Efficient battery with three-layer electrode structure

An electrode structure and battery technology, applied in the fields of electricity and electronics, can solve the problems of low utilization rate of positive electrode materials, insufficient battery energy density, and inability to meet the needs of electric vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

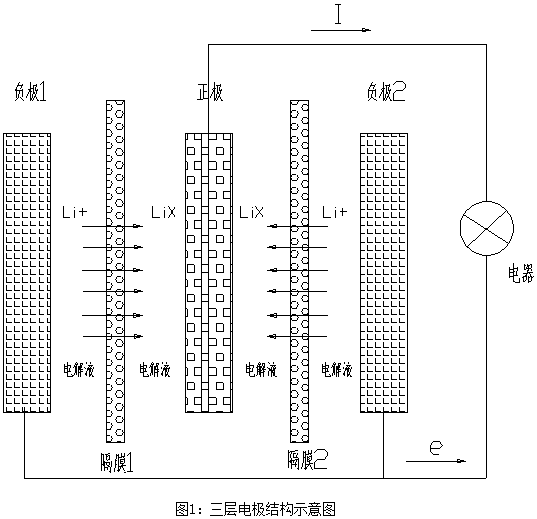

[0025] Such as figure 1 As shown, a high-efficiency lithium-ion battery with a three-layer electrode structure is composed of a negative electrode 1, a separator 1, a positive electrode, a separator 2, a negative electrode 2, and an electrolyte between the positive and negative electrodes. Negative electrode 1 and negative electrode 2 are connected to the negative electrode of the shell at the same time when the battery core is packaged. When the battery is working, when the same discharge current is required, compared with the traditional battery structure, the working area between the internal electrodes is doubled, the internal current will be doubled, and the heat generation and internal resistance will be doubled, so that The battery works more stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com