Combined multi-level ecological unit system for deeply treating secondary effluent of sewage plant

A technology of secondary effluent and advanced treatment, applied in the field of energy and environmental engineering, can solve the problems of complex management, high treatment costs, high operation and maintenance costs, and achieve the effect of improving purification efficiency and reducing operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

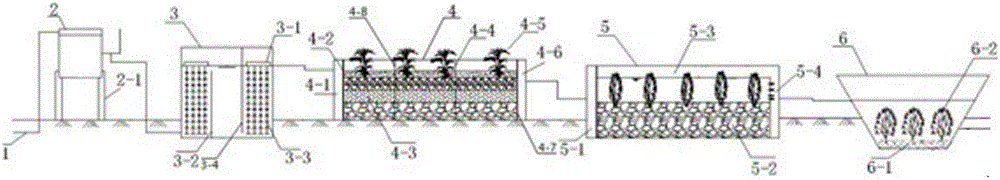

Image

Examples

Embodiment 1

[0036] The tail water COD concentration of a sewage treatment plant is 25-35mg / L, the TN concentration is 10-15mg / L, the ammonia nitrogen concentration is 0.5-2.5mg / L, and the TP concentration is 0.2-0.5mg / L, and the system of the present invention is used for treatment :

[0037] The sewage is collected through the water distribution tank and enters the ecological pond. The ecological pond is 1.5m long * 0.7m wide * 1.5m high. There are three ecological floating islands on the water surface of the ecological pond, and 25 strings of three-dimensional elastic fillers are suspended under each ecological floating island , each string of three-dimensional elastic fillers contains 10 fillers, and the length of each string of three-dimensional elastic fillers is 1.0m. There are also two baffles in the ecological pond. The setting of the two baffles can deflect sewage and increase the contact between microorganisms and water bodies area, strengthen the decomposition of organic matter...

Embodiment 2

[0040] The tail water COD concentration of a sewage treatment plant is 25-35mg / L, the TN concentration is 10-15mg / L, the ammonia nitrogen concentration is 0.5-2.5mg / L, and the TP concentration is 0.2-0.5mg / L, and the system of the present invention is used for treatment :

[0041] The sewage is collected through the water distribution tank and enters the ecological pond. The ecological pond is 1.5m long * 0.7m wide * 1.5m high. There are three ecological floating islands on the water surface of the ecological pond, and 25 strings of three-dimensional elastic fillers are suspended under each ecological floating island , each string of three-dimensional elastic fillers contains 10 fillers, and the length of each string of three-dimensional elastic fillers is 1.0m. There are also two baffles in the ecological pond. The setting of the two baffles can deflect sewage and increase the contact between microorganisms and water bodies area, strengthen the decomposition of organic matter...

Embodiment 3

[0044] The tail water COD concentration of a sewage treatment plant is 25-35mg / L, the TN concentration is 10-15mg / L, the ammonia nitrogen concentration is 0.5-2.5mg / L, and the TP concentration is 0.2-0.5mg / L, and the system of the present invention is used for treatment :

[0045] The sewage is collected through the water distribution tank and enters the ecological pond. The ecological pond is 1.5m long * 0.7m wide * 1.5m high. There are three ecological floating islands on the water surface of the ecological pond, and 25 strings of three-dimensional elastic fillers are suspended under each ecological floating island , each string of three-dimensional elastic fillers contains 10 fillers, and the length of each string of three-dimensional elastic fillers is 1.0m. There are also two baffles in the ecological pond. The setting of the two baffles can deflect sewage and increase the contact between microorganisms and water bodies Area, strengthen the decomposition of organic matter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com