Method for treating sewage containing heavy metals

A heavy metal and sewage technology, applied in sludge treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of reducing COD value of sewage, unable to remove heavy metal elements and COD from sewage at the same time, and achieve low COD value and heavy metal Element content, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

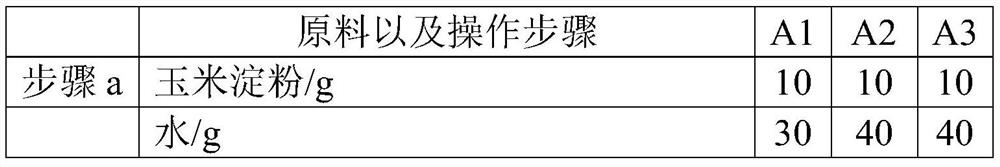

[0070] Starch-modified polymers were prepared according to the following method, and starch-modified polymers A1-A3 were prepared respectively.

[0071] Step a: In a four-necked flask equipped with a thermometer, a condenser tube, an agitator and a dropping funnel, add cornstarch and water, stir under nitrogen protection, and carry out reaction I;

[0072] Step b: Cool down to 50-65°C, add cerium ammonium nitrate nitric acid solution to carry out reaction II; then add acrylamide dropwise, carry out heat preservation reaction III, stop nitrogen;

[0073] Step c: cooling down to 30-50°C, in the presence of alkaline solution, adding carbon disulfide to carry out reaction IV;

[0074] Step d: The product is washed with ethanol several times, and dried at 60° C. to obtain the product.

[0075] Table 1

[0076]

[0077]

Embodiment 1

[0079] (1) Adjust the pH value of the sewage to 8.0 in the sewage regulating tank;

[0080] (2) Sewage flows into the reaction tank, L-cysteine is added at 60 mg per L of sewage, starch-modified polymer A1 is added at 80 mg per L of sewage, and after stirring for 15 minutes, sulfuric acid is added at 2400 mg per L of sewage Iron, after stirring and reacting for 10 minutes, add cationic polyacrylamide with a cationic degree of 60% at 14 mg per L of sewage, and continue stirring and reacting for 8 minutes;

[0081] (3) The mixed solution flows into the sedimentation tank for solid-liquid separation, and the residence time is 15min. After the flocs are concentrated, they are press-filtered and landfilled.

[0082] (4) The effluent from the sedimentation tank enters the electrocatalytic oxidation reaction tank, in which the anode plate is Ti / PbO 2 -Dy, the cathode plate is graphite, the current density is 60mA / cm 2 , the time is 15min.

[0083] The heavy metal content and COD...

Embodiment 2

[0085] (1) Adjust the pH value of the sewage to 5.8 in the sewage regulating tank;

[0086] (2) Sewage flows into the reaction pool, L-cysteine is added at 30 mg per L of sewage, starch-modified polymer A1 is added at 50 mg per L of sewage, and after stirring for 4 minutes, chlorine is added at 1000 mg per L of sewage Iron oxide, after stirring for 4 minutes, add cationic polyacrylamide with a cationic degree of 40% at 5 mg per L of sewage, and continue stirring for 4 minutes;

[0087] (3) The mixed solution flows into the sedimentation tank for solid-liquid separation. The residence time is 5 minutes. After the flocs are concentrated, they are press-filtered and landfilled.

[0088] (4) The effluent from the sedimentation tank enters the electrocatalytic oxidation reaction tank, in which the anode plate is Ti / IrO 2 -Tm, the cathode plate is titanium, the current density is 30mA / cm 2 , the time is 8min.

[0089] Analysis of the heavy metal content and COD value of the eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com