Inner groove porous strengthened boiling micro-channel structure, manufacture method and application

A technology of micro-channel structure and manufacturing method, applied in lighting and heating equipment, indirect heat exchangers and other directions, can solve problems such as large flow resistance, and achieve the effects of low production cost, convenient operation and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

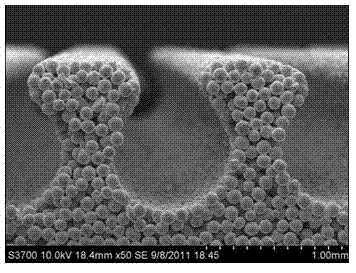

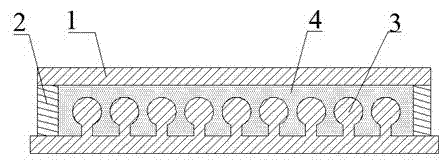

[0040] A porous reinforced boiling microchannel structure with internal grooves includes a metal sintered felt 4 with uniform particle distribution formed by sintering metal powder, and a number of internal grooves are evenly distributed on the metal sintered felt 4. Such as figure 1 As shown, the cross-sectional shape of the inner groove is an inverted "Ω" shape. The metal powder is copper powder, and the particle shape of the metal powder is spherical.

[0041] The manufacturing method of the above-mentioned inner groove porous enhanced boiling microchannel structure includes the following steps:

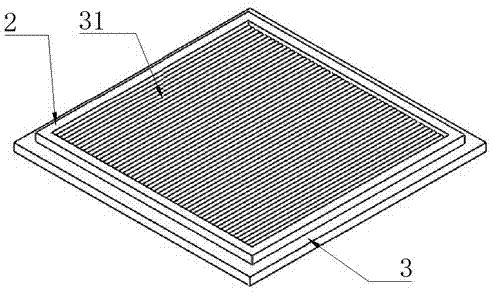

[0042] (1) Use wire cutting technology to process flat graphite molds; figure 2 with 3 As shown, the planar graphite mold is composed of three parts: the upper mold 1, the middle mold 2, and the lower mold 3. The lower mold 3 forms an evenly distributed axial convex structure by wire cutting, and the axial convex structure is complementary to the inner groove structure. The shape of ...

Embodiment 2

[0049] This embodiment is the same as Embodiment 1 except for the following features: Figure 8 As shown, the particle shape of the metal powder is dendritic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com