Method for preparing sheath for cold isostatic pressing

A technology of cold isostatic pressing and sheathing, which is applied in the field of preparation of sheathing for static pressure, and can solve problems such as easy generation of dead angles, oil ingress of compacts, and poor sealing performance of vacuum sealing and welding, so as to achieve easy extraction of air and reduction of The effect of investment cost and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

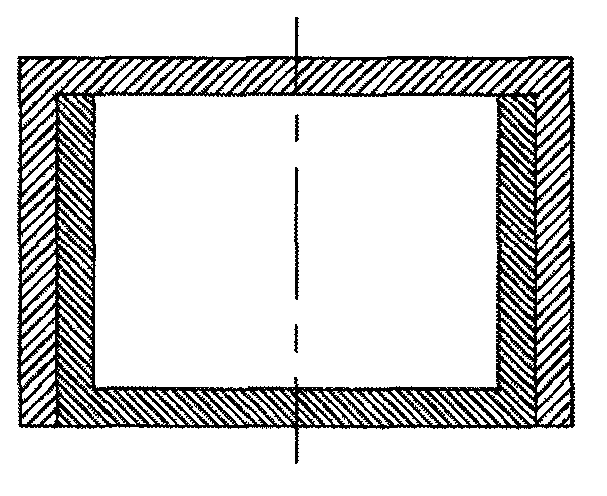

[0019] Nickel steel powder is formed by wrapping cardboard, and the particle size of the powder is 63-106 μm, such as figure 1 As shown, the processing shape is a rectangular 150*100*70mm block, and cardboard with a thickness of 3mm is used. The inner size of the lower cardboard is 187*125*87mm, and the inner size of the upper cardboard is 193*131*90mm. O-phenylphenol is used as the coating material, and the water-based polyurethane adhesive is used to coat the inside and outside of the cardboard. The coating is for easy peeling after the product is formed. Use it after the finished box is completely dry and hardened. The lower cardboard is used as a cavity to fill the powder, and the bulk density of the powder is 2.2g / cm 3 Around, the density after vibration is 3.3g / cm 3 about. Cover the upper cardboard, put it into a vacuum packaging bag synthesized by nylon and polycarbonate for vacuum sealing, and the thickness of the vacuum bag is 0.2mm. Under the relative vacuum pre...

Embodiment 2

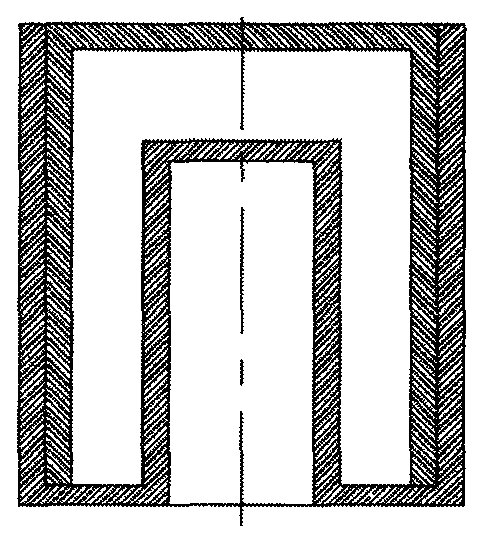

[0021] Such as figure 2 As shown, a cup-shaped nickel-steel powder material with an outer diameter of 200mm, a wall thickness of 30mm, and a height of 100mm is processed with a cardboard sheath, and a cardboard with a thickness of 10mm is used. The upper and lower covers are scaled to make a cardboard sheath, and a plastic film is used. As a coating material, the water-based polyurethane adhesive covers the inside and outside of the cardboard, and the coating is for easy peeling of the product after molding. Use it after the finished box is completely dry and hardened. The lower cardboard is used as a cavity to fill the powder, and the bulk density of the powder is 2.2g / cm 3 Around, the density after vibration is 3.3g / cm 3 about. Cover the upper cardboard, put it into a plastic vacuum packaging bag for vacuum sealing, and the thickness of the vacuum bag is 0.2mm. Under the relative vacuum pressure of 0.08Mpa, the vacuuming time is 30 seconds, the heat sealing time is 3 se...

Embodiment 3

[0023] Nickel steel powder is formed by wrapping cardboard, and the particle size of the powder is 63-106 μm, such as figure 1 As shown, the processing shape is a rectangular 150*100*70mm block, and cardboard with a thickness of 1mm is used. The inner size of the lower cardboard is 187*125*87mm, and the inner size of the upper cardboard is 193*131*90mm. Plastic film is used as the coating material, and the water-based polyurethane adhesive is used to cover the inside and outside of the cardboard. The purpose of the coating is to make the product easy to peel off after molding. Use it after the finished box is completely dry and hardened. The lower cardboard is used as a cavity to fill the powder, and the bulk density of the powder is 2.2g / cm 3 Around, the density after vibration is 3.3g / cm 3 about. Cover the upper cardboard, put it into a plastic vacuum packaging bag for vacuum sealing, and the thickness of the vacuum bag is 0.2mm. Under the relative vacuum pressure of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com