Electrochemical filter for removing total nitrogen in water

A filter, electrochemical technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of electrode rejection of reactants, reaction gas accumulation, small reaction area, etc., to increase the reaction active site. point, weaken the adverse effects, the effect of large reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for preparing a ruthenium-iridium-titanium porous anode containing a nano-tip structure, the preparation steps are as follows:

[0063] (1) Pretreatment of the titanium screen substrate: put the titanium screen in a mixed acid solution containing hydrofluoric acid, nitric acid and high-purity water for 10 seconds to remove the oxide film on the surface, and then put the titanium screen in a mixed acid solution containing hydrofluoric acid, nitric acid and high-purity water The volume ratio is 1:4:5. Then, in a constant temperature water bath at 90° C., the oil on the titanium substrate was removed by treating with a 30 wt.% NaOH solution for 30 minutes.

[0064] (2) Acid etching: Put the above-mentioned washed titanium mesh into an oxalic acid solution with a mass fraction of 10%, and etch it in a constant temperature water bath at 90°C for 1.5 hours. After the treatment, rinse the substrate with a large amount of water Oxalic acid and titanium oxalate remaini...

Embodiment 2

[0069] A method for preparing a porous cathode containing a nano-tip structure, the preparation steps are as follows:

[0070] (1) Pretreatment of the barbed wire base: put the barbed wire into 0.5mol / L hydrochloric acid to remove the oxide layer, then ultrasonically treat it in ethanol solution for 10min, and then soak it in 1mol / L sodium hydroxide solution for 30min to remove the material Contaminants on the surface.

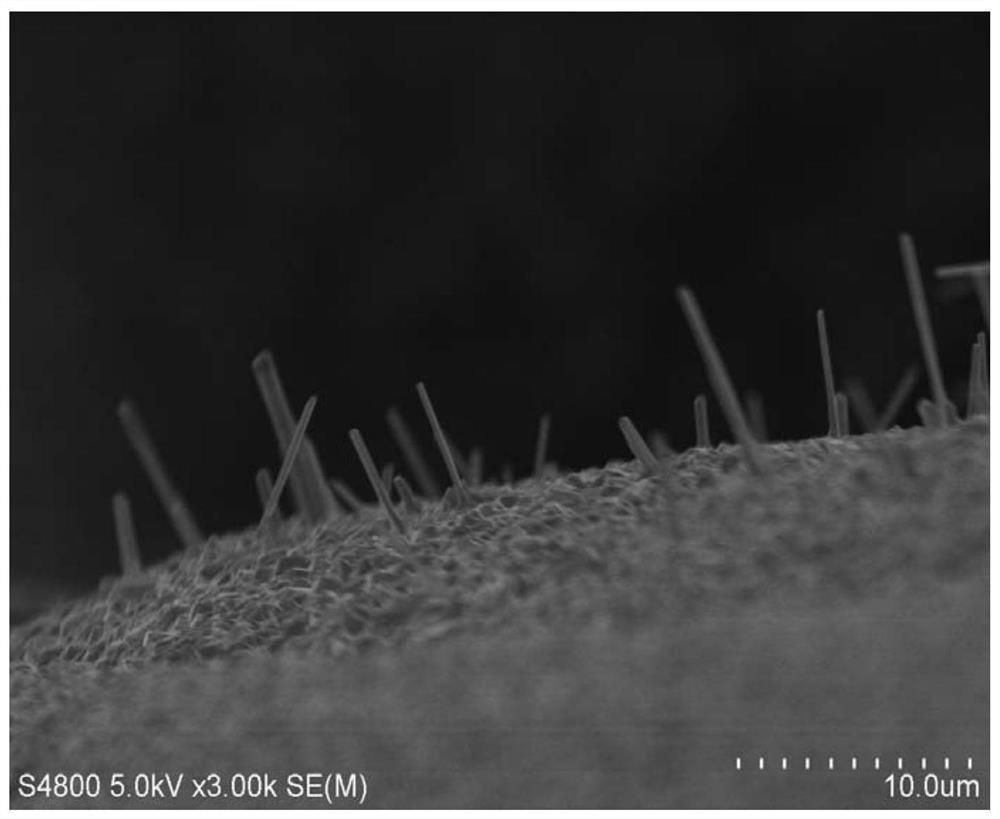

[0071] (2) Anodizing: Then in a constant temperature of 40°C, in a 2mol / L sodium hydroxide electrolyte, control the current density to 15mA / cm 2 , after anodizing for 10 min, a three-dimensional nano-tip porous cathode is obtained, such as image 3 shown.

Embodiment 3

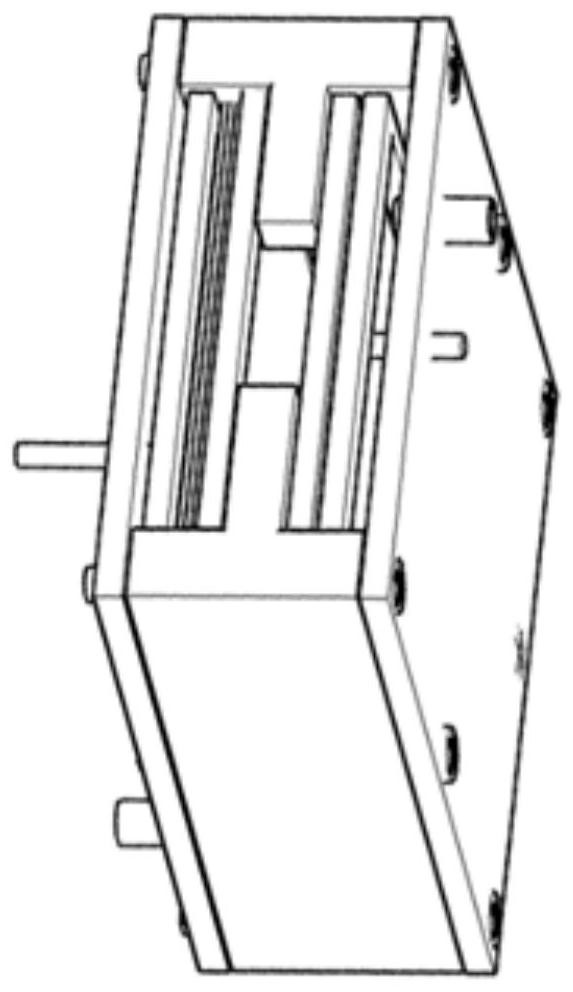

[0073] combine figure 1 Describe this embodiment, an electrochemical filter for removing total nitrogen in water in this embodiment includes a cathode tank cover 3, a cathode terminal 1, a water inlet 2, a cathode reaction tank 8, a sealing rubber pad 4, and a three-dimensional nano-tip porous cathode 5 , filter tank main body 6, support column 7, anode reaction tank 9, three-dimensional nano-tip porous anode 10, 11, anode tank cover 14, anode terminal 12, water outlet 13;

[0074] The electrochemical filter water inlet 2 is located at the cathode reaction tank 8 side, and the position is obliquely below the cathode tank cover 3; the water outlet 13 is located at the anode reaction tank 9 side, and the position is obliquely above the anode tank cover 14; the cathode terminal 1 and the anode The horizontal position of the terminal post 12 is 15 mm higher than the horizontal position of the water outlet 13 .

[0075] The three-dimensional nano-tip porous cathode 5 is formed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com