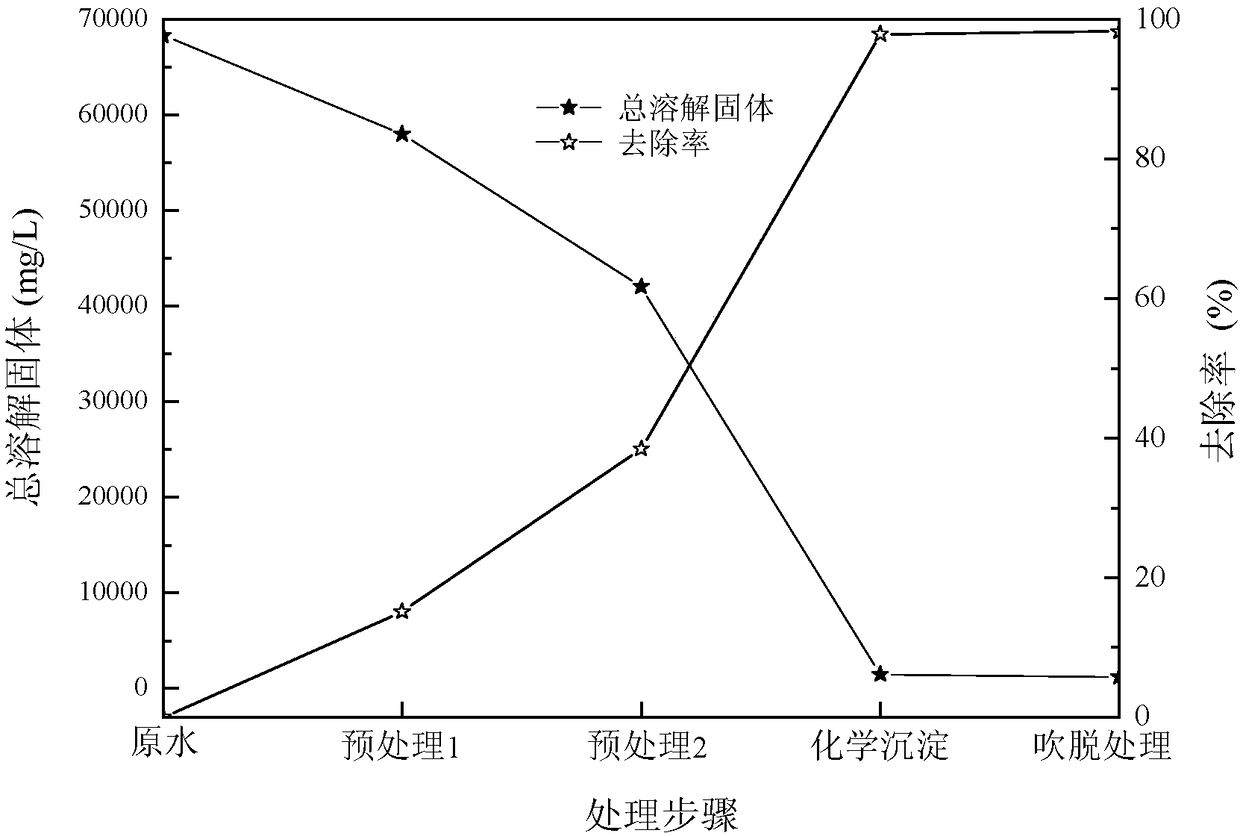

InactiveCN108328789ARealize synchronous removalLow costWater aerationTreatment involving filtrationCalcium hydroxideTotal dissolved solids

The invention relates to a method for simultaneously removing sulfate and ammonia nitrogen in smelting wastewater. The method for simultaneously removing the sulfate and ammonia nitrogen in the smelting wastewater aims at solving the technical problems of high difficulty in treatment of smelting wastewater containing sulfate, ammonia nitrogen and metal ions and high running cost in the prior art.The method comprises the following steps of pretreating the smelting wastewater by a sodium hydroxide solution twice; adding calcium hydroxide to chemically precipitate; finally, stripping to remove the ammonia nitrogen in the wastewater, so as to simultaneously remove the sulfate, ammonia nitrogen and metal ions. After the smelting wastewater is treated by the method, the removal rate of sulfatereaches 99.99%; the removal rate of ammonia nitrogen reaches 99.52%; the removal rate of total dissolved solids reaches 98.23%. The method has the advantages that the investment is small, the runningcost is low, and the method can be used for the wastewater treatment and circulation utilization.

Owner:CHENGDU UNIV OF INFORMATION TECH

A light-weight slow-release denitrification and dephosphorization material and its preparation method and application

ActiveCN110002806BLarge specific surface areaDensity controllableWater treatment parameter controlTreatment with aerobic and anaerobic processesConstructed wetlandFoaming agent

The invention discloses a lightweight slow-release nitrogen and phosphorus removal material and a preparation method and application thereof, and belongs to the field of environment function materialsand sewage treatment. The preparation method comprises the following steps: uniformly mixing cement, pyrite, a foaming agent and a foam stabilizer to obtain dry-mixed mortar; adding water into the dry-mixed mortar, and stirring to prepare the lightweight slow-release nitrogen and phosphorus removal material. The lightweight slow-release nitrogen and phosphorus removal material of the invention has characteristics of high specific surface area, controllable density, high reactivity, easy microbial biofilm formation, slow-release electron donor nitrogen-removal and iron ion phosphorus-removal,etc., can be used as a filling material for sewage treatment fluidized beds and fixed beds, a filling materials for constructed wetlands and in-situ and ex-situ purifying material for polluted water bodies, and has a good purifying effect on pollutants in water, especially on total nitrogen and total phosphorus.

Owner:NANJING UNIV

Device and method for synchronously treating domestic sewage and late landfill leachate by coupling short-cut nitrification-anaerobic ammonia oxidation with denitrification

ActiveCN113023871AFavorable for short-range nitrificationReduce aeration energy consumptionWater treatment parameter controlBiological treatment regulationNitrogen removalMicroorganism

The invention discloses a device and a method for synchronously treating domestic sewage and late landfill leachate by coupling short-cut nitrification-anaerobic ammonia oxidation with denitrification, and belongs to the field of biological sewage treatment. The device comprises a raw water tank, a short-cut nitrification reactor, a middle water tank and an anaerobic ammonia oxidation coupling denitrification reactor. Domestic sewage enters the short-cut nitrification reactor, short-cut effluent is realized through low-oxygen aeration and real-time control, and effluent NO2 <->-N enters the middle water tank and enters the anaerobic ammonia oxidation coupling denitrification reactor after being mixed with part of late landfill leachate. A synergistic reaction of anaerobic ammonia oxidation nitrogen removal and denitrification nitrogen removal is realized in the anaerobic ammonia oxidation coupling denitrification reactor at the same time, so that the nitrogen removal effect is achieved. According to the invention, efficient and energy-saving urban sewage denitrification is realized by fully utilizing the synergistic effect among microorganisms.

Owner:BEIJING UNIV OF TECH

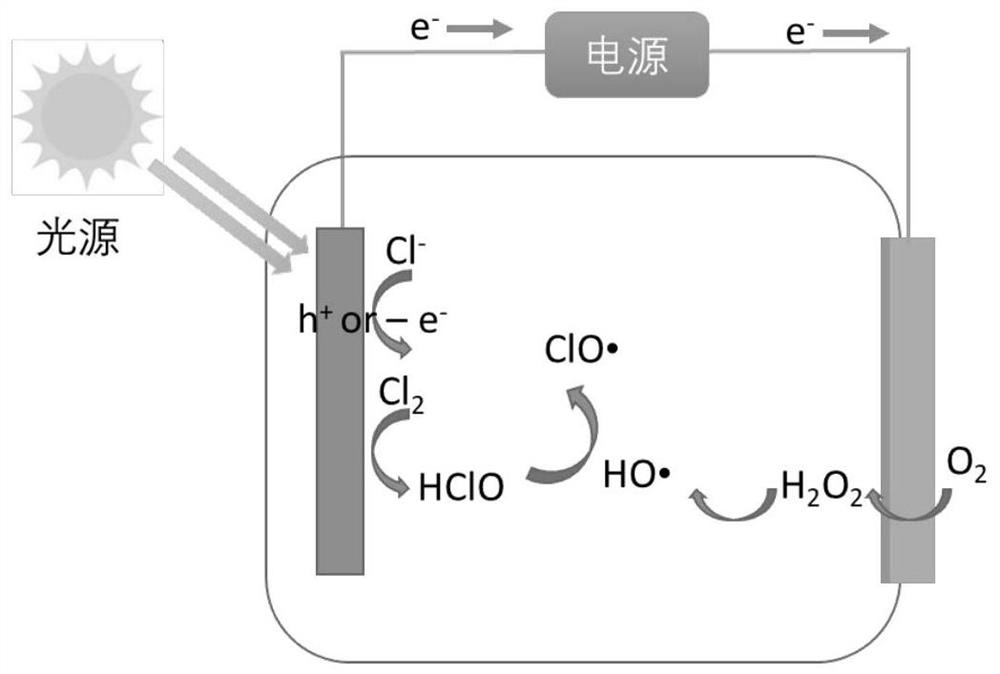

Method for treating aquaculture seawater tail water based on free radicals generated by photoelectrocatalysis

PendingCN113800605ARealize processingRealize synchronous removalWater/sewage treatment by irradiationWater treatment compoundsAir cathodeAntibiotic drug

The invention discloses a method for treating aquaculture seawater tail water based on free radicals generated by photoelectrocatalysis. The method comprises the steps of firstly, preparing an electrode for generating active chlorine by photoelectrocatalysis and an air cathode; and secondly, taking the prepared electrode for generating active chlorine through photoelectrocatalysis as a photo-anode, covering the surface of the prepared air cathode with a layer of copper net, additionally applying 1.1-5.0 V voltage, and achieving seawater treatment. Under the assistance of natural illumination, a certain bias voltage is applied, the photo-anode is subjected to a photoelectrocatalytic reaction to generate Cl2, then HClO is generated, and the HClO can play a role in killing algae and bacteria; the cathode is subjected to an oxygen reduction reaction to generate H2O2, the H2O2 forms OH. under the catalytic action of copper, and the OH. can directly oxidize and remove antibiotics and organic matters; and meanwhile, HClO reacts with OH. to generate a chlorine-oxygen free radical ClO., ammonia nitrogen and antibiotics in the water body are removed through oxidation, and then simultaneous removal of multiple pollutants is achieved.

Owner:NANKAI CANGZHOU BOHAI NEW AREA GREENING CHEM RES CO LTD

Process and device for strengthening short-cut denitrification anaerobic ammonia oxidation denitrification and synchronous phosphorus recovery

PendingCN114212881AGood removal effectStable recyclingWater treatment parameter controlBiological treatment apparatusSodium acetateAcetic acid

The invention provides a process and a device for strengthening short-cut denitrification anaerobic ammonia oxidation denitrification and synchronous phosphorus recovery, according to the process, iron powder is added in a short-cut denitrification anaerobic ammonia oxidation reaction area, and acetic acid is adopted to replace a traditional carbon source sodium acetate. When the acetic acid is used as a carbon source substance, the effects of slowing down oxidation of iron powder and accelerating conversion of zero-valent iron to Fe < 2 + > can be achieved, removal of nitrogen is enhanced, meanwhile, effective combination of phosphorus and Fe < 2 + > is guaranteed, blue iron ore with economic value is generated and is adsorbed and recycled by a permanent magnet, and therefore synchronous removal of nitrogen and phosphorus and effective recycling of phosphorus can be achieved. According to the method, the coupling effect of the acetic acid carbon source and the zero-valent iron is utilized to solve the problems that the activity period of the zero-valent iron is short, the phosphorus removal efficiency of the short-cut denitrification anaerobic ammonia oxidation process is low and phosphorus cannot be effectively recycled, extra equipment does not need to be added, and good economic performance is achieved.

Owner:BEIJING UNIV OF TECH

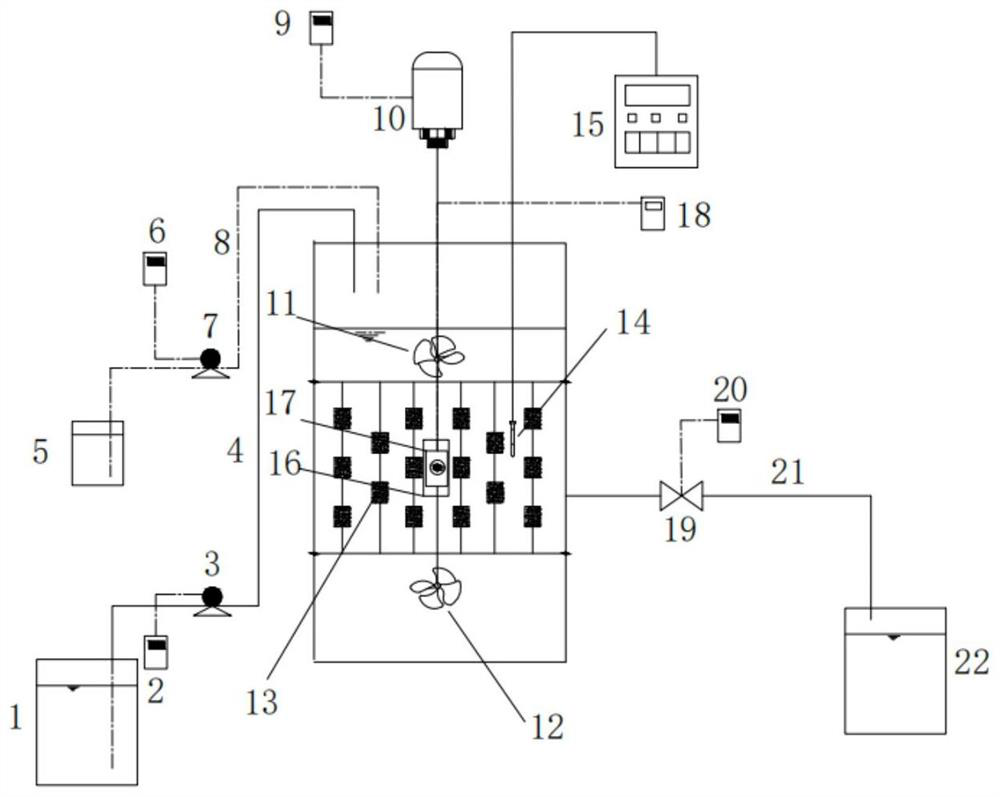

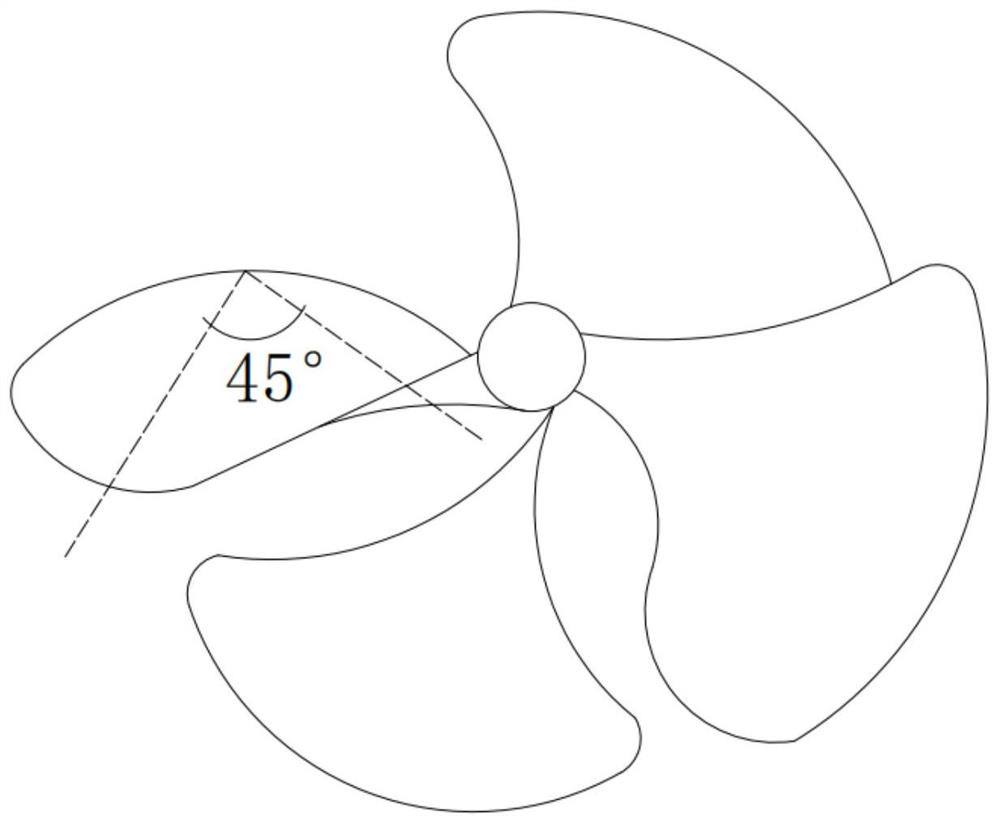

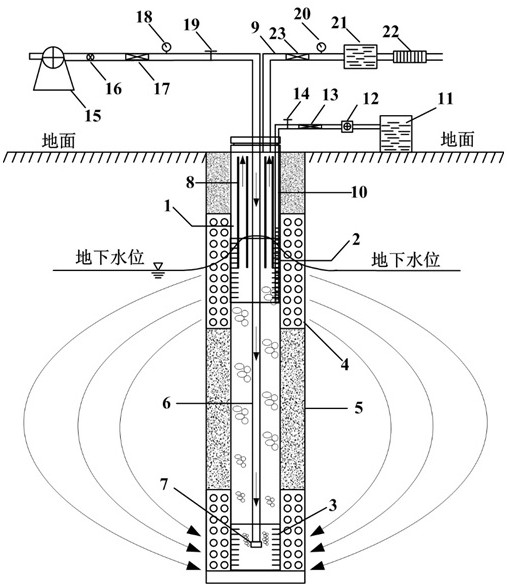

Underground water pollution in-situ circulation remediation system based on bubble pulsation theory

ActiveCN113277577AAchieve cycleRealize synchronous removalGas treatmentDispersed particle separationEnvironmental engineeringWater circulation

The invention relates to an underground water pollution in-situ circulation remediation system based on a bubble pulsation theory, and belongs to the technical field of underground water pollution control and remediation. Upper and lower sections of permeable sieve holes are distributed in the upper and lower parts of a circulating well casing, a gas injection pipe is mounted in the circulating well casing, and a perforated aeration head is mounted at the bottom of the gas injection pipe; a plurality of layers of airflow partition plates are installed in the circulating well casing, permeable sieve holes are distributed in the upper portions of the airflow partition plates, and the airflow partition plates are evenly installed between the gas injection pipe and the circulating well casing; and a tail gas recovery pipe and a medicament injection pipe are mounted in the circulating well casing. According to the invention, only one circulating well casing which does not need to be specially designed is used, gas or water does not need to be pumped and injected to provide power for underground water circulation, the underground water circulation is realized only through the bubble pulsation effect, and tail gas collection is directly realized by using the pressure in the well, so that volatile and semi-volatile organic pollutants in the underground water are effectively and quickly removed, the well structure and the technological process are simplified, the equipment maintenance probability is reduced, and the remediation cost is saved.

Owner:JILIN UNIV

Comonas testosteroni with denitrification and dephosphorization functions and application thereof

ActiveCN102531202ARealize synchronous removalSolve bottlenecksBacteriaMicroorganism based processesPhosphateInorganic phosphorus

The invention relates to application of Comamonas Testosteroni with hetetrophic nitrification-aerobic denitrification and dephosphorization functions to wastewater treatment. The strain can metabolize by taking organic carbon as a unique carbon source and ammonia nitrogen as a unique nitrogen source, and the ammonia nitrogen is directly converted into a gas product through a hetetrophic nitrification-aerobic denitrification effect to fulfill the denitrification aim; the strain also can take nitrate nitrogen as a unique nitrogen source and converts the nitrate nitrogen into a gas product through an aerobic denitrification effect; and the strain also can intake inorganic phosphorus under the aerobic condition and convert the inorganic phosphorus into own components to fulfill the aim of removing the phosphorus from sewage. When the strain is applied to wastewater treatment, the nitrogen and the phosphorus can be synchronously removed under the single aerobic condition, a problem that wastewater is subjected to anaerobic phosphate release, anoxic denitrification and aerobic nitrification phosphorus-uptake by stages in the traditional wastewater treatment is well solved, and the invention has a wide application prospect.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com